Abstract

This paper investigates the influence of design parameters on fluid leakage in axial piston pumps. Particular emphasis is placed on the analysis of operating clearances, sealing surfaces, and geometric relationships that affect volumetric efficiency and system reliability. Through a systematic review of 32 relevant sources, key components contributing to both internal and external leakage are identified, along with approaches for their optimization through material selection, microgeometry, tolerances, and thermodynamic conditions. Modern methods for diagnostics and leakage prediction are also considered, including the application of artificial intelligence and numerical simulations. The findings of this review may serve as a basis for improving the design and maintenance of axial pumps, with the aim of increasing efficiency and reducing losses.

1. Introduction

Axial piston pumps are widely used in modern hydraulic systems due to their compact design, high operating pressures, and favorable volumetric efficiency. They are essential in industrial, mobile, and aerospace applications, where precise and reliable fluid control is required. However, fluid leakage, whether internal or external, remains a major limitation, affecting energy efficiency, component durability, and system reliability.

These pumps can exceed 350 bar while remaining compact, making them attractive for mobile hydraulics and aerospace [1,2]. Their high efficiency relies on precise tolerances, fluid quality, and sealing integrity [3,4].

While a certain amount of leakage is inherent to hydraulic operation, excessive fluid loss can result from various design-related, material, and tribological factors. Key engineering challenges lie in optimizing operational clearances to ensure functionality, while simultaneously providing effective sealing to minimize leakage.

Axial piston pumps often operate under mixed and boundary lubrication at the valve plate–cylinder block interface [5,6]. Oil film stability is crucial to avoid wear, but micro-defects or thermal instability can hasten degradation and leakage [7,8]. These tribological processes are closely tied to pump lifetime and efficiency.

Aluminum pumps reduce weight, fuel use, and emissions, with reinforcements enhancing strength, yet pure aluminum suffers from low strength, poor tribological behavior, and high thermal expansion; material choice governs wear, dominated by adhesive wear, surface damage, and friction that accelerate piston–cylinder degradation [9].

Understanding the mechanisms of fluid loss requires a detailed analysis of construction parameters such as surface finish, groove geometry, sealing design, material compatibility, and fluid stability. Recent advances in diagnostics and simulation have enabled more accurate modeling of these phenomena, offering new opportunities for predictive analysis and optimization.

Typical failures in axial piston pumps involve piston–cylinder wear, cavitation near grooves, valve plate fatigue, and thermal distortion of sliding pairs [5,10,11]. These failures stem from design geometry, lubrication, and material behavior, highlighting the need for multidisciplinary optimization.

This paper reviews 32 studies on leakage in axial piston pumps, highlighting critical components, effects of wear and deformation, and design strategies for improved sealing, with emphasis on modern tools such as numerical modeling, metrology, micro-texturing, and AI, to guide future development of efficient and reliable pumps.

2. Construction of Axial Piston Pumps

2.1. Basic Structural Elements

Axial piston pumps use a swashplate to convert shaft rotation into piston motion, with fluid directed by the valve plate; critical leakage risks arise at O-ring seals and the cylinder block–valve plate interface, while long-term wear of control pistons reduces stability and efficiency.

These pumps, classified as positive displacement types, typically feature multiple axially arranged pistons and deliver high pressure with continuous fluid flow, which makes them suitable for demanding applications such as aerospace and industrial systems [1].

2.2. Design Variants and Engineering Characteristics

Cyclic forces and vibrations caused by angled pistons on a curved swashplate can indicate wear and are used for spectral diagnostics [12]. The swashplate angle and piston count influence flow variability and dynamic stability, while precise alignment of the cylinder block and valve plate is essential for minimizing leakage [2,3]. Surface finish and tolerance selection affect pressure balance and responsiveness [4], and increasing the number of pistons reduces flow pulsations [13]. Modified axis layouts and accurate fitting of components can lower stress and leakage without dimensional growth [14,15]. Constant and variable displacement types differ in complexity and leakage sensitivity [15].

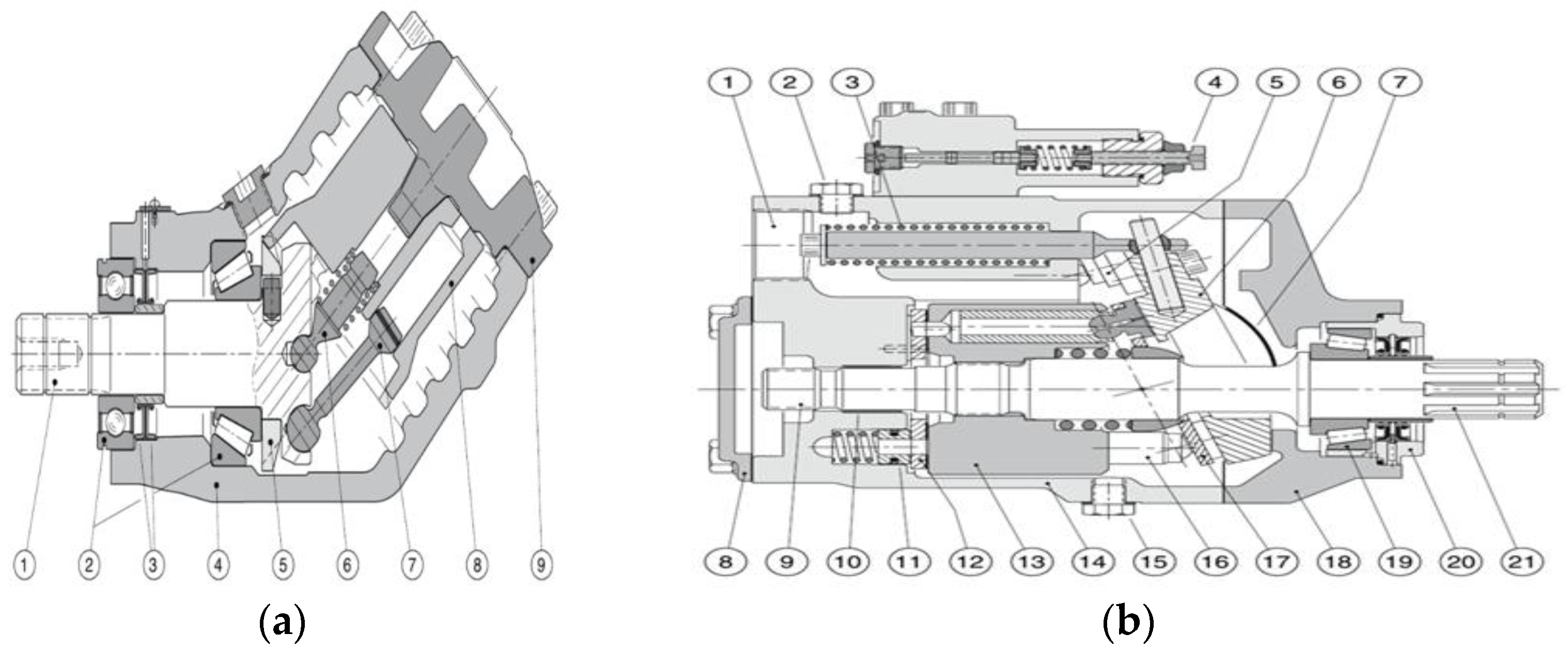

To illustrate the structural differences affecting leakage, part (a) presents a typical constant-displacement axial piston pump, showing the arrangement of the cylinder block, pistons, sealing joints, and bearings—highlighting critical contact areas prone to leakage. Part (b) depicts a variable-displacement version with added components such as swashplate adjustment mechanisms and piston–slipper assemblies. While enabling dynamic flow regulation, this configuration introduces greater structural complexity, increasing the risk of internal leakage and thermomechanical distortion.

The labeled components in Figure 1 illustrate the internal structure of both pump types. In part (a), the main elements of a constant-displacement axial piston pump are as follows: (1) input shaft, (2) bearings, (3) shaft seal, (4) housing, (5) timing gear, (6) support bearing, (7) piston with piston ring, (8) cylinder barrel, and (9) end cap. Functional zones with sliding motion and oil pressure are clearly visible, representing potential leakage points.

Figure 1.

(a) Cross-section of an axial piston pump with constant displacement [16]; (b) Cross-section of an axial piston pump with variable displacement [16]. Reprinted with permission from Ref. [16]. Copyright 2007, Parker Hannifin Corporation.

In part (b), the variable-displacement configuration includes the following: (1) input shaft, (2) high-pressure oil passage, (3) support bearing, (4) housing, (5) bearing support, (6) control piston, (7) return spring, (8) swashplate, (9) retainer plate, (10) ball joint, (11) slipper pad, (12) piston, (13) cylinder barrel, (14) valve plate, (15) return oil passage, (16) cylinder oil channels, (17) sealing rings, (18) thrust spring, (19) swashplate stop, (20) side cover, and (21) swashplate support.

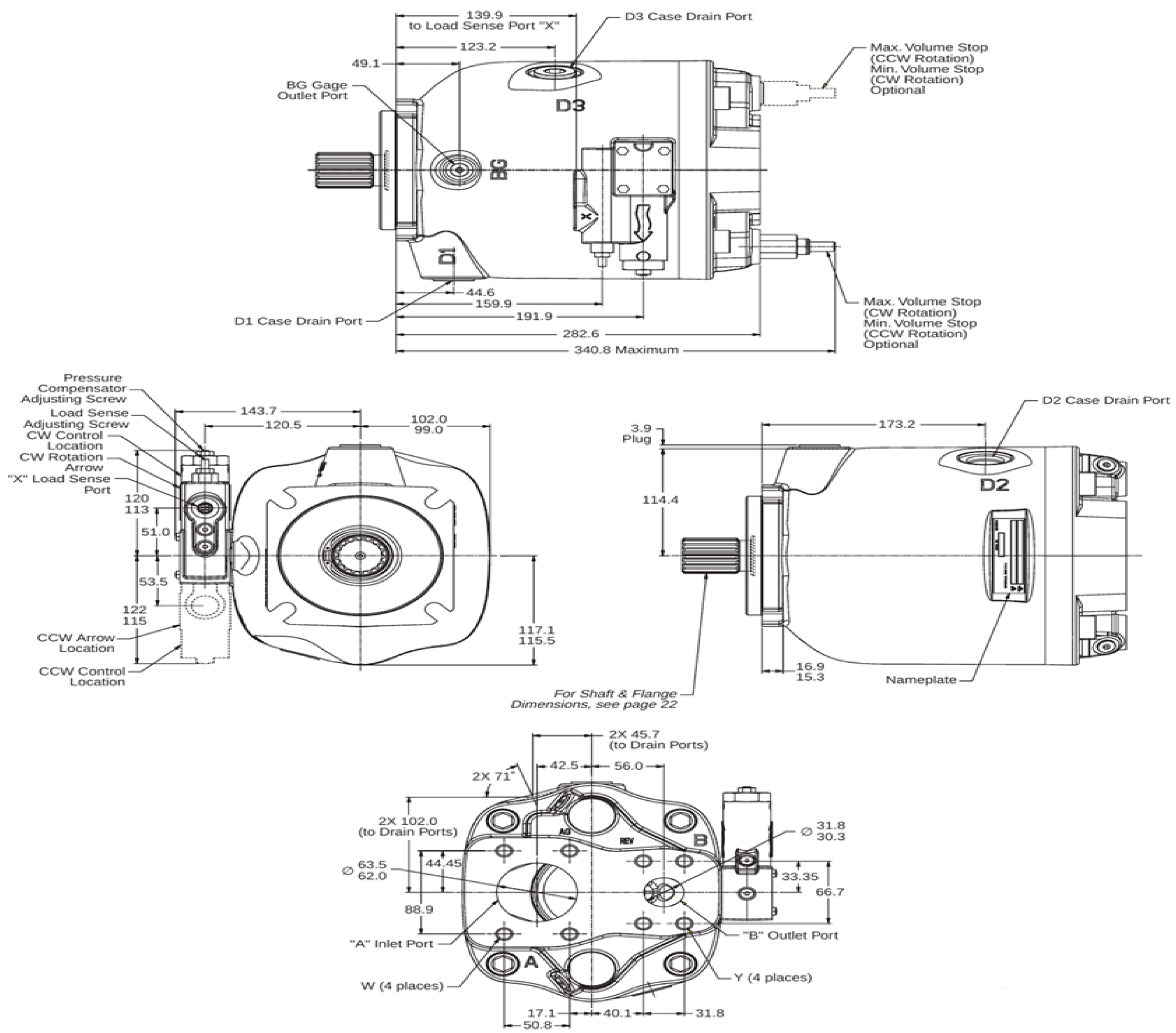

Figure 2 illustrates a variable displacement axial piston pump with key dimensions for integration and port alignment, helping prevent installation errors.

Figure 2.

Technical drawing of the axial piston pump with variable displacement [17]. Reprinted with permission from Ref. [17]. Copyright 2005, Parker Hannifin Corporation.

The external dimensions of the pump are shown, including the orientation of ports (A—inlet, B—outlet), case drain ports (D1, D2, D3), pressure gauge port (BG), and locations of control elements such as adjustment screws and valve positions. Dimensions are provided in millimeters, enabling precise installation of the pump within a hydraulic system.

3. Leakage Locations and Causes

3.1. Operating Clearances and Functional Tolerances

The most common leakage zones in axial piston pumps include the piston–cylinder clearance, valve plate, and inlet–outlet channels. Although clearance is essential for piston motion and lubrication, it also creates fluid loss paths. Proper joint design must minimize clearance while maintaining lubrication to avoid chamber leakage [2]. Even micro-clearances around 9.78 × 10−6 m can lead to measurable losses under high pressure, as shown in Equation (1) [13].

where —cylinder diameter, —radial clearance between the piston and the cylinder, —dynamic viscosity, —current displacement of the piston, —cylinder pressure, —suction pressure and —fluid density in the cylinder.

Micrometer-scale clearances under high pressure significantly increase leakage [15], with oil film stability depending on joint accuracy [1]. Reliability tests on piston compressor bearings showed that axial clearance above 0.09 mm and temperatures over 73 °C indicate fatigue and deformation [10]. Optimal clearance must ensure piston movement without fluid loss, as improper values lead to wear, jamming, or thermal distortion [3]. Excessive clearances prolong cylinder contact under low force, while smaller ones increase force and wear [18]. Losses are influenced by fluid viscosity, temperature, and path geometry, with spiral clearances responsible for over 90% of leakage in some cases [7,19].

3.2. Contact Surfaces and Tribological Challenges

The valve plate–cylinder interface is exposed to intense thermomechanical loads, making oil film stability essential; its failure leads to boundary friction and leakage [1,5]. Pressure oscillations during suction can also cause local leakage [20]. Wear between the piston and slipper alters axial clearance, detectable via vibration analysis [12,20]. Surface micro-texturing enhances hydrodynamic support and reduces leakage through dimples [21], though results depend on dimple depth—certain textures may increase leakage under specific conditions [22].

3.3. Geometric Factors and Thermal Effects

Surface microdefects and finishing influence volumetric losses, even at low pressures [4]. Temperature and viscosity changes can destabilize the sealing layer, especially under poor cooling and limited reservoir capacity, leading to up to 27% thermal rise and clearance instability [2,8]. Groove geometry critically affects flow: improper design causes turbulence, cavitation, and pressure variations, while accurate dimensions support oil film formation [1,15,23]. Spring stiffness deviations may cause leakage variation exceeding 237% [24], and slipper grooves, though stabilizing tilt, can increase losses [11]. Boundary lubrication wear and viscosity shifts at moderate temperatures also impact film stability [4,6]. Optimizing groove layout on valve plates improves volumetric efficiency by reducing losses near dead centers [25].

4. Design Optimization

4.1. Clearance Measurement and Diagnostics

High-precision diagnostics using the ADS 2000-CADEX ultra-rapid measuring system, as reported in [20], with 4096 samples per revolution, allows detection of leakage-critical clearances under pressures up to 200 bar. An educational PLC-controlled hardware system based on a Siemens S7-300 controller demonstrates real-time diagnostics, fault detection, and structured testing for improved reliability in fluid systems [26]. Modeling of slipper–swashplate interaction shows that uneven pressure distribution causes oil film breakdown, while adjusting internal tilt reduces overturning moments and volumetric losses [27].

4.2. Working Fluid Quality and Thermodynamic Influences

Impurities in hydraulic fluid cause abrasion and leakage in highly loaded joints, making filtration and fluid cleanliness critical for system reliability [2]. Fluid preparation, including control of microemulsions and condensate, is essential in leakage prevention [4]. Elevated temperatures reduce viscosity and increase leakage, especially between the slipper and sliding surfaces [19]. Thermal stability of the fluid is key to maintaining clearance and sealing performance [3,4,8]. Increasing reservoir volume significantly lowers temperature, improving fluid viscosity and sealing efficiency [8].

4.3. Materials, Geometry, and Surface Texture

Materials with low friction and high thermal conductivity reduce wear and leakage [3,6]. Lightweight aluminum housings reduce pump mass, fuel use, and emissions, but their leakage and durability depend on material behavior: while reinforcements partly restore strength and wear resistance, unalloyed aluminum suffers from low strength, poor tribological properties, and high thermal expansion, with studies showing adhesive wear, surface damage, and friction under marginal lubrication as dominant failure modes [9]. Optimal combinations, such as CuPb15Sn5 and 38CrMoAl QTN, offer minimal wear with sealing thresholds around 2.5 MPa [6]. Rounded pistons and rectangular ports enhance pressure stability and efficiency [13,28]. Groove geometry optimization via CFD (Computational Fluid Dynamics) and Reynolds equation helps balance return torque and leakage [5,9]. Stiff central springs improve oil film stability [24], while thicker valve plates reduce stress below fatigue limits [3,14]. Micro-dimples increase load capacity and reduce leakage, though excessive depth may increase losses, highlighting the need for optimal surface texturing [1,7,21,22]. Numerical simulations confirm that surface geometry significantly affects pressure distribution and leakage behavior, enabling precise optimization without extensive physical testing [7].

4.4. Advanced Models and Dynamic Optimization

Modern approaches include deep learning models, such as LSTM (Long Short-Term Memory) networks, for predicting leakage, oil film thickness, and pressure in slipper pockets, offering higher accuracy than traditional methods [22]. MCDM (Multi-Criteria Decision-Making) techniques like FUCA (Full Consistency Method) and PSI (Preference Selection Index) support balanced decision-making in pump design based on technical and economic criteria [29]. The Taguchi method enables reliable pump parameter optimization by reducing the number of tests while clearly identifying key factors and their optimal values [30]. The Taguchi method improves hydraulic pump design efficiency by reducing experiments, lowering costs, and reliably identifying key factors with their optimal values [31]. Increasing the number of pistons improves stability but requires tighter tolerances [13,15]. TEHD (Thermo-Elasto-HydroDynamic) models highlight thermal deformation effects and the role of microtexturing and coatings in oil film preservation [5]. Additional tools, such as MVH (Multi-Variant Histogram) analysis and 1D vibration models, enable diagnostics and optimization without complex experiments [12,32]. Trapped-volume valve plates eliminate grooves and improve volumetric efficiency [25].

5. Discussion

The analysis presented in this review confirms that fluid leakage in axial piston pumps is the result of complex interactions between geometric design, material properties, surface treatment, fluid quality, and operating conditions. While optimizing functional clearances remains essential, it must be accompanied by careful control of tribological interfaces, thermal effects, and sealing behavior.

Advanced diagnostic tools and numerical simulations allow for early identification of critical leakage points and provide a cost-effective means for exploring design variants. The integration of artificial intelligence methods, particularly deep learning models, has opened new possibilities for predicting leakage behavior and improving design decisions during the early development phases.

Surface texturing techniques, such as micro-dimples, have shown promise in stabilizing the oil film and reducing wear, though their effectiveness depends on precise dimensional control. Similarly, improvements in groove geometry, valve plate configuration, and port alignment contribute to pressure uniformity and reduced volumetric losses.

Material selection also plays a key role in ensuring sealing performance, especially under boundary lubrication and elevated loads. Alloys with favorable tribological characteristics and thermal stability support the long-term reliability of high-pressure hydraulic systems.

Overall, a multidisciplinary optimization approach—combining mechanical design, tribology, fluid dynamics, simulation, and intelligent diagnostics—proves necessary for developing axial piston pumps with high efficiency, minimal leakage, and robust performance across demanding applications.

6. Conclusions

Fluid leakage in axial piston pumps remains one of the most critical challenges affecting energy efficiency, operational stability, and component lifespan. It arises from the complex interaction of design geometry, material properties, tribological behavior, and thermodynamic conditions. Even minimal deviations in clearance, surface finish, or pressure balance can lead to significant volumetric losses, particularly under high-pressure regimes.

This paper focuses on identifying and analyzing the structural, functional, and dynamic factors that contribute to leakage, with particular attention to operational clearances, sealing interfaces, surface textures, and fluid behavior. A comprehensive review of relevant literature enables the classification of key leakage zones, evaluation of optimization strategies, and identification of sensitive components.

Modern diagnostic systems, simulation models, and artificial intelligence techniques have significantly improved the ability to predict leakage behavior and support design decisions. These tools allow for virtual testing and optimization, reducing the reliance on costly experimental procedures.

By integrating mechanical design, tribology, thermal modeling, and intelligent diagnostics, this review aims to provide a framework for developing high-performance axial piston pumps with reduced leakage and extended service life.

The insights presented in this review may serve as a foundation for further research focused on adaptive sealing mechanisms, real-time leakage monitoring, and the integration of smart materials and control systems into next-generation hydraulic pump design.

Author Contributions

Conceptualization, M.M.; methodology, M.M., E.D. and B.N.; investigation, M.M., B.N. and L.R.; resources, M.M., E.D., B.N., L.R. and J.P.; writing—original draft preparation, M.M.; writing—review and editing, E.D., B.N. and L.R.; visualization, M.M.; supervision, E.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Salam, M.A. Fundamentals of Pneumatics and Hydraulics; Springer: Berlin/Heidelberg, Germany, 2022; ISBN 981-19-0854-0. [Google Scholar]

- Parr, A. Hydraulics and Pneumatics: A Technician’s and Engineer’s Guide, 3rd ed.; Elsevier: Oxford, UK, 2011; ISBN 978-0-08-096674-8. [Google Scholar]

- Jovanovic, Z. Hidraulika i Pneumatika. 2015. Available online: https://ljbozicva.wordpress.com/wp-content/uploads/2020/03/hidraulika-i-pneumatika-knjiga.pdf (accessed on 14 January 2026).

- Korbar, R. Pneumatika i Hidraulika; Veleučilište u Karlov: Karlovac, Croatia, 2007; p. 122. [Google Scholar]

- Zhao, J.; Fu, Y.; Ma, J.; Fu, J.; Chao, Q.; Wang, Y. Review of Cylinder Block/Valve Plate Interface in Axial Piston Pumps: Theoretical Models, Experimental Investigations, and Optimal Design. Chin. J. Aeronaut. 2021, 34, 111–134. [Google Scholar] [CrossRef]

- Huang, J.; Dou, Z.; Wang, Z.; Quan, L.; Niu, L. Tribological Properties of Cylinder Block/Valve Plate Interface of Axial Piston Pump on the Tribometer. Chin. J. Mech. Eng. 2021, 34, 122. [Google Scholar] [CrossRef]

- Li, F.; Wang, D.; Lv, Q.; Haidak, G.; Zheng, S. Prediction on the Lubrication and Leakage Performance of the Piston–Cylinder Interface for Axial Piston Pumps. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 5887–5896. [Google Scholar] [CrossRef]

- Novaković, B.Z.; Djordjević, L.; Đurđev, M.; Radovanović, L.; Zuber, N.; Desnica, E.; Bakator, M. Effect of Changes in Hydraulic Parameters and Tank Capacity of the Hydraulic Press System on the Heating of the Hydraulic Oil. Maint. Reliab./Eksploat. Niezawodn. 2024, 26, 190826. [Google Scholar] [CrossRef]

- Milojević, S.; Stojanović, B. Determination of Tribological Properties of Aluminum Cylinder by Application of Taguchi Method and ANN-Based Model. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 571. [Google Scholar] [CrossRef]

- Mikic, D.; Desnica, E.; Asonja, A.; Stojanovic, B.; Epifanic-Pajic, V. Reliability Analysis of Ball Bearing on the Crankshaft of Piston Compressors. J. Balk. Tribol. Assoc. 2016, 22, 5060–5070. [Google Scholar]

- Haynes, J.M. Axial Piston Pump Leakage Modelling and Measurement; Cardiff University (United Kingdom)–ProQuest LLC 2013: Cardiff, UK, 2007; ISBN 1-303-22455-0. [Google Scholar]

- Bayer, C.; Enge-Rosenblatt, O. Modeling of Hydraulic Axial Piston Pumps Including Specific Signs of Wear and Tear. In Proceedings of the 8th International Modelica Conference–Modelica’2011, Dresden, Germany, 20–22 March 2011; pp. 461–466. [Google Scholar]

- Radosavljević, M.; Stošić, L.; Mihajlović, S.R.; Đorđević, N.G.; Petrović, R.; Lozanović, J. The Influence of the Number of Pistons on the Pressure Pulsations and Vibration of the Axial Piston Pump Housing. Appl. Sci. 2025, 15, 2004. [Google Scholar] [CrossRef]

- Nikolenko, I.; Khomyak, Y.M.; Zheglova, V.M.; Kibakov, O.; Medvedev, S. The Design of Responsible Details of an Axial Piston Hydraulic Machine Improving; IOP Publishing: Bristol, UK, 2020; Volume 408, p. 012006. [Google Scholar]

- Bergada, J.M.; Kumar, S.; Watton, J. Axial Piston Pumps, New Trends and Development. In Fluid Dynamics, Mechanical Applications and Role in Engineering; Nova Science Pub Inc.: Hauppauge, NY, USA, 2012; pp. 1–158. [Google Scholar]

- Parker, H.C. Truck Hydraulics Fixed and Variable Displacement Pumps, Motors and Accessories; Parker Hannifin Corporation: Cleveland, OH, USA, 2007. [Google Scholar]

- Parker, H.C. P1 Series Axial Piston Pumps Variable Displacement Zp; Parker Hannifin Corporation: Cleveland, OH, USA, 2005. [Google Scholar]

- Lee, B.; Yu, Y.; Cho, Y.-J. Effect of Piston Clearance on the Lubrication Performance in Axial Piston Pump. Ind. Lubr. Tribol. 2020, 72, 146–150. [Google Scholar] [CrossRef]

- Zawistowski, T.; Kleiber, M. Gap Flow Simulation Methods in High Pressure Variable Displacement Axial Piston Pumps. Arch. Comput. Methods Eng. 2017, 24, 519–542. [Google Scholar] [CrossRef] [PubMed]

- Petrović, R.; Todić, N.; Savić, S.; Andjelković, M. Results of Identification and Optimization of the Parameters of Axial Piston Pump; University of Maribor Press: Maribor, Slovenia, 2021; pp. 133–140. [Google Scholar]

- Ye, S.; Tang, H.; Ren, Y.; Xiang, J. Study on the Load-Carrying Capacity of Surface Textured Slipper Bearing of Axial Piston Pump. Appl. Math. Model. 2020, 77, 554–584. [Google Scholar] [CrossRef]

- Özmen, Ö.; Sinanoğlu, C.; Caliskan, A.; Badem, H. Prediction of Leakage from an Axial Piston Pump Slipper with Circular Dimples Using Deep Neural Networks. Chin. J. Mech. Eng. 2020, 33, 28. [Google Scholar] [CrossRef]

- Kumar, S.; Bergada, J.M. The Effect of Piston Grooves Performance in an Axial Piston Pumps via CFD Analysis. Int. J. Mech. Sci. 2013, 66, 168–179. [Google Scholar] [CrossRef]

- Ma, H.; Liu, W.; Wu, D.; Shan, H.; Xia, S.; Xia, Y. Modeling and Analysis of the Leakage Performance of the Spherical Valve Plate Pair in Axial Piston Pumps. Eng. Sci. Technol. Int. J. 2023, 45, 101498. [Google Scholar] [CrossRef]

- Manring, N.D.; Zhang, Y. The Improved Volumetric-Efficiency of an Axial-Piston Pump Utilizing a Trapped-Volume Design. J. Dyn. Sys. Meas. Control 2001, 123, 479–487. [Google Scholar] [CrossRef]

- Miljević, N.; Ratković Kovačević, N.; Dihovični, D.; Slišković, D. Maintenance, Testing And Automatic Control Of The Cup Filling Maschine. Adv. Eng. Lett. 2023, 2, 49–57. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, J.; Yang, H. Investigation on Structural Optimization of Anti-Overturning Slipper of Axial Piston Pump. Sci. China Technol. Sci. 2012, 55, 3010–3018. [Google Scholar] [CrossRef]

- Luo, X.; Niu, Z.; Shi, Z.; Hu, J. Analysis and Design of an Axial Piston Water-Pump with Piston Valve. J. Mech. Sci. Technol. 2011, 25, 371–378. [Google Scholar] [CrossRef][Green Version]

- Trung, D.D.; Bao, N.C.; Van Duc, D.; Ašonja, A.; Dudić, B. Selecting Mini Water Pump by Using Multi-Criteria Decision-Making Technique: Comparison of FUCA and PSI Methods. In Proceedings of the 2024 23rd International Symposium INFOTEH-JAHORINA (INFOTEH), Sarajevo, Bosnia and Herzegovina, 20–22 March 2024; IEEE: Sarajevo, Bosnia and Herzegovina, 2024; pp. 1–7. [Google Scholar]

- Ivanović, L.; Stojanović, B.; Blagojević, J.; Bogdanović, G.; Marinković, A. Analysis of the Flow Rate and the Volumetric Efficiency of the Trochoidal Pump by Application of Taguchi Method. Teh. Vjesn. 2017, 24, 265–270. [Google Scholar] [CrossRef]

- Ivanović, L.; Veličković, S.; Stojanović, B.; Kandeva, M.; Jakimovska, K. The Selection of Optimal Parameters of Gerotor Pump by Application of Factorial Experimental Design. FME Trans. 2017, 45, 159–164. [Google Scholar] [CrossRef]

- Kivelä, T.; Mattila, J. Internal Leakage Fault Detection for Variable Displacement Axial Piston Pump. In Proceedings of the ASME/BATH 2013 Symposium on Fluid Power and Motion Control, Sarasota, FL, USA, 6–9 October 2013; American Society of Mechanical Engineers: Sarasota, FL, USA, 2013; p. V001T01A027. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.