Abstract

The thermally efficient and lightweight TRC/CLCi composite panels for functional and smart building envelopes, funded by the iclimabuilt project (Grant Agreement no. 952886), offer innovative solutions to sustainably address common failure risks in facade systems. This work specifically emphasizes strategies for mitigating structural, thermal, and fire-related failures through targeted material selection, advanced design methodologies, and rigorous validation protocols. To effectively mitigate structural failures, high-pressure concrete (HPC) reinforced with carbon fibers is utilized, significantly enhancing tensile strength, reducing susceptibility to cracking, and improving overall durability. To counteract thermal bridging—a critical failure mode compromising energy efficiency and structural integrity—the panels employ specially designed glass-fiber reinforced pins connecting HPC outer layers through the cellular lightweight concrete (CLC) insulation core that has a density of around 70 kg/m3 and a thermal conductivity in the range 35 mW/m∙K comparable to those of expanded polystyrene and Rockwool. These connectors ensure effective load transfer and maintain optimal thermal performance. A central focus of the failure mitigation strategy is robust fire behavior. The developed panels undergo rigorous standardized fire tests, achieving an exceptional reaction to fire classification of A2. This outcome confirms that HPC layers maintain structural stability and integrity even under prolonged fire exposure, effectively preventing catastrophic failures and ensuring occupant safety. In conclusion, this work highlights explicit failure mitigation strategies—reinforced concrete materials for structural stability, specialized glass-fiber connectors to prevent thermal bridging, rigorous fire behavior protocols, and comprehensive thermal performance validation—to produce a facade system that is robust, energy-efficient, fire-safe, and sustainable for modern buildings.

1. Introduction

Facade systems in modern construction face multiple challenges, including structural durability, thermal efficiency, and fire safety. Conventional solutions often optimize one property at the expense of others, resulting in performance gaps and long-term risks. The present work, developed within the iclimabuilt project, addresses these challenges through the development of multifunctional lightweight TRC/CLCi composite panels. The panels integrate structural strength, insulation capacity, and fire resistance into a single envelope solution. This paper presents the design, testing, and validation of these panels, with emphasis on integrated strategies to mitigate structural, thermal, and fire failures. Related eco-composite sandwich facade panels have been reported in the literature [1] and [2].

2. Materials and Methods

The TRC/CLCi panels are designed as sandwich structures consisting of HPC outer layers reinforced with carbon fibers and an insulating CLC core enhanced with hydrophobic aerogels. To connect the layers, GFRP pins were used, balancing mechanical load transfer with thermal bridging reduction [3]. Two versions of the panels, TC4.0 and TC4.1, were fabricated: TC4.0 with conventional carbon fibers and TC4.1 with eco-friendly lignin-based carbon fibers. Experimental tests covered structural properties (compressive strength, tensile strength, bending, and pull-out tests), thermal conductivity and transmittance, durability (freeze–thaw and water vapor transmission), and fire resistance per EN 13823 [4] and EN ISO 1716 [5]. The goal is to establish a transparent method to compare panels reinforced with conventional vs. lignin-based carbon fibers within the TRC/CLCi concept. Functional unit: 1 m2 of facade panel achieving the same target U-value and structural/fire performance. System boundary: Cradle-to-gate (raw materials → panel leaving the factory). Use identical panel geometry and connectors; vary only the reinforcement type and core recipe when pertinent. Key inventory items: carbon fibers (conventional vs. lignin-based), high-performance concrete (HPC) matrices, CLC core (with/without aerogel), GFRP pins, and process energy. Impact category (screening): Global Warming Potential (GWP, kg CO2e per functional unit); additional categories may be considered in extended LCA. Assumptions/limitations: Supplier-specific datasets and process energy data are being compiled; therefore, this paper reports no numeric LCA results. Instead, we provide this framework and integrate it with the presented mechanical/thermal/fire data to enable a consistent comparative assessment in a follow-up publication.

For clarity across the manuscript, we adopt the following naming: TC4.0 (Basic) uses conventional CF; TC4.1 (improved) explores aerogel-modified CLC cores; TC4.2 (eco) focuses on sustainability measures (e.g., lignin-based CF); TC4.3 (functional) integrates additional functionalities. Mechanical and thermal/fire testing data are reported against this naming (see Table 1).

Table 1.

Panel variants.

3. Results

The TC4 concept proposes thermally efficient and lightweight composite panels that can be installed as a load-bearing sandwich facade element. The starting point for the conceptualization of TC4 was the efficient combination of high-performance carbon fiber reinforcements for good structural properties with ultra-light CLCi for tailored climate and thermal insulation properties to achieve a multifunctional composite. From that starting point, a TC4.0 Basic panel was defined that uses only advanced cement-based materials (TRC/CLC) of PL4. In addition to the Basic panel, 3 sub-TCs for different development goals and functionalities were conceived for investigation. Within the sub-TCs, different functions such as static, thermal, ecological, as well as multifunctional have been considered.

- TC4.0—Basic Panel

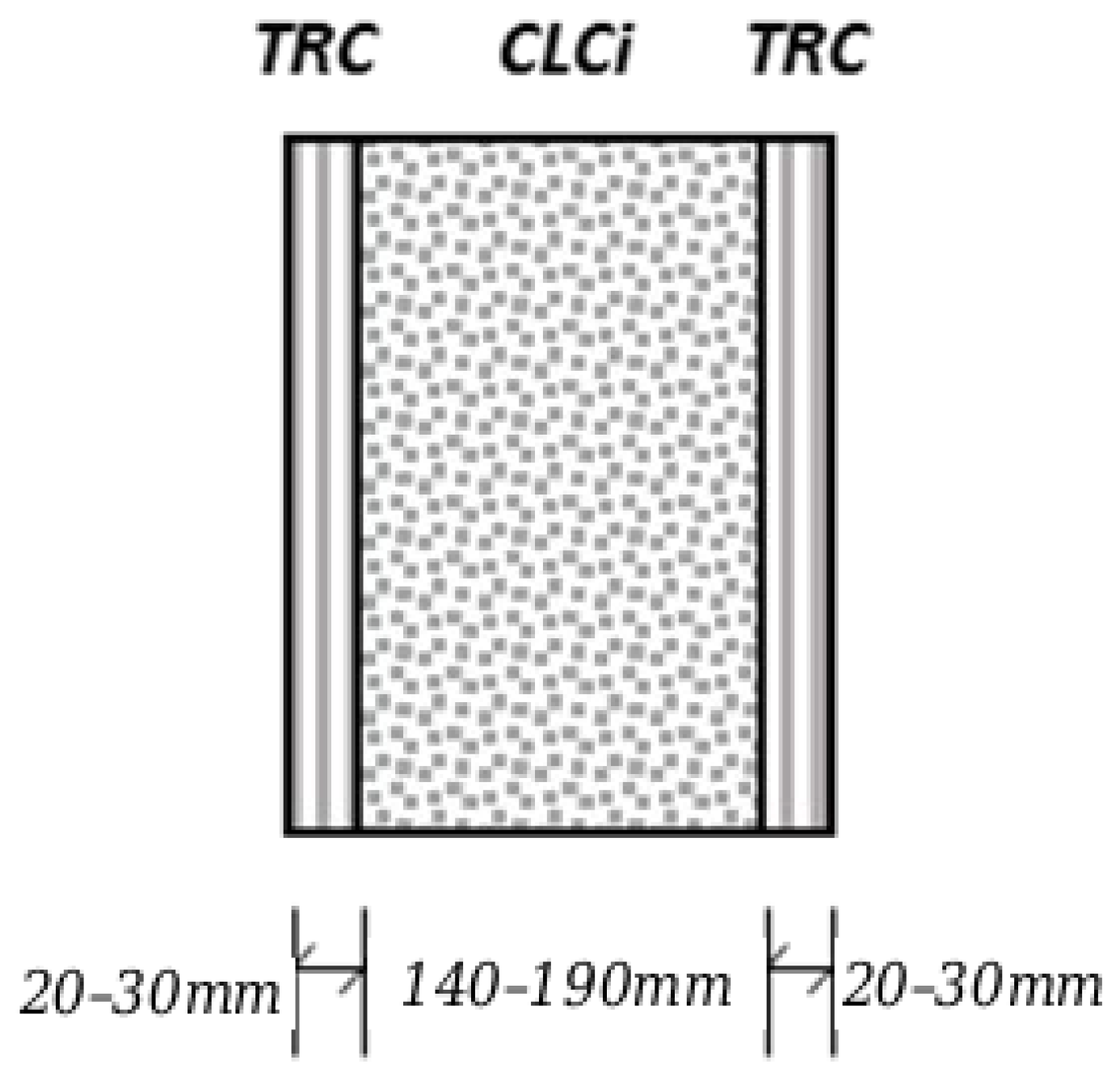

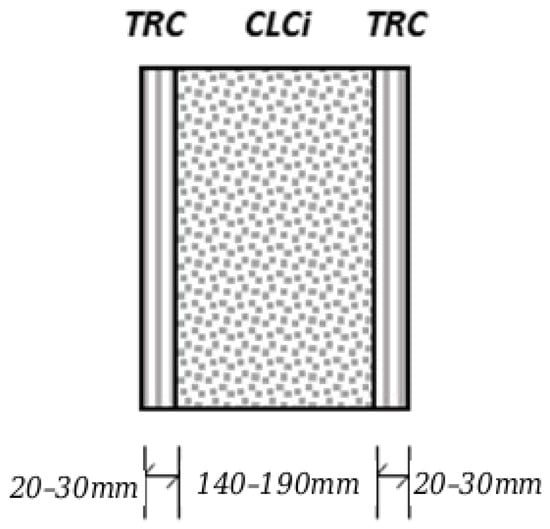

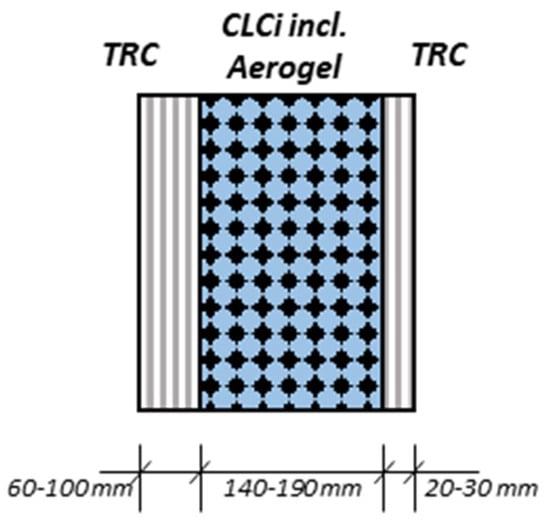

The Basic panel serves as a reference object. The Basic panel as facade load-bearing sandwich panel with improved thermal performance consists of cellular lightweight concrete (CLC) as insulation and two thin textile reinforced top layers of concrete. The CLC is incorporated in the panels either during casting or in the form of prefabricated panels/block (Figure 1). The thickness of the panel can be adjusted based on the achieved thermal conductivity to comply with the requirements of the U-values in EU countries. Within this base case, different aspects of CLC insulation can be explored as part of PL4 (usage of hydrophobic agents, prefabrication of CLC panels/blocks, and pre-carbonation of CLC panels prior to implementation in the panel). The base-case TC4.0 sandwich concept is illustrated in Figure 1.

Figure 1.

Schematic of base case for TC4.

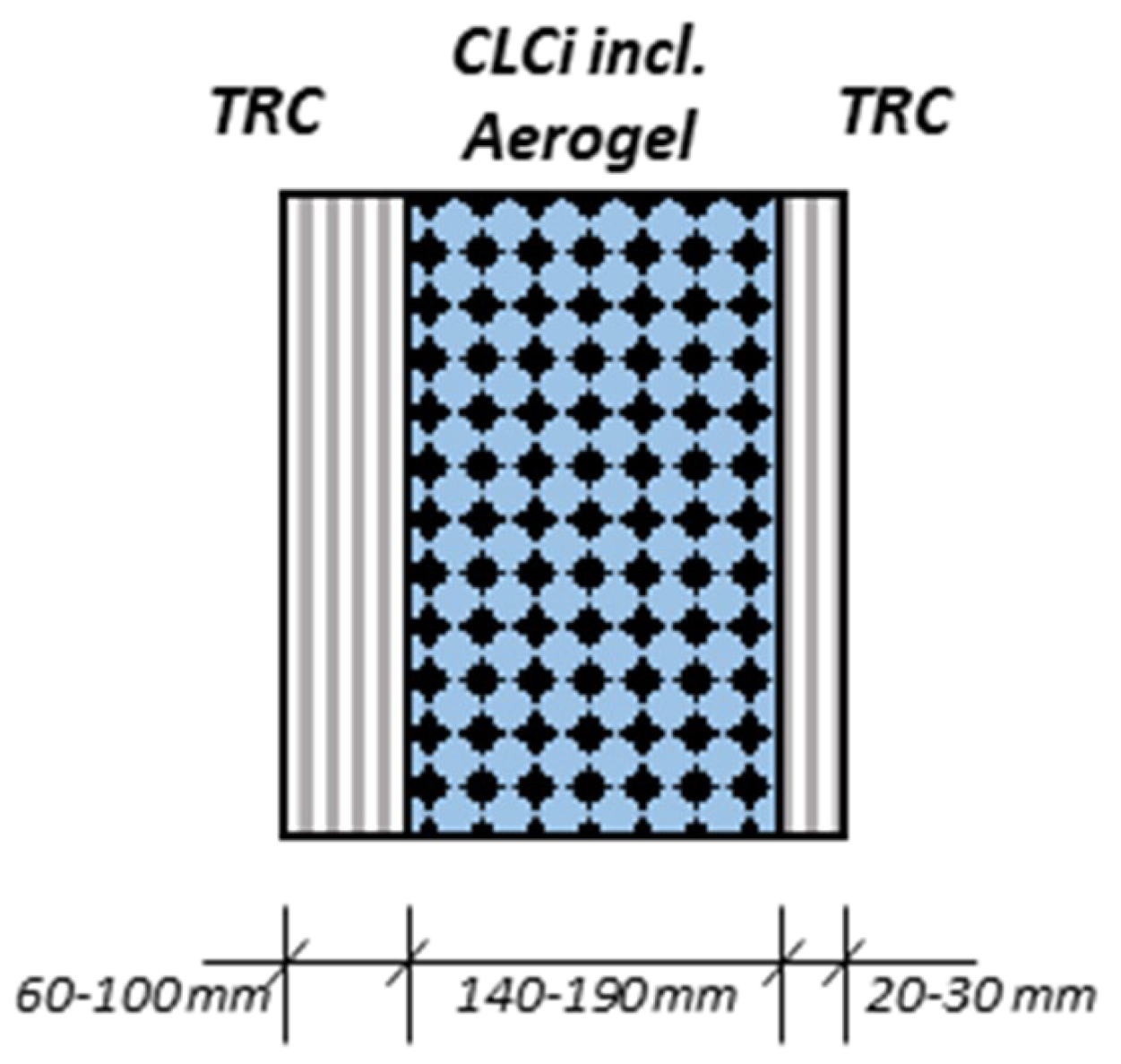

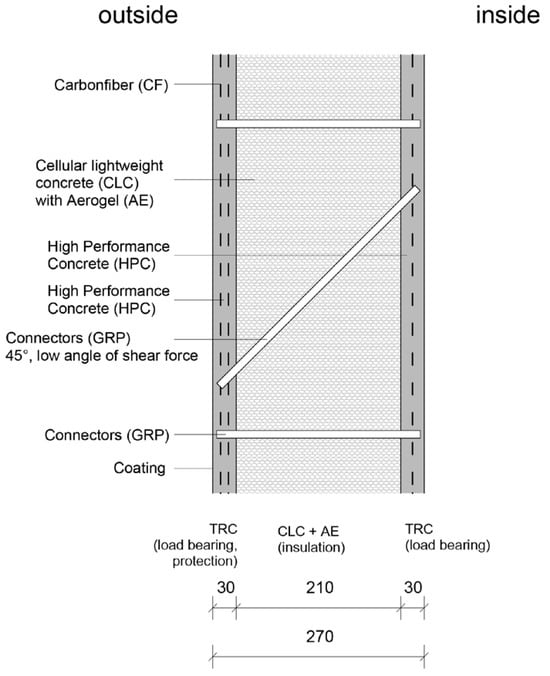

The TC4.1 is a facade load-bearing sandwich panel with improved thermal performance of the cellular lightweight concrete (CLC) insulation by incorporation of silica aerogels (Figure 2). The combination of CLC and aerogels can reduce the insulation layer thickness while maintaining thermal efficiency. The single material tests showed no relevant improvements. In using a different, more adequate aerogel as a hydrophobic one, the thermal insulation should be improved within the next testing. Parallel to the material testing, these hydrophobic aerogels are mixed within the CLC for the TC4.1 Living Labs. The CLC can be incorporated in the panels either during casting or in form of prefabricated panels/block. The thickness of the panel can be adjusted based on the structural capacity of the element. Most important is the defined U-value in different climatic zones. The TC4.1 concept variant is illustrated in Figure 2.

Figure 2.

Schematic representation of TC4.1.

The development of the lignin carbon fibers, as “green” fibers, has been agreed with the project partner TUD. The lignin carbon fibers will be implemented within the panels that will be produced for the Living Labs. The material tests of the eco improved high-performance concrete (HPC) support its usage. Therefore, the main focus is on the development of the new improved panel (Table 2). HTWK, TUD, and RI.SE contribute, define, and test the material components, mixtures, and combinations to reach the KPIs. As alternative of the TC4.1, there is the chance to test the aerogel as single core material within the TC4 panel.

Table 2.

The layers of TC4 panel.

- TC4.2—Eco Panel

Test case 4.2 is called the eco panel and pursues the goal of improving performance in terms of sustainability and recycling. The eco-friendly thermally efficient and load bearing facade sandwich elements was planned of concrete-based waste plastic or foam-based waste clays insulation. The Pilot lines involved in TC4.2 are as follows:

PL4: Pilot line for advanced cement-/concrete-based materials for wall facades (textile-reinforced concrete).

PL6: Pilot line for waste insulation materials.

- TC4.3—Functional Panel

The carbon concrete layers can be improved as functional wall panels with heating structures, with PCM, or with a photovoltaic system. These improve the multifunctionality of the wall. The functional samples can be implemented as technology demonstrators. The TC4 design includes three layers. The TC4 materials, i.e., TRC (textile-reinforced concrete) and CLC (cellular lightweight concrete with aerogel) for insulation are organized in three layers as shown in Table 2 [6].

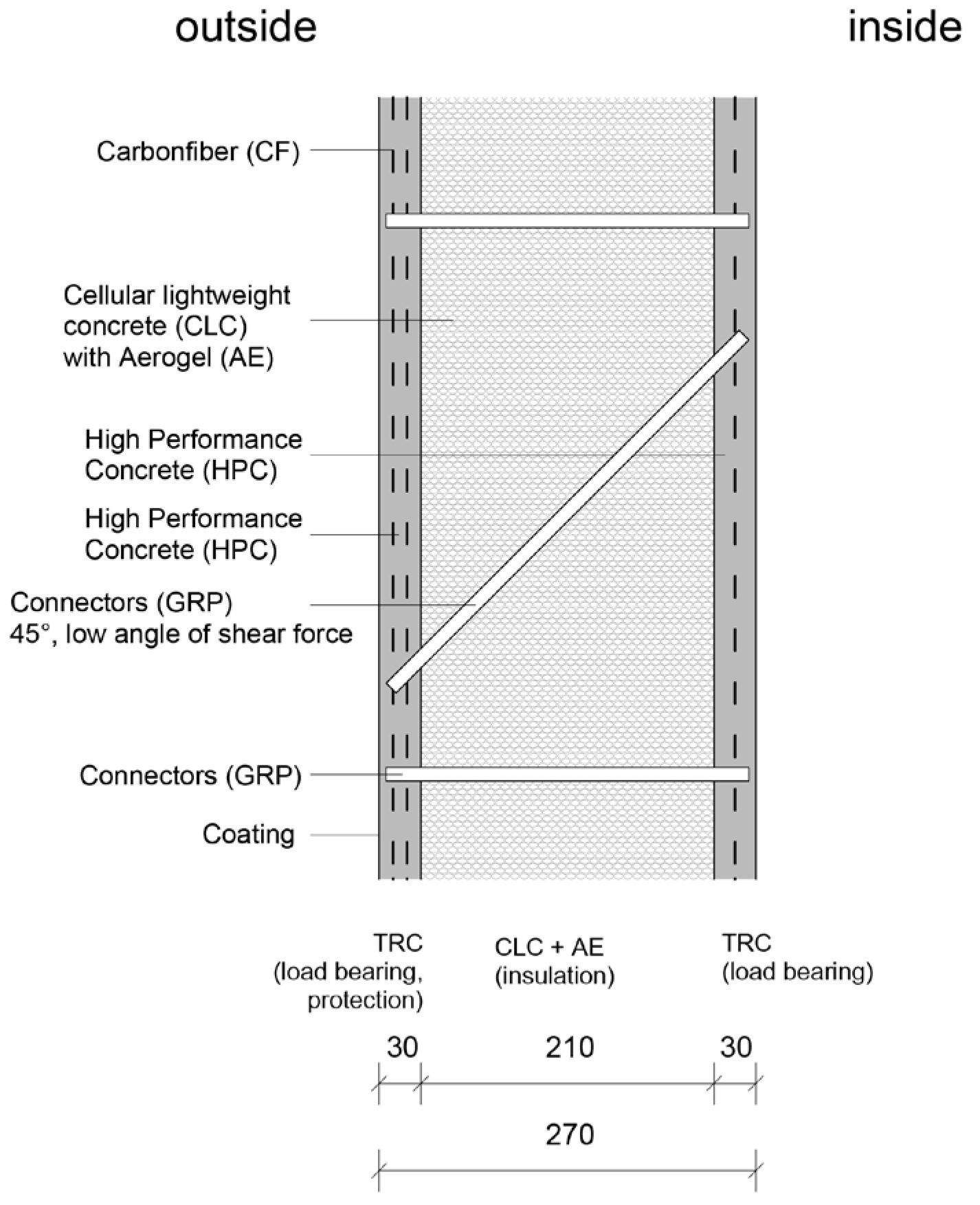

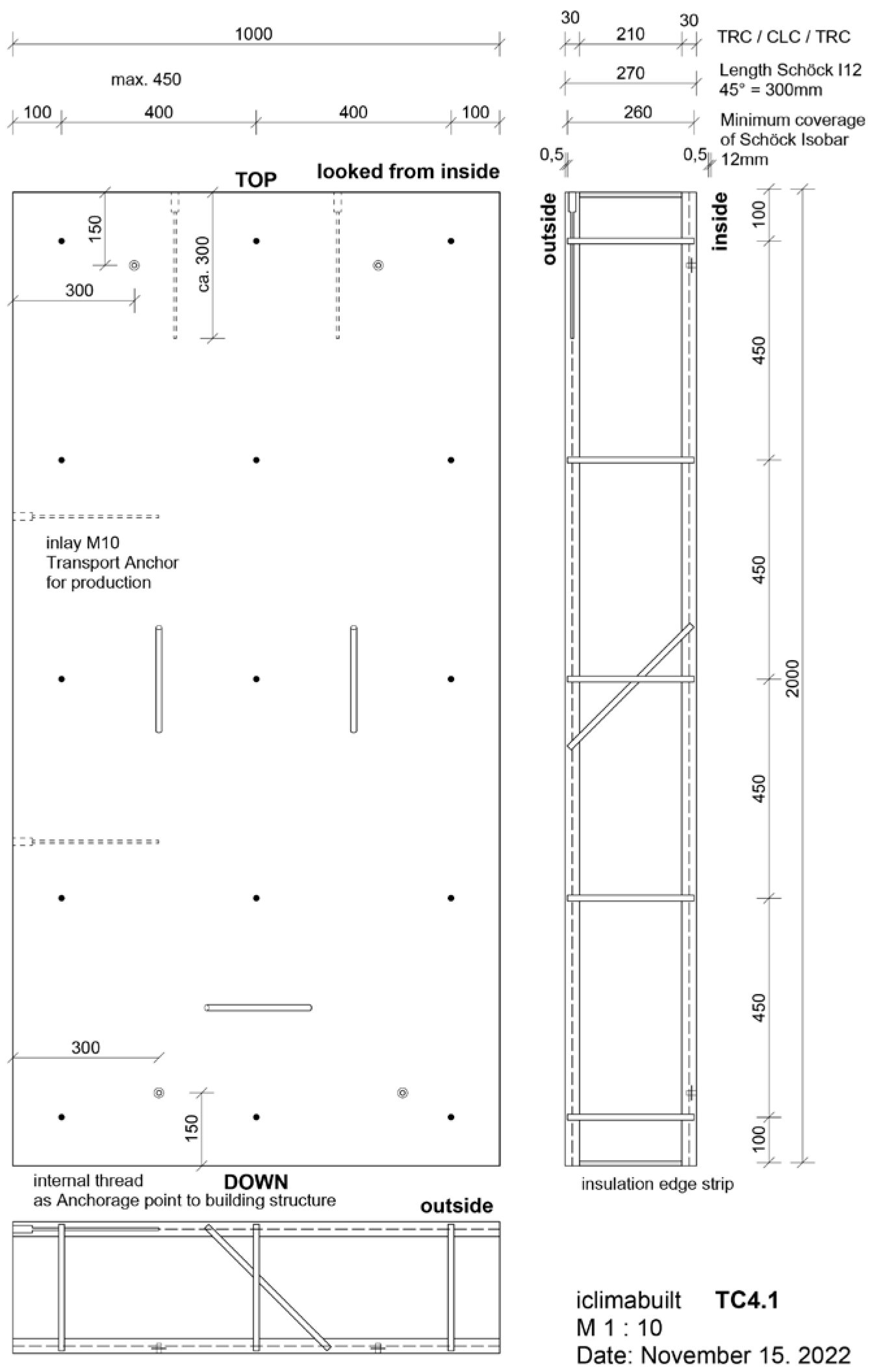

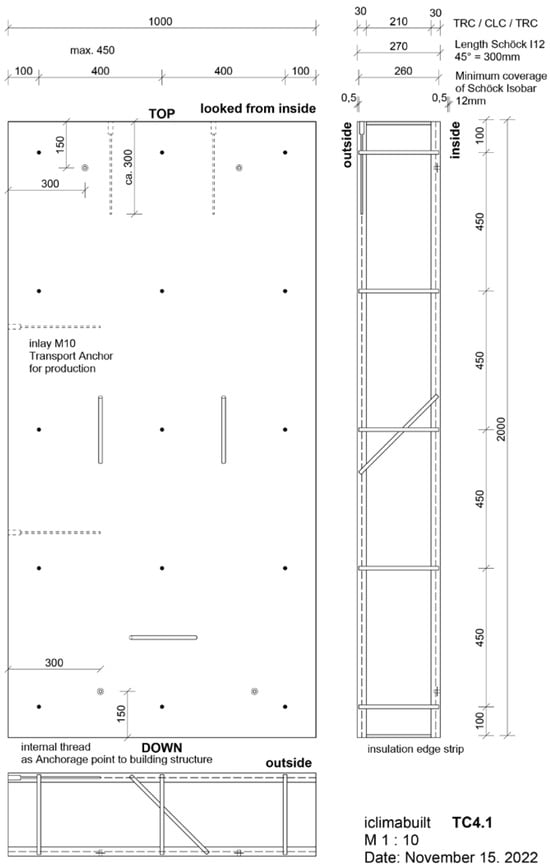

An overview of the TC4 layer build-up and the connector concept is provided in Figure 3. The panel geometry and principal dimensions are illustrated in Figure 4.

Figure 3.

General drawing of the TC4, showing the TC4 layers and connectors.

Figure 4.

Detailed drawing of a TC4 panel measuring 1 m width × 2 m height.

High-performance concrete (HPC):

Both high-performance concrete (HPC) layers with carbon textile reinforcement are the supporting structure of the whole panel. At the same time, they protect the inlayed CLC insulation layer.

Cellular lightweight concrete (CLC):

This cellular lightweight concrete is a very light and brittle panel with open pores. No water or condensed water should go in. The three layers TRC/CLC/TRC are connected with pins. The numbers and intervals of the pins are calculated based on the material and building properties.

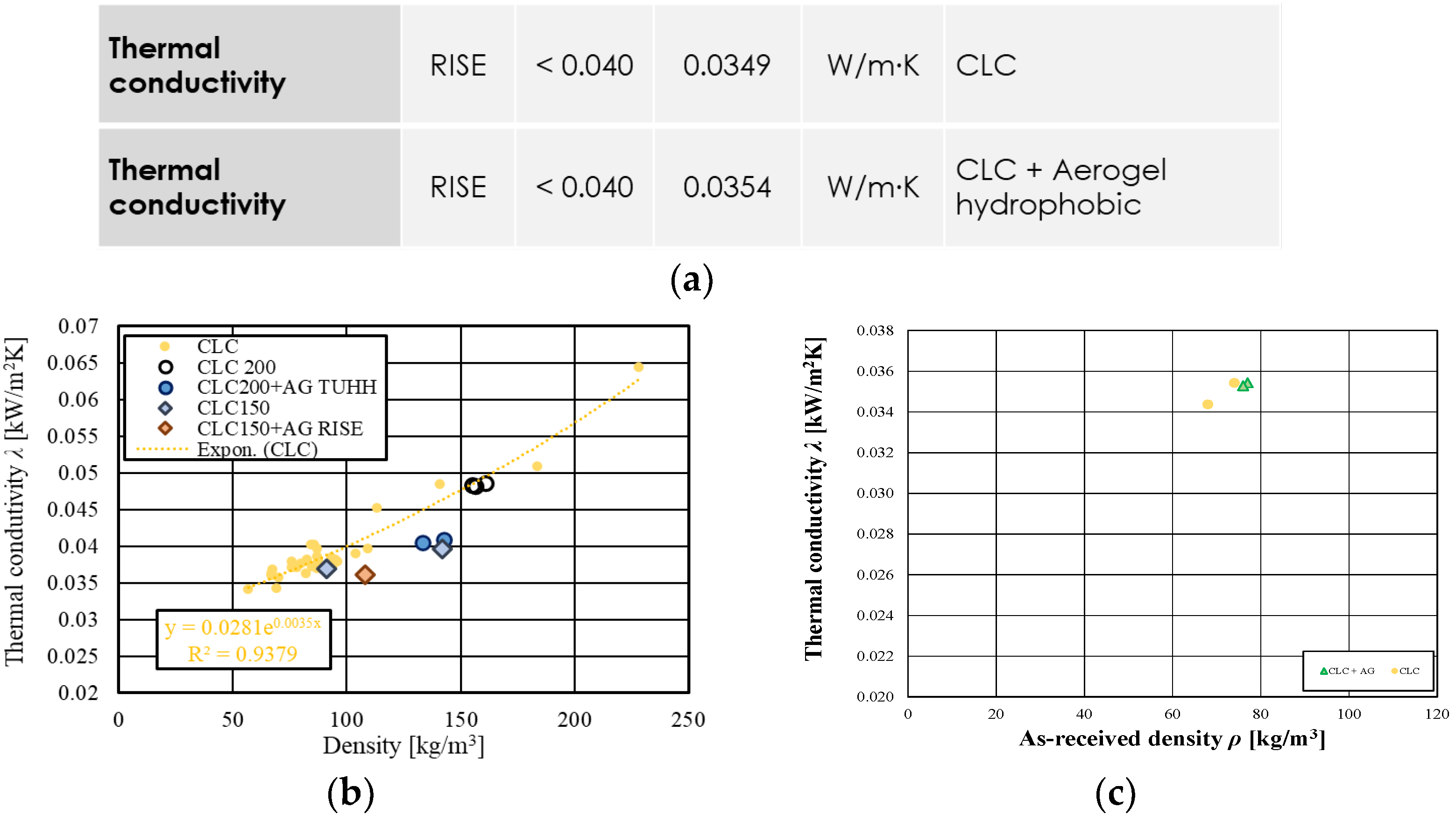

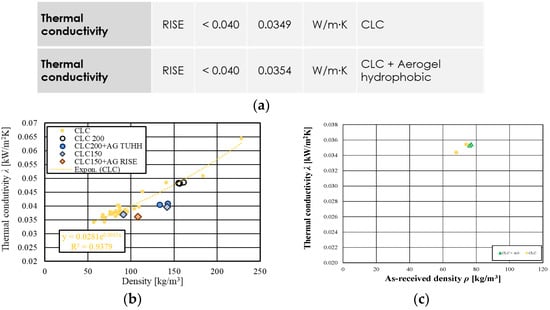

Measured thermal conductivities for baseline CLC and aerogel-modified CLC are summarized in Figure 5.

Figure 5.

(a) Improvement of thermal behavior (target thermal conductivity: 0.040 W/mK); (b) target and measured thermal conductivity for baseline CLC and CLC + aerogel; (c) thermal conductivity vs. density trend for CLC variants; (c) comparison of baseline CLC and CLC + aerogel.

Test Sample(s) Description and Preparation

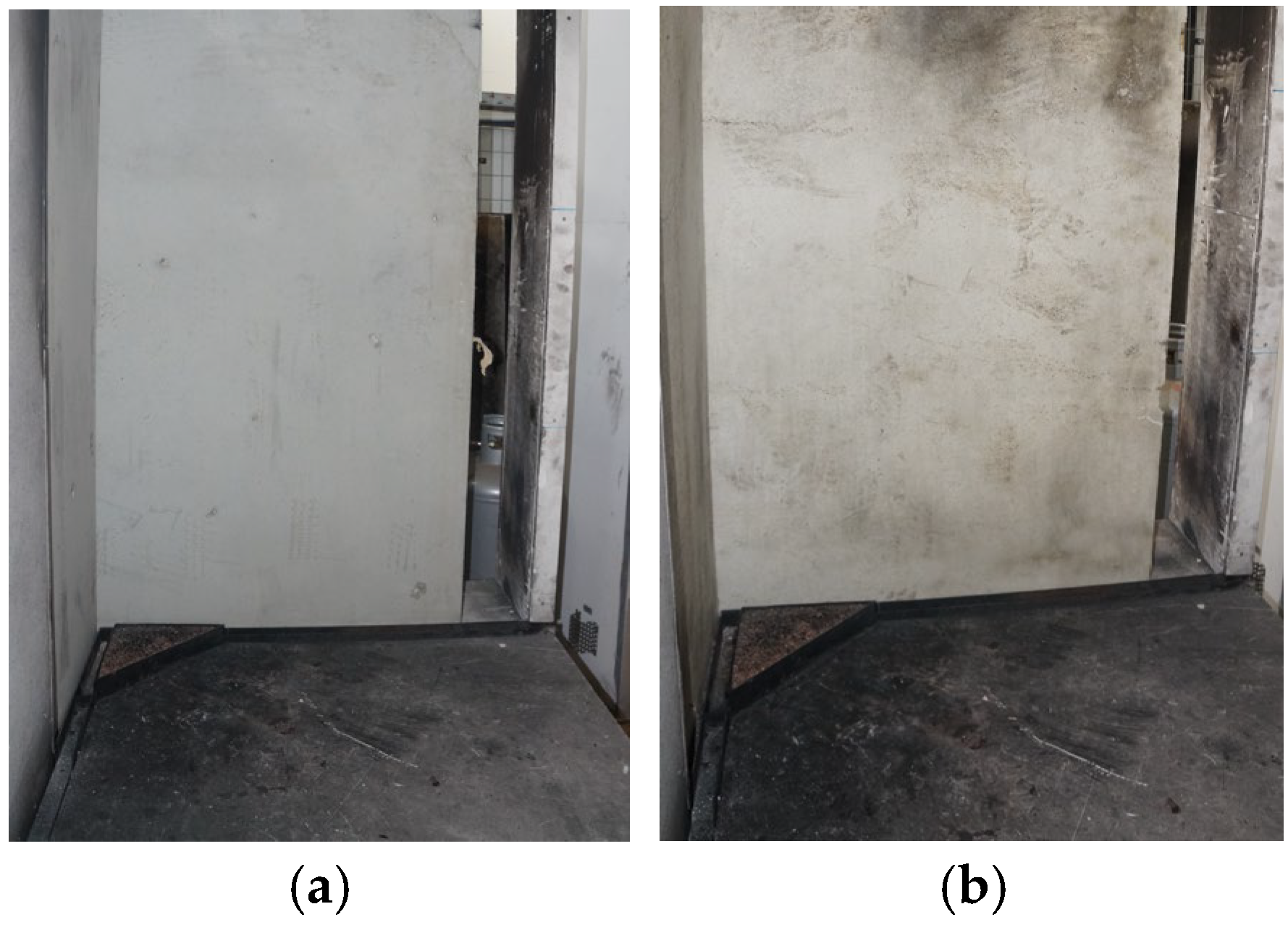

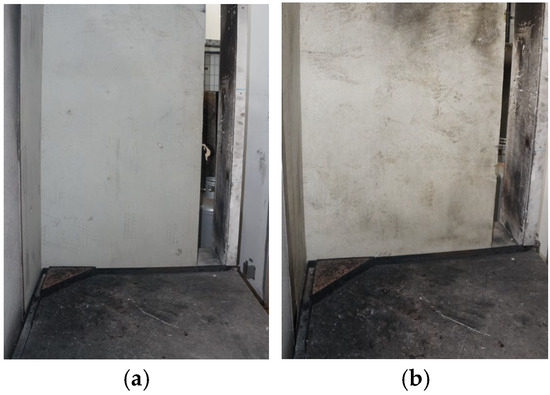

Two specimens were tested. The specimens were identical; one was tested with the indoor side exposed to the fire, while the second was tested with the outdoor side exposed to the fire. The two test specimens and their exposed sides are shown in Figure 6.

Figure 6.

(a) TC4-indoor and (b) TC4-outdoor.

The test conditions that were considered are the following:

- Barometric pressure 98,700 Pa, 99,300 Pa;

- Relative humidity 51%, 46%;

- Ambient temperature 19 °C, 19 °C.

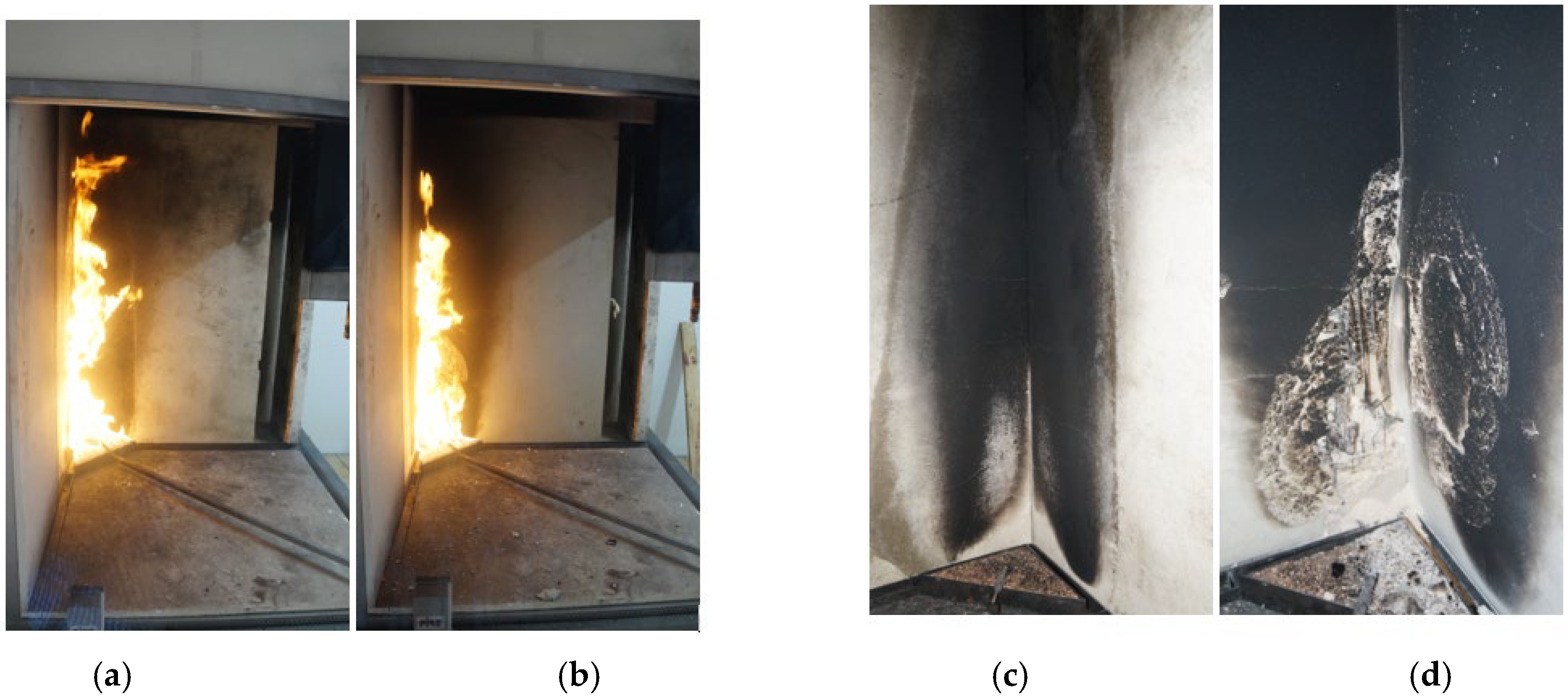

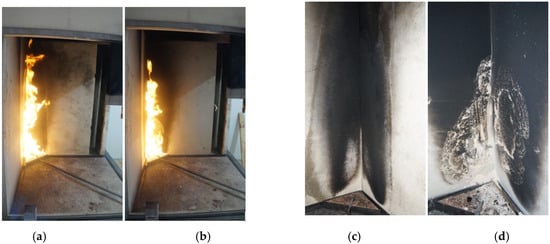

The post-test appearance of the specimens is documented in Figure 7.

Figure 7.

(a) TC4-indoor and (b) TC4-outdoor 10 min after the ignition; (c) TC4-indoor and (d) TC4-outdoor after the experiment.

The TC4-outdoor, although having similar fire performance to the TC4-indoor, caused an eruption during the test. This does not affect the reaction to fire performance but has to be taken into account when designing a building. By combining test results obtained in the two standard fire tests and based on the classification criteria [3], presented in the table, using the combined EN 1716 [5] and EN 13823 [4] results, the estimated reaction-to-fire classification is A2-s1,d0 (A1 possible pending EN ISO 1182 [7]). The eruption observed in the outdoor-exposed configuration does not alter the classification but must be considered in design.

EN 1716 [5]: Commonly known as the oxygen bomb. Determination of the heat of combustion of a material (substantial and non-substantial components of a product). It is required for classification A1 and A2.

EN 11925-2 [8]: Ignitability of building products subjected to direct impingement of flame—Part 2: single-flame source test results are required for a classification E—B, combined with test results from EN 13823 [4].

4. Discussion

Techno-Economic Screening of Aerogel Addition

We estimate the cost per unit U-value improvement for substituting CLC with CLC + aerogel in the core, at equal panel thickness. Let ΔU be the modeled U-value change from measured λ (guarded by uncertainty) and CΔ the net material cost difference per m2; (aerogel-containing mix vs. baseline CLC). A simple screening metric is cost-effectiveness = CΔ/|ΔU| [€·m2·K/W], to be compared with the project-specific energy-savings value over service life. For the current mixes (no λ benefit observed), ΔU ≈ 0 ⇒ no economic case. This motivates focusing on mix designs with hydrophobic aerogel and moisture control during curing, then re-evaluating with the same metric (A full techno-economic analysis—capex/opex, energy savings by climate, and payback—will follow when improved λ data are available.). The results demonstrate the feasibility of integrating structural performance, insulation efficiency, and fire safety in a lightweight sandwich panel. Lignin-based carbon fibers offer a sustainable alternative to conventional fibers without compromising performance. While aerogel addition slightly improved thermal properties, its cost–benefit ratio remains negative. Moisture management during production was found essential to maintain thermal performance. Overall, the multifunctional TRC/CLCi panels meet key performance indicators for building envelopes and offer a sustainable alternative to conventional systems.

Strict moisture control during CLC production and curing remains essential to preserve thermal performance and to avoid variability in λ.

5. Conclusions

Finally, we introduce a screening LCA framework to substantiate the sustainability narrative around lignin-based carbon fibers in future work; quantified LCA results will be disseminated as the inventory is finalized.

The developed TRC/CLCi panels provide an integrated solution for structural, thermal, and fire failure mitigation. Key findings include (i) sufficient load-bearing capacity with eco-friendly materials, (ii) thermal conductivities below the target of 0.040 W/m·K, (iii) excellent freeze–thaw durability and low water absorption, and (iv) fire classification of A2-s1,d0. These outcomes highlight the panels’ suitability as multifunctional, sustainable facade solutions for modern energy-efficient buildings.

Author Contributions

Conceptualization, P.V. and V.T.; methodology, P.V., M.S., R.B., L.S., H.F.M.P., M.T., M.P., J.S., D.K., A.K., M.M.D. and C.C.; investigation, all authors; writing—original draft preparation, P.V. and V.T.; writing—review and editing, all authors; supervision, V.T. and C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Union’s Horizon 2020 project, grant agreement no. 952886, iclimabuilt-Functional and advanced insulating and energy harvesting/storage materials across climate adaptive building envelopes.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors gratefully acknowledge the support of the iclimabuilt consortium and testing facilities provided by partner institutions. All individuals mentioned have consented to being acknowledged.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Teixeira, M.H.; Amorim, L.; Araújo, A.; Sousa, S.; Santos, R. Performance of eco-composite sandwich panels manufactured by vacuum bagging infusion. In Proceedings of the National Congress of Composite Materials (MATCOMP 2023), Gijón, Spain, 13–15 June 2023; pp. 1–12. [Google Scholar] [CrossRef]

- Sousa, S.; Araújo, A.; Amorim, L.; Rocha, R.; Teixeira, M.H.; Santos, R. Multifunctional Fibre-Reinforced Composite Sandwiches for Eco-Friendly Buildings. In Proceedings of the 20th European Conference on Composite Materials (ECCM20), Lausanne, Switzerland, 26–30 June 2022. [Google Scholar] [CrossRef]

- EN 13501-1; Fire Classification of Construction Products and Building Elements—Part 1: Classification Using Test Data from Reaction to Fire Tests. CEN: Brussels, Belgium, 2019.

- EN 13823; Reaction to Fire Tests for Building Products—Building Products Excluding Floorings Exposed to the Thermal attack By a Single Burning Item. CEN: Brussels, Belgium, 2020.

- EN ISO 1716; Reaction to Fire Tests for Products—Determination of the Gross Heat of Combustion (Calorific Value). CEN: Brussels, Belgium, 2018.

- Ali, A.; Kieseritzky, E.; Bogacz, A.; Tsiokou, V.; Susana, P.B.S. Innovative integration of phase change materials and conceptional design of test cases—New products for the building envelope. J. Phys. Conf. Ser. 2023, 2654, 012101. [Google Scholar] [CrossRef]

- EN ISO 1182; Reaction to Fire Tests for Products—Non-Combustibility Test. CEN: Brussels, Belgium, 2020.

- EN 11925-2; Reaction to Fire Tests for Building Products—Ignitability of Products Subjected to Direct Impingement of flame—Part 2: Single-Flame Source Test. CEN: Brussels, Belgium, 2002.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).