An Advanced Stochastic 1D Inverse Finite Element Method for Strain Extrapolation with Experimental Validation †

Abstract

1. Introduction

2. Methodology

2.1. The 1D Inverse Finite Element Method

2.2. Gaussian Process

2.3. Combining iFEM and Gaussian Process

3. Case Study

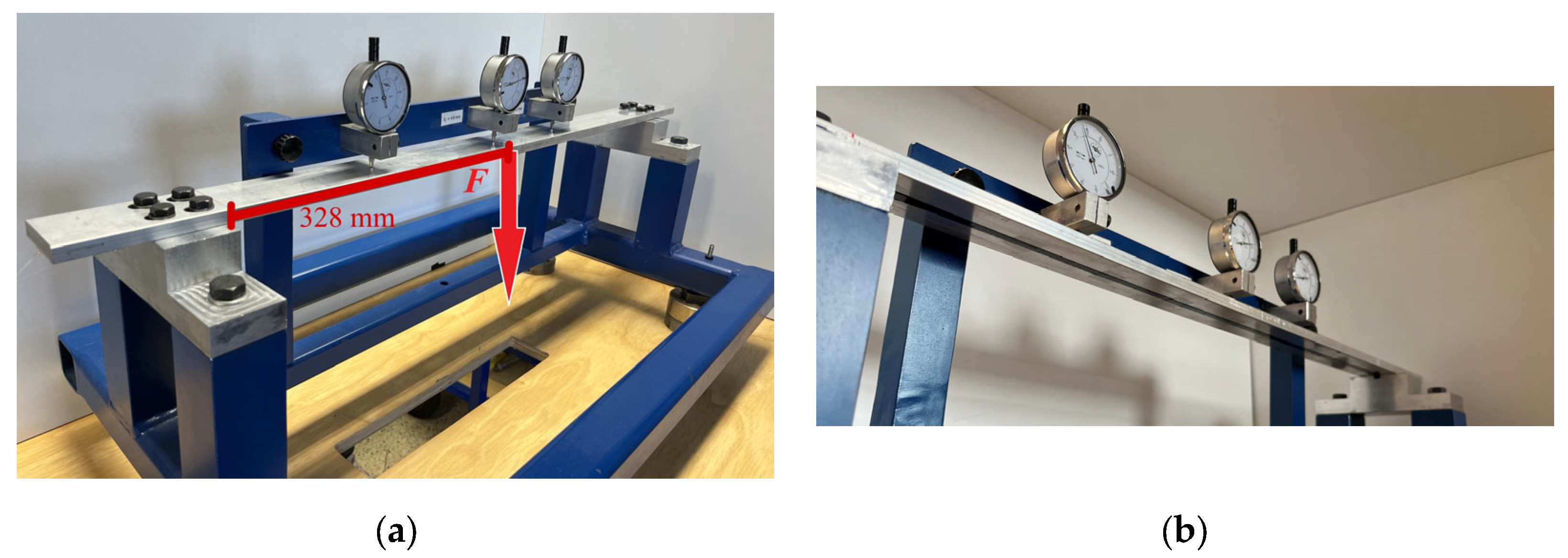

3.1. Experimental Test

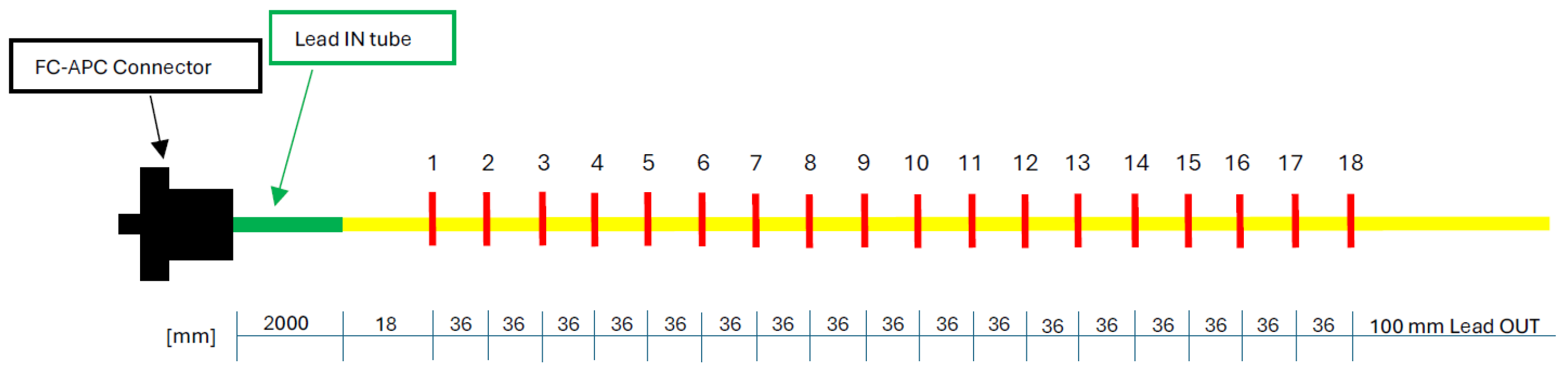

3.2. The Sensor Network

3.3. The Inverse FE Model

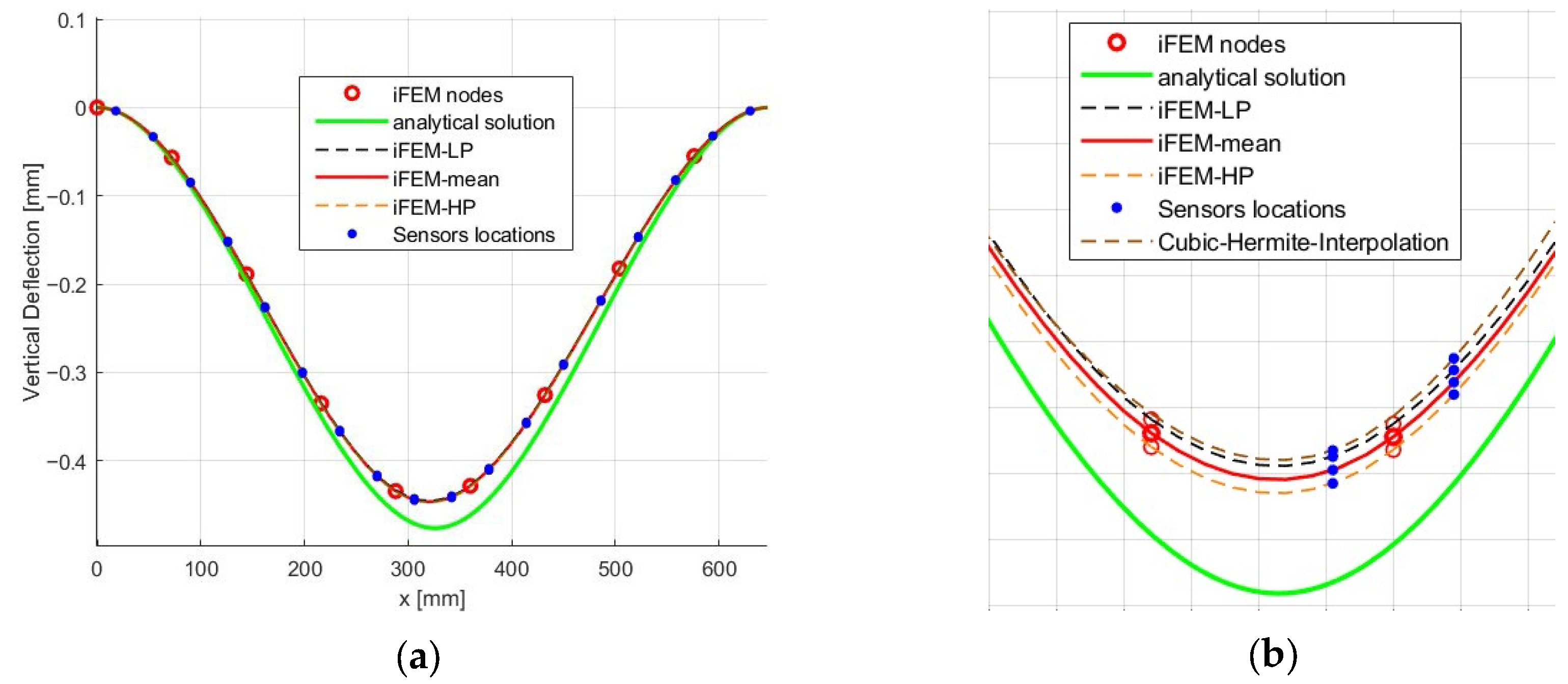

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Worden, K.; Cross, E.J.; Dervilis, N.; Papatheou, E.; Antoniadou, I. Structural Health Monitoring: From Structures to Systems-of-Systems. IFAC-PapersOnLine 2015, 48, 1–17. [Google Scholar] [CrossRef]

- Pallarés, F.J.; Betti, M.; Bartoli, G.; Pallarés, L. Structural Health Monitoring (SHM) and Nondestructive Testing (NDT) of Slender Masonry Structures: A Practical Review. Constr. Build. Mater. 2021, 297, 123768. [Google Scholar] [CrossRef]

- Ma, Z.; Choi, J.; Sohn, H. Structural Displacement Sensing Techniques for Civil Infrastructure: A Review. J. Infrastruct. Intell. Resil. 2023, 2, 100041. [Google Scholar] [CrossRef]

- Poloni, D.; Morgese, M.; Wang, C.; Taylor, T.; Giglio, M.; Ansari, F.; Sbarufatti, C. Reference-Free Distributed Monitoring of Deflections in Multi-Span Bridges. Eng. Struct. 2025, 323, 119277. [Google Scholar] [CrossRef]

- Savino, P.; Gherlone, M.; Tondolo, F. Shape Sensing with Inverse Finite Element Method for Slender Structures. Struct. Eng. Mech. 2019, 72, 217–227. [Google Scholar] [CrossRef]

- Oboe, D.; Colombo, L.; Sbarufatti, C.; Giglio, M. Comparison of Strain Pre-Extrapolation Techniques for Shape and Strain Sensing by iFEM of a Composite Plate Subjected to Compression Buckling. Compos. Struct. 2021, 262, 113587. [Google Scholar] [CrossRef]

- Poloni, D.; Oboe, D.; Sbarufatti, C.; Giglio, M. Towards a Stochastic Inverse Finite Element Method: A Gaussian Process Strain Extrapolation. Mech. Syst. Signal Process. 2023, 189, 110056. [Google Scholar] [CrossRef]

- Rasmussen, C.E.; Williams, C.K.I. Gaussian Processes for Machine Learning, 1st ed.; MIT Press: Cambridge, MA, USA, 2005. [Google Scholar] [CrossRef]

- Gherlone, M.; Cerracchio, P.; Mattone, M.; Di Sciuva, M.; Tessler, A. An Inverse Finite Element Method for Beam Shape Sensing: Theoretical Framework and Experimental Validation. Smart Mater. Struct. 2014, 23, 045027. [Google Scholar] [CrossRef]

- Ebden, M. Gaussian processes: A quick introduction. arXiv 2015, arXiv:1505.02965. [Google Scholar] [CrossRef]

- Schulz, E.; Speekenbrink, M.; Krause, A. A Tutorial on Gaussian Process Regression: Modelling, Exploring, and Exploiting Functions. J. Math. Psychol. 2018, 85, 1–16. [Google Scholar] [CrossRef]

- Petit, S.J.; Bect, J.; Feliot, P.; Vazquez, E. Parameter Selection in Gaussian Process Interpolation: An Empirical Study of Selection Criteria. SIAM/ASA J. Uncertain. Quantif. 2023, 11, 1308–1328. [Google Scholar] [CrossRef]

- Jidling, C. Strain Field Modelling Using Gaussian Processes. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2017. [Google Scholar]

- Abdessalem, A.B.; Dervilis, N.; Wagg, D.J.; Worden, K. Automatic Kernel Selection for Gaussian Processes Regression with Approximate Bayesian Computation and Sequential Monte Carlo. Front. Built Environ. 2017, 3, 52. [Google Scholar] [CrossRef]

- Duvenaud, D.; Lloyd, J.R.; Grosse, R.; Tenenbaum, J.B.; Ghahramani, Z. Structure Discovery in Nonparametric Regression through Compositional Kernel Search. In Proceedings of the 30th International Conference on Machine Learning (ICML), Atlanta, GA, USA, 16–21 June 2013. [Google Scholar] [CrossRef]

| Trial | N° of Sensors | Sensors’ Index 1 | Weight for Extrapolated Strains 2 |

|---|---|---|---|

| 1 | 18 | Theoretical | |

| 2 | 9 | Theoretical |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bardiani, J.; Marotta, R.; Petriconi, E.; Aravanis, G.; Manes, A.; Sbarufatti, C. An Advanced Stochastic 1D Inverse Finite Element Method for Strain Extrapolation with Experimental Validation. Eng. Proc. 2025, 119, 8. https://doi.org/10.3390/engproc2025119008

Bardiani J, Marotta R, Petriconi E, Aravanis G, Manes A, Sbarufatti C. An Advanced Stochastic 1D Inverse Finite Element Method for Strain Extrapolation with Experimental Validation. Engineering Proceedings. 2025; 119(1):8. https://doi.org/10.3390/engproc2025119008

Chicago/Turabian StyleBardiani, Jacopo, Roberto Marotta, Emanuele Petriconi, Georgios Aravanis, Andrea Manes, and Claudio Sbarufatti. 2025. "An Advanced Stochastic 1D Inverse Finite Element Method for Strain Extrapolation with Experimental Validation" Engineering Proceedings 119, no. 1: 8. https://doi.org/10.3390/engproc2025119008

APA StyleBardiani, J., Marotta, R., Petriconi, E., Aravanis, G., Manes, A., & Sbarufatti, C. (2025). An Advanced Stochastic 1D Inverse Finite Element Method for Strain Extrapolation with Experimental Validation. Engineering Proceedings, 119(1), 8. https://doi.org/10.3390/engproc2025119008