Abstract

Ductile iron—also known as spheroidal graphite iron (SGI)—is a versatile material that exhibits a wide range of applications. In addition to the matrix structure itself, graphite morphology and material defects, such as graphite degenerations, also have a decisive influence on its mechanical properties. Missing or incomplete classifications of these deviating graphite morphologies in common standards, alongside insufficient knowledge regarding their effects, leads to a more complicated lifetime assessment and often results in rejection of SGI components. Therefore, relevant material parameters were derived from experimental quasi-static and fatigue investigations on SGI materials with different graphite degenerations and correlated with microstructural parameters quantified by an optimized digital image analysis method. While a linear correlation between the amount and mechanical properties was identified for spiky graphite, for chunky graphite, the presence in general can lead to a detrimental reduction in mechanical properties.

1. Introduction

Ductile iron, i.e., spheroidal graphite iron (SGI), is a versatile material with a wide range of applications through various material grades. The mechanical properties of SGI materials highly depend on the microstructure, which is a combination of a ferritic, pearlitic, or ferritic–pearlitic matrix with a spheroidal graphite morphology. The metallic matrix, along with the graphite morphology, is affected by several factors, including the alloying components of the melt, the casting system, and the solidification conditions. With increasing wall thickness of SGI components, the associated local solidification times as well as the risk of an accumulation of impurities are present in the melt rise, leading to larger graphite nodules and often local deviations in graphite morphology. This includes chunky graphite (CHG) and spiky graphite (SPG), as well as general deviations from the ideally spherical graphite shape (form VI and V according to [1]) to a more vermicular shape (form III [1]). These deviations in graphite morphology, particularly the different types of graphite degenerations, can lead to an increased notch effect within the material and ultimately to lower mechanical properties [2,3,4,5]. However, their influence on mechanical properties is often not sufficiently known. To estimate the fatigue strength of a SGI component in presence of graphite degenerations, and thus optimally exploit the strength as well as the lightweight potential in the design of cast components, it is necessary to develop methods for a generalized classification of deviating graphite morphologies and identify their effects on mechanical material properties. Therefore, specimens taken from SGI castings with different graphite degenerations were used for quasi-static and cyclic material tests. Metallographic analysis was carried out to identify parameters for the classification of the graphite morphology, with focus on graphite degenerations. Finally, the correlation between the mechanical properties and the proportion of graphite degenerations was investigated.

2. Materials and Methods

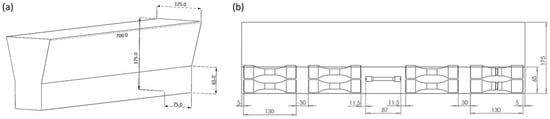

Based on the investigations described in [6], blocks from different molds with chemical compositions based on EN-GJS-500-14 (Table 1) were used. The relevant wall thickness of these YIV blocks is 75 mm (Figure 1a). By utilizing long solidification times and adding the element antimony, the intention was to provoke the formation of spiky graphite in these castings (A-500-1 and A-500-2). For one mold (A-500-4), the addition of antimony was omitted to use these blocks as a reference material.

Table 1.

Chemical compositions of the investigated materials.

Figure 1.

(a) Geometry of the investigated YIV blocks, (b) specimen removal plan.

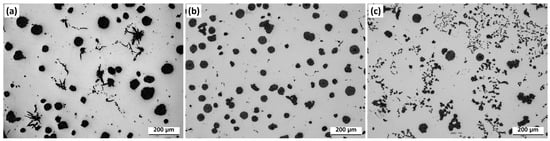

Metallographic examinations of the YIV blocks conducted before the specimen removal confirmed the presence of spiky graphite and intercellular–lamellar graphite (Figure 2a) in the blocks with antimony addition. In contrast, only a few locations of an undisturbed microstructure (Figure 2b) were identified in the blocks without the addition of antimony, whereas chunky graphite (Figure 2c) was frequently observed. These findings correspond with the established relationship that long solidification times combined with high silicon contents promote the formation of chunky graphite in SGI materials [2]. Conversely, the results indicate that adding antimony under these processing conditions suppresses chunky graphite and leads to the formation of spiky graphite instead.

Figure 2.

Comparison of microstructures of (a) a specimen containing spiky graphite; (b) a specimen without graphite degeneration; (c) a specimen containing chunky graphite.

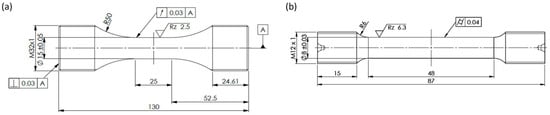

The tensile and fatigue specimens with the geometry shown in Figure 3 were extracted from the YIV blocks regarding the specimen removal plan illustrated in Figure 1b. Subsequently, tensile tests and cyclic material investigations were conducted. The fatigue strength tests were performed force-controlled at stress ratios of Rσ = −1 and Rσ = 0 on electromagnetic resonance pulsers. The corresponding results were used for the determination of the S-N lines estimated using the maximum likelihood method [7,8] and assuming a slope in the very high cycle lifetime (VHCF) regime of k* = 44.89 according to [9]. Additionally, metallographic and fractographic examinations were performed. Due to the absence of options automatically classifying graphite degenerations in commercial image analysis software, the image digital analysis described in [10,11] was conducted to evaluate the proportions of graphite degenerations.

Figure 3.

Geometry of (a) the used fatigue specimens; (b) the used tensile specimens.

3. Results

The results of the quasi-static material investigations of the three material conditions are compared in Table 2 with the characteristic values of EN-GJS-500-14 from the DIN EN 1563 standard [12] for a component wall thickness of 30–60 mm. In addition to these averaged results from the 12 tensile specimens per material, the standard deviation is provided to verify the scattering in the values. Notably, the elongation at break A5 is significantly higher in all three materials compared to the standard, despite the presence of graphite degenerations. The tensile strength Rm and yield strength Rp0.2 of the materials also exceed the characteristic values listed in the standard. In case of the scattering, A-500-4 exhibited higher standard deviations for tensile strength and elongation at break, indicating a more heterogeneous microstructure than the other materials.

Table 2.

Quasi-static properties of the examined material conditions compared to minimum required properties of an EN-GJS-500-14 given by DIN EN 1563 [12].

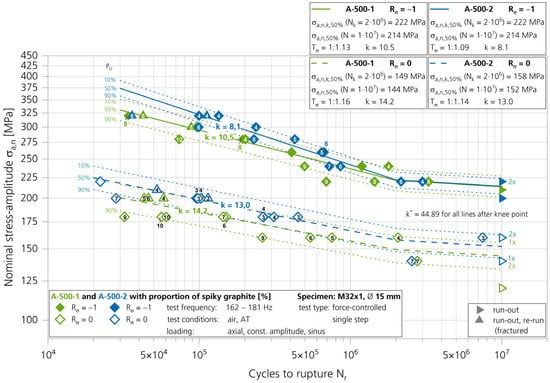

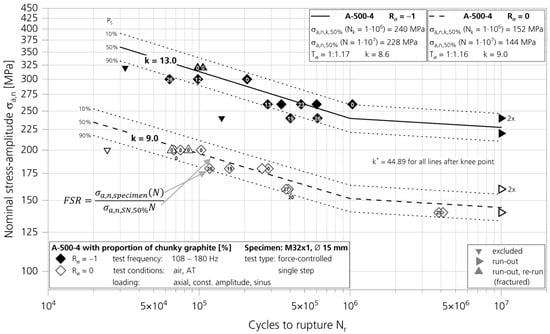

For each test series of the material states investigated, approximately 17 specimens were used for cyclic testing. The resulting S-N curves are presented in Figure 4 for A-500-1 and A-500-2 as well as in Figure 5 for A-500-4, indicating the proportions of graphite degenerations—spiky graphite in Figure 4 and chunky graphite in Figure 5—as percentage values in the symbols of the individual specimens. It is apparent that for all materials, specimens with higher proportions tend to exhibit shorter lifetimes.

Figure 4.

S-N curve of A-500-1 and A-500-2 at Rσ = −1 and Rσ = 0 with noted fraction of spiky graphite.

Figure 5.

S-N curve of A-500-4 at Rσ = −1 and Rσ = 0 with noted fraction of chunky graphite as well as the determination of the fatigue strength ratio FSR exemplary shown for one specimen.

To quantify this negative impact on fatigue strength, the fatigue strength ratio (FSR) is used. The determination of the FSR is illustrated in Figure 5. This ratio describes, according to Equation (1), the relationship between the nominal stress amplitude of an individual specimen and the nominal stress amplitude of the corresponding S-N curve for a survival probability of 50% at the same number of cycles to failure.

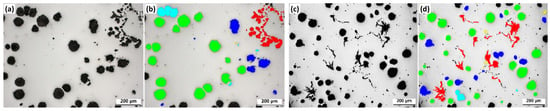

For a more detailed investigation of the correlation between the mechanical properties and the microstructure, metallographic and fractographic analyses were conducted. The fracture surface analyses using a scanning electron microscope revealed only minimal occurrences of pores and shrinkages in the crack initiation sites, indicating that other defects in the microstructure, such as graphite degenerations, dominated the crack initiation. The metallographic examinations showed a nearly completely ferritic matrix for all three material states. To quantify the graphite morphology focusing on graphite degenerations, digital image analysis according to [10] was performed on microsections close to the fracture surface of the individual specimens. The used digital image analysis method allowed for an accurate determination of the content of graphite degenerations as a fraction of the total area of all graphite precipitates for each tensile and fatigue specimen (Figure 6). On average, the proportion of spiky graphite for A-500-1 was 6%, and for A-500-2, the fraction was 5%. In the case of A-500-4, no spiky graphite was identified. However, the average chunky graphite proportion was determined to 10% for A-500-4.

Figure 6.

Overview of micrographs with spiky graphite (a) and chunky graphite (c); assessment of the graphite particles with spiky graphite (b, red), chunky graphite (d, red), spheroidal graphite (b,d, green, blue, and cyan), and other graphite (b,d, yellow).

4. Discussions

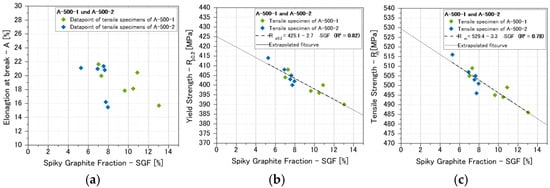

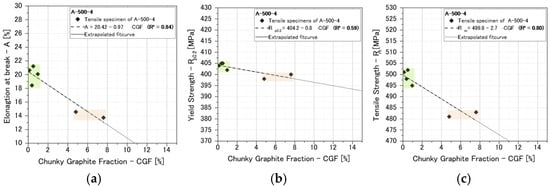

For further investigations of the influence of graphite degenerations on the quasi-static characteristic values, the individual results of the tensile strength Rm, the yield strength Rp0.2 and the elongation at break A5 were correlated with the determined proportions of graphite degenerations for each tensile specimen (Figure 7 and Figure 8). A direct relationship between the amount of spiky graphite and the tensile strength Rm as well as the yield strength Rp0.2 was observed. This linear correlation demonstrates that an increased proportion of spiky graphite directly leads to reduced strength. In the case of the elongation at break A5, only a trend about the negative effect of spiky graphite is apparent. For the material A-500-4, only two tensile samples exhibited a significant proportion of chunky graphite in the microsection close to the fracture surface. For these two specimens analyzed, as shown in Figure 8, there was a significant decrease in all quasi-static properties compared to the remaining tensile specimens, illustrating the negative influence of chunky graphite.

Figure 7.

Correlation between the results of the tensile tests and the fraction of spiky graphite of the A-500-1 and A-500-2: (a) elongation at break; (b) yield strength; (c) tensile strength.

Figure 8.

Correlation between the results of the tensile tests and the fraction of chunky graphite of the A-500-4: (a) elongation at break; (b) yield strength; (c) tensile strength.

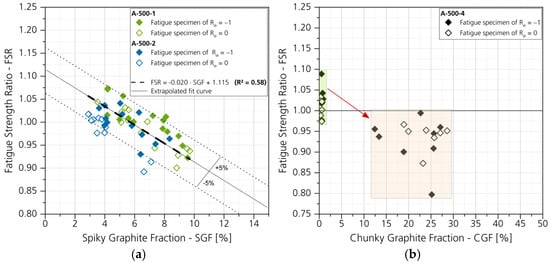

Thus, alongside the quasi-static characteristic values, a negative impact of graphite degenerations on the cyclic material properties was also identified. In Figure 9, the fatigue strength ratios (FSRs) of the individual fatigue samples are compared to the determined proportions of graphite degenerations. As with the quasi-static characteristic values, there is a direct correlation between the proportion of spiky graphite and the FSR. For the investigated materials, an increase in the spiky graphite proportion from 3% to 10% reduces the FSR, on average, from 1.05 to 0.92, equivalent to a decrease in fatigue strength of 12%. For the material A-500-4 with chunky graphite, a linear relationship between the FSR and the chunky graphite proportion cannot be identified. Nonetheless, the comparison indicates that the general occurrence of chunky graphite already leads to a reduction in the cyclic properties, while the exact proportion of chunky graphite is of minor importance.

Figure 9.

(a) Correlation between fatigue strength ratio (FSR) and the fraction of spiky graphite (SPG); (b) correlation between fatigue strength ratio (FSR) and the fraction of chunky graphite (CHG).

5. Conclusions

To investigate the impact of graphite degenerations on the mechanical properties of SGI, tensile tests, fatigue tests, and metallographic analysis were performed at three high-silicon cast iron materials with varying amounts antimony added. The metallographic results revealed that without antimony addition, the combination of the chosen alloy composition and the casting parameters, especially long solidification times, promote the formation of chunky graphite. The addition of antimony leads to the formation of spiky graphite instead of chunky graphite.

The mechanical investigations demonstrated that quasi-static and cyclic material properties are negatively affected by chunky graphite and spiky graphite. For the materials with antimony addition, a linear correlation between the increasing proportion of spiky graphite and the reduction in material properties was observed. Although this linear relationship could not be determined for the elongation at break, a general decrease in elongation with increasing spiky graphite proportion was noted. In the case of the material state without antimony addition, either no chunky graphite or proportions of 10–30% were determined in the microsections close to the fracture surface for the corresponding specimens. The specimens containing chunky graphite exhibited significantly lower quasi-static properties and fatigue strengths compared to specimens without chunky graphite. However, no linear correlation was found between the proportion of chunky graphite and the quasi-static or cyclic results.

Fundamentally, the metallographic results demonstrated that the combination of a high silicon alloy composition and long solidification times lead to chunky graphite formation and should therefore be avoided in the production of SGI components. With the addition of antimony, the chunky graphite can be suppressed, but this addition should be used carefully, as it promotes the formation of spiky graphite. The studies showed that spiky graphite leads to a decrease in mechanical, which is linearly related to its amount. This means that the formation of spiky graphite in SGI components could be less critical, as long as the formation occurs outside the highly stressed regions of the component and generally only in low amounts. Due to the finer distribution of spiky graphite in the microstructure compared to chunky graphite, a precise prediction of its hotspots is necessary for an optimized assessment of SGI components. This requires further investigations with different SGI grades as well as with varying amounts of graphite degenerations. In the end, these results will create opportunities to evaluate the influence of occurring graphite degenerations more comprehensively and reliably in the future, thus reducing the rejection of SGI components.

Author Contributions

Conceptualization, T.S. and J.N.; methodology, T.S.; software, T.S.; validation, T.S. and J.N.; formal analysis, T.S.; investigation, T.S.; resources, T.S.; data curation, T.S.; writing—original draft preparation, T.S.; writing—review and editing, T.S. and J.N.; visualization, T.S.; supervision, T.S.; project administration, T.S.; funding acquisition, J.N. All authors have read and agreed to the published version of the manuscript.

Funding

The results of this paper originate from the research project “DeGra”, which was funded by the Federal Ministry for Economic Affairs and Energy (BMWE) on the basis of a decision by the German Bundestag, grant number 03EE2019A.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this work is available on request from the corresponding author. Additionally, data supporting reported results can be found in the final report of the research project “DeGra”, available at https://doi.org/10.34657/19672 (in German).

Acknowledgments

We would like to thank the project partners of the research project “DeGra”, who contributed to the success of this project through their participation and active support.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| CHG | Chunky graphite |

| FSR | Fatigue strength ratio |

| SGI | Spheroidal graphite iron/ductile iron |

| SPG | Spiky graphite |

| VHCF | Very high cycle fatigue lifetime |

References

- DIN EN ISO 945-1:2019-10; Mikrostruktur von Gusseisen—Teil 1: Graphitklassifizierung durch visuelle Auswertung (ISO 945-1:2019). Deutsches Institut für Normung (DIN): Berlin, Germany, 2019.

- Baer, W. Chunky Graphite in Ferritic Spheroidal Graphite Cast Iron: Formation, Prevention, Characterization, Impact on Properties: An Overview. Int. J. Met. 2020, 14, 454–488. [Google Scholar] [CrossRef]

- Sertucha, J.; Artola, G.; de La Torre, U.; Lacaze, J. Chunky Graphite in Low and High Silicon Spheroidal Graphite Cast Irons–Occurrence, Control and Effect on Mechanical Properties. Materials 2020, 13, 5402. [Google Scholar] [CrossRef] [PubMed]

- Borsato, T.; Berto, F.; Ferro, P.; Carollo, C. Influence of Solidification Defects on the Fatigue Behaviour of Heavy-Section Silicon Solution-Strengthened Ferritic Ductile Cast Iron. FFEMS 2018, 41, 2231–2238. [Google Scholar] [CrossRef]

- Lacaze, J.; Asenjo, I.; Méndez, S.; Sertucha, J.; Larrañaga, P. Experimental Evidence for Metallurgical Modification Associated to Chunky Graphite in Heavy-Section Ductile Iron Castings. Int. J. Met. 2012, 6, 35–42. [Google Scholar] [CrossRef]

- Hoffmann, P.; Bleicher, C.; Kaufmann, H. Zum Einfluss von degeneriertem Graphit auf das Schwingfestigkeitsverhalten von Gusseisen mit Kugelgraphit. In Proceedings of the Tagung Werkstoffprüfung 2021, 39. Vortrags- und Diskussionstagung, Düsseldorf, Germany; 2–3 December 2021; pp. 325–330, ISBN 978-3-941269-98-9. [Google Scholar]

- Störzel, K. Statistical Evaluation of Fatigue Tests Using Maximum Likelihood. Mater. Test. 2021, 63, 8. [Google Scholar] [CrossRef]

- Spindel, J.E.; Haibach, E. The method of maximum likelihood applied to the statistical analysis of fatigue data. Int. J. Fatigue 1979, 1, 81–88. [Google Scholar] [CrossRef]

- Sonsino, C.M. Course of SN-curves especially in the high- cycle fatigue regime with regard to component design and safety. Int. J. Fat. 2007, 29, 2246–2258. [Google Scholar] [CrossRef]

- Pittel, C.; Steingräber, T.; Bleicher, C. Beschreibung des Zyklisch Dehnungsbasierten Werkstoffverhaltens von EN-GJS-400-18 mit Chunky-Graphit. In Proceedings of the Tagung Werkstoffprüfung 2021, 39. Vortrags- und Diskussionstagung, Düsseldorf, Germany; 2–3 December 2021; pp. 307–312, ISBN 978-3-941269-98-9. [Google Scholar]

- Gogolin, J.; Tonn, B.; Steingräber, T.; Hoffmann, P.; Niewiadomski, J. Influence of alloying and trace elements on micro-structure and mechanical properties of ductile cast iron. In Proceedings of the InCeight Casting C8—International Congress of the Foundry Industry, Darmstadt, Germany; 6–8 March 2023; pp. 25–37, ISBN 978-3-8396-1892-9. [Google Scholar] [CrossRef]

- DIN EN 1563:2019-04; Gießereiwesen—Gusseisen mit Kugelgraphit; Deutsche Fassung EN 1563:2018. Deutsches Institut für Normung (DIN): Berlin, Germany, 2019.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.