Abstract

Efficient grain storage is critical for ensuring food security, particularly in regions with hot and humid climates where environmental fluctuations can accelerate spoilage. This study presents the development of a low-cost, Arduino-based microcontroller platform Smart Grain Monitoring System designed to continuously monitor key storage parameters. The system integrates sensors to measure temperature, relative humidity, air quality, and the weight of stored grains—factors essential for the early detection of microbial activity, fermentation, or structural degradation. Data is transmitted wirelessly in real time to a mobile application via the Blynk Internet of Things (IoT) platform, allowing for remote access, alerts, and trend analysis. The system is designed to be affordable, scalable, and easy to deploy in agricultural settings with limited infrastructure. To enhance mechanical performance and usability, the sensor system is housed in a reflective glass silo enclosure that provides both thermal insulation and visual grain access. A three-dimensional computer-aided design (3D CAD)model was developed to optimize the placement of electronics and ensure structural integrity. Key features include custom mounts for sensors and electronics, a top lid for grain refill and hygiene, and a stable base for load cell installation. This integrated framework offers a reliable, real-time monitoring solution that supports proactive grain management and reduces post-harvest losses in rural storage environments.

1. Introduction

Food grain storage is a fundamental component of global food supply chains, with storage losses significantly affecting food security and economic stability, particularly in developing countries. According to the FAO, post-harvest losses of cereal grains in some developing countries can exceed 30%, mostly due to improper storage conditions and lack of monitoring systems [1]. In tropical and subtropical regions, high temperatures and humidity levels provide ideal conditions for the growth of molds, proliferation of insects, and increased microbial activity, all of which contribute to spoilage and deterioration of grain quality [2].

Traditional storage systems often rely on manual inspections and lack real-time data collection. This results in delayed responses to environmental fluctuations that could lead to irreversible damage to stored grains [1]. In recent years, the advent of the Internet of Things (IoT) has enabled the development of automated systems that can remotely monitor environmental parameters critical to grain preservation, such as temperature, relative humidity, CO2 levels, and weight [3].

Numerous studies have highlighted the benefits of IoT-based monitoring in agricultural contexts. Ref. [4] demonstrated the positive impact of a mobile IoT solution on maize drying and storage in Rwanda, leading to improved grain safety. Similarly, Ref. [5] used an ESP32-based system to track grain moisture levels with high accuracy, proving the effectiveness of such platforms in data collection and cloud transmission. Ref. [6] emphasized the importance of modular design and real-time alert systems to improve user interaction and reduce dependence on manual observation.

Despite these advances, many existing solutions still suffer from drawbacks such as high power consumption, complex wiring, and reliance on GSM networks with recurring costs [7]. There remains a need for low-cost, energy-efficient, and Wi-Fi-based systems that are easy to deploy in low-resource environments. This work aims to address these gaps by introducing a fully integrated smart grain monitoring system that utilizes a single ESP32 board to collect, process, transmit, and visualize data. The use of a reflective enclosure, 3D-printed components, and a rechargeable battery ensures that the system is not only functional but also sustainable and adaptable to real-world agricultural scenarios.

2. Methods

2.1. System Architecture

The system comprises the following components:

- DHT11: for temperature and humidity

- MQ135: for CO2 and air quality

- Load Cell (HX711 amplifier): for grain weight

- ESP32 microcontroller

- 16 × 2 LCD with I2C module

- Rechargeable lithium-ion battery with TP4056 charger module

- Data Transmission: via the Blynk platform over Wi-Fi

- 3D Housing: transparent, reflective acrylic silo with modular slots for electronics

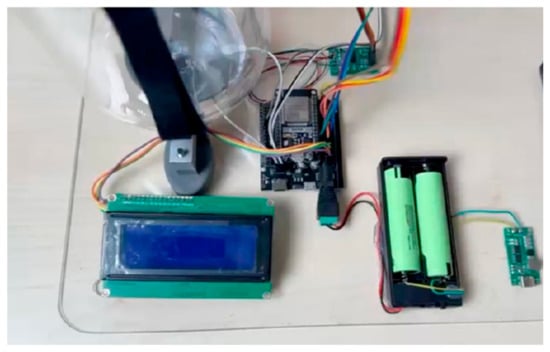

The ESP32 is programmed to collect data every 30 s, transmit it to the Blynk dashboard, and trigger local alarms if critical thresholds are breached (e.g., >27 °C or >70% RH). The overall architecture of the Smart Grain Monitoring (SGM) system is illustrated in Figure 1.

Figure 1.

Diagram of the Smart Grain Monitoring (SGM) System. The setup integrates a DHT11 sensor (temperature and humidity), MQ135 sensor (air quality), load cell (weight), ESP32 microcontroller, rechargeable battery with charging circuit, LCD display, and Blynk IoT platform for real-time data visualization.

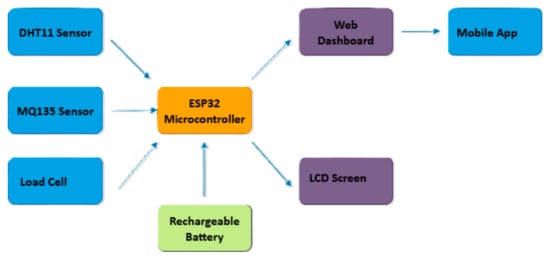

The block diagram of the proposed Smart Grain Monitoring System, showing the integration of temperature, humidity, carbon dioxide (CO2), and weight sensors with the ESP32 microcontroller and Internet of Things communication, is presented in Figure 2.

Figure 2.

Block diagram of the proposed Smart Grain Monitoring System, integrating temperature, humidity, CO2, and weight sensors with ESP32 microcontroller, power supply, and IoT communication via the Blynk platform.

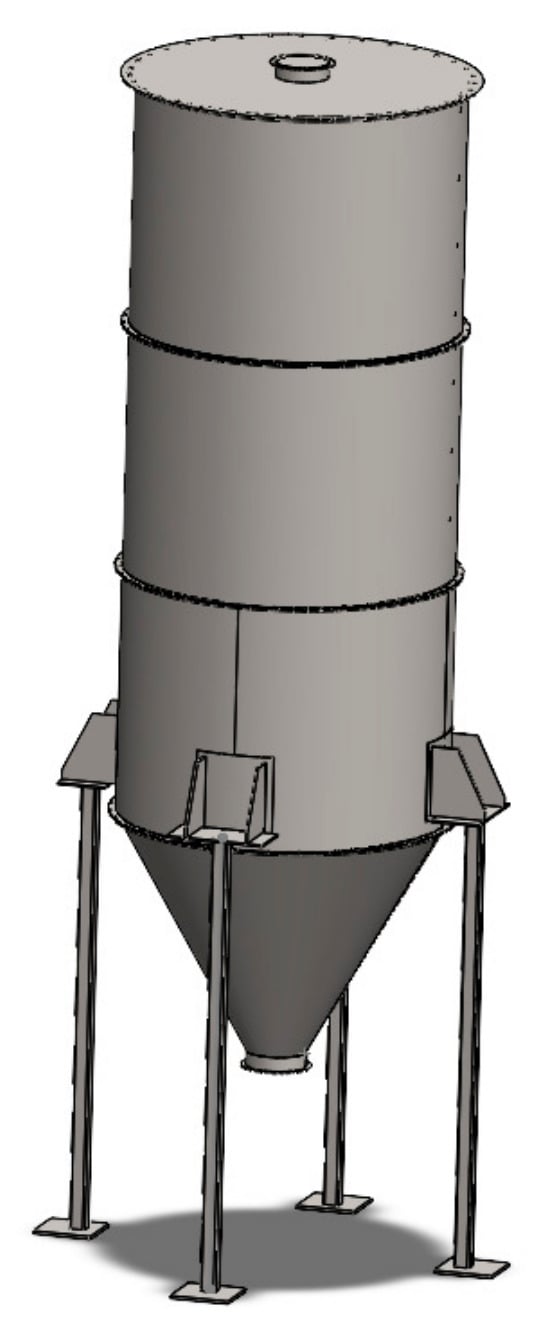

2.2. 3D Design and Fabrication

Using SolidWorks (version 2023), a cylindrical enclosure was modeled to house the sensors in optimal vertical alignment. The design includes a top lid for refilling grains, sensor mounts, and a bottom platform for the load cell. The enclosure comprises three key structural zones: (1) the sensor mounts, positioned around the middle cylindrical section, are designed as flanged protrusions to accommodate sensors for temperature, humidity, and gas detection; (2) the grain chamber, forming the main vertical body, stores the grain and enables consistent sensor exposure; and (3) the base platform, located at the bottom, supports the entire structure and provides a flat surface for integrating load cells to measure the grain weight. The material selection considered thermal insulation, structural rigidity, and visibility [6] as detailed in Table 1. The mechanical structure of the storage enclosure was modeled using SolidWorks (version 2023) to ensure optimal sensor alignment and component accessibility (Figure 3).

Table 1.

Selected materials for key components of the Smart Grain Monitoring System enclosure, based on mechanical performance, thermal insulation, corrosion resistance, and visibility requirements.

Figure 3.

SolidWorks (version 2023) three-dimensional computer-aided design (3D CAD) model of the Smart Grain Monitoring System enclosure, showing the sensor mounts, grain chamber, and base for load cell integration.

3. Results and Discussion

3.1. Environmental Monitoring

Field tests showed accurate sensor readings within ±2% of calibrated values. Over a 48-h trial, the system reliably detected humidity spikes during simulated wet conditions and CO2 build-up during grain fermentation. The ideal and observed values for key grain storage parameters are summarized in Table 2. The ideal ranges were adapted from prior studies on post-harvest storage conditions [1,2]. Real-time monitoring of grain storage parameters was achieved through the Blynk mobile application, enabling visualization of temperature, humidity, carbon dioxide (CO2), and weight trends.

Table 2.

Influences on main factors of grain preservation.

These results align with [4], who reported similar performance in real-world grain storage monitoring scenarios.

3.2. Power and Connectivity

The rechargeable battery supported approximately three days of operation per charge. Blynk-based Wi-Fi transmission remained stable across 2.4 GHz networks in rural test areas. Users accessed alerts and trend data remotely via smartphone.

3.3. Comparison with Other Systems

Unlike systems that depend on GSM networks, spreadsheets, or multi-board setups [2,5], this design consolidates all functions into a single ESP32 board. The Blynk platform eliminates the need for cellular data plans or complex cloud backends.

4. Conclusions

This paper presents a compact and cost-effective IoT solution for real-time grain monitoring. The integration of temperature, humidity, air quality, and weight sensing on a single ESP32 board offers a simple, scalable system suitable for remote or under-resourced settings. 3D design enhancements ensure thermal efficiency and maintain hygiene. Future work includes solar integration, LoRaWAN communication, and AI-based spoilage detection.

Author Contributions

Conceptualization, S.A.; methodology, S.A., A.A., M.A. and F.A.; software, A.A., M.A. and F.A.; validation, S.A.; formal analysis, S.A.; investigation, A.A., M.A. and F.A.; resources, S.A.; data curation, S.A., A.A., M.A. and F.A.; writing—original draft preparation, S.A.; writing—review and editing, S.A.; visualization, A.A., M.A. and F.A.; supervision, S.A.; project administration, S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors gratefully acknowledge the support of the Higher Colleges of Technology for providing laboratory facilities and equipment used during the development of this system.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shilpa, J.S.B.; Sheeba, G.M. Automated real time monitoring for food grain storage. Int. J. Pure Appl. Math. 2018, 118, 1314–3395. [Google Scholar]

- Hema, L.K.; Velmurugan, S.; Sunil, D.N.; Thariq Aziz, S.; Thirunavkarasu, S. IoT-based real-time control and monitoring system for food grain procurement and storage. IOP Conf. Ser. Mater. Sci. Eng. 2020, 993, 012079. [Google Scholar] [CrossRef]

- Kavya, P.; Pallavi, K.N.; Shwetha, M.N.; Swetha, K.; Jayasri, B.S. Use of smart sensor & IoT to monitor the preservation of food grains at warehouse. Int. J. Res. Trends Innov. 2017, 2, 449–454. Available online: http://www.ijrti.org (accessed on 5 August 2025).

- Viviane, I.; Masabo, E.; Joseph, H.; Rene, M.; Bizuru, E. IoT-based real-time crop drying and storage monitoring system. Int. J. Distrib. Sens. Netw. 2023, 2023, 4803000. [Google Scholar] [CrossRef]

- Ramadhan, M.D.; Wisaksono, A.; Jamaaluddin, J.; Ahfas, A. Prototype of moisture content meter in grain using ESP32 based on spreadsheet. J. Comput. Netw. Arch. High Perform. Comput. 2024, 6, 502–513. [Google Scholar] [CrossRef]

- Swathi, M.D.; Aparna, R.; Krishna, V.V.; Prashanth, J.; Raviteja, N. Intelligent food and grain storage management system for warehouse. Int. J. Creat. Res. Thoughts 2024, 12, d775–d778. Available online: http://www.ijcrt.org (accessed on 5 August 2025).

- Mabrouk, S.; Abdelmonsef, A.; Toman, A. Smart grain storage monitor and control. Am. Sci. Res. J. Eng. Technol. Sci. 2017, 31, 156–162. Available online: http://asrjetsjournal.org (accessed on 5 August 2025).

- Strong, A.B. Plastics: Materials and Processing, 3rd ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Davis, J.R. Aluminum and Aluminum Alloys; ASM International: Materials Park, OH, USA, 1993. [Google Scholar]

- Sedriks, A.J. Corrosion of Stainless Steels, 2nd ed.; Wiley-Interscience: New York, NY, USA, 1996. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).