Abstract

A piezoelectric ultrasonic transducer has been developed to detect flow rate, occlusion, and bubble formation in a portable peritoneal dialysis system. This transducer works by utilizing the piezoelectric effect to convert electrical energy into ultrasonic waves and detect the reflected waves through the tube wall. In addition, organic thin film transistors (OTFTs) were tested at annealing temperatures of 75 °C, 100 °C, and 125 °C to evaluate the effect of temperature on mobility and on/off ratio. The best results were obtained at 100 °C with a mobility of 0.816 cm2/Vs and an on/off ratio of 1.4 × 103 correlated with grain size. This study aims to report the fabrication process and initial characterization of the OTFT device as a first step towards the development of a portable biosensor that can be integrated into a point-of-care system. The transducer is designed for use in PeritoCare® (Bangi, Malaysia), a portable peritoneal dialysis system developed by Universiti Kebangsaan Malaysia (UKM). The integration of piezoelectric transducers and OTFTs into the PeritoCare® system enables the development of a more flexible, efficient, and mobile peritoneal dialysis system for young, active end-stage renal disease (ESRD) patients.

1. Introduction

Chronic Kidney Disease (CKD) is a significant public health problem globally [1,2]. The main risk factors for CKD include diabetes, high blood pressure, cardiovascular disease, a family history of CKD, and age over 60. The main consequences of CKD are progression to kidney failure, complications from impaired kidney function, and an increased risk of cardiovascular disease. The disease is often asymptomatic until it reaches an advanced stage, so many patients are diagnosed only when they are already nearing symptomatic kidney failure, when the opportunity to prevent serious complications is already limited [3]. Patients with chronic kidney disease (CKD) who require rapid dialysis but do not yet have permanent access typically begin hemodialysis using a central venous catheter. However, several studies have suggested that abrupt initiation of peritoneal dialysis (PD) may be a viable alternative for these patients [4].

In the last decade, there has been an increasing demand for simple, selective, accurate, and reliable analysis of key human metabolites that can be used to control health status [5]. A piezoelectric ultrasonic transducer has been developed to detect flow rate, occlusion, and the presence of bubbles in portable peritoneal dialysis systems. Flow is one of the most important parameters to measure. Ultrasonic flowmeters offer advantages such as high accuracy, fast response, and the ability to measure large flow rates [6]. Similarly ultrasonic fluid bubbles detection is crucial in clinical medicine as it helps avoid deadly mechanical malfunctions and life-threatening situations [7]. This piezoelectric transducer generates and transmits ultrasonic signals across the tubing wall and detects the reflected waves. Piezoelectric ultrasonic transducers convert electrical energy into ultrasonic waves and vice versa, utilizing the piezoelectric effect. When a voltage is applied to a piezoelectric transducer, its shape changes, producing mechanical vibrations that then become ultrasonic waves. Conversely, when the returning (reflected) ultrasonic waves distort the piezoelectric material, a voltage is generated.

Integration between piezoelectric sensors and OTFTs can improve sensor performance. Correia et al., developed a fully printed 5 × 5 piezoresistive sensor matrix, where an organic thin film transistor (OTFT) was placed in each sensor to allow independent reading of each sensor, thereby reducing signal interference (crosstalk) between sensors [8]. Cosseddu et al., carried out a new approach to obtain a force/pressure sensor device using OTFT (Organic Thin-Film Transistor) and piezoelectric polymer on a flexible polyethylene therephtalate (PET) substrate, this device can be operated at very low voltages [9]. Organic Field Effect Transistor (OFET)-based sensors consisting of small molecules or polymers as the active layer have attracted significant attention in recent years due to their high flexibility and sensitivity, low fabrication cost, and excellent substrate suitability [10].

Therefore, the development of a Piezoelectric Ultrasonic Transducer supported by a high-performance OTFT is a strategic step in creating a portable peritoneal dialysis system that is intelligent, efficient, and user-friendly. The integration between the Piezoelectric ultrasonic transducer (PUT) and OTFT not only enables system miniaturization but also enhances real-time monitoring capabilities and process automation, which are crucial for patient comfort and safety.

2. Materials and Methods

In this study, OTFTs based on SiO2 substrates were fabricated using the diketopyrrolopyrrole-dithienothiophene (DPP-DTT) (with a molecular weight of approximately 203,956), purchased from Ossila, as the organic semiconductor. The substrates were first cleaned using acetone and isopropanol, then dried with nitrogen gas to ensure the removal of contaminants. A DPP-DTT solution dissolved in chloroform at a concentration of 6.5 mg/mL was applied to the substrate via spin coating at 1000 rpm for 120 s to achieve a film thickness of approximately 50 nm. Subsequently, the OTFTs were annealed at varying temperatures of 75 °C, 100 °C, and 125 °C in a vacuum oven for 15 min under a pressure of approximately 25 InHg. The same procedure was also conducted at room temperature as a control. In this study, the channel length (L) of the OTFT used was 80 μm, while its width (W) was set at 1 mm. The OTFT device with DPP-DTT thin film was characterized by measuring the I–V characteristics for electrical testing using two Keithley 236 source measure units with four-point mode. Atomic Force Microscopy (AFM5000II, Hitachi, Japan) was performed to obtain topographic and morphological images to observe the surface roughness of DPP-DTT, film thickness, and the formation of nanoparticle size. Meanwhile, X-ray Diffraction (XRD Bruker D8 Advance) measurements were performed to obtain detailed information regarding the crystallographic structure, chemical composition, and physical properties of DPP-DTT.

3. Results and Discussion

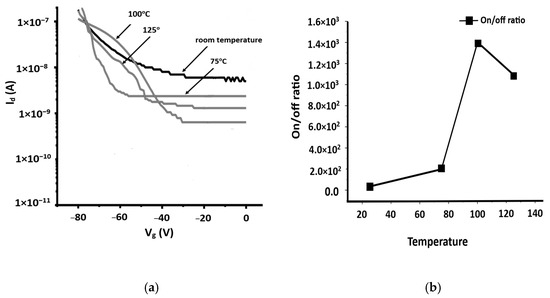

Electrical characterization (I–V) of the OTFT device was performed to examine the heating effect on the transistor performance shown in Figure 1a. Mobility is one of the parameters to measure OTFT performance [11], which can be affected by the annealing temperature [12]. In Table 1, it can be seen that the effect of annealing temperature on the mobility value and on/off ratio shows an increasing trend at room temperature up to 1000 C, and then decreases at 125 °C.

Figure 1.

(a). Transfer characteristics of OTFT for at room temperature, 75 °C, 100 °C, and 125 °C (b) the correlation between the on/off ratio and temperature.

Table 1.

Mobility and On/off ratio of OTFT devices with temperature annealing variations.

Annealing after film deposition is necessary to completely remove high-boiling solvents from thin films after deposition [13]. Increasing the mobility value by increasing the annealing temperature is known to increase the grain size of organic semiconductor thin films, which is important for the electrical properties of OTFTs. In addition, the number of interfacial trap states can be reduced after thermal treatment [14,15].

In this study, DPP-DTT was used as a p-type organic semiconductor polymer [16,17]. Organic semiconductors (OSCs) have shown potential for use in OTFTs. The main advantages of using OSCs are low cost, low processing temperature, and compatibility with flexible substrates, which results in lightweight and robust devices [18]. To improve the crystallinity and alignment of polymer chains that can affect charge transport, one of the simplest processing techniques is post-deposition annealing [12]. Chabinyc et al., in their research, showed how the microstructure of PBTTT, a semiconducting polymer that forms thin film transistors, is affected by interfacial chemistry and by thermal annealing [19].

The decrease in mobility value with increasing temperature can be caused by the dewetting effect (surface peeling) resulting in more defects appearing on the surface of the device [20] and a decrease in the level of regularity of the molecular arrangement [21]. This structural irregularity causes localization of electronic charges and the formation of traps within the molecular stack, which limits charge transport [22]. T Ahn et al. found that thermal annealing treatment after fabrication of pentacene at a temperature of 50 °C increased the mobility value from 0.19 to 0.36 cm2/Vs, increased the on/off current ratio, and improved the regularity of the pentacene molecules compared to devices that did not undergo annealing process. However, if the thermal annealing temperature reaches 70 °C or more, the pentacene film loses its crystallinity and causes a decrease in OTFT performance [23].

In OTFT, a good mobility value is >0.1 cm2/Vs, to indicate that the OTFT can function properly [24]. The highest mobility was achieved at an annealing temperature of 100 °C, with a value of 0.816 cm2/Vs. In contrast, the lowest mobility was observed at room temperature, measuring only 0.002 cm2/Vs. Meanwhile, at annealing temperatures of 75 °C and 125 °C, the mobility values were relatively similar, ranging between 0.1 and 0.2 cm2/Vs. In Figure 1b we can see the correlation between temperature and on/off ratio, where the temperature of 100 °C obtained the highest on/off ratio value. The highest on/off ratio value at 100 °C is 1.4 × 103 and the lowest at 3.6 × 101.

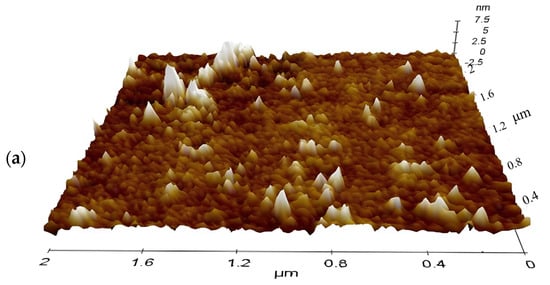

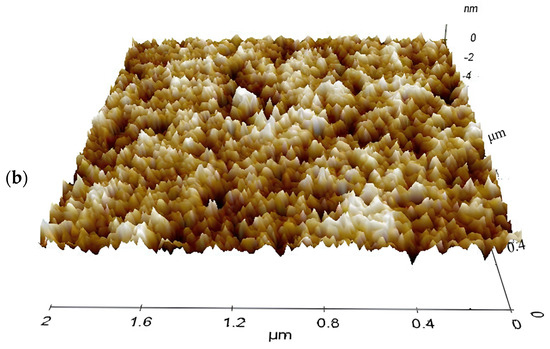

Subsequently, the effect of annealing temperature on the film structure was investigated using Atomic Force Microscopy (AFM) and X-ray Diffraction (XRD). AFM analysis was performed to examine the surface morphology changes due to thermal treatment. For this purpose, only two OTFT samples were analyzed: one annealed at room temperature as a control, and the other at 100 °C, which exhibited the highest mobility and on/off ratio compared to samples annealed at 75 °C and 125 °C. In Figure 2a, the morphology of the film deposited at room temperature shows a disordered surface with nanoscale features. The presence of small and rough grain structures suggests limited crystallization. Under these conditions, the DPP-DTT solvent did not fully evaporate, resulting in a poorly formed DPP-DTT layer. In contrast, Figure 2b shows that the film annealed at 100 °C exhibits larger and more uniformly arranged grains. As the grain size increases, the crystal growth becomes denser, and the boundaries between grains are significantly reduced. This change allows the molecules to pack more closely together, facilitating more consistent charge carrier hopping between molecules.

Figure 2.

AFM surface analysis of OTFT films at (a) room temperature and (b) after annealing at 100 °C.

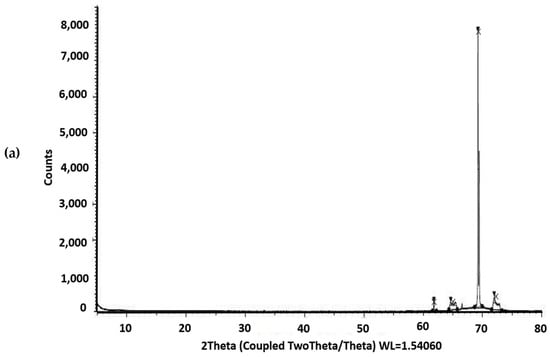

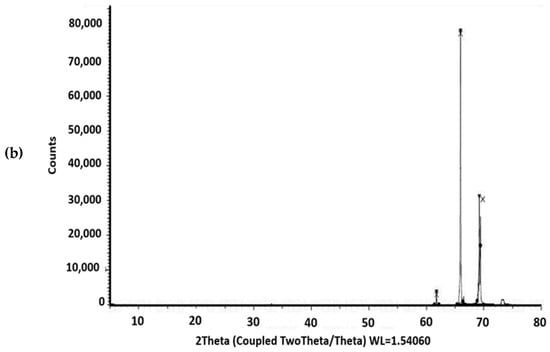

Figure 3 a,b show the XRD patterns of the films treated at room temperature and annealed at 100 °C, respectively. Both patterns exhibit the same peak positions. However, in Figure 3b, a new, sharp, and intense peak appears at 2Theta (2θ) = 67. The emergence of this new peak indicates a high intensity and serves as an indicator of crystallization on the surface of the sample.

Figure 3.

XRD patterns of the OTFT at (a) room temperature and (b) after annealing at 100 °C.

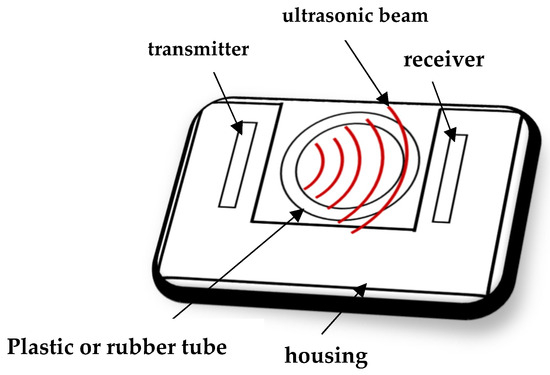

In this study, the fabrication process and initial characterization of the OTFT device are presented as a first step towards the development of a portable biosensor, designed for integration into a point-of-care system. The transducers are aimed to be embedded into PeritoCare®, a portable peritoneal dialysis system developed in Universiti Kebangsaan Malaysia (UKM), Malaysia (Figure 4). The detection system was tested with 5mm OD and 3 mm ID tube, with a dialysate flow rate of 100–150 mL/min. The ultrasonic transducer can detect the presence of bubble of diameter down to approximately 10% of the ID of the tube, with detection time as fast as 20 ms. PeritoCare® has a pump in/pump out 100–180 mL/min, with dialysate dwell time of 1–3 h. The dialysate amount used is 1–1.5L for tidal peritoneal dialysis (TAPD) setting, for performing dialysis in portable mode, and 2–2.5L for automated peritoneal dialysis (APD) setting. On the other hand, conventional ultrasonic technologies for bubble detection still rely on PZT (Lead Zirconate Titanate)–based piezoelectric transducers, which are limited by their bulky size, high power consumption, and challenges in integrating with integrated circuits (ICs) [7]. Moreover, the large size of conventional piezoelectric ceramic transducers restricts their use to small-diameter pipes [6]. Conventional piezoelectric ultrasound transducers have long dominated the market due to their mature fabrication technology. However, creating small, high-performance devices remains a challenge [25].

Figure 4.

Anatomy and working principle of PeritoCareTM Ultrasonic sensor.

In another flow rate sensor prototype, which consisted of one ceramic heater and two infrared sensors, a response time of approximately 30 s was required [26]. Another device equipped with thin-film transistor (TFT) technology for monitoring and controlling intravenous infusion flow, specifically for air bubble detection, achieved a response time of less than 20 ms [27]. The implementation of piezoelectric ultrasonic transducers and OTFTs into PeritoCare® enables the development of a portable peritoneal dialysis system that can reduce mobility limitations in young, active ESRD (end-stage renal disease) patients. With the machine, unlike conventional dialysis, patients will now be able to move around doing their activities while performing dialysis. Moreover, ESRD patients will now be able to travel abroad since they are now not tied up to big dialysis machine. This is something they are unable to do before.

Micromachined ultrasonic transducers have been studied as an alternative to traditional piezocomposite ultrasonic transducers, primarily due to the advantages offered by microelectromechanical systems (MEMS) technology. Small-sized ultrasonic systems require ultrasonic transducers that can be integrated with complementary metal-oxide-semiconductor circuits [28]. OTFT-based flexible miniature piezoelectric sensors offer several advantages over conventional Metal–Oxide–Semiconductor Field-Effect Transistor (MOSFET) sensors, such as lower production costs, the ability to be fabricated in flexible surface-contouring arrays [29], and biocompatibility [30]. The OTFT, located in close proximity to the sensor, serves as a signal amplifier, enhancing the output generated by the piezoelectric sensing element [29].

4. Conclusions

Annealing temperature of organic semiconductor polymers has been reported to affect the performance of OTFTs on mobility and on/off ratio. In this study, we investigated the effect of post-deposition annealing on the mobility of DPP-DTT-based OTFTs fabricated and tested under ambient conditions. Among the tested annealing temperatures of 75 °C, 100 °C, and 125 °C, the device annealed at 100 °C showed the highest mobility and on/off ratio were 0.816 cm2/Vs and 1.4 × 103, respectively. A strong correlation was found between mobility and grain size as a function of post-deposition annealing temperature. Increasing mobility with increasing grain size indicates an increase in the degree of crystallinity in the polymer as can be seen from the XRD results. Therefore, this study contributes to the understanding of the effect of annealing temperature on organic semiconductor polymers. The fabrication and characterization process of this OTFT device serves as an initial step in the development of a portable biosensor that can be integrated into point-of-care systems. The implementation of piezoelectric ultrasonic transducers and OTFTs into PeritoCare® enables the development of a portable peritoneal dialysis system that alleviates mobility issues among young, active ESRD patients on the go.

5. Patents

PeritoCare™—Portable Peritoneal Dialysis System, COMSTECH Best Patent Award 2021.

Author Contributions

R.S.N., Writing—original draft, review and editing; Y.Y., Methodology, Writing—original draft; J.S., Review; A.A.H., Writing—review and editing; A.G.I., Funding acquisition, Supervision, writing—review and editing; J.Y., Concept; A.H.A.G., Concept and review; R.M., Review; A.H.M.S., concept and design; A.S.A.R., review. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the grants Dana Impak Perdana 2.0, Universiti Kebangsaan Malaysia (DIP-2023-020) and Fundamental Research Grant Scheme, Ministry of Higher Education (FRGS/1/2023/STG07/UKM/02/5).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shemesh, O.; Golbetz, H.; Kriss, J.P.; Myers, B.D. Limitations of creatinine as a filtration marker in glomerulopathic patients. Kidney Int. 1985, 28, 830–838. [Google Scholar] [CrossRef] [PubMed]

- Groth, T.; Stegmayr, B.G.; Ash, S.R.; Kuchinka, J.; Wieringa, F.P.; Fissell, W.H.; Roy, S. Wearable and implantable artificial kidney devices for end-stage kidney disease treatment: Current status and review. Artif. Organs 2023, 47, 649–666. [Google Scholar] [CrossRef] [PubMed]

- Vassalotti, J.A.; Stevens, L.A.; Levey, A.S. Testing for Chronic Kidney Disease: A Position Statement from the National Kidney Foundation. Am. J. Kidney Dis. 2007, 50, 169–180. [Google Scholar] [CrossRef] [PubMed]

- Htay, H.; Johnson, D.W.; Craig, J.C.; Teixeira-Pinto, A.; Hawley, C.; Cho, Y. Urgent-start peritoneal dialysis versus haemodialysis for people with chronic kidney disease (Protocol). Cochrane Database Syst. Rev. 2017, 1, CD012899. [Google Scholar]

- Soldatkina, A.P.; Montoriolc, J.; Santc, W.; Marteleta, C.; Jaffrezic-Renault, N. Development of potentiometric creatinine-sensitive biosensor based on ISFET and creatinine deiminase immobilised in PVA/SbQ photopolymeric membrane. Mater. Sci. Eng. C 2002, 21, 75–79. [Google Scholar] [CrossRef]

- Liu, T.; Li, Z.; Zhang, J.; Li, D.; Dou, H.; Wu, P.; Yang, J.; Zhang, W.; Mu, X. AGasFlowMeasurement System Based on Lead Zirconate Titanate Piezoelectric Micromachined Ultrasonic Transducer. Micromachines 2024, 15, 45. [Google Scholar] [CrossRef]

- Yuan, J.; Li, Z.; Ma, Q.; Li, J.; Li, Z.; Zhao, Y.; Qin, S.; Shi, X.; Zhao, L.; Yang, P.; et al. Noninvasive fluid bubble detection based on capacitive micromachined ultrasonic transducers. Microsyst. Nanoeng. 2023, 9, 20. [Google Scholar] [CrossRef]

- Correia, V.; Oliveira, J.; Perinka, N.; Costa, P.; Sowade, E.; Mitra, K.Y.; Baumann, R.R.; Lanceros-Mendez, S. All-Printed piezoresistive sensor matrix with organic thin-film transistors as a switch for crosstalk reduction. ACS Appl. Electron. Mater. 2020, 2, 1470−1477. [Google Scholar] [CrossRef]

- Cosseddu, P.; Viola, F.; Lai, S.; Raffo, L.; Seminara, L.; Pinna, L.; Valle, M.; Dahiya, R.; Bonfiglio, A. Tactile sensors with integrated piezoelectric polymer and low voltage organic thin-film transistors. In Proceedings of the Sensors, 2014 IEEE, Valencia, Spain, 2–5 November 2014. [Google Scholar]

- Amna, B.; Ozturk, T. Organic field-effect transistor-based sensors: Recent progress, challenges and future outlook. J. Mater. Chem. C 2025, 13, 8354–8424. [Google Scholar] [CrossRef]

- Wahab, N.Z.A.; Abdulhameed, A.; Ismail, A.G.; Ramli, M.M.; Mohd Sidek, R.; Shafie, S.; Mohd, N.M. Review—Charge Carrier Mobility of Organic Thin Film Transistor: Intrinsic and Extrinsic Influencing Factors Based on Organic Semiconducting Materials. ECS J. Solid State Sci. Technol. 2023, 12, 044002. [Google Scholar] [CrossRef]

- Afzal, T.; Iqbal, M.J.; Iqbal, M.Z.; Sajjad, A.; Raza, M.A.; Riaz, S.; Kamran, M.A.; Numan, A.; Naseem, S. Effect of post-deposition annealing temperatute on the charge carrier mobility and morphology of DPP-DTT based organic field effect transistors. Chem. Phys. Lett. 2020, 750, 137507. [Google Scholar] [CrossRef]

- Akkerman, H.B.; Li, H.; Bao, Z. TIPS-pentacene crystalline thin film growth. Org. Electron. 2012, 13, 2056. [Google Scholar] [CrossRef]

- Bae, J.; Choi, Y. Solid-state electronics reduction of the trap density at the organic—Organic interface and resultant gate-bias dependency of the mobility in an organic thin-film transistor. Solid-State Electron. 2012, 72, 44–47. [Google Scholar] [CrossRef]

- Kwan, M.C.; Cheng, K.H.; Lai, P.T.; Che, C.M. Improved carrier mobility for pentacene TFT by NH3 annealing of gate dielectric. Solid-State Electron. 2007, 51, 77–80. [Google Scholar] [CrossRef]

- Li, J.; Zhao, Y.; Tan, H.S.; Guo, Y.; Di, C.-A.; Yu, G.; Liu, Y.; Lin, M.; Lim, S.H.; Zhou, Y.; et al. A stable solution-processed polymer semiconductor with record high-mobility for printed transistors. Sci. Rep. 2012, 2, 754. [Google Scholar] [CrossRef]

- Barron, J.; Pickett, A.; Glaser, J.; Guha, S. Solution-Processed Organic and ZnO Field-Effect Transistors in Complementary Circuits. Electron. Mater. 2021, 2, 60–71. [Google Scholar] [CrossRef]

- Ismail, A.G. The Impact of Alkyl Phosphonic Acid Monolayer Modified Dielectrics on the Performance of n-Channel Organic Thin-Film Transistors. Mater. Focus 2018, 7, 480–484. [Google Scholar] [CrossRef]

- Chabinyc, M.L.; Toney, M.F.; Kline, R.J.; McCulloch, I.; Heeney, M. X-ray Scattering Study of Thin Films of Poly(2,5-bis(3-alkylthiophen-2-yl)thieno [3,2-b]thiophene). J. Am. Chem. Soc. 2007, 129, 3226–3237. [Google Scholar] [CrossRef]

- Huang, L.; Liu, F.; Bao, J.; Li, X.; Wu, W. High-Performance Organic Field-Effect Transistors of Liquid Crystalline Organic Semiconductor by Laser Mapping Annealing. Materials 2024, 17, 1395. [Google Scholar] [CrossRef]

- Kim, S.; Kim, A.; Jang, K.-S.; Yoo, S.; Ka, J.-W.; Kim, J.; Yi, M.H.; Won, J.C.; Hong, S.-K.; Kim, Y.H. The effect of thermal annealing on the layered structure of smectic liquid crystalline organic semiconductor on polyimide gate insulator and its OFET performance. Synth. Met. 2016, 220, 311–317. [Google Scholar] [CrossRef]

- Paquin, F.; Rivnay, J.; Salleo, A.; Stingelin, N.; Silva, C. Multi-phase semicrystalline microstructures drive exciton dissociation in neat plastic semiconductors. arXiv 2013, arXiv:1310.8002. [Google Scholar]

- Ahn, T.; Jung, H.; Suk, H.J.; Yi, M.H. Effect of postfabrication thermal annealing on the electrical performance of pentacene organic thin-film transistors. Synth. Met. 2009, 159, 1277. [Google Scholar] [CrossRef]

- Ling, M.M.; Bao, Z. Thin Film Deposition, Patterning, and Printing in Organic Thin Film Transistors. Chem. Mater. 2004, 16, 4824–4840. [Google Scholar] [CrossRef]

- He, Y.; Wan, H.; Jiang, X.; Peng, C. Piezoelectric micromachined ultrasound transducer technology: Recent advances and applications. Biosensors 2023, 13, 55. [Google Scholar] [CrossRef]

- Chui, H.C.; Xu, Y.; Wang, Z.; Zhang, X.; Li, R.; Qin, K.R. Flow Rate Sensor inside Infusion Tube. Inventions 2024, 9, 89. [Google Scholar] [CrossRef]

- Aini, R.A.N.; Setiawan, R.; Pramudijanto, J. Intravenous Infusion Monitoring and Flow Control System Equipped with Automatic Air Bubble Detection. J. Biomim. Biomater. Biomed. Eng. 2022, 55, 204–215. [Google Scholar]

- Jung, J.; Lee, W.; Kang, W.; Shin, E.; Ryu, J.; Choi, H. Review of piezoelectric micromachined ultrasonic transducers and their applications. J. Micromech. Microeng. 2017, 27, 113001. [Google Scholar] [CrossRef]

- Jia, T.; Kathiresan, M.; Nair, S.; Jung, S.; Natarajan, V.; Vishnubhatla, R.M.R.; Varadan, V.K. Design and Fabrication of OTFT based Flexible Piezoelectric Sensor. In Proceedings of the SPIE, San Diego, CA, USA, 21–22 March 2007; Volume 6528, p. 65281P. [Google Scholar]

- Song, J.; Liu, H.; Zhao, Z.; Lin, P.; Yan, F. Flexible Organic Transistors for Biosensing: Devices and Applications. Adv. Mater. 2024, 36, 2300034. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).