Abstract

Runout is a common failure of brake discs. The detection of this fault usually depends on the driver, as there is a vibration in the car and on the brake pedal. As Advanced Driver Assistant Systems are implemented and autonomous driving modes are available, braking is carried out by the car instead. Brake disc runout can cause longer braking distance, so it is essential to recognize and repair it. NVH measurements have been validated to be one of the solutions to detect the fault immediately without disassembling the brake unit. In this article, the previous vibration measurements are extended with other methods that can also be used for fault detection. Brake fluid pressure measurement and integration of the disc rotation angle sensor enable the detection of faults without additional sensors. The aim of the research is to design a measurement method that can be compared with previously validated measurements.

Keywords:

brake disc runout; NVH; acceleration; FFT; vibration; fault detection; pressure measurement; pressure; brake fluid 1. Introduction

Brake disc runout or vibrations occur due to a defect in one or more parts of the braking system. This issue is most often noticed as a “banging” sensation when applying the brakes, with the brake pedal pressed down, resulting in either mild or, in severe cases, strong shaking felt through the steering wheel or throughout the vehicle. Passengers seated in either the front or rear of the car may also experience this vibration, depending on which wheel’s brake disc is affected. Additionally, this condition can be accompanied by a loud, grinding noise. The worsening of brake disc hitting can be quite unsettling and may impact stopping distance, potentially increasing the risk of accidents. Consequently, it is a critical issue that requires proper measurement and analysis to understand its real-world effects.

Since the runout can be perceptible to the driver, especially in autonomous driving systems, it is crucial to be able to identify such faults without relying on human sensors. Implementing self-diagnostic systems is vital for ensuring safety and facilitating effective maintenance.

The most frequent cause of vibrations is a variation in the thickness of the brake disc, a condition often referred to as “brake disc wobble.” This wear discrepancy can result from uneven brake pad wear or dirt lodged between the braking surfaces, causing the pad to contact the disc unevenly during braking. Another potential cause is a manufacturing defect, where the brake disc has an imperfect shape or geometry right from the factory.

2. Literature Review

Ideally, the friction surface of a brake disc should be perfectly flat and perpendicular to the axis of rotation. However, deviations from this ideal condition can occur, known as runout—or more specifically, axial runout. This is typically quantified by measuring the difference between the highest and lowest points on the disc surface during rotation [1,2]. Even new, manufactured discs for commercial vehicles can exhibit runout, which may be caused by insufficient stress relief during casting. Additionally, buckling of the disc, as discussed earlier, can also present itself as runout. One potential cause of runout is warping of the disc resulting from uneven tightening of the mounting bolts during installation. Another contributing factor is contamination—such as dust or debris—on the mounting surface during fitting. Permanent distortions may also develop when residual stresses from casting are relieved at elevated temperatures [3,4]. Moreover, Hofwing [5], through numerical simulations, demonstrated that residual stresses are present in the disc following casting and machining processes.

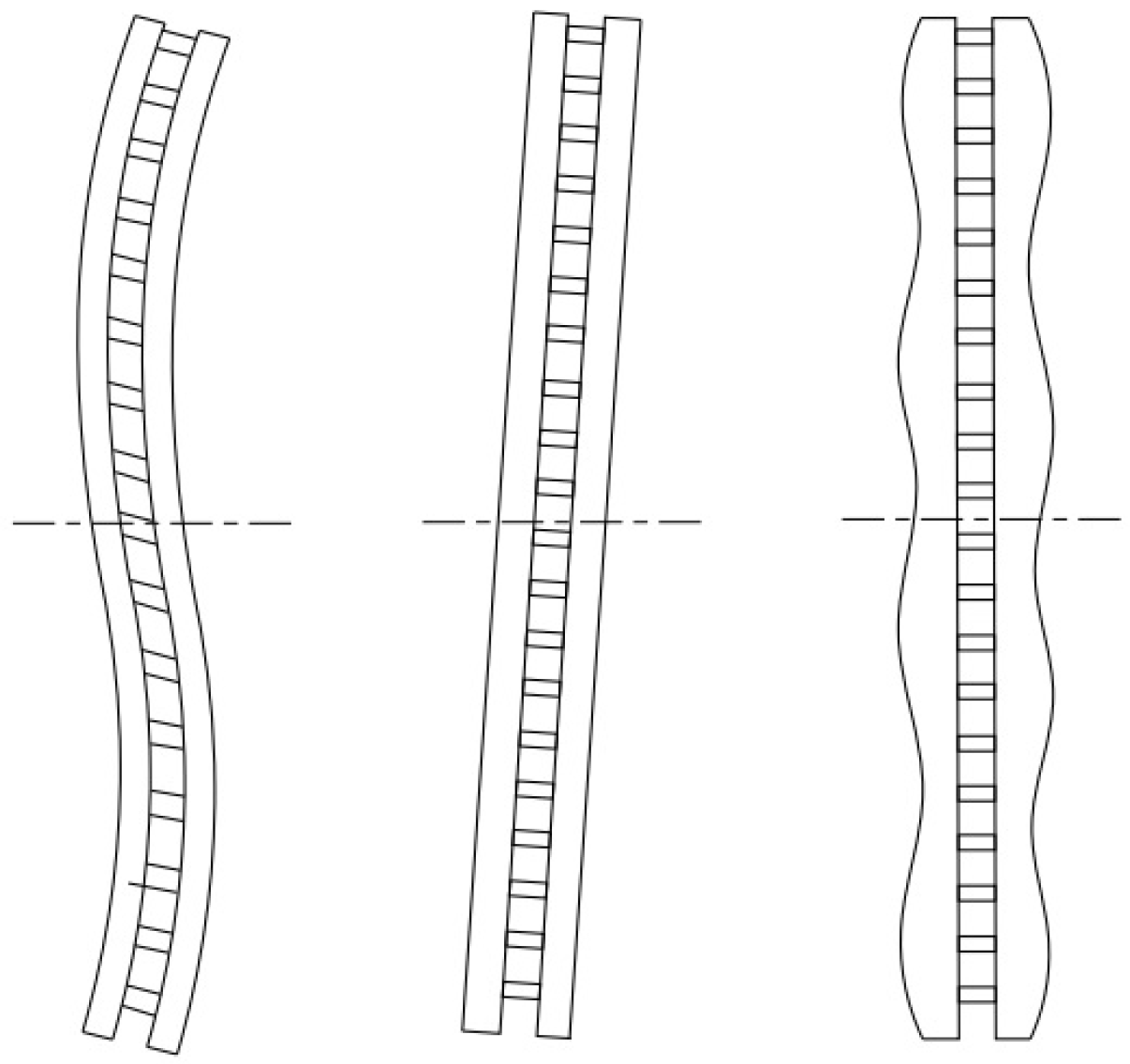

Normally, a brake disc should have a uniform thickness throughout its surface. However, in practice, variations in thickness—known as disc thickness variation (DTV)—can occur. Figure 1 illustrates a schematic representation of DTV on a disc. There are numerous potential causes for DTV. Even new discs for commercial vehicles may exhibit DTV right from manufacturing [6]. Additionally, once a disc develops runout, certain areas may prevent the brake pad from making contact, while other regions experience higher contact pressure. This increased pressure generates more heat, causing localized expansion of the material. Such expansion can lead to temporary DTV, which might diminish as the disc cools and regains its original shape. However, wear mechanisms can also contribute, as material is gradually removed from regions with higher contact pressure and temperature, resulting in permanent DTV. Moreover, if the temperature of a cast iron disc exceeds around 700 °C (or 738 °C as per [4]) and cools rapidly afterward, phase transformation to martensite can occur [6,7,8]. Since martensite occupies a greater volume than pearlite, this transformation can cause localized expansion, leading to persistent DTV. Additionally, uneven formation of the transfer film on the disc surface can also play a role in developing DTV.

Figure 1.

Schematic figure of brake disc runout and disc thickness variation.

To detect and validate the faults, there are several methods that can be used. First of all, the most precise measurement is the mechanical measurement with a dial indicator gauge. In this case, the wheels must be dismounted, and the measurements can only be performed with a standing vehicle. As the usual tolerance is between 0.02 and 0.06 mm [9], during runout measurements the fault cannot be detected with human eyes, but there are laser and optoelectric technologies that allow non-contact measurements. In these cases, the measurement units must be mounted on the car as well, so it has an advantage only in evaluation time. There are some indirect measurement possibilities, for example, roller bench measurements, where the brake forces are recorded on each wheel. There were previously some studies that state that indirect measurements are not accurate: “Analyzing the results, it is observed that it cannot be established a correlation between the ovality value obtained by using the roller tester and the lateral run-out measured using a dial gauge. This is because of differences between the influences acting in these two methods” [9].

In our previous studies on this topic, several measurements were performed with accelerometers. Vibration measurement is also an indirect method to detect geometry faults of the brake disc, but the correlation between the vibration and faults could be validated [10].

While reviewing the scientific literature on this topic, two possible measurement methods rarely appear in articles: pressure and rotation angle measurement. As the contact between the brake pad and disc is not constant, theoretically, the brake disc hits the pad during every rotation, which results in brake pressure fluctuation.

Both brake fluid pressure and rotational speed can be measured during operation, and the vibration measurement can be tested for correlation with the brake disc failures. As the brake force is dependent on brake fluid pressure and friction coefficient, and previous studies claim that force measurement did not lead to a positive outcome in correlation to runout, no measurements could be found. Usually, the friction coefficient is determined as a constant value, and due to this approximation, the brake force is usually considered to be proportional to the brake fluid pressure. This would mean that if the fluctuation of the brake force is not proportional to the brake disc failure, we should assume that it is not proportional to the brake fluid pressure. Since no study has been performed to confirm or disconfirm this, it is worth hypothesizing that the friction coefficient is not constant during braking due to the encounter of uneven surfaces and that the conditional fluctuation in brake fluid pressure may provide useful information on the condition of the brake disc.

Similar considerations apply to the analysis of the ABS signal. When examining the wheel speed sensor signal, it is worth looking at the pole wheel pitch and the frequency of the faults to be tested relative to the wheel frequency. In this case, we can also assume that, given the correct pole wheel pitch, the fault can be detected from the fluctuations in the frequency of the square wave signal from the inductive transducer. It is therefore possible to hypothesize that by observing the derivative of the angular velocity, the angular acceleration, we can infer the geometric errors in the brake disc. It can be assumed that the angular deceleration will not be uniform in defective cases.

A diagnostic procedure based on the principle of angular acceleration observation exists for internal combustion engines, where the working strokes of the different cylinders are compared with the angular acceleration values measured on the crankshaft position sensor [11]. Roy, Sankar & Mohanty have shown the efficacy of the Instantaneous Angular Acceleration signal to detect combustion in a four-stroke single-cylinder gasoline engine. Instantaneous Angular Acceleration signal contains various frequencies such as combustion frequency, rotational frequency, and harmonics of them. Therefore, the Instantaneous Angular Acceleration signal is filtered by the Discrete Wavelet Transform to detect each combustion time. Thus, the Instantaneous Angular Acceleration signal becomes effective for online condition monitoring. Hence, the filtered Instantaneous Angular Acceleration signal is compared with the filtered Instantaneous Angular Speed signal for the detection of combustion. However, the Instantaneous Angular Acceleration signal is found to be more efficient than the Instantaneous Angular Speed signal for combustion detection.

3. Comparison of Different Possible Methods to Detect the Brake Disc Failure

As the possible measurement methods were collected, the next step is to compare them across different aspects (Table 1). To use the proper aspects and scales, first, the aim of the measurements must be defined.

Table 1.

Comparison of different measurement methods on the basis of usability.

The long-term aim of the research is to implement a system in the vehicle that can detect the faults onboard without disassembling the wheels and can be used during vehicle operation. Any faults in the brake system can increase the braking distance of the vehicle [12,13]. In emergency cases, a few meters of difference can mean that a life is saved.

The summary shows that the fluid pressure measurement and the ABS sensor have the potential to be used for brake disc fault detection. For the validation of the two potential methods, a new measurement system should be set up.

4. New Measurement Setup for Brake Disc Failure Detection

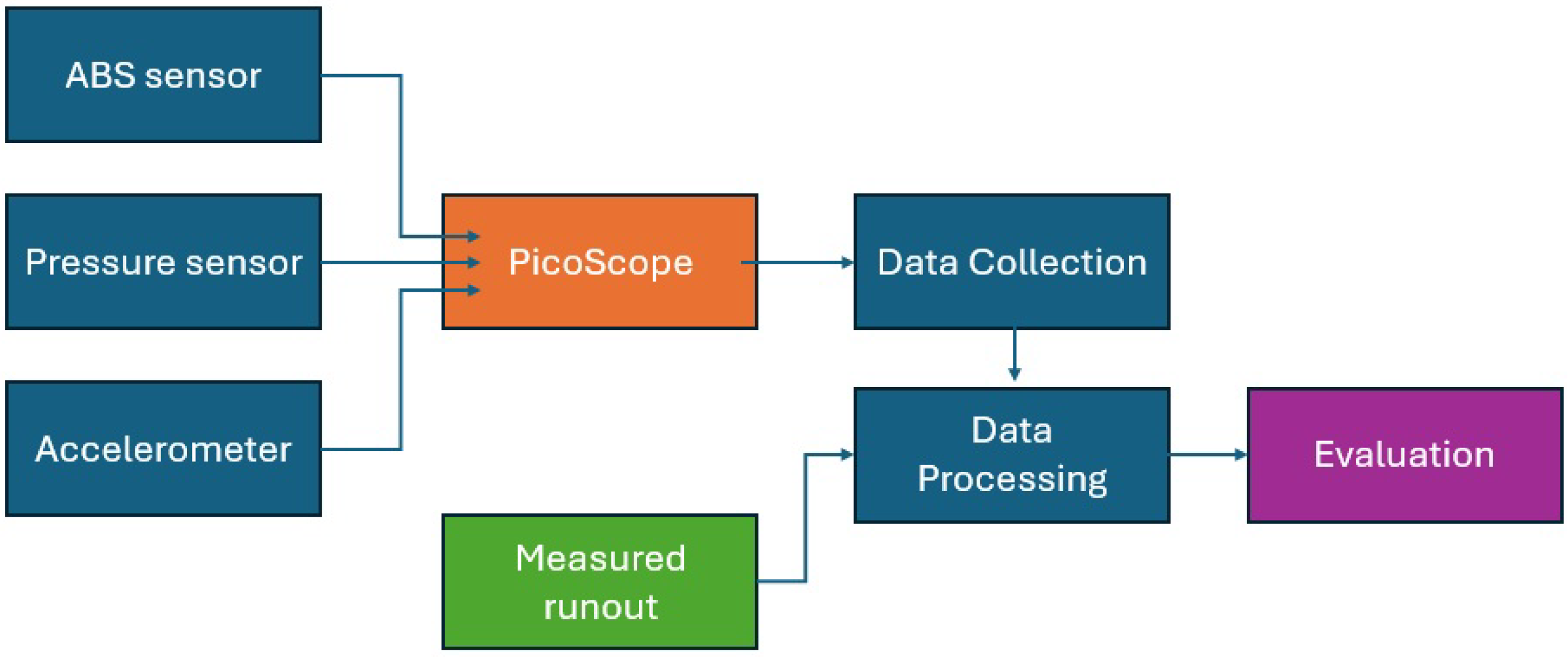

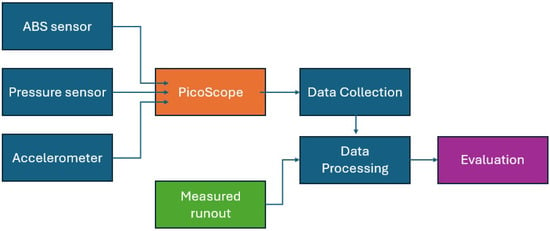

For the measurements, the vehicle from the former research can be used. For the e-Golf, several brake discs have been manufactured with different runouts. With the different brake discs, several measurements can be performed with the same sensor setup (Figure 2).

Figure 2.

Schematic figure of the measurement system.

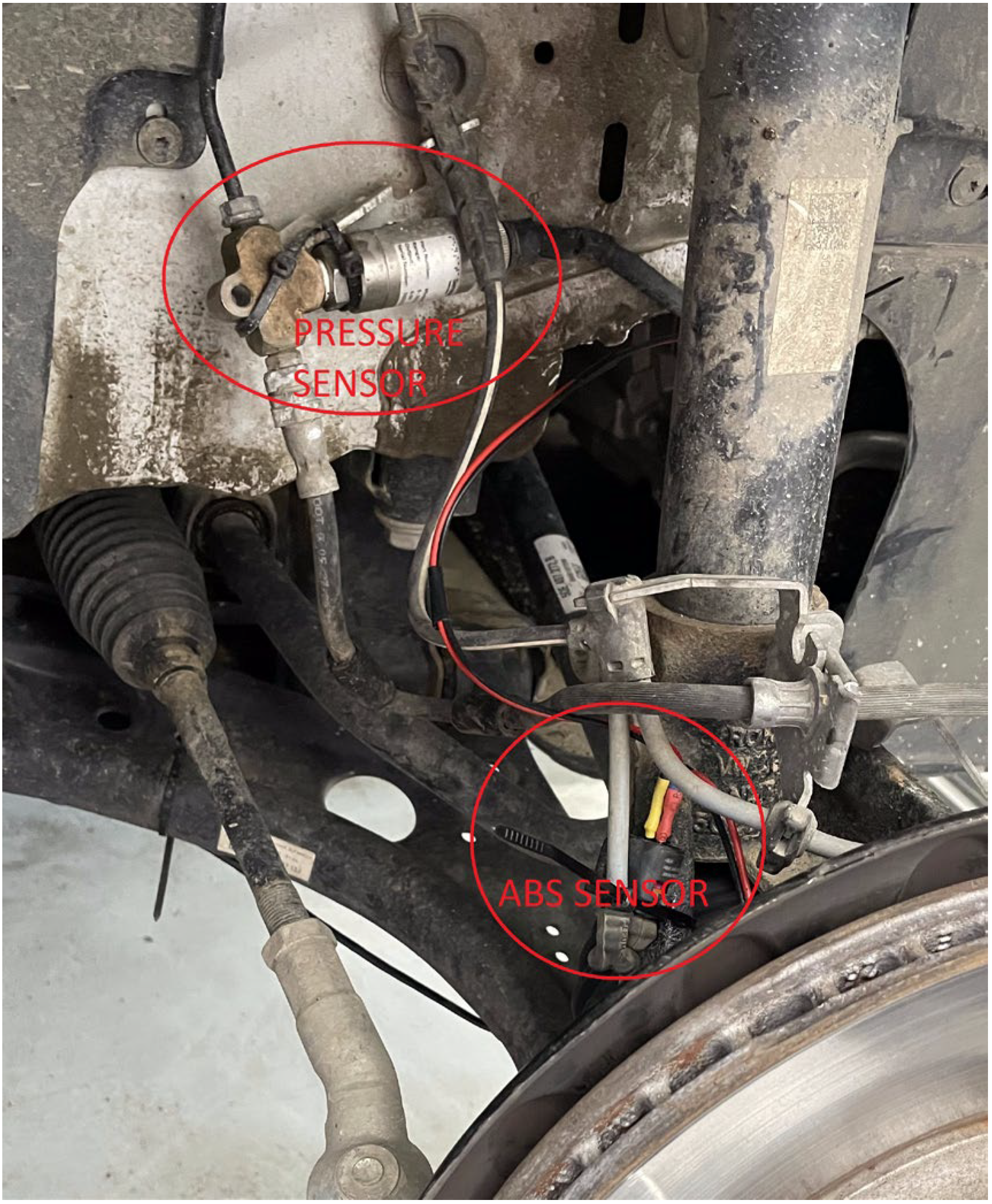

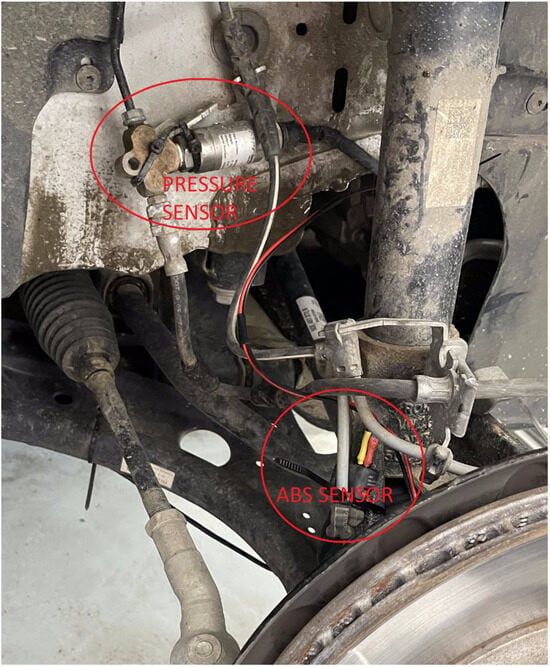

The sensors have been applied to the vehicle as the first step to check the space around the wheels. The pressure sensor is placed in the front right brake line as close to the brake calliper as possible (Figure 3).

Figure 3.

Sensors on the vehicle.

The measurements should be performed with different discs and different brake forces applied by the driver. The measurement plan is described in Table 2.

Table 2.

Measurement plan to validate the ABS sensor and brake fluid pressure sensor.

5. Summary

There is no doubt that the condition of the brake system should be monitored in vehicles. Various periodic test methods are carried out, but they need some disassembling work or expensive equipment. The onboard diagnostic methods are not just useful but also increase safety as the driver is informed immediately when a failure occurs in a system. As there is no route where using brakes is not needed, permanent monitoring of the system is necessary. The measurement method discussed in this article can determine the missing values of Table 1, so one method can be chosen that can be used in onboard applications.

Author Contributions

Conceptualization, P.Ő.; methodology, P.Ő. and I.L.; formal analysis, P.Ő.; investigation, P.Ő.; resources, P.Ő. and I.L.; writing—original draft preparation, P.Ő.; writing—review and editing, P.Ő.; visualization, P.Ő.; supervision, I.L.; project administration, I.L.; funding acquisition, I.L. All authors have read and agreed to the published version of the manuscript.

Funding

The European Union supported the research within the National Laboratory for Autonomous Systems framework (RRF-2.3.1-21-2022-00002).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Raikar, D.; Sadwilkar, O. Disc Brake Run-Out Detection System. Int. J. Res. Appl. Sci. Eng. Technol. 2022, 10. [Google Scholar] [CrossRef]

- Leslie, A.C. Mathematical Model of Brake Caliper to Determine Brake Torque Variation Associated with Disc Thickness Variation (DTV) Input. SAE Trans. 2004, 113, 1193–1203. Available online: http://www.jstor.org/stable/44724946 (accessed on 27 May 2025).

- Rashid, A. Overview of Disc Brakes and Related Phenomena—A Review. Int. J. Veh. Noise Vib. 2014, 10, 257–301. [Google Scholar] [CrossRef]

- Eggleston, D. An Investigation into Frictional Surface Interactions and Their Effect on Brake Judder. Ph.D. Thesis, Sheffield Hallam University, Sheffield, UK, 2000. [Google Scholar]

- Shin, M.W.; Jang, G.H.; Kim, J.K.; Kim, H.Y.; Jang, H. The Effect of Residual Stress on the Distortion of Gray Iron Brake Disks. J. Mater. Eng. Perform. 2013, 22, 1129–1135. [Google Scholar] [CrossRef]

- Kao, T.K.; Richmond, J.W.; Douarre, A. Brake Disc Hot Spotting and Thermal Judder: An Experimental and Finite Element Study. Int. J. Veh. Des. 2000, 23, 276–296. [Google Scholar] [CrossRef]

- Barber, J.R. Thermoelastic Instabilities in the Sliding of Conforming Solids. Proc. R. Soc. Lond. A 1969, 312, 381–394. [Google Scholar] [CrossRef]

- Panier, S.; Dufrénoy, P.; Weichert, D. An Experimental Investigation of Hot Spots in Railway Disc Brakes. Wear 2004, 256, 764–773. [Google Scholar] [CrossRef]

- Toma, M.; Andreescu, C.; Micu, D. Comparative Study on the Lateral Run-Out of Friction Surfaces Measurement of Brake Discs Using a Brake Roller Tester and a Dial Gauge. MATEC Web Conf. 2017, 112, 07010. [Google Scholar] [CrossRef]

- Dózsa, T.; Ori, P.; Szabari, M.; Simonyi, E.; Soumelidis, A.; Lakatos, I. Brake Disc Deformation Detection Using Intuitive Feature Extraction and Machine Learning. Machines 2024, 12, 214. [Google Scholar] [CrossRef]

- Roy, S.; Mohanty, A.R. Combustion Detection in IC Engine by Analysis of Instantaneous Angular Acceleration. In Proceedings of the International Conference on Sustainable Technologies, Dhaka, Bangladesh, 19–20 December 2020; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Tang, T.; Anupam, K.; Kasbergen, C.; Scarpas, A. Study of Influence of Operating Parameters on Braking Distance. Transp. Res. Rec. 2017, 2641, 139–148. [Google Scholar] [CrossRef]

- Kudarauskas, N. Analysis of Emergency Braking of a Vehicle. Transport 2007, 22, 154–159. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).