Abstract

During tribometer experiments, the condition of the applied lubricants plays a crucial role in determining friction and wear properties. Oil degradation can significantly influence measurement outcomes, making it essential to understand the chemical changes that may occur during tribometric experiments. The objective of this study is to systematically investigate the source of silicone contamination and its temperature dependence. Tribometer experiments were conducted at 40, 60, 80, 100, and 120 °C, followed by FT-IR spectroscopy to analyze the lubricant after each measurement. Additionally, wear scars were examined using X-ray photoelectron spectroscopy to determine the presence of silicone within the surface layers. To assess potential alternative contamination sources, a single-drop system was employed, which excludes tubing, thereby providing a controlled environment to verify the origin of the silicone peaks. The results of this study are expected to enhance the reliability of tribometer measurements by identifying contamination sources and optimizing the experimental setup.

1. Introduction

Tribometer-based testing enables the investigation of various lubricants and surface coatings under simplified yet representative conditions, utilizing standardized test specimens and procedures. Depending on the tribometer’s design and the selected test configuration, various contact geometries—such as ball-on-disc, cylinder liner-ring, and pin-on-disc—can be implemented, along with diverse material pairings and lubrication systems. Numerous studies have explored wear and frictional behaviour under various lubrication regimes, ranging from dry contact to boundary and hydrodynamic lubrication conditions.

For instance, Khairallah et al. investigated the effect of iron oxide nanoparticles on friction and wear in dry sliding conditions, using a reciprocating pin-on-disc tribometer [1]. Additionally, a 2020 study aimed to evaluate the effect of graphite-based surface texturing on friction in dry contact, utilizing an SRV 5 tribometer with a rotating pin-on-disc setup [2]. However, tribometric studies often feature test configurations in which the lubricant is essential for creating boundary or mixed lubrication regimes. This can be achieved through methods such as oil bath lubrication [3], oil circulation systems [4], or single-drop lubrication techniques [5]. Thachnatharen et al. employed a four-ball tribometer to explore the effects of hexagonal boron nitride nanoparticle additives in SAE 20W-50 engine oil, specifically for military vehicles [6]. Moreover, Forder et al. designed a reciprocating tribometer to investigate friction between the piston ring and cylinder liner using low-viscosity oils [7].

Lubricants experience chemical and physical deterioration during prolonged operation or when subjected to heavy thermal and mechanical stress. Such degradation can impact tribological performance and may cause misinterpretation of experimental findings. Numerous studies have explored the degradation processes of lubricants under actual operating conditions [8,9,10] and those of artificially aged oils [11,12], both of which can influence the lubricant’s overall effectiveness.

Therefore, it is essential to investigate whether the lubricant’s condition has changed due to contamination or mechanical and thermal stress during a tribometer test sequence, and whether these changes have impacted the experimental results. One widely used method for assessing lubricant condition is Fourier-transform infrared spectroscopy (FT-IR). This technique can detect oxidation and nitration occurring in the lubricant [13], provide insights into the presence of anti-wear additives such as zinc-dialkyldithiophosphate (ZDDP) [14], and indicate the level of fuel dilution [15]. In addition to lubricant analysis, examining the wear scars on test specimens is crucial, as changes in lubricant composition can significantly impact the formation and properties of the tribological boundary layer at the contact interface. X-ray photoelectron spectroscopy (XPS) remains one of the most established methods for this analysis, providing valuable information about the chemical composition of tribofilms formed through the reactions of anti-wear additives [16] and their resulting thicknesses [17].

This study explores the presence of silicone contamination resulting from tribometer tests using FT-IR and XPS methodologies. During previous experiments at the Tribology Laboratory of the Department of Propulsion Technology, FT-IR analysis detected silicone in the oils after tribometer runs. The contamination clearly appeared during these tests, leading to several possible conclusions. The contamination may originate from the disc material–since 100Cr6 steel also contains silicon as an alloying element–as well as from environmental contamination or from the silicone tubes used for the measurements. The main focus of the research is a systematic investigation of measurements with silicone tubes, which are known to swell and lose mechanical strength when exposed to hydrocarbons [18]. The primary goal of this research is to identify the source of contamination; therefore, it does not examine the mechanisms by which the contamination affects wear.

2. Materials and Methods

2.1. Tribological Experiments

The lubricant used in this experiment was a fresh, commercially available SAE 0W-20 viscosity-grade engine oil. Tribometer tests were conducted using an Optimol SRV 5 oscillating tribometer (Optimol Instruments Prüftechnik GmbH, Munich, Germany) configured in a ball-on-disc setup. The material properties of the test specimens are summarized in Table 1.

Table 1.

Material properties of the specimens.

In the one-hour tribometer tests, the first five minutes consisted of a running-in phase with a load of 50 N, followed by an increase to 150 N for the remainder of the experiment. To assess the influence of temperature on silicone contamination, measurements were recorded at five different temperatures: 40, 60, 80, 100, and 120 °C. Lubrication between the contact surfaces was performed using two methods: a continuous oil flow at a rate of 225 mL/h (13 mL) provided by a peristaltic pump, and a single-drop method (0.3 mL) where the lubricant was applied using a pipette. The reason for using these two methods was that if the hypothesis is correct—that silicone originates from the tubing—then under the single-drop lubrication method, no silicone leaching from the tubing should be detectable. Each test was repeated three times to analyze repeatability and variability. The tests are detailed in Table 2.

Table 2.

Parameters applied during tribometer tests.

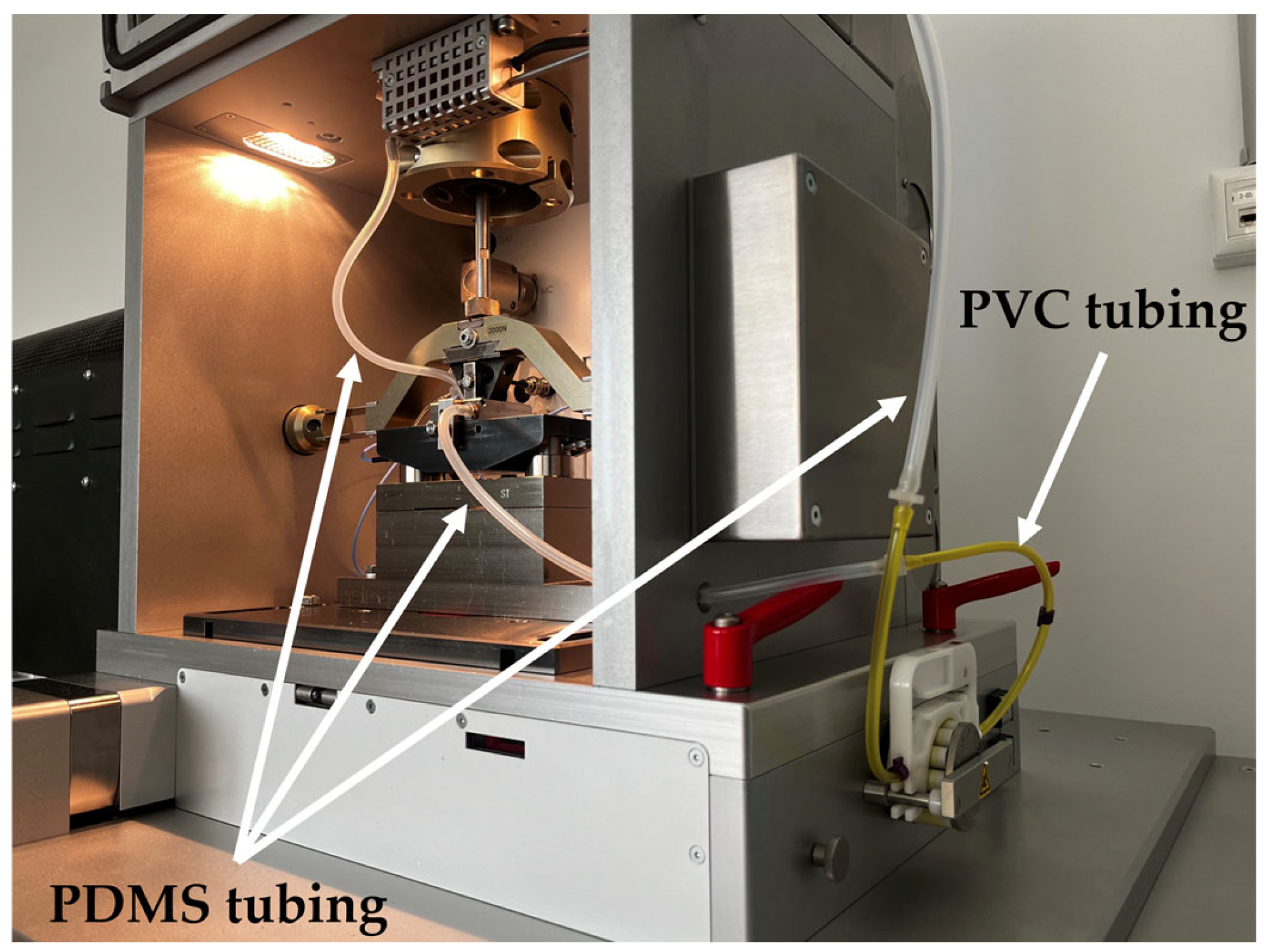

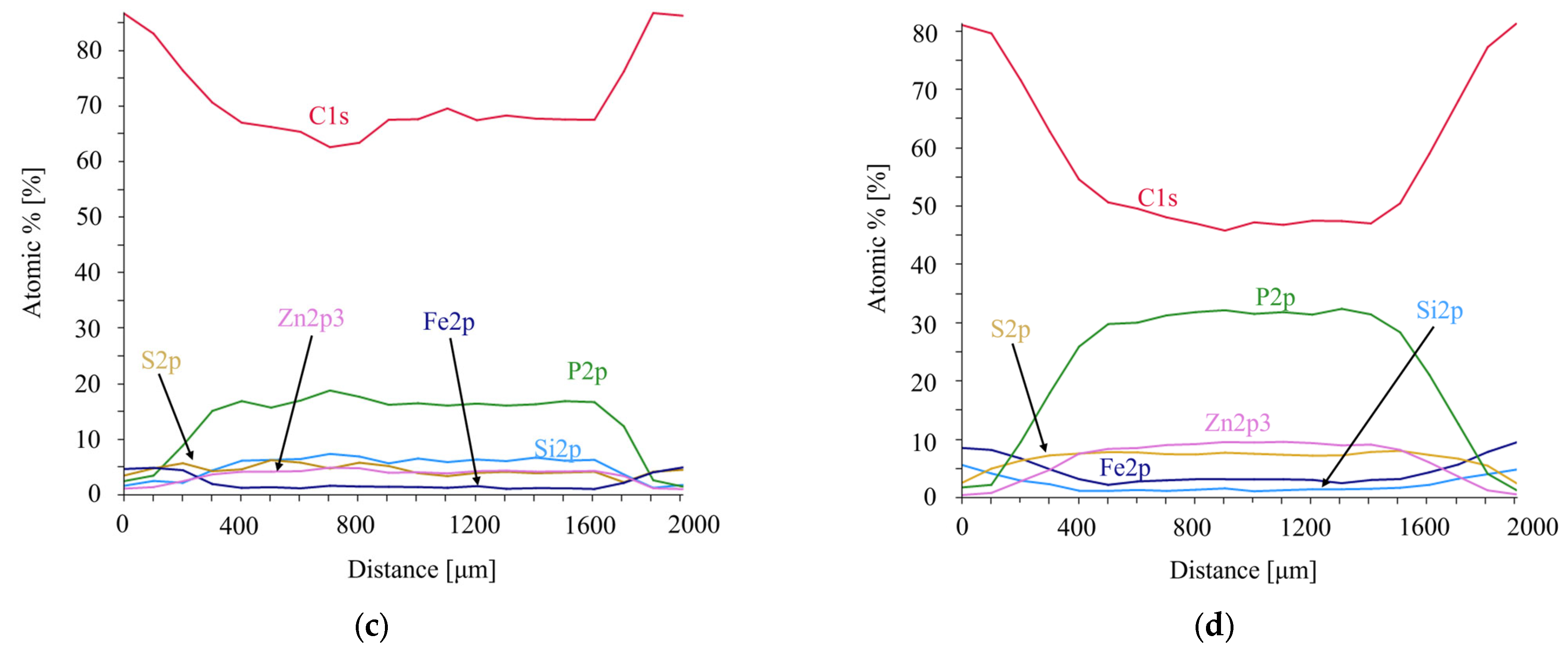

In the continuous circulation system, a segment of PVC tubing that is resistant to hydrocarbons was used, alongside three segments of transparent polydimethylsiloxane (PDMS) tubing, which, by contrast, is not resistant to hydrocarbons, as shown in Figure 1. This setup was chosen in the Tribology Laboratory of the Department of Propulsion Technology because it is significantly more cost-effective than using only PVC tubing. To ascertain the origin of silicone contamination from the tubing, two distinct lubrication methods were implemented. A fresh reference lubricant was used for each test, with a primary focus on the degradation of the silicone tubing.

Figure 1.

The Optimol SRV5 tribometer setup utilizes a peristaltic pump and two types of tubing.

2.2. Wear Analysis

After the tribometer experiments, the test specimens were cleaned using a three-step ultrasonic cleaning process (15 min in cyclohexane at 50 °C, 15 min in acetone at 0 °C, and 15 min in isopropyl alcohol at 50 °C). The wear scars on the specimens were examined using a Keyence VHX-1000 digital optical microscope (Keyence International, Mechlin, Belgium), equipped with a VH-Z100R objective. Average wear scar diameters (AWSD) were determined by measuring the average width and depth of the scars, providing a representative measure of the worn surface. The analysis of wear scars was carried out to assess measurement repeatability and evaluate the variability of the results.

2.3. Oil Analysis

Oil samples were analyzed using a Bruker INVENIO S Fourier-transform infrared (FT-IR) spectrometer (Bruker Corporation, Billerica, MA, USA), which had a potassium bromide (KBr) cell and attenuated total reflectance (ATR) technology. This approach allows for the detection of chemical changes in the lubricant by comparing it to a fresh reference sample. The ATR technique was chosen for single-drop samples because their volume was insufficient for transmission measurements using the KBr cell. The key distinction between the two measurement techniques is their sensitivity: ATR typically shows lower absorbance values, making it less effective at identifying minor changes in oil composition. Therefore, ATR was utilized for single-drop samples, while oil samples from continuous flow tests were analyzed using both ATR and the more sensitive KBr transmission method. After each measurement, the cell was cleaned with cyclohexane, and a background scan was performed before each acquisition to account for water vapour and carbon dioxide present in the ambient air. This study primarily examines contamination from PDMS tubing, which can be identified in spectral regions of 789–796 cm−1 (-CH3 rocking and Si-C stretching in Si-CH3), 1020–1074 cm−1 (Si-O-Si stretching), and 1259–1260 cm−1 (CH3 deformation in Si-CH3) [19].

2.4. Surface Analysis

Surface analytical characterization of the disc specimens was performed using a Thermo Scientific Nexsa G2 X-ray photoelectron spectrometer (Thermo Fisher Scientific, Waltham, MA, USA) with a monochromatic Al Kα radiation source (1486.6 eV). A focused spot measuring 200 µm in diameter was utilized to collect spectra from the centre of the wear scar, and the data obtained were analyzed through the Smart peak fitting algorithm. Additionally, elemental analysis along the wear scar was conducted using a 100 µm focused spot in line scan mode to assess variations in atomic concentrations across the studied surface. This analysis included silicon (Si), carbon (C), and iron (Fe) from the disc material; zinc (Zn), phosphorus (P), and sulphur (S) from anti-wear additives in the lubricant; and silicon (Si) due to contamination from the PDMS tubing.

3. Results and Discussion

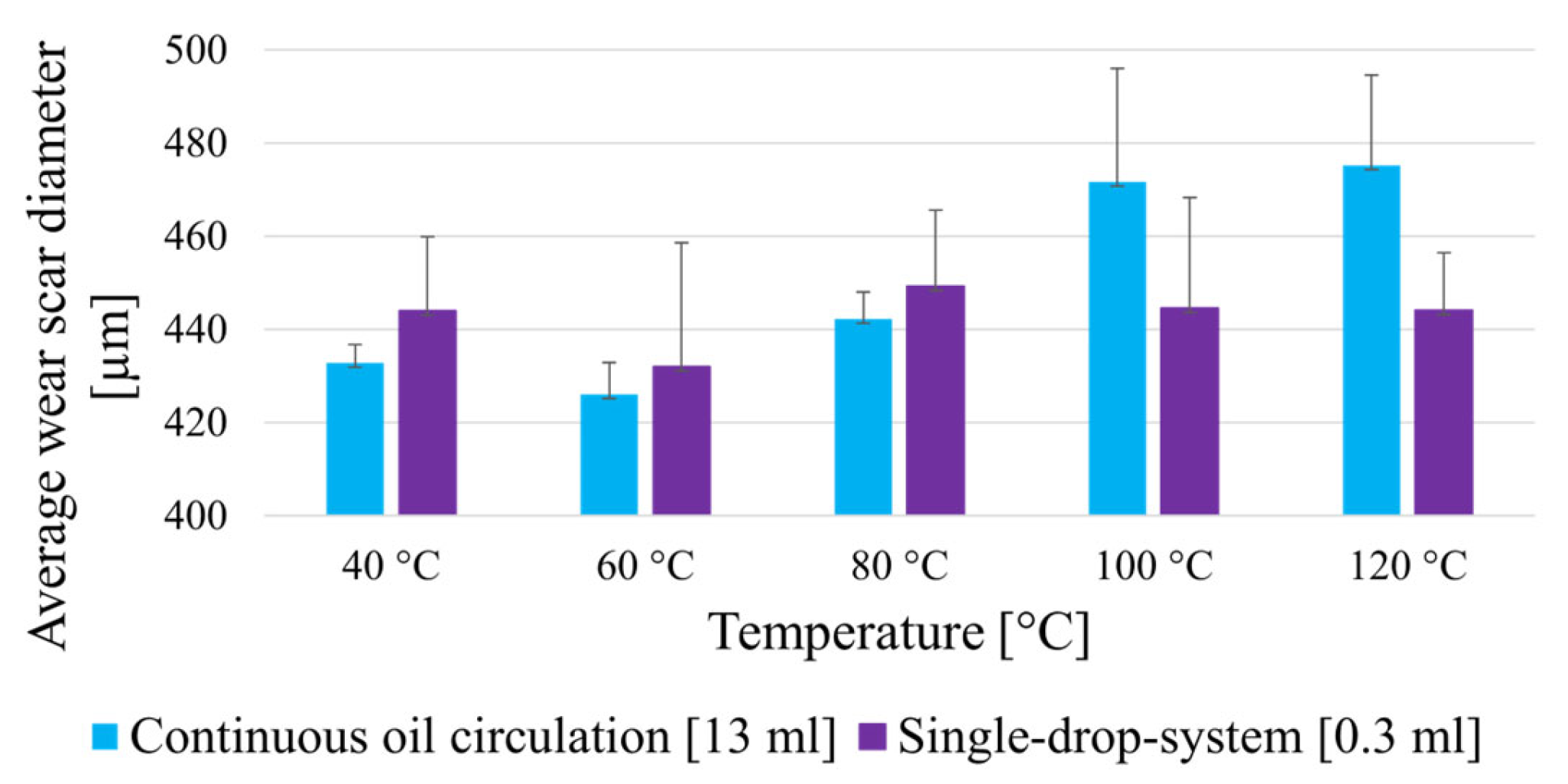

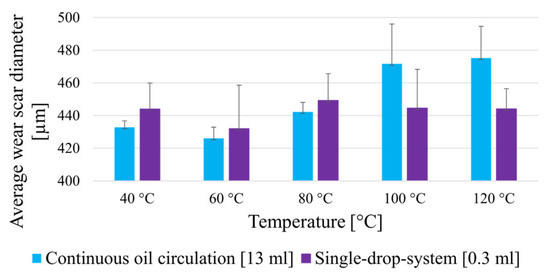

This study focused on confirming silicone contamination and identifying its source, rather than examining how it may affect wear. Alongside the standardized measurement of the average wear scar diameter on the ball specimens [20], the wear marks on the disc specimens were analyzed, as these were selected for XPS analysis. As shown in Figure 2, the coefficient of variation (CV) for the ball specimens ranged from 0.9% to 6.17%, while for the disc specimens, the CV values varied between 0.53% and 3.27%. These results suggest that assessing a single wear scar through surface analysis methods can yield representative findings for a specific test series. Therefore, examining 30 distinct samples using XPS is unnecessary.

Figure 2.

Variation in wear scar diameters for ball specimens.

3.1. FT-IR Analysis

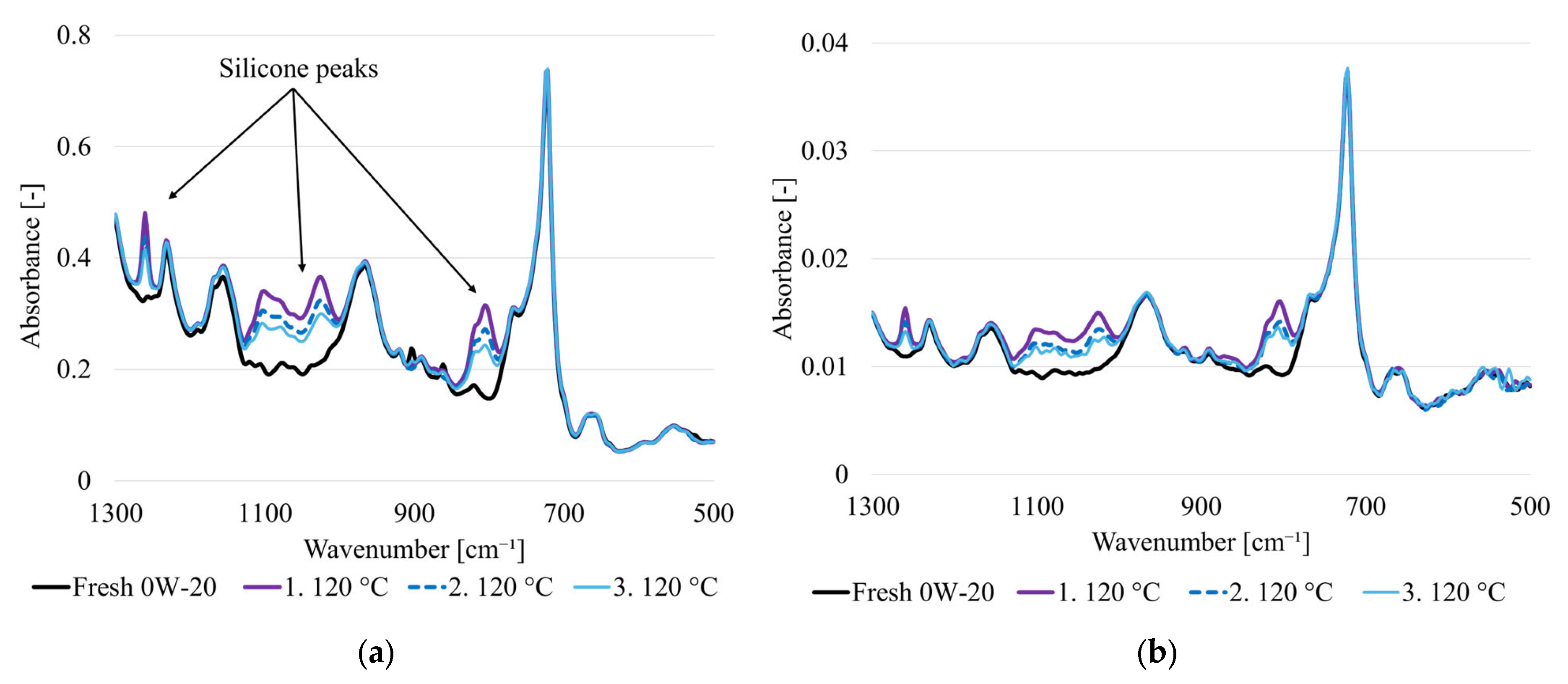

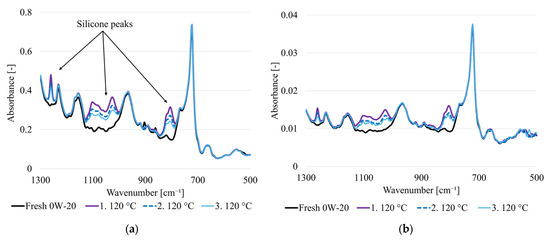

Oil analysis using Fourier-transform infrared spectroscopy was conducted after each tribometer test. For circulated oil samples, both a potassium bromide (KBr) cell and the attenuated total reflectance (ATR) method were used. In the single-drop system, only ATR was used due to the limited sample volume. Figure 3 compares the KBr and ATR results obtained from the circulated oil samples. The spectra indicate that, despite lower absorbance values from ATR measurements, this method still yielded adequate information about chemical changes in the lubricant. Furthermore, Figure 3 shows that, compared to the reference oil, the used oil samples exhibited spectral deviations in the 1260 cm−1, 1020–1074 cm−1, and 789–796 cm−1 regions, corresponding to characteristic absorption bands of PDMS-based silicone contamination [19]. The most significant silicone dissolving from the PDMS tubing was observed during the first test, with a gradual reduction noted in the second and third tests.

Figure 3.

(a) Relevant spectral region of oil samples circulated at 120 °C using a KBr transmission cell; (b) Relevant spectral region of oil samples circulated at 120 °C using ATR.

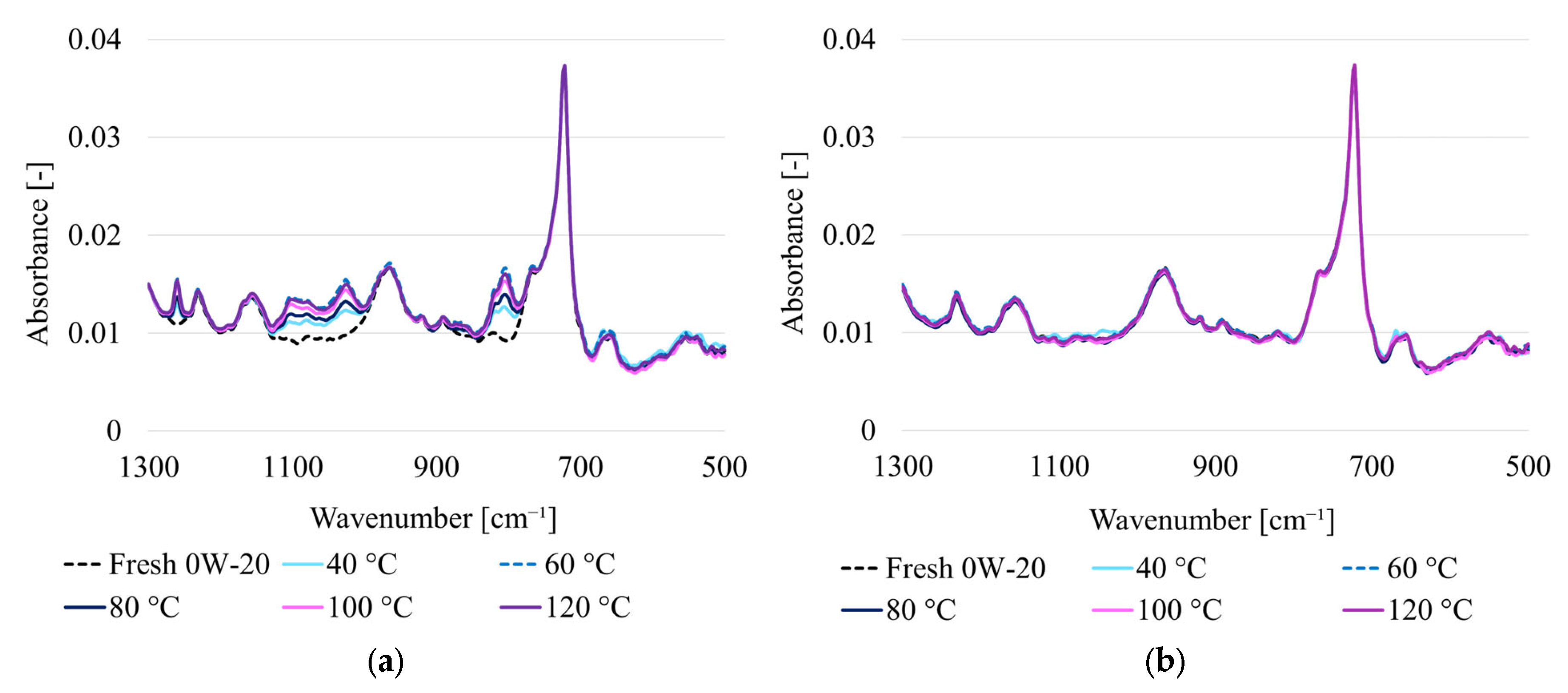

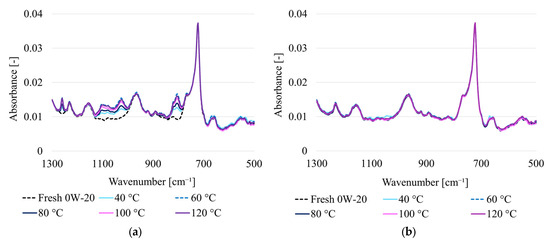

As a result of the comparative evaluation of the KBr and ATR methodologies, all subsequent analyses of both the circulated and single-drop oil samples were conducted using the ATR method. Based on Figure 4, it can be established that silicone contamination originated from the PDMS tubing used in the experimental setup, as the characteristic silicone-related peaks appeared only in the spectra of the circulated oil samples. Figure 4a shows that the level of silicone contamination does not exhibit a clear correlation with increasing temperature. Therefore, no definitive conclusions can be made regarding the temperature dependence of silicone dissolution.

Figure 4.

(a) Spectra of oil samples run with continuous oil circulation at different temperatures in the examined spectral regions; (b) Spectra of oil samples run with the single-drop system at different temperatures in the examined spectral regions.

3.2. XPS Analysis

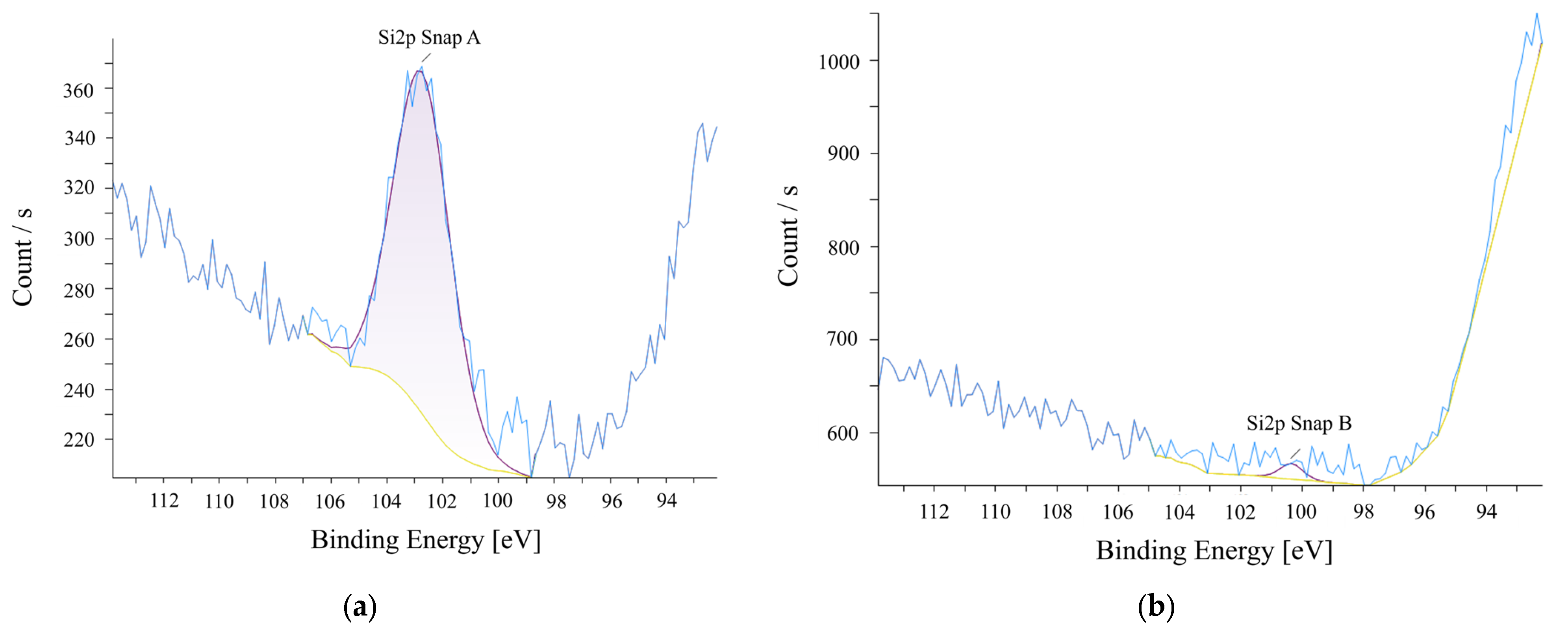

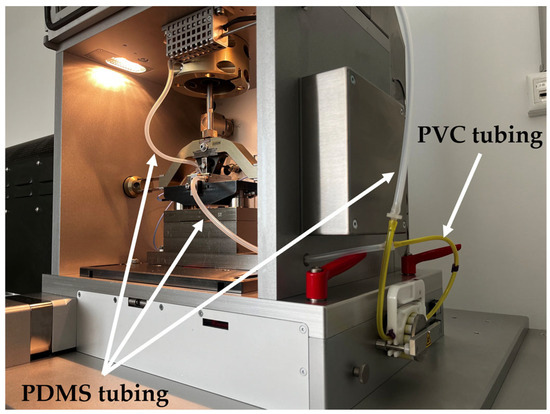

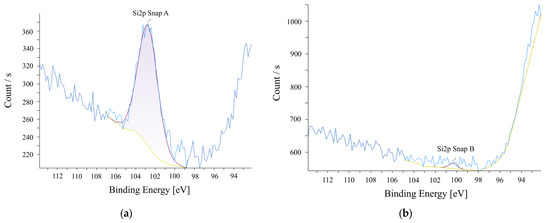

During the surface analysis, it was essential to differentiate between the silicon alloy component (Si0) and the disc material, as well as the PDMS ((-Si(CH3)2O-)ₙ) contamination originating from the tribometer test. Analyzing the centre of the wear scars on the disc operated at 120 °C under continuous oil circulation revealed a significant Si2p peak at a binding energy of 102.7 eV, as illustrated in Figure 5a. After applying charge correction based on the C1s peak, the Si2p peak shifted to 102.46 eV, aligning with the 102.4 eV value reported by the National Institute of Standards and Technology (NIST), which is characteristic of the Si 2p binding energy in PDMS [21]. In contrast, Figure 5b indicates that in the sample tested with the single-drop system at 120 °C, a smaller intensity peak appears at 100.37 eV, corresponding to Si0 from the disc material.

Figure 5.

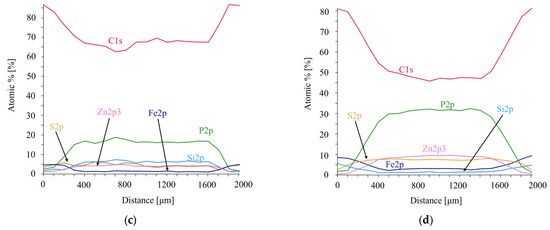

(a) Si2p peak shows PDMS contamination on the surface of the sample run with continuous circulation (120 °C); (b) Si2p peak reveals the silicon alloying element in the sample operated under the single-drop system (120 °C); (c) Variation in atomic percentage of the analyzed elements along the wear scar of the sample operated under continuous oil circulation (120 °C); (d) Variation in atomic percentage of the analyzed elements along the wear scar of the sample operated with the single-drop system (120 °C).

Figure 5c illustrates the changes in atomic percentages of elements originating from the disc material (Si 2p, C 1s, Fe 2p), the oil’s anti-wear additives (Zn 2p3, P 2p, S 2p), and the silicone contamination (Si 2p) along the wear scar of the continuously circulated oil sample. At the start of the wear scar, a decrease in elements derived from the disc material can be observed, likely due to the formation of a ZDDP tribofilm and the presence of PDMS contamination. Figure 5d shows the elemental distribution along the wear scar of the sample lubricated by the single-drop system. Notably, the Si content is higher at the edge of the wear scar compared to within it, which can similarly be attributed to the formation of a boundary layer. However, further depth profiling will be necessary to confirm this hypothesis.

4. Conclusions

This study investigated the presence and origin of silicone contamination resulting from tribometer tests. Fourier-transform infrared spectroscopy revealed the presence of silicone (PDMS) in the oil samples subjected to continuous oil circulation, which contained silicone (PDMS) within the relevant spectral regions. In contrast, the oil samples not exposed to PDMS tubing did not show such contamination. After identifying the source of contamination, surface analytical characterization of the wear scars on the disc specimens was performed using X-ray photoelectron spectroscopy (XPS). This analysis aimed to confirm whether the silicone dissolved in the oil was also present in the wear scars that formed. The results confirmed the presence of PDMS in the wear scars of samples that were continuously circulated. Meanwhile, in the single-drop system tests, only silicon from the disc material was identified. These findings suggest that silicone may influence wear; however, the current study did not investigate the underlying mechanisms involved in this effect. Further tribometer experiments are necessary to examine the impact of silicone contamination on wear scars, ideally using hydrocarbon-resistant tubing for oil circulation. Future investigations will include surface analytical assessments of wear scars through depth profiling techniques to explore the impact of silicone contamination on the thickness of the surface boundary layer.

Author Contributions

Conceptualization, D.P. and M.K.; methodology, M.K. and D.P.; investigation, D.P.; writing—original draft preparation, M.K. and D.P.; writing—review and editing, D.P. All authors have read and agreed to the published version of the manuscript.

Funding

This article is published in the framework of the project “Synthetic fuels production and validation in cooperation between industry and university”, project number “ÉZFF/956/2022-ITM_SZERZ”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data for the study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study, the collection, analysis, or interpretation of data, the writing of the manuscript, or the decision to publish the results.

References

- Khairallah, W.; Autay, R.; Bensalah, W.; Baouab, M.H.V. Tribological and mechanical behaviors of Fe3O4NPs reinforced UHMWPE biocomposite. J. Thermoplast. Compos. Mater. 2025, 38, 1950–1967. [Google Scholar] [CrossRef]

- Wos, S.; Koszela, W.; Pawlus, P. The effect of graphite surface texturing on the friction reduction in dry contact. Tribol. Int. 2020, 151, 106535. [Google Scholar] [CrossRef]

- Ferreira, R.; Carvalho, Ó.; Pires, J.; Sobral, L.; Carvalho, S.; Silva, F. A new tribometer for the automotive industry: Development and experimental validation. Exp. Mech. 2022, 62, 483–492. [Google Scholar] [CrossRef]

- Paulovics, L.; Kuti, R.; Rohde-Brandenburger, J.; Tóth-Nagy, C. Development of comparative investigation method for timing chain wear analysis using oscillating tribometer. Acta Tech. Jaurinensis 2021, 14, 406–423. [Google Scholar] [CrossRef]

- Tortora, A.M.; Veeregowda, D.H. Effects of two sliding motions on the superlubricity and wear of self-mated bearing steel lubricated by aqueous glycerol with and without nanodiamonds. Wear 2017, 386, 173–178. [Google Scholar] [CrossRef]

- Thachnatharen, N.; Khalid, M.; Arulraj, A.; Sridewi, N. Tribological performance of hexagonal boron nitride (hBN) as nano-additives in military grade diesel engine oil. Mater. Today Proc. 2022, 50, 70–73. [Google Scholar] [CrossRef]

- Forder, M.D.; Morris, N.; King, P.; Balakrishnan, S.; Howell-Smith, S. An experimental investigation of low viscosity lubricants on three piece oil control rings cylinder liner friction. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 2261–2271. [Google Scholar] [CrossRef]

- Idzior, M. Aging of engine oils and their influence on the wear of an internal combustion engine. Combust. Engines 2021, 185, 15–20. [Google Scholar] [CrossRef]

- Agocs, A.; Nagy, A.L.; Tabakov, Z.; Perger, J.; Rohde-Brandenburger, J.; Schandl, M.; Dörr, N. Comprehensive assessment of oil degradation patterns in petrol and diesel engines observed in a field test with passenger cars–Conventional oil analysis and fuel dilution. Tribol. Int. 2021, 161, 107079. [Google Scholar] [CrossRef]

- Agocs, A.; Besser, C.; Brenner, J.; Budnyk, S.; Frauscher, M.; Dörr, N. Engine oils in the field: A comprehensive tribological assessment of engine oil degradation in a passenger car. Tribol. Lett. 2022, 70, 28. [Google Scholar] [CrossRef]

- Dörr, N.; Brenner, J.; Ristić, A.; Ronai, B.; Besser, C.; Pejaković, V.; Frauscher, M. Correlation between engine oil degradation, tribochemistry, and tribological behavior with focus on ZDDP deterioration. Tribol. Lett. 2019, 67, 62. [Google Scholar] [CrossRef]

- Agocs, A.; Budnyk, S.; Besser, C.; Ristic, A.; Frauscher, M.; Ronai, B.; Dörr, N. Production of used engine oils with defined degree of degradation in a large-scale device: Correlation of artificially altered oils with field samples. Acta Tech. Jaurinensis 2020, 13, 131–150. [Google Scholar] [CrossRef]

- Heredia-Cancino, J.A.; Carrillo-Torres, R.C.; Félix-Domínguez, F.; Álvarez-Ramos, M.E. Experimental characterization of chemical properties of engine oil using localized surface plasmon resonance sensing. Appl. Sci. 2021, 11, 8518. [Google Scholar] [CrossRef]

- Akbari, S.; Kovač, J.; Kalin, M. Effect of ZDDP concentration on the thermal film formation on steel, hydrogenated non-doped and Si-doped DLC. Appl. Surf. Sci. 2016, 383, 191–199. [Google Scholar] [CrossRef]

- Conklin, A., Jr.; Goldcamp, M.J.; Barrett, J. Determination of ethanol in gasoline by FT-IR spectroscopy. J. Chem. Educ. 2014, 91, 889–891. [Google Scholar] [CrossRef]

- Ueda, M.; Spikes, H. ZDDP tribofilm formation and removal. Tribol. Lett. 2024, 72, 109. [Google Scholar] [CrossRef]

- Costa, H.L.; Evangelista, K.S.; Cousseau, T.; Acero, J.S.R.; Kessler, F. Use of XANES and XPS to investigate the effects of ethanol contamination on anti-wear ZDDP tribofilms. Tribol. Int. 2021, 159, 106997. [Google Scholar] [CrossRef]

- Lee, J.N.; Park, C.; Whitesides, G.M. Solvent compatibility of poly(dimethylsiloxane)-based microfluidic devices. Anal. Chem. 2003, 75, 6544–6554. [Google Scholar] [CrossRef] [PubMed]

- Johnson, L.M.; Gao, L.; Shields IV, C.W.; Smith, M.; Efimenko, K.; Cushing, K.; López, G.P. Elastomeric microparticles for acoustic mediated bioseparations. J. Nanobiotechnol. 2013, 11, 22. [Google Scholar] [CrossRef] [PubMed]

- ISO 19291:2016(E); Lubricants—Determination of Tribological Quantities for Oils and Greases—Tribological Test in the Translator Oscillation Apparatus. International Organization for Standardization: Geneva, Switzerland, 2016.

- NIST X-Ray Photoelectron Spectroscopy Database. Available online: https://srdata.nist.gov/xps/ (accessed on 12 June 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).