Abstract

Digital Twins provide comprehensive capabilities to solve critical logistics problems such as visibility, monitoring, optimization, prediction, and simulation. This study explores the existing DT readiness assessment models in SCs and logistics, discovers their limitations, and proposes a conceptual model based on an organization’s internal and external attributes to strategize DT implementation in logistic functions. The results showed that the existing readiness assessment models have weaknesses and drawbacks, motivating the researchers to develop a new logistic DT readiness assessment model. This study identified six main organizational dimensions directly affecting measuring overall logistics’ DT readiness, which are management readiness, personnel readiness, information readiness, organization readiness, product readiness, and process flow readiness. Their relationship is mediated by Technology Integration and moderated by Supply Chain Complexity, which was tested using partial least squares structural equation modeling to show the importance of strategizing DT implementation in logistics.

1. Introduction

A supply chain (SC) is a complex, global network of different, independent, and linked organizations that work together to create value for customers. The planning, controlling, and monitoring of the SC is known as supply chain management (SCM). An SC contains multiple elements belonging to multiple stakeholders and includes every step that is involved in getting a finished product or service to the customer. To optimize the functional performance of SCs, organizations are now heavily dependent on digital transformation. Under this paradigm, organizations are exploring emerging technologies in the context of logistics to withstand the global competitive environment [1]. Following this need, logistics functions are now adopting the fourth wave of the industrial revolution, known as Industry 4.0. In the paradigm of Industry 4.0, Digital Twins (DTs) play a crucial role [2]. A DT is a digital representation of physical assets, systems, or processes. The use of DTs for industries other than space has been a trending topic over the last decade, with manufacturing being prominent. Manufacturing firms are now at a high maturity rate in DT adoption, and as a result, logistics are also being subjected to the influence of DTs [3]. Using DTs in logistics will allow for the creation of a virtual simulation model of the entire logistics process, where organizations can perform continuous cycles of improvements and adjustments in near-real time [4], providing a view of end-to-end processes.

The development and implementation of DTs for logistics is a complex and sophisticated exercise due to the complexity of the SC hierarchy and the technicality of DTs. All the elements of an SC should be interconnected and share information in real time, and these SC systems require various technologies to replicate their physical processes in a virtual world. Hence, the adoption of DTs for logistics needs a strategic approach. From a technology management perspective, this strategic approach should follow a readiness assessment before implementation. Properly measuring the readiness level of a firm’s SC acts as the foundation for strategizing its DT adoption [5]. In the accessible literature, resources and findings related to assessing the readiness of logistics to adopt DTs are limited. The available limited number of studies focus on the readiness of individual aspects of an organization, but due to the complexity of SCs, a holistic assessment framework covering internal and external organizational attributes is needed. Identifying this research gap, this study focused on exploring and comparing the available readiness level frameworks for DT adoption in SCs, including logistics, and proposing a conceptualized exploratory design model to navigate an organization’s logistics through the hierarchical levels of DT readiness.

Research Objectives:

- What are the existing Digital Twin readiness assessment frameworks in supply chain management, including logistics?

- What key dimensions and indicators should be included in the framework to measure Digital Twin readiness in logistics?

To answer these questions, this study critically reviewed the existing literature to explore the current DT readiness frameworks for SCs and then compared the existing models to identify their limitations. Based on the limitations, we propose a six-element framework to test and validate using Smart PLS 4 (Version 4.0.9.7, SmartPLS GmbH, Düsseldorf, Germany).

2. Methodology

This systematic literature review (SLR) was based on content analysis to gather the existing knowledge about DT readiness assessment models and identify the main elements of the macro- and microenvironments of an organization that impact successful DT implementation in SCM. First, as seen in Table 1 keywords were identified through a rigorous database search, and after selection, they were classified based on the PEO framework.

Table 1.

Classification of keywords based on PEO framework.

Using Scopus and Web of Science as primary databases for keyword search, a total of 570 articles were initially identified for the literature review. Using the PRISMA methodology [6], applying inclusion and exclusion criteria like period of publications and focused industries, 180 articles were selected for screening. Out of them, 72 articles were eligible for full-text reading after screening for abstracts. 25 articles were included in the review after excluding studies based on relevance. The content of these articles was analyzed to explore the existing readiness assessment frameworks (RAFs). The identified frameworks were then compared against 5 evaluation criteria [7], and we identified their limitations. From the RAF evaluation, the findings showed that no research has been performed to assess DT readiness specifically in supply chain management (SCM). Referring to [8]’s evolution of the SCM framework, this study divides SCM into 4 pillars: logistics, marketing, strategic planning, and information technology. Using the SAE J4000 standard introduced by the Society of Automotive Engineers (SAE) [9], this study identifies 6 main readiness measurement dimensions (RMDs) for each of the four pillars above.

3. Systematic Literature Review

Through the SLR conducted to identify DT readiness assessment frameworks in SCs, only two studies were identified related to the scope of logistics. This provides clear emphasis on the lack of research performed in this area. Hence, the search string was extended to Industry 4.0 readiness assessments in SCs under the assumption that since Digital Twins are an element of Industry 4.0 enabling technology stack, an SC’s readiness to implement DTs can be assessed using Industry 4.0 readiness assessment frameworks [10]. This study explores 10 readiness assessment frameworks from the past 10 years. Ref. [11] proposed the AECO organizational framework (RAF 1), which targets DT implementation in construction supply chains and considers policy, workflow, and government enforcement to be key elements. Ref. [12] introduced a Digital Twin and supply chain (SC) transparency framework (RAF 2) that assesses readiness based on data readiness, perceived values and benefits, organizational preparedness, and leadership support. Ref. [13] developed the Connected Enterprise Maturity Model (RAF 3), which evaluates an organization’s Industry 4.0 readiness through secure and upgraded network infrastructure, structured working data, and collaboration through analytics. Ref. [14] proposed the SIMMI 4.0 model (RAF 4) to assess the IT and software landscape for Industry 4.0 adoption, focusing on dimensions such as IT infrastructure, data management, organizational culture, skills, and strategic leadership. In the context of defense supply chains, ref. [15] developed the Industry 4.0 Maturity Assessment Framework (RAF 5), highlighting factors such as the Factory of the Future, people and culture, and strategy. Ref. [16] contributed a comprehensive readiness and maturity framework (RAF 6) for manufacturing enterprises, addressing aspects like strategy, leadership, customers, products, operations, governance, and technology. The I4.0/Digital Operations-Self Assessment (RAF 7), based on the 2016 Global Industry 4.0 Survey, provides a roadmap for value chain readiness, emphasizing empowered customers, data analytics, culture, and investment impact. Ref. [17] proposed the Logistics 4.0 Maturity Model (RAF 8), tailored specifically to inbound and outbound logistics processes, with focus areas including management and the flow of materials and information. Ref. [18] introduced the Maturity and Readiness Model for I4.0 Strategy (RAF 9), addressing strategy, organizational structure, operations, and product development within manufacturing supply chains. Ref. [19] presented the Delivery Process Maturity Model—DPMM 4.0 (RAF 10), which assesses digital maturity across five progressive levels from basic digitization to fully optimized and integrated processes in delivery operations.

The identified RMFs were evaluated based on five criteria. These criteria were identified based on [7] and modified to satisfy the needs of this study. These criteria evaluate the gaps existing among these models, their strengths, and their weaknesses. A Likert scale from 1 to 10 was introduced to evaluate the accomplishment of these criteria by each RAF. None of the available RAFs fully accomplish the defined criteria. RAF 3, RAF 4, RAF 5, and RAF 6 concentrate on Industry 4.0 readiness in multiple areas across an organization’s value chain. RAF 5, RAF 8, RAF 9, and RAF 10 focus on the SC’s readiness to implement Industry 4.0 but not on DT readiness. Only RAF 1 and RAF 2 directly address Digital Twin readiness in supply chains, focusing more on organizational readiness, policy, workflow, and data transparency. However, they are limited to specific supply chain functions. DT applications demand high granularity in data collection, real-time analytics, and synchronization between physical and virtual systems. Though the explored Industry 4.0 RAFs focus on data analytics, they do not emphasize the specific requirements for continuous, real-time data flow and feedback loops, which are crucial for DTs [20]. DTs demand a higher level of integration across SC functions if they are to be implemented [21]. None of the RAFs explore organizational interconnectivity across SCs, which is an essential success factor for successful DT adoption. Unlike in Industry 4.0 RAFs, DT readiness models should focus on sophisticated simulation capabilities for predictive analytics and decision-making. This requirement surpasses the capabilities of the basic dimensions introduced in the explored RAFs.

The existing Digital Twin/Industry 4.0 readiness models’ ability to assess the readiness of logistic functions for DT adoption is limited to certain areas. Due to this lack of technical depth and scope necessary for DT readiness assessment for logistics, the existing RAFs cannot be used as a guide for assessing the readiness of logistics to implement DTs. A dedicated model should be developed to integrate complex SC hierarchies and SCM functions, ensuring the logistic functions are adequately prepared for the complex demands of DT functions. The results received from the literature review provide a holistic view of the key dimensions that should be properly addressed before DT implementation. However, these factors have different meanings and definitions across the functions of the value chain. Using the brainstorming methodology, this new conceptual model was developed to address the literature gaps identified during the SLR.

4. Model Development

Based on the literature review, it was evident that there is a need for a proper readiness assessment framework for DT implementation in logistics. Using the SAE J4000 standard introduced by the Society of Automotive Engineers (SAE) [9], this study identifies six main readiness measurement dimensions (RMD) for logistics (Table 2). The SAEJ4000 represents six areas of an organization in which lean practices are evaluated. This estimates the degree of lean adoption of each of these elements using a set of indicators. Though this model is related to lean manufacturing, several studies have used this to identify internal and external organizational attributes that impact technology adoption, including Industry 4.0 [10]. Achieving readiness in each of these dimensions will improve the overall readiness of logistics for DT implementation [22]. These readiness dimensions are preconditions for logistic readiness.

Table 2.

Readiness dimensions (RDs) for logistics based on SAEJ4000 framework.

Technology Integration (TI) serves as the bridge between these dimensions and logistic readiness because, without exploiting internal capabilities like TI, an organization cannot make maximum use of its internal and external resources. Therefore, TI is positioned as a mediating construct that operationalizes the six readiness dimensions into measurable logistic readiness outcomes [23,24]. Supply Chain Complexity (SCC) is conceptualized as a moderator variable, influencing the strength of the relationship between organizational readiness dimensions and logistics outcomes. In highly complex environments, the impact of readiness factors may be constrained or require additional adaptation mechanisms. While DT systems are designed to absorb complexity [25], the effectiveness of DT readiness still depends on the level of structural, regulatory, and operational variability.

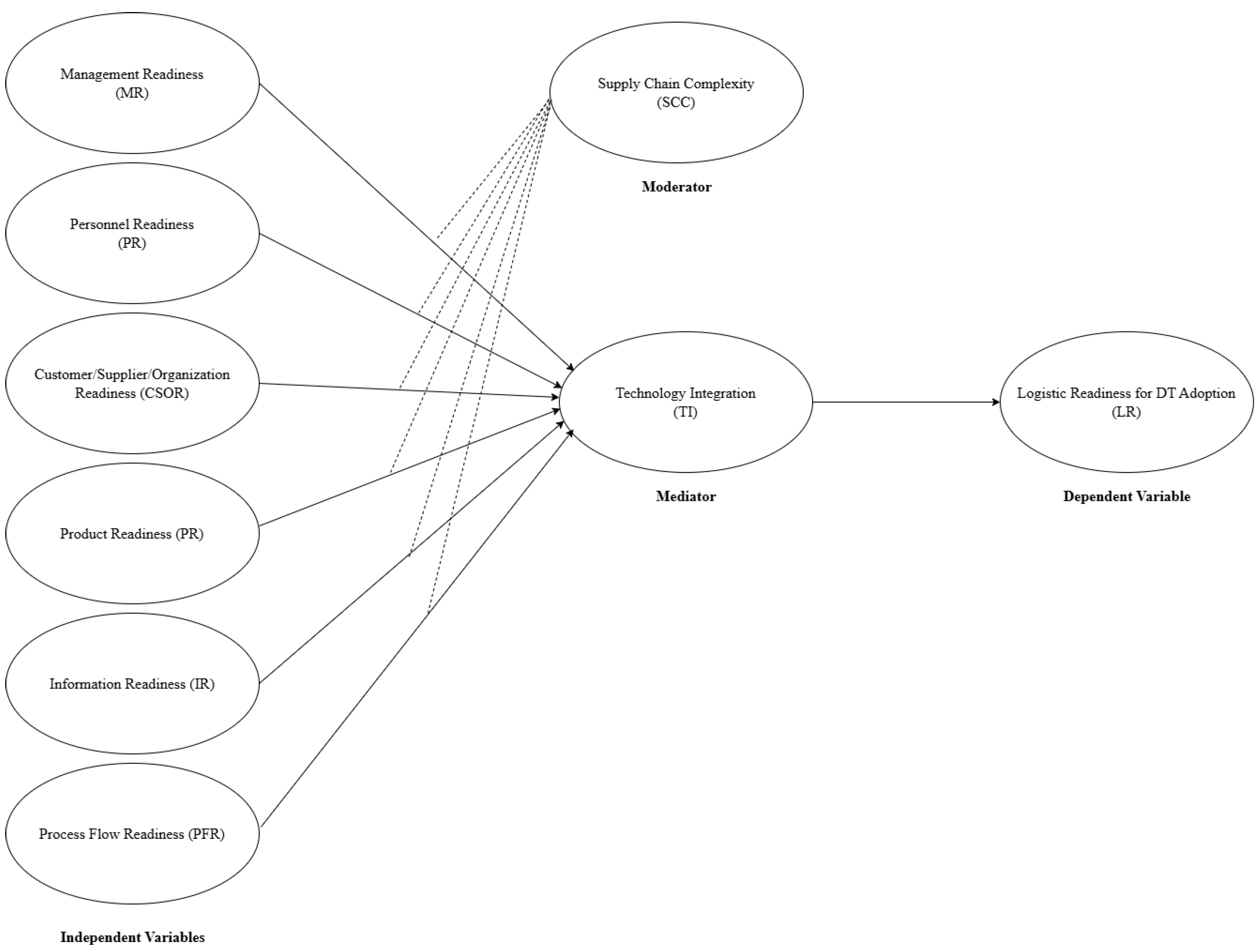

Based on the below-derived hypothesis, a conceptual model was created to be tested and validated using PLS-SEM (Figure 1). PLS-SEM was used as the data analysis tool because of its ability to handle complex models, mediator and moderator analysis, and its ability to work with smaller sample sizes. These latent variables were operationalized using reflective indicators found during the literature review. Management’s commitment to implementing DTs for inbound and outbound logistics is a key indicator for measuring readiness. Managers should define the roles and responsibilities of the personnel involved in DT implementation, and necessary support should be provided to secure funding and budget allocations [19]. Personnel readiness refers to the readiness of human resources involved in logistic functions to adopt DTs. Staff in logistics functions should be skilled in data interpretation and logistics process optimization. They should be provided with necessary training, specifically related to real-time logistics monitoring and data gathering [26]. Information readiness refers to several qualities of a company’s information ecosystem. The enterprise’s data architecture should facilitate a seamless data transfer across different nodes in its logistics process.. The information flow should consist of data-capturing services and devices, and the nature of the data passed should be compatible with at least GS1 standards or equivalent. The suppliers, customers, and clients’ readiness refers to their preparedness to collaborate on DT implementation. Logistic partners should be ready to share their data and integrate their systems with the DTs of the company. They should have the necessary resources and the commitment to be aligned with the company’s DT strategies. Product readiness means the readiness of the manufactured products/services to be used in DT systems. The products and resources related to logistics should be compatible with sensors and IoT applications. The process flows in logistic processes should be ready to implement DTs. Clearly defined and streamlined logistic processes should be available and should have the ability to conduct business process re-engineering, both in physical and virtual process flows, when needed.

Figure 1.

Proposed conceptual model for readiness assessment for DT adoption in logistics.

- H1a. Management readiness positively influences DT readiness in logistics.

- H1b. Personnel readiness positively influences DT readiness in logistics.

- H1c. Customer/organization/supplier readiness positively influences DT readiness in logistics.

- H1d. Information readiness positively influences DT readiness in logistics.

- H1e. Product readiness positively influences DT readiness in logistics.

- H1f. Process flow readiness positively influences DT readiness in logistics.

- H1g. Technology Integration mediates the relationship between independent variables and logistic readiness.

- H1h. Supply Chain Complexity moderates the relationship between independent variables and logistic readiness.

5. Conclusions and Future Implications

Digital Twinning is a complex information technology concept that utilizes data to realistically present the behavior of a product or a service. Due to the complex technicalities and high costs involved in DTs and the complexity of SCs, it is crucial to test the preparedness of an organization to adopt DT applications in its logistics. Hence, a proper readiness assessment of the logistics’ readiness for DT implementation should be conducted prior to any implementation/adoption.

This study explored 10 DT and Industry 4.0 readiness models and evaluated them against pre-defined criteria. As for the results, the existing DT readiness models and industry 4.0 readiness models do not satisfy the micro- and macro-readiness needs of a DT readiness assessment for logistics. The scope and the dimensions used in these frameworks have limitations in technical detailing and area of coverage. These frameworks focus on singular functions in SCs without considering the holistic SCM view, and specific contributions required for DT implementations for logistics from internal and external organizational environments are not addressed. Hence, a dedicated model should be developed to integrate complex SC hierarchies and logistic functions, ensuring that SCs are adequately prepared for the complex demands of DT functions. This study proposed a conceptual model based on six organizational readiness dimensions: management readiness (MR), personnel readiness (PR); customer, supplier, and organization readiness (CSOR); information readiness (IR); product readiness (PRR); and process flow readiness (PFR). The model will examine how these constructs influence logistics readiness (LR) for Digital Twins, both directly and indirectly through Technology Integration (TI) as a mediator, and explore the moderating role of Supply Chain Complexity (SCC).

To validate this model, we propose using a mixed method involving interviews with Digital Twin industry experts to improve the proposed model, followed by a questionnaire. Responses received from the questionnaire will be analyzed using partial least squares structural equation modeling (PLS-SEM) through SmartPLS, and using the results, the validity of the model will be evaluated.

The intention of the empirical validation of this model is to contribute to managerial applications in the field of DTs in logistics. By bridging theory and practice, this study provides a foundation for advancing DT practices in logistics and, ultimately, enhancing the resilience, flexibility, and efficiency of logistic operations in the digital era.

Author Contributions

Conceptualization, L.V.B. and L.B.; methodology, L.V.B. and L.B.; software, L.V.B.; resources, L.V.B.; writing—original draft preparation, L.V.B.; writing—review and editing, L.B.; visualization, L.V.B.; supervision, L.B.; project administration, L.B. All authors have read and agreed to the published version of the manuscript.

Funding

This publication was created in the framework of Széchenyi István University’s VHFO/416/2023-EM_SZERZ project, entitled “Preparation of digital and self-driving environmental infrastructure developments and related research to reduce carbon emissions and environmental impact” (Green Traffic Cloud).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jenet, F.A.; Anderson, S.B.; Kleiner, V.; Rudnitsky, A.; Zalevsky, Z.; Hanada, M.; Liu, J.; Rinaldi, E.; Agrawal, P.; Narain, R. Digital Supply Chain Management: An Overview. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar] [CrossRef]

- Luo, Y.; Ball, P. Expanding the Scope of Manufacturing Digital Twins to Supply Chain. Adv. Transdiscipl. Eng. 2023, 44, 120–125. [Google Scholar] [CrossRef]

- Ren, S.; Zhao, X.; Huang, B.; Wang, Z.; Song, X. A framework for shopfloor material delivery based on real-time manufacturing big data. J. Ambient Intell. Hum. Comput. 2018, 10, 1093–1108. [Google Scholar] [CrossRef]

- Vasant, P.; Zelinka, I.; Weber, G.-W. Advances in Intelligent Systems and Computing; Springer: Berlin/Heidelberg, Germany, 2019; Volume 1072. [Google Scholar]

- Bunjaridh, Y.; Rahman, R.A.; Yusof, L.M. Digital Twin Production in the Architecture, Engineering, Construction and Operation Industry: Organizational Attributes and Strategies. J. Eng. Proj. Prod. Manag. 2023, 13, 0019. [Google Scholar]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef] [PubMed]

- Lakmali, E.; Vidanagamachchi, K.; Nanayakkara, J. Industry 4.0 Readiness Assessment for Apparel Industry: A Study in the Sri Lankan Context. In Proceedings of the International Research Conference on Smart Computing and Systems Engineering (SCSE), Colombo, Sri Lanka, 24 September 2020; pp. 174–181. [Google Scholar] [CrossRef]

- Hesse, M.; Rodrigue, J.P. The Transport Geography of Logistics and Freight Distribution. J. Transp. Geogr. 2004, 12, 171–184. [Google Scholar] [CrossRef]

- SAE Standard J4000_202104; Recommended Practice, Identification and Measurement of Best Practice in Implementation of Lean Operation. SAE International: Warrendale, PA, USA, 2021. [CrossRef]

- Lucato, W.C.; Pacchini, A.P.T.; Facchini, F.; Mummolo, G. Model to Evaluate the Industry 4.0 Readiness Degree in Industrial Companies. IFAC-PapersOnLine 2019, 52, 1808–1813. [Google Scholar] [CrossRef]

- Patil, A.; Srivastava, S.; Paul, S.K.; Dwivedi, A. Digital Twins’ Readiness and Its Impacts on Supply Chain Transparency and Sustainable Performance. Ind. Manag. Data Syst. 2024, 124, 2532–2566. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2017, 94, 3563–3576. [Google Scholar] [CrossRef]

- Rockwell Automation. The Connected Enterprise Maturity Model. Rockwell Autom. 2014, 12, 1–12. [Google Scholar]

- Leyh, C.; Schäffer, T.; Bley, K.; Forstenhäusler, S. Assessing the IT and Software Landscapes of Industry 4.0-Enterprises: The Maturity Model SIMMI 4.0. In Information Technology for Management: New Ideas and Real Solutions; Lecture Notes in Business Information Processing; Springer: Cham, Switzerland, 2017; Volume 277, pp. 103–119. [Google Scholar] [CrossRef]

- Bibby, L.; Dehe, B. Defining and Assessing Industry 4.0 Maturity Levels—Case of the Defence Sector. Prod. Plan. Control. 2018, 29, 1030–1043. [Google Scholar] [CrossRef]

- Schumacher, A.; Erol, S.; Sihn, W. A Maturity Model for Assessing Industry 4.0 Readiness and Maturity of Manufacturing Enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Oleśków-Szłapka, J.; Stachowiak, A. The Framework of Logistics 4.0 Maturity Model. In Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2019; Volume 835, pp. 771–781. [Google Scholar] [CrossRef]

- Akdil, K.Y.; Ustundag, A.; Cevikcan, E. Maturity and Readiness Model for Industry 4.0 Strategy. In Industry 4.0: Managing The Digital Transformation; Springer Series in Advanced Manufacturing; Springer: Cham, Switzerland, 2018; pp. 61–94. [Google Scholar] [CrossRef]

- Asdecker, B.; Felch, V. Development of an Industry 4.0 Maturity Model for the Delivery Process in Supply Chains. J. Model. Manag. 2018, 13, 840–883. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Scavarda, L.F.; Gavião, L.O.; Ivson, P.; de Mattos Nascimento, D.L.; Garza-Reyes, J.A. A Fuzzy Rule-Based Industry 4.0 Maturity Model for Operations and Supply Chain Management. Int. J. Prod. Econ. 2021, 231, 107883. [Google Scholar] [CrossRef]

- Piras, G.; Agostinelli, S.; Muzi, F. Digital Twin Framework for Built Environment: A Review of Key Enablers. Energies 2024, 17, 436. [Google Scholar] [CrossRef]

- Samayamantri, S.; Vaddy, R.K. Sustainable Development Through Digital Twin Technology: Optimizing the Supply Chain. In Sustainable Development Through Machine Learning, AI and IoT. ICSD 2024; CCIS; Springer: Cham, Switzerland, 2025; Volume 2196, pp. 92–101. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Springer: Cham, Switzerland, 2016; pp. 85–113. [Google Scholar] [CrossRef]

- Vukovic, M.; Mazzei, D.; Chessa, S.; Fantoni, G. Digital Twins in Industrial IoT: A Survey of the State of the Art and of Relevant Standards. In Proceedings of the 2021 IEEE International Conference on Communications Workshops (ICC Workshops), Montreal, QC, Canada, 14–23 June 2021. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).