Abstract

The growing demand for rare-earth-free electric machines, driven by supply shortages and price volatility of rare earth elements, has accelerated research into applying alternative hard magnetic materials. This study investigates the challenging complete replacement of high-performance rare earth permanent magnets with low-cost ferrites, which exhibit significantly lower magnetic properties, in permanent magnet synchronous motors (PMSMs) for light electric vehicles (LEVs). While maintaining the original stator structure, output power, and speed requirements of a reference spoke-type PMSM, the research employs ANSYS Motor-CAD for comprehensive electromagnetic analysis and mass minimization of different design variants. The obtained results demonstrate the feasibility of ferrite-based designs while quantifying critical trade-offs in power density versus substantial cost and material availability advantages. This work provides valuable insights into the practical limitations and optimization approaches for rare-earth-free PMSM designs in sustainable mobility applications.

1. Introduction

The global shift toward electrification and the green energy transition have significantly increased the demand for rare earth permanent magnets (REPMs), particularly in permanent magnet synchronous machines (PMSMs), which are widely used in light electric vehicles (LEVs) [1]. However, the heavy reliance on REPMs presents several challenges, including supply chain vulnerabilities, price volatility, geopolitical risks, and environmental concerns associated with rare earth (RE) mining [2,3]. This study investigates the feasibility of reducing REPM usage in spoke-type PMSMs by fully substituting them with ferrite permanent magnets (PMs), aiming to enhance material sustainability without significantly compromising key performances.

The main objective is to develop and assess alternative PMSM designs that reduce dependence on RE materials while maintaining or even improving overall performance. The analysis compares a reference PMSM using REPMs with alternative configurations using ferrite permanent magnets, keeping the same stator structure and outer diameter. The study explores the trade-offs in terms of material requirements, power density, efficiency, and cost, highlighting the implications of using lower-magnetic-quality materials.

ANSYS Motor-CAD, a comprehensive design and simulation framework, supports the analysis of various PM structures in spoke-type PMSMs. Finite element analysis (FEA) is used to evaluate electromagnetic performance, while cost assessments help quantify the economic impact of material substitution.

The obtained results demonstrate that acceptable performance levels can also be maintained without REPMs, with the proposed designs offering substantial cost reductions and improved supply chain resilience. However, this comes at a significant trade-off: requiring increased quantities of active materials, resulting in reduced power and torque density, and greater susceptibility to demagnetization under thermal and electrical stresses. By demonstrating the viability of lower-cost and more widely available ferrites in PMSMs, this research contributes to more sustainable and economically viable LEV propulsion systems. The findings provide valuable guidance for electrical machine designers and policymakers striving to balance performance, sustainability, and affordability in support of the green energy transition.

This paper begins by presenting the reference spoke-type PMSM design and the performance analysis methodology. Next, some REPM-free PMSM configurations are proposed and evaluated. For each design variant, comprehensive electromagnetic characteristics are analyzed and compared in detail, with particular focus on performance trade-offs, material efficiency, and cost implications.

2. The Electromagnetic Analysis of the PMSM Considered as Reference

The starting point of this study was a spoke-type PMSM, a configuration widely used in modern industrial applications and developed in our research center.

2.1. The Reference Electrical Machine

This PMSM was selected due to its optimized rotor architecture, featuring high-quality NdFeB N30UH PMs arranged radially in a flux concentration configuration. This structure provides ample space for increasing both the thickness and length of the PMs. This flexibility was essential for achieving the primary objective of this study: replacing REPMs with ferrite magnets. To compensate for the lower performance of ferrites and maintain the functional characteristics of the electrical machine, it is necessary to use significantly larger volumes of this material. On the other hand, this topology facilitates the integration of PMs inside the rotor, providing excellent mechanical protection against centrifugal forces acting on the rotor. Embedding PMs is particularly important in cases where ferrite magnets are used, as they are more susceptible to demagnetization.

Therefore, the choice of a spoke-type PM rotor was not only a good theoretical option but also a decision based on the need to create a versatile, robust, and adaptable structure that allows for the integration of large quantities of ferrites within the rotor.

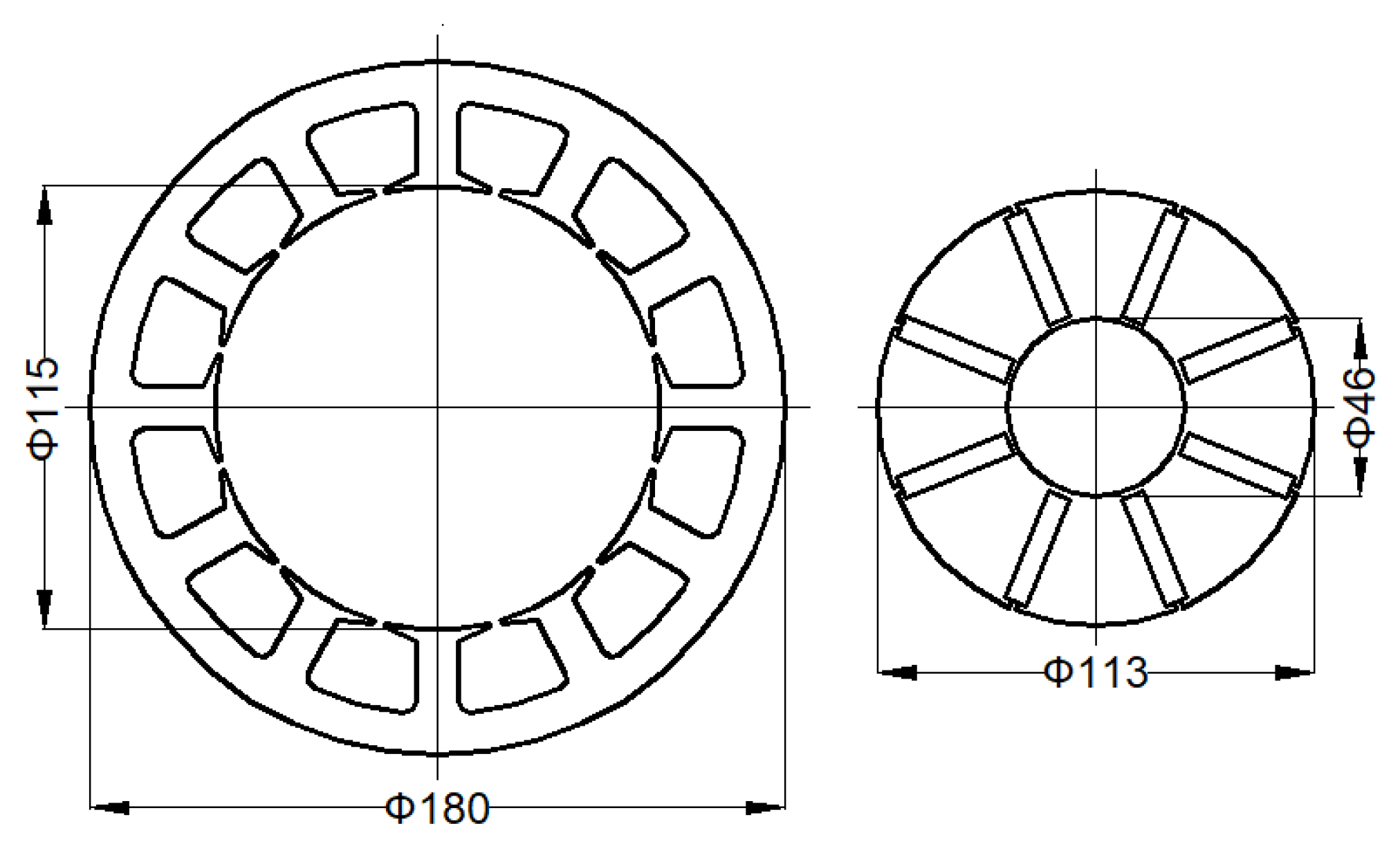

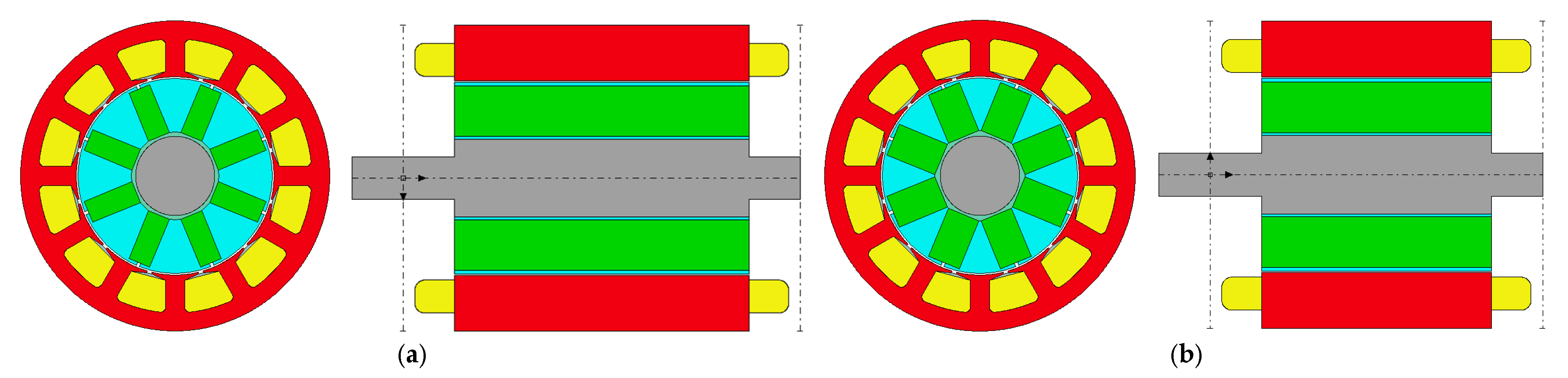

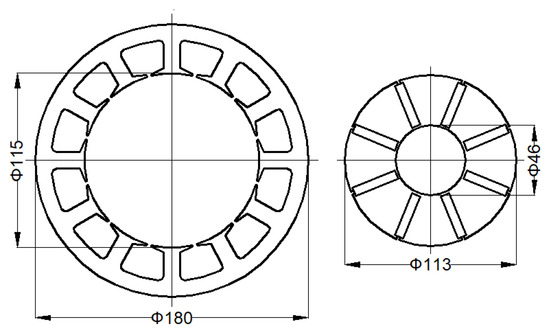

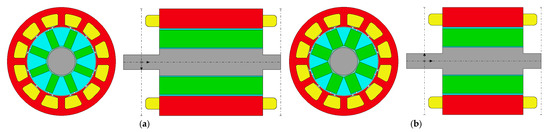

The reference spoke-type PMSM, featuring 12 stator slots and 8 PMs in its rotor, as can be seen in Figure 1, has a rated power and speed of 9 kW and 3000 r/min, respectively.

Figure 1.

The stator and rotor laminations of the reference PMSM.

The reference electrical machine chosen for this study was this specific PMSM, not only for its suitability in diverse applications but also due to the complete availability of technical data required for modeling. This includes its main dimensions, winding data, types of materials used, and other essential parameters needed for its modeling.

2.2. The Electromagnetic Analysis of the Reference Machine

The electromagnetic behavior of all the electrical machine configurations considered in the paper was analyzed by using the ANSYS Motor-CAD v15.1.2.1 software, which applies both analytical computations and FEA to accurately simulate and quantify key performance parameters.

2.2.1. The ANSYS Motor-CAD Program

ANSYS Motor-CAD is a specialized design and analysis software tailored for electrical machines development. The program integrates several key modules, including the electromagnetic (EMag) module used here, as well as thermal, drive cycle, and mechanical analysis, allowing for a comprehensive understanding of the electrical machines under study [4].

One of the key advantages of this program is its speed. Thanks to its optimized 2D FEA models, the program can deliver fast yet reliable results, making it well-suited for early-stage design iterations. It supports parametric sweeps and optimization studies, enabling users to quickly identify the most balanced and efficient design options. With its intuitive graphical user interface and output capabilities tailored to industry needs, ANSYS Motor-CAD facilitates informed decision-making for electric machine development and optimization.

2.2.2. Model Setup

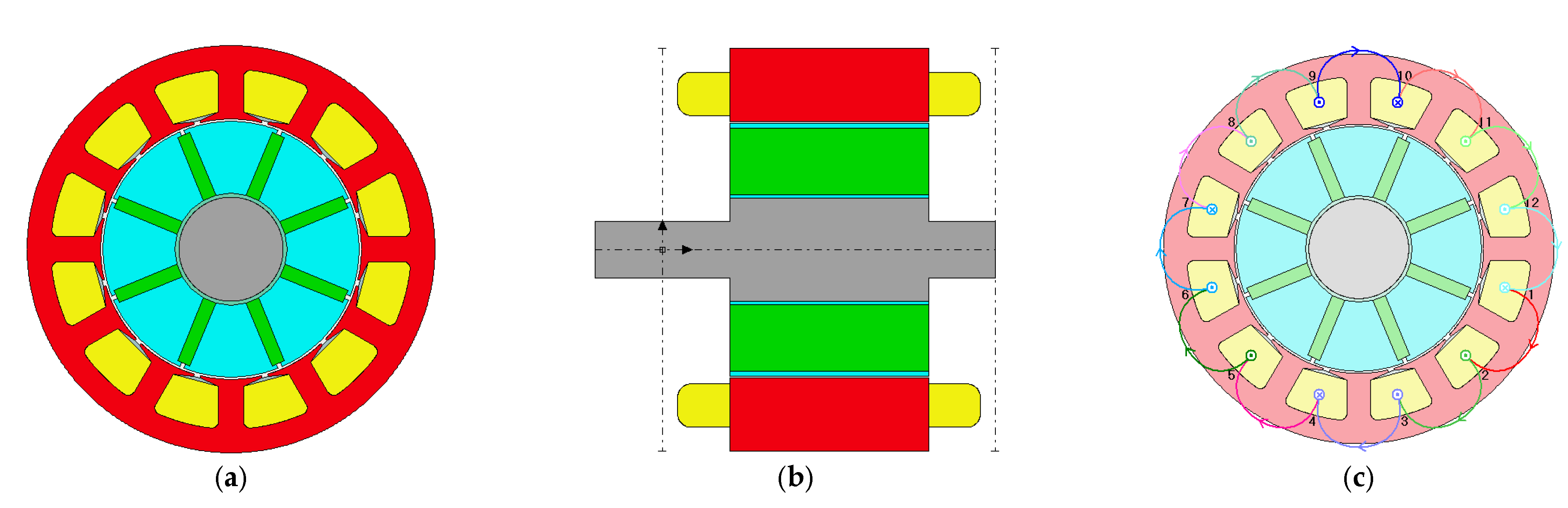

The modeling process begins with selecting an appropriate PMSM template and specifying its parameters, including rotor and stator dimensions, PM layout, material selection, and winding configuration. Next, the supply and operating conditions must be determined. The resulting model is provided in Figure 2.

Figure 2.

The model of the reference PMSM (a) Transversal view; (b) Axial view; (c) Winding pattern.

For all simulations performed, the rated speed of 3000 r/min and current of 120 ARMS were imposed. Torque calculations were carried out using 90 points per cycle, while 30 points per cycle were used for back-EMF and cogging torque evaluations.

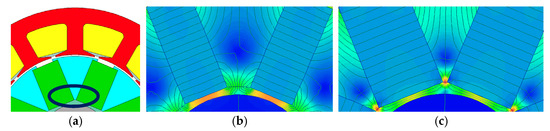

2.2.3. Results Extraction

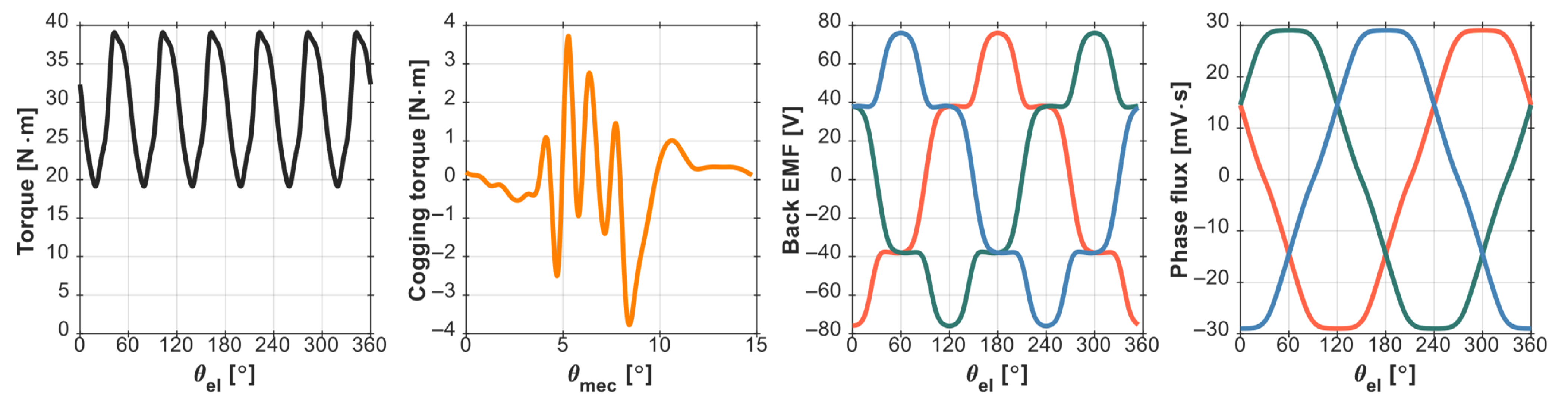

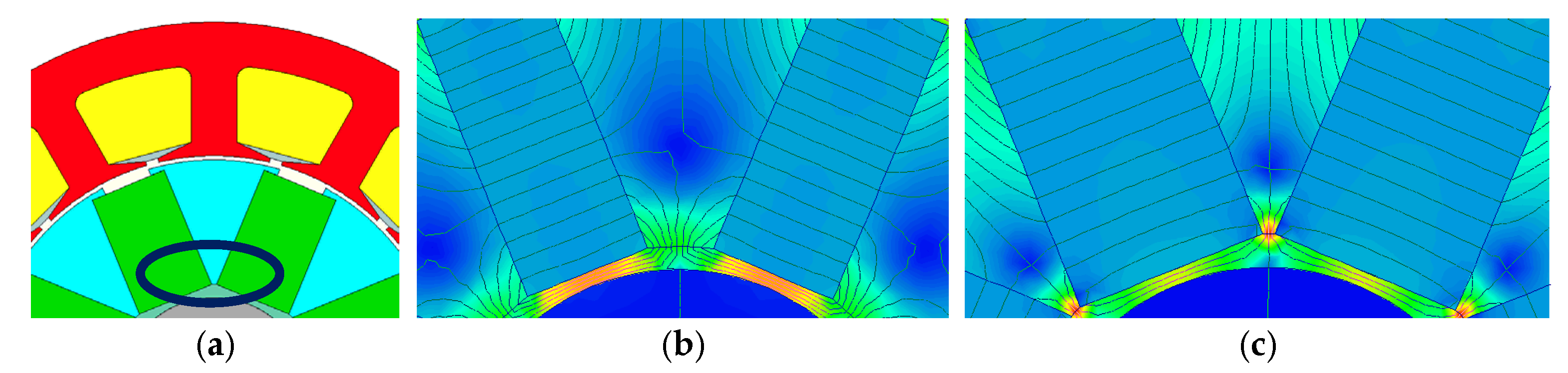

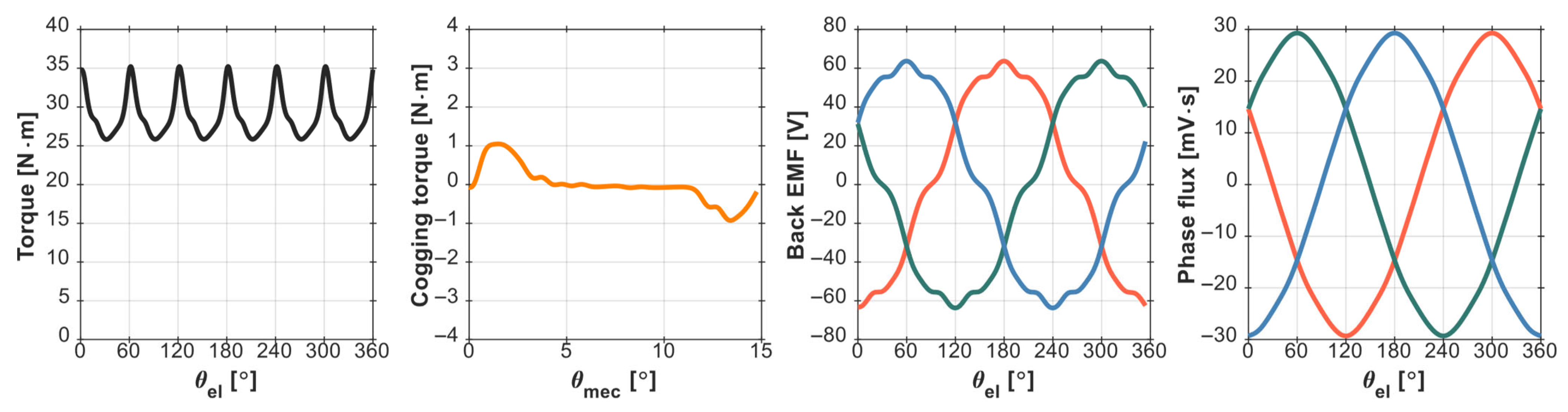

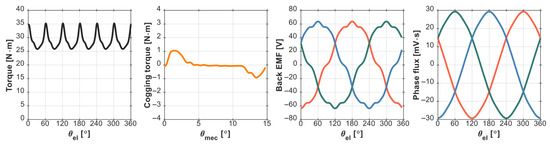

For the comparative study, the variation in four quantities was considered: torque, cogging torque, back-EMF, and phase magnetic flux. Their changes concerning angular displacement (θ) were plotted in MATLAB (R2025a) and are shown in Figure 3.

Figure 3.

Variation in torque, cogging torque, back-EMF, and phase magnetic flux in a PMSM using ferrite magnets with the dimensions as the REPMs in the reference machine.

As can be seen, the analyzed PMSM exhibits significant torque ripple and cogging torque, while the back-EMF contains substantial harmonic content. The main electromagnetic characteristics and the masses of its key components were extracted from the ANSYS Motor-CAD program for further analysis.

3. Replacement of REPMs with Ferrite PMs

As a first step, the evident performance losses due to the use of lower-quality PMs were analyzed by studying the same PMSM structure, replacing the REPMs with ferrites of identical dimensions. Ferrites have a maximum energy product (BHmax) of up to 40 kJ/m3, whereas REPMs can reach values as high as 440 kJ/m3.

3.1. Performance Evaluation of PMSM with Ferrite Substitution for REPMs of Identical Size

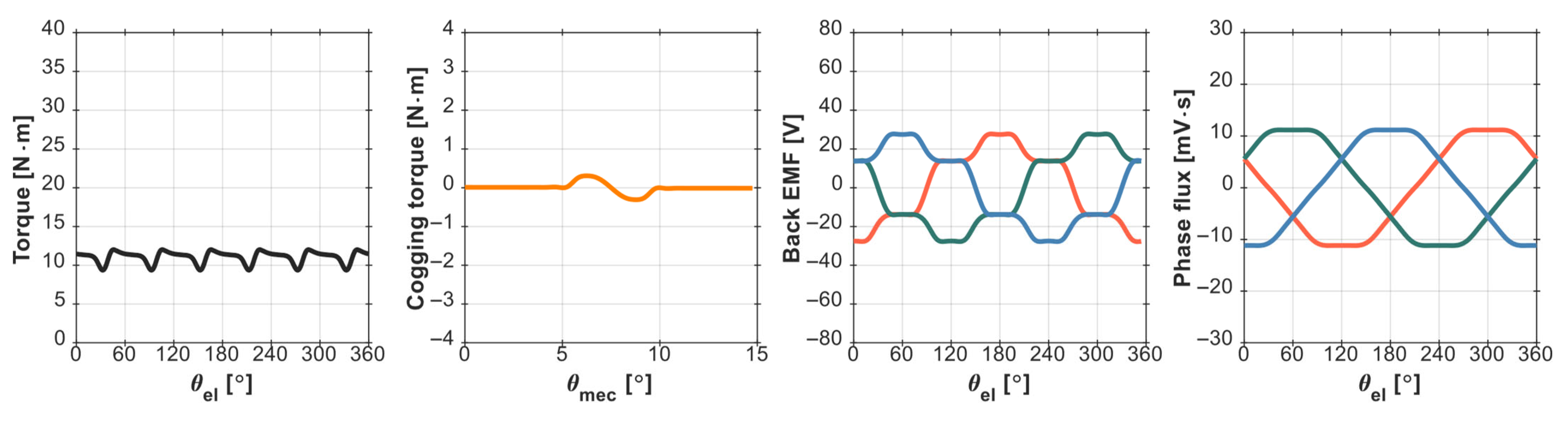

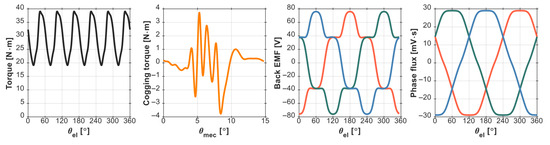

The reference PMSM model in ANSYS Motor-CAD was modified by replacing the PMs with Y34-type ferrite material while maintaining all other model parameters. Figure 4 presents the resulting variations in key physical quantities. For consistent comparison across all studied cases, identical axis scales were maintained in all plots to clearly highlight performance differences between the configurations.

Figure 4.

Variation in the four main performance quantities in the PMSM after replacing NdFeB PMs with ferrites of identical dimensions.

3.2. Determining the Best Ferrite Arrangement to Match Reference PMSM Performance

The results indicate a significant performance gap, with the ferrite-based design achieving just 37% of the torque output of the reference PMSM and also failing to meet other critical performance targets. This shortfall necessitates a considerable increase in ferrite volume within the rotor structure to approach the reference specifications.

Since increasing ferrite height is constrained by the fixed stator and rotor diameters, only two design modifications remain feasible: widening the spoke-type ferrites and extending their length (requiring a proportional increase in the active axial length of the PMSM).

To determine the optimal width and length for the required ferrite volume expansion, a parametric sensitivity analysis was conducted in ANSYS Motor-CAD software. This tool automates multi-variable optimization by systematically changing the ferrite magnet width and length within defined bounds, simulating electromagnetic performance for each combination, and ranking designs based on prescribed performance metrics. Through this approach, systematic optimization of ferrite volume was achieved by rapidly evaluating trade-offs between performance and PM dimensions, significantly reducing trial-and-error iterations and overall study time.

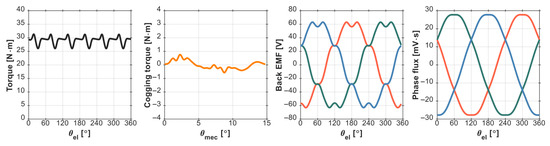

To optimize computational efficiency while maintaining thorough design exploration, 13 focused sensitivity analyses were performed on precisely constrained PM dimension variations. This methodology successfully identified 13 qualified PMSM configurations satisfying the imposed output power requirement. Figure 5 presents the two limit-case designs: the configurations with the narrowest and the widest ferrite magnets.

Figure 5.

The two limit-case permanent magnet width geometries: (a) the narrowest and (b) widest ferrites.

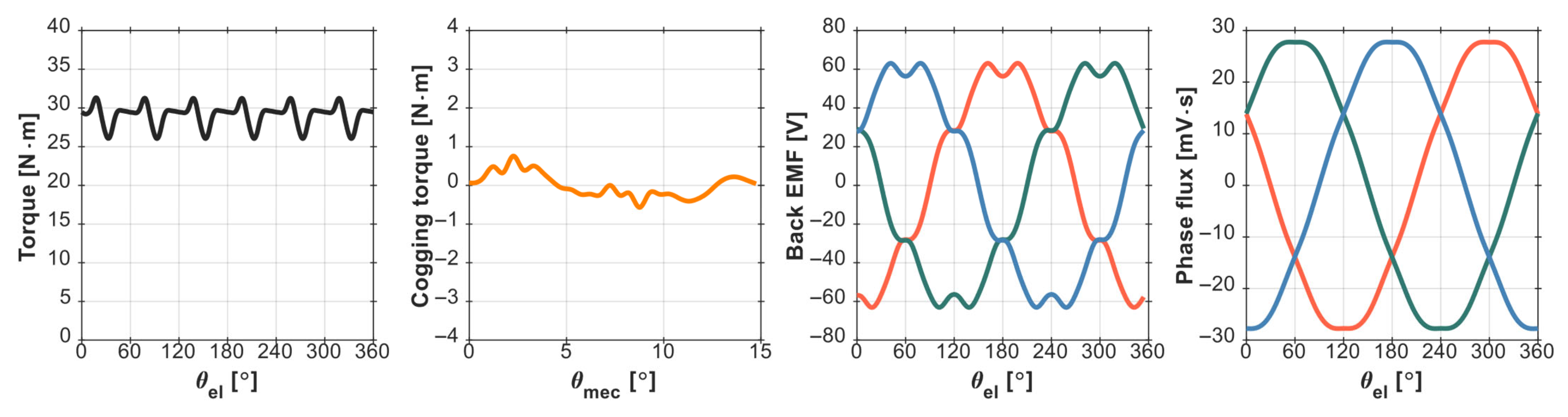

During the analysis of the spoke-type PMSM, it was observed that the inner end of the rotor lamination (the shaft contact area shown in Figure 6a) significantly affects performance. This part of the lamination has dual functions: as a mandatory mechanical support of the iron core and as an unintended magnetic short-circuit path. The latter effect increases flux leakage, reducing useful flux (as can be seen in Figure 6b,c), and consequently decreasing both torque output and efficiency. Furthermore, insufficient thickness risks mechanical failure or magnetic saturation. These constraints ultimately limited the maximum permissible ferrite magnet width in the study [5].

Figure 6.

Rotor lamination details and flux distribution: (a) Close-up of the critical inner end region, (b) Flux distribution at minimum-width ferrite magnets, and (c) at maximum-width ones.

The comparison of the 13 design variants revealed that while increasing ferrite width and its mass, the required mass of other active components (iron cores and windings) decreased, leading to an overall reduction in total PMSM mass and active material costs. Consequently, the configuration with the greatest possible PM width (19 mm) emerged as optimal based on the performed comprehensive sensitivity analyses. Figure 7 presents the performance characteristics of this selected variant, showing variations in the four key parameters: torque, cogging torque, back-EMF, and magnetic flux.

Figure 7.

Performance characteristics of the ferrite-optimized PMSM with maximum permissible PM width (19 mm).

Notably, both torque ripple and cogging torque are further reduced compared even to the RE PMSM used as a reference (see Figure 3).

A detailed comparison of these PMSM variants will be provided in Section 3.4.

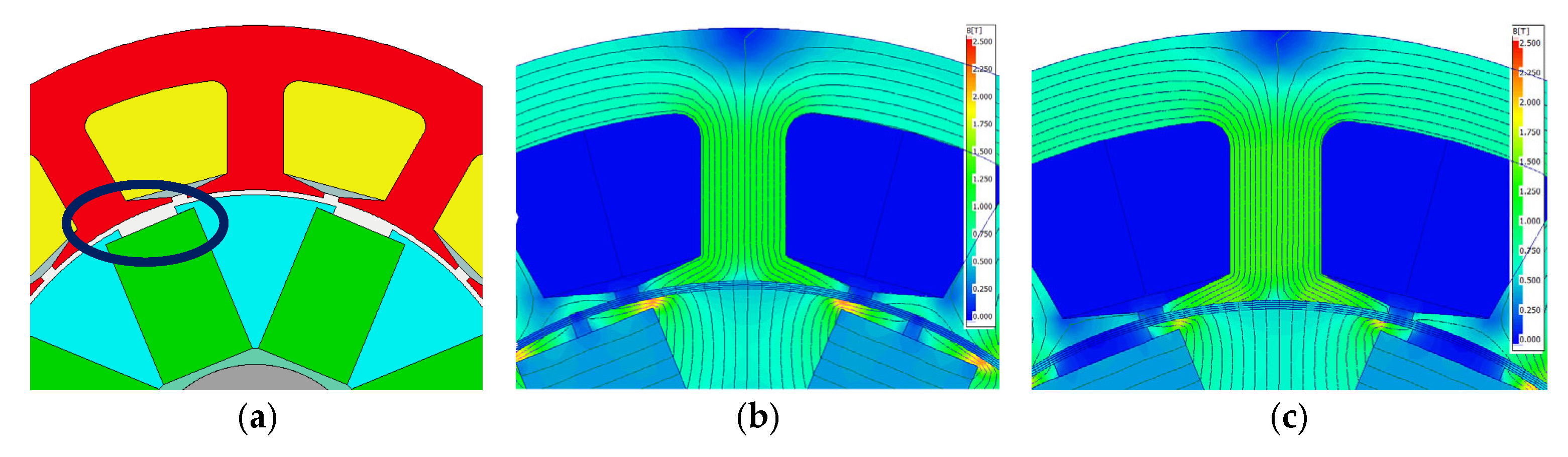

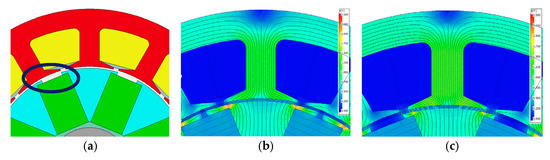

3.3. Impact of PM Opening Distance Modifications

Analysis of the spoke-type PMSM revealed that the PM opening size (illustrated in Figure 8a) critically impacts both electromagnetic performance and mechanical integrity, analogous to the inner end region of the rotor lamination previously discussed. This opening dimension directly influences air-gap magnetic flux concentration (see the magnetic flux distributions provided in Figure 8b,c). Simulation results showed that increasing to the maximum possible (12 mm) the PM opening distance improves both developed power and average torque output by approximately 10%, but at the cost of significantly higher torque ripple.

Figure 8.

PM details and flux distribution: (a) Close-up of the critical area, (b) Flux distribution at the lowest (2 mm), and (c) at the greatest possible opening distance (12 mm).

Consequently, when both the ferrite magnet width and PM opening are maximized (19 mm and 12 mm, respectively) to achieve the required 9 kW output power, shorter ferrite magnets become sufficient. This configuration enables a reduced active axial length for the PMSM while maintaining performance targets.

To determine the optimal PM length, another sensitivity analysis was employed. This revealed that using the previously specified dimensions (19 mm width and 12 mm opening), a 124 mm PM length suffices to meet all performance requirements.

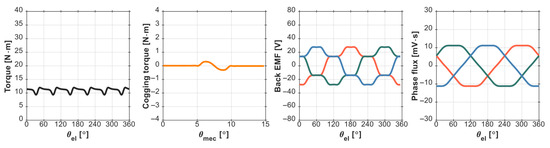

The analysis of the characteristics of this PMSM variant (Figure 9) reveals, as in the previous cases, variations in four key parameters: torque, cogging torque, back-EMF, and magnetic flux. These results demonstrate that the reduction in PM mass comes with a critical performance compromise: a significant increase in torque. This trade-off must be carefully evaluated against application-specific requirements for smooth operation.

Figure 9.

Variation in the main quantities in the PMSM having the greatest possible PM opening.

3.4. Comparative Analysis of Optimized Spoke-Type PMSM Configurations

For the final comparative study, the following PMSMs detailed previously were considered in Table 1: (1) the reference PMSM with REPMs, (2) PMSM with direct ferrite replacement, (3) PMSM with optimized ferrite width/length, and (4) PMSM with expanded PM opening. The prices of raw materials used in this calculation were as follows: cold-rolled steel for the shaft at 0.7 €/kg, electrical steel for ferromagnetic cores at 5 €/kg, winding conductor at 10 €/kg, NdFeB PM at 100 €/kg, and ferrite at 5 €/kg [2,6,7].

Table 1.

The main characteristics of the four PMSM variants studied.

Variant #2 data appears in gray in the comparison table, as it evidently did not meet the specified performance requirements. This variant was retained in the analysis exclusively to highlight the comparative performance between NdFeB and ferrite-based PMSMs while maintaining identical dimensions. For enhanced data visualization, the best performance values are indicated in green, while the worst ones are marked in red.

As can be seen from the table, ferrite-based designs achieve 30–36% lower material costs than the reference PMSM, despite needing 2–3 times more PM mass due to lower energy density. This trade-off increases total mass by 25–36% from larger PMs and adjusted iron core and windings active length. Performance shows key compromises: 14–20% lower power factor but 54–75% reduced torque ripple and 51–65% lower back-EMF THD, with efficiency nearly unchanged. Variant #4 balances the lowest cost with better power factor and specific power, while Variant #3 excels in torque ripple reduction (17% vs. 68%) but sacrifices more power factor.

The choice between these designs depends on application priorities. For most general purposes where the overall cost–benefit balance is key, Variant #4 offers the most favorable compromise. In specialized applications where low torque ripple is paramount, the Variant #3 configuration may justify its performance trade-offs. Both ferrite options successfully demonstrate the feasibility of REPM replacement while highlighting the inherent compromises between cost, mass, and electromagnetic performance characteristics.

4. Conclusions

This comparative study demonstrated that in conventional spoke-type PMSMs, REPMs can be successfully replaced with ferrites while maintaining key performance characteristics, including output power and efficiency. The replacement yields even improvements, such as reducing the power factor, torque ripple, THD of back-EMF, and material costs. However, this modification comes with a trade-off: a 30% increase in mass and a corresponding reduction in specific power.

The use of ferrites is particularly viable in spoke-type PMSMs due to their rotor design, which assures sufficient space to place the larger volume of ferrite material required.

For applications where mass and specific power are not critical constraints, the adoption of ferrite magnets in spoke-type PMSMs is strongly recommended as a solution to mitigate supply chain vulnerabilities associated with RE materials.

Author Contributions

Conceptualization, K.G. and L.S.; methodology, L.S.; software, K.G.; investigation, K.G. and L.S.; writing—original draft preparation, K.G. and L.S.; writing—review and editing, L.S.; visualization, K.G. and L.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article material. Further inquiries can be directed to the corresponding author.

Acknowledgments

This paper benefited from the linguistic and stylistic enhancements provided by Microsoft Copilot, ensuring clarity, grammatical accuracy, and consistency.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Vandycke, N.; Viegas, J.M. Sustainable Mobility in a Fast-Changing World: From Concept to Action; Palgrave Macmillan: London UK, 2022. [Google Scholar]

- Popa, D.-C.; Szabó, L. Securing Rare Earth Permanent Magnet Needs for Sustainable Energy Initiatives. Materials 2024, 17, 5442. [Google Scholar] [CrossRef] [PubMed]

- Popa, D.-C.; Szabó, L. Overcoming Catch-22 for rare earth metals in green transition: Solutions in electrical machine manufacturing. Renew. Sustain. Energy Rev. 2025, 207, 1149172024. [Google Scholar] [CrossRef]

- Coteț, F.-A.; Văscan, I.; Szabó, L. On the usefulness of employing ANSYS Motor-CAD software in designing permanent magnet synchronous machines. Designs 2023, 7, 7. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, K.; Xu, J. Design optimization of rotor bridge and fixing hole for spoke-type PMSM. IEEE Trans. Magn. 2023, 59, 8102105. [Google Scholar] [CrossRef]

- Jang, G.-H.; Rehman, A.; Choi, G. Comparative Analysis and Design Optimization of Ferrite-Based Surface PM Vernier Machines. Energies 2024, 17, 1687. [Google Scholar] [CrossRef]

- Hemsen, J.; Nowak, N.; Eckstein, L. Production cost modeling for permanent magnet synchronous machines for electric vehicles. Automot. Engine Technol. 2023, 8, 109–126. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).