Abstract

The optimization and evaluation of 3D-printed polylactic acid (PLA) and ABS materials present a promising approach for enhancing the reinforcement of concrete elements, thereby advancing sustainable construction technologies. This study examines the degradation of the structural integrity of 3D-printed PLA- and ABS-reinforced concrete after 28 days of underwater curing. The research focuses on macroscopic analysis and microscopic characterization using a digital microscope and a high-resolution camera to investigate the crystalline structures formed during curing. The findings will offer valuable insights into the structural transformations occurring within concrete elements and potential interactions between concrete and PLA structures, paving the way for future civil engineering applications.

Keywords:

concrete; reinforcement; PLA materials; ABS; PLA reinforced concrete; digital microscope; camera 1. Introduction

Three-dimensional printing is gaining ground in various engineering industries, particularly automotive, rail and building construction. One of the most significant advantages of FDM technology is that it can be used with a wide range of materials. Besides the versatility of materials, it also provides an environmentally friendly, sustainable solution through recyclable alternatives.

The issue of strengthening the structural integrity of concrete by various methods and studying the mechanical properties of such structures has long been an important research topic [1,2,3]. In addition to the traditional reinforcements (steel) used in the railway industry, other alternatives are being explored, such as crushed stone aggregates [4] or the use of sustainable materials [5]. One of the sustainable solutions, a recycling method, involves reusing 3D printing waste to reinforce concrete structures in an amorphous form [5] or creating 3D printing reinforcement structures with a defined geometry to locally strengthen the structure [6]. Another important aspect of railway construction is the study of developing the environment itself and its methods [7,8], as well as the numerical and parametric verification or modeling of possible scenarios [9].

The degradation of a concrete structure’s structural integrity is a crucial factor, as weakening can lead to the structure’s failure. In the majority of studies [10,11,12], the possible causes of degradation are phenomena called alkali-silicate reaction (ASR) and delayed ettringite formation (DEF). Delayed ettringite formation (DEF) and alkali-silicate reaction (ASR) are different but sometimes co-occurring concrete failures. The two are based on different mechanisms but share common characteristics such as swelling, cracking, and moisture-dependent activation.

ASR is a chemical process between alkali cations and hydroxyl ions in the pore solution of hydrated cement paste and specific reactive silica phases found in some concrete aggregates [12]. The reaction is characterized by gel development and swelling, degrading the structure’s structural integrity. For the formation of reactive silica (SiO2) in the additive (e.g., amorphous quartz, opal, volcanic glass), a high-pH pore solution (usually above 12.5) with NaOH or KOH present and moisture (water), which promotes gel swelling, is required [13].

On the other hand, DEF is an intrinsic reaction of sulfuric acid that occurs due to a delayed reaction between the aluminates and sulfates in cement when the concrete is exposed to high temperatures (usually above 65–70 °C) during the early stages of setting. In the process, ettringite (Ca6Al2(SO4)3(OH)12-26H2O) is formed in the early stages of hydration, which requires high temperatures and moisture. As the concrete cools and gains moisture, the remaining ettringite is subsequently formed in pores and cracks in a delayed manner. The crystals’ formation results in the structure’s cracking and swelling and a decrease in the structure’s integrity, which is a common point with ASR.

The link between the two failure modes is that they are both water-dependent, create internal pressure within the structure, and exhibit similar crack patterns, although they differ in their microstructure. A further danger is that if they occur simultaneously, they can mutually amplify each other’s intensity [14].

Although numerous studies have addressed the formation, progression, and consequences of DEF and ASR, there is currently no documented case in the scientific literature that describes these phenomena occurring under the specific conditions examined in this study. Notably, the observed deterioration occurred without any prior heat treatment, at ambient room temperature, and within a relatively short time span of only 56 days. This research seeks to explore the environmental and material-related factors that contribute to the onset of these concrete degradation mechanisms. In performing so, it also evaluates the potentially detrimental interactions between cementitious materials and various types of reinforcement used in additive manufacturing processes, particularly in 3D printing applications.

Building upon findings from a previous investigation [15], this paper places particular emphasis on the chemical interactions and equilibrium shifts between the concrete matrix and five types of polymer-based reinforcing materials—specifically, four different polylactic acid (PLA) variants and one acrylonitrile butadiene styrene (ABS) material. As noted in earlier work [15], crystalline precipitates were found on the surfaces of submerged specimens. These formations serve as the focus point of the current study, which presents a detailed macroscopic and microscopic analysis to better understand their origin, structure, and implications for the integrity of 3D-printed reinforced concrete composites.

2. Materials and Methods

The specimens were prepared step by step, in each case following the steps of 3D printing the reinforcement in the mold, placing the reinforcement in the mold, and casting and curing under water after external solidification in the mold.

2.1. Preparations of the 3D-Printed Reinforcement Elements

During the 3D printing, a Creality Ender 3—V2 (Creality 3D Technology Co., Ltd., China, Shenzhen) 3D printer was used for the reinforcements, and a Bambu Lab A1 3D printer was used for the casting molds. As several (5) materials, all from Filaticum (manufacturer) (Szigetszentmiklós, Hungary), were used, different parameters were applied to the materials, except for the following parameters, which were the same in all cases: cooling fan set to 100%, layer height 0.2 mm, nozzle size 0.4 mm, print speed 50 mm/s and skirt applied.

The settings for the individual configuration parameters, based on the proposed parameters, are summarized in Table 1.

Table 1.

Overview of printing parameters used for specimens and molds.

The choice of materials is not random, as they are all utilized in various engineering fields due to their outstanding properties [15]. HI offers superior impact resistance and flexibility, while ENG withstands high temperatures and provides exceptional mechanical strength. ESD prevents electrostatic buildup due to conductive additives. GYP is ideal for modeling thanks to its easy post-processing, and ABS, although harder to print, excels in structural applications and offers valuable interaction with concrete environments. Due to its easy handling, only generic PLA was used solely for single-use casting molds.

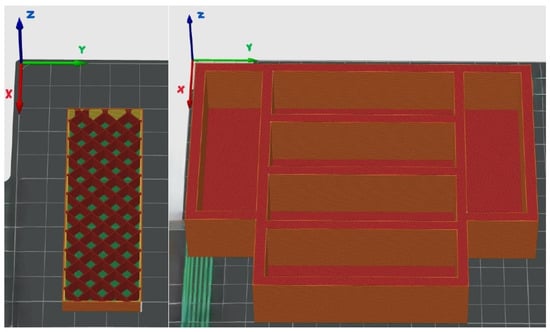

The inside of the casting was the same size as the test specimens, 25.0 × 25.0 × 80.0 mm (in accordance with the standard MSZ EN 12390-1:2021 [16]). Three base layers were applied, and the wall thickness was set to 0.5 mm during printing. The layout of the reinforcing specimen within the concrete beams was 80 × 25.0 × 5 mm. Each piece was 3D printed with a grid infill pattern at 10% density, and both the top and bottom layers were set to zero, thereby fully exposing the internal grid structure. Figure 1 illustrates the reinforcement, designed using SolidWorks 2016 x64 Edition (SolidWorks Corporation, Waltham, MA, USA) in the Bambu Lab (Bambu Lab, Shenzhen, China) and created with slicing software.

Figure 1.

Printing layout of the reinforcing element (left) and casting mold (right).

In summary, generic PLA was used solely for the mold, while the other materials were utilized to print the reinforcements for three test specimens per material.

2.2. Casting of the Reinforced Specimens

For practical reasons, before casting, the reinforcing elements were placed into the casting molds in the lower one-third of the cavity. The reinforcement had to be positioned away from the neutral axis, as this was the only way it could demonstrate a reinforcing effect if one existed. The placement of the reinforcements was followed by casting, where a specific concrete mixture was used, as shown in Table 2 for the concrete composition per 106 mm3 of the mixture.

Table 2.

Material composition for a 106 mm3 of concrete mixture.

Following a 24 h setting period in the mold, in accordance with standard MSZ EN 12390-2:2019 [17], the concrete elements were submerged in tap water with a pH value of 7.0 for an additional 27 days to ensure completion of the internal curing process.

2.3. Measurement Set-Up and Underwater Treatment of the Specimens

After the casting, the bending tests took place, which were carried out with Zwick 1454 (Zwick Roell Group, US, Singapore) at 7.6 mm/min loading speed with load cell HBM U3 20 kN (HBM Ltd., Hungary, Budapest) and data collector HBM quantum MX840A (HBM Ltd., Hungary, Budapest); also DIC (digital image correlation) GOM ARAMIS (GOM, Germany, Braunschweig) camera technology has been used to measure the displacement of the specimens. Then, the broken specimens were placed underwater in the same container for four weeks, plus one week. All in all, the specimens were submerged underwater for 8 weeks without changing the water. Thus, the change in the pH of the aqueous medium could not have been influenced by any external factor since the test specimens were covered in the same medium.

During the underwater curing process, the pH value and temperature of the specimens were measured weekly by a WTW 720 pH meter (Weilheim, Bayern, Germany). The measurement of the specimens took four weeks, which was the total curing time of the concrete. After the start of the observation, at week 8, an additional week was added to the measurement, as any outliers could be detected by that time. The results of the measurements are presented in Table 3; the first part is identical to that in previous research [15].

Table 3.

Measured pH and temperature values of the aqueous medium over eight weeks [15].

3. Results and Discussion

By week #3, a white ettringite-like precipitate had formed at the reinforcement/concrete interface in all cases except ABS, where only the color of the reinforcement turned from black to gray at the fracture site. The growth and spread of the crystal increased every week. Another observation was that the gel-like material was floating in the water medium, and a gel formed on the surface of the HI specimens.

The occurrence of this gel raises the suspicion that an alkali-silicate reaction (ASR), which occurs when concrete is cured in an aqueous medium, has taken place. The gel itself is a harmful occurrence in the medium because, upon forming, it absorbs water, swells, and causes internal stress and cracks in the concrete. This type of chemical reaction requires two conditions to be met in order to occur fully. One is an aqueous medium with a relatively high pH value (around 13), which criterion has not been fulfilled in this case (the pH was at most 8.19); only the wet environment met the requirement. Despite these observations, the ASR gel formed earlier, and after the carbonation of the pore solution (CO2 diffusion (pH drop), it could not continue.

According to Taylor et al. [10], ASR is usually accompanied by DEF, where ettringite is formed—a crystal-like material that forms both inside and outside the concrete medium. During the observation, although the test specimens were stored in an aqueous medium, the temperature was nowhere near the temperature required for ettringite development (around 70 °C), as the specimens were not heat treated but kept at around room temperature (around 20–22 °C). Although not all the requirements for DEF were met, ettringite-like crystals were formed at the contact between the reinforcement and the concrete. The following paragraphs summarize the macroscopic and microscopic analysis of the submerged specimens.

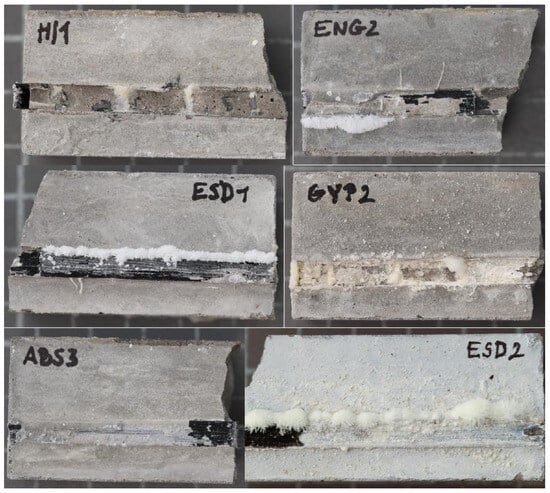

High-quality and high-resolution photos were taken of the specimens using a Canon EOS-R8 camera, a Canon RF 100 mm f/2.8 L lens, and a Keyence VHX-1000 digital microscope equipped with a 5–50× lens. Each piece dried for 24 h before the pictures were taken, as illustrated in Figure 2.

Figure 2.

Macroscopic images of the specimens after the curing period.

The surface alterations caused by the crystal formations have different characteristics. Like crystals found on specimen ESD1, ESD2 and ENG2 are fibroradiated and have a needle-like structure, while the alterations on GYP2 and HI1 are more coherent and crystalline and focused on the placement of the reinforcing element.

None of these changes have been observed in the ABS specimen. Only the color of the material changed from black to gray, as well as it did in the previous research [15], during the dissolution tests in the case of HI specimens.

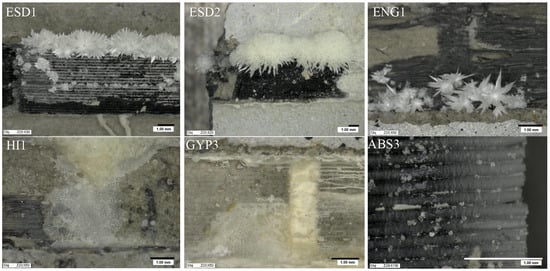

Figure 3 illustrates the microscopic images of the unique alterations of the specimens.

Figure 3.

Microscopic images of the surface alteration observed on the specimens.

The microscopic images were taken with Z20:×20 (ESD2), Z20:×30 (ESD1), Z20:×50 (ENG1, HI1, GYP3) and Z20:×150 (ABS3) objectives. The Z20 refers to the magnification range of the lens (or lenses), i.e., 20×, while ×20, ×30, ×50, and ×150 refer to the optical magnification (from 20× to 150×). The upper three pictures in Figure 3 represent the fibro-radiated crystals formed on the surface, where each differs in its formation location, shape, and color. The lower three images show the more coherent crystals formed in a block shape. The last image represents the extent of decolorization of the ABS3 specimen.

Another observation made before the microscopic inspection of the surface is that, in the case of all specimens except ABS, the texture of the 3D-printed reinforcing element changed from firm and defined to friable, smearable, and deformed in nature.

Microscopic imaging provides valuable insight into the surface alterations of the test specimens, enabling the identification and interpretation of the chemical reactions. Through careful examination of the morphological features and the nature of the surface changes, it becomes possible to infer the underlying chemical processes responsible for the observed transformations. These visual and structural indicators serve as critical evidence in diagnosing concrete degradation mechanisms.

Drawing upon a detailed review and analysis of the relevant literature [18,19,20], it can be concluded that three predominant chemical phenomena are commonly associated with the deterioration of concrete structures. The first is the formation of ASR gel, a hygroscopic substance that causes expansion and cracking within the concrete matrix. The second is the presence of the calcium silicate hydrate (C-S-H) phase, which, although the primary binding component in concrete, can undergo structural changes or leaching that compromise its mechanical integrity. The third is the formation of contaminated calcium-based gels (Ca gel), which often results from the interaction of calcium compounds with various deleterious ions or pollutants, leading to changes in the microstructure and reduced durability. Together, these phenomena significantly contribute to the progressive failure of concrete and are key indicators of chemical instability within the material.

Table 4 presents the characteristics of ASR gel, C-S-H, and Ca gels, including their microscopic appearance (optical), typical alkalis that facilitate their formation, and typical locations. In addition, Table 4 also summarizes, based on the characteristics presented, the failure category to which the specimens shown in Figure 3 belong.

Table 4.

Classification of materials for reinforcing elements based on the characteristics of ASR gels, C-S-H and Ca gels.

4. Conclusions

Based on the microscopic images and the locations of the abnormalities, it was possible to classify the specimens, which had different reinforcement materials, according to the chemical reaction they had undergone, based on the surface alterations. These points summarize the research:

- Based on microscopic images and the location of the alterations, the samples can be classified according to the different reinforcing agents and the chemical reactions they induce. However, further SEM, EDX, and FTIR studies are needed to determine the exact location.

- The origin of the gel can be identified by FTIR and EDX by analyzing the Ca/Si ratio and alkali presence: Ca/Si < 1.0 and alkali presence for ASR gel, 1.2–2.0 for the C-S-H phase, and >2.0 for carbonate calcium gel or secondary reaction product.

- It can be assumed that reinforcing agents, such as GYP, have affected the chemical balance of the concrete and contributed to the occurrence of surface alterations; therefore, further FTIR studies are needed to investigate the exact mechanism of deterioration.

- To identify the causes of these phenomena, the experiments will be repeated using separately stored samples to determine which substances have dissolved and how they affect the structural integrity.

- The aim of this research is to expand sustainable construction methods by excluding weakening materials, thereby making 3D-printed reinforced structures more attractive and promoting the recycling of industrial waste in the construction industry.

Author Contributions

Conceptualization, H.C., S.S. and S.F.; methodology, H.C., S.S., A.N., A.L.N., G.B. and S.F.; software, H.C., S.S. and S.F.; validation, H.C., S.S. and S.F.; formal analysis, H.C., S.S. and S.F.; investigation, H.C., S.S., A.N., A.L.N., G.B. and S.F.; resources, H.C., S.S. and S.F.; data curation, H.C., S.S. and S.F.; writing—original draft preparation, H.C., S.S., A.N., A.L.N., G.B. and S.F.; writing—review and editing, H.C., S.S., A.N., A.L.N., G.B. and S.F.; visualization, H.C., S.S. and S.F.; supervision, H.C., S.S. and S.F.; project administration, H.C., S.S. and S.F.; funding acquisition, H.C., S.S. and S.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are available within the paper.

Acknowledgments

This paper was prepared by the research team “SZE-RAIL”. This research was supported by the SIU Foundation’s project ‘Sustainable Railways—Investigation of the energy efficiency of electric rail vehicles and their infrastructure’.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Fischer, S. Investigation of the Settlement Behavior of Ballasted Railway Tracks Due to Dynamic Loading. Spectr. Mech. Eng. Oper. Res. 2025, 2, 24–46. [Google Scholar] [CrossRef]

- Kuchak, A.J.T.; Marinkovic, D.; Zehn, M. Parametric Investigation of a Rail Damper Design Based on a Lab-Scaled Model. J. Vib. Eng. Technol. 2021, 9, 51–60. [Google Scholar] [CrossRef]

- Kuchak, A.T.J.; Marinkovic, D.; Zehn, M. Finite Element Model Updating—Case Study of a Rail Damper. Struct. Eng. Mech. 2020, 73, 27–35. [Google Scholar] [CrossRef]

- Ézsiás, L.; Tompa, R.; Fischer, S. Investigation of the Possible Correlations between Specific Characteristics of Crushed Stone Aggregates. Spectr. Mech. Eng. Oper. Res. 2024, 1, 10–26. [Google Scholar] [CrossRef]

- Csótár, H.; Baranyai, G.; Szalai, S.; Fischer, S. Sustainable Uses of 3D Printing Applied to Concrete Structures. Eng. Proc. 2024, 79, 55. [Google Scholar] [CrossRef]

- Csótár, H.; Szívós, B.F.; Szalai, S.; Fischer, S. Production and Testing of 3D Printed PLA Structures with DIC Technology for the Reinforcement of Concrete Elements. In Proceedings of the 3rd Cognitive Mobility Conference, COGMOB 2024, Budapest, Hungary, 7–8 October 2024; Zöldy, M., Ed.; Lecture Notes in Networks and Systems. Springer: Cham, Switzerland, 2025; Volume 1258, p. 17. [Google Scholar] [CrossRef]

- Fischer, S.; Harangozó, D.; Németh, D.; Kocsis, B.; Sysyn, M.; Kurhan, D.; Brautigam, A. Investigation of Heat-Affected Zones of Thermite Rail Weldings. Facta Univ. Ser. Mech. Eng. 2024, 22, 689–710. [Google Scholar] [CrossRef]

- Fischer, S.; Kocsis Szürke, S. Detection Process of Energy Loss in Electric Railway Vehicles. Facta Univ. Ser. Mech. Eng. 2023, 21, 81–99. [Google Scholar] [CrossRef]

- Németh, A.; Ibrahim, S.K.; Movahedi Rad, M.; Szalai, S.; Major, Z.; Kocsis Szürke, S.; Jóvér, V.; Sysyn, M.; Kurhan, D.; Harrach, D.; et al. Laboratory and Numerical Investigation of Pre-Tensioned Reinforced Concrete Railway Sleepers Combined with Plastic Fiber Reinforcement. Polymers 2024, 16, 1498. [Google Scholar] [CrossRef]

- Taylor, H.F.; Famy, C.; Scrivener, K. Delayed Ettringite Formation. Cem. Concr. Res. 2001, 31, 683–693. [Google Scholar] [CrossRef]

- Feng, X.; Li, J.; Chen, Q.; Xu, J.; Chen, G.; Sun, Y.; Jiang, Z.; Zhu, H. Effect of Flowing Water on the Ettringite-Induced Healing of Concrete Cracks by Electrodeposition: Experiments and Molecular Dynamics Simulations. Constr. Build. Mater. 2024, 443, 137718. [Google Scholar] [CrossRef]

- Maalouf, J.; Cagnon, H.; Verdier, J.; Multon, S.; Jabbour, J.; Bouhjiti, D. Impact of Alkali-Silica Reaction and Delayed Ettringite Formation-Induced Cracking on Air Permeability and Water Diffusivity in Concrete. Case Stud. Constr. Mater. 2025, 22, e04183. [Google Scholar] [CrossRef]

- Rajabipour, F.; Giannini, E.; Dunant, C.; Ideker, J.H.; Thomas, M.D.A. Alkali-Silica Reaction: Current Understanding of the Reaction Mechanisms and the Knowledge Gaps. Cem. Concr. Res. 2015, 76, 130–146. [Google Scholar] [CrossRef]

- Sanjeewa, H.V.A.N.; Asamoto, S.; Nagai, K.; Luo, J. Investigation of the Compressive Behaviour of Restrained Concrete with DEF and ASR-DEF Deteriorations. Constr. Build. Mater. 2025, 481, 141586. [Google Scholar] [CrossRef]

- Csótár, H.; Szalai, S.; Kurhan, D.; Sysyn, M.; Fischer, S. Evaluating 3D-Printed Polylactic Acid (PLA)-Reinforced Materials: Mechanical Performance and Chemical Stability in Concrete Mediums. Appl. Sci. 2025, 15, 2165. [Google Scholar] [CrossRef]

- MSZ EN 12390-1:2021; Testing Hardened Concrete. Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds. European Committee for Standardization: Brussels, Belgium, 2021; pp. 1–13.

- MSZ EN 12390-2:2019; Testing Hardened Concrete. Part 2: Making and Curing Specimens for Strength Tests. European Committee for Standardization: Brussels, Belgium, 2019; pp. 1–9.

- Zhang, Z.; Scherer, G.W.; Bauer, A. Morphology of Cementitious Material during Early Hydration. Cem. Concr. Res. 2018, 107, 85–100. [Google Scholar] [CrossRef]

- Xie, Y.; Zhou, H.; Wang, J.; Meng, H.; Wei, S.; Sun, J.; Hu, Y. Enhancing Autoclaved Aerated Concrete Performance via Replacement of Fly Ash with Granite Stone Powder and Steel Slag: Critical Role of Ca/Si Ratio. Constr. Build. Mater. 2025, 477, 141360. [Google Scholar] [CrossRef]

- Mishra, S.; Rajabipour, F.; Olek, J.; Peethamparan, S. Sustainable Alkali-Activated Concrete with Unconventional Precursors for ASR Mitigation: Mechanisms and Alternative Predictors Using the Miniature Concrete Prism Test. Clean. Mater. 2025, 16, 100307. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).