Abstract

Sustainable building heat recovery ventilation is a key factor in modern structural design and production, which can be achieved by the combination of cutting-edge, energy-economical technologies, such as counter flow flat-plats, heat pipes and simple design arrangements like a light well. To achieve low energy use and good indoor air quality, natural ventilation should be applied as often as possible. In this article, an energy simulation study is presented, which is focused on an in-built natural ventilation system of an existing vacant office building. It has been demonstrated that a substantial amount of energy can be saved by utilizing natural ventilation in a building, while it was also proven that obsolete buildings can be energy-efficiently operated, without the need for demolition, if they are cautiously re-designed.

1. Introduction

As global priorities shift towards sustainability, the construction industry is increasingly adopting environmentally conscious and energy-efficient practices such as heat pumps or solar energy [1]. In terms of energy performance, a building’s annual energy demand can be broadly categorized into two main components [2], which are the energy demand for space heating and cooling and the energy demand associated with ventilation, including heating and cooling of the supplied air.

With regard to ventilation, a significant amount of energy can be saved by applying smart building design, where natural ventilation is also systematically planned [3]. The effectiveness of natural ventilation is influenced by factors such as the design, orientation and location of the building, as well as the size and positioning of openings [4]. These factors affect the interaction between wind pressure, buoyancy and the building’s interior spaces [5]. Nevertheless, this ventilation system cannot be exclusively utilized; however, there are periods of the year when natural ventilation can provide the right comfort without the use of an air handler [4].

Several advantages can be achieved by natural ventilation; for example, the energy demand of fans is saved. Furthermore, precise temperature control of natural ventilation can be achieved in each room with its own fan coil system. This way, natural ventilation is used in a temperature range where the temperature of the blown air does not cause a large temperature difference in the air in the room. Note that this ventilation approach is in the range of the sustainable retrofitting strategies as a viable path toward decarbonizing the existing building stock [5,6,7].

In this article an energy simulation study is presented, which is focused on an in-built natural ventilation system of an existing vacant office building. The proposed system combines mechanical and natural ventilation, with the mode of operation dynamically adjusted based on indoor and outdoor temperature and humidity levels. This control is managed by an integrated building management system (BMS) to optimize energy performance and indoor air quality.

The aim of this study is twofold. First, it can be demonstrated that a substantial amount of energy can be saved by including natural ventilation in the design of a building.

Second, if this kind of ventilation is constructed, such buildings can be successfully renovated and operated energy-efficiently without the need for demolition. It must be mentioned, that natural ventilation can be efficiently used if the outdoor temperature ranges between 20 °C and 26 °C and mainly during the warmer seasons (preferably summer and early autumn). In addition, only temperature thresholds were considered, while humidity effects were not included in the scope of the analysis.

2. Materials and Methods

The first part of this study introduces the building at hand, together with the basics about ventilation systems.

The second part of the study involves analytical calculations, which include the selection of air handling units that meet the design specifications, as well as determining the annual energy demand of the air-to-water heat pump responsible for supplying heating and cooling via calorifiers. Additionally, the setup process for the simulation environment is described in detail.

The third part includes the dynamic energy simulations, which are conducted by using Ladybug Tools within the Grasshopper visual scripting environment. This software is a component of Rhinoceros 3D software (version 8).

Once configured, this simulation workflow can be reused throughout the project, enabling iterative performance assessments during the design and analysis stages.

2.1. Building Ventilation System: Basics

Building ventilation system refers to the intake of fresh air and the extraction, treatment and exhaust or recirculation of used air. It is intended to regulate and condition the air space, by which we mean regulating temperature, humidity, air quality, oxygen and carbon dioxide levels and, last but not least, air circulation. The system comprises three core components: a heating system, a cooling system and a heat recovery ventilation (HRV) system. The HRV system plays a crucial role in enhancing energy efficiency year-round, supporting cooling in summer and heating in winter. During the summer months, the system introduces air that is significantly cooler than the outside temperature (aided by a cooling calorifier), thereby reducing the load on the cooling unit, which then only needs to manage the temperature differential. Each approach offers distinct advantages depending on the building design, climate conditions and energy efficiency objectives [8].

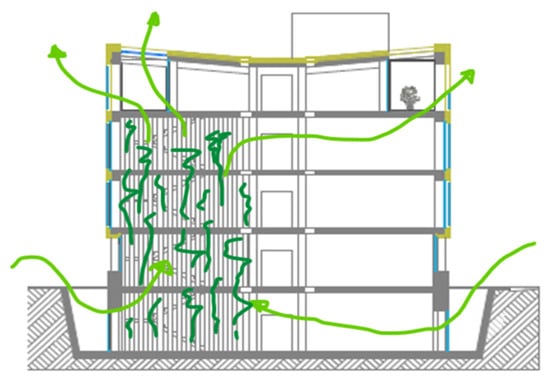

In order to use natural ventilation, an air well has been planned adjacent to the building (Figure 1), allowing cooler outside air to enter the interior spaces through natural airflow. The building’s floors are designed as open-air, open-plan office spaces that promote natural ventilation and the continuous flow of fresh, oxygen-rich air.

Figure 1.

Air flow in case of natural ventilation in the analyzed building.

In addition, a centrally located atrium connects all levels of the building; therefore, it plays a key role in regulating humidity and facilitating air exchange. This is achieved through a chimney effect: warm, stale air rises and is expelled through the atrium via a ventilation system managed by the building management system (BMS). Simultaneously, cooler, fresh air is drawn into the building at the basement level through English windows and a BMS-regulated ventilation system, ensuring efficient and sustainable air circulation throughout the structure.

As a result, a well-regulated, natural ventilation is achieved throughout the entire building (Figure 1), ensuring both thermal comfort and a continuous supply of fresh air for occupants.

2.2. Calculation of Annual Energy Demand by Analytical Method

For the purpose of this study, the annual energy demand required for ventilating the building was determined primarily through analytical calculations [9], which can be divided into three main categories:

- Determination of the building’s air volume requirements.

- Calculation of the annual electrical energy demand (from the thermal energy needs of selected air handling units, based on the area of application and operating time).

- Energy consumption associated with heating and cooling coils (calorifiers).

In order to achieve accurate results, the necessary calculations were carried out for every floor and room within the building. Below is an excerpt from the Excel spreadsheet used in the analysis, showing the air volume requirements for the basement level, broken down by room.

The top row of Table 1 lists the official standards used for the calculation, for example, MSZ CR 1752:2000 [10,11]. The second tab of the excel table contains the data table for the determination of the fresh air demand of the above-mentioned standard.

Table 1.

Air volumes for rooms.

For the calculations, a method was used that takes into account the floor area of the room. After the air volumes were determined, the air handling units were selected and the results were sorted into three different groups according to their functions. Percentages of room use were then presented, broken down into time bands. To calculate the power demand of the air handling units, the current power output of the fans and extractors associated with the units were taken into account.

It must be noted that, besides the consumption of air handling equipment, the electrical energy required to heat and cool the air must also be considered. To determine the heating/cooling energy demand, the annual electrical energy demand of the air-to-water heat pump was taken into account, which provides the heat dissipation of the comfort air [12,13].

The calculations were based on nominal flow rates, pressure values and efficiencies.

The daily energy demand for ventilation of the building was determined according to activity level. The summation was made by aggregating the power activity for the air handling units for a single load in a row. As a result of the aggregation of these data, the energy demand of the air handling units ventilating the building was obtained on a daily basis (the number of workers in the building occupying the room was taken into account to determine the final result). Therefore, the energy demand for building ventilation was 42.65 kWh/day at normal operation for a relatively ideal working point.

Thereafter, the annual energy demand of the building ventilation system was summarized and divided into two parts. The smaller part is the annual electricity demand of the air handling unit fan, which resulted in 10,747 kWh/year (cca. 8.4% of the complete energy demand), while the more robust part is the total annual electrical energy demand of the heating and cooling calorifiers, which resulted in 116,478 kWh/year (cca. 91.6% of the complete energy demand).

Consequently, the total estimated annual electrical energy demand for ventilating the building was 127,226 kWh/year.

The energy that can be saved by natural ventilation is approximately equal to the energy that can be saved by the annual electrical energy demand of the fan of the air handling units. Some of the total annual electrical energy demand of the heating and cooling calorifiers can also be saved by natural ventilation, and this has been taken into account in the simulation. When natural ventilation is present, the heat pumps of the heat exchangers are also at standstill. In the model, we have calculated that, with natural ventilation, the heat pumps’ fans are running at negligible levels; thus, it is possible to maintain comfort by designing and controlling the ventilation openings appropriately.

2.3. Dynamic Energy Simulations

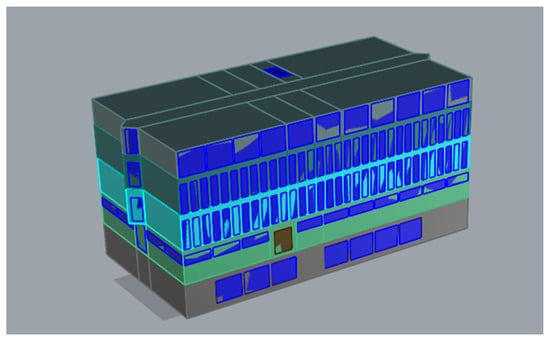

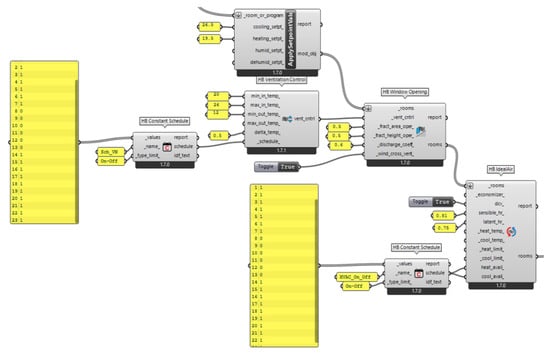

For the simulations, Rhino 8 design software was used, which allowed the creation of a 3D model, and a built-in software called Grasshopper, which allowed the creation of dynamic energy simulations. The Ladybug and Honeybee plugins were used to perform the calculations (Figure 2).

Figure 2.

Three-dimensional model of the building.

Dynamic energy simulation provides information to ensure that there is no significant discrepancy between the data determined in the design state and the values generated in reality. It allows the user to investigate the expected behavior of the building over a whole year, broken down into at least hourly data series. In addition, the term dynamic also refers to the possibility of running a combination of different variables in the simulation in order to select and apply an optimal operating pattern for the building.

During the design of the 3D model, the parts of the building that have a functional role in the simulation were designed in detail. These parts included the rooms that made up the building and the windows and doors that opened into them. The design of the openings at the top of the building has also been defined, as they provided the horn effect through the atrium.

In addition to the building, companion buildings adjacent to the building in the model space were also created. This was necessary due to the reason that they had a shading effect on the simulated building. After modeling the building, the simulation test was performed on the Grasshopper interface.

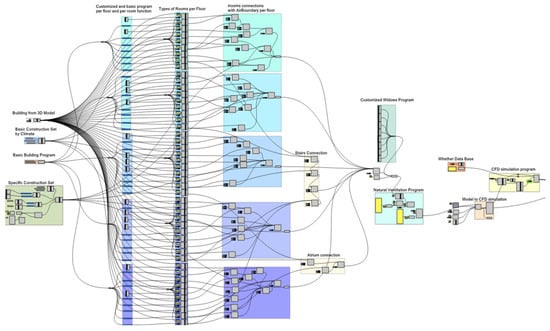

The model is created by coupling the Grasshopper interface, a standards-based base program, which also defines the energy properties of the materials used in the building structure, and the Rhino, which describes the building and its properties (Figure 3).

Figure 3.

Simulation program structure.

The simulation takes into account the climate type of the building and the type of construction. The program also assigns standard data for these parameters, resulting in energy data from the climate zone.

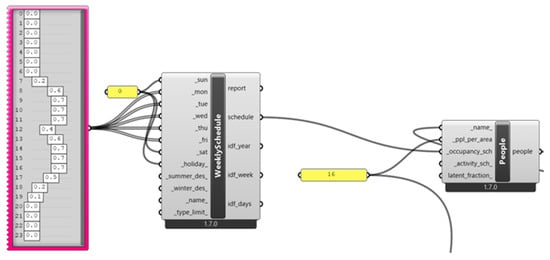

In order to run the simulation successfully, it is essential to determine the environmental conditions and weather data from meteorological centers all over the world. Once the input data had been determined, the rooms in the building were defined according to levels and functions (zones). This was necessary in order to determine the energy data for each zone, taking into account the different uses. In order to obtain the most accurate results possible, a specific program was used for each location where a number of occupancy levels could be reached. Within the specific program, one of the inputs is the number of occupants in the room. As shown in Figure 4, the number of people in the room and the resulting room occupancy were entered. It is important to note that the input parameter for people varies by room due to the number of people planned.

Figure 4.

Room occupancy.

It was also necessary to specify the lighting demand in order to obtain an accurate result. Energy from electronic equipment was calculated by multiplying the power output of the workstations by the number of people in the room.

In the case of the building under consideration, the floors were planned to be open-plan, which meant that no partition walls were planned between the office spaces and the corridors. Therefore, it is required to define the relationship between the open office spaces and the rooms in order to assure free airflow. This relationship was arranged in the Grasshopper’s interface by the so-called “AirBoundaries” boundary condition, which allowed the program to consider an air boundary between the specified rooms during the simulation to ensure free airflow between rooms. This design was employed for all levels.

First, the so-called “Setpoints” parameters had to be determined for the natural ventilation system (Figure 5). This was a necessary step for the system to operate within certain limits, which were defined in temperature. At 26.5 °C the mechanical cooling system activated, while at 19.5 °C the heating system did activate as well.

Figure 5.

Structure of the natural ventilation program.

After defining the input parameters, the opening properties of the windows were determined for the whole building using the “HB Opening Window” module. The opening properties assigned to this module determine the type of ventilation during the simulation, which can be single-sided or wind-driven cross-ventilation.

It must be mentioned that buoyancy flow could occur for all openings, while wind-driven flow could only occur if there was a pressure difference between the windows on opposite sides of the room.

3. Results

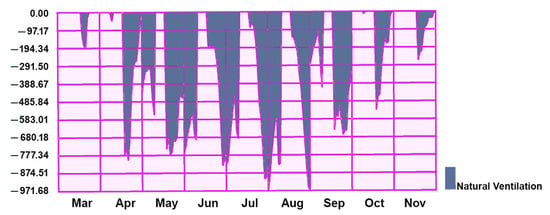

To illustrate simulation results, a monthly breakdown chart is given in Figure 6, where the sum of the blue areas is equal to the annual savings in kWh.

Figure 6.

The result of the natural ventilation program.

The resulting data were aggregated to obtain the annual energy demand reduction of the analyzed building for the retrofitted natural ventilation system. Figure 6 shows the distribution of the annual energy demand for the natural ventilation system with the given operating parameters. The temperature range of the natural ventilation system is 20–26 °C. The energy demand shown in the diagram is to be deducted from the energy demand of operating mechanical ventilation system, as this energy is not used for the building but for the environment.

Therefore, this figure reflects the amount of reduction in the estimated annual energy demand that can be achieved. To quantify the result, the simulated energy saving is summarized in Figure 6, which resulted in 54,803 kWh/year.

The distribution in the diagram is only for working days during a certain period of the year (252 days). There are breaks in the function, where the months of January, February and December are missing. This is due to the reason that, in Hungary (and in Central-Eastern Europe), natural ventilation cannot be applied in consequence of the cold weather.

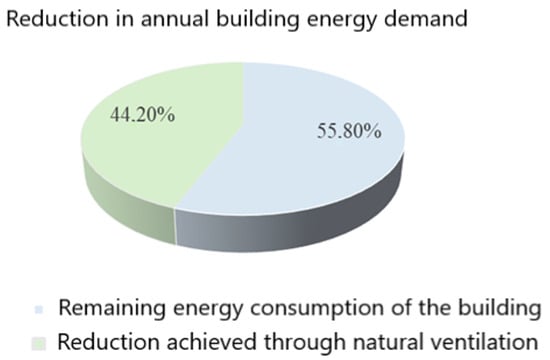

Summarizing the results of the analytical calculations and the simulation, a considerable reduction in energy can be saved in the annual energy demand of the building if it is operated with a complemented natural ventilation system (Table 2).

Table 2.

Annual energy demand of the building and saving with natural ventilation.

After the energy reduction, the remaining annual energy demand was reduced to close to half. As shown in Table 2, by operating the simulated natural ventilation system, the annual energy demand of the building was reduced by more than 44% (Figure 7).

Figure 7.

Reduction in annual building energy demand.

4. Conclusions

In Hungary, there are approximately more than 4 million m2 of office buildings with outdated mechanical systems. According to the 2022 MVM energy mix, 1 kWh of energy is equivalent to about 329 g of carbon dioxide emissions [14]. Taking this figure into account, the analyzed office building is responsible for more than 41 tons of carbon dioxide emissions per year. By operating this building with an upgraded natural ventilation system, carbon dioxide emission can be reduced by almost 19 tons.

By using heat pipes, a significant energy saving can already be achieved, which can be further reduced by using natural ventilation. The obtained results confirm that not only can new or newly constructed office buildings be operated in an environmentally friendly way but a significant reduction in emissions can be achieved by upgrading existing, obsolete office buildings. As a further development, instead of using the outside temperature to control ventilation, the temperature of the air leaving the air well can take the role of regulating temperature. This can extend the duration of natural ventilation and energy saving.

Author Contributions

Conceptualization, I.M., F.S., G.F., Á.J. and I.M.; software, B.A.V.; validation, B.A.V. and I.M.; formal analysis, G.F. and F.S.; investigation, B.A.V. and I.M.; resources, I.M.; data curation, B.A.V.; writing—original draft preparation, I.M., F.S. and G.F.; writing—review and editing, I.M., F.S. and G.F.; visualization, B.A.V.; supervision, I.M., F.S. and G.F.; project administration, I.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Firoozi, A.A.; Ovejobi, D.O.; Firoozi, A.A. Innovations in energy-efficient construction: Pioneering sustainable building practices. Clean. Eng. Technol. 2025, 23, 7–17. [Google Scholar] [CrossRef]

- Wang, S.; Yan, C.; Xiao, F. Quantitative energy performance assessment methods for existing buildings. Energy Build. 2012, 55, 877–885. [Google Scholar] [CrossRef]

- Yeretzian, A.; Karam, J. Optimizing the use of natural ventilation while reducing energy cost: Case study for retrofitting an old residential apartment in a Mediterranean city. Energy Build. 2023, 296, 113371. [Google Scholar] [CrossRef]

- Kleiven, T. Natural Ventilation in Buildings. Ph.D. Thesis, Norwegian University of Science and Technology, Faculty of Architecture and Fine Art, Department of Architectural Design, History and Technology, Trondheim, Norway, 2003; pp. 30–112. [Google Scholar]

- ASHRAE. Standard 90.1, 2019 Update Focuses on Energy-Saving Measures, Addresses Fan Efficiency, Pump Requirements. Available online: https://www.ashrae.org/news/hvacrindustry/2019-update-of-standard-90-1 (accessed on 2 March 2025).

- Elhassan, Z.A. Energy consumption performance using natural ventilation in dwelling design and CFD simulation in a hot dry climate: A case study in Sudan. Front. Built Environ. 2023, 9, 1145747. [Google Scholar] [CrossRef]

- Emmerich, S.J. Simulated performance of natural and hybrid ventilation systems in an office building. HVAC&R Res. 2006, 12, 975–1004. [Google Scholar] [CrossRef]

- SERCO Informatika. Épületfelügyeleti rendszer (BMS—Building Management System). Available online: https://www.serco.hu/tudastar/szotar/e/epuletfelugyeleti-rendszer-bms-building-management-system (accessed on 1 April 2025).

- Gellért, V. Légtechnikai tervezési segédlet (A Magyar Szabványügyi Testület jóváhagyásával az MSZ CR 175:2000 alapján). Available online: https://itsolution.lindab.com/lindabwebproductsdoc/assets/production/Nzc4MGE4NWQtNmRjYy00M2M5LWFkOWItZDljY2U1Mzg3MTcy/5250254190336045883/Lindab_Legtechnika_Tervezesi_segedlet.pdf (accessed on 1 July 2025).

- MSZ CR 1752:2000; Magyar Szabvány—Épületek Szellőztetése. Épületek Belső Környezetének Tervezési Alapjai. Hungarian Standard Commitment: Budapest, Hungary, 2000. Available online: https://www.mszt.hu (accessed on 3 July 2024).

- MSZ EN 16798-1:2019; Magyar Szabvány—Épületek Energetikai Teljesítőképessége. 1. Rész: Beltéri Bemeneti ParaméTerek.M1-6 Modul. European Committee for Standardization: Brussels, Belgium, 2019. Available online: https://www.mszt.hu/hu-hu/szabvanyositas/hirek/2019/09/epuletek-energiahatekonysaganak-megallapitasa (accessed on 22 January 2025).

- Országos Területfejlesztési és Területrendezési Információs Rendszer (TEIR). Available online: https://www.oeny.hu/oeny/teir/#/tablo/8 (accessed on 11 April 2024).

- Escandon, R.; Ferrari, S.; Cardelli, R.; Blazquez, T.; Suarez, R. How do natural ventilation strategies affect thermal comfort in educational buildings? A comparative analysis in the Mediterranean climate. Appl. Sci. 2025, 15, 6606. [Google Scholar] [CrossRef]

- Patocskai, M. A fenntartható fejlődés mérhetőségének egyik lehetősége a karbonlábnyom. Mod. Geogr. 2011, 1, 18–20. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).