Effect of Printing Parameters on the Tensile Mechanical Properties of 3D-Printed Thermoplastic Polyurethane †

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

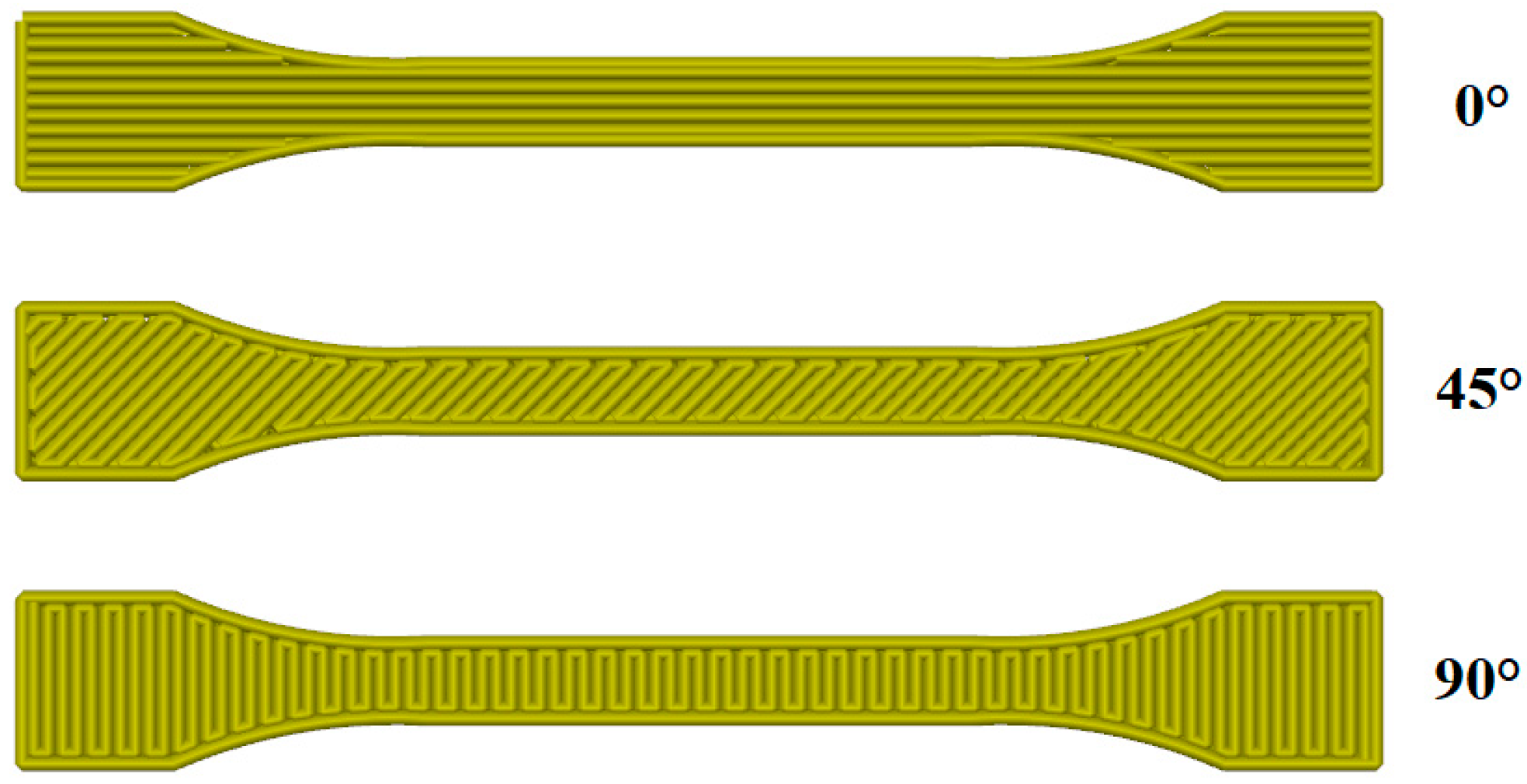

2.2. Processing

2.3. Characterization

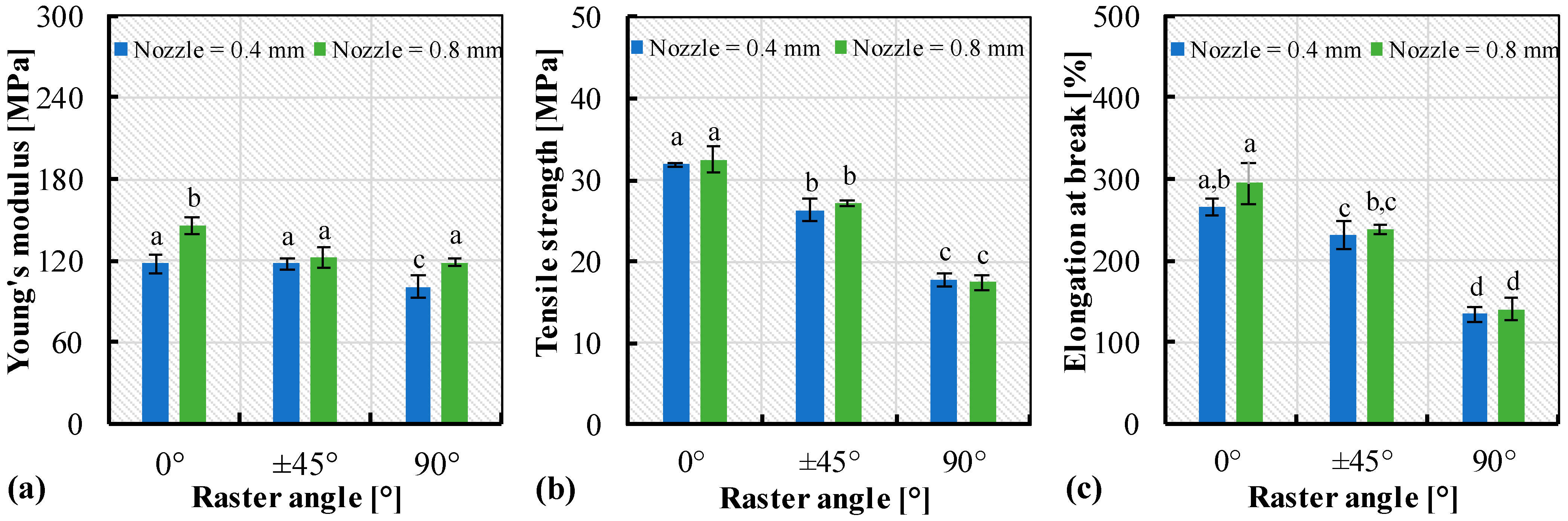

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, K.; Acherjee, B. Revolutionizing manufacturing: A comprehensive overview of additive manufacturing processes, materials, developments, and challenges. J. Manuf. Process. 2023, 107, 574–619. [Google Scholar] [CrossRef]

- Wang, L.; Mosher, R.; Duett, P. Additive Manufacturing in the Aerospace Industry. Am. J. Eng. Appl. Sci. 2024, 17, 116–125. [Google Scholar] [CrossRef]

- Mobarak, M.H.; Islam, M.A.; Hossain, N.; Al Mahmud, M.Z.; Rayhan, M.T.; Nishi, N.J.; Chowdhury, M.A. Recent advances of additive manufacturing in implant fabrication—A review. Appl. Surf. Sci. Adv. 2023, 18, 100462. [Google Scholar] [CrossRef]

- Hassan, H.; Rodriguez-Ubinas, E.; Al Tamimi, A.; Trepci, E.; Mansouri, A.; Almehairbi, K. Towards innovative and sustainable buildings: A comprehensive review of 3D printing in construction. Autom. Constr. 2024, 163, 105417. [Google Scholar] [CrossRef]

- Colorado, H.A.; Cardenas, C.A.; Gutierrez-Velazquez, E.I.; Escobedo, J.P.; Monteiro, S.N. Additive Manufacturing in Armor and Military Applications: Research, Materials, Processing Technologies, Perspectives, and Challenges. J. Mater. Res. Technol. 2023, 27, 3900–3913. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive Manufacturing: A Comprehensive Review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Henriksen, T.E.; Brustad, T.F.; Dalmo, R.; Pedersen, A. Computer-Aided Optimisation in Additive Manufacturing Processes: A State of the Art Survey. J. Manuf. Mater. Process. 2024, 8, 76. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Sztorch, B.; Brząkalski, D.; Pakuła, D.; Frydrych, M.; Špitalský, Z.; Przekop, R.E. Natural and Synthetic Polymer Fillers for Applications in 3D Printing—FDM Technology Area. Solids 2022, 3, 508–548. [Google Scholar] [CrossRef]

- Lendvai, L.; Fekete, I.; Jakab, S.K.; Szarka, G.; Verebélyi, K.; Iván, B. Influence of environmental humidity during filament storage on the structural and mechanical properties of material extrusion 3D-printed poly(lactic acid) parts. Results Eng. 2024, 24, 103013. [Google Scholar] [CrossRef]

- Cardona, C.; Curdes, A.H.; Isaacs, A.J. Effects of Filament Diameter Tolerances in Fused Filament Fabrication. IU J. Undergrad. Res. 2016, 2, 44–47. [Google Scholar] [CrossRef]

- Lendvai, L.; Jakab, S.K.; Fekete, I.; Rigotti, D.; Pegoretti, A. Effect of Filament Humidity on the Properties of Material Extrusion 3D-Printed Acrylonitrile Butadiene Styrene/Hexagonal Boron Nitride Composites. Emergent Mater. 2025. [Google Scholar] [CrossRef]

- Lakshman Sri, S.V.; Karthick, A.; Dinesh, C. Evaluation of Mechanical Properties of 3D Printed PETG and Polyamide (6) Polymers. Chem. Phys. Impact 2024, 8, 100491. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ghasemi, F.A.; Rajaee, P.; Fasihi, M. Evaluation of Fracture Properties of 3D Printed High Impact Polystyrene According to Essential Work of Fracture: Effect of Raster Angle. Addit. Manuf. 2022, 59, 103191. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhang, S.; Chen, J.; Guo, B.; Chen, D. Mechanical Performance of 3D-Printed Polyethylene Fibers and Their Durability against Degradation. Materials 2023, 16, 5182. [Google Scholar] [CrossRef]

- Viccica, M.; Giordano, M.; Galati, M. Additive Manufacturing of Flexible Thermoplastic Polyurethane (TPU): Enhancing the Material Elongation through Process Optimisation. Prog. Addit. Manuf. 2025, 10, 2877–2891. [Google Scholar] [CrossRef]

- Backes, E.H.; Harb, S.V.; Pinto, L.A.; de Moura, N.K.; de Melo Morgado, G.F.; Marini, J.; Passador, F.R.; Pessan, L.A. Thermoplastic polyurethanes: Synthesis, fabrication techniques, blends, composites, and applications. J. Mater. Sci. 2024, 59, 1123–1152. [Google Scholar] [CrossRef]

- Le, D.; Nguyen, C.H.; Pham, T.H.N.; Nguyen, V.T.; Pham, S.M.; Le, M.T.; Nguyen, T.T. Optimizing 3D Printing Process Parameters for the Tensile Strength of Thermoplastic Polyurethane Plastic. J. Mater. Eng. Perform. 2023, 32, 10805–10816. [Google Scholar] [CrossRef]

- Bruère, V.M.; Lion, A.; Holtmannspötter, J.; Johlitz, M. The influence of printing parameters on the mechanical properties of 3D printed TPU-based elastomers. Prog. Addit. Manuf. 2023, 8, 693–701. [Google Scholar] [CrossRef]

- Gonzalez, Y.E.; Mendoza, J.M.; Restrepo Durán, J.; Tapia Vertel, L.C.; Rhenals-Julio, J.D. Effect of printing parameters on mechanical properties and processing time of additively manufactured parts. Matéria 2023, 28, e20230111. [Google Scholar] [CrossRef]

- Ameen, A.A.; Takhakh, A.M.; Abdal-hay, A. Mechanical compressive properties of TPU 3D printed with various parameters. Al-Qadisiyah J. Eng. Sci. 2024, 17, 371–382. [Google Scholar] [CrossRef]

- ISO 527; Plastics—Determination of Tensile Properties. ISO: Geneva, Switzerland, 2019.

- Czyżewski, P.; Marciniak, D.; Nowinka, B.; Borowiak, M.; Bieliński, M. Influence of Extruder’s Nozzle Diameter on the Improvement of Functional Properties of 3D-Printed PLA Products. Polymers 2022, 14, 356. [Google Scholar] [CrossRef] [PubMed]

- Khosravani, M.R.; Berto, F.; Ayatollahi, M.R.; Reinicke, T. Characterization of 3D-Printed PLA Parts with Different Raster Orientations and Printing Speeds. Sci. Rep. 2022, 12, 1016. [Google Scholar] [CrossRef]

- Sugavaneswaran, M.; Arumaikkannu, G. Analytical and Experimental Investigation on Elastic Modulus of Reinforced Additive Manufactured Structure. Materials and Design 2015, 66, 29–36. [Google Scholar] [CrossRef]

- Eryildiz, M. Effect of Build Orientation on Mechanical Behaviour and Build Time of FDM 3D-Printed PLA Parts: An Experimental Investigation. Eur. Mech. Sci. 2021, 5, 116–120. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of Strength Properties of FDM Printed Parts—A Critical Review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef]

- Sudin, M.N.; Daud, N.M.; Ramli, F.R.; Yusuff, M.A. The Effect of Nozzle Size on the Tensile and Flexural Properties of PLA Parts Fabricated Via FDM. Sci. Eng. Technol. 2023, 3, 33–43. [Google Scholar] [CrossRef]

- Lang, L.; Antunes, R.; Dutra, T.A.; Aguiar, M.L.d.; Pereira, N.; Gaspar, P.D. Mechanical Characterization and Computational Analysis of TPU 60A: Integrating Experimental Testing and Simulation for Performance Optimization. Materials 2025, 18, 240. [Google Scholar] [CrossRef] [PubMed]

| Description | Unit | Value |

|---|---|---|

| Nozzle temperature | °C | 230 |

| Bed temperature | °C | 60 |

| Average speed | mm/s | 50 |

| Nozzle diameter | mm | 0.4/0.8 |

| Layer height | mm | 0.2 |

| Infill density | % | 100 |

| Shell layer number | - | 1 |

| Shell layer thickness | mm | 0.8/1.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jakab, S.K.; Lendvai, L. Effect of Printing Parameters on the Tensile Mechanical Properties of 3D-Printed Thermoplastic Polyurethane. Eng. Proc. 2025, 113, 19. https://doi.org/10.3390/engproc2025113019

Jakab SK, Lendvai L. Effect of Printing Parameters on the Tensile Mechanical Properties of 3D-Printed Thermoplastic Polyurethane. Engineering Proceedings. 2025; 113(1):19. https://doi.org/10.3390/engproc2025113019

Chicago/Turabian StyleJakab, Sándor Kálmán, and László Lendvai. 2025. "Effect of Printing Parameters on the Tensile Mechanical Properties of 3D-Printed Thermoplastic Polyurethane" Engineering Proceedings 113, no. 1: 19. https://doi.org/10.3390/engproc2025113019

APA StyleJakab, S. K., & Lendvai, L. (2025). Effect of Printing Parameters on the Tensile Mechanical Properties of 3D-Printed Thermoplastic Polyurethane. Engineering Proceedings, 113(1), 19. https://doi.org/10.3390/engproc2025113019