Abstract

The transition from Industry 4.0 to Industry 5.0 marks a pivotal shift toward human-centric manufacturing, where advanced technologies are designed to enhance rather than replace human capabilities. Human Factors and Ergonomics (HFE) play a vital role in ensuring that this transformation balances both worker well-being and system performance. However, existing research reveals a notable gap in fully understanding HFE’s role across the different levels of human–system interactions. This paper presents a comprehensive literature review, offering key insights and future directions to address this gap and highlighting the need for broader perspectives in designing human-centric systems.

1. Introduction

Industry 5.0 represents a significant evolution in manufacturing, shifting the focus from automation and efficiency toward a value-driven approach that prioritizes worker well-being and fosters collaboration between humans and advanced technologies [,]. While Industry 4.0 emphasized smart automation, cyber-physical systems, and data- driven decision-making, Industry 5.0 integrates human centricity to ensure that techno- logical advancements enhance rather than replace human capabilities [].

This shift introduces new challenges and opportunities for the design of human-centric systems where Human Factors and Ergonomics (HFE) is crucial for understanding the complex interactions between workers, technology, and the work environment []. However, a review of current research indexed in the SCOPUS database reveals a lack of comprehensive studies examining the role of HFE in Industry 5.0, particularly from a human-centric perspective and across all levels of human–system interactions.

To address this gap, this paper conducts a comprehensive literature review and offers a multi-level analysis of HFE within the context of Industry 5.0, connecting individual ergonomics, organizational policies, and societal considerations to support the development of human-centric manufacturing systems.

2. Outlook on HFEs

2.1. Definitions and Terminology

The International Ergonomics Association defines Human Factors and Ergonomics (HFE), terms often used interchangeably or together, as “The scientific discipline concerned with the understanding of interactions among humans and other elements of a system, and the profession that applies theory, principles, data, and methods to design in order to optimize human well-being and overall system performance” []. The term “Ergonomics” has been used in professional practice in the UK since 1950 and internationally since 1961, while “Human Factors” has been used in the USA since 1957. These terms have been unified in countries like the USA, UK, Australia, and New Zealand. However, in most non-English-speaking countries, the term “Ergonomics” remains predominant []. In this paper, HFE is used to refer to this discipline.

2.2. HFE Characteristics

HFE is a human-centered and design-driven discipline that employs a system approach to enhance both human well-being and global performance.

- System Approach: A system is defined as “a set of interacting and interdependent components that form an integrated whole” []. HFE is concerned with the design of goal-oriented systems that consider human interactions within their environment []. The human elements are physical, physiological, psychological (affective and cognitive), and social factors, where the environmental elements include physical, informational, organizational, and social factors [,].

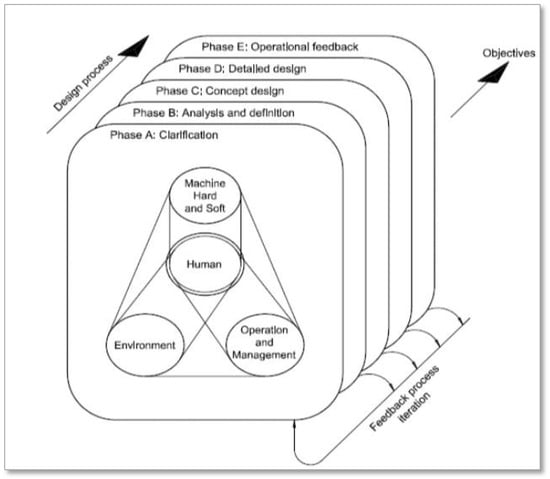

- Human-centered Design: At its core, HFE prioritizes understanding human needs, capabilities, and limitations to ensure systems are designed to adapt to humans rather than requiring humans to conform to pre-designed systems []. As outlined in ISO 11064, it emphasizes the harmonious integration of human components, machines (hardware and software), work environments, operations, and management throughout all phases of the design process. This iterative process consists of five stages: clarification, analysis and definition, concept design, detailed design, and operational feedback (see Figure 1) [].

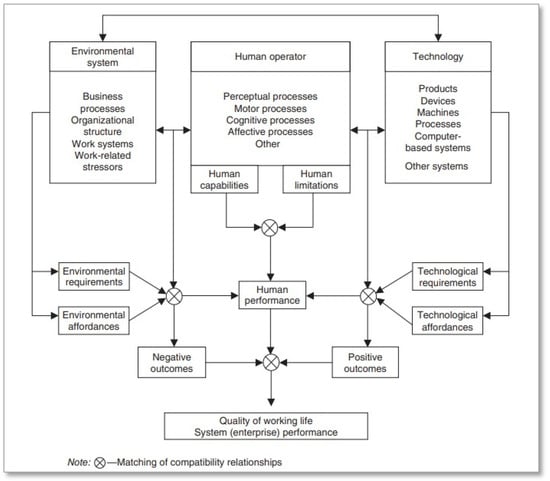

- Outcome—Performance and Human Well-being: By adapting the environment to hu- mans, HFE seeks to optimize both performance (e.g., efficiency, flexibility, reliability, and sustainability) and well-being (e.g., health, safety, satisfaction, and personal development) []. Most research typically focuses on one domain, but studies addressing both reveal that they often co-vary, either improving or degrading together [,]. Figure 2 presents the human–system compatibility approach, showing how the alignment between humans, technology, and the environment affects these outcomes.

Figure 1.

Ergonomic approach to system designs [].

Figure 2.

Human–system compatibility approach to HFE [].

2.3. HFE Levels

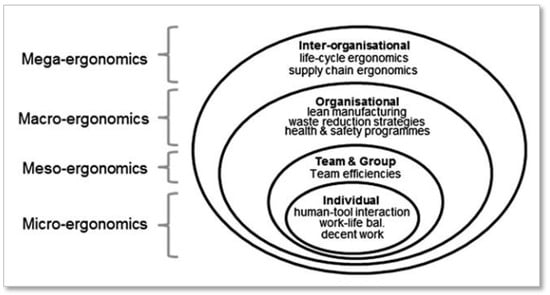

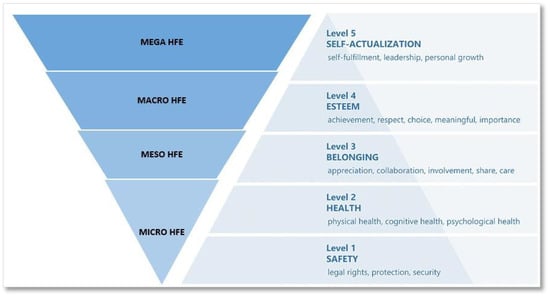

HFE operates at various levels—micro, meso, macro, and mega. As illustrated in Figure 3, each level addresses distinct aspects of human–system interactions [,]:

Figure 3.

HFE levels [].

- Micro level: It considers individual interactions with tools, tasks, and work environments with the aim of minimizing the mental workload, reducing physical strain, and designing user-friendly interfaces and workstations.

- Meso level: It focuses on group interactions, examining how individuals collaborate in shared environments, and seeks to optimize workflows and technical processes to enhance group performance.

- Macro level: It investigates organizational factors such as culture, management practices, and socio-technical systems to ensure global performance and human well-being.

- Mega level: It expands to inter-organizational and societal networks, addressing large-scale systems and global challenges. It emphasizes designing human-centric frameworks for interconnected organizations, such as global supply chains and crisis management systems.

2.4. HFE Evolution in the Industry

The concept of HFE has evolved alongside the phases of industrial revolutions, beginning with its roots in human prehistory. Early HFE principles are evident in ancient tools, such as shaped rocks and bones, and in Hippocrates’ fifth-century B.C. guidelines for designing surgical workspaces to maximize safety and efficiency []. Over time, these principles continued to evolve within each industrial revolution and to be applied in various industries such as healthcare, automotive, construction, and the military [].

- Industry 1.0: As industry relied heavily on human labor during the first industrial revolution, early concepts of HFE began to emerge for improving productivity. The focus was on designing industrial tools that were better suited to human capabilities [].

- Industry 2.0: With the rise in assembly lines and mass production, HFE principles were applied to improve workers’ efficiency. For instance, Frederick W. Taylor im- proved efficiency via task analysis, where Frank and Lillian Gilbreth improved efficiency and reduced fatigue via time-motion analysis and standardizing tools, materials, and processes [].

- Industry 3.0: The advent of military equipment, such as warplanes and radar systems during World War II, highlighted the need to design human–machine interfaces that could account for cognitive and physical limitations. This era saw significant advancements in control and display design to reduce operator errors []. The Third Industrial Revolution, driven by the introduction of computers, further introduced the human–computer interaction, which marked a shift from corrective HFE (observing and adjusting after systems were built) to interaction design, emphasizing task analysis during the design process [].

- Industry 4.0: The digital revolution of industries, driven by automation, artificial intelligence, and smart systems, led to the emergence of Human Systems Integration (HSI). Combining systems engineering with Human-Centered Design, HSI incorporates activity analysis using virtual prototyping and human-in-the-loop simulations to address human needs and capabilities throughout a system’s lifecycle [].

3. HFE in Industry 5.0

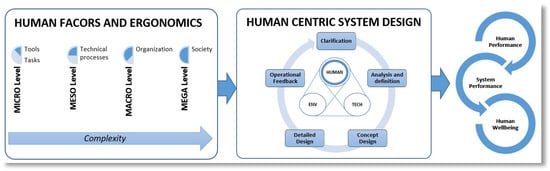

Industry 5.0 adopts a human-centric approach that prioritizes human needs and interests within the production process []. It focuses on leveraging technology to support workers while respecting their fundamental rights, including autonomy, privacy, and dignity []. This approach is aligned with the HFE’s dual objective, as it prioritizes societal considerations alongside economic goals []. Accordingly, Figure 4 presents the concept of HFEs in Industry 5.0.

Figure 4.

HFE approach in Industry 5.0 (ENV: environment, TECH: technology).

The full spectrum of human–system interactions should be addressed in this revolution, balancing the different factors in all levels to optimize workers’ well-being and system performance. Figure 5 illustrates industrial human needs and their correspondent levels of HFE based on the human needs pyramid [].

Figure 5.

HFE levels mapped to industrial human needs pyramid.

Micro HFE addresses safety (legal rights, protection, and security) and health (physical, cognitive, and psychological). Meso HFE focuses on belonging, fostering collaboration, appreciation, and involvement. Macro HFE aligns with esteem, emphasizing achievement, respect, and meaningful work. At the highest level, Mega HFE represents self-actualization, promoting leadership, personal growth, and fulfillment. Thus, HFE in Industry 5.0 supports a human-centric approach, ensuring workplaces meet fundamental and higher-level human needs while fostering performance and well-being.

Industry 5.0 is redefining workers as valuable investments rather than costs []. Accordingly, Operator 5.0 is considered to be “a smart and skilled operator that uses human creativity, ingenuity, and innovation empowered by information and technology as a way of overcoming obstacles in the path to create new, frugal solutions for guaranteeing manufacturing operations sustainable continuity and workforce wellbeing in light of difficult and/or unexpected conditions” []. Operator 5.0 works in human-centric manufacturing, which is defined as “manufacturing practices that place human wellbeing at the center of manufacturing systems and processes, providing a safe, comfortable, and motivating environment for working, learning and growth, thereby creating a virtuous circle in which individual wellbeing and sustained manufacturing growth are mutually reinforcing” [].

Based on the above definitions and the literature review, Table 1 outlines the internal and external factors (Operator 5.0 and its environment) that should be considered in Industry 5.0. It also indicates the advanced technologies and relevant studies corresponding to each level.

Table 1.

HFE in Industry 5.0.

At the Micro HFE, individual cognitive, physical, and psychological states, along with workstation conditions, are supported by wearables and AI-driven tools. The Meso HFE focuses on team dynamics and workplace layout, enhanced by collaborative robots and digital twins. At the Macro HFE, organizational culture, policies, and technology integration are optimized through ERP systems, IoT, and AI analytics. Finally, the Mega HFE considers societal trends, regulations, and global challenges, with the block chain and green technologies promoting transparency and sustainability

4. Conclusions and Future Directions

This paper demonstrates how HFE is fully aligned with the human-centric vision of Industry 5.0, highlighting its crucial role in adapting technological advancements to hu- man needs. HFE can be analyzed across multiple levels—micro, meso, macro, and mega—each addressing distinct aspects of worker interactions with their environment and technology.

Future research must expand beyond immediate workplace design and integrate broader considerations, particularly on how policies, regulations, and economic factors shape human-centric systems in Industry 5.0. Key directions include the following:

- Investigating how policies can be defined to support the ethical and culturally sensitive implementation of advanced technologies in various societal contexts.

- Advancing theoretical AI frameworks toward practical implementation, prioritizing worker acceptance, system reliability, and ethical considerations.

- Developing a comprehensive safety framework integrating cognitive and emotional considerations alongside physical safety.

- Ensuring inclusivity and diversity by addressing gender, age, and worker capability in systems design.

- Promoting sustainable and green technologies to align human-centric initiatives with environmental responsibility.

By addressing these elements, HFE in Industry 5.0 can evolve beyond operational efficiency to create inclusive and ethically responsible manufacturing systems that prioritize both societal and environmental factors alongside economic goals.

Author Contributions

Conceptualization, H.M., S.A., S.E. and L.E.A.; methodology, H.M., S.A., S.E. and L.E.A.; software, H.M., S.A., S.E. and L.E.A.; validation, H.M., S.A., S.E. and L.E.A.; formal analysis, H.M., S.A., S.E. and L.E.A.; investigation, H.M., S.A., S.E. and L.E.A.; resources, H.M., S.A., S.E. and L.E.A.; data curation, H.M., S.A., S.E. and L.E.A.; writing—original draft preparation, H.M.; writing—review and editing, H.M., S.A., S.E. and L.E.A.; visualization, H.M., S.A., S.E. and L.E.A.; supervision, H.M., S.A., S.E. and L.E.A.; project administration, L.E.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| HFE | Human Factors and Ergonomics |

| AR | Augmented Reality |

| MR | Mixed Reality |

| ERP | Enterprise Resource Planning |

| IoT | Internet of Things |

| AI | Artificial Intelligence |

| ENV | Environment |

| TECH | Technology |

References

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, Conception and Perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Mouhib, H.; Amar, S.; Elrhanimi, S.; Abbadi, L.E. Maximizing Efficiency and Collaboration: Comparing Robots and Cobots in the Automotive Industry-A Multi-Criteria Evaluation Approach. Int. J. Ind. Eng. Manag. 2024, 15, 238–253. [Google Scholar] [CrossRef]

- Paschek, D.; Mocan, A.; Draghici, A. Industry 5.0—The Expected Impact of next Industrial Revolution. In Proceedings of the Thriving on Future Education, Industry, Business, and Society, Proceedings of the MakeLearn and TIIM International Conference. Piran, Slovenia, 15–17 May 2019; pp. 15–17. [Google Scholar]

- Karwowski, W. Ergonomics and Human Factors: The Paradigms for Science, Engineering, Design, Technology and Management of Human-Compatible Systems. Ergonomics 2005, 48, 436–463. [Google Scholar] [CrossRef] [PubMed]

- IEA. What Is Ergonomics (HFE)? | International Ergonomics Association. Available online: https://iea.cc/about/what-is-ergonomics/ (accessed on 1 January 2025).

- Hignett, S.; Jones, E.L.; Miller, D.; Wolf, L.; Modi, C.; Shahzad, M.W.; Buckle, P.; Banerjee, J.; Catchpole, K. Human Factors and Ergonomics and Quality Improvement Science: Integrating Approaches for Safety in Healthcare. BMJ Qual. Saf. 2015, 24, 250–254. [Google Scholar] [CrossRef]

- Dul, J.; Bruder, R.; Buckle, P.; Carayon, P.; Falzon, P.; Marras, W.S.; Wilson, J.R.; van der Doelen, B. A Strategy for Human Factors/Ergonomics: Developing the Discipline and Profession. Ergonomics 2012, 55, 377–395. [Google Scholar] [CrossRef]

- O’Dea, A.; Sharafkhani, M.; Codd, M.; Browne, M.; O’Connor, P.; Ward, M.E. Principles for the Conduct of Human Factors/Ergonomics in Healthcare: A Scoping Study of the Published Evidence. BMJ Open Qual. 2025, 14, e003222. [Google Scholar] [CrossRef]

- Hasanain, B. The Role of Ergonomic and Human Factors in Sustainable Manufacturing: A Review. Machines 2024, 12, 159. [Google Scholar] [CrossRef]

- Aas, A.; Johnsen, S. Improvement Of Human Factors In Control Centre Design-Experiences Using ISO 11064 In The Norwegian Petroleum Industry And Suggestions For Improvements. In Proceedings of the International Petroleum Technology Conference (IPTC 2007), Dubai, United Arab Emirates, 4–6 December 2007; p. IPTC–11762. [Google Scholar]

- Sgarbossa, F.; Grosse, E.H.; Neumann, W.P.; Battini, D.; Glock, C.H. Human Factors in Production and Logistics Systems of the Future. Annu. Rev. Control 2020, 49, 295–305. [Google Scholar] [CrossRef]

- Karwowski, W.; Zhang, W. The Discipline of Human Factors and Ergonomics. In Handbook of Human Factors and Ergonomics; John Wiley & Sons, Ltd: Hoboken, NJ, USA, 2021; pp. 1–37. ISBN 978-1-119-63611-3. [Google Scholar]

- ISO 11064-1:2000(En); Ergonomic Design of Control Centres—Part 1: Principles for the Design of Control Centres. Available online: https://www.iso.org/obp/ui/es/#iso:std:iso:11064:-1:ed-1:v1:en (accessed on 8 January 2025).

- Thatcher, A.; Yeow, P.H.P. (Eds.) Ergonomics and Human Factors for a Sustainable Future; Springer: Singapore, 2018; ISBN 978-981-10-8071-5. [Google Scholar]

- Ismaila, S.O.; Samuel, T.M. Human-Centered Engineering: The Challenges of Nigerian Engineer. J. Eng. Des. Technol. 2014, 12, 195–208. [Google Scholar] [CrossRef]

- Emergency Services Ergonomics and Wellness. Available online: https://www.usfa.fema.gov/a-z/health-safety-wellness/ergonomics/ch1-origin-ergonomics-human-factors.html (accessed on 3 January 2025).

- Pandve, H.T. Historical Milestones of Ergonomics: From Ancient Human to Modern Human. J Ergon. 2017, 7, e169. [Google Scholar] [CrossRef]

- Khayal, O. Human Factors and Ergonomics. Available online: https://www.researchgate.net/publication/334458657 (accessed on 1 January 2025).

- Boy, G.A. Human-Centered Design of Complex Systems: An Experience-Based Approach. Des. Sci. 2017, 3, e8. [Google Scholar] [CrossRef]

- Antanasijević, D.; Ristić, S.; Vještica, M.; Stefanović, D.; Dimitrieski, V.; Pisarić, M. A Prototype of a Domain-Specific Modeling Language for Formal Specification of a Human Worker. Acta Electrotech. Et Inform. 2023, 23, 33–40. [Google Scholar] [CrossRef]

- Directorate-General for Research and Innovation (European Commission); Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human Centric and Resilient European Industry; Publications Office of the European Union. Available online: https://data.europa.eu/doi/10.2777/308407 (accessed on 28 January 2025).

- Mouhib, H.; Amar, S.; Elrhanimi, S.; Abbadi, L.E. An Extended Review of the Manufacturing Transition Under the Era of Industry 5.0. In Proceedings of the 2023 7th IEEE Congress on Information Science and Technology (CiSt), Agadir-Essaouira, Morocco, 16–22 December 2023; pp. 709–714. [Google Scholar]

- Lu, Y.; Zheng, H.; Chand, S.; Xia, W.; Liu, Z.; Xu, X.; Wang, L.; Qin, Z.; Bao, J. Outlook on Human-Centric Manufacturing towards Industry 5.0. J. Manuf. Syst. 2022, 62, 612–627. [Google Scholar] [CrossRef]

- Sheikh, R.A.; Ahmed, I.; Faqihi, A.Y.A.; Shehawy, Y.M. Global Perspectives on Navigating Industry 5.0 Knowledge: Achieving Resilience, Sustainability, and Human-Centric Innovation in Manufacturing. J. Knowl. Econ. 2024. [Google Scholar] [CrossRef]

- Romero, D.; Stahre, J. Towards the Resilient Operator 5.0: The Future of Work in Smart Resilient Manufacturing Systems. In Proceedings of the Procedia CIRP; Mourtzis, D., Ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2021; Volume 104, pp. 1089–1094. [Google Scholar]

- Pistolesi, F.; Baldassini, M.; Lazzerini, B. A Human-Centric System Combining Smartwatch and LiDAR Data to Assess the Risk of Musculoskeletal Disorders and Improve Ergonomics of Industry 5.0 Manufacturing Workers. Comput. Ind. 2024, 155, 104042. [Google Scholar] [CrossRef]

- Tomelleri, F.; Sbaragli, A.; Picariello, F.; Pilati, F. Digital Ergonomic Assessment to Enhance the Physical Resilience of Human- Centric Manufacturing Systems in Industry 5.0. J. Manuf. Syst. 2024, 77, 246–265. [Google Scholar] [CrossRef]

- Nadaffard, A.; Oliveri, L.M.; D’Urso, D.; Facchini, F.; Sassanelli, C. Exploring the Cognitive Workload Assessment According to Human-Centric Principles in Industry 5.0. In Proceedings of the Advances in Production Management Systems. Production Management Systems for Volatile, Uncertain, Complex, and Ambiguous Environments, Chemnitz, Germany, 8–12 September 2024; Thürer, M., Riedel, R., von Cieminski, G., Romero, D., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 457–469. [Google Scholar]

- Papetti, A.; Ciccarelli, M.; Palpacelli, M.C.; Germani, M. How to Provide Work Instructions to Reduce the Workers’ Physical and Mental Workload. In Proceedings of the 56th CIRP International Conference on Manufacturing Systems (Procedia CIRP, 2023), Cape Town, South Africa, 24–26 October 2023; Elsevier: Amsterdam, The Netherlands, 2023; Volume 120, pp. 1167–1172. [Google Scholar]

- Tomelleri, F.; Sbaragli, A.; Piacariello, F.; Pilati, F. Safe Assembly in Industry 5.0: Digital Architecture for the Ergonomic Assembly Worksheet. In Proceedings of the 10th CIRP Conference on Assembly Technology and Systems (CIRP CATS 2024), Karlsruhe, Germany, 24–26 April 2024; Elsevier: Amsterdam, The Netherlands, 2024; Volume 127, pp. 68–73. [Google Scholar]

- Khafaga, A.A.A.E.M.A.; Moreira, L.C.; Horan, B. Towards Industry 5.0: Augmented Reality Assistance Systems for People-Centred Digitalisation and Smart Manufacturing. In Proceedings of the 28th International Conference on Automation and Computing (ICAC 2023), Birmingham, UK, 30 August–1 September 2023; pp. 1–7. [Google Scholar]

- Khamaisi, R.K.; Brunzini, A.; Grandi, F.; Peruzzini, M.; Pellicciari, M. UX Assessment Strategy to Identify Potential Stressful Conditions for Workers. Robot. Comput. Integr. Manuf. 2022, 78, 102403. [Google Scholar] [CrossRef]

- Agostinelli, T.; Generosi, A.; Ceccacci, S.; Mengoni, M. Validation of Computer Vision-Based Ergonomic Risk Assessment Tools for Real Manufacturing Environments. Sci. Rep. 2024, 14, 27785. [Google Scholar] [CrossRef]

- Suh, S.; Rey, V.F.; Lukowicz, P. Wearable Sensor-Based Human Activity Recognition for Worker Safety in Manufacturing Line. In Artificial Intelligence in Manufacturing: Enabling Intelligent, Flexible and Cost-Effective Production Through AI; Artificial Intelligence in Manufacturing; Soldatos, J., Ed.; Springer: Cham, Switzerland, 2023; pp. 303–317. ISBN 978-3-031-46452-2. [Google Scholar]

- Lou, S.; Zhang, Y.; Tan, R.; Lv, C. A Human-Cyber-Physical System Enabled Sequential Disassembly Planning Approach for a Human-Robot Collaboration Cell in Industry 5.0. Robot. Comput.-Integr. Manuf. 2024, 87, 102706. [Google Scholar] [CrossRef]

- Pluchino, P.; Pernice, G.F.A.; Nenna, F.; Mingardi, M.; Bettelli, A.; Bacchin, D.; Spagnolli, A.; Jacucci, G.; Ragazzon, A.; Miglioranzi, L.; et al. Advanced Workstations and Collaborative Robots: Exploiting Eye-Tracking and Cardiac Activity Indices to Unveil Senior Workers’ Mental Workload in Assembly Tasks. Front. Robot. AI 2023, 10, 1275572. [Google Scholar] [CrossRef] [PubMed]

- Keshvarparast, A.; Berti, N.; Chand, S.; Guidolin, M.; Lu, Y.; Battaia, O.; Xu, X.; Battini, D. Ergonomic Design of Human-Robot Collaborative Workstation in the Era of Industry 5.0. Comput. Ind. Eng. 2024, 198, 110729. [Google Scholar] [CrossRef]

- Ghorbani, E.; Keivanpour, S.; Sekkay, F.; Imbeau, D. Human-Centric Robotic Assembly Line Design: A Fuzzy Inference System Approach for Adaptive Workload Management. Int. J. Adv. Manuf. Technol. 2024, 134, 3805–3827. [Google Scholar] [CrossRef]

- Abdous, M.-A.; Delorme, X.; Battini, D.; Berger-Douce, S. Multi-Objective Collaborative Assembly Line Design Problem with the Optimisation of Ergonomics and Economics. Int. J. Prod. Res. 2023, 61, 7830–7845. [Google Scholar] [CrossRef]

- Ling, S.; Yuan, Y.; Yan, D.; Leng, Y.; Rong, Y.; Huang, G.Q. RHYTHMS: Real-Time Data-Driven Human-Machine Synchronization for Proactive Ergonomic Risk Mitigation in the Context of Industry 4.0 and Beyond. Robot. Comput.-Integr. Manuf. 2024, 87, 102709. [Google Scholar] [CrossRef]

- Ranasinghe, T.; Grosse, E.H.; Lerher, T. Aging in Industry 5.0: Enhancing Human-Robot Synergy in Manufacturing and Logistics. In Proceedings of the 18th IFAC Symposium on Information Control Problems in Manufacturing INCOM 2024, Vienna, Austria, 28–30 August 2024; Elsevier: Amsterdam, The Netherlands, 2024; Volume 58, pp. 367–372. [Google Scholar]

- Grosse, E.H.; Sgarbossa, F.; Berlin, C.; Neumann, W.P. Human-Centric Production and Logistics System Design and Management: Transitioning from Industry 4.0 to Industry 5.0. Int. J. Prod. Res. 2023, 61, 7749–7759. [Google Scholar] [CrossRef]

- Lagorio, A.; Cimini, C.; Piffari, C.; Galimberti, M.; Pirola, F.; Pinto, R. Operationalisation and Validation of a Human Factors- Based Decision Support Framework for Technology Adoption in the Logistics Sector. Int. J. Logist. Res. Appl. 2024, 27, 2238–2260. [Google Scholar] [CrossRef]

- Nazarejova, J.; Soltysova, Z.; Rudeichuk, T. Requirements and Barriers for Human-Centered SMEs. Sensors 2024, 24, 4681. [Google Scholar] [CrossRef]

- Battini, D.; Berti, N.; Finco, S.; Zennaro, I.; Das, A. Towards Industry 5.0: A Multi-Objective Job Rotation Model for an Inclusive Workforce. Int. J. Prod. Econ. 2022, 250, 108619. [Google Scholar] [CrossRef]

- Destouet, C.; Tlahig, H.; Bettayeb, B.; Mazari, B. Multi-Objective Sustainable Flexible Job Shop Scheduling Problem: Balancing Economic, Ecological, and Social Criteria. Comput. Ind. Eng. 2024, 195, 110419. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Umbrello, S. Value-Oriented and Ethical Technology Engineering in Industry 5.0: A Human-Centric Perspective for the Design of the Factory of the Future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).