Abstract

This experimental study investigates the effects of conventional and non-conventional (Electrical Discharge Machining, EDM) techniques on the performance of threading dies fabricated from H13 die steel. The research focuses on variations in material properties, operational efficiency, and failure mechanisms. Results indicate that conventional machining significantly increases die hardness, leading to higher mechanical stress and premature failure. In contrast, EDM maintains structural integrity with minimal hardness variation. Microstructural analysis confirms superior grain structure stability in EDM-processed dies. Performance testing showed that conventional threading dies failed after threading 16 inches of mild steel rods, while EDM-fabricated dies successfully threaded up to 20 inches. These findings underscore the detrimental effect of mechanically induced stress in conventional techniques and highlight the superior durability and dimensional precision achievable through non-conventional machining methods.

1. Introduction

The manufacturing performance and operational lifespan of dies within the die fabrication field depend heavily on the selection of appropriate machining techniques for these critical manufacturing components, which include molding tools, along with threading and tapping technologies [1]. Tapping and threading dies represent essential categories which produce accurately threaded elements that serve multiple engineering applications. Material properties of these dies change substantially during machining due to variations in hardness, combined with microstructure variations and the formation of residual stresses, since these factors act as primary indicators of die operational life and wear capability. Traditional turning and milling operations and grinding procedures generate major residual stress because these manufacturing methods require contact between the tool and workpiece surface. The necessary shaping stress increases material hardness while making it more prone to cracking with threading operations that induce large amounts of material stress and interface friction [2]. Non-conventional machine methods, including Electrical Discharge Machining (EDM), provide an alternative processing method through the avoidance of direct tool–workpiece interaction. Electrical power eliminates material through electrical discharges, thus, diminishing residual stress formation and maintaining the die’s structural condition. Electrical Discharge Machining has gained wider recognition because it produces exact high-quality dies which exhibit superior properties compared to traditional production methods. Threaded operations require die tools to maintain their structural strength to perform cutting operations at full capacity while avoiding failures and minimizing tool wear [3]. EDM could be a broadly utilized instrument within industries to guarantee great work on all sorts of items, such as the exact machining of electronic materials, the hardness of steel, metal amalgams, graphite, and indeed, a few ceramic materials notwithstanding. Micro-EDM is broadly utilized within the micro-mold plan industry to make molds, cavities, and indeed, complex 3D models. The primary advantage of electro-discharge machining or micro-EDM over other machining forms is that it is an electro-warmed preparation that expels metal depending on its hardness, and the strength and property of the workpiece are irrelevant. In this manner, the mistake caused by the misshaping constraint of the gadget is nearly zero [4]. In expansion, since there is no coordinated contact between the cathode and the workpiece, there are no splitting, stretch, and vibration issues amid machining [5].

2. Literature Review

Die manufacturing plays a crucial role in various industries, particularly in metal forming and injection molding. Traditional (conventional) machining methods, such as turning, milling, and grinding, have long been utilized for die production. However, these methods encounter significant challenges due to increased material hardness, reduction in grain structure diameter, and excessively high cutting temperatures [6]. These challenges lead to undesirable alterations in material properties, thereby affecting the performance and durability of dies. Non-conventional machining (NCM) methods, such as Electrical Discharge Machining (EDM), Laser Beam Machining (LBM), and Abrasive Water Jet (AWJ), offer viable alternatives to overcome these limitations. This literature review aims to explore recent research addressing the effectiveness of non-conventional machining methods in die manufacturing and their advantages over conventional approaches [7].

2.1. Challenges in Conventional Machining of Dies

This article [8] provided a comprehensive analysis of the constraints associated with conventional machining of hard materials used in die manufacturing. The study highlighted key issues such as excessive heat generation, tool wear, and microstructural alterations, which negatively impact die performance. Conventional machining struggles with maintaining precision and surface integrity when working with hardened materials, leading to frequent tool replacement and increased manufacturing costs. Furthermore, machining-induced residual stresses often compromise the fatigue strength of dies, reducing their lifespan [9]. This article [10] extended the discussion by evaluating the microstructural effects of machining on materials. The study demonstrated that high-temperature conditions in conventional machining result in grain structure refinement and hardness increment, leading to brittle behavior in dies. The reduction in formability due to machining-induced structural changes underscores the need for alternative manufacturing approaches.

2.2. Advancements in Non-Conventional Machining Methods

Recent advancements in non-conventional machining offer promising solutions. A novel bimetal-gradient-layer surfacing technique [7] demonstrated enhanced microstructural integrity by minimizing thermal effects and maintaining original material properties. Further research [11] into methods like Abrasive Water Jet (AWJ) and Electrical Discharge Machining (EDM) showed improved dimensional accuracy and surface finish without damaging the microstructure. A comprehensive review [12] confirmed that EDM and Laser Beam Machining (LBM) deliver superior surface quality and extended tool life, effectively overcoming the thermal and structural limitations of conventional methods and paving the way for more efficient and durable die manufacturing.

2.3. Conventional vs. Non-Conventional Machining

A comparative analysis of conventional and non-conventional machine methods highlights the clear advantages of non-conventional approaches. While conventional machines remain prevalent for their cost-effectiveness and accessibility, they struggle with hardened materials, often leading to tool wear, poor surface quality, and undesirable microstructural changes. In contrast, non-conventional machining techniques offer higher precision, better surface finishes, and minimal thermal damage, making them more suitable for complex die manufacturing [13]. The reviewed literature underscores how these advanced methods address key challenges of traditional machining, such as hardness-related difficulties and grain structure alterations—ultimately enhancing die performance and durability. Future research should aim to optimize non-conventional parameters and explore hybrid methods to further boost efficiency in die production [14]. However, there is a research gap in identifying machining methods that can overcome these limitations. Non-conventional machining procedures address this gap by offering effective machining techniques that minimize hardness, enhance generation rates, improve surface finish, extend tool life, and achieve higher precision without compromising the material’s microstructure.

3. Experimental Setup

This experimental section describes the detail regarding the material composition, machining parameters for both processes, experimental steps, and the output parameters as shown in Table 1.

Table 1.

EDM process parameters.

The EDM parameters were experimentally optimized through trial runs (some from literature as shown in Table 1) to ensure stable machining, controlled hardness, and effective material removal for H13 steel dies.

The dies were manufactured using H13 die steel, with its chemical composition presented in Table 2. The elemental composition was verified through spectrographic analysis.

Table 2.

Material composition of die [15].

The threading dies were prepared with the dimensions listed in Table 3. Fabrication was carried out using both conventional machining processes (turning, drilling, and tapping) and non-conventional methods (EDM wire-cutting and EDM die-sinking).

Table 3.

Die dimensions.

In conventional machines, the direct interaction between the cutting tool and the workpiece induces substantial alterations in the material’s internal structure, which can lead to early die failure. Conversely, non-conventional machining, such as EDM, eliminates mechanical contact, thereby preserving structural integrity. To comparatively assess the effects of both machining approaches, experiments were conducted under equivalent conditions, with parameters standardized based on material removal rate. The specific parameters used for conventional machining are presented in Table 4.

Table 4.

Machining parameters.

The machining framework for the non-conventional machining process, as presented in Table 4, is structured with reference to the material removal rate (MRR). Two identical threading dies, fabricated from the same material, were employed for external threading operations to facilitate the analysis of machining effects.

3.1. Analysis Parameters

- Microstructure analysis

- Effect on hardness

- Die strength (number of pieces produced)

The primary objective of this study is to compare the technical advantages of non-conventional machining over conventional methods in die fabrication. Non-conventional processes, capable of shaping materials from simple to highly complex geometries, were employed to minimize the adverse effects of machining on dying integrity. Cracks observed during production were attributed to material distortion caused by machining stress. The optimal machining process was determined based on three key criteria: higher number of parts produced, lower post-machining hardness, and larger grain area observed in microstructural analysis ensuring enhanced die performance and durability.

3.2. Experimental Methodology and Process Design

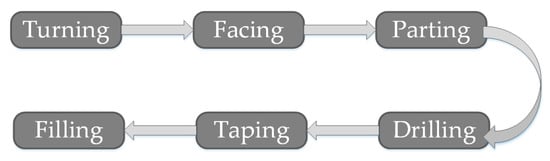

Experimental methodology and process design are as follows:

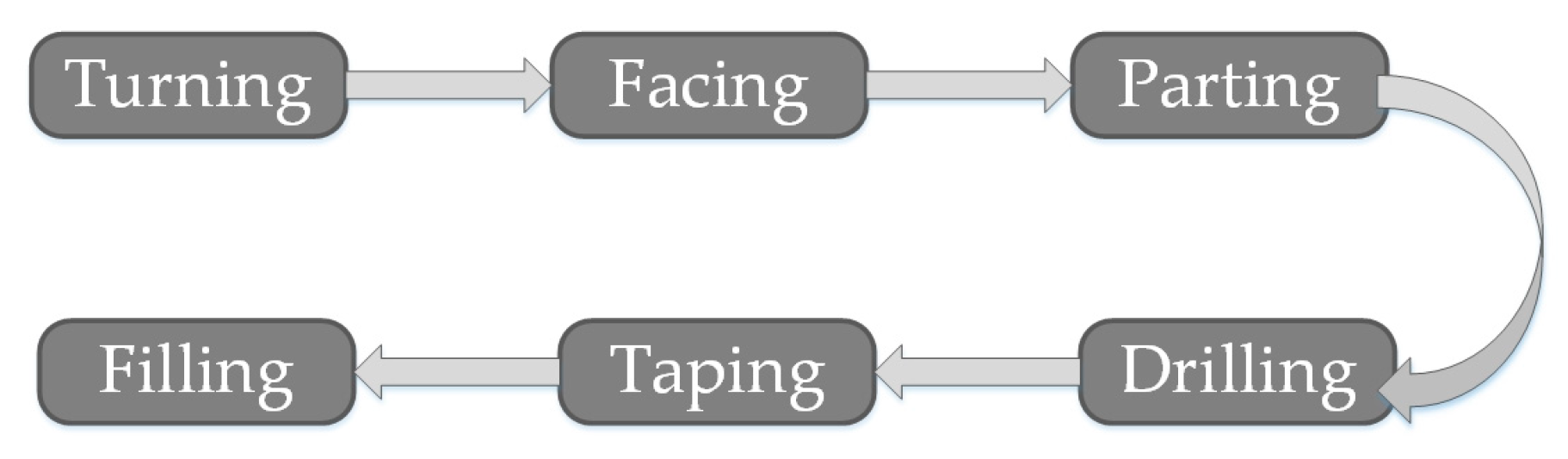

The conventional die fabrication sequence, illustrated in Figure 1, involves turning, facing, and parting, followed by drilling, tapping, and filling. An iterative loop from parting to drilling emphasizes precise dimension control before threading and final finishing operations.

Figure 1.

Process plan for conventional die.

3.2.1. Conventional Experimental Procedure

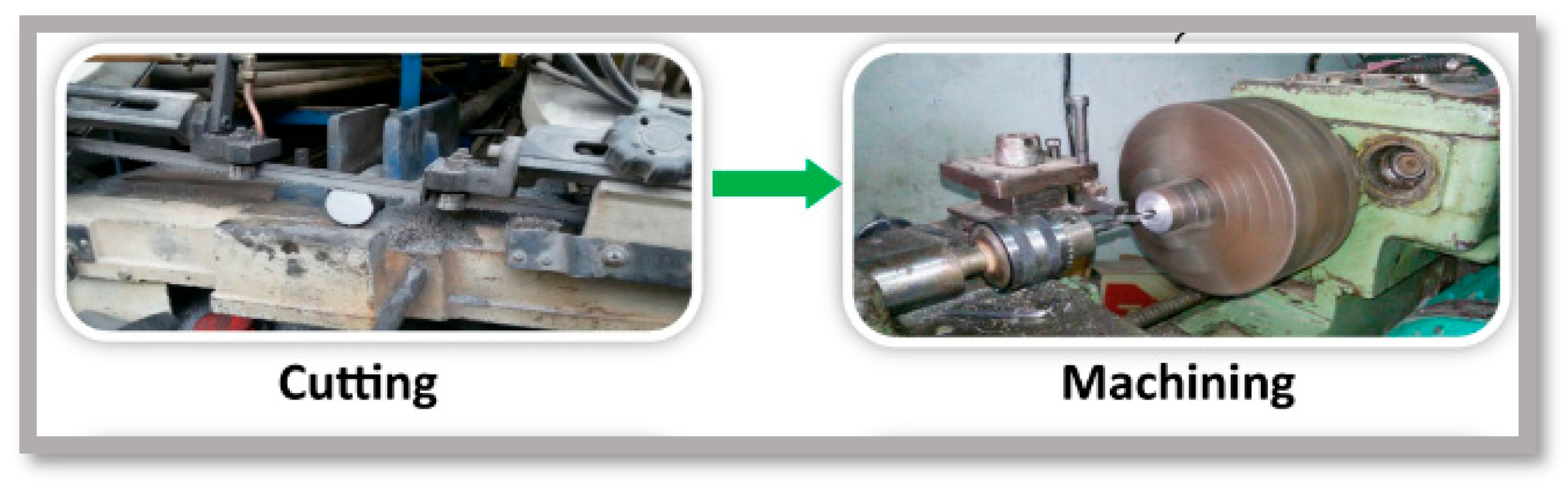

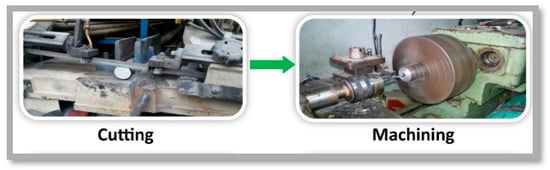

A die steel workpiece measuring 60 mm in length and 40 mm in width was selected for conventional machining. The surface was turned and faced, followed by cutting into 14 mm segments according to the specified die dimensions. Drilling operations were then performed to create 10 mm diameter holes. Tapping was carried out using a sequence of taper, second (bottoming), and plug taps. After side-hole tapping on the die face, the finishing process was completed through manual filing. The final holes maintained a consistent diameter of 10 mm, as illustrated in Figure 2.

Figure 2.

Conventional machining operation.

3.2.2. EDM

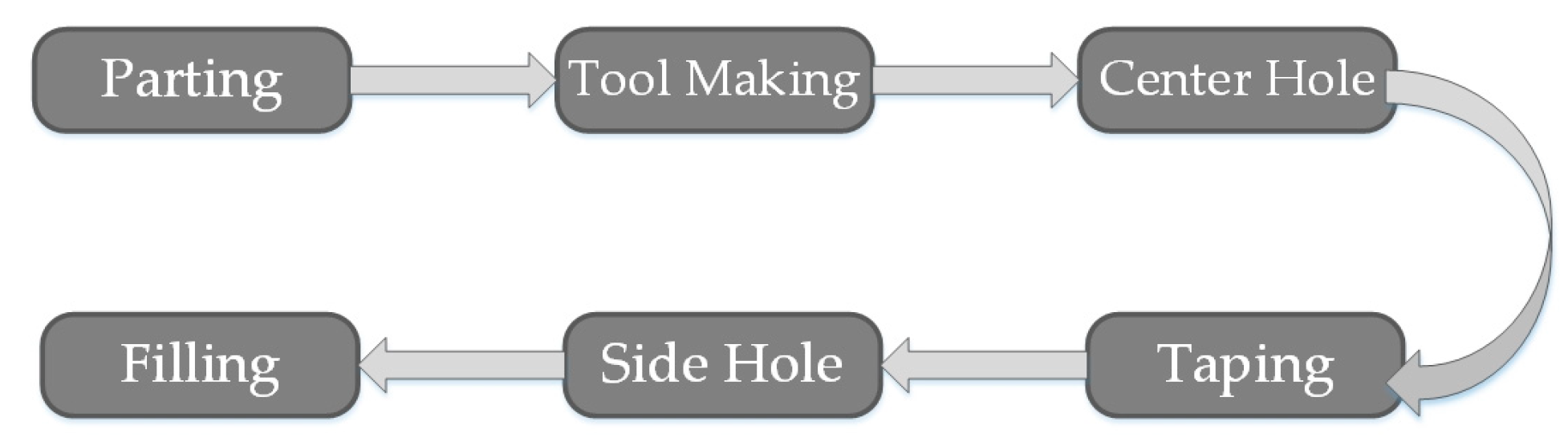

The fabrication of the non-conventional die using EDM was initiated in accordance with a structured process plan, following the sequential stages typically observed in conventional die manufacturing. The process begins with parting and tool preparation, followed by center hole drilling, tapping, side hole machining, and final filling. An iterative loop returning to the tapping stage after center hole formation is incorporated, as illustrated in Figure 3.

Figure 3.

Process plan for non-conventional die.

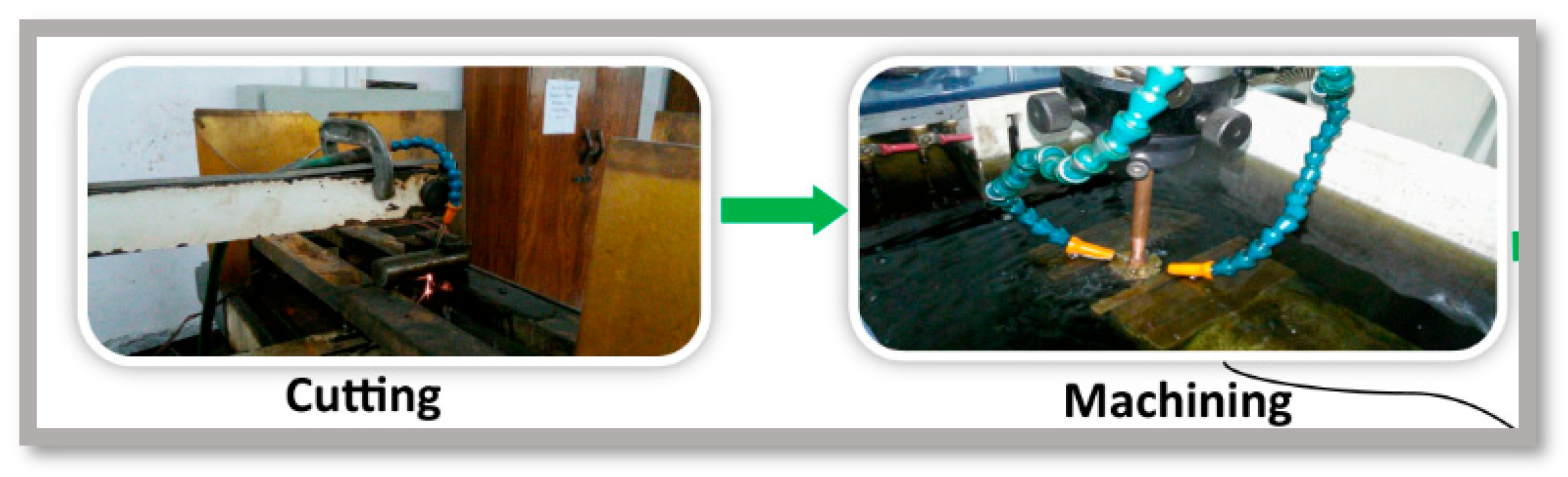

3.2.3. EDM Experimental Procedure

In this experiment, EDM metal-cutting and EDM mold-opening processes were employed for the fabrication of the non-conventional die. Copper tools were utilized as electrodes during the EDM mold-opening, with copper rods selected to match the required final dimensions of the mold cavity. EDM metal-cutting was applied for precise separation tasks, ensuring minimal impact on the workpiece. Centering operations were also performed using EDM, as illustrated in Figure 4. The copper electrode diameter was equivalent to the target hole size, allowing for accurate cavity formation. Threading was subsequently performed using taps, followed by EDM to complete and refine the side holes.

Figure 4.

Non-conventional machining processes.

3.2.4. Hardness Testing

Following the machining operations, hardness testing was conducted on both dies to evaluate the impact of the respective machining processes on material properties. The parameters used for hardness testing are presented in Table 5, while the results are detailed in the Results.

Table 5.

Rockwell Hardness Test parameters.

Following the hardness testing, the microstructure of the dies was analyzed to assess the effects of machining. Grain size determination was carried out in accordance with ASTM E112 using the planimetric method. Detailed microstructural results are presented in the Results Section 4. Subsequently, a heat treatment process was performed to enhance the dies’ capability for threading mild steel rods, enabling evaluation of die life and performance.

3.2.5. Heating

An electrical furnace is used (as shown in Figure 5) for heat treatment process of threading dies [16], which has a temperature range of approximately 1000 Celsius; we then used the water for the quenching of dies for hardening purpose. Both conventional and non-conventional tools can be heated in the oven. We preheated the mold to 800 degrees Celsius and then let the mold sit for 40 min (1 inch steel requires 1 h of holding time). The heating temperature of the two molds (normal mold and unusual mold) are the same.

Figure 5.

Heat treatment of dies.

3.2.6. Quenching

After the mold is completed, water is used as a quenching medium to increase the hardness of the mold. After quenching, the hardness of the dies are tested. As the hardness due to quenching increases from the range of hardness which is defined for the dies, tempering is needed for to achieve the required level.

3.2.7. Tempering of Threading Dies

Higher temperatures result in higher ductility and lower quality and hardness [17]. Low treating temperature does not provide ductility, but provides high strength and hardness. For mold tempering, we will preheat the mold to 500 degrees Celsius and give it a holding time of about an hour before removing the mold from the oven and cooling it at room temperature to keep our conditions non-ideal.

4. Results and Discussion

Analysis of this research is based on three factors, and every factor has its own importance. The following are the parameters of this research.

4.1. Hardness

Table 6 shows that the hardness of conventional die increased during the machining, and that it is the cause of failure. Increase in the hardness after machining is dangerous because when we heat-treat a hard die, it forms cracks in its internal structure, and this may be a cause of failure of the die at the initial stage.

Table 6.

Hardness Comparison.

The observed changes in the internal structure of the material are attributed to elevated cutting temperatures, mechanical stresses, and direct tool–workpiece contact inherent in conventional machining. These factors result in increased hardness, necessitating post-machining heat treatment to achieve the desired hardness range of 40–45 HRC for threading dies. Following water quenching, die hardness increased to 48–52 HRC, exceeding the required range; therefore, tempering was performed to reduce hardness. After tempering, the hardness of both dies was adjusted to 42–44 HRC, aligning with operational requirements. Since the non-conventional (EDM) process exhibited negligible hardness variation post-machining, it was deemed more suitable for die manufacturing. However, due to the relatively lower hardness of EDM-fabricated dies, this method may be less appropriate for applications requiring high-strength mold performance.

4.2. Microstructure Analysis

Planimetry involves precisely counting the number of objects in a known region. The number of grains per unit range NA is utilized to decide the ASTM grain measure number G. The precision of this strategy may be dependent on grain number.

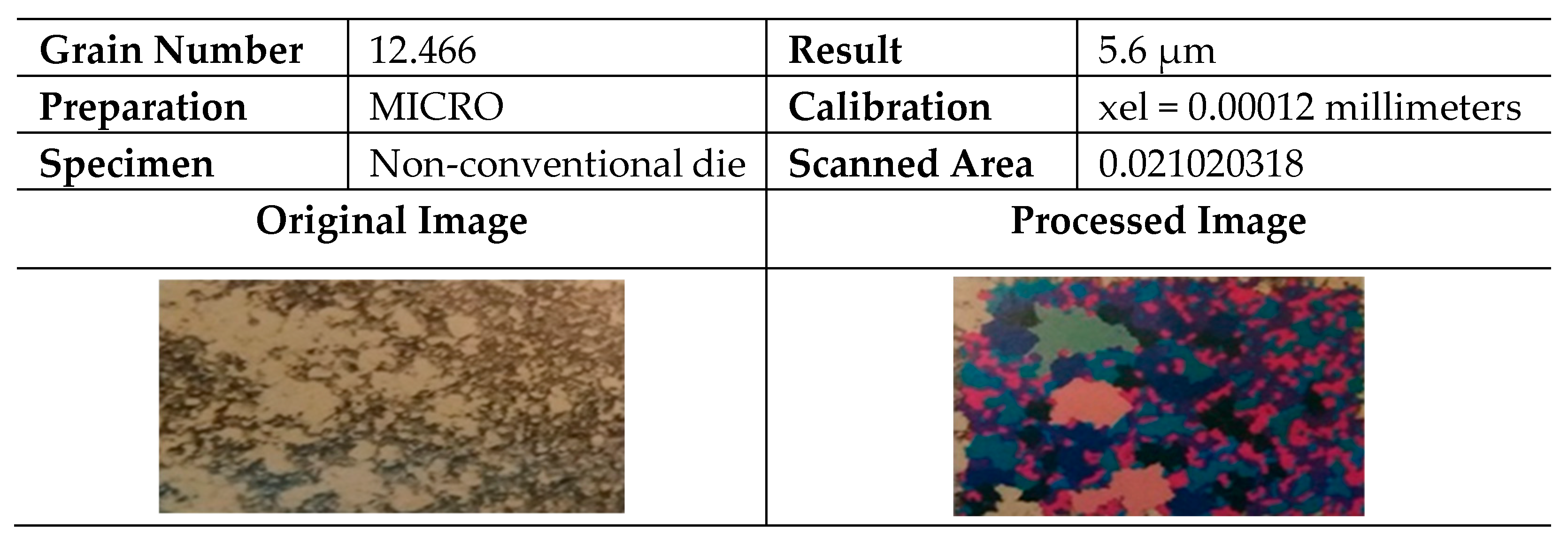

4.2.1. Non-Conventional Grain Size

Microstructure research reveals that the original picture displays the spacing between the grains and the prepared picture appears the grain number for Non-Conventional Pass on is 12.466 Figure 6 shows the result of microstructure test.

Figure 6.

Non-conventional grain size results.

The data presented in Table 7 indicate that the average grain diameter is approximately 5.6 µm, with a corresponding average grain area of 31.5 µm2.

Table 7.

Comparison of the results.

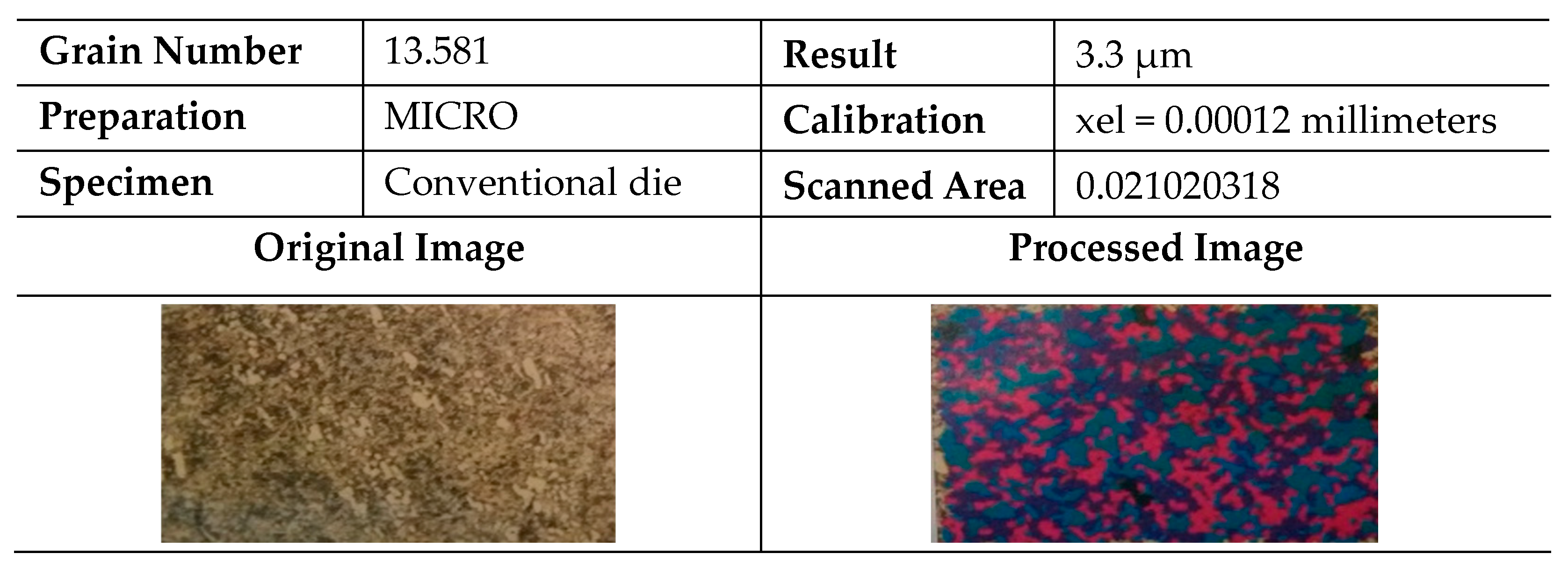

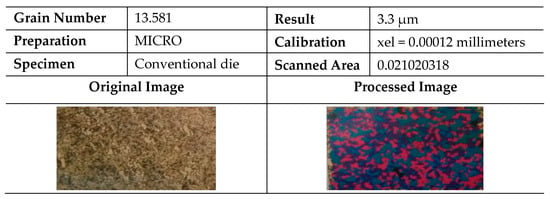

4.2.2. Conventional Die Grain Size

Microstructural analysis of the conventional die revealed distinct grain boundaries in the initial image, while the processed image yielded a grain number of 13.58. The corresponding grain diameter and structure are illustrated in Figure 7.

Figure 7.

Conventional die grain size results.

According to the standard grain size reference table, the average grain diameter for the conventional die is 3.3 µm, with an average grain area of 11.1 µm2. A comparative analysis of these results is presented in Table 7.

4.2.3. Number of Parts to Be Produced

The third parameter of this research is part to be produced. The following are the results of this parameter.

- Conventional Die: Dies are used to cut threads on small steel bars. We formed threads in the middle of the stick. The tool is made for MS bar thread lengths up to 16 inches (406.6 mm). It is brittle and its efficiency is low due to the hardness increase and change in its internal structure.

- Non-Conventional Die: These dies are very strong and very efficient. These are also used for the purpose of threading on the surface of MS steel rod. Non-conventional dies make thread up to 20 inches (508 mm) and these dies are now in working order.

The final dies, both conventional and non-conventional, with parts produced by both types of dies, are shown in Figure 8.

Figure 8.

Number of parts to be produced.

5. Conclusions and Recommendations

5.1. Conclusions

So, as a result, this study highlights the significant differences between conventional and non-conventional machining techniques in die fabrication, particularly in terms of material properties, efficiency, and failure mechanisms. The experimental results demonstrate that conventional machined dies are more prone to cracking, as evidenced by the substantial increase in hardness; the study demonstrated a significant difference in performance during threading operations. Conventional dies failed after threading up to 16 inches, whereas non-conventional dies were able to successfully produce threads up to 20 inches, indicating a longer operational lifespan. The observed mechanical stresses induced by conventional machines due to direct tool–workpiece contact contributed to increased hardness and were a primary factor leading to early die failure. Overall, the results underscore the superior advantages of non-conventional machining techniques, such as EDM, in die manufacturing, including improved precision, reduced hardness variations, and enhanced durability, which collectively offer a more reliable and efficient solution for die fabrication.

5.2. Recommendations

In future, this research work can be applied on a broad level in the industries for the manufacturing process of different dies.

- (1)

- Other tool steels or advanced materials with superior machinability, wear resistance, and thermal stability may be considered to enhance productivity. Potential alternatives includeAISI D2 Steel High: Good wear resistance and good toughness.AISI P20 Steel: Suitable for plastic mold applications with better machinability.AISI M2 High-Speed Steel: Offers excellent hardness and heat resistance.Titanium Alloys (Ti-6Al-4V): Lightweight with high strength and corrosion resistance.Carbide Composites: Enhanced durability for high-performance applications.

- (2)

- Advanced machining techniques like Water Jet Machining (WJM), Electrochemical Machining (ECM), and other precision manufacturing methods may be used to improve efficiency, accuracy, and overall part quality. The selection of the most suitable process should align with the material properties and desired performance characteristics.

Author Contributions

Z.A. contributed through supervision, methodological guidance, and final critical review of the overall work. M.U. led the research by conducting an extensive literature review, conceptualizing the research problem, designing the experiments, executing technical tasks, analyzing and interpreting data, writing the manuscript, and coordinating the overall project. A.K. assisted in the experimental setup, supported data collection and technical implementation, and contributed to drafting specific sections of the manuscript. M.H. contributed to data preprocessing, visualization, and supported the statistical analysis and interpretation of results. S.H.K. aided in refining the research methodology, conducting background research, and reviewing manuscript drafts. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article. Further inquiries can be directed at the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hazra, R.; Doloi, B. Non-conventional machining of SiC reinforced Aluminum metal matrix composites: A Review. J. Phys. Conf. Ser. 2024, 2818, 012035. [Google Scholar] [CrossRef]

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A comparison of traditional manufacturing vs additive manufacturing, the best method for the job. Procedia Manuf. 2019, 30, 11–18. [Google Scholar] [CrossRef]

- Manjaiah, M.; Narendranath, S.; Basavarajappa, S. Review on non-conventional machining of shape memory alloys. Trans. Nonferrous Met. Soc. China 2014, 24, 12–21. [Google Scholar] [CrossRef]

- Altan, T.; Lilly, B.; Yen, Y.C. Manufacturing of dies and molds. CiRP Ann. 2001, 50, 404–422. [Google Scholar] [CrossRef]

- Shabadi, A.M.H.; Ramesh, S.R.; Sharma, S.S. A comprehensive review on the conventional and non-conventional machining of nickel-titanium shape memory alloys. Metals 2023, 13, 585. [Google Scholar]

- Kim, K.S.; Okuyucu, C.; Pottore, N.S.; Zhu, H.; Tasan, C.C. Understanding cutting-induced reduction in sheet metal formability: An in-situ investigation of microstructural effects. J. Mater. Process. Technol. 2025, 341, 118894. [Google Scholar] [CrossRef]

- Li, Y.; Chen, X.; Zhang, J. The microstructure and properties change of dies manufactured by the bimetal-gradient-layer surfacing method. Int. J. Adv. Manuf. Technol. 2015, 78, 147–157. [Google Scholar]

- Younas, T.; Manzoor, M.; Kumari, J. Non-conventional machining processes as expedient alternatives for conventional machining processes. In Proceedings of the 2017 IEEE 3rd International Conference on Engineering Technologies and Social Sciences (ICETSS), Bangkok, Thailand, 7–8 August 2017. [Google Scholar]

- Hölker, R.; Tekkaya, A.E. Advancements in the manufacturing of dies for hot aluminum extrusion with conformal cooling channels. Int. J. Adv. Manuf. Technol. 2016, 83, 1209–1220. [Google Scholar] [CrossRef]

- Huang, Y.; Liang, S.Y. Material microstructure affected machining: A review. Int. J. Adv. Manuf. Technol. 2017, 88, 383–404. [Google Scholar]

- Kwame, J.S.; Yakushina, E.; Blackwell, P. Effect of machining induced microstructure changes on the edge formability of titanium alloys at room temperature. In Forming the Future; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Saoud, F.B.; Korkmaz, M.E. A review on machinability of shape memory alloys through traditional and non-traditional machining processes: A review. İmalat Teknol. Uygulamaları 2022, 3, 14–32. [Google Scholar] [CrossRef]

- Dunleavey, J.; Marimuthu, S.; Antar, M. Non-conventional machine of metal matrix composites. In Advances in Machining of Composite Materials: Conventional and Non-Conventional Processes; Springer International Publishing: Cham, Switzerland, 2021; pp. 183–217. [Google Scholar]

- Jawahir, I.S.; Stephenson, D.A.; Wang, B. A review of advances in modeling of conventional machining processes: From merchant to the present. J. Manuf. Sci. Eng. 2022, 144, 110801. [Google Scholar] [CrossRef]

- Bao, Z.J.; Yang, H.Y.; Dong, B.X.; Chang, F.; Li, C.D.; Jiang, Y.; Chen, L.Y.; Shu, S.L.; Jiang, Q.C.; Qiu, F. Development trend in composition optimization, microstructure manipulation, and strengthening methods of die steels under lightweight and integrated die casting. Materials 2023, 16, 6235. [Google Scholar] [CrossRef] [PubMed]

- Schlegel, J. Manufacturing Processes. In The World of Steel: On the History, Production and Use of a Basic Material; Springer: Wiesbaden, Germany, 2023; pp. 297–355. [Google Scholar]

- Lehmhus, D. Advances in metal casting technology: A review of State of the art, challenges and trends—Part II: Technologies new and revived. Metals 2024, 14, 334. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).