Investigation of Triple-Microcantilever Sensor for Ultra-Low Mass-Sensing Applications †

Abstract

1. Introduction

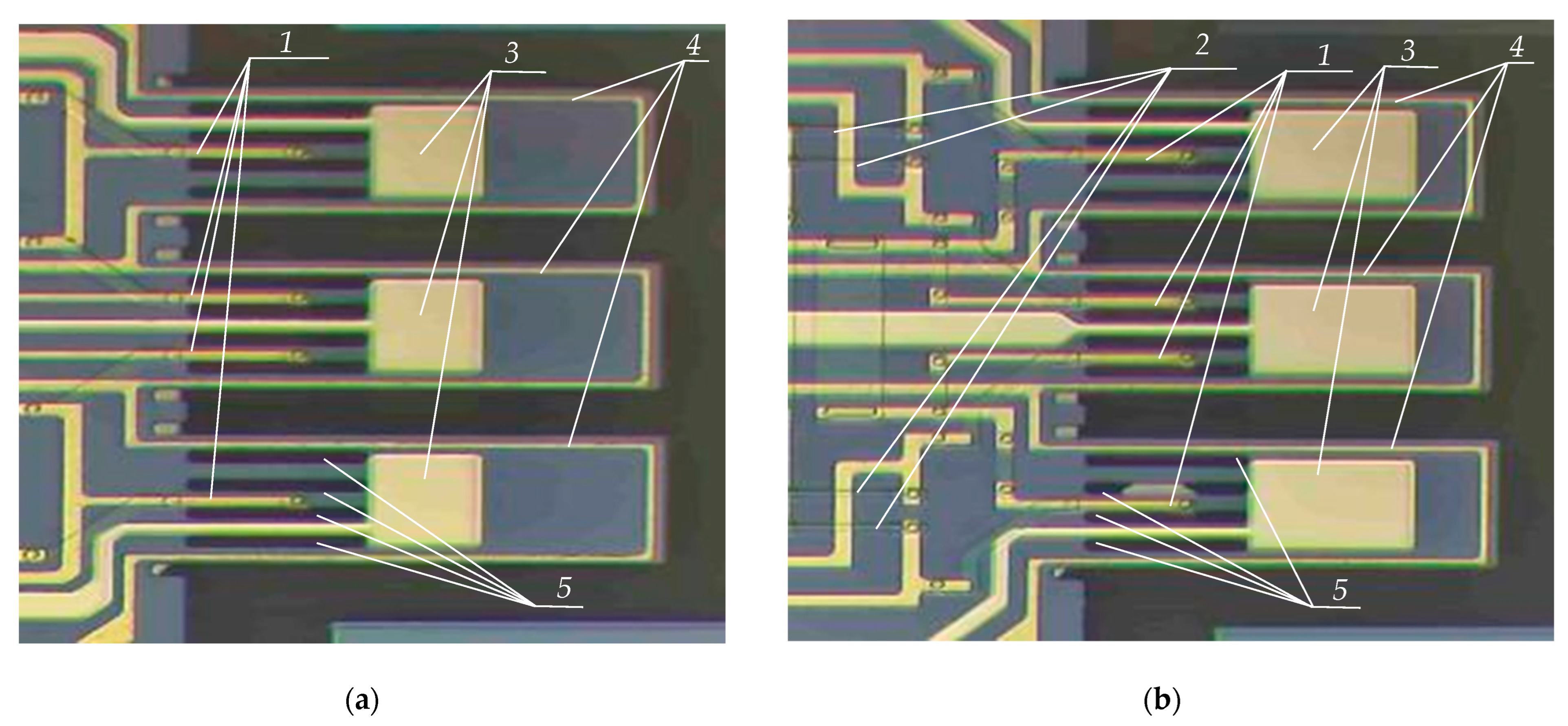

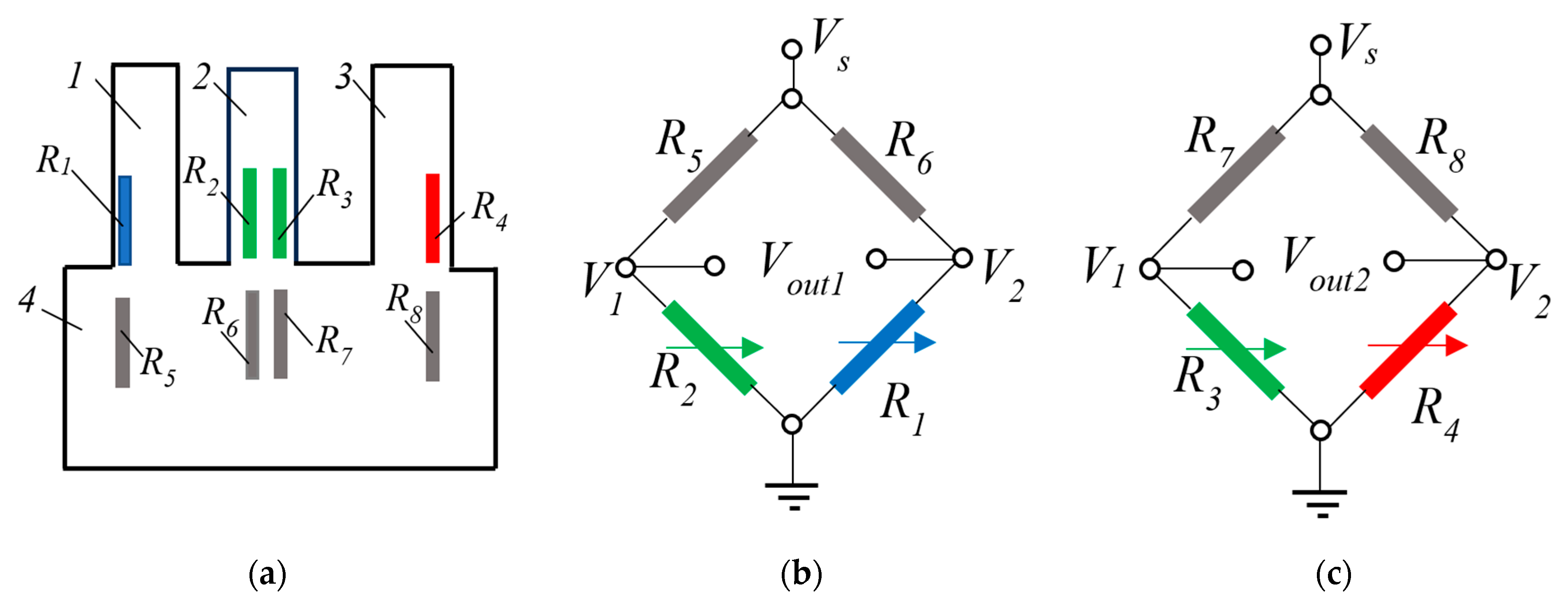

2. Design Concepts and Features of the Investigated Tri-Microcantilever Sensors

3. Compilation of an Electromechanical Model of the Triple-Microcantilever Sensor

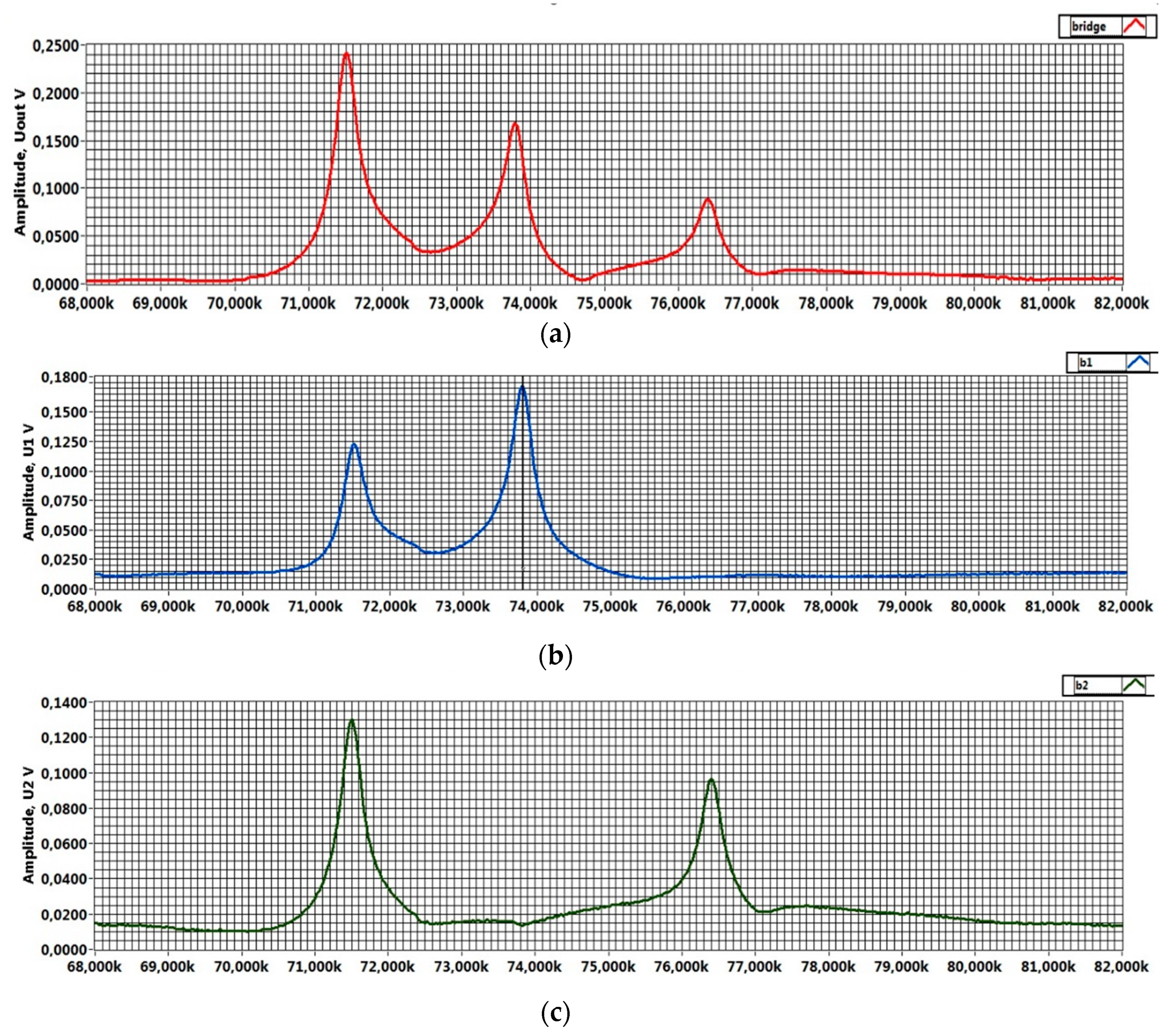

4. Experimental Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Koçum, C.; Ülgen, Ş.D.; Çubukçu, E.; Pişkin, E. Atomic Force Microscopy Tips (Cantilevers) as Molecular Nucleic Acid Sensors. Ultramicroscopy 2006, 106, 326–333. [Google Scholar] [CrossRef] [PubMed]

- Alunda, B.O.; Lee, Y.J. Review: Cantilever-Based Sensors for High Speed Atomic Force Microscopy. Sensors 2020, 20, 4784. [Google Scholar] [CrossRef] [PubMed]

- Ramos, D.; Calleja, M.; Mertens, J.; Zaballos, A.; Tamayo, J. Measurement of the Mass and Rigidity of Adsorbates on a Microcantilever Sensor. Sensors 2007, 7, 1834–1845. [Google Scholar] [CrossRef] [PubMed]

- Jin, D.; Li, X.; Liu, J.; Zuo, G.; Wang, Y.; Liu, M.; Yu, H. High-Mode Resonant Piezoresistive Cantilever Sensors for Tens-Femtogram Resoluble Mass Sensing in Air. J. Micromech. Microeng. 2006, 16, 1017–1023. [Google Scholar] [CrossRef]

- Lang, H.P.; Gerber, C. Microcantilever Sensors. In Topics in Current Chemistry; Samori, P., Ed.; Springer: Berlin/Heidelberg, Germany, 2008; Volume 285, pp. 1–27. [Google Scholar]

- Tang, L.; Xu, P.; Li, M.; Yu, H.; Li, X. Integrated Resonant Dual-Microcantilevers Combined Sensor with Accurate Identification and Highly-Sensitive Detection to H2S Gas. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019; pp. 338–341. [Google Scholar]

- Boisen, A.; Thundat, T. Design & Fabrication of Cantilever Array Biosensors. Mater. Today 2009, 12, 32–38. [Google Scholar] [CrossRef]

- Baller, M.K.; Lang, H.P.; Fritz, J.; Gerber, C.; Gimzewski, J.K.; Drechsler, U.; Rothuizen, H.; Despont, M.; Vettiger, P.; Battiston, F.M.; et al. A Cantilever Array-Based Artificial Nose. Ultramicroscopy 2000, 82, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Alodhayb, A.; Rahman, S.M.S.; Rahman, S.; Georghiou, P.E.; Beaulieu, L.Y. A 16-Microcantilever Array Sensing System for the Rapid and Simultaneous Detection of Analyte. Sens. Actuators B Chem. 2016, 237, 459–469. [Google Scholar] [CrossRef]

- Tian, F.; Hansen, K.M.; Ferrell, T.L.; Thundat, T.; Hansen, D.C. Dynamic Microcantilever Sensors for Discerning Biomolecular Interactions. Anal. Chem. 2005, 77, 1601–1606. [Google Scholar] [CrossRef] [PubMed]

- Banchelli, L.F.; Ganev, B.T.; Todorov, T.S. Sustainability Validation of a LabVIEW Based System for Biomarkers Detection. In Proceedings of the 2023 XXXII International Scientific Conference Electronics (ET), Sozopol, Bulgaria, 13–15 September 13 2023; pp. 1–6. [Google Scholar]

- Banchelli, L.; Todorov, G.; Stavrov, V.; Ganev, B.; Todorov, T. Evaluation of the Influence of Lorentz Forces on the Natural Frequencies of a Dual-Microcantilever Sensor for Ultralow Mass Detection. Micro 2024, 4, 572–584. [Google Scholar] [CrossRef]

- Banchelli, L.; Todorov, G.; Stavrov, V.; Ganev, B.; Todorov, T. Investigating a Detection Method for Viruses and Pathogens Using a Dual-Microcantilever Sensor. Micromachines 2024, 15, 1117. [Google Scholar] [CrossRef] [PubMed]

- Pakdast, H.; Lazzarino, M. Triple Coupled Cantilever Systems for Mass Detection and Localization. Sens. Actuators A Phys. 2012, 175, 127–131. [Google Scholar] [CrossRef]

- NT-MDT Spectrum Instruments. Theoretical Background of SPM, 2.1.2 Deflections Under the Vertical (Normal) Force Component. Available online: https://www.ntmdt-si.com/resources/spm-theory/theoretical-background-of-spm/2-scanning-force-microscopy-(sfm)/21-cantilever/212-deflections-under-the-vertical-normal-force-component (accessed on 3 April 2025).

- Allen, J.J. Micro Electro Mechanical System Design, 1st ed.; Taylor & Francis Group, LLC: Boca Raton, FL, USA, 2005; Volume 1. [Google Scholar]

- Liu, C. Foundations of MEMS, 2nd ed.; Prentice Hall, 2 Pearson Education, Inc.: Upper Saddle River, NJ, USA, 2011. [Google Scholar]

- Salehi-Khojin, A.; Bashash, S.; Jalili, N.; Müller, M.; Berger, R. Nanomechanical Cantilever Active Probes for Ultrasmall Mass Detection. J. Appl. Phys. 2009, 105, 013506. [Google Scholar] [CrossRef]

- Davis, Z.J.; Abadal, G.; Helbo, B.; Hansen, O.; Campabadal, F.; Pérez-Murano, F.; Esteve, J.; Figueras, E.; Verd, J.; Barniol, N.; et al. Monolithic Integration of Mass Sensing Nano-Cantilevers with CMOS Circuitry. Sens. Actuators A Phys. 2003, 105, 311–319. [Google Scholar] [CrossRef]

- Gil-Santos, E.; Ramos, D.; Jana, A.; Calleja, M.; Raman, A.; Tamayo, J. Mass Sensing Based on Deterministic and Stochastic Responses of Elastically Coupled Nanocantilevers. Nano Lett. 2009, 9, 4122–4127. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.W.; Liew, K.M.; He, L.H. Ultra-Sensitive Analysis of a Cantilevered Single-Walled Carbon Nanocone-Based Mass Detector. Nanotechnology 2013, 24, 125703. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banchelli, L.; Stavrov, V.; Ganev, B.; Nikolov, N.; Todorov, T. Investigation of Triple-Microcantilever Sensor for Ultra-Low Mass-Sensing Applications. Eng. Proc. 2025, 100, 60. https://doi.org/10.3390/engproc2025100060

Banchelli L, Stavrov V, Ganev B, Nikolov N, Todorov T. Investigation of Triple-Microcantilever Sensor for Ultra-Low Mass-Sensing Applications. Engineering Proceedings. 2025; 100(1):60. https://doi.org/10.3390/engproc2025100060

Chicago/Turabian StyleBanchelli, Luca, Vladimir Stavrov, Borislav Ganev, Nikolay Nikolov, and Todor Todorov. 2025. "Investigation of Triple-Microcantilever Sensor for Ultra-Low Mass-Sensing Applications" Engineering Proceedings 100, no. 1: 60. https://doi.org/10.3390/engproc2025100060

APA StyleBanchelli, L., Stavrov, V., Ganev, B., Nikolov, N., & Todorov, T. (2025). Investigation of Triple-Microcantilever Sensor for Ultra-Low Mass-Sensing Applications. Engineering Proceedings, 100(1), 60. https://doi.org/10.3390/engproc2025100060