Abstract

This study focuses on optimizing the laser micromachining process to achieve precise geometric features. The main objective is to develop a systematic approach for analyzing the process parameters that influence the repeatability of laser material removal for edge-rounding of 50 and 75 μm in radius. The research employs the Taguchi method for the experimental design, allowing the identification of optimal process parameters that ensure high consistency. Repeatability is assessed through the evaluation of eight consecutive layers in depth, where the laser removes material, and the average depth is calculated by dividing the total removed depth by eight. This statistical approach allows for a comprehensive analysis of process stability. A key aspect of this study is the development of a predictive model based on experimental data, allowing a selection of the most influential parameters to achieve the desired outcome. By implementing a structured optimization process, this research aims to enhance process efficiency, minimize deviations, and improve the overall quality of laser micromachining. These findings contribute to the advancement of precision manufacturing techniques by providing a reliable methodology for process control and repeatability enhancement.

1. Introduction

In modern manufacturing, precision and repeatability are essential for achieving high-quality products. Laser processing has emerged as a key technology in micromachining, offering unparalleled accuracy and control over material removal. With applications spanning industries such as aerospace, medical devices, and electronics, laser-based techniques enable the fabrication of complex geometries with minimal material waste and high efficiency. However, optimizing laser processing parameters remains a critical challenge due to the multitude of factors influencing material interaction, including laser power, scanning speed, pulse duration, and focal positioning [1,2,3,4].

To address these challenges, experimental design methods play a crucial role in systematically analyzing and optimizing the process parameters. Among these, the Taguchi method and other statistical approaches provide structured frameworks for identifying the most significant factors affecting process stability and repeatability. By minimizing variability and enhancing robustness, these methods contribute to the development of efficient and reliable laser machining processes. Experimental planning allows for the reduction of trial-and-error iterations, leading to more predictable and reproducible outcomes [3,4,5,6,7].

This study focuses on the laser micromachining of cutting inserts made from cubic boron nitride (CBN), a material known for its exceptional hardness and thermal stability. Due to its widespread application in precision machining, optimizing laser processing parameters for CBN is crucial to achieving consistent and high-quality results. This paper explores the application of experimental design techniques in laser micromachining, aiming to improve process control and optimize key parameters. By leveraging statistical models and systematic experimentation, this research seeks to enhance the repeatability of laser processing, ensuring high precision and consistency in manufactured components [6,8,9,10,11].

2. Materials and Methods

To achieve precision and repeatability in laser processing, a structured methodology is essential. This study employs a systematic approach based on experimental design techniques to identify and optimize the key process parameters influencing laser material removal. By utilizing statistical models, this research ensures that the process is both efficient and highly controllable [11,12,13,14].

A crucial aspect of the approach is the application of design of experiment (DOE) methods, with a particular focus on the Taguchi method. This technique allows for a systematic variation in multiple parameters to determine their effect on process stability and repeatability. By optimizing the experimental setup, this study aims to minimize deviations and enhance the robustness of the laser machining process [15,16,17].

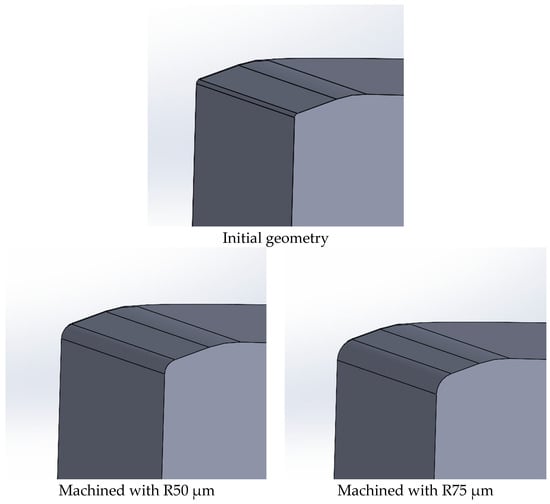

On Figure 1 is shown 3D models of the cutting edge of the insert – the initial geometry and the targeted geometry with 50µm and 75µm radii.

Figure 1.

Virtual modeling of target geometry.

The methodology involves layer-by-layer analysis, where the material removal consistency is evaluated through repeated laser passes. This step enables the extraction of statistical insights, ensuring that the chosen parameters lead to a predictable and uniform machining outcome. Additionally, data-driven modeling techniques are employed to assess the influence of critical variables and refine the process further [15].

3. Results

3.1. Experimental Results and Process Evaluation

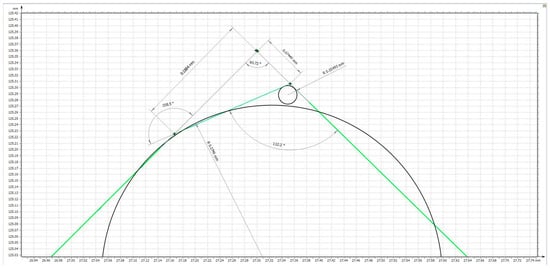

To evaluate the effect of laser processing on the plate, an initial measurement is performed on the edge zone of the unprocessed plate (Figure 2). This measurement provides information about the initial geometry and any deviations in the microtopography that could influence the process. Analyzing these initial characteristics is essential for comparison with the results after laser processing.

Figure 2.

Initial measurement on the plate.

The approach involves systematic experimentation using the Taguchi experimental design method to achieve the precise rounding of 50 and 75 µm radii to determine the process parameters that ensure the highest repeatability of material removal.

For finding the best results, six key process parameters for achieving a systematic and stable cutting depth in laser processing are examined (Table 1). These parameters include the depth per cut (mm), scanning speed (mm/s), laser frequency (kHz), pulse duration (µm), on delay (µs), and off delay (µs). To systematically analyze their impact on repeatability, a Taguchi L8 (27) orthogonal array was employed.

Table 1.

Taguchi design of experiment and process parameters.

For the engraving radii, the Lasertec 40 3D by DMG high-precision laser machining system was used (Figure 3). The machine is situated in Technical University of Sofia, Bulgaria.

Figure 3.

Lasertec 40 SAUER.

The laser ablation process was carried out by scanning the material surface layer by layer, with each test consisting of eight consecutive layers. As the laser ablated the material, the depth of each layer was measured and averaged to assess the consistency of the process. The recorded depth values from each experiment were used to calculate the mean depth per layer, providing a quantitative assessment of the cutting precision and repeatability.

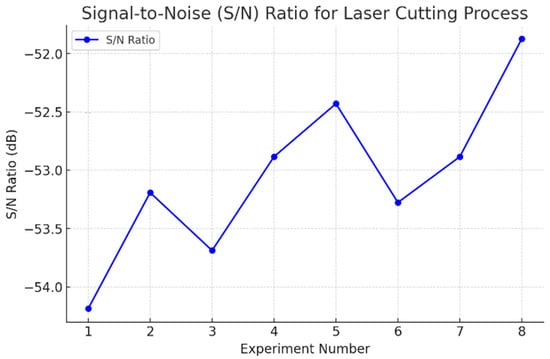

A signal-to-noise (S/N) ratio analysis was performed (Figure 4) to identify the most influential parameters for optimal repeatability.

Figure 4.

A signal-to-noise (S/N) ratio analysis.

The signal-to-noise (S/N) ratio analysis identifies Experiment 8 as the optimal configuration, as it exhibits the highest S/N ratio. A higher S/N ratio implies greater stability and consistency in the process, minimizing the impact of external variations. The superior performance of Experiment 8 can be attributed to the specific combination of parameters, particularly the depth per cut (0.0025 mm), scanning speed (600 mm/s), and frequency (60 kHz), which likely contribute to a more controlled material removal process.

Table 2 presents the average layer thickness measured at different depths for four probes. The arithmetic mean value of 2.54465 µm suggests a stable and repeatable process, as the variations in layer thickness across different depths remain minimal. The relationship between these values and process repeatability lies in their consistency—if the depth per layer were highly variable, it would indicate fluctuations in material removal, leading to reduced repeatability. The near-constant thickness observed here confirms that the laser micromachining process maintains a uniform removal rate across consecutive layers, contributing to enhanced precision and repeatability.

Table 2.

Laser experimental calibration.

3.2. Assessment of Accuracy

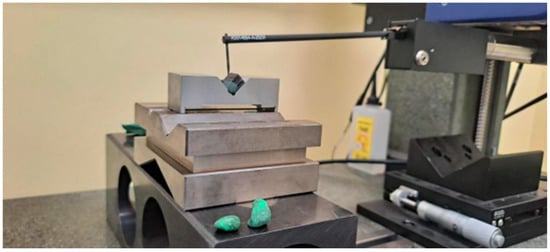

To evaluate the precision of the laser cut radii, a physical measurement was conducted. The setup consisted of a high-resolution optical measurement system contour tracer profilometer Form Talysurf i-Series (Figure 5), capturing the detailed geometry of the processed edges. The machine is manufactured by Taylor Hobson (Leicester, England)

Figure 5.

Measurement equipment.

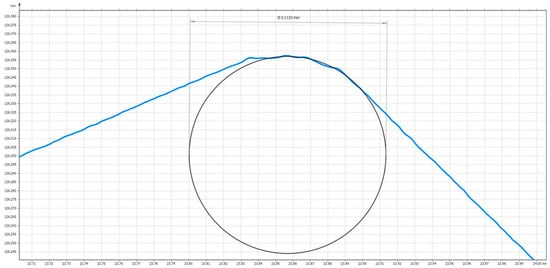

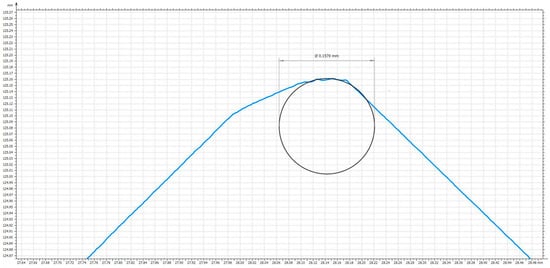

The measured radii were analyzed using a profile evaluation method, comparing the achieved shapes to the intended 50 µm and 75 µm targets. The results indicate actual radii of 56 µm and 78 µm, respectively (Figure 6 and Figure 7). These findings provide insight into the accuracy of the selected process parameters and highlight potential areas for further optimization.

Figure 6.

Measurement results of radius ~56 µm.

Figure 7.

Measurement results of radius ~78 µm.

The results demonstrate a high level of precision in laser machining, with the achieved radii of 56 µm and 78 µm closely matching the target values of 50 µm and 75 µm, respectively. These minimal deviations (+6 µm and +3 µm) indicate excellent process stability and repeatability.

4. Conclusions

This study successfully optimized laser machining parameters to achieve the precise edge-rounding of 50 µm and 75 µm radii using the Taguchi method. By systematically analyzing six key process parameters, this research identified an optimal parameter set that ensures high repeatability and minimal deviation.

The experimental results demonstrated that the achieved radii (56 µm and 78 µm) closely match the target values, confirming the stability and precision of the laser processing method. Signal-to-noise (S/N) ratio analysis further validated the process robustness, identifying the most influential parameters contributing to repeatable material removal.

These findings contribute to high-precision manufacturing, offering a reliable methodology for optimizing laser cutting processes. Future work may focus on further refinement of parameters to minimize deviations and enhance control over micro-scale machining.

Author Contributions

Conceptualization, T.G. and Y.S.; methodology, H.N.; software, A.T.; formal analysis, H.N.; investigation, T.T.T.; resources, A.T.; data curation, A.T.; writing-original draft properation, T.T.T.; writing-review and editing, T.T.T.; project administration, T.G.; funding acquisition, Y.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Union–Next Generation EU through the National Recovery and Resilience Plan of the Republic of Bulgaria, project № BG-RRP-2.004-0005, and supported by the program “Research, Innovation and Digitalization for Smart Transformation,” co-financed by the European Regional Development Fund, Grant Agreement No. BG16RFPR002-1.014-0014-C01, “Development and Sustainability Program with a Business Plan for a Laboratory Complex at Sofia Tech Park”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The equipment for this study is financed by the European Union-Next Generation EU through the National Recovery and Resilience Plan of the Republic of Bulgaria, project № BG-RRP-2.004-0005. This work is supported by the program “Research, Innovation and Digitalization for Smart Transformation, “co-financed by the European Regional Development Fund, Grant Agreement No. BG16RFPR002-1.014-0014-C01, “Development and Sustainability Program with a Business Plan for a Laboratory Complex at Sofia Tech Park”.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kasman, Ş.; Saklakoglu, I.E. Determination of process parameters in the laser micromilling application using Taguchi method: A case study for AISI H13 tool steel. Int. J. Adv. Manuf. Technol. 2012, 58, 201–209. [Google Scholar] [CrossRef]

- Sun, Y.Q.; Zhou, J.Z.; Chen, Y.B.; Huang, S. Optimization of laser peening parameters using Taguchi method. Appl. Mech. Mater. 2007, 10–12, 692–696. [Google Scholar] [CrossRef]

- Lin, H.L.; Chou, C.P. Modeling and optimization of Nd:YAG laser micro-weld process using Taguchi method and a neural network. Int. J. Adv. Manuf. Technol. 2007, 37, 513–522. [Google Scholar] [CrossRef]

- Badkar, D.S.; Pandey, K.S.; Buvanashekaran, G. Parameter optimization of laser transformation hardening by using Taguchi method and utility concept. Int. J. Adv. Manuf. Technol. 2010, 52, 1067–1077. [Google Scholar] [CrossRef]

- Velotti, C.; Astarita, A.; Leone, C.; Genna, S.; Memola Capece Minutolo, F.; Squillace, A. Surface laser marking optimization using an experimental design approach. Appl. Phys. A 2017, 123, 80. [Google Scholar]

- Chae, J.; Park, S.S.; Freiheit, T. Investigation of micro-cutting operations. Int. J. Mach. Tools Manuf. 2006, 46, 313–332. [Google Scholar] [CrossRef]

- Kandeva, M.; Zagorski, M.; Nikolić, R.; Stojanović, B.; But, A.; Botko, F.; Piteľ, J.; Vencl, A. Friction Properties of the Heat-Treated Electroless Ni Coatings Embedded with c-BN Nanoparticles. Coatings 2022, 12, 1008. [Google Scholar] [CrossRef]

- Pham, D.T.; Dimov, S.S.; Ji, C.; Petkov, P.V.; Dobrev, T. Laser milling as a ‘rapid’ micromanufacturing process. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2004, 218, 1–7. [Google Scholar] [CrossRef]

- Dubey, A.K.; Yadava, V. Experimental study of Nd:YAG laser beam machining—An overview. J. Mater. Process. Technol. 2008, 195, 15–26. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Ludovico, A.D.; Bonserio, C.; Cavalluzzi, P.; Cinquepalmi, M. Experimental analysis of the laser milling process parameters. J. Mater. Process. Technol. 2007, 191, 220–223. [Google Scholar] [CrossRef]

- Yang, W.H.; Tarng, Y.S. Design optimization of cutting parameters for turning operations based on the Taguchi method. J. Mater. Process. Technol. 1998, 84, 122–129. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, Y.F.; Wang, D.A.; Li, H.S. Optimization of machining parameters in magnetic force assisted EDM based on Taguchi method. J. Mater. Process. Technol. 2009, 209, 3374–3383. [Google Scholar] [CrossRef]

- Savaş, Ö.; Kayıkçı, R. Application of Taguchi’s methods to investigate some factors affecting microporosity formation in A360 aluminium alloy casting. Mater. Des. 2007, 28, 2224–2228. [Google Scholar] [CrossRef]

- He, X.; Yu, Z.; Lai, X. Robust parameters control methodology of microstructure for heavy forgings based on Taguchi method. Mater. Des. 2009, 30, 2084–2089. [Google Scholar] [CrossRef]

- Milanova, G.; Zagorski, M.; Petrov, K.; Kandeva, M.; Rangelov, R. Influence of graphite particle size on microhardness and roughness of refractory coatings. J. Balk. Tribol. Assoc. 2023, 29, 87–96. [Google Scholar]

- Puertas, I.; Luis, C.J. A study on the machining parameters optimization of electrical discharge machining. J. Mater. Process. Technol. 2003, 143–144, 521–526. [Google Scholar] [CrossRef]

- Su, C.T.; Chiang, T.L. Optimizing the IC wire bonding process using a neural networks/genetic algorithms approach. J. Intell. Manuf. 2003, 14, 229–238. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).