Optimization of Accuracy and Repeatability in Laser Micro-Processing Using Experimental Design †

Abstract

1. Introduction

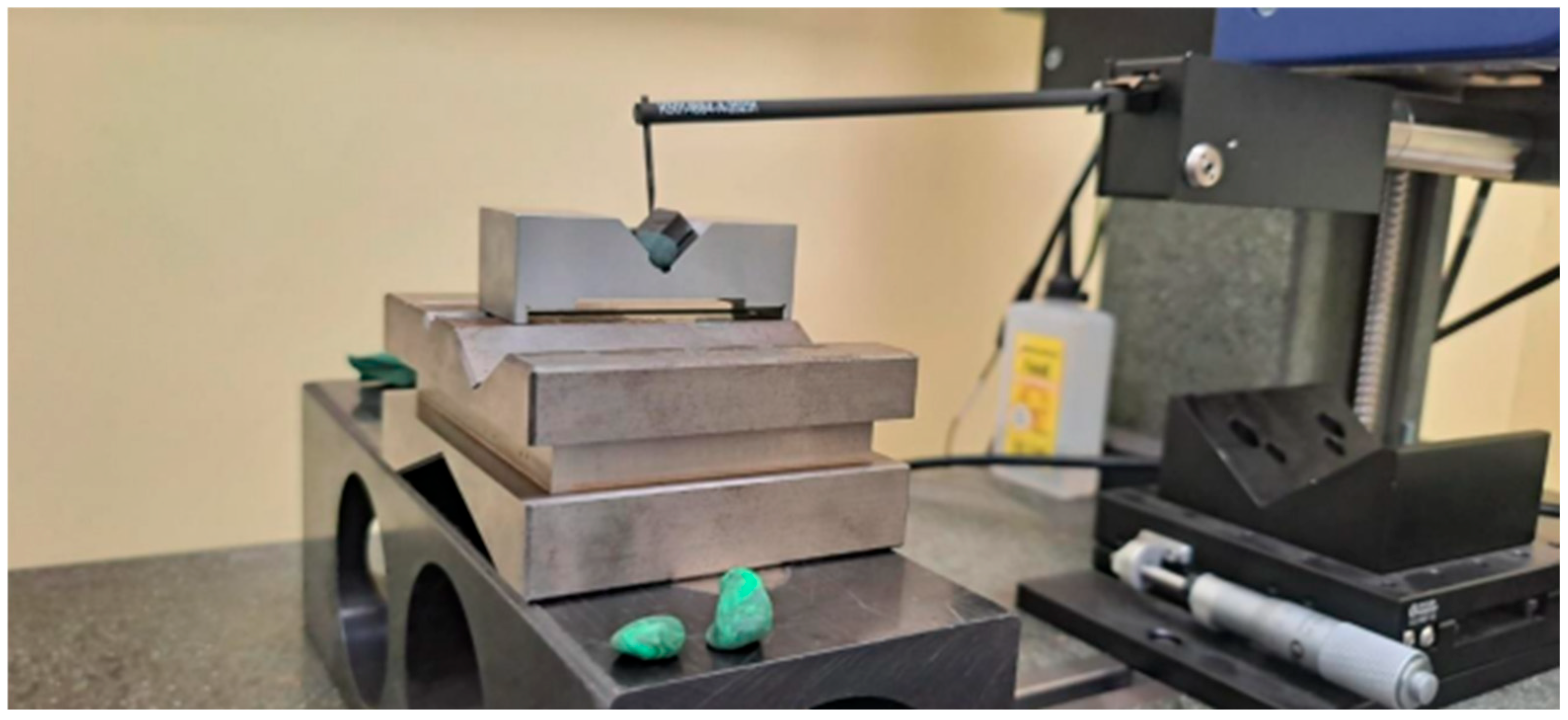

2. Materials and Methods

3. Results

3.1. Experimental Results and Process Evaluation

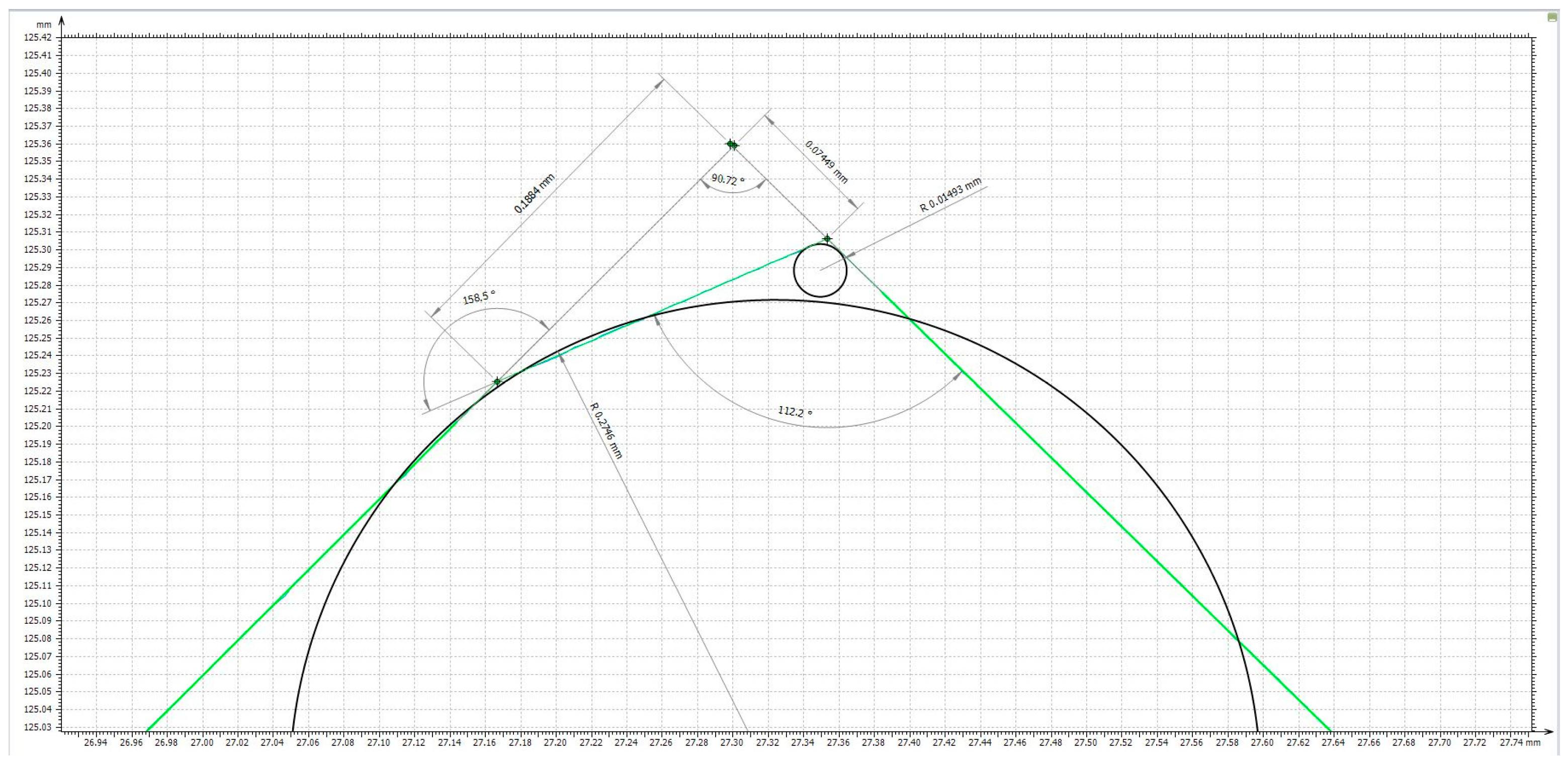

3.2. Assessment of Accuracy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kasman, Ş.; Saklakoglu, I.E. Determination of process parameters in the laser micromilling application using Taguchi method: A case study for AISI H13 tool steel. Int. J. Adv. Manuf. Technol. 2012, 58, 201–209. [Google Scholar] [CrossRef]

- Sun, Y.Q.; Zhou, J.Z.; Chen, Y.B.; Huang, S. Optimization of laser peening parameters using Taguchi method. Appl. Mech. Mater. 2007, 10–12, 692–696. [Google Scholar] [CrossRef]

- Lin, H.L.; Chou, C.P. Modeling and optimization of Nd:YAG laser micro-weld process using Taguchi method and a neural network. Int. J. Adv. Manuf. Technol. 2007, 37, 513–522. [Google Scholar] [CrossRef]

- Badkar, D.S.; Pandey, K.S.; Buvanashekaran, G. Parameter optimization of laser transformation hardening by using Taguchi method and utility concept. Int. J. Adv. Manuf. Technol. 2010, 52, 1067–1077. [Google Scholar] [CrossRef]

- Velotti, C.; Astarita, A.; Leone, C.; Genna, S.; Memola Capece Minutolo, F.; Squillace, A. Surface laser marking optimization using an experimental design approach. Appl. Phys. A 2017, 123, 80. [Google Scholar]

- Chae, J.; Park, S.S.; Freiheit, T. Investigation of micro-cutting operations. Int. J. Mach. Tools Manuf. 2006, 46, 313–332. [Google Scholar] [CrossRef]

- Kandeva, M.; Zagorski, M.; Nikolić, R.; Stojanović, B.; But, A.; Botko, F.; Piteľ, J.; Vencl, A. Friction Properties of the Heat-Treated Electroless Ni Coatings Embedded with c-BN Nanoparticles. Coatings 2022, 12, 1008. [Google Scholar] [CrossRef]

- Pham, D.T.; Dimov, S.S.; Ji, C.; Petkov, P.V.; Dobrev, T. Laser milling as a ‘rapid’ micromanufacturing process. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2004, 218, 1–7. [Google Scholar] [CrossRef]

- Dubey, A.K.; Yadava, V. Experimental study of Nd:YAG laser beam machining—An overview. J. Mater. Process. Technol. 2008, 195, 15–26. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Ludovico, A.D.; Bonserio, C.; Cavalluzzi, P.; Cinquepalmi, M. Experimental analysis of the laser milling process parameters. J. Mater. Process. Technol. 2007, 191, 220–223. [Google Scholar] [CrossRef]

- Yang, W.H.; Tarng, Y.S. Design optimization of cutting parameters for turning operations based on the Taguchi method. J. Mater. Process. Technol. 1998, 84, 122–129. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, Y.F.; Wang, D.A.; Li, H.S. Optimization of machining parameters in magnetic force assisted EDM based on Taguchi method. J. Mater. Process. Technol. 2009, 209, 3374–3383. [Google Scholar] [CrossRef]

- Savaş, Ö.; Kayıkçı, R. Application of Taguchi’s methods to investigate some factors affecting microporosity formation in A360 aluminium alloy casting. Mater. Des. 2007, 28, 2224–2228. [Google Scholar] [CrossRef]

- He, X.; Yu, Z.; Lai, X. Robust parameters control methodology of microstructure for heavy forgings based on Taguchi method. Mater. Des. 2009, 30, 2084–2089. [Google Scholar] [CrossRef]

- Milanova, G.; Zagorski, M.; Petrov, K.; Kandeva, M.; Rangelov, R. Influence of graphite particle size on microhardness and roughness of refractory coatings. J. Balk. Tribol. Assoc. 2023, 29, 87–96. [Google Scholar]

- Puertas, I.; Luis, C.J. A study on the machining parameters optimization of electrical discharge machining. J. Mater. Process. Technol. 2003, 143–144, 521–526. [Google Scholar] [CrossRef]

- Su, C.T.; Chiang, T.L. Optimizing the IC wire bonding process using a neural networks/genetic algorithms approach. J. Intell. Manuf. 2003, 14, 229–238. [Google Scholar] [CrossRef]

| Experiment | Depth per Cut (mm) | Speed (mm/s) | Frequency (kHz) | Pulse Duration (µm) | On Delay (µs) | Off Delay (µs) |

|---|---|---|---|---|---|---|

| 1 | 0.002 | 500 | 50 | 8 | 800 | 150 |

| 2 | 0.002 | 500 | 60 | 10 | 854 | 165 |

| 3 | 0.002 | 600 | 50 | 10 | 800 | 165 |

| 4 | 0.002 | 600 | 60 | 8 | 854 | 150 |

| 5 | 0.0025 | 500 | 50 | 10 | 854 | 150 |

| 6 | 0.0025 | 500 | 60 | 8 | 800 | 165 |

| 7 | 0.0025 | 600 | 50 | 8 | 854 | 165 |

| 8 | 0.0025 | 600 | 60 | 10 | 854 | 165 |

| Probe 1 | Probe 2 | Probe 3 | Probe 4 | |

|---|---|---|---|---|

| Layers | µm | µm | µm | µm |

| 8 | 2.005 | 2.453 | 2.656 | 2.671 |

| 16 | 2.043 | 2.608 | 2.594 | 2.446 |

| 32 | 2.551 | 2.738 | 2.897 | 2.728 |

| 40 | 2.44 | 2.381 | 2.095 | 3.195 |

| 48 | 2.193 | 2.912 | 2.555 | 2.732 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gavrilov, T.; Todorov, T.T.; Sofronov, Y.; Nikolova, H.; Todorov, A. Optimization of Accuracy and Repeatability in Laser Micro-Processing Using Experimental Design. Eng. Proc. 2025, 100, 11. https://doi.org/10.3390/engproc2025100011

Gavrilov T, Todorov TT, Sofronov Y, Nikolova H, Todorov A. Optimization of Accuracy and Repeatability in Laser Micro-Processing Using Experimental Design. Engineering Proceedings. 2025; 100(1):11. https://doi.org/10.3390/engproc2025100011

Chicago/Turabian StyleGavrilov, Todor, Todor T. Todorov, Yavor Sofronov, Hristiana Nikolova, and Angel Todorov. 2025. "Optimization of Accuracy and Repeatability in Laser Micro-Processing Using Experimental Design" Engineering Proceedings 100, no. 1: 11. https://doi.org/10.3390/engproc2025100011

APA StyleGavrilov, T., Todorov, T. T., Sofronov, Y., Nikolova, H., & Todorov, A. (2025). Optimization of Accuracy and Repeatability in Laser Micro-Processing Using Experimental Design. Engineering Proceedings, 100(1), 11. https://doi.org/10.3390/engproc2025100011