Textural Evaluation of Milk Products: Instrumental Techniques, Parameters, and Challenges

Abstract

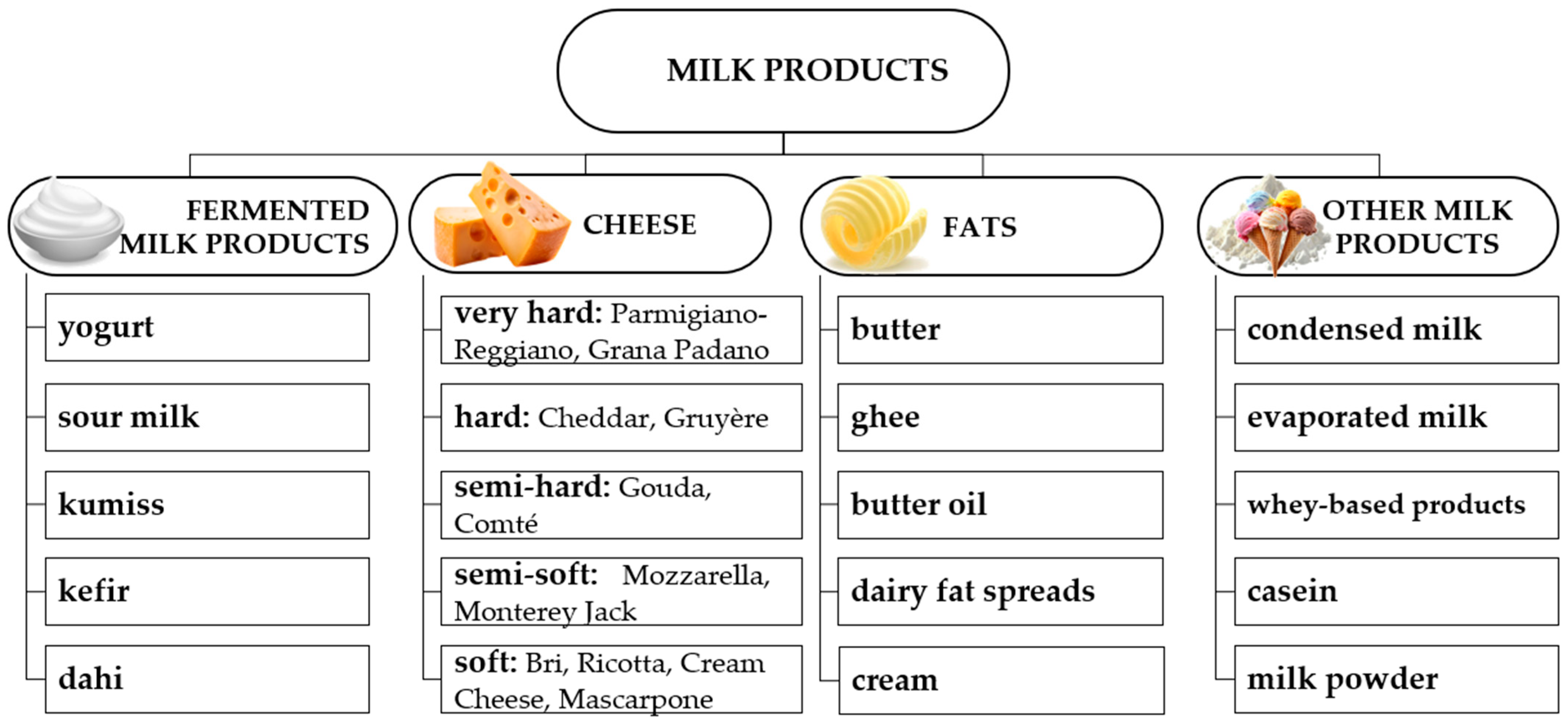

1. Milk Products: Diversity and History

2. The Nutritional Impact and Significance of Milk Products

3. Food Texture: Concepts and Definitions

| Mechanical Texture Property | Conceptual Explanation | Physical States of Food Samples | Dairy Lexicon | Bibliography |

|---|---|---|---|---|

| Hardness | Indicates the force required to deform or penetrate a product, typically perceived by compressing it between teeth (for solids) or between tongue and palate (for semi-solids). | Solid and semi-solids | hard soft | [31] |

| Cohesiveness | Describes the degree to which a food sample can withstand deformation before undergoing structural failure. | Solids and semi-solids | springy gummy | [32] |

| Viscosity | Represents the fluid’s resistance to flow, quantifying the force required to transfer the liquid from a utensil to the tongue or to spread it across a surface. | Semi-solids | milky yogurt-like creamy spreadable unctuous | [27] |

| Springiness/Elasticity | Describes both the rate and degree of shape recovery of a food sample after the deforming force has been removed | Solids and semi-solids | springy plastic | [33] |

| Adhesiveness | Indicates the force necessary to detach food that adheres to the mouth or a substrate. | Solids and semi-solids | sticky gluey | [27] |

| Fracturability/Brittleness | Pertains to the food material’s cohesiveness and the force required to crumble, crack, or shatter it into fragments. | Rather for solids | crumbly brittle fragile | [31] |

| Chewiness | Related to cohesiveness, it is defined as the time or number of chewing cycles required to masticate a solid product, at a constant rate of force application, until it reaches a consistency suitable for swallowing. | Solid | chewy tender | [27] |

| Gumminess | Represents the perceived denseness that is sustained throughout mastication or the mechanical energy needed to break down a food sample to a consistency suitable for swallowing, assessed by compressing the sample between the tongue and palate. | Semi-solid | gummy | [33] |

- (i)

- Descriptive sensory analysis or human sensory methods—a subjective measurement;

- (ii)

3.1. Subjective Texture Measurement

3.2. Objective Texture Measurement

4. Instrumental Methods for Evaluating the Texture of Milk Products

4.1. Puncture Tests

4.2. Spreadability Test

4.3. Texture Profile Analysis Test (TPA)

4.4. Creep and Stress–Relaxation Tests

4.4.1. Stress Relaxation Test

4.4.2. Creep Test

4.5. Novel Approaches in Food Texture Evaluation

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- CXS 206-1999; General Standard for Use of Dairy Terms. FAO: Rome, Italy, 1999. Available online: https://www.fao.org/fao-who-codexalimentarius/standards/list/en/ (accessed on 8 July 2025).

- Amaral, J.S.; Mafra, I.; Pissard, A.; Fernández Prieto, J.A.; Baeten, V. Milk and Milk Products. In The FoodIntegrity Handbook; Eurofins Analytics: Nantes, France, 2018; ISBN 978-2-9566303-0-2. [Google Scholar]

- Mat Out Now: IFCN Dairy Report 2024: Improved Global Milk Production Growth and Recovery in Demand in 2023. IFCN Dairy Research Network. 2024. Available online: https://ifcndairy.org (accessed on 10 July 2025).

- Production of Cow Milk Worldwide: Major Producers 2024. Available online: https://www.statista.com/statistics/268191/cow-milk-production-worldwide-top-producers/ (accessed on 22 September 2025).

- Eurostat Milk and Milk Product Statistics; European Commission: Brussels, Belgium, 2024.

- Fox, P.F. Introduction|History of Dairy Products and Processes. In Encyclopedia of Dairy Sciences, 2nd ed.; Fuquay, J.W., Ed.; Academic Press: San Diego, CA, USA, 2011; pp. 12–17. ISBN 978-0-12-374407-4. [Google Scholar]

- Tamime, A.Y. Fermented Milks: A Historical Food with Modern Applications—A Review. Eur. J. Clin. Nutr. 2002, 56, S2–S15. [Google Scholar] [CrossRef]

- Pădureţ, S. The Effect of Fat Content and Fatty Acids Composition on Color and Textural Properties of Butter. Molecules 2021, 26, 4565. [Google Scholar] [CrossRef] [PubMed]

- Kindstedt, P.S. The History of Cheese. In Global Cheesemaking Technology; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017; pp. 1–19. ISBN 978-1-119-04616-5. [Google Scholar]

- McSweeney, P.L.H.; Ottogalli, G.; Fox, P.F. Chapter 31—Diversity and Classification of Cheese Varieties: An Overview. In Cheese, 4th ed.; McSweeney, P.L.H., Fox, P.F., Cotter, P.D., Everett, D.W., Eds.; Academic Press: San Diego, CA, USA, 2017; pp. 781–808. ISBN 978-0-12-417012-4. [Google Scholar]

- Lamichhane, P.; Kelly, A.L.; Sheehan, J.J. Symposium Review: Structure-Function Relationships in Cheese. J. Dairy Sci. 2018, 101, 2692–2709. [Google Scholar] [CrossRef] [PubMed]

- Tunick, M.H.; Van Hekken, D.L. Dairy Products and Health: Recent Insights. J. Agric. Food Chem. 2015, 63, 9381–9388. [Google Scholar] [CrossRef]

- Balthazar, C.F.; Teixeira, S.; Bertolo, M.R.V.; Ranadheera, C.S.; Raices, R.S.L.; Russo, P.; Spano, G.; Junior, S.B.; Cruz, A.G.; Sant’Ana, A.S. Functional Benefits of Probiotic Fermented Dairy Drink Elaborated with Sheep Milk Processed by Ohmic Heating. Food Biosci. 2024, 59, 103781. [Google Scholar] [CrossRef]

- Salehi, F. Quality, Physicochemical, and Textural Properties of Dairy Products Containing Fruits and Vegetables: A Review. Food Sci. Nutr. 2021, 9, 4666–4686. [Google Scholar] [CrossRef]

- Sharma, H.; Ozogul, F.; Bartkiene, E.; Rocha, J.M. Impact of Lactic Acid Bacteria and Their Metabolites on the Techno-Functional Properties and Health Benefits of Fermented Dairy Products. Crit. Rev. Food Sci. Nutr. 2023, 63, 4819–4841. [Google Scholar] [CrossRef]

- Huth, P.J.; DiRienzo, D.B.; Miller, G.D. Major Scientific Advances with Dairy Foods in Nutrition and Health. J. Dairy Sci. 2006, 89, 1207–1221. [Google Scholar] [CrossRef]

- Holven, K.B.; Sonestedt, E. Milk and Dairy Products—A Scoping Review for Nordic Nutrition Recommendations 2023. Food Nutr. Res. 2024, 68, 10486. [Google Scholar] [CrossRef]

- Schröder, M.; Vetter, W. Detection of 430 Fatty Acid Methyl Esters from a Transesterified Butter Sample. J. Am. Oil Chem. Soc. 2013, 90, 771–790. [Google Scholar] [CrossRef]

- Huppertz, T.; Kelly, A.L.; Fox, P.F. Milk Lipids—Composition, Origin and Properties. In Dairy Fats and Related Products; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2009; pp. 1–27. ISBN 978-1-4443-1622-3. [Google Scholar]

- Amores, G.; Virto, M. Total and Free Fatty Acids Analysis in Milk and Dairy Fat. Separations 2019, 6, 14. [Google Scholar] [CrossRef]

- Gebauer, S.K.; Chardigny, J.-M.; Jakobsen, M.U.; Lamarche, B.; Lock, A.L.; Proctor, S.D.; Baer, D.J. Effects of Ruminant Trans Fatty Acids on Cardiovascular Disease and Cancer: A Comprehensive Review of Epidemiological, Clinical, and Mechanistic Studies. Adv. Nutr. 2011, 2, 332–354. [Google Scholar] [CrossRef]

- Stender, S.; Astrup, A.; Dyerberg, J. Ruminant and Industrially Produced Trans Fatty Acids: Health Aspects. Food Nutr. Res. 2008, 52, 1651. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Textural Perceptions and Food Quality. J. Food Qual. 1991, 14, 75–85. [Google Scholar] [CrossRef]

- Deman, J.M. Teaching of Food Texture in the Department of Food Science, University of Guelph. J. Texture Stud. 1974, 5, 271–272. [Google Scholar] [CrossRef]

- Matz, S.A. Food Texture; Avi Publishing Company: Ann Arbor, MI, USA, 1962. [Google Scholar]

- Szczesniak, A.S. Classification of Textural Characteristics. J. Food Sci. 1963, 28, 385–389. [Google Scholar] [CrossRef]

- ISO 11036 Sensory Analysis—Methodology—Texture Profile. Available online: https://www.iso.org/standard/76668.html (accessed on 4 April 2025).

- Davis, J.G. 162. The Rheology of Cheese, Butter and Other Milk Products. (The Measurement of “Body” and “Texture”). J. Dairy Res. 1937, 8, 245–264. [Google Scholar] [CrossRef]

- McKenna, B.M. Texture in Food. Volume 1, Semi-Solid Foods; Woodhead Publishing: Cambridge, UK, 2003. [Google Scholar]

- Lewis, M. Texture of Dairy Products. In Food Texturology: Measurement and Perception of Food Textural Properties; Rosenthal, A., Chen, J., Eds.; Springer International Publishing: Cham, Switzerland, 2024; pp. 355–371. ISBN 978-3-031-41900-3. [Google Scholar]

- Szczesniak, A.S. Texture Profile Analysis-Methodology Interpretation Clarified. J. Texture Stud. 1996, 27, R6–R7. [Google Scholar]

- Bondu, C.; Salles, C.; Weber, M.; Guichard, E.; Visalli, M. Construction of a Generic and Evolutive Wheel and Lexicon of Food Textures. Foods 2022, 11, 3097. [Google Scholar] [CrossRef] [PubMed]

- Bourne, M.C. Chapter 7—Sensory Methods of Texture and Viscosity Measurement. In Food Texture and Viscosity, 2nd ed.; Bourne, M.C., Ed.; Food Science and Technology; Academic Press: London, UK, 2002; pp. 257–291. ISBN 978-0-12-119062-0. [Google Scholar]

- Alsebaeai, M.; Alark, A.A.; Algadr, M.; Al-Qubati, S. Texture Profile Analysis of Selected Dairy Products. ISRG J. Multidiscip. Stud. (ISRGJMS) 2025, III, 21–27. [Google Scholar] [CrossRef]

- Bourne, M.C. Chapter 1—Texture, Viscosity, and Food. In Food Texture and Viscosity, 2nd ed.; Bourne, M.C., Ed.; Food Science and Technology; Academic Press: London, UK, 2002; pp. 1–32. ISBN 978-0-12-119062-0. [Google Scholar]

- Chen, L.; Opara, U.L. Texture Measurement Approaches in Fresh and Processed Foods—A Review. Food Res. Int. 2013, 51, 823–835. [Google Scholar] [CrossRef]

- Bourne, M. Food Texture and Viscosity: Concept and Measurement; Elsevier: Amsterdam, The Netherlands, 2002; ISBN 978-0-08-049133-2. [Google Scholar]

- Kilcast, D. Texture in Food: Volume 2: Solid Foods; Taylor & Francis: Oxfordshire, UK, 2004; ISBN 978-0-8493-2537-3. [Google Scholar]

- Rosenthal, A.J. Food Texture: Measurement and Perception; Springer: Berlin/Heidelberg, Germany, 1999; ISBN 978-0-8342-1238-1. [Google Scholar]

- Drake, M.A. Invited Review: Sensory Analysis of Dairy Foods. J. Dairy Sci. 2007, 90, 4925–4937. [Google Scholar] [CrossRef] [PubMed]

- Foegeding, E.A.; Drake, M.A. Invited Review: Sensory and Mechanical Properties of Cheese Texture. J. Dairy Sci. 2007, 90, 1611–1624. [Google Scholar] [CrossRef] [PubMed]

- Arana, I. Physical Properties of Foods: Novel Measurement Techniques and Applications; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Bulancea, M.; Iordăchescu, G. Textura Produselor Alimentare; Editura Aius: Galaţi, Romania, 2006. [Google Scholar]

- Jha, S.N.; Jaiswal, P.; Narsaiah, K.; Kaur, P.P.; Singh, A.K.; Kumar, R. Textural Properties of Mango Cultivars during Ripening. J. Food Sci. Technol. 2013, 50, 1047–1057. [Google Scholar] [CrossRef] [PubMed]

- Guiné, R.P.F.; Fontes, L.; Lima, M.J. Evaluation of Texture in Serra Da Estrela Cheese Manufactured in Different Dairies. Open Agric. 2019, 4, 475–486. [Google Scholar] [CrossRef]

- Lis, A.; Staniewski, B.; Ziajka, J. A Comparison of Butter Texture Measurements with the AP 4/2 Penetrometer and TA.XT. Plus Texture Analyzer. Int. J. Food Prop. 2021, 24, 1744–1757. [Google Scholar] [CrossRef]

- Benedito, J.; Simal, S.; Clemente, G.; Mulet, A. Manchego Cheese Texture Evaluation by Ultrasonics and Surface Probes. Int. Dairy J. 2006, 16, 431–438. [Google Scholar] [CrossRef]

- Simão, R.S.; de Souza, P.G.; Monteiro, R.L.; de Andrade, C.J.; Laurindo, J.B.; Carciofi, B.A.M. Mozzarella Cheese Snacks Produced by Microwave Vacuum Drying: Protein Profile, Protein Digestibility, Flavor, and Texture. Food Chem. 2025, 478, 143660. [Google Scholar] [CrossRef]

- Liu, Y.-X.; Cao, M.-J.; Liu, G.-M. 17—Texture Analyzers for Food Quality Evaluation. In Evaluation Technologies for Food Quality; Zhong, J., Wang, X., Eds.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2019; pp. 441–463. ISBN 978-0-12-814217-2. [Google Scholar]

- O’Callaghan, T.F.; Faulkner, H.; McAuliffe, S.; O’Sullivan, M.G.; Hennessy, D.; Dillon, P.; Kilcawley, K.N.; Stanton, C.; Ross, R.P. Quality Characteristics, Chemical Composition, and Sensory Properties of Butter from Cows on Pasture versus Indoor Feeding Systems. J. Dairy Sci. 2016, 99, 9441–9460. [Google Scholar] [CrossRef] [PubMed]

- ISO 11036:1994; Sensory Analysis—Methodology—Texture Profile. ISO: Geneva, Switzerland, 1994.

- Staniewski, B.; Ogrodowska, D.; Staniewska, K.; Kowalik, J. The Effect of Triacylglycerol and Fatty Acid Composition on the Rheological Properties of Butter. Int. Dairy J. 2021, 114, 104913. [Google Scholar] [CrossRef]

- ISO 16305:2005; Butter—Determination of Firmness. ISO: Geneva, Switzerland, 2005. Available online: https://www.iso.org/standard/29865.html (accessed on 27 May 2025).

- Bobe, G.; Hammond, E.G.; Freeman, A.E.; Lindberg, G.L.; Beitz, D.C. Texture of Butter from Cows with Different Milk Fatty Acid Compositions. J. Dairy Sci. 2003, 86, 3122–3127. [Google Scholar] [CrossRef]

- Bobe, G.; Zimmerman, S.; Hammond, E.G.; Freeman, A.E.; Porter, P.A.; Luhman, C.M.; Beitz, D.C. Butter Composition and Texture from Cows with Different Milk Fatty Acid Compositions Fed Fish Oil or Roasted Soybeans. J. Dairy Sci. 2007, 90, 2596–2603. [Google Scholar] [CrossRef]

- Franco, I.; Bargiela, V.; Tovar, C.A. Effect of Vacuum Packaging on the Biochemical, Viscoelastic, and Sensory Properties of a Spanish Cheese during Chilled Storage. Foods 2023, 12, 1381. [Google Scholar] [CrossRef]

- Sołowiej, B. Effect of PH on Rheological Properties and Meltability of Processed Cheese Analogs with Whey Products. Pol. J. Food Nutr. Sci. 2007, 57, 125–128. [Google Scholar]

- Ipate, G.; Pana, G.F.; Ilie, F. Computerized Penetrometry Methodology Assisted by Advanced Algorithms Applied in the Multi-Dimensional Analysis of the Rheology of Mold-Ripened Cheeses. Appl. Sci. 2024, 14, 8429. [Google Scholar] [CrossRef]

- Leclercq-Perlat, M.-N.; Saint-Eve, A.; Picque, D.; Trelea, I.-C. Microbiological, Physicochemical, and Sensory Changes throughout Ripening of an Experimental Soft Smear-Ripened Cheese in Relation to Salt Concentrations. J. Dairy Sci. 2024, 107, 6393–6411. [Google Scholar] [CrossRef] [PubMed]

- Ghorbel, D.; Ben Bettaïeb, N.; Ghrib, F.; Ben Slema, M.; Attia, H. Textural Properties of Commercial Processed Cheese Spreads: Instrumental and Sensory Evaluations. Int. J. Food Prop. 2016, 19, 1513–1521. [Google Scholar] [CrossRef]

- Brighenti, M.; Govindasamy-Lucey, S.; Lim, K.; Nelson, K.; Lucey, J.A. Characterization of the Rheological, Textural, and Sensory Properties of Samples of Commercial US Cream Cheese with Different Fat Contents. J. Dairy Sci. 2008, 91, 4501–4517. [Google Scholar] [CrossRef]

- Ziarno, M.; Derewiaka, D.; Florowska, A.; Szymańska, I. Comparison of the Spreadability of Butter and Butter Substitutes. Appl. Sci. 2023, 13, 2600. [Google Scholar] [CrossRef]

- Pădureţ, S. Effects of Fatty Acid Composition and Temperature on Texture and Spreadability: A Comparative Study of Butter and Lard. Carpathian J. Food Sci. Technol. 2025, 17, 106–120. [Google Scholar]

- Bayarri, S.; Carbonell, I.; Costell, E. Viscoelasticity and Texture of Spreadable Cheeses with Different Fat Contents at Refrigeration and Room Temperatures. J. Dairy Sci. 2012, 95, 6926–6936. [Google Scholar] [CrossRef] [PubMed]

- Glibowski, P.; Zarzycki, P.; Krzepkowska, M. The Rheological and Instrumental Textural Properties of Selected Table Fats. Int. J. Food Prop. 2008, 11, 678–686. [Google Scholar] [CrossRef]

- Macias-Rodriguez, B.A.; Marangoni, A.G. Rheology and Texture of Cream, Milk Fat, Butter and Dairy Fat Spreads. In Dairy Fat Products and Functionality: Fundamental Science and Technology; Truong, T., Lopez, C., Bhandari, B., Prakash, S., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 245–275. ISBN 978-3-030-41661-4. [Google Scholar]

- Rønholt, S.; Kirkensgaard, J.J.K.; Pedersen, T.B.; Mortensen, K.; Knudsen, J.C. Polymorphism, Microstructure and Rheology of Butter. Effects of Cream Heat Treatment. Food Chem. 2012, 135, 1730–1739. [Google Scholar] [CrossRef]

- Swenson, B.J.; Wendorff, W.L.; Lindsay, R.C. Effects of Ingredients on the Functionality of Fat-Free Process Cheese Spreads. J. Food Sci. 2000, 65, 822–825. [Google Scholar] [CrossRef]

- Lučan, M.; Ranilović, J.; Slačanac, V.; Cvetković, T.; Primorac, L.; Gajari, D.; Tomić Obrdalj, H.; Jukić, M.; Lukinac Čačić, J. Fizikalno-kemijska svojstva, mazivost i prihvatljivost krem sira sa sniženim udjelom natrija. Mljekarstvo: Časopis Za Unaprjeđenje Proizv. I Prerade Mlijeka 2020, 70, 13–27. [Google Scholar] [CrossRef]

- Fiol, C.; Prado, D.; Romero, C.; Laburu, N.; Mora, M.; Iñaki Alava, J. Introduction of a New Family of Ice Creams. Int. J. Gastron. Food Sci. 2017, 7, 5–10. [Google Scholar] [CrossRef]

- Gouda, M.; Sheng, L.; Aadil, R.M.; Liu, Y.; Ma, M.; Li, X.; He, Y.; Munekata, P.E.S.; Lorenzo, J.M. Interaction of Bioactive Mono-Terpenes with Egg Yolk on Ice Cream Physicochemical Properties. Foods 2021, 10, 1686. [Google Scholar] [CrossRef]

- Rosenthal, A.J. Texture Profile Analysis—How Important Are the Parameters?: Parameters in Texture Profile Analysis. J. Texture Stud. 2010, 41, 672–684. [Google Scholar] [CrossRef]

- Peleg, M. The Instrumental Texture Profile Analysis Revisited. J. Texture Stud. 2019, 50, 362–368. [Google Scholar] [CrossRef] [PubMed]

- Nishinari, K.; Kohyama, K.; Kumagai, H.; Funami, T.; Bourne, M.C. Parameters of Texture Profile Analysis. Food Sci. Technol. Res. 2013, 19, 519–521. [Google Scholar] [CrossRef]

- Bähler, B.; Kunz, A.; Hinrichs, J. Hot Brining of Pasta Filata Cheese: Effect of Sodium and Calcium Chloride on Composition, Yield, and Hardness. Dairy Sci. Technol. 2016, 96, 703–714. [Google Scholar] [CrossRef]

- Bähler, B.; Nägele, M.; Weiss, J.; Hinrichs, J. Temperature and Time-Dependent Relaxation of Compressed Cheese Curd Cubes: Effect on Structuring of Pasta-Filata Cheese: Relaxation of Compressed Cheese. J. Texture Stud. 2016, 47, 58–67. [Google Scholar] [CrossRef]

- Chatziantoniou, S.E.; Thomareis, A.S. Physical, Textural and Sensory Properties of Spreadable Processed Whey Cheese as Affected by Addition of Polysaccharides. Sustainability 2024, 16, 10996. [Google Scholar] [CrossRef]

- Prow, L.A.; Metzger, L.E. Melt Analysis of Process Cheese Spread or Product Using a Rapid Visco Analyzer. J. Dairy Sci. 2005, 88, 1277–1287. [Google Scholar] [CrossRef]

- Sasmazer, R.C.; Korukluoglu, M.; Ginoyan, R.V.; Platova, G.I. White Cheese Texture Profile at Different Storage Temperatures. IOP Conf. Ser. Earth Environ. Sci. 2022, 1052, 012061. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, Z.; Mo, B. Texture Profile Analysis of Sliced Cheese in Relation to Chemical Composition and Storage Temperature. J. Chem. 2016, 2016, 8690380. [Google Scholar] [CrossRef]

- Wang, W.; Jia, R.; Hui, Y.; Zhang, F.; Zhang, L.; Liu, Y.; Song, Y.; Wang, B. Utilization of Two Plant Polysaccharides to Improve Fresh Goat Milk Cheese: Texture, Rheological Properties, and Microstructure Characterization. J. Dairy Sci. 2023, 106, 3900–3917. [Google Scholar] [CrossRef]

- Cai, H.; Bijl, E.; Sala, G.; Scholten, E. Relationship between the Perception of Complex Textural Attributes and the Bolus Properties of Cheese. Food Hydrocoll. 2024, 150, 109713. [Google Scholar] [CrossRef]

- Lapčíková, B.; Lapčík, L.; Valenta, T.; Kučerová, T. Functional and Quality Profile Evaluation of Butters, Spreadable Fats, and Shortenings Available from Czech Market. Foods 2022, 11, 3437. [Google Scholar] [CrossRef] [PubMed]

- Gupta, M.K.; Torrico, D.D.; Ong, L.; Gras, S.L.; Dunshea, F.R.; Cottrell, J.J. Plant and Dairy-Based Yogurts: A Comparison of Consumer Sensory Acceptability Linked to Textural Analysis. Foods 2022, 11, 463. [Google Scholar] [CrossRef] [PubMed]

- Bruzzone, F.; Ares, G.; Giménez, A. Consumers’ Texture Perception of milk Desserts. II—Comparison with Trained Assessors’ Data. J. Texture Stud. 2012, 43, 214–226. [Google Scholar] [CrossRef]

- Homayouni, A.; Javadi, M.; Ansari, F.; Pourjafar, H.; Jafarzadeh, M.; Barzegar, A. Advanced Methods in Ice Cream Analysis: A Review. Food Anal. Methods 2018, 11, 3224–3234. [Google Scholar] [CrossRef]

- Lee, W.J.; Pon, S.Y.; Chong, G.H. Textural and Rheological Properties of Stevia Ice Cream. Int. Food Res. J. (Malays.) 2015, 22, 1544–1549. [Google Scholar]

- Veer, S.J.; Pawase, P.A.; Gadhave, R.K. Studies on Textural Profile, Nutritional Profile and Microbial Studies of Ashwagandha Root Powder Added Ice Cream. Int. J. Food Sci. Nutr. 2021, 4, 107–110. [Google Scholar]

- Vetorazi, M.G.; De Oliveira, E.F.; Macedo, L.L.; Da Silva Araújo, C.; Saraiva, S.H.; Coelho, J.M. High-Intensity Ultrasound Improves Texture Profile and Technological Characteristics of Cupuaçu (Theobroma Grandiflorum) Ice Cream. J. Food Sci. Technol. 2024, 62, 1742–1749. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Hamid, M.; Hamed, A.M.; Walker, G.; Romeih, E. Yogurt Fortified with Various Protein Hydrolysates: Texture and Functional Properties. Food Chem. 2024, 461, 140861. [Google Scholar] [CrossRef]

- Al-Bedrani, D.I.; ALKaisy, Q.H.; Rahi, A.K. Evaluation of Milk Source on Physicochemical, Texture, Rheological and Sensory Properties of Yogurts. J. Appl. Nat. Sci. 2023, 15, 128. [Google Scholar] [CrossRef]

- Batista, L.F.; Marques, C.S.; dos Santos Pires, A.C.; Minim, L.A.; Soares, N.d.F.F.; Vidigal, M.C.T.R. Artificial Neural Networks Modeling of Non-Fat Yogurt Texture Properties: Effect of Process Conditions and Food Composition. Food Bioprod. Process. 2021, 126, 164–174. [Google Scholar] [CrossRef]

- Kose, Y.E.; Altun, I.; Kose, S. Determination of Texture Profile Analysis of Yogurt Produced by Industrial and Traditional Method. Int. J. Sci. Technol. Res. 2018, 4, 66–70. [Google Scholar]

- Mousa, A.H.; Abdeldaiem, A.M.; Abd Al-Gwad, A.; Mohamed, A.A.A.; Ali, A.H. Analysis of the Physicochemical Properties, Texture, and Microbial Profile of Set-Type Buffalo Milk Yogurt Fortified with Zinc Oxide Micro-and Nanoparticles. LWT 2025, 224, 117834. [Google Scholar] [CrossRef]

- Mousavi, M.; Heshmati, A.; Daraei Garmakhany, A.; Vahidinia, A.; Taheri, M. Texture and Sensory Characterization of Functional Yogurt Supplemented with Flaxseed during Cold Storage. Food Sci. Nutr. 2019, 7, 907–917. [Google Scholar] [CrossRef]

- Mudgil, D.; Barak, S.; Khatkar, B.S. Texture Profile Analysis of Yogurt as Influenced by Partially Hydrolyzed Guar Gum and Process Variables. J. Food Sci. Technol. 2017, 54, 3810–3817. [Google Scholar] [CrossRef]

- Oroian, M.; Paduret, S. Influence of Citrus Fibre Addition on Textural and Rheological Properties of Yogurt. Food Environ. Saf. J. 2016, 13, 335–341. [Google Scholar]

- Pădureţ, S.; Ghinea, C.; Prisacaru, A.E.; Leahu, A. Physicochemical, Textural, and Antioxidant Attributes of Yogurts Supplemented with Black Chokeberry: Fruit, Juice, and Pomace. Foods 2024, 13, 3231. [Google Scholar] [CrossRef]

- Ravindran, A.; Kiran, G.S.; Selvin, J. Revealing the Effect of Lipopeptide on Improving the Probiotics Characteristics: Flavor and Texture Enhancer in the Formulated Yogurt. Food Chem. 2022, 375, 131718. [Google Scholar] [CrossRef] [PubMed]

- Song, C.; Xie, J.; Pan, Y. System Sensory Analysis of Yogurt Based on Texture Analyzer. J. Dairy Sci. 2024. [Google Scholar] [CrossRef] [PubMed]

- Del Nobile, M.A.; Chillo, S.; Mentana, A.; Baiano, A. Use of the Generalized Maxwell Model for Describing the Stress Relaxation Behavior of Solid-like Foods. J. Food Eng. 2007, 78, 978–983. [Google Scholar] [CrossRef]

- Logan, A.; Lopez, C.; Xu, M.; Day, L.; Oiseth, S.; Augustin, M.A. Tempering Governs the Milk Fat Crystallisation and Viscoelastic Behaviour of Unprocessed and Homogenised Creams. Food Res. Int. 2021, 147, 110557. [Google Scholar] [CrossRef]

- Ramaswamy, H.S.; Chen, C.R.; Rattan, N.S. Comparison of Viscoelastic Properties of Set and Stirred Yogurts Made from High Pressure and Thermally Treated Milks. Int. J. Food Prop. 2015, 18, 1513–1523. [Google Scholar] [CrossRef]

- Subramanian, R.; Muthukumarappan, K.; Gunasekaran, S. Linear Viscoelastic Properties of Regular- and Reduced-Fat Pasteurized Process Cheese During Heating and Cooling. Int. J. Food Prop. 2006, 9, 377–393. [Google Scholar] [CrossRef]

- Myhan, R.; Jeliński, T.; Białobrzewski, I.; Sadowska, J.; Jachimczyk, E. The Effect of Milk Fat Substitution on the Rheological Properties of Edam-Type Cheese. Eur. Food Res. Technol. 2020, 246, 2443–2450. [Google Scholar] [CrossRef]

- Fox, P.F.; Guinee, T.P.; Cogan, T.M.; McSweeney, P.L.H. Cheese: Structure, Rheology and Texture. In Fundamentals of Cheese Science; Springer: Boston, MA, USA, 2017; pp. 475–532. ISBN 978-1-4899-7679-6. [Google Scholar]

- Tunick, M.H. Cheese Rheology and Texture. In Handbook of Cheese Chemistry; Tunick, M.H., Ed.; The Royal Society of Chemistry: Philadelphia, PA, USA, 2023. [Google Scholar]

- Steffe, J.F. Rheological Methods in Food Process Engineering; Freeman Press: Cranbury, NJ, USA, 1996; ISBN 978-0-9632036-1-8. [Google Scholar]

- Dimitreli, G.; Thomareis, A.S. Texture Evaluation of Block-Type Processed Cheese as a Function of Chemical Composition and in Relation to Its Apparent Viscosity. J. Food Eng. 2007, 79, 1364–1373. [Google Scholar] [CrossRef]

- Sahin, S.; Sumnu, S.G. Physical Properties of Foods; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Pădureţ, S. The effect of maturation conditions on physicochemical and viscoelastic properties of Kashkaval cheese. Ovidius Univ. Ann. Chem. 2023, 34, 34–40. [Google Scholar] [CrossRef]

- Verdini, R.A.; Rubiolo, A.C. Texture Changes During the Ripening of Port Salut Argentino Cheese in 2 Sampling Zones. J. Food Sci. 2002, 67, 1808–1813. [Google Scholar] [CrossRef]

- Betten, J. Creep Mechanics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-85051-9. [Google Scholar]

- Chakespari, A.G.; Rajabipour, A.; Mobli, H. Anisotropic Relaxation and Creep Properties of Apple (Cv. Shafi Abadi and Golab Kohanz). Adv. J. Food Sci. Technol. 2010, 2, 200–205. [Google Scholar]

- Sharma, P.; Munro, P.A.; Gillies, G.; Wiles, P.G.; Dessev, T.T. Changes in Creep Behavior and Microstructure of Model Mozzarella Cheese during Working. LWT-Food Sci. Technol. 2017, 83, 184–192. [Google Scholar] [CrossRef]

- Olivares, M.L.; Zorrilla, S.E.; Rubiolo, A.C. Rheological Properties of Mozzarella Cheese Determined by Creep/Recovery Tests: Effect of Sampling Direction, Test Temperature and Ripening Time. J. Texture Stud. 2009, 40, 300–318. [Google Scholar] [CrossRef]

- Karaman, S.; Yilmaz, M.T.; Cankurt, H.; Kayacier, A.; Sagdic, O. Linear Creep and Recovery Analysis of Ketchup–Processed Cheese Mixtures Using Mechanical Simulation Models as a Function of Temperature and Concentration. Food Res. Int. 2012, 48, 507–519. [Google Scholar] [CrossRef]

- Toǧrul, H.; Arslan, N. Mathematical Model for Prediction of Apparent Viscosity of Molasses. J. Food Eng. 2004, 62, 281–289. [Google Scholar] [CrossRef]

- Zare, D.; Ebadi, H.; Ghofrani, A. Determination of Viscoelastic Properties of Dates (Mazafati Variety). Agric. Eng. Int. CIGR J. 2017, 19, 210–216. [Google Scholar]

- Karaman, S.; Yilmaz, M.T.; Toker, O.S.; Dogan, M. Stress Relaxation/Creep Compliance Behaviour of Kashar Cheese: Scanning Electron Microscopy Observations. Int. J. Dairy Technol. 2016, 69, 254–261. [Google Scholar] [CrossRef]

- Venugopal, V.; Muthukumarappan, K. Stress Relaxation Characteristics of Cheddar Cheese. Int. J. Food Prop. 2001, 4, 469–484. [Google Scholar] [CrossRef]

- Huang, L.; Fan, J.; Han, C.; Du, C.; Wei, Z.; Du, D. Methods and Instruments for the Evaluation of Food Texture: Advances and Perspectives. Food Res. Int. 2025, 208, 116162. [Google Scholar] [CrossRef] [PubMed]

- Nakamoto, H.; Shimizu, T. Food Texture Prediction Method Using Multiple Measurement and Template Data. IEEE Access 2024, 12, 124834–124844. [Google Scholar] [CrossRef]

- Ikram, A.; Mehmood, H.; Arshad, M.T.; Rasheed, A.; Noreen, S.; Gnedeka, K.T. Applications of Artificial Intelligence (AI) in Managing Food Quality and Ensuring Global Food Security. CyTA-J. Food 2024, 22, 2393287. [Google Scholar] [CrossRef]

- Cosme, F.; Rocha, T.; Marques, C.; Barroso, J.; Vilela, A. Innovative Approaches in Sensory Food Science: From Digital Tools to Virtual Reality. Appl. Sci. 2025, 15, 4538. [Google Scholar] [CrossRef]

- Gill, A.; Bihola, A.; Vashisht, P.; Bohra, M.; Dwivedi, A.; Verma, D.; Adil, S. The Future of Artificial Intelligence Technologies in Yoghurt Manufacturing—A Review. Indian Food Industry Mag. 2025, 7, 46–57. [Google Scholar]

- Cai, Z.; Wang, Z.; Zhang, M.; Zhang, A.; Ye, G.; Liang, S.; Ren, X. Texture Analysis of Chinese Dried Noodles during Drying Based on Acoustic–Mechanical Detection Methods. Foods 2024, 13, 268. [Google Scholar] [CrossRef] [PubMed]

- Nakamoto, H.; Nagahata, Y.; Kobayashi, F. A Magnetic Food Texture Sensor and Comparison of the Measurement Data of Chicken Nuggets. Sensors 2021, 21, 3310. [Google Scholar] [CrossRef]

| Parameter | Cheese | Bibliography | Butteer | Bibliography |

|---|---|---|---|---|

| Probe type | cylindrical (2, 3, 5, 6, 10 mm), conical (9°, 19°, 45°, and 90°) | [48,56,57,58,59,60] | spherical, cylindrical (5 mm), or conical probe (40°, 120°) | [8,46,55] |

| Test speed, mm/min | 6, 12, 24, 30, 60, 240, 600 | [48,56,58,59,60,61] | 10–120 | [8,46,54,62] |

| Penetration depth, mm | 10, 15, 20 | [48,57,59] | 2.5–14 | [8,54,62] |

| Sample form | cube cylindrical | [48,56] | cylindrical plastic containers | [63] |

| Sample dimensions, mm | cube 15 cylindrical, 20 × 30 120 × 68 × 30 | [48,56,61] | 35 mm in both height and diameter | [63] |

| Testing temperature, °C | 20 | [48,56] | 4–23, recommended 10 | [52,53,55] |

| Textural properties | hardness, adhesiveness, work of penetration, apparent viscosity | [48,58] | hardness, adhesiveness, work of penetration (plasticity) viscosity (adhesion force) | [8,46,62] |

| Statistical Parameters | Equation | Statistical Parameters | Equation | ||

|---|---|---|---|---|---|

| ADD | (3) | χ2 | (6) | ||

| (4) | MBE | (7) | |||

| MPE | (5) | RMSE | (8) | ||

| Where are the experimental data, are the predicted data, N is the total number of data points, and n is the number of model parameters. | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pădureţ, S. Textural Evaluation of Milk Products: Instrumental Techniques, Parameters, and Challenges. Dairy 2025, 6, 58. https://doi.org/10.3390/dairy6050058

Pădureţ S. Textural Evaluation of Milk Products: Instrumental Techniques, Parameters, and Challenges. Dairy. 2025; 6(5):58. https://doi.org/10.3390/dairy6050058

Chicago/Turabian StylePădureţ, Sergiu. 2025. "Textural Evaluation of Milk Products: Instrumental Techniques, Parameters, and Challenges" Dairy 6, no. 5: 58. https://doi.org/10.3390/dairy6050058

APA StylePădureţ, S. (2025). Textural Evaluation of Milk Products: Instrumental Techniques, Parameters, and Challenges. Dairy, 6(5), 58. https://doi.org/10.3390/dairy6050058