1. Introduction

The global agricultural sector is facing unprecedented challenges driven by a confluence of factors: a growing labor shortage in rural areas, the urgent need to ensure food security for a growing population, and the need to reduce the environmental impact of agricultural practices [

1,

2]. These pressures are exposing the limitations of traditional and even early automated agricultural models, which suffer from low resource utilization and difficulty adapting to complex, unstructured environments [

2].

To this end, autonomous agricultural machinery represents a critical advancement. Technologies such as camera-guided tractors show potential in reducing operator workload and improving the precision of basic operations [

3,

4]. However, these standalone automated systems still have significant limitations. Their effectiveness decreases on large farms, and their limited environmental perception prevents them from handling complex, dynamic scenarios [

5,

6]. Most existing research still focuses on a single technical dimension, such as optimization algorithms for path planning, operation status recognition models, or sensor-based local monitoring systems [

7]. Although significant improvements have been made in the accuracy of single-machine operations, these methods often lack consideration of comprehensive factors such as multi-machine collaboration, operation spatiotemporal constraints, and system-level resilience, making it difficult to meet the intelligent needs of future complex agricultural ecosystems.

Against this backdrop, AI-driven cooperative control emerges as a transformative solution to these intertwined challenges. By enabling teams of autonomous tractors and supporting equipment to perceive, decide, and act in a coordinated manner, this paradigm transcends the capabilities of isolated machines. It not only directly addresses labor shortages by enabling fatigue-free multi-agent operation, but also enhances food security by improving operational efficiency and optimizing yields at scale. Furthermore, by enabling precise, location-specific resource application, it paves the way for a more sustainable and resource-efficient agricultural future.

This technological evolution is gaining strong policy and market momentum. policies such as India’s digital agriculture mission, the EU’s common agricultural policy (CAP) subsidies, and China’s smart agriculture action plan are providing strong impetus for technology implementation [

8]. Driven by both policy and technology, market expansion and acceptance are rapidly increasing: the unmanned tractor market is projected to grow from US dollar 2.2 billion in 2025 to US dollar 5.2 billion in 2030 (a compound annual growth rate of 18.6%). The Asia-Pacific region will lead the global market with a 46.3% share in 2024. The annual growth rate of over 23% for fully autonomous and electric models also confirms the rapid adoption of the technology [

9].

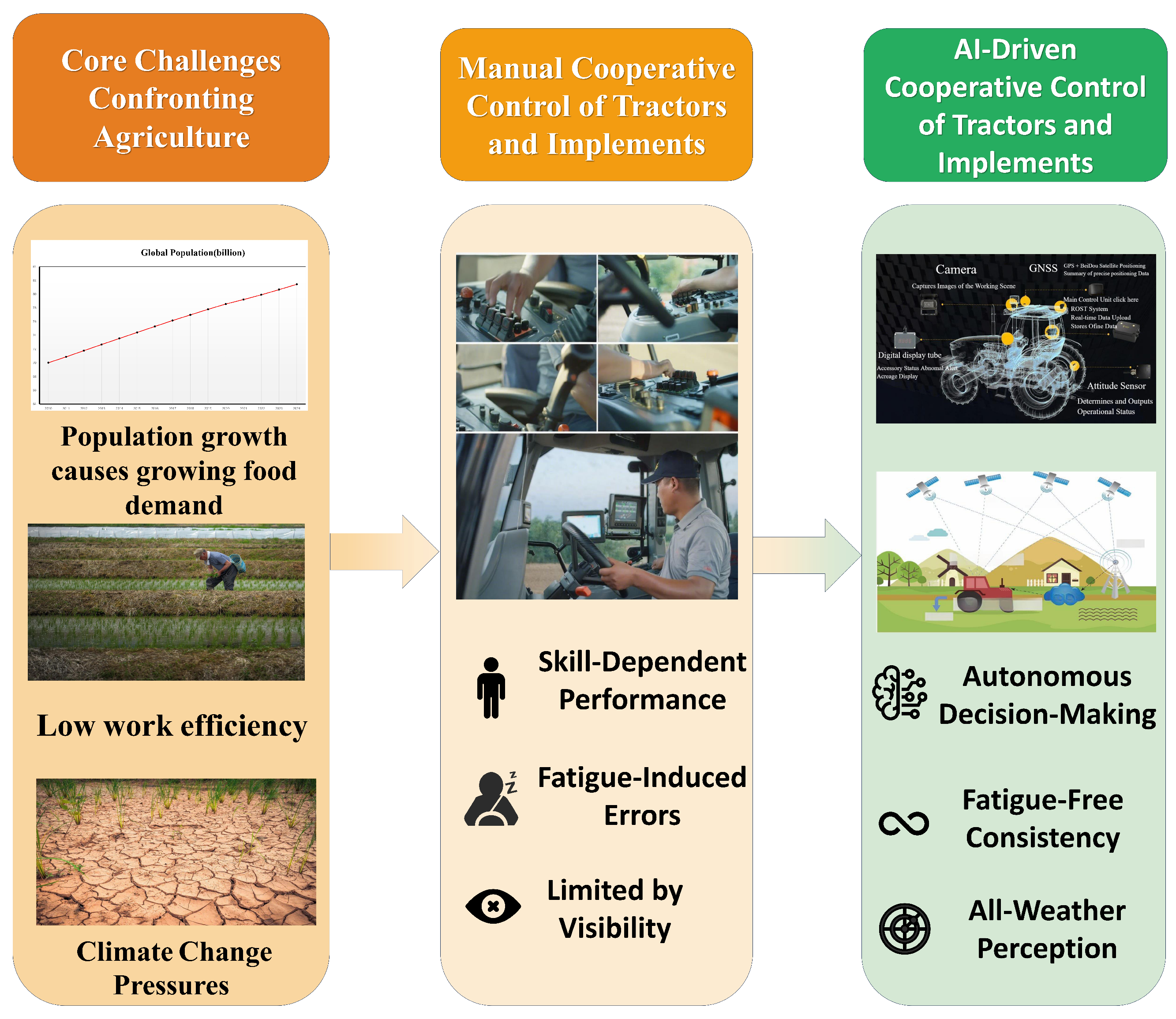

Figure 1 clearly depicts the path of technological evolution: starting from the core challenges facing agriculture, progressing through the inefficient and limited precision of manual collaborative control, and ultimately towards AI-driven autonomous operation of tractors and equipment. This diagram highlights how technology simultaneously addresses the dual challenges of production efficiency and ecological sustainability, presenting a comprehensive overview of the evolution of intelligent agricultural machinery from concept to system.

This review is the first attempt to systematically examine AI-driven cooperative control technologies for autonomous tractors and implements, aiming to construct a comprehensive technical landscape. While existing research covers many specific areas [

1,

10,

11,

12,

13], it has yet to achieve a systematic integration. Our discussion is guided by four interrelated technical pillars. First, we establish a collaborative intelligence foundation by embedding agricultural knowledge into AI systems and building intelligent decision-making models that conform to the physical laws of farmland [

14]. We then expand this to a multi-agent collaborative framework, encompassing mechanisms for swarm intelligence formation and distributed learning methods adapted to plot separation and heterogeneous resources [

15]. We focus on the physical interaction and control of tractors and implements, addressing key issues such as dynamic terrain-implement coupling, adaptive traction, and soil resistance response [

16,

17]. Finally, we analyze cognitive applications across different agronomic processes and comprehensively evaluate the practical effectiveness and potential of collaborative control technologies from sowing to harvest [

18,

19].

Our contributions are threefold:

We formalize knowledge-embedded AI frameworks that ensure physically consistent tractor-implement interactions.

We advance physically aware control strategies that dynamically adapt to field heterogeneity.

We propose an integrated cooperative control ecosystem combining neuromorphic computing and FarmOS to overcome real-time coordination bottlenecks.

2. Foundational Architecture for Cooperative Intelligence

As an advanced operational paradigm in agriculture, cooperative intelligence integrates multiple actors, including autonomous agricultural machinery, a central dispatch system, sensor networks, and human-machine interfaces. Through deep integration and collaboration, the system achieves optimized resource allocation, precise task scheduling, and agile adaptation to the environment. This structured interactive system helps each unit overcome its limitations in perception and cognition, thereby building an intelligent collaborative network that spans time, space, and functions. Its operational mechanism is based on a hierarchical collaboration framework, enhanced by different knowledge layers.

2.1. Hierarchical Collaboration Framework

The proposed hierarchical collaboration framework adopts a dual-control architecture. The vertical functional dimension focuses on the core capabilities within the unit, covering perception, decision-making, and execution, building a complete workflow from data collection and task planning to precise implementation. The horizontal coordination dimension is dedicated to coordinating the cross-temporal and spatial interactions between different agents (such as tractors, drones, and central dispatch systems), focusing on resolving resource conflicts, optimizing group task allocation and scheduling, and enabling knowledge sharing through multi-agent communication, thereby comprehensively improving the efficiency of system collaboration. The framework first ensures the autonomy and functional integrity of individual agents through the vertical functional layer.

2.1.1. Vertical Functional Hierarchy

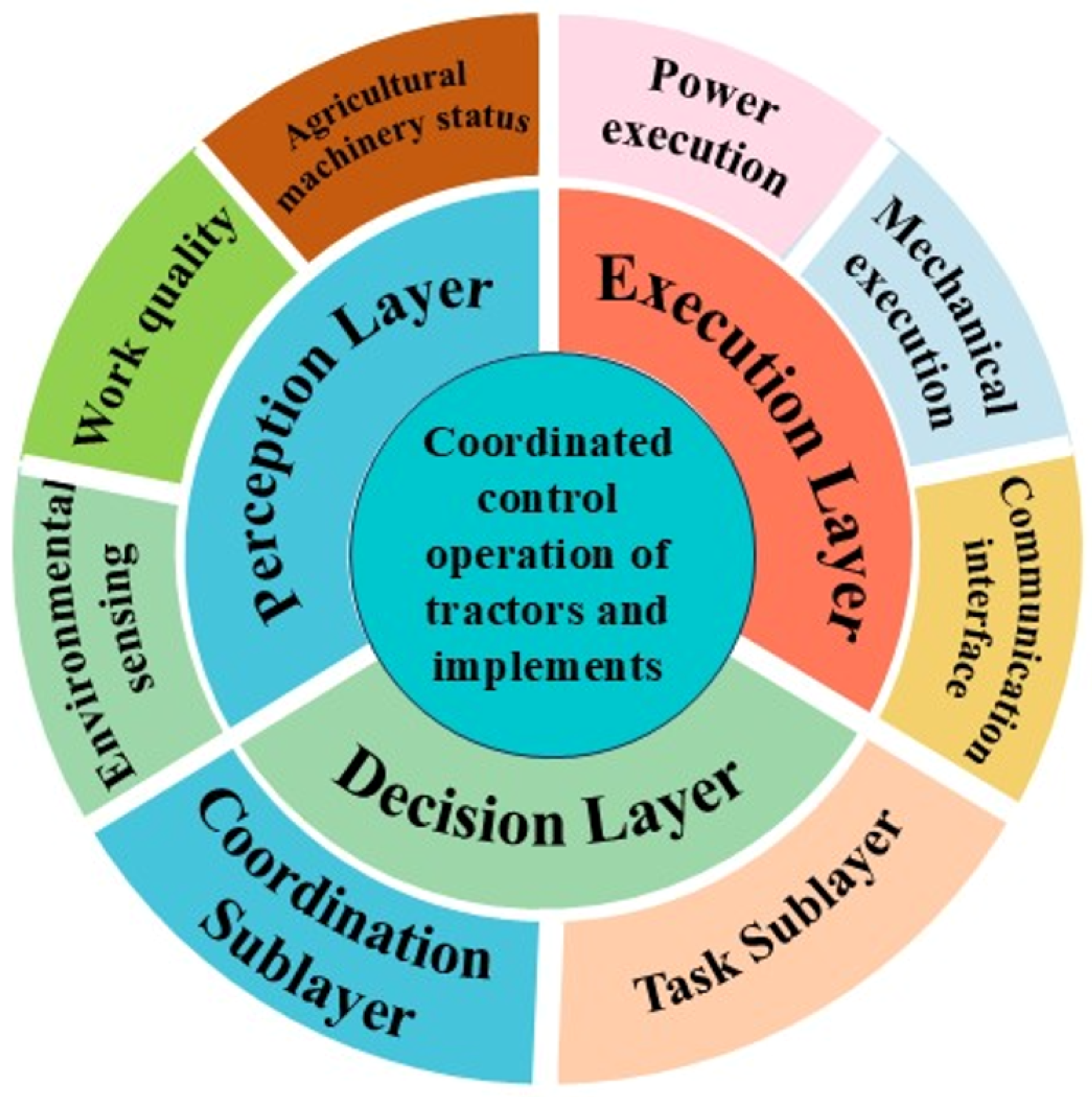

The vertical functional layer, composed of three closely interconnected sub-architectures, aims to address the core challenges of agricultural collaborative system integration by organically combining hierarchical functions with horizontal coordination mechanisms between agents. These challenges include high heterogeneity in sensory data, lack of global consistency in decision-making processes, response delays in execution, and physical constraint conflicts. To this end, this study establishes a three-layer architecture of “perception-decision-execution” as the core improvement mechanism for the vertical functional layer. As shown in

Figure 2, the system integrates three modules: the perception layer is responsible for environmental perception, operation quality monitoring, and implementation status tracking; the decision layer encompasses collaborative control and task planning; and the execution layer includes power regulation, machine operation, and communication. The core goal of this design is to alleviate integration bottlenecks in multi-source information fusion, complex constraint optimization, and dynamic execution feedback through a layered mechanism, thereby establishing a closed-loop adaptive optimization capability from data to action. Ultimately, through the organic synergy of these multiple modules, the system achieves efficient, stable, and intelligent collaborative operations in dynamic farmland environments.

The perception layer fuses multi-source sensor data and combines it with terrain correction technology to generate centimeter-level farmland maps. To address the unstable environmental perception issues inherent in traditional systems, which are caused by high sensor data noise and calibration errors, this study introduces multi-sensor fusion and optimization algorithms into the perception layer. For example, a high-speed precision seed drill can simultaneously utilize laser, ultrasonic, and angle sensors to operate at speeds of 12–16 km/h [

20]. The collected data is first preprocessed using a Kalman filter and then optimized using an improved sparrow search algorithm (combined with an extended Kalman filter). Test results demonstrate excellent performance, with a mean absolute error of only 0.083 cm, a root mean square error of 0.103 cm, and a correlation coefficient of 0.979. This design significantly enhances the system’s ability to ensure accuracy and stability in highly dynamic operating environments. Furthermore, the high accuracy of the perception layer relies not only on advanced filtering algorithms but also incorporates prior knowledge of sensor operating principles and the physical relationships between measurements, making the perception results more reliable and more relevant to real-world applications.

The decision-making layer utilizes multi-agent reinforcement learning (MARL) and the generation of collaborative agents to collaboratively resolve conflicts within multiple agricultural constraints. Incorporating domain prior knowledge is crucial to ensure that each decision adheres to physical laws and biological mechanisms. Multi-agent reinforcement learning introduces multiple autonomous agents into complex agricultural systems, enabling them to collaborate and compete in dynamic environments to jointly optimize overall returns [

21]. Unlike single-agent reinforcement learning, MARL can effectively address multi-dimensional issues in agricultural operations, such as multi-machine coordination, resource sharing, and spatial conflicts. For example, different agricultural machines operating on the same plot may need to coordinate path planning, energy allocation, and operation timing. MARL strikes a balance between global and local reward mechanisms, enabling each agent to achieve individual optimization while maintaining overall system performance. In terms of algorithm design, a centralized training, decentralized execution (CTDE) framework is often adopted. Global information is optimized through a centralized value function or policy network, and independent decision-making by each agent during the execution phase, thus balancing efficiency and stability. Some research has incorporated graph neural network (GNN) architectures to capture the interactions between agricultural machines, enabling collaborative scheduling and obstacle avoidance control. Furthermore, to address uncertainties in the farmland environment (such as climate fluctuations and surface heterogeneity), MARL models can incorporate Bayesian reinforcement learning or meta-learning mechanisms to enhance generalization and adaptability. Physical constraints such as machine range and power limits, as well as agronomic rules such as minimum irrigation requirements based on cumulative temperature and optimal sowing time, are explicitly embedded in the decision-making algorithm, making them hard constraints or goal-oriented in the optimization process. This embedding of constraints based on prior knowledge not only improves the interpretability and reliability of decisions but also ensures that each strategy output by the algorithm can be implemented under real-world physical conditions. Ultimately, the results generated by the decision-making layer can provide the execution layer with highly accurate and feasible operational instructions, driving the development of agricultural automation systems towards intelligent collaboration and adaptive control.

The execution layer precisely translates strategic decisions from the upper layer into specific actions for the tractor and implement, placing particular emphasis on motion coordination. By seamlessly integrating prior knowledge, the system ensures that each operation is physically feasible, safe, and efficient. The control architecture embeds a dynamic model of the tractor-implement system and the dynamics of soil-machine interaction, employing control algorithms such as proportional-integral-differential (PID) and multi-processor control (MPC) for precise control. Physical constraints such as the upper limit of actuator speed and the maximum safe tilt angle of the machine body, as well as expert experience such as vibration tolerance under different operating conditions, are translated into constraints or optimization objectives within the control algorithm. For example, deep soil compaction, common in rice-wheat rotations, can reach 1.01 MPa at a depth of 0–4 cm under long-term no-tillage conditions, and can even exceed 2.0 MPa at depths of 30 to 34 cm [

22]. Given these operating conditions revealed by measurement data, the control strategy at the execution layer must be adjusted accordingly. Blindly adjusting tillage depth will either fail to effectively break up the compacted layer or excessively damage the soil structure. Therefore, based on prior knowledge of soil mechanics, the precision motion control module will accurately calculate the target depth range and scientific force application strategy, thereby achieving precise loosening of the soil, which not only promotes crop growth but also significantly reduces compaction damage.

2.1.2. Horizontal Coordination Hierarchy

However, the high degree of autonomy of individual agents is not the end point of cooperative intelligence in agriculture. To achieve global optimization, a horizontal coordination layer must be used to manage interactions between different types of agents and build a collaborative network that spans space, time, and functions. This system achieves global goals beyond the capabilities of a single agent through distributed algorithms and communication frameworks. In task optimization, the system employs a MARL mechanism to dynamically allocate field work areas and transportation routes, effectively resolving conflicts caused by overlapping paths and resource sharing [

13]. Sequence planning, based on a spatiotemporal hierarchical model of work unit tasks [

23], systematically optimizes work sequences and significantly reduces idle waiting time between machines.

To achieve the aforementioned task optimization and conflict resolution, information fusion and knowledge sharing among agents are crucial foundations. This mechanism enables agents to exchange diverse data types, including local perception information such as soil moisture distribution, optimization decisions such as route updates, and learning models such as terrain traction characteristics. However, this frequent data exchange places high demands on the communication system. Given limited communication bandwidth, the system combines an event-triggered mechanism with edge cloud collaborative computing to effectively enhance overall environmental perception capabilities and lay the foundation for subsequent consensus building.

The theoretical basis of this coordination mechanism stems primarily from the distributed optimal control method [

24]. Its core concept is to decompose global objectives, such as reducing total energy consumption or shortening total operation time, into multiple interconnected local subproblems. Agents collaborate through boundary coupling variables (such as shared virtual paths, resource availability signals, or consensus states). The system also achieves consensus building and conflict resolution by generating collaborative agents or using distributed optimization methods. This system coordinates individual agent objectives with global agricultural rules (such as shared operation schedules and farm energy conservation requirements [

25]), ultimately ensuring the consistency and efficiency of the overall system operation.

However, practical applications still face challenges such as communication latency, heterogeneous interface compatibility [

26], and fault tolerance requirements. Addressing these challenges requires robust communication protocols that embed knowledge of system operational constraints to achieve stable and reliable coordinated control.

In summary, the horizontal coordination hierarchy aims to address the interaction issues between multiple agents. Achieving its ideal effectiveness relies on a comprehensive set of theories and methodologies. The challenges discussed above, such as communication latency, heterogeneous compatibility, global goal decomposition, and conflict resolution, essentially constitute a typical multi-agent system (MAS) coordination problem. Therefore, it is necessary to examine and address these challenges from a more macroscopic and systematic perspective: the multi-agent coordination framework (MACF). This framework encompasses core elements such as collective architecture, learning mechanisms, and task orchestration, as detailed below.

This dual-control architecture adheres to the core principle of “high-level goals guiding low-level actions, while low-level feedback optimizes high-level decisions”. The key lies in the continuous embedding of physical, biological, and agricultural operational knowledge into the agent’s functional units and coordination mechanisms, ensuring that feedback loops operate stably within feasible production constraints and enabling collaborative operations to effectively span spatial and temporal scales [

27]. For example, in multi-machine collaborative operations, a cluster of agricultural machines implements task sequence planning and conflict resolution through a horizontal coordination layer, significantly reducing idle time [

23]. Each machine, however, relies on its own vertical architecture (perception, decision-making, and execution) to accurately complete its assigned subtasks. Embedded knowledge, such as machine performance, field management rules, and soil characteristics, jointly shapes the operating rules and constraints at both levels.

2.2. Knowledge-Embedded AI Foundations

To achieve its vision of “intelligent collaboration”, the aforementioned hierarchical collaboration framework relies on underlying AI technology. However, purely data-driven AI models often face semantic barriers, decision-making distortion, and insufficient adaptability in the complex physical environment of agriculture. Therefore, knowledge embedding is key to improving system credibility, interpretability, and practicality. Its theoretical foundation is hybrid modeling, which integrates three complementary modeling approaches: mechanistic physics models, symbolic models, and data-driven agent models. Mechanistic physics models include Newtonian dynamics [

28], which describe the laws of mechanical motion, and soil-agricultural machinery interaction models, which simulate tillage resistance [

29]. Symbolic models encompass crop growth calendars that guide the sequence of agricultural operations and irrigation strategies based on moisture thresholds. Data-driven agent models, trained with sensor data, can capture complex dynamics that are difficult to describe using other methods [

30].

To clearly compare the characteristics of different methods,

Table 1 compares the actual effects of various knowledge embedding strategies from three dimensions: system architecture, application scenarios, and performance.

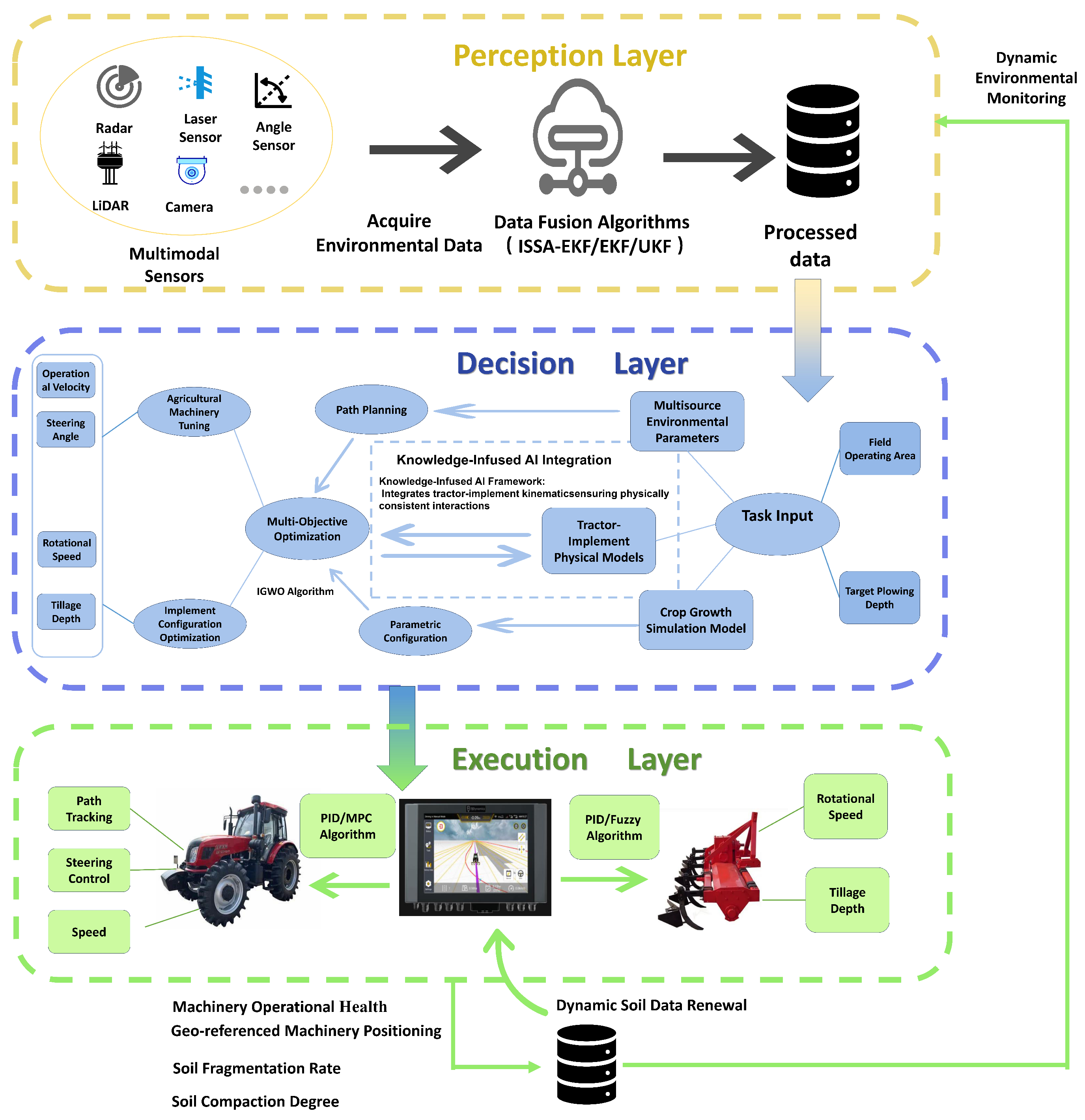

From a system architecture perspective, the effectiveness of knowledge embedding depends not only on the strategy itself but also on its synergistic effect within the overall system. The three-tiered vertical functional framework for intelligent agricultural machinery, shown in

Figure 3, embodies this synergistic concept. This framework demonstrates that while the core role of knowledge embedding is concentrated at the decision-making level, its value permeates the entire system: the perception layer improves data quality by embedding sensor physics knowledge; the decision-making layer integrates agronomic and physical constraints for optimization; and the execution layer incorporates an understanding of organizational dynamics to achieve precise control.

However, layered design alone is insufficient to address the structural weaknesses of model integration. In this framework, the introduction of formalized agronomic constraints and mechanical dynamics models is crucial for achieving credible decisions and feasible control. Its design is theoretically highly consistent with the “constrained reinforcement learning” framework proposed by Liu et al. [

35]. Both approaches explicitly incorporate agronomic and physical constraints into the decision-making optimization process to avoid the mismatch between semantic understanding, physical consistency, and safety feasibility inherent in data-driven models.

Specifically, the constrained reinforcement learning framework models agricultural autonomous control as a constrained Markov decision process. By introducing immediate and cumulative constraints into the reward function, the model is able to achieve operational objectives while satisfying agronomic constraints such as energy consumption, safety, and crop protection. This mechanism provides theoretical support for the integration of formalized agronomic constraints and mechanical dynamics. Correspondingly, in this research framework, formalized agronomic constraints guide operational logic (e.g., matching crop growth stage with tillage depth), while the mechanical dynamics model constrains energy transfer and motion response through differentiable equations, ensuring that the action strategy converges within the physically feasible domain.

This design, which embeds agronomic constraints and dynamics laws into the decision-making process, essentially implements a “constrained reinforcement learning”-style knowledge embedding. By imposing explicit feasibility conditions within the AI reasoning chain, the system ensures that the learning results converge under the dual constraints of agronomic semantics and physical consistency, significantly improving the model’s stability, interpretability, and security. This echoes the constrained optimization concept proposed by Liu et al. [

35] in automated agriculture, validating the theoretical feasibility and generalization potential of this framework in complex agricultural environments.

Thus, the combination of formalized agronomic constraints and mechanical dynamics not only provides an algorithmic optimization mechanism but also forms a cross-level coordination structure, enabling perception, decision-making, and execution to work together in a unified physical and agronomic semantic space. This design is a key path to realizing “intelligent collaborative” agricultural AI systems.

The practical effectiveness of the knowledge-embedded AI framework based on the integration of agronomic constraints and mechanical dynamics is verified through the following application cases. For tractor plowing depth control, researchers embed engine load characteristics as additional constraints into a neural network prediction model, enabling the system to significantly reduce fuel consumption while maintaining high operating power [

31]. Another study, focusing on hybrid tractor energy management, develops a learning system that incorporates physical rules. This system introduces a fuzzy PI controller into the equivalent fuel consumption minimization strategy (ECMS). By dynamically adjusting the equivalent factor to ensure the battery state of charge (SOC) remains within a reasonable range, it successfully reduces fuel consumption by 6.71% [

25]. Further research employs a differentiable mechanics model for plowing depth control and combines it with a Kalman filter for online calibration, strengthening the correlation between implement angle and actual cutting depth and significantly improving system reliability [

32]. These examples demonstrate that knowledge embedding can effectively address the shortcomings of purely data-driven models and enhance the reliability and efficiency of systems in real-world physical environments.

3. Multi-Agent Coordination Framework

As discussed in

Section 2, the horizontal coordination mechanism of agricultural cooperative intelligence inherently requires orderly collaboration among multiple agents. This requirement creates an urgent need for systematic coordination theories and methods. The MACF serves as the theoretical foundation for this purpose. It transcends the autonomous capabilities of individual agents and focuses on managing swarms of heterogeneous equipment, such as tractors, drones, and harvesters, enabling them to function as a coordinated team, truly realizing swarm intelligence where the whole is greater than the sum of its parts. Farms increasingly rely on collaborative teams comprised of various intelligent machines, such as tractors, crop-spraying drones, and harvesters, to achieve higher efficiency with less investment. The MACF forms the key theoretical foundation for the efficient coordination of these systems, making complex swarm operations possible. This framework integrates three core capabilities: onboard autonomous decision-making, orderly knowledge sharing between devices, and flexible and adaptable dynamic task scheduling. This allows agricultural swarms to effectively adapt to changing field environments, diverse agricultural tasks, and unevenly distributed resource allocation [

36,

37]. Research has shown that this collaborative mechanism significantly outperforms traditional single-machine decision-making models, paving the way for building next-generation intelligent farm systems capable of self-adjustment and overall optimization.

To address specific weaknesses in traditional agricultural system integration, such as information silos, delayed decision-making, and unbalanced resource scheduling, the MACF design emphasizes a distributed multi-agent collaborative optimization mechanism. By combining a modular architecture with a highly reliable communication protocol, the system enables efficient task decomposition, state sharing, and real-time feedback across different types of agricultural machinery, overcoming the bottlenecks of single-center control architectures in complex and dynamic environments. This design not only improves the system’s scalability and robustness but also provides a unified interface and coordination logic for subsequent collective intelligence architectures and task orchestration systems.

For example, in the scenario of coordinated fertilization and field logistics scheduling, the framework integrates a dynamic task allocation model with execution time and distribution distance as joint optimization objectives. Practical applications have shown that in field trials conducted in Jimo district, Qingdao, the introduction of the chaos-cauchy fireworks algorithm (CCFWA) significantly reduced resource distribution variance by over 48% compared to traditional methods [

15]. This not only enables precise seed and fertilizer application, but also effectively improves agronomic coordination efficiency by balancing nutrient supply.

3.1. Collective Intelligence Architecture

Collective intelligence architecture is a concrete blueprint for realizing the horizontal coordination layer’s goals of “building a cross-temporal, cross-functional intelligent collaborative network” and “achieving global goals through distributed algorithms”. Within the framework of multi-agent coordination, collective intelligence architecture specifically refers to the systematic control logic and communication interaction paradigm designed to enable the collaborative operation of heterogeneous agricultural agent clusters, namely multiple self-driving tractors and various intelligent agricultural machinery attachments. This architecture treats each independent agricultural machine as an autonomous agent, sharing real-time status and environmental data through high-speed communication networks and relying on AI algorithms for distributed decision-making, ultimately enabling the entire cluster to exhibit globally optimized collaborative behavior. Its core research focuses on exploring different coordination mechanisms, such as centralized control, distributed negotiation, or hybrid decision-making, to improve the system’s operating efficiency, task adaptability, and overall robustness in complex farmland environments, thereby laying the core theoretical foundation for the realization of large-scale unmanned farms. The collective intelligence architecture was designed to further optimize coordination delays and data consistency issues common in distributed systems. By introducing an adaptive synchronization protocol and a multi-level communication topology, the system maintains efficient collaboration among agents even in environments with fluctuating networks or limited bandwidth. Furthermore, a shared situational awareness model based on a knowledge graph enables diverse agents to form a unified understanding of the environment and collaborative decision-making foundation despite heterogeneous sensors and execution units, fundamentally alleviating information asymmetry and task conflicts.

The collective intelligence architecture, built on an efficient and reliable communication network and a shared situational awareness model, enables heterogeneous tractors and agricultural implements to exchange multi-source sensory data in real time, such as soil moisture distribution maps and crop growth images, to jointly construct and continuously update a unified global field operation model [

13]. Based on this, the system’s decision-making unit can adopt various design approaches, such as a centralized planner, distributed negotiation, or a hybrid hierarchical model. It dynamically decomposes macro-agricultural goals (such as completing a full field harvest before rain or minimizing total system energy consumption) into a series of executable subtasks, precisely allocating tasks based on the capabilities and status of each agent [

13]. In practice, multiple machines complete complex agronomic tasks through rigorous collaborative motion planning and operation sequencing. Relying on continuous environmental feedback and internal state interaction, they achieve real-time closed-loop optimization of perception, decision-making, and execution.

This collaborative strategy has achieved remarkable results. In areas with dispersed fields, the system deeply integrates multi-source maps, positioning information, and real-time machine status to dynamically generate coordinated and optimized operating paths, significantly improving the overall efficiency of the fleet. Research has shown that collaborative optimization significantly improves overall operational efficiency by optimizing tasks across the entire system and reducing idle time [

37]. This fully demonstrates the practical value of distributed intelligent scheduling in modern agriculture.

However, the successful operation of this mechanism still faces many limitations, particularly due to the highly heterogeneous agricultural environment. Interface differences between different types of agricultural machinery must be overcome, and the reliability and real-time nature of data communication must be ensured within the limited bandwidth of the field [

38]. Furthermore, the accuracy and interoperability of sensory data (for example, identifying plot boundaries using machine vision) directly impact the effectiveness of group coordination and operational strategy execution. Currently, how to achieve a consistent understanding of sensor data among different agents and to develop efficient and reliable multi-source information fusion mechanisms remain key research areas of widespread concern [

38].

The collective intelligence architecture establishes the system structure and interaction principles for multi-agent collaboration. To achieve the adaptive behavior and strategy optimization of intelligent agents on this architecture, it is necessary to rely on the cooperative learning mechanism to provide algorithmic support.

3.2. Cooperative Learning Mechanism

Collaborative learning mechanisms, such as MARL, are core technologies for implementing distributed optimization methods and cooperative strategy generation at the horizontal coordination layer. These methods enable groups of agents to optimize operational strategies by sharing knowledge and exchanging experiences, thereby achieving swarm-level cooperative evolution, far exceeding the efficiency of single-agent learning. Through distributed decision-making and cooperative learning, these methods enable intelligent systems to adaptively cope with the uncertainties of complex agricultural environments.

Despite its significant advantages, cooperative learning still faces multiple challenges in practical agricultural applications. The primary challenge stems from unreliable communication environments. Fluctuations in field networks and uneven signal coverage can introduce significant communication delays and even packet loss. This makes it difficult for agents to synchronize models or gradient updates in real time. Decisions are based on outdated and inconsistent global information, ultimately causing policy drift and seriously damaging the overall cooperative effectiveness of the system. Another key challenge lies in data heterogeneity. Different operating units have different local environments (such as soil type, crop density, and agricultural machinery load), resulting in completely different distributions of the data they collect. This non-independent and identically distributed data not only slows down the convergence of a unified optimal strategy, but can also cause policy conflicts between agents, affecting the overall cooperative effect. In addition, resource constraints and safety requirements in agricultural scenarios further increase the complexity of the design of cooperative learning algorithms.

Several innovative solutions have been proposed to address these challenges. Xie et al. propose a switching system framework designed to mitigate network latency and packet loss, which significantly improves the scalability and robustness of systems in dynamic network environments [

39]. Building on the enhanced network stability of this framework, Li and Wei further explore the challenges posed by data processing and heterogeneity, and propose an output synchronization control method based on data-driven and adaptive dynamic programming [

40]. This method effectively improves the system’s adaptability to heterogeneity and external interference. Together, they enhance the overall performance of complex network systems from both the communication and data processing levels.

Building on this foundation, federated learning (FL), a distributed collaborative learning framework, enables multi-agent collaborative training while protecting data privacy and is gradually being introduced into the collaborative learning process of multi-agent systems. The core concept of FL is “local training − parameter update − global aggregation”. Specifically, each agent independently trains a model locally using its own sensory data, then uploads only the model parameters or gradients, not the original data. A central coordination node or aggregation mechanism generates a global model, which is then distributed back to each agent to achieve knowledge sharing. Specifically, each agricultural agent (such as a tractor, drone, or harvester) trains its model locally and periodically sends model updates to a global aggregator. The global aggregator generates a global policy using algorithms such as federated averaging and distributes the updated model to each agent, achieving cross-device policy synchronization and collaborative optimization.

This mechanism significantly reduces communication overhead, avoids the privacy risks associated with centralized transmission of sensitive data, and improves the system’s learning stability in low-bandwidth and highly heterogeneous environments. In agricultural scenarios, FL enables smart devices distributed across different plots and facing diverse environmental conditions to perceive differentiated data locally while aggregating a global model to form a shared optimal strategy, effectively addressing the uncertainty of field tasks and uneven data distribution.

In recent years, researchers have further proposed the federated multi-agent reinforcement learning (FMARL) framework, combining the privacy-preserving and distributed collaboration advantages of FL with the multi-agent decision-making capabilities of MARL. This framework enables agents to perform reinforcement learning training locally while simultaneously enabling cross-agent collaboration through global policy aggregation, thereby improving overall learning efficiency and decision robustness [

41]. This approach not only ensures system scalability and privacy security but also accelerates the convergence of collaborative strategies in complex agricultural networks, providing a feasible path for the practical application of multi-agent collaborative learning.

It’s worth noting that current research still has some limitations. Most algorithms have been validated only in simulation environments and lack the support of large-scale field experiments. Furthermore, existing methods require high computing resources, making their deployment on resource-constrained agricultural equipment challenging. Future research could focus on lightweight algorithm design, optimizing the communication-computation trade-off, and ensuring security and fault-tolerance mechanisms.

The cooperative learning mechanism realizes the collaborative optimization of intelligent agent strategies. However, in order to convert the optimized strategies into specific executable task sequences and coordinate multiple intelligent agents to jointly achieve complex goals, the specific scheduling and management of the task orchestration system (TOS) is required.

3.3. Task Orchestration System

The TOS is the core implementation vehicle for functions such as “precise task scheduling”, “optimal resource allocation”, “sequence planning”, and “conflict resolution” in the horizontal coordination layer. It aims to systematically address the aforementioned coordination challenges. As a core component of the MACF, the TOS’s core function is to transform complex global missions into executable collaborative action plans. Specifically, it parses and dynamically decomposes high-level goals, generating a series of dependent subtasks or atomic behaviors. These tasks are then efficiently and rationally assigned to heterogeneous agent members based on the agent’s state and capability set. Furthermore, the system monitors and schedules the entire task execution process in real time, replanning and handling exceptions in the event of uncertainties such as agent failures, task timeouts, or sudden environmental changes, ultimately ensuring robust and efficient completion of the overall task [

42]. In the hierarchical architecture of MAS, the TOS plays a critical role in connecting the upper and lower levels. It serves as both the “executive arm” of high-level decision-making and planning modules, translating macro-strategies into operational instructions; and the “coordination hub” of the autonomous control units of the underlying agents, integrating the dispersed individual behaviors to generate coordinated swarm intelligence [

43]. Therefore, its performance directly determines the overall collaborative effectiveness and adaptability of the MAS in complex and dynamic scenarios. However, designing an efficient TOS faces numerous core challenges, with research focusing primarily on resolving the interconnected problems of “decomposition-allocation-scheduling-coordination”.

3.3.1. Centralized Orchestration Methods

Centralized task orchestration methods utilize a single control node architecture and rely on a central controller to make global task decomposition, allocation, and scheduling decisions. These methods typically employ global optimization models, applying mathematical programming methods (such as mixed-integer linear programming, MILP) or market-based algorithms (such as the consensus bundling algorithm, CBBA) to solve the model and theoretically achieve the optimal task allocation. Based on complete system state information (including the capabilities of all agents and task requirements), the central controller generates specific execution instructions through an optimization algorithm. This approach offers the advantage of ensuring consistent and globally optimal system behavior, making it particularly suitable for scenarios with complex inter-task dependencies and the need for high levels of coordination. However, this approach also has significant limitations. For example, Peng et al. construct a multi-agent architecture and MILP framework based on deep reinforcement learning, which, while improving the efficiency of allocating large-scale and concurrent tasks to a certain extent, still faced challenges such as high model training data requirements and poor interpretability [

44]. Ye et al. employ a CBBA to address multi-task allocation with task coupling constraints, demonstrating its feasibility in specific scenarios such as search and rescue [

45]. However, such methods are generally applicable only to environments with fixed tasks or fixed resource information, and struggle to cope with dynamic task scheduling requirements. Bi et al. model UAV formation force allocation as an integer linear programming problem and proposed a distributed multi-UAV task reallocation algorithm [

46]. While this algorithm mitigated the impact of platform losses on task execution to some extent, it still failed to effectively address the coordination deficiencies and inefficiencies caused by resource competition and synergy. Furthermore, centralized approaches also suffer from high risk of single-point failure of central nodes, large communication bandwidth requirements, and limited system scalability. In dynamic environments, the computational overhead of resolving the optimization problem is significant, making it difficult to meet the requirements of applications with high real-time requirements, further limiting their application in complex real-world systems.

3.3.2. Distributed Orchestration Methods

Distributed task orchestration methods employ a decentralized agent architecture, achieving task coordination through local interactions and autonomous decision-making, without relying on a central control node. These methods are typically based on distributed algorithmic design, such as negotiation mechanisms like the contract net protocol (CNP) or consensus algorithms (such as the CBBA) to achieve inter-agent coordination and self-organization. Under the assumption that each agent relies solely on local observations and has a limited communication range, they gradually reach a consensus on task allocation through multiple rounds of iteration and interaction with neighbors. Distributed architectures offer excellent fault tolerance and system scalability, effectively addressing dynamic changes in network topology and single points of failure, making them particularly suitable for highly dynamic environments such as vehicular networks. Furthermore, since they do not require global information sharing, distributed methods offer significant advantages in privacy protection, avoiding the security risks associated with the centralized transmission of sensitive data. However, these methods also have significant limitations. For example, Agrawal et al. employ deep MARL to handle multi-robot task allocation in dynamic logistics warehouses [

47]. While this approach demonstrates good local responsiveness, it lacks a global optimization perspective, which can easily lead to resource allocation conflicts and overall performance fluctuations. Liu et al. propose a graph neural network-enhanced deep reinforcement learning scheme, which shortens task completion time by establishing a Markov decision process [

48]. However, without an explicit coordination mechanism, the overall system efficiency is still limited. Some studies attempt to combine federated learning frameworks to aggregate policy gradients in a distributed manner, relying solely on local observations to achieve joint sub-channel and power optimization for vehicle-to-vehicle links. While this approach significantly reduces communication overhead, it still does not fully address spectrum contention and model convergence stability issues in high-density scenarios. In general, despite the good scalability and privacy protection capabilities of distributed approaches, they typically converge only to suboptimal solutions, incur high communication overhead during negotiation, and struggle to guarantee convergence speed and final decision quality in scenarios with complex task dependencies and highly dynamic environments, limiting their application in systems with high real-time requirements.

3.3.3. Hierarchical Orchestration Methods

Hierarchical task orchestration methods employ a hybrid control architecture, combining the advantages of centralized global coordination with distributed local autonomy. They are typically designed as a two- or multi-layer control structure. Upper-layer controllers (such as cloud centers or domain master nodes) are responsible for macro-task planning, cross-domain resource coordination, and coarse-grained task allocation. Lower-layer agents (such as edge servers or end devices) perform fine-grained task scheduling and real-time adaptive adjustments based on local environmental information. Typical implementations include leader-follower and federated architectures. In these approaches, upper-layer nodes formulate global task decomposition and resource allocation strategies, while lower-layer nodes execute specific tasks while maintaining a certain degree of autonomy and can dynamically respond to local state. This approach demonstrates significant advantages in cloud-edge-end collaborative computing. For example, Cai et al. propose a three-tier collaborative computing architecture centered on mobile edge computing [

49]. By constructing a “large-small resource tree” model, they achieve multi-layer resource awareness and unified management. Task segmentation and preliminary scheduling are performed at the edge layer, while global decision-making is made at the cloud layer. This approach improves resource utilization efficiency while maintaining system scalability. Cai et al. utilize long short-term memory for resource prediction and a double deep Q network-based hierarchical scheduling mechanism (LST-DDQN) [

49]. This enables efficient parallel offloading and execution of tasks across the cloud, edge, and end, significantly reducing task completion latency and energy consumption. Despite this, layered architectures also face challenges such as high design complexity, difficulty demarcating inter-layer responsibility boundaries, and difficulty developing communication protocols. Failures in high-level control nodes can still impact overall scheduling performance. Furthermore, achieving policy consistency and information synchronization across different layers, particularly in highly dynamic mobile environments such as vehicular networks, remains a key research challenge.

3.3.4. Learning-Based Intelligent Orchestration Methods

Learning-based intelligent task orchestration methods primarily leverage machine learning techniques, particularly MARL and graph neural networks (GNN), to autonomously learn and optimize task allocation policies through a data-driven approach. These methods typically employ a “centralized training, distributed execution” framework, such as the multi-agent deep deterministic policy gradient (MADDPG) algorithm. During training, global state information is used to optimize the policy network. During execution, each agent relies solely on local observations for decision-making, thus balancing the requirements of global coordination and local autonomy.

In recent years, these methods have demonstrated significant advantages in complex task allocation. The multi-agent system designed by Peng et al. via deep reinforcement learning, paired with an automated MILP framework, accelerates the processing of extensive parallel workloads [

44]. A deep MARL approach introduced by Aakriti Agrawal coordinates task assignment among multiple robots in dynamic logistics warehouses [

47]. A graph-augmented deep reinforcement learning (GA-DRL) scheme, proposed by Liu et al. through the combination of graph neural networks and reinforcement learning, leverages Markov decision process modeling to effectively shorten task completion time [

48]. Li et al. improve the multi-agent deep deterministic policy gradient algorithm, improving the rationality of task allocation while reducing decision complexity [

50]. These methods are capable of handling high-dimensional state spaces and dynamic environmental changes, avoiding complex manual rule design in an end-to-end manner, and exhibiting strong generalization and environmental adaptability. However, they still face several challenges: first, they require a large amount of training data and computing resources, resulting in an unstable model training process; second, the learned policies are difficult to interpret, making reliability verification and system certification difficult in safety-critical scenarios such as military command and emergency response. Therefore, while learning-based approaches offer new solutions for multi-agent task orchestration, their theoretical completeness and practical implementation still require further exploration and improvement.

To systematically compare the characteristics of mainstream task orchestration methods,

Table 2 compares four typical approaches: centralized orchestration, distributed orchestration, hierarchical orchestration, and learning-based intelligent orchestration, across seven key areas: control structure, scalability, robustness, optimality, communication overhead, typical use cases, and core challenges. This comparison is an important reference for selecting appropriate orchestration strategies in complex system coordination scenarios, such as intelligent agricultural machinery systems.

Overall, research on multi-agent TOS has evolved from centralized control to distributed collaboration, and finally to hierarchical hybrid architectures, with the field now thriving towards intelligentization. Each approach has its own unique characteristics: centralized approaches pursue global optimality but suffer from limited scalability; distributed approaches prioritize robustness but face a trade-off between solution quality and communication overhead; hierarchical approaches achieve a good balance in practice; and learning-based approaches demonstrate significant potential for addressing complex problems. Currently, this field faces several key challenges. First, existing research largely assumes homogeneous agents, leaving in-depth research on coordination mechanisms for heterogeneous systems. Second, as system scale expands, ensuring orchestration quality while maintaining low computational and communication complexity presents a significant challenge. Third, the reliability and interpretability of learning-based approaches in safety-critical scenarios remain to be improved. Furthermore, achieving hybrid-enhanced orchestration for human-machine collaboration and addressing the migration from simulation to reality are crucial areas requiring urgent breakthroughs. Future research should focus on adaptive allocation theory for heterogeneous systems, lightweight distributed consensus algorithms, learning frameworks under security constraints, human-machine collaborative decision-making paradigms, and simulation migration technologies. Through multidisciplinary integration, we can ultimately achieve an efficient, reliable, and scalable intelligent TOS.

4. Physics-Aware Implement Control

Although the multi-agent collaboration framework lays the foundation for machine clusters, achieving precise on-site operations requires complex implementation controls to address the core challenge of perceptual robustness under environmental interference.

This section elaborates on the technical pillars of intelligent implement control: dynamic tractor-implement modeling, adaptive control, and standardized security pairing, each providing essential support for advancing smart agriculture. Dynamic tractor-implement modeling lays the foundation for understanding the physical characteristics of the system by constructing high-fidelity digital twins. Adaptive control takes this model as its core, endowing agricultural machinery with the decision-making and execution capabilities to deal with complex environments, and it is the core link to achieve precise autonomous operation. Standardized security pairing, as the ultimate guarantee, ensures that the above-mentioned intelligence can be reliably and credibly executed in the collaboration of heterogeneous devices.

4.1. Dynamic Tractor-Implement Modeling

Dynamic modeling is the foundation for dealing with environmental disturbances and enhancing the robustness of systems. It converts unmeasurable environmental disturbances into predictable model parameters and state disturbances by constructing high-fidelity dynamic models, thereby providing crucial forward-looking and compensation basis for subsequent adaptive control.

Modeling the dynamic interaction between tractors and implements is crucial, as machinery often consists of complex multibody components and operates in uncertain environments. Traditional nonholonomic constraint models cannot capture this complexity [

51]. To improve accuracy and computational performance, Redon et al. introduce an adaptive joint selection mechanism that rigidifies less critical joints, ensuring that the computational load increases with the number of kinematic joints [

52]. Building on this, Gayle et al. introduce hierarchical collision detection, using blended bounding boxes to quickly eliminate inactive regions and utilizing a custom Jacobian matrix to reduce the complexity of the collision response to a sublinear level [

53]. In light of the current research status and actual demands, for agricultural implements directly connected to tractors, their interaction modeling can be further simplified: there is no need to construct a dedicated high-dimensional complex interaction model. Instead, it can be abstracted as a command-response system and embedded in a reinforcement learning framework for collaborative optimization [

54]. Specifically, the tractor, as the main body of intelligent control, sends action instructions to the farm tools, which then form response states based on sensor feedback. Reinforcement learning agents, through continuous interaction with the environment, autonomously learn the dynamic mapping relationship between commands and responses, thereby achieving efficient control and task optimization of tractor-farm tool systems without the need for explicit modeling of farm tool dynamics.

In addition to kinematics, accurate traction force prediction is crucial for energy-saving control and precise trajectory planning. Mechanical modeling based on Buckingham II theorem abstractions 13 parameters into 5 dimensionless groups, simplifying complexity while maintaining physical consistency [

55], by optimizing tire pressure to 80 kPa and operating under low soil moisture conditions, the traction efficiency can be significantly improved [

56]. These findings provide a basis for the development of intelligent decision-making systems [

57]. Meanwhile, intelligent algorithms such as artificial neural networks have made breakthroughs in prediction accuracy [

58]. It provides a new idea for the prediction of traction force under complex working conditions.

In the field of tractor transmission system optimization, by using computer simulation technology to analyze the structural characteristics and energy consumption performance of the transmission system, a theoretical basis can be provided for subsequent optimization. Experimental verification link focuses on the actual performance of power output device, such as continuous working ability and work quality key indicators [

28,

59]. Intelligent algorithms are widely applied in parameter optimization, achieving performance improvement by balancing multi-objective constraints [

60]. It is particularly worth noting that the development of the new type of electromechanical hydraulic composite transmission system provides an innovative solution for power distribution, and its modular design concept significantly enhances the system’s adaptability [

25].

4.2. Adaptive Control Strategies

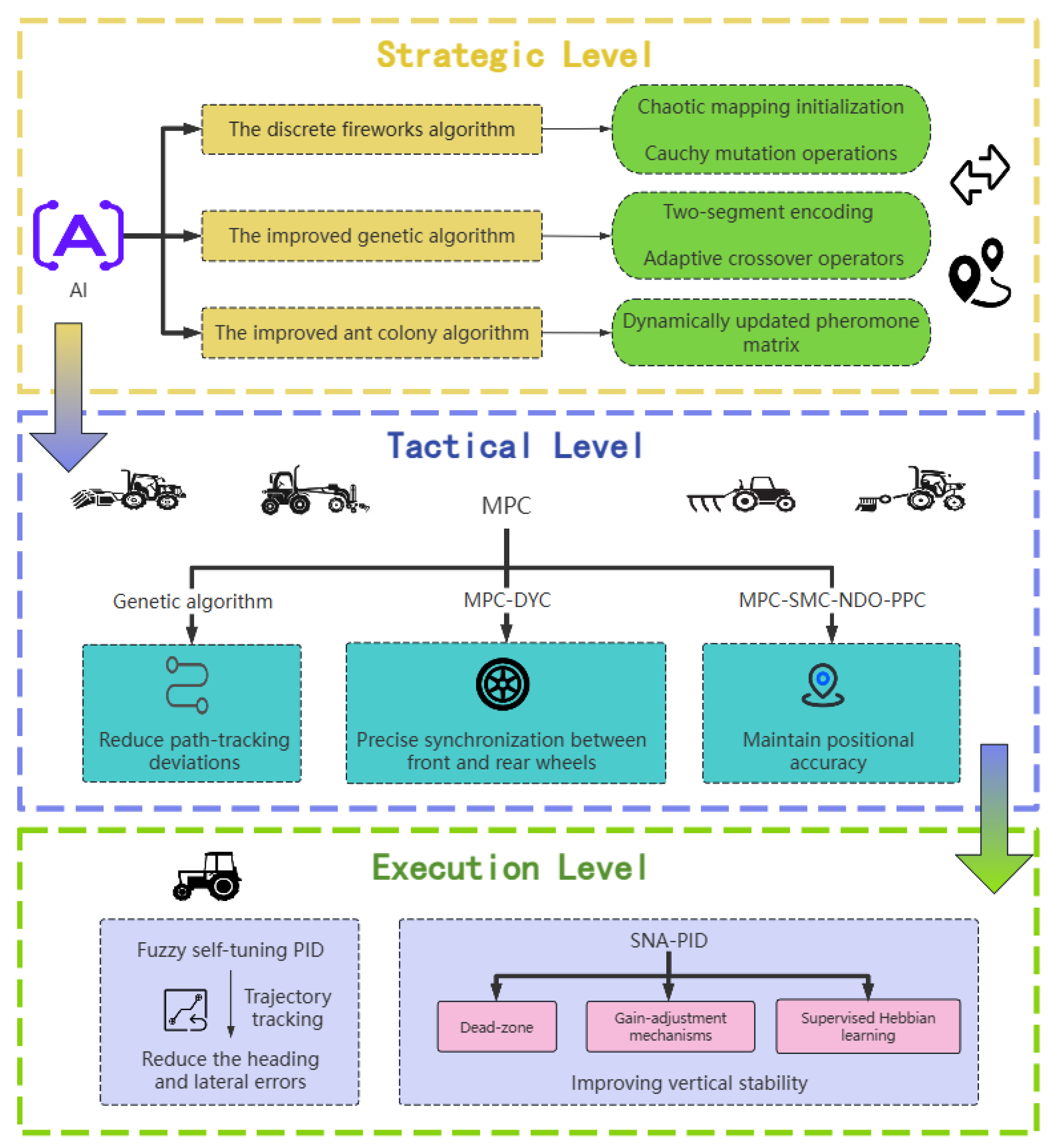

Dynamic modeling provides a theoretical basis for tractor control. However, the agricultural environment is highly variable, which poses a challenge to the reliability of precise models. Fixed control parameters cannot adapt to all working conditions, which is precisely a manifestation of the lack of system robustness. Therefore, modern intelligent agricultural systems adopt adaptive control strategies to enhance accuracy and robustness under complex conditions. As shown in

Figure 4, we advance physically aware control strategies that dynamically adapt to field heterogeneity. By optimizing task allocation and path optimization through intelligent algorithms at the strategic level, achieving precise trajectory planning and real-time adjustment through model predictive control (MPC) at the tactical level, and ensuring real-time regulation through adaptive PID and neural network control at the execution level, we can achieve centimeter-level positioning accuracy in complex farmland environments and significantly enhance operational efficiency and system reliability. The feasibility of this adaptive strategy has been widely supported. Bhat and Wang point out that AI and adaptive control are the key trends to deal with the uncertainty of the agricultural environment [

26], while Che et al.’s field experiments confirm that such strategies can achieve centimeter-level path tracking accuracy [

61].

Strategic level: The discrete fireworks algorithm [

15] effectively solves the problems of task allocation and path optimization in multi-machine collaborative operations through chaotic mapping initialization and Cauchy mutation operations. The improved genetic algorithm [

62] adopts two-segment encoding and adaptive crossover operators to address the issues of load imbalance and path crossover in the allocation of large-scale farmland tasks. The improved ant colony algorithm [

63] introduces a dynamically updated pheromone matrix, which not only solves the problem of uneven agricultural machinery load caused by “nearby allocation”, but also realizes efficient task reallocation in a dynamic environment.

Tactical level: MPC combined with robust controllers facilitates trajectory planning and real-time adjustment. For articulated tractors navigating orchard alleys, prediction and control horizons are adaptively optimized via genetic algorithms, markedly reducing path-tracking deviations [

64]. In four-wheel-independent-drive self-steering vehicles, model predictive control - direct yaw-moment control (MPC-DYC) architectures achieve precise synchronization between front and rear wheels, minimizing crop damage [

65]. Additionally, a layered architecture (MPC for outer-loop planning, sliding mode control for dynamic tracking, nonlinear disturbance observer for disturbance rejection, and prescribed performance control for error bounds) maintains positional accuracy under sudden loads within 0.1 m [

66].

Execution level: Real-time regulation is achieved through adaptive PID and neural PID controllers. The fuzzy self-tuning PID in the dual-loop scheme reduces the heading and lateral errors in trajectory tracking [

67], while the single-neuron adaptive PID (SNA-PID) applies supervised Hebbian learning, combined with dead zone and gain adjustment mechanisms, improving vertical stability on different terrains [

68].

This orchestrated framework empowers agricultural machinery with centimeter-level positioning precision even in challenging field conditions, significantly boosting operational efficiency and reliability. It thus represents a key enabler for scalable, resilient, and intelligent agriculture.

4.3. Standardized Secure Pairing for Farm Equipment

Adaptive control strategies endow agricultural machinery with core intelligence to deal with complex environments. However, to reliably transform this intelligence into productivity in a heterogeneous device collaborative network, it is necessary to establish a standardized security pairing mechanism as the underlying guarantee.

The current blockchain-based internet of things (IoT) security technology is evolving in a diversified manner.

Table 3 compares four leading mechanisms for secure pairing and integration across heterogeneous agricultural equipment. The automated verification of smart contracts enables the automation of the entire lifecycle management in cross-brand device pairing [

69]. A lightweight ECC encryption approach combined with blockchain anchoring enhances the security performance for devices with limited computational capabilities [

70]. Zero-knowledge proof (ZKP) effectively addresses the core contradiction in equipment leasing scenarios, where it is essential to verify the legitimacy of the equipment while preserving the confidentiality of the manufacturer’s algorithms [

71,

72]. Furthermore, multimodal biometric features strengthen anti-tampering capabilities through physical-layer feature authentication [

36].

These techniques operate in a layered security hierarchy: biometric identification confirms physical device ownership; ZKPs ensure cryptographic identity privacy; smart contracts automate verification logic; and the blockchain provides immutable audit trails.

The security of the IoT in agriculture needs to balance the intensity of protection and the implementation cost. Core data can be encrypted with ZKP advanced encryption, and lightweight solutions can be used for regular communication. Protocol optimization and hardware acceleration can enhance verification efficiency, making solutions like ZKP more practical. The actual deployment should be handled in a hierarchical manner: basic encryption should meet the requirements of self-owned equipment, ZKP is suitable for high-value leasing scenarios, and a hybrid architecture is applicable to data exchange. The optimal solution is a layered design: biometric authentication at the device layer, efficient encryption at the network layer, and enabling advanced protocols for critical services, ensuring security while controlling costs.

Current research trends aim to evolve interoperability frameworks in three dimensions: from point-in-time certification to full life-cycle trust management, from generic solutions to agriculture-specific protocols, and from technical validation to integration with operational business models.

5. Stage-Specific Cognitive Applications

Having established the technical underpinnings for autonomous agricultural machinery, this section illustrates how these capabilities translate into practice across three key field scenarios: field preparation synergy, plant protection coordination, and harvest logistics orchestration. These stage-specific applications exemplify the critical transition of smart agriculture from controlled environments to real-world deployment.

5.1. Field Preparation Synergy

Field preparation synergy operates at both the operational planning and real-time execution levels. At the planning level, utilizing the hybrid particle swarm optimization and neighborhood strategy search (HPSO-NS) method that considers sequence-dependent setup times to generate optimal task sequences and schedules for agricultural machinery, which outperforms the traditional particle swarm optimization (PSO) by 7.328% in solution quality [

73]. This method incorporates the conversion time of agricultural machinery into the optimization objective by establishing a six-stage tillage model (pre-land preparation, soil loosening, ploughing, post-land preparation, land leveling, and fertilization). Its output is a high-level work plan that dictates the order and timing of machinery operations, making it particularly suitable for compound farmlands that require multiple tillage and preparation operations. At the execution level, for hilly areas with complex terrain, an adaptive ploughing depth control method based on engine load characteristics produces real-time actuator commands [

31]. This system dynamically adjusts the ploughing depth by real-time monitoring of engine speed, throttle opening, and hydraulic pressure. The final output is a control signal to the hydraulic system, ensuring that the tractor always operates within the optimal power range during the execution of the planned tasks.

The innovative design of the combined tillage machine [

74] has achieved a technological breakthrough in completing seedbed preparation in a single operation. This technology integrates the rotary tiller, disc rake and flat soil plate into the same frame. Through the hydraulic system, the working components can be quickly switched, effectively solving the negative traction problem caused by traditional combined machinery. It is suitable for plain areas with relatively uniform soil conditions. Meanwhile, based on the fuzzy analytic hierarchy process and the improved grey wolf optimizer (IGWO) [

75], a multi-objective optimization method is adopted, which is 20.33% higher than the traditional grey wolf optimizer (GWO). By constructing an integrated multi-sensor tillage depth monitoring system and a cutter roller speed adjustment system, precise control over the forward speed, tillage depth and cutter roller speed is achieved.

5.2. Plant Protection Operation Coordination

Sowing machinery and tractors have formed a highly integrated operation system in modern agriculture. The tractor provides traction power and electrical support for the seeder, and at the same time achieves mechanical connection through a three-point suspension system [

76]. Modern intelligent seeders use motor-driven seed placement devices and, in combination with tractor navigation systems, achieve precise sowing, solving the problem of missed sowing in traditional mechanical transmission.

The vision-based precision weeding system has established a complete closed-loop control process, integrating perception, decision-making, and execution [

77]. This system acquires field images through the visual sensors carried by the tractor, and uses the YOLOv3 algorithm to identify and locate weeds. After the visual system identifies the position of the weeds in real time, it transmits control instructions to the actuator. At the same time, the action timing of the weeding tool is precisely matched with the traveling speed of the tractor to ensure that the weeding operation is completed at the correct position. The system adopts a modular design, which is convenient for installation and adjustment, and can adapt to different operation requirements. At the same time, power transmission and real-time obstacle avoidance control [

78] can be achieved through three-point suspension connection. The coordinated optimization of the obstacle detection signal acquisition device and the tractor’s traveling speed significantly improves the weeding coverage rate.

The joint operation parameter optimization system [

79] realizes the integrated operation of “sowing − fertilizing − weeding” through the synergy of the vertical active straw removal device and the spray system. The power output shaft of the tractor simultaneously drives the straw removal device and the spray system. Through the optimization of the mechanical transmission ratio, the synchronous operation of each component is ensured. The practical value of this research lies in solving the problem of easy clogging of traditional plant protection machinery under straw covering conditions, and achieving the integration of agricultural machinery and agronomy through institutional innovation.

5.3. Harvest Logistics Coordination

Following field preparation and plant protection, the focus shifts to the final, time-critical stage of the agricultural chain: harvest logistics coordination.

The integration of sliding mode control (SMC) with radial basis function (RBF) neural network techniques offers an effective approach to addressing model uncertainty and external disturbances in harvest collaboration systems [

80]. This methodology begins by constructing a dynamic model of the tractor-trailer system that incorporates nonholonomic constraints, describing the system behavior through second-order Euler-Lagrange error dynamics. The RBF neural network is employed to estimate and compensate in real time for uncertainties arising from factors such as soil resistance and load variations, while the sliding mode control mechanism ensures system robustness in the presence of estimation errors. This approach is particularly well-suited for addressing common agricultural challenges such as uneven terrain and time-varying loads. Its engineering significance lies in enabling stable control performance without reliance on precise prior modeling information.

Furthermore, the PID control strategy that integrates prescribed performance control (PPC) with neural networks provides guaranteed performance bounds for harvest synergy systems [

81]. This method employs nonlinear transformation to convert constrained relative pose errors into unconstrained variables and utilizes a multi-layer feedforward neural network to approximate system uncertainties. The incorporation of PPC techniques allows explicit constraints on error convergence rate and overshoot through a defined performance function, ensuring that the inter-machine distance remains within a predefined safety range. The academic contribution of this method stems from its pioneering application of PPC to the collaborative control of agricultural machinery, effectively addressing the limitation of traditional approaches in simultaneously ensuring transient performance and steady-state accuracy.

Considering the practical issue of unreliable velocity sensors in field operations, an output feedback control scheme based on a saturation function is proposed. This method introduces a state observer to estimate unmeasurable velocity signals and employs a generalized saturation function to constrain both the control input and observer state amplitudes. An adaptive law based on the projection operator ensures boundedness of neural network weights, thereby preventing parameter drift. The comparative simulation shows that this scheme reduces the root mean square value of the distance tracking error from 13.26 m to 7.73 m, an increase of more than 40% [

82]. The innovation of this approach lies in its effective resolution of common sensor limitations encountered in agricultural machinery, with strict constraints on control signal amplitude that align with real-world actuator capabilities, thereby enhancing engineering applicability.

6. Enabling Technology Ecosystem

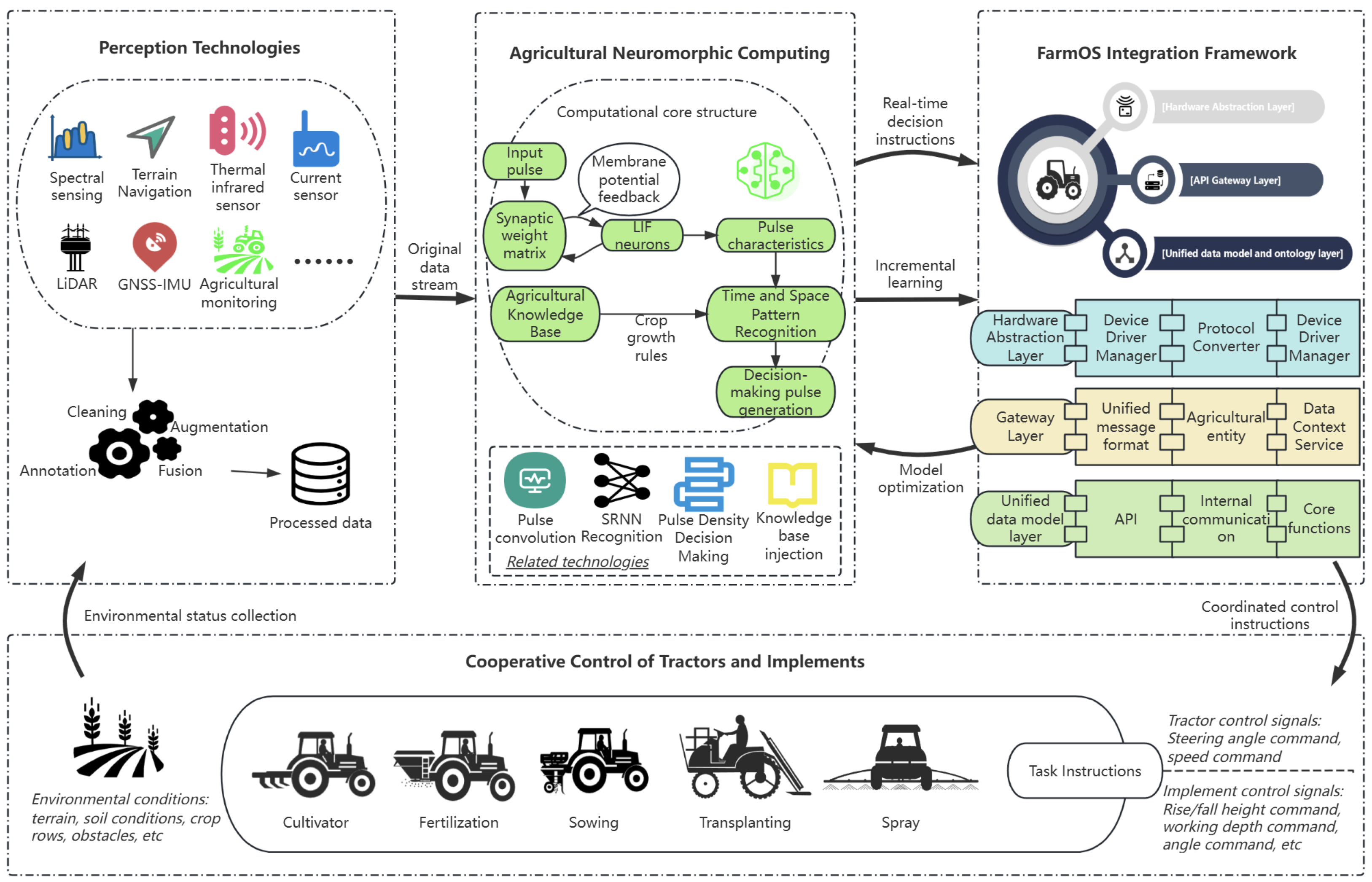

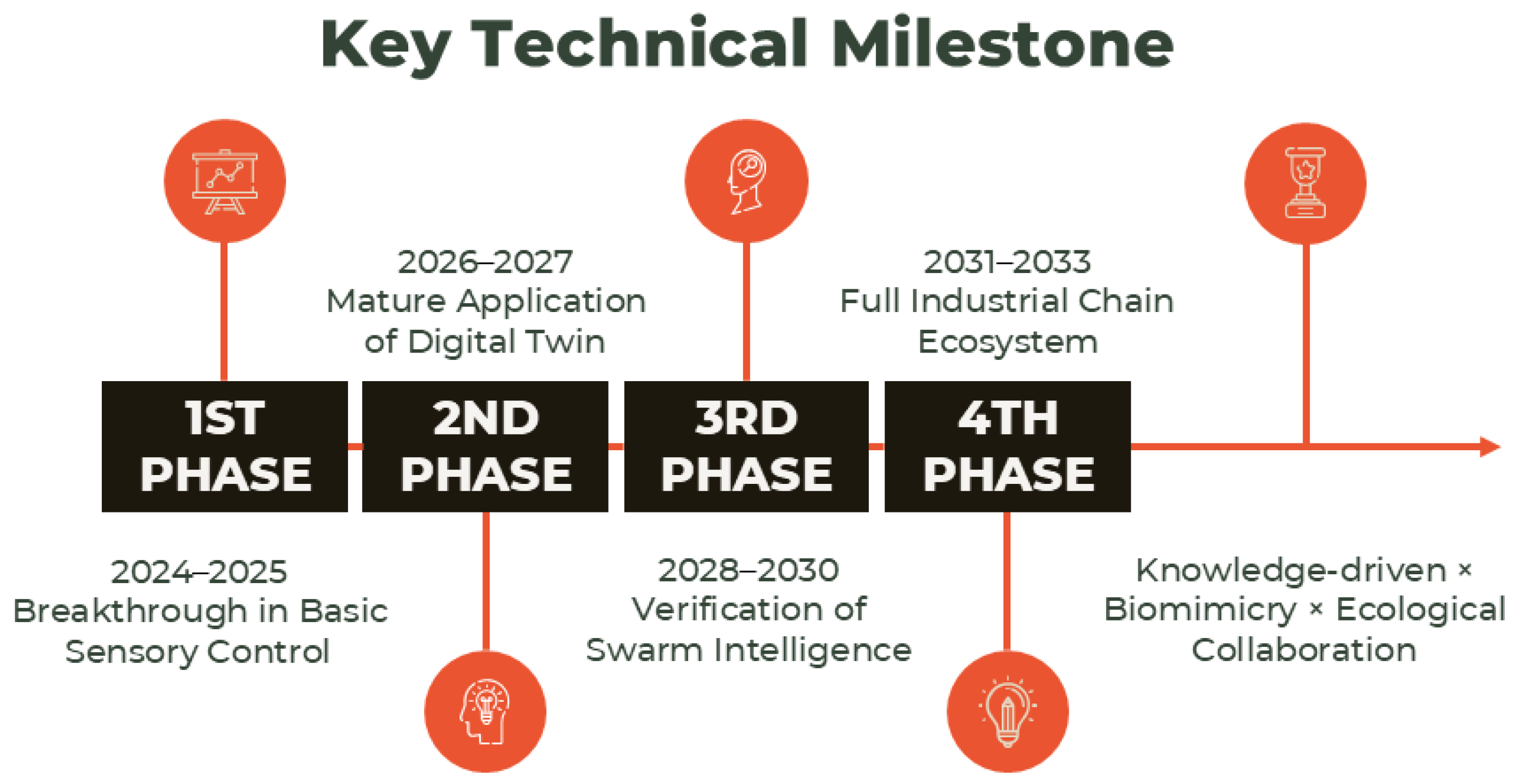

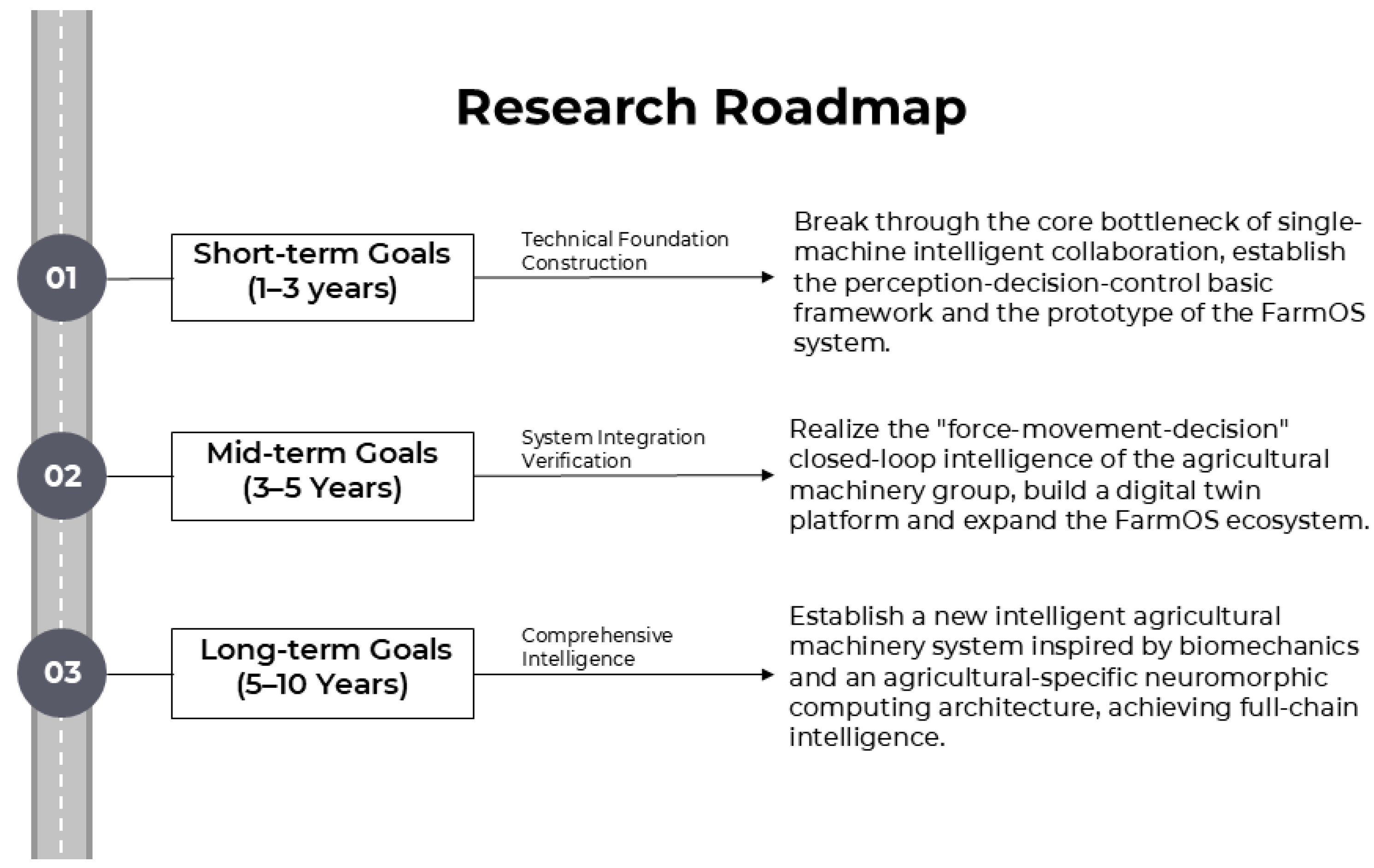

Our complex cognitive applications across various operational phases rely on a robust ecosystem of enabling technologies. This ecosystem, comprised of key hardware and software modules, enables autonomous agricultural machinery to effectively perceive, reason, and act in dynamic field environments. To achieve reliable and scalable collaborative control, this ecosystem must adhere to core design principles and cultivate advanced technological capabilities to ensure interoperability, flexibility, and adaptability across devices and scenarios. The coordinated combination of multiple enabling technologies, including neuromorphic computing for distributed intelligence and FarmOS for system integration, forms the integrated foundation necessary to achieve advanced collaborative control in precision agriculture. As shown in

Figure 5, we propose an integrated cooperative control ecosystem combining neuromorphic computing and FarmOS to overcome real-time coordination bottlenecks, a concept central to this integrated foundation.

Specifically, this technology ecosystem supports collaborative control through a multi-layered converged architecture. At the perception layer, multimodal sensing technologies (such as LiDAR, vision, and GNSS-IMU fusion) provide environmental awareness and positioning capabilities for tractors and implements. Tractor-specific sensing focuses on navigation and terrain processing, while implement-specific sensing monitors work quality and status. These two enable data sharing and fusion through collaborative sensing (such as UWB-based relative pose estimation and implement obstacle detection), providing a unified scene understanding for real-time decision-making. At the decision-making layer, agricultural neuromorphic computing, through an event-driven spiking neural network architecture, enables distributed real-time decision-making with microsecond latency and milliwatt power consumption. This effectively addresses the performance bottlenecks of traditional computing architectures in resource-constrained edge environments and provides an efficient computing paradigm for multi-machine collaborative path planning and dynamic task allocation. At the integration layer, FarmOS, an integrated middleware framework, solves the interoperability challenges between heterogeneous devices through a hardware abstraction layer, a unified data model, and an API gateway, enabling plug-and-play, dynamic identification, and collaborative task planning, scheduling, and execution for cross-brand agricultural machinery fleets. These technology modules operate not in isolation but are tightly integrated to form a synergistic whole. For example, event stream perception data processed by the neuromorphic computing unit can be connected to the system’s decision loop via FarmOS’s standardized interfaces, while device status information managed by FarmOS can in turn optimize the neural network’s collaborative control strategy [

83]. This deep integration enables the entire ecosystem to support complex application scenarios such as dynamically adjusting plow depth based on real-time soil resistance and coordinating grain unloading during multi-machine collaborative harvesting, significantly improving the efficiency, precision, and sustainability of agricultural operations.

In short, through technological innovation and deep integration at the three levels of perception, decision-making, and integration, this technology ecosystem has built an infrastructure capable of supporting highly autonomous, adaptive, and scalable cooperative control of agricultural machinery and implements, providing a comprehensive solution to the real-time, energy-efficiency, and interoperability challenges of precision agriculture.

6.1. Perception Technologies for Cooperative Control

The foundation of effective collaborative control lies in a multimodal perception system capable of generating a dynamic and highly realistic model of the environment. This integrated perception capability is crucial for achieving real-time coordination between autonomous tractors and implements, moving beyond independent operation to true collaborative collaboration. The perception architecture must encompass three complementary areas: tractor-centric navigation, implement-centric task monitoring, and crucially, collaborative perception. Collaborative perception bridges these two systems, overcoming coordination bottlenecks.

Tractor-centric perception provides global context for navigation and terrain control. Technologies such as GNSS-inertial measurement unit fusion and real-time leveling are crucial for maintaining operational stability and accuracy, especially in complex terrain. Otherwise, significant ground slopes can severely impact accuracy [

84]. These systems enable the tractor to determine its precise position and orientation, establishing a base coordinate system for all subsequent collaborative operations. Forward-looking sensors such as LiDAR and stereo vision further enhance situational awareness, enabling advanced terrain mapping and obstacle detection, allowing the entire system to anticipate and respond to upcoming challenges.

Implement-centric perception focuses on monitoring the interaction between tools and their environment, as well as their operational status, providing critical feedback for task execution. This includes spectral perception technology, which combines hyperspectral imaging with neural network methods to eliminate response differences between equipment and establish unified quality assessment standards for equipment clusters [

85,

86]. Meanwhile, vibration and current sensors integrated with multi-state recognition models enable real-time monitoring of the health and load conditions of implements, supporting adaptive control strategies that significantly improve operational reliability [

87]. These capabilities ensure that implements not only perform their primary functions but also communicate their status and requirements to the broader system.

The most critical advancement comes from collaborative perception technology, which establishes a continuous dialogue between tractors and implements. This includes technologies such as ultra-wideband (UWB) positioning for relative pose estimation, enabling precise spatial relationship tracking [

88]; traction force sensing for adaptive power management [