Advances in Lead-Barium-Zinc-Silicate-Type Glazed Warming Bowl Related to the Chinese Xuande Reign (1426–1435)

Abstract

1. Introduction

The Investigated Bowl and the Xuande Emperor

2. Materials and Methods

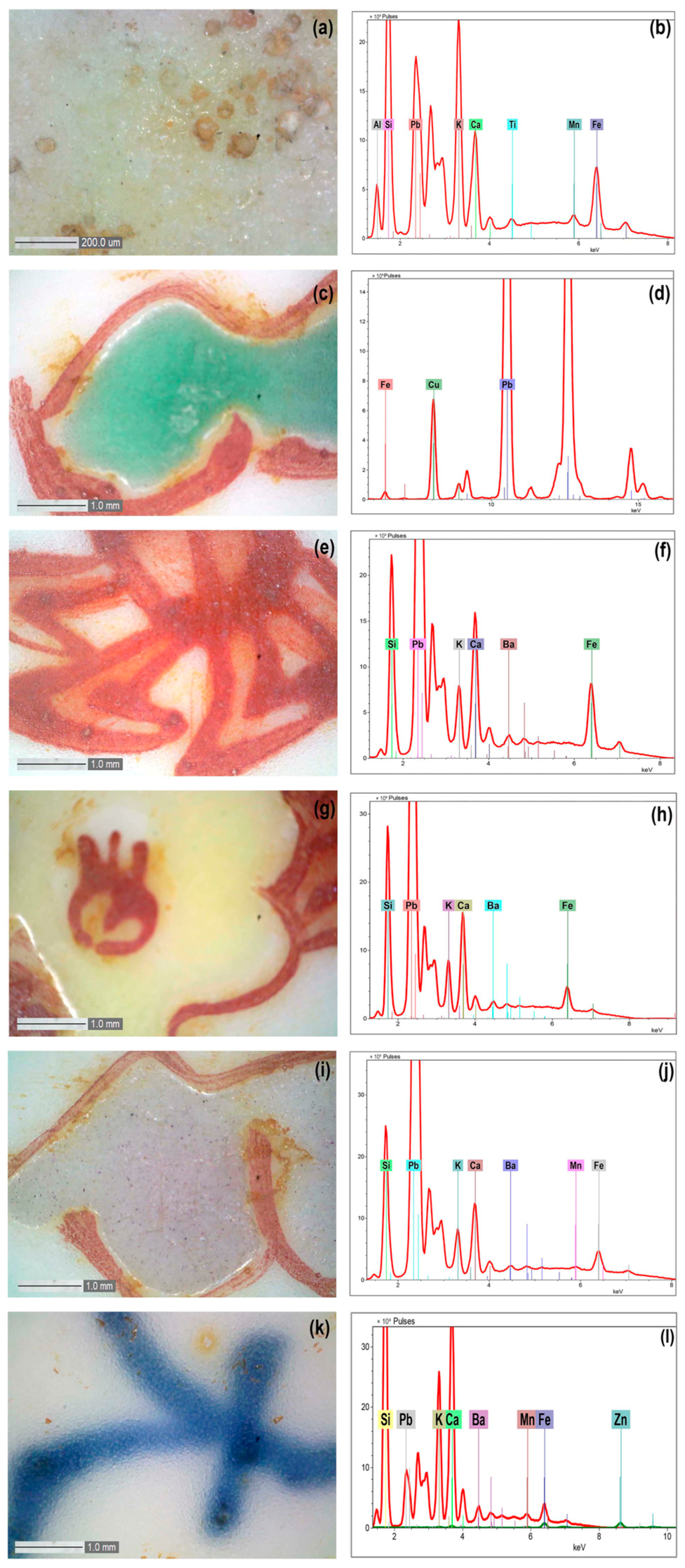

2.1. Handheld USB Digital Microscope (DM)

2.2. Optical Endoscopy (OE)

2.3. Energy-Dispersive X-ray Fluorescence (ED-XRF)

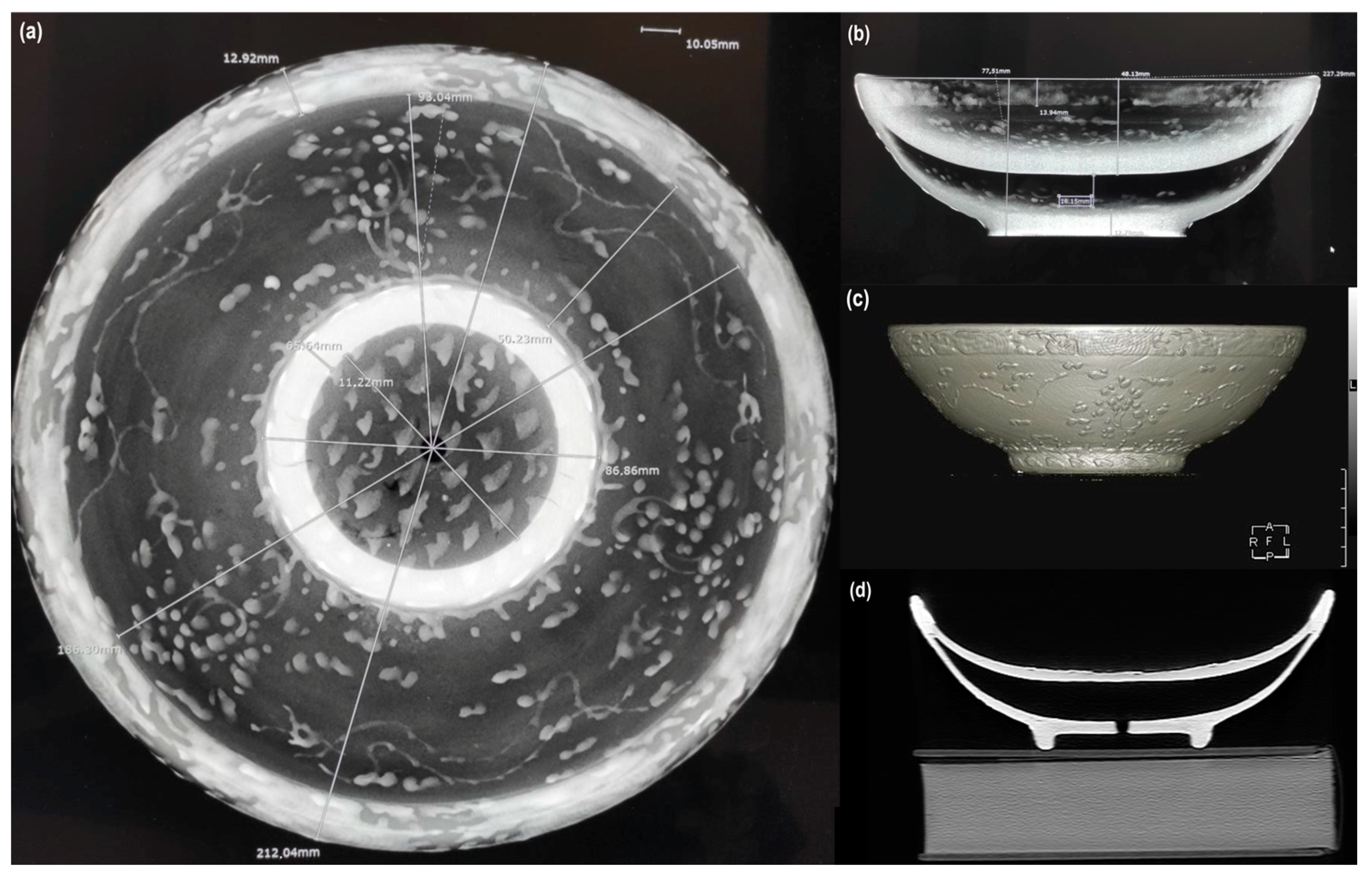

2.4. Radiography (X-ray) and Computed Tomography (CT)

2.5. Sampling

2.6. Scanning Electron Microscopy Coupled with Energy Dispersive X-ray Detector (SEM/EDX)

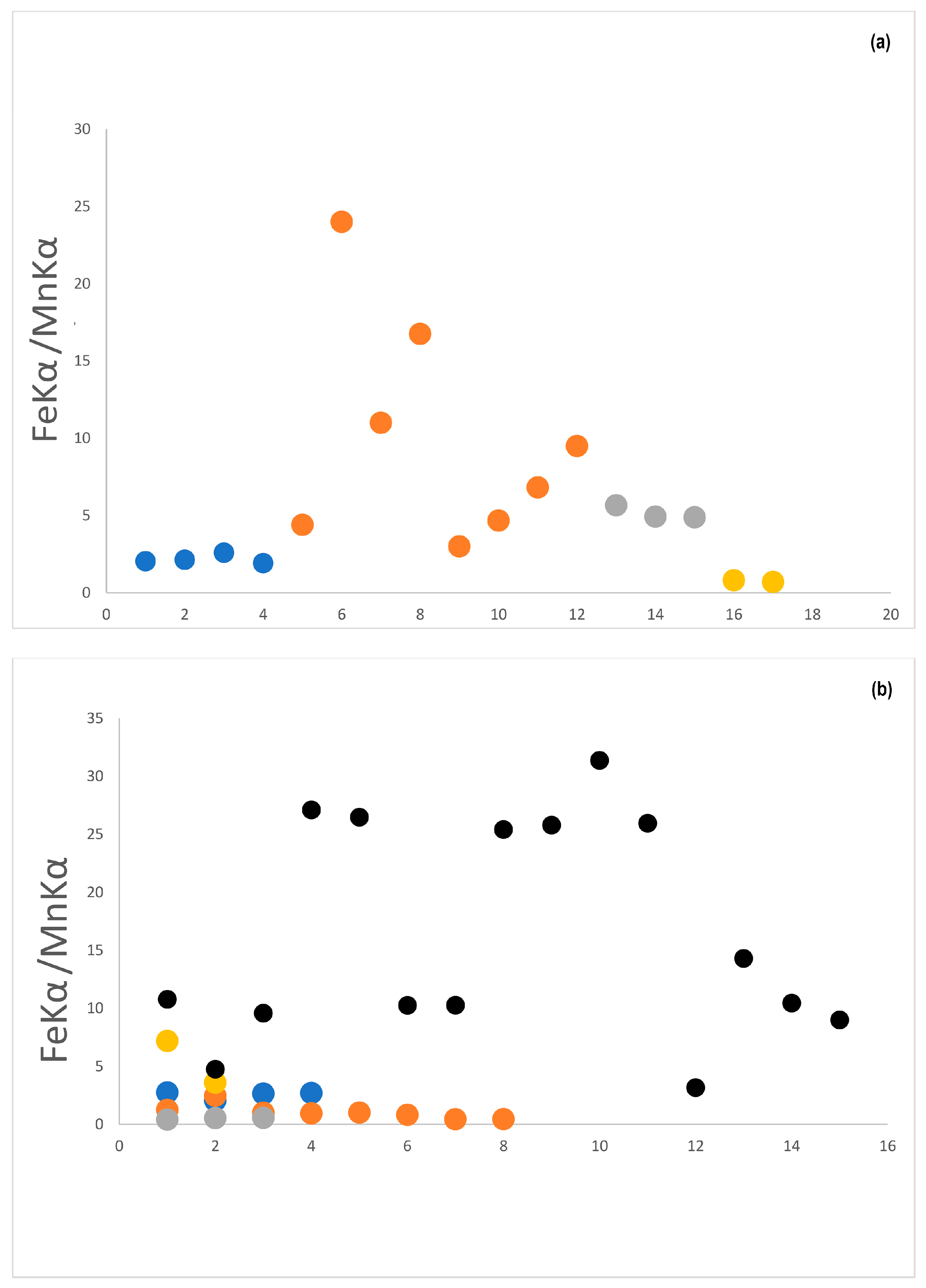

3. Results and Discussion

3.1. The Double-Walled Worming Bowl

3.2. The Chinese Texts on the Use of Barium, Lead, and Zinc

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kwon, C.L. Efficacious Underworld: The Evolution of Ten Kings Paintings in Medieval China and Korea; University of Hawai’i Press: Honolulu, HI, USA, 2019. [Google Scholar]

- Komaroff, L. Beyond the Legacy of Genghis Khan; Brill Academic Publishers: Leiden, The Netherlands, 2006; p. 320. [Google Scholar]

- Lu, Y.; Qian, C.; He, H. A History of Chinese Science and Technology; Springer: Berlin/Heidelberg, Germany, 2014; Volume 2, p. 392. [Google Scholar]

- Zhang, B.; Wang, X. Analysis of the Type of High Ancient Ceramic Bowl. Design 2018, 3, 25–31. [Google Scholar] [CrossRef]

- Peiyu, Y.; Min, L. The Derivative Design Research of Artistic Conception in New Chinese Style—Taking Ceramic Design as an Example. In Advances in Social Science, Education and Humanities Research ASSEHR, Proceedings of the 2020 International Conference on Language, Art and Cultural Exchange (ICLACE), Xiamen, China, 22–24 May 2020; Atlantis Press SARL: Zhengzhou, China, 2020; Volume 445, pp. 188–192. [Google Scholar]

- Pregadio, F. (Ed.) The Encyclopedia of Taoism I–II; Routledge: London, UK; New York, NY, USA, 2008; pp. 355, 853, 1003. [Google Scholar]

- Yushu, Z. (Ed.) Kangxi Dictionary (12 Volumes); Jilin Literature and History Publishing House: Changchun, China, 2016. [Google Scholar]

- Zhangjian, H. (Ed.) “Documents of Emperor Yingzong” Contained in Volume 161 of “Records of the Ming Dynasty” (with Collation Notes) (183 Volumes); Institute of History and Philology, Academia Sinica, Zhonghua Book Company: Beijing, China, 2016. [Google Scholar]

- Yu, K.N.; Miao, J.M. Characterization of blue and white porcelains using Mn/Fe ratio from EDXRF, with particular reference to porcelains of the Xuande period (1426 to 1435 A.D.). Appl. Radiat. Isot. 1999, 51, 279–283. [Google Scholar] [CrossRef]

- El Amraoui, M.; Haddad, M.; Bejjit, L.; Ait Lyazidi, S.; Lakhal, R. On-site XRF characterization of archaeological materials in CERA center of Rissani (Morocco). IOP Conf. Ser. Mater. Sci. Eng. 2017, 186, 012029. [Google Scholar] [CrossRef]

- Jamaludin, A.R.; Kasim, S.R.; Ahmad, Z.A. The Effect Of CaCo3 Addition on the Crystallization Behavior of ZnO Crystal Glaze Fired at Different Gloss Firing and Crystallization Temperatures. Sci. Sinter. 2010, 42, 345–355. [Google Scholar] [CrossRef]

- Pradell, T.; Molera, J. Ceramic technology. How to characterise ceramic glazes. Archaeol. Anthropol. Sci. 2020, 12, 189. [Google Scholar] [CrossRef]

- Wood, N. Chinese Glazes. Their Origins, Chemistry and Re-Creation; Herbert Press: London, UK, 2023; pp. 64, 187, 194–195, 224. [Google Scholar]

- Wen, R.; Wang, C.S.; Mao, Z.W.; Huang, Y.Y.; Pollard, M. The chemical composition of blue pigment on Chinese blue- and-white porcelain of the Yuan and Ming Dynasties (AD 1271–1644). Archaeometry 2007, 49, 101–115. [Google Scholar] [CrossRef]

- Feng, D.U.; BaoRu, S.U. Further study of sources of the imported cobalt-blue pigment used on Jingdezhen porcelain fom late 13 to early 15 centuries. Sci. China Ser. E-Technol. Sci. 2008, 51, 249–259. [Google Scholar] [CrossRef]

- Tite, M.S.; Freestone, I.C.; Wood, N. An Investigation into the Relationship between the Raw Materials used in the production of Chinese porcelain and stoneware bodies and the resulting microstructures. Archaeometry 2012, 54, 1. [Google Scholar] [CrossRef]

- Brill, R.H.; Chen, M. A compilation of Lead Isotope Ratios of some Ores from China published by Chen Yuwei, Mao Cunxiao, and Zhu Bingquan. In Scientific Research in Early Chinese Glass; Brill, R.H., Martin, J.H., Eds.; The Corning Museum of Glass: New York, NY, USA, 1991; pp. 167–180. [Google Scholar]

- Cui, J.; Wu, X.; Huang, B. Chemical and lead isotope analysis of some lead-barium glass wares from the Warring States Period, unearthed from Chu tombs in Changde City, Hunan Province. China J. Archaeol. Sci. 2011, 38, 1671–1679. [Google Scholar] [CrossRef]

- Fuxi, G. Origin and evolution of ancient Chinese glass. In Ancient Glass Research along the Silk Road; Fuxi, G., Brill, R., Shouyu, T., Eds.; World Scientific Publishing: Singapore, 2009; p. 20. [Google Scholar]

- Henderson, J. Ancient Glass: An Interdisciplinary Exploration; Cambridge University Press: Cambridge, UK, 2013; p. 123. [Google Scholar]

- Henderson, J.; An, J.; Ma, H. The Archaeometry and Archaeology of Ancient Chinese Glass: A Review. Archaeometry 2018, 60, 88–104. [Google Scholar] [CrossRef]

- Kim, F.C. Early Chinese Lead Barium Glass: Its Production and Use from the Warring States to Han Periods (475 BC–220 CE). Master’s Thesis, John Brown University, Siloam Springs, AR, USA, 2012. [Google Scholar]

- Ma, Q.; Braekmans, D.; Shortland, A.; Pollard, A.M. The Production and Composition of Chinese Lead-Barium Glass through Experimental Laboratory Replication. J. Non-Cryst. Solids 2021, 551, 2. [Google Scholar] [CrossRef]

- Wu, J.; Leung, P.L.; Li, J.Z.; Stokes, M.J.; Li, M.T.W. EDXRF studies on blue and white Chinese Jingdezhen porcelain samples from the Yuan, Ming and Qing dynasties. X-Ray Spectrom. 2000, 29, 239–244. [Google Scholar] [CrossRef]

- Živković, J.; Power, T.; Georgakopoulou, M.; Carvajal López, J.C. Defining new technological traditions of Late Islamic Arabia: A view on Bahlā Ware from al-Ain (UAE) and the lead-barium glaze production. Archaeol. Anthropol. Sci. 2019, 11, 4705. [Google Scholar] [CrossRef]

- Klein, S.; Fischer-Lechner, S.; Berthold, C.; Sessing, J.; Kirnbauer, T.; Zeiler, M.; Essling-Wintzer, W. Lead-Glazed Ceramic Fragments: Intentional Glazing or Metallurgical Accident? Metallogr. Microstruct. Anal. 2023, 12, 246–261. [Google Scholar] [CrossRef]

- Tang, Y.; Bi, X.; Fayek, M.; Stuart, F.M.; Wua, L.; Jiang, G.; Xu, L.; Liang, F. Genesis of the Jinding Zn-Pb deposit, northwest Yunnan Province, China: Constraints from rare earth elements and noble gas isotopes. Ore Geol. Rev. 2017, 90, 970–986. [Google Scholar] [CrossRef]

- Zhao, D.; Han, R.; Wang, L.; Ren, T.; Wang, J.; Zhang, X.; Cui, J.; Ding, J. Genesis of the Lehong large zinc–lead deposit in northeastern Yunnan, China: Evidences from geological characteristics and C–H–O–S–Pb isotopic compositions. Ore Geol. Rev. 2021, 135, 104219. [Google Scholar] [CrossRef]

- Li, Y.; Kong, Z.; Zhang, C.; Wu, Y.; Yang, X.; Wang, Y.; Chen, G. Pore Variation Characteristics of Altered Wall Rocks in the Huize Lead–Zinc Deposit, Yunnan, China and Their Geological Significance. Minerals 2023, 13, 363. [Google Scholar] [CrossRef]

- Li, Y.; Zou, H.; Said, N.; Liu, H. A new classification of barite deposits in China. Ore Energy Resour. Geol. 2023, 14, 100019. [Google Scholar] [CrossRef]

- Yin, X.; Huang, T.J.; Hao Gong, H. Chemical evolution of lead in ancient artifacts -A case study of early Chinese lead-silicate glaze. J. Eur. Ceram. Soc. 2020, 40, 2222–2228. [Google Scholar] [CrossRef]

- Chen, Q. A Primary Study on Simulated Sintering Experiment of Manmade Barium Silicate Products in Ancient, China. Master’s Thesis, University of Science and Technology of China, Hefei, China, 2014. [Google Scholar]

- Liu, Z.; Mehta, A.; Tamura, N.; Pickard, D.; Rong, B.; Zhou, T.; Pianetta, P. Influence of Taoism on the invention of the purple pigment used on the Qin terracotta warriors. J. Archaeol. Sci. 2007, 34, 1878–1883. [Google Scholar] [CrossRef]

- Gao, Z.X. Study of glass disks and sword-decorations unearthed from Hunan Province. In Proceedings of Beijing International Conference on Chinese Ancient Glass; Gan, F.X., Ed.; China Architecture and Building Press: Beijing, China, 1986; pp. 53–56. (In Chinese) [Google Scholar]

- Hou, D.J. The Production of Ores, Metals, Lacquer and Glass in Ancient Chu Kingdom; Hubei Scientific and Technical Publishers: Wuhan, China, 1995; pp. 270–275. (In Chinese) [Google Scholar]

- Dong, J.; Li, Q.; Liu, S. Scientific Analysis of Some Glazed Pottery Unearthed from Warring States Chu Tombs in Jiangling, Hubei Province: Indication for the Origin of the Low-Fired Glazed Pottery in China; John Wiley & Sons Ltd.: New York, NY, USA, 2020; pp. 1–15. [Google Scholar]

- Chen, Y.; Wen, R.; Wang, T. The origins of low-fire polychrome glazed pottery in China. Antiquity 2020, 94, e30. [Google Scholar] [CrossRef]

- Fuxi, G.; Huansheng, C.; Qinghui, L. Origin of Chinese ancient glasses—Study on the earliest Chinese ancient glasses. Sci. China Ser. E 2006, 49, 709. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, Y.; Chen, X.; Li, H.; Xu, Y.; Li, X. The research of burning ancient Chinese lead-barium glass by using mineral raw materials. J. Cul. Herit. 2016, 21, 797. [Google Scholar] [CrossRef]

- Fuxi, G. Introduction to the Symposium Papers. In Scientific Research in Early Chinese Glass; Brill, R.H., John, H.M., Eds.; The Corning Museum of Glass: New York, NY, USA, 1991; pp. 2–3. [Google Scholar]

- Gao, D. Complete Tang Dynasty; Art Publishing House: Beijing, China, 2018. [Google Scholar]

- Yuan, W.; Changling, H. Classic of the Emperors of the World; Taiwan University: Taiwan, China, 1989. [Google Scholar]

- You, L. (Ed.) Facts of the Song Dynasty; Yiya Publishing House: Beijing, China, 2018. [Google Scholar]

- Menglong, F. Warning Words; ZheJiang Publishing United Group: Frankfurt, Germany, 2018. [Google Scholar]

- Kejun, Y. The Complete Texts of Three Ancient Dynasties, Qin, Han, Three Kingdoms and Six Dynasties; Art China Network: Beijing, China, 1999. [Google Scholar]

- Zhong, G. Guanzi—Book of Master Guan (Full Text, Full Annotation, Full Translation); United Press: Beijing, China, 2023. [Google Scholar]

- Zumo, Z. (Ed.) Guangyun School Version (Two Volumes); Zhonghua Book Company: Beijing, China, 2022. [Google Scholar]

- Zhen, L. Manual of Tripod Vases of the Xuande Kingdom; Commercial Press: Shanghai, China, 1936. [Google Scholar]

- Wang, Z.G.; Wang, K.Y.; Wan, D.; Konare, Y.; Liang, Y.H. Genesis of the Huanggoushan Pb–Zn–Au polymetallic deposit in southern Jilin Province, NE China: Constraints from fluid inclusions and C–H–O–S–Pb isotope systematics. Geol. J. 2020, 55, 3112–3138. [Google Scholar] [CrossRef]

- Yingxing, S. The Exploitation of the Works of Nature, (a Critical Translation with Annotations of Tiangongkaiwu, by J. Pan); Shanghai Guji Chubanshe: Shanghai, China, 1993. [Google Scholar]

- Campana, A. Farmacopea Ferrarese del Dottore Antonio Campana Professore di Chimica Farmaceutica Nella Università di Ferrara; Catellacci Publisher: Firenze, Italy, 1840. [Google Scholar]

- Chen, H.; Souza, G.B. China’s emerging demand and development of a key base metal: Zinc in the Ming and early Qing, C. 1400–1680s. J. Mater. Cult. 2017, 22, 183. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, B.; Juleff, G.; Huang, W.; Li, D.; Bai, J. Ancient zinc smelting in the Upper and Middle Yangtze River region. Antiquity 2020, 94, e17. [Google Scholar] [CrossRef]

| Description | Code | Al K12 | Si K12 | Pb L1 | K K12 | Ca K12 | Ti K12 | Ba L1 | Mn K12 | Fe K12 | Co K12 | Cu K12 | Zn K12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Green edge | cdf1 | 1 | 1398 | 20,042 | 53 | 430 | 1 | 40 | 71 | 197 | 8 | 2923 | 10 |

| Green edge | cdf15 | 1 | 759 | 14,265 | 11 | 265 | 1 | 33 | 41 | 113 | 5 | 2090 | 5 |

| Green drop | cdf6 | 26 | 3136 | 5605 | 1114 | 2475 | 1 | 192 | 28 | 326 | 3 | 837 | 126 |

| Green leaf | cdf13 | 1 | 1243 | 2479 | 639 | 1487 | 1 | 113 | 12 | 220 | 3 | 285 | 78 |

| Green dragon crest | cdf14 | 3 | 1304 | 1976 | 669 | 1479 | 1 | 116 | 6 | 227 | 4 | 180 | 89 |

| Red dragon body | cdf4 | 7 | 2286 | 3569 | 533 | 1796 | 1 | 163 | 50 | 771 | 4 | 12 | 182 |

| Red cloud | cdf16 | 29 | 2224 | 1185 | 987 | 2114 | 1 | 170 | 17 | 310 | 3 | 6 | 125 |

| Red dragon claw | cdf18 | 1 | 2231 | 4564 | 464 | 1597 | 1 | 141 | 51 | 632 | 9 | 12 | 163 |

| Yellow cloud | cdf5 | 1 | 2865 | 10,987 | 593 | 1767 | 2 | 160 | 50 | 314 | 3 | 8 | 110 |

| Grey cloud | cdf7 | 41 | 3768 | 6675 | 1191 | 2664 | 1 | 209 | 60 | 311 | 5 | 34 | 129 |

| Grey cloud | cdf12.1 | 1 | 9264 | 18,082 | 1901 | 5159 | 1 | 425 | 331 | 431 | 9 | 15 | 137 |

| Grey tree | cdf17 | 13 | 2151 | 3168 | 808 | 1970 | 1 | 164 | 21 | 230 | 3 | 215 | 122 |

| Grey tree | cdf17.1 | 1 | 5113 | 5477 | 1351 | 3954 | 1 | 365 | 114 | 263 | 1 | 145 | 105 |

| Blue mark | cdf8 | 252 | 6971 | 228 | 2738 | 4404 | 1 | 322 | 118 | 324 | 58 | 8 | 350 |

| Blue mark | cdf11 | 223 | 6308 | 225 | 2701 | 4458 | 1 | 327 | 147 | 303 | 69 | 8 | 353 |

| Blue mark | cdf12 | 271 | 7588 | 193 | 3056 | 4949 | 1 | 361 | 132 | 350 | 51 | 7 | 357 |

| Blue mark | cdf19 | 99 | 3833 | 153 | 1972 | 3230 | 1 | 245 | 92 | 248 | 48 | 7 | 271 |

| Blue mark | cdf20 | 54 | 2636 | 283 | 1498 | 2446 | 1 | 176 | 29 | 216 | 5 | 34 | 219 |

| White background | cdf2 | 233 | 6712 | 184 | 2784 | 4518 | 1 | 328 | 69 | 310 | 12 | 8 | 357 |

| White background | cdf9 | 119 | 4869 | 1109 | 1914 | 3655 | 1 | 276 | 51 | 338 | 3 | 44 | 156 |

| White background | cdf10 | 1 | 2301 | 14,583 | 228 | 975 | 5 | 103 | 40 | 363 | 3 | 7 | 106 |

| White background | cdf16.1 | 1 | 4634 | 3391 | 1082 | 3827 | 16 | 329 | 105 | 523 | 6 | 153 | 141 |

| Base of the bowl | cdf3 | 437 | 3288 | 816 | 2274 | 1153 | 49 | 72 | 161 | 695 | 8 | 20 | 91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amadori, M.L.; Cardellini, S.; Mengacci, V. Advances in Lead-Barium-Zinc-Silicate-Type Glazed Warming Bowl Related to the Chinese Xuande Reign (1426–1435). Heritage 2024, 7, 1496-1509. https://doi.org/10.3390/heritage7030072

Amadori ML, Cardellini S, Mengacci V. Advances in Lead-Barium-Zinc-Silicate-Type Glazed Warming Bowl Related to the Chinese Xuande Reign (1426–1435). Heritage. 2024; 7(3):1496-1509. https://doi.org/10.3390/heritage7030072

Chicago/Turabian StyleAmadori, Maria Letizia, Serse Cardellini, and Valeria Mengacci. 2024. "Advances in Lead-Barium-Zinc-Silicate-Type Glazed Warming Bowl Related to the Chinese Xuande Reign (1426–1435)" Heritage 7, no. 3: 1496-1509. https://doi.org/10.3390/heritage7030072

APA StyleAmadori, M. L., Cardellini, S., & Mengacci, V. (2024). Advances in Lead-Barium-Zinc-Silicate-Type Glazed Warming Bowl Related to the Chinese Xuande Reign (1426–1435). Heritage, 7(3), 1496-1509. https://doi.org/10.3390/heritage7030072