Abstract

Vibration-based predictive maintenance is an essential element of reliability engineering for modern automotive powertrains including internal combustion engines, hybrids, and battery-electric platforms. This review synthesizes advances in sensing, signal processing, and artificial intelligence that convert raw vibration into diagnostics and prognostics. It characterizes vibration signatures unique to engines, transmissions, e-axles, and power electronics, emphasizing order analysis, demodulation, and time–frequency methods that extract weak, non-stationary fault content under real driving conditions. It surveys data acquisition, piezoelectric and MEMS accelerometry, edge-resident preprocessing, and fleet telemetry, and details feature engineering pipelines with classical machine learning and deep architectures for fault detection and remaining useful life prediction. In contrast to earlier reviews focused mainly on stationary industrial systems, this review unifies vibration analysis across combustion, hybrid, and electric vehicles and connects physics-based preprocessing to scalable edge and cloud implementations. Case studies show that this integrated perspective enables practical deployment, where physics-guided preprocessing with lightweight models supports robust on-vehicle inference, while cloud-based learning provides cross-fleet generalization and model governance. Open challenges include disentangling overlapping sources in compact e-axles, coping with domain and concept drift from duty cycles, software updates, and aging, addressing data scarcity through augmentation, transfer, and few-shot learning, integrating digital twins and multimodal fusion of vibration, current, thermal, and acoustic data, and deploying scalable cloud and edge AI with transparent governance. By emphasizing inverter-aware analysis, drift management, and benchmark standardization, this review uniquely positions vibration-based predictive maintenance as a foundation for next-generation vehicle reliability.

1. Introduction

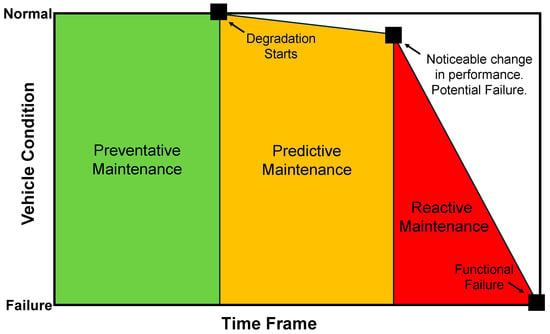

Predictive maintenance (PdM) is a maintenance strategy that monitors the condition and performance of equipment during normal operation to detect signs of deterioration. This allows maintenance to be scheduled before a failure occurs, as shown in Figure 1. It has become a strategic priority in automotive engineering as manufacturers aim to increase uptime, reduce warranty costs, and manage complex powertrains across internal combustion, hybrid, and battery-electric platforms. Unlike time-based preventive maintenance, PdM infers equipment health from operational data, enabling interventions before failure and extending service life. Early work in condition-based maintenance (CBM) established a pipeline of signal acquisition, health indicator extraction, condition assessment, and degradation forecasting, forming the basis now adapted to embedded and fleet-wide contexts []. Recent surveys show that connectivity, edge computing, and advanced analytics have expanded CBM into large-scale data-driven programs, improving availability and lifecycle cost for vehicles [].

Figure 1.

Schematic showing the relationship between preventative maintenance, predictive maintenance, and reactive maintenance as they relate to vehicle condition and time frame.

Within this broader framework, vibration analysis has become a cornerstone for monitoring rotating and reciprocating components. It is nonintrusive, sensitive to early mechanical faults, and compatible with low-cost accelerometers []. Harmonics, sidebands, and envelopes can reveal defects in bearings, gears, and valvetrains, enabling rapid and interpretable diagnostics [,]. Compared with temperature or pressure measurements, vibration provides better temporal and spectral resolution for incipient faults and supports order tracking to account for speed effects [,]. It applies across the powertrain spectrum, from combustion and imbalance in engines and drivelines to electromagnetic and switching content in electric machines, inverters, and e-axles. Core techniques such as band selection, demodulation, and order analysis remain effective when adapted for inverter states and torque commands, making vibration a unifying signal for assessing the health of engines, transmissions, traction motors, and hybrid couplings [].

Advances in signal processing and feature engineering have improved sensitivity to weak or nonstationary faults. Adaptive demodulation, optimal band selection, and time–frequency transforms enhance signal-to-noise ratio while preserving interpretability [,]. At the fleet level, engineered indicators support health indexing and anomaly scoring, which inform service analytics and parts planning []. Artificial intelligence further strengthens PdM by learning patterns from raw or lightly processed vibration data. Supervised classifiers, deep architectures, and transfer-learning approaches complement physics-based features, improving robustness under diverse conditions [,]. Challenges remain, including nonstationary environments, sensor variability, and limited labeled failures [,,]. Addressing domain drift, improving data efficiency, and validating predictions against maintenance outcomes are essential, as is integrating predictive outputs into service workflows, thresholds, technician guidance, and logistics planning [,].

Building on these foundations, this paper synthesizes the state of the art in vibration-based PdM for automotive powertrains. It provides a comprehensive overview of vibration signatures across internal combustion, hybrid, and electrified systems, and links these physical phenomena to sensing technologies and fleet-scale data acquisition strategies. The review then examines the signal-processing and feature-extraction methods that enhance interpretability and diagnostic sensitivity, before exploring how machine learning and deep learning approaches enable fault detection, remaining useful life prediction, and online model adaptation. Together, these perspectives create an integrated view of how vibration data evolve from raw signals into actionable maintenance insights.

This work extends prior surveys by explicitly bridging the mechanical, electrical, and data-science domains that currently define modern automotive health monitoring. Earlier reviews often treated vibration analysis as an isolated topic within rotating machinery or industrial settings. In contrast, this review connects the physics of combustion and driveline dynamics with inverter-aware preprocessing, digital-twin modeling, and the realities of edge and cloud deployment. It highlights how laboratory-grade techniques can be translated into scalable, automotive-ready frameworks that incorporate governance, explainability, and benchmark standardization. In doing so, the review aims to serve not only as a synthesis of current methods but also as a deployment-oriented guide for PdM in next-generation vehicle diagnostics.

The novelty of this review lies in its cross-domain integration. It unifies vibration characterization across combustion-based, hybrid, and fully electric platforms, linking physics-informed band selection with practical edge and cloud-based machine learning. It further advances the field by framing how predictive models can be governed and by emphasizing automotive-specific metrics such as time-to-detect at fixed false-alarm rates, alert stability, and lifecycle cost impact. Through this combined focus on physical insight, data-driven intelligence, and operational governance, the review provides a cohesive framework for realizing robust, scalable, and explainable vibration-based predictive maintenance in the modern automotive domain.

2. Vibration Signatures in Modern Powertrains

Accurate interpretation of vibration data requires a clear understanding of the physical mechanisms that generate characteristic responses in automotive powertrains. Conventional internal combustion systems, transmissions, drivelines, and mounting structures each introduce distinct orders, sidebands, and resonances. Electrified and hybrid architectures add electromagnetic and power-electronic excitations, while operating conditions such as road roughness, load variation, and mode transitions shape the observed spectra. These phenomena interact across mechanical, electrical, and structural domains, producing complex signatures that must be disentangled for effective diagnostics. Understanding these mechanisms clarifies why particular frequency bands and demodulation strategies are used in later sections and what practitioners should monitor to maintain robustness under real driving conditions.

Table 1 summarizes the principal vibration sources, their typical frequency content, and representative diagnostic methods for major subsystems. It serves as a reference for the detailed discussions that follow, linking physical origins to appropriate signal-processing strategies. The subsequent subsections address conventional powertrain components, electrified and hybrid systems, and the influence of operating conditions, establishing the foundation for later sections on feature engineering and PdM analytics.

Table 1.

Principal vibration sources, typical frequency ranges, and representative diagnostic methods for major automotive subsystems.

2.1. Conventional Powertrain Components

In internal combustion engines (ICE) the main vibration sources are combustion excitation, imbalance from reciprocating and rotating parts, and kinematic discontinuities in the valvetrain and accessory drives. Combustion impulses excite orders tied to firing frequency (half order for four stroke engines and higher multiples for multi cylinder layouts). Variability between cylinders, misfire, and knock alter the amplitude modulation and spectral envelopes of these orders. Studies by Nithin et al. and Novillo et al. showed that clearance growth in piston liner and wrist pin joints increased impulsiveness such as kurtosis and crest factor and produces sidebands around engine orders [,]. Analysts combine order tracking with envelope or cepstral analysis to separate combustion from structural resonance, improving robustness to speed ramps and rough road input [].

Gearboxes and drivelines add periodic content at the harmonics of the gear mesh frequency (GMF), which is defined as the product of the number of teeth and the shaft speed. Modulation sidebands at shaft speed indicate misalignment, eccentricity, or looseness. As gears wear, mesh stiffness fluctuates, increasing modulation around GMF. Contaminated lubrication enlarges transmission error and sharpens sidebands, allowing wear to be tracked. Mao et al. and Feng et al. showed that combining transmission error with demodulated vibration enables early and stable detection of surface wear even under variable load [,]. Downstream parts such as propeller shafts, CV joints, and differentials create subharmonics and cross order couplings, so wideband sensing and several measurement points are often required.

Although electrification is growing, these vibration sources remain important in hybrids and range-extended systems where an engine operates. The engine signature must be interpreted with high frequency content from electric machines and inverters. Baselines for engine orders in mixed drivetrains and features tolerant of spectral overlap and speed changes are essential. Order synchronous averages and band limited demodulation near known mesh and firing bands are effective [,]. Transfer learning from electric vehicle diagnostics supports normalization and domain adaptation for conventional subsystems subject to frequent mode changes [].

Mounting systems also shape the signal. Engine mounts and subframe bushings filter mid to high frequency content while amplifying some body modes. Degradation changes transmissibility, which can resemble primary faults if not modeled. Workflows maintain bands for component dynamics and for integration effects such as mounts and body modes. Ratios and order contrasts stabilize diagnostics across vehicles and installations [,,]. This layered view of component, assembly, and vehicle supports baseline libraries for adaptive and fleet scale analytics [].

2.2. Electrified and Hybrid Systems

Electrified powertrains add electromagnetic and power-electronic excitations to mechanical sources. Permanent-magnet and induction motors produce radial force harmonics linked to slot and pole combinations as well as spatial harmonic orders. These map to mechanical vibration orders at multiples of electrical frequency and can couple with stator or rotor structural modes. Faults such as partial demagnetization or eccentricity modify the distribution and sideband symmetry of these harmonics, enabling detection through order analysis and high-resolution spectra [,]. Because electric motors often run at higher speeds than ICEs, their harmonics occupy mid to high frequencies and overlap with gear mesh content in e-axles.

Inverter switching introduces further high-frequency components. Pulse width modulation (PWM) strategies and switching frequencies generate discrete lines and broadband noise that can obscure weak mechanical signatures. Hua et al. and Kim et al. showed that inverter noise and efficiency depend on PWM strategy and operating point, shifting diagnostic bandwidths and interacting with motor harmonics during torque transients [,]. Effective pipelines use anti-aliasing and notch filters or time–frequency methods to separate transient inverter artifacts from persistent mechanical tones.

Hybrid electric vehicles add complexity through mode changes, engine start-stop events, regenerative braking, and shifts between series and parallel drive. These transitions alter torsional stiffness and damping, producing short bursts and frequency glides that challenge stationary spectral assumptions. Gear wear studies highlight transmission error as a robust indicator even under contaminated lubrication, particularly when combined with demodulated vibration to track wear progression [,]. Bearing diagnostics remain critical in e-axles and motor supports; resampling and multi-rate modeling preserve defect frequencies across wide speed ranges [].

Compact gear reductions and planetary stages in electrified systems align gear mesh frequencies with motor electrical orders, producing dense sidebands. Multi-sensor layouts and multidimensional features, correlating signatures across locations and axes, improve separation of overlapping sources and help localize faults to motors, gearboxes, or differentials []. Rolling-element bearings remain common failure points; modeling and reviews guide the choice of envelope bands and kurtosis-based detectors that retain effectiveness in electromagnetic environments []. Domain adaptation is essential when transferring models between platforms. Variations in slot and pole counts, switching strategies, and gear ratios result in shifts in absolute frequencies even when relative physics remains consistent. Transfer learning and normalization across electrical and mechanical order spaces support cross-platform diagnostics, as noted by EV-specific reviews [].

2.3. Operating Conditions and Load Variability

Vehicle vibration is strongly influenced by ambient and operational conditions. Road roughness introduces broadband low-frequency content, while slope and payload affect torque demand. Driver behavior, including throttle use, coasting, and regenerative braking preferences, produces wide variations in speed and load. In electric vehicles, PWM settings and switching frequencies can vary with efficiency maps, shifting high-frequency artifacts. In ICE and hybrid platforms, engine start-stop events and mode changes create nonstationarity that challenges steady-state assumptions [,]. These effects motivate order tracking, time-frequency analysis, and event-aware segmentation, such as separating coastdown, regeneration, and launch phases, to reduce false alarms when spectral peaks drift or transient bursts occur for valid operational reasons.

Component-level monitoring must account for multi-speed operation. Bearing indicators, such as band-limited envelope spectra around defect frequencies, and gear-health metrics based on sideband energy ratios require normalization for speed and load to avoid confusion between operating changes and degradation. Research shows that optimized wavelet and demodulation methods preserve weak-fault cues during speed sweeps, improving early detection of bearing damage in real driving cycles []. System-level analysis benefits from cross-location correlation and vector features that compare housings, axes, or driveline ends, helping to separate global load effects from localized faults, particularly in complex transmissions [].

Variability also arises across vehicles and fleets. Even when physics is similar, differences in sensor placement, mount stiffness, and body structure alter amplitudes and transmissibility, making domain adaptation essential. Transfer learning aligns feature spaces or learns domain-invariant embeddings, improving stability across vehicles, model years, and suppliers []. Over time, concept drift degrades static models as usage patterns, software calibrations, and environmental exposures evolve, requiring drift-aware monitoring and continual learning to maintain accuracy []. Fleet studies confirm the impact of duty-cycle heterogeneity. Delivery, transit, and logistics vehicles show distinct speed, load, and stop profiles that define normal vibration behavior; models that ignore context risk false alarms or missed faults [,]. Contextual baselining and adaptive thresholds tied to operating state enhance precision and recall at scale. For electrified fleets, deep transfer learning supports diagnostic consistency across architectures and updates throughout a vehicle’s life [].

2.4. Key Takeaways

This review found that the most effective diagnostic strategies are grounded in physical principles. Tracking engine firing orders and gear mesh frequencies, along with their sidebands, provides a clear representation of combustion and gear mesh behaviors. The use of envelope and cepstral analyses, combined with order tracking, enables the separation of impulsive combustion signatures from stiffness-modulated mesh tones across varying speeds.

For electrified drivelines, the review identified that mapping electrical orders such as slot and pole harmonics and their sidebands alongside mechanical orders reduces spectral congestion and allows precise isolation of inverter switching effects in the time and frequency domains. Normalizing diagnostic features through order-to-order ratios compensates for variations in mounting and transmissibility. Maintaining internal combustion engine baselines in hybrid configurations, even during electric machine operation, preserves diagnostic continuity across platforms.

These practices collectively yield stable and transferable diagnostic features that maintain sensitivity under real-world driving variability.

3. Sensor Technologies and Data Acquisition

Reliable condition monitoring depends not only on advanced analytics but also on how vibration data are acquired at the source. Sensor selection, placement, and data-handling architecture directly determine whether downstream algorithms can detect early degradation. This section therefore links physical sensing hardware to the data quality requirements of predictive-maintenance analytics, showing how sensor type, connectivity, and fidelity influence diagnostic sensitivity and fleet scalability.

3.1. Types of Vibration Sensors

Modern automotive PdM relies mainly on piezoelectric and micro-electromechanical system (MEMS) devices for accelerometers, with strain-based sensors used selectively for torsional or structural measurements. Piezoelectric accelerometers remain the benchmark for wide bandwidth, low noise, and high linearity, which are essential for detecting bearing resonances, gear-mesh sidebands, and high-frequency inverter or motor content. Surveys describe how these sensors maintain stability across temperature and dynamic range and outline mounting methods, such as stud or adhesive, which preserve high-frequency fidelity []. For harsh or remote locations, including rotating or elevated-temperature components, charge-mode piezoelectric variants with nearby charge amplifiers are still preferred to limit cable noise and maintain signal integrity [].

MEMS accelerometers have advanced rapidly. They provide compact size, low power use, and integrated digitization at attractive cost, with bandwidth sufficient for most powertrain harmonics and bearing bands in e-axles. Improvements in noise and cross-axis sensitivity make them suitable for embedded arrays where spatial coverage is more valuable than the highest precision of a single sensor [,]. Studies from robotics and mobile platforms note issues such as bias drift, temperature effects, and shock saturation, but also show that redundancy and outlier rejection can raise their reliability to automotive standards []. At fleet scale, this resilience may outweigh the per-channel advantage of piezoelectric devices.

Strain gauges and strain-based accelerometers complement inertial sensors by mapping load paths. Thin-film strain gauges on housings, brackets, or shafts reveal torsional oscillations, mount aging, and load-sharing anomalies that inertial devices only infer indirectly. When combined with acceleration data, strain helps separate global inputs such as road or driver actions from local defects such as bearing or gear faults, improving diagnostic specificity []. Triboelectric nanogenerator vibration sensors have also emerged as a self-powered option with wide frequency response, useful for long-life nodes in rotating or enclosed parts []. Although their stability and environmental robustness are still developing, early studies show promising sensitivity across broad spectra [].

Table 2 summarizes the advantages, disadvantages, and ideal application for the different sensor types. As shown in Table 2, sensor choice depends on application. Piezoelectric devices are suited for high-speed bearings or fine gear wear. MEMS sensors work well for dense, low-cost arrays. Strain sensors support load-path and structural analysis, while triboelectric sensors may be effective where power is limited. Many manufacturers combine a small number of high-grade piezoelectric channels with several MEMS units to balance spectral reach, coverage, and cost, then normalize features across modalities using calibration pulses and fleet baselining [,].

Table 2.

Advantages, disadvantages, and ideal applications for different sensor types.

3.2. Wireless and Embedded Systems

Automotive deployments are moving from portable data loggers to embedded, networked nodes that capture or summarize vibration in real time. Edge-computing condition-monitoring systems now combine sensors, analog-to-digital convertors, digital signal processing, and lightweight machine learning to extract features, compress data, and detect events before sending summaries to gateways. This reduces bandwidth and latency while enabling local alarms []. Reference architectures from industrial monitoring adapt well to vehicles, where local buffering, time synchronization, and over-the-air updates allow models and filters to evolve with software and powertrain calibrations []. For mobile systems, high sampling rates (25–50 kHz for bearing or gear bands), GPS or timecode alignment, and health metadata such as gain, temperature, and self-tests are essential for reliable analytics.

Remote vibration monitoring with edge gateways has been shown for engines. On-device preprocessing, including root-mean square (RMS) and kurtosis tracking, envelope spectra, and band power near firing or mesh orders, supports decision logic that operates without constant connectivity []. Prototypes for agriculture and off-highway equipment have demonstrated the feasibility of multi-axis arrays that survive harsh conditions, while also revealing concerns such as enclosure sealing, connector fatigue, and the need for self-diagnostics to detect sensor or cable failures []. These studies emphasize graceful degradation, where redundant nodes maintain observability if one sensor fails.

From a system perspective, automotive predictive-maintenance nodes fit within a cyber-physical stack that links sensors, edge analytics, vehicle gateways, and fleet services. Guidance from cyber-physical systems research highlights modular design, semantic data models, and standardized interfaces so vibration features can be combined with vehicle signals such as speed, torque, or inverter mode for context-aware decisions []. On-board classifiers can report explanatory cues such as a rise in sidebands around gear-mesh frequencies, which improves serviceability and trust. In electrified platforms, coordinating vibration nodes with inverter or motor controllers enables event-synchronous capture during changes in pulse-width modulation or regenerative braking, maximizing diagnostic value for a given telemetry budget [].

Power management shapes sensor design and maintainability. Battery-powered wireless nodes benefit from duty-cycled sampling, adaptive bandwidth, and wake-on-event triggers, while tethered units can sample continuously and achieve higher dynamic range. Energy harvesting from thermal or mechanical sources, including triboelectric generators, can extend service life on rotating components but introduces variable power levels that edge firmware must handle [,]. Across all architectures, accurate clocks, anti-aliasing filtering, and lossless timestamping are essential to preserve the physics contained in high-frequency data [,].

3.3. Signal Quality and Data Fidelity

High-quality vibration data requires proper sensor placement. Sensors should be positioned close to likely sources such as bearings, gear housings, and motor end bells, along axes that transmit defect energy while avoiding nodal lines of structural modes. Cross-channel coherence and multidimensional interpretation improve fault localization and reduce false alarms compared with single-channel analysis in complex transmissions []. For fleets, these findings support standardized placement drawings and installation validation through tap tests and coherence checks to limit variability between units [].

Signal conditioning determines usable bandwidth once sensors are installed. Strong anti-aliasing, gain settings that maintain headroom for shocks, and temperature-aware calibration protect signal quality. Filtering must be tailored to the application. High-pass or detrending removes low-frequency drifts and road inputs. Band-pass filtering around structural resonances with envelope extraction supports gear and bearing demodulation. Notch or band-stop filtering aligned with pulse-width modulation or switching harmonics helps remove inverter artefacts without discarding diagnostically useful content []. Adaptive filters and online residual checks can correct baseline drift and minor sensor degradation, stabilizing indicators without manual retuning [].

Bandwidth planning should follow a fault-to-frequency map. Outer and inner bearing race faults often radiate energy above 3–5 kHz, sometimes reaching tens of kilohertz. Fine gear wear modulates mesh frequencies into mid and high bands, while torsional events occur at lower frequencies. Electrified drivetrains add electromagnetic and inverter content in the upper range. Sampling at 25–50 kHz with flat amplitude and phase response to approximately 10–20 kHz is recommended when early detection is important. Lower rates can support torsional or mounting channels but should use order tracking during speed changes to avoid spectral smearing [,,]. When telemetry limits prevent raw streaming, edge-extracted features such as RMS, kurtosis, crest factor, band power, envelope peaks, and sideband ratios, along with short spectral snapshots keyed to events, can preserve diagnostic fidelity [].

Data governance is equally important. Work on commercial vehicles shows that context tagging for speed, load, gear, and mode, along with metadata such as sensor serial numbers, mounting torque, and calibration history, improves reliability at fleet scale []. Automated data-quality checks for dropouts, axis swaps, and saturation reduce the risk of corrupt inputs. When only one sensor can be installed, self-consistency monitors that track spectrum shape or ratios between adjacent bands detect debonding or reorientation, reducing silent failures and stabilizing inputs over time []. Together, careful placement, focused filtering, appropriate bandwidth, and continuous validation produce datasets that retain the weak-fault signatures required by modern signal processing and machine learning.

3.4. Key Takeaways

The literature emphasizes the importance of mechanics-informed sensor placement and coherence validation to ensure that defect energy is effectively transmitted to the transducer. High-grade piezoelectric sensors should be used on select channels to capture high-frequency content with precision, while distributed MEMS sensors provide broader spatial coverage. Strain measurements can be incorporated where additional load-path insight is required.

This review found that shifting lightweight preprocessing to the edge improves diagnostic performance. Deterministic sampling at or above 25 kHz for bearing and gear frequency bands, synchronized clocks, and integrated self-diagnostics enhance data quality and reduce latency. Integrating vibration features with contextual information such as speed, torque, and operating mode reduces bandwidth demands while improving the quality of decision-making.

Data fidelity is best preserved through the use of anti-aliasing filters, temperature-compensated calibration, and notch filtering aligned with pulse-width modulation frequencies. Each data record should be tagged with detailed installation and operating metadata to maintain traceability. In large fleet applications, these foundational choices have a greater impact on predictive maintenance accuracy than the complexity of downstream analytical models.

4. Feature Engineering and Extraction Workflow

In production vehicles, vibration analytics exist within minimal computation and bandwidth budgets, making the selection of proper features an extremely important consideration for early-fault detectability and false-alarm rates. This section clarifies the role of each analysis path, names proven operators with automotive precedent, and points to selection/compression steps that preserve diagnostic power for cloud/edge pipelines.

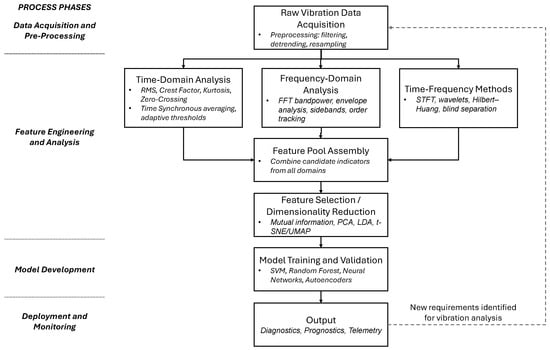

Effective vibration-based condition monitoring depends on extracting informative features from raw signals through a structured series of steps. Figure 2 summarizes this process, which begins beginning with data acquisition and optional preprocessing. The workflow then branches into three parallel analysis paths: time-domain, frequency-domain, and time–frequency methods. Each path contributes complementary indicators, from simple statistics such as RMS and crest factor to advanced transforms like wavelets and the Hilbert–Huang method. The results converge in a feature pool, where selection and dimensionality-reduction techniques refine the most valuable indicators for diagnostics, prognostics, or low-bandwidth telemetry. The following subsections describe these approaches in detail, highlighting how they combine to provide robust health assessment for rotating and reciprocating components, even under variable operating conditions.

Figure 2.

Structured workflow for vibration-based condition monitoring.

4.1. Time-Domain Analysis

The on-board screening techniques most commonly used for PdM primarily rely on time-domain statistics because they are inexpensive to compute, easy to interpret, and correlate well with broad fault classes. RMS measures overall vibration energy and detects progressive imbalance, misalignment, and load changes. Crest factor highlights occasional high-amplitude bursts typical of early bearing and gear pitting. Kurtosis emphasizes impulsiveness, making it useful for identifying localized defects that produce sparse shock trains. Zero-crossing rate approximates dominant band content and stationarity in low-compute settings. Lou and Loparo showed that pairing wavelet-derived features with fuzzy inference yielded robust bearing classification under noise and operating variability, establishing the enduring value of simple time-domain/impulsiveness indices []. Ericsson et al. subsequently detailed adaptive thresholding and robust estimation schemes that stabilized time-domain statistics against speed/load variation for automatic local bearing-defect detection [].

Time-domain features improve when synchronized to machine kinematics. Time Synchronous Averaging (TSA) suppresses non-synchronous noise and emphasizes fault-locked impulses in gear trains. Modern implementations address leakage, cycle count selection, and transient preservation, which is critical for vehicles with rapidly changing speeds []. For gradually degrading assets, tracking RMS, impulsiveness, and band-limited kurtosis over time can be embedded into functional data analysis to predict residual life, linking low-cost features to prognostics []. Nonstationary automotive inputs such as road roughness and shifting drive modes require pairing time-domain indicators with context tags and order-tracked windowing. Computing statistics within speed-normalized frames or over envelope signals maintains comparability across duty cycles. Recent work has shown that even unsupervised learning on raw time-domain signals can surface meaningful fault distinctions without labels; for instance, K-means clustering achieved perfect class separation (homogeneity/completeness = 1.00) on temperature-tagged bearing data and ran in under 4 ms per inference on embedded hardware []. In bandwidth-limited applications, these features often serve as the sole telemetry transmitted to the cloud, making their stability and calibration essential.

4.2. Frequency-Domain Analysis

Frequency-domain analysis transforms raw vibration into physically meaningful indicators that maintenance will be required. FFT-based band power metrics around gear-mesh frequency, its harmonics, and sidebands at shaft orders reveal gear wear, eccentricity, and misalignment. For bearings, envelope analysis followed by FFT highlights BPFO (outer race), BPFI (inner race), BSF (rolling element), FTF (cage), and their sidebands, enabling early fault detection even when the carrier is dominated by other excitations.

Not all frequency bands are equally informative. Kappaganthu and Nataraj used mutual information to select gear/bearing bands that maximized health–fault separability, replacing ad-hoc band picks with a principled criterion []. Barszcz and Jabłoński’s optimal band-selection method (as a Kurtogram alternative) formalized where to place the demodulation filter so impulsive content, and the resulting envelope spectrum, is maximized []. In transmissions and e-axles with multiple excitation paths, multi-location spectral interpretation using coherences, transmissibility, and cross-spectral features helps distinguish local fault signatures from global road-induced content, reducing false alarms []. Practical vehicle pipelines integrate anti-aliasing, deterministic sampling with flat magnitude and phase to the highest diagnostic band, and compact spectral thumbnails around GMF and bearing bands. These thumbnails, combined with sideband ratios and harmonic indices, provide high diagnostic yield at minimal bandwidth and are compatible with both traditional classifiers and modern machine learning methods.

4.3. Time-Frequency Methods

Real driving introduces nonstationarity as faults generate bursts that drift in time and frequency with changing speed and load. Time–frequency methods address this by localizing energy jointly in time and frequency to allow for accurate prediction of maintenance needs. The Short-Time Fourier Transform provides interpretable maps but suffers from fixed resolution trade-offs and is most effective for order-tracked, short-window snapshots of gear-mesh transients during shifts or torque ramps. Wavelet transforms adapt resolution to frequency, capturing both slow trends and high-frequency bursts from incipient defects, and remain widely used for envelope-like demodulation and multi-scale energy features [].

When signals include contributions from multiple sources, blind separation and sparse or resonance-based decompositions improve isolability. Antoni demonstrated blind separation of overlapping vibration contributors in rotating machinery, while Huang, Sun, and Wang reviewed resonance-based sparse decompositions that surface masked impulsive bearing/gear responses [,]. Feng et al. introduced fast random wavelet kernel convolution as an efficient method to project signals onto randomized multi-scale dictionaries, enabling weak-fault extraction in rotating machinery with practical runtime for embedded systems []. Their results found that the Hilbert–Huang Transform, based on empirical mode decomposition and Hilbert spectral analysis, captured instantaneous frequency and amplitude in nonlinear, variable-load gear systems without assuming stationarity. When paired with self-organizing maps, it accurately separated different gear-fault states under realistic operating conditions []. In practice, robust time–frequency pipelines combine speed- or context-aware gating, wavelet or RBSSD-style denoising, and compacted features including time–frequency energy along selected ridges or instantaneous order statistics, which feed downstream classifiers.

4.4. Feature Selection and Dimensionality Reduction

With dozens to hundreds of candidate features spanning time, envelope, spectral, and time–frequency domains, feature selection and dimensionality reduction are essential for generalization and computational efficiency. Jaros et al. surveyed advanced constant modulus (CM) signal processing and emphasized filter/wrapper/embedded selection strategies, warning that selection must be nested within cross-validation to avoid optimistic bias []. Mutual information provides a physics-aligned criterion, selecting features such as sideband ratios, band-limited kurtosis, or wavelet energies that maximize dependency with fault labels while minimizing redundancy, improving classifier stability across duty cycles and sensors [].

Principal Component Analysis is widely used for dimensionality reduction, compressing correlated features into orthogonal components that preserve variance and often separate health states in the first few axes. Mathew and Zhang exemplified a WPT + PCA pipeline that condenses multi-band energies into compact health vectors and tunes model hyperparameters (via Bayesian optimization) for robustness under variable operating conditions []. Linear Discriminant Analysis further enhances separability when class labels are available, maximizing between-class variance relative to within-class variance and effectively highlighting narrow-band differences such as specific sideband patterns.

For exploration and monitoring, t-SNE or UMAP visualizations allow engineers to inspect cluster structures, detect drift, and flag outliers before retraining, which is particularly useful in fleet analytics where domain shift is common. A practical workflow is to first curate a physics-informed candidate pool, then apply mutual-information filtering to 20–40 high-value features, perform PCA to reduce dimensions to 5–10 components for modeling or telemetry, and finally use LDA or t-SNE for validation dashboards. This approach balances interpretability, bandwidth, and robustness and integrates effectively with both traditional and deep learning pipelines, especially in low-SNR settings.

4.5. Cyclostationary and Cyclo-Order Analysis

Cyclostationary analysis exploits the repetitive structure of modulated signals in rotating machinery by extracting cyclic spectral features such as cyclic modulation spectra (CMS) or cyclic spectral coherence (CSC). These tools enhance weak-fault detection by isolating modulated components tied to gear meshing, bearing defects, or electromagnetic excitation. In electric vehicles, cyclostationarity induced by pulse-width modulation and torque ripple creates periodic artifacts that traditional FFT smears. For instance, Kim et al. [] showed how PWM schemes impacted the excitation spectrum, motivating order-locked processing. Cyclo-order tracking techniques convert time-domain signals into order domain representations aligned with shaft speed, stabilizing features under variable operating conditions and enabling the use of cyclostationary metrics for early fault detection [,].

4.6. Cepstrum and Higher-Order Spectral Techniques

Cepstral analysis, particularly through liftering and cepstrum subtraction, enables deconvolution of periodic sidebands caused by gear meshing or bearing defects. By transforming spectra into quefrency space, cepstrum techniques isolate echoes and periodic modulations, making them effective for separating fault-induced modulations from dominant carriers. Bispectrum and bicoherence, as third-order spectral techniques, capture phase coupling and non-Gaussian signal behavior that second-order methods overlook. They have been used to detect bearing and gear nonlinearities under load variability []. However, their computational cost and sensitivity to noise constrain their embedded feasibility. These methods are best suited for offline diagnostics or cloud-based analysis where compute and bandwidth are less restricted [,].

4.7. Key Takeaways

Table 3 summarizes the advantages, limitations, and ideal applications of each feature extraction method. Time-domain statistical analysis is well suited for low-latency screening, provided that signals are synchronized with kinematics through techniques such as time-synchronous averaging or order-tracked windows. This synchronization stabilizes impulsiveness measures across varying speeds and loads. Meanwhile, in the frequency domain, diagnostic value is maximized through principled band selection, such as identifying demodulation bands guided by mutual information, and by focusing on compact spectral regions near gear mesh and bearing defect frequencies. These approaches enhance diagnostic yield while minimizing data volume. Under conditions of nonstationarity or source overlap, combining wavelet or Hilbert–Huang transforms with resonance-based sparse decompositions and contextual gating helps reveal weak or transient fault signatures.

Table 3.

Advantages, limitations, and ideal applications for different feature extraction methods.

Data compression should be approached carefully. Filtering a physics-curated pool of features into a small, nonredundant set improves efficiency while maintaining interpretability. Principal component analysis can enhance telemetry and model performance, and visual tools such as linear discriminant analysis or t-SNE assist in monitoring drift prior to retraining. Cyclostationary and cyclo-order methods effectively capture periodic modulation associated with inverter-driven systems and rotating components. Cepstral liftering and bispectral analysis further strengthen robustness to nonlinear and phase-coupled faults, though often with increased computational cost.

5. Machine Learning and Deep Learning Integration

PdM ultimately depends on converting vibration features into calibrated decisions under tight computational, safety, and data-availability constraints. Automotive powertrains present nonstationary operating regimes, limited labels for rare faults, and evolving software calibrations, all of which can erode model validity. This section situates classical, hybrid, and deep learning methods within those constraints, clarifies when engineered features outperform end-to-end models, and shows how remaining-useful-life forecasting and online adaptation extend detection to planning. Establishing these roles up front enables principled trade-offs between interpretability, latency, generalization across platforms, and lifecycle maintainability in fleet deployments.

Machine learning extends vibration analysis by turning raw or engineered features into actionable health insights. Classical algorithms remain effective for lightweight, interpretable diagnostics, while deep learning models capture complex, non-linear patterns directly from signals. Together they support detection, fault classification, remaining useful life prediction, and continuous adaptation as operating conditions change.

5.1. Traditional ML Approaches

Classical machine learning algorithms remain highly effective for vibration-based diagnostics when features are carefully engineered. Support Vector Machines were early strong baselines for bearing and gearbox faults because they handle high-dimensional, nonlinearly separable features via kernels and margin maximization. Early studies demonstrated reliable generalization across operating points compared with simple thresholds or linear discriminants []. Hybrid pipelines combining evolutionary feature selection with SVMs or Artificial Neural Networks showed that curated feature subsets, such as envelope sideband ratios and band-limited kurtosis, could achieve both accuracy and computational efficiency suitable for embedded ECUs []. In production, decision trees and random forests are valued for interpretability and robustness to mixed-scale features, while k-NN performs well with dense labeled datasets but suffers under class imbalance or drift [].

Multimodal acoustic–vibration applications, such as compressor monitoring, show that classical models can meet low-latency, low-power constraints when paired with compact features like wavelet packet band energies or MFCC-style descriptors. Careful hyperparameter tuning using Bayesian or grid search often achieves near state-of-the-art performance without deep models []. For nonstationary drivetrains, features invariant or normalized to speed and load, order-based statistics, demodulated envelopes, or context-gated windows help stabilize classifier boundaries and reduce false alarms caused by driver behavior or road roughness.

For heavily time-varying spectra, time–frequency representations can be reduced to low-dimensional embeddings before applying classical ML. Hilbert–Huang Transform combined with Self-Organizing Maps has proven effective for gear-fault state discovery under variable speeds, as instantaneous frequency captures modulation that fixed-window FFTs smear []. Unsupervised feature learning, such as sparse or autoencoder representations, can feed traditional classifiers with more linearly separable projections, bridging classical ML and modern deep pipelines while remaining feasible for embedded use []. In practice, many automotive predictive-maintenance stacks still adopt a two-layer approach: physics-guided feature engineering followed by lightweight classical ML, reserving deep models for cloud retraining or complex edge nodes.

5.2. Deep Learning Architectures

Deep learning enables end-to-end mapping from raw or minimally processed vibration signals to health states. Convolutional Neural Networks trained on spectrograms or envelope spectra outperform hand-crafted features for subtle faults or signals masked by nonstationary loads. Compact CNNs have demonstrated real-time motor fault detection on embedded hardware, confirming feasibility for on-vehicle inference []. Zhao, Tang, and Shao described effective architectures including 1D CNNs on order-tracked time series, 2D CNNs on STFT or WPT maps, and late fusion across sensing channels [,,]. Recent advances in attention-based fusion further improve cross-sensor robustness. For example, the Collaborative Fusion Attention Mechanism (CFAM) integrates domain-specific encoders and spatial–temporal attention to jointly extract and weight signal contributions, significantly enhancing vehicle fault prediction under multimodal inputs []. Lang highlights CNN backbones augmented with domain priors, such as order-aware pooling and harmonic attention, for EV and HEV traction-motor diagnostics [].

Temporal dependencies, such as fault progression and load cycles, motivate recurrent and sequence models. LSTMs and GRUs capture longer horizons to track regime changes like ICE-to-electric transitions or regenerative braking transients, improving stability over windowed classifiers. CNN–LSTM hybrids combine local pattern extraction with temporal smoothing, achieving strong bearing diagnosis under variable speeds []. When labeled data is limited or conditions shift, transfer learning is critical: pretraining CNNs on source fleets and fine-tuning across sensors or vehicles improves generalization [,,].

Class imbalance and limited failure examples remain challenges. GAN-based augmentation produces realistic minority-class examples to improve recall for rare faults []. Few-shot learning strategies extract transferable similarity metrics from few exemplars, enabling rapid adaptation to new fault types or fleet deployments [].

Deep learning models often outperform classical ML methods. For instance, in automotive suspension fault diagnosis, a transfer-learned CNN (VGG16) achieved ≈98.3% classification accuracy, compared to about 95.9% using a Random Forest classifier []. This highlights a significant performance boost over traditional vibration-based classifiers (typically ~88–96% accuracy). Expanding on these results, emerging approaches blend model-based reasoning with deep learning: foundation models fine-tuned for motor PdM orchestrate feature extraction, model selection, and explanation, pointing toward agentic diagnostic stacks that enhance maintainability and transparency [].

5.3. Remaining Useful Life (RUL) Prediction

Remaining useful life forecasting extends fault detection to maintenance planning. Reviews categorize methods into model-based, data-driven statistical, and hybrid approaches, highlighting how sensor availability, physics knowledge, and operating variability guide method selection [,,]. Deep convolutional models that regress RUL from vibration sequences or spectrograms bypass hand-crafted degradation indicators and achieve competitive accuracy on rotating machinery benchmarks by learning monotonic wear surrogates without explicit physics [].

For example, a global automaker deployed a cloud-based vehicle health-monitoring solution for brake pads and clutch plates that leveraged driving-profile telemetry and machine learning RUL models to optimize maintenance intervals and reduce unscheduled downtime []. Vehicle deployment benefits from context conditioning using speed or torque, order tracking, and calibration layers that map predicted RUL to confidence intervals for decision support. In one pilot with a heavy-duty trucking fleet, an Autoencoder-LSTM hybrid RUL model claimed to have cut unplanned downtime by 73% and achieved 92.4% prediction accuracy across major drivetrain subsystems [].

Probabilistic frameworks are essential for uncertainty quantification. Functional data analysis treats degradation signals such as band-limited RMS or envelope kurtosis as smooth functions, enabling state-trajectory modelling and prediction bands that communicate risk to planners []. In automotive applications, these methods have been applied to electric drive bearings and suspension bushings, where uncertainty bounds inform whether a detected trend warrants immediate inspection or deferred maintenance. Dynamic Bayesian Networks and related graphical models capture discrete regime transitions such as gear selection, drive mode changes, and hybrid-electric switching events, fusing heterogeneous evidence including vibration, current, and temperature, and support robust RUL estimation even under missing or intermittent data []. Recent vehicle trials have demonstrated that Bayesian filtering and particle-based uncertainty propagation improve RUL reliability for inverter-fed motor bearings by accounting for operational variability and thermal cycling.

For safety-critical fleets, system-theoretic approaches integrate prognostics with risk and decision thresholds, ensuring maintenance deferral aligns with operational safety envelopes []. In automotive fleet scheduling, RUL outputs are often fed into enterprise asset-management systems (EAM) or computerized maintenance-management systems (CMMS) so that predicted failure windows trigger parts ordering, technician dispatch, and vehicle downtime planning. A case study of a taxi-fleet optimization simulation used predicted RULs for engine, spring, brake-pad and tyre components to generate rolling-horizon maintenance schedules via multi-objective evolutionary algorithms, reducing cost and downtime [].

Cross-domain studies demonstrate the value of domain adaptation and structure-aware priors. Rail-vehicle wheels show that on-board vibration-derived wear proxies combined with geometry and usage priors yield accurate RUL estimates, an approach directly transferable to automotive braking and driveline components []. In practice, organizations adopt a tiered architecture: detection via classifiers, health-index smoothing, RUL estimation through probabilistic regression, and decision policies encoding cost and risk, consistent with comprehensive prognostics guidance [,].

5.4. Adaptive Thresholding and Online Learning

Production vehicles experience concept drift: wear, firmware updates, seasonal effects, and changing driver populations alter data distributions over time. Online learning and adaptive thresholds are therefore essential. Classical optimization frameworks integrate predictive models with maintenance policies, showing that value arises not only from accurate prediction but also from co-designing decisions, a principle central to modern closed-loop PdM orchestration []. Drift at the model layer can appear as covariate shifts (speeds or loads), prior shifts (fault rates), or genuine concept shifts (new failure modes). Lu et al. and Gama et al. provided taxonomies, detection tests such as DDM and ADWIN, and adaptation mechanisms applicable to condition monitoring [,].

In practice, automotive pipelines maintain dual pathways: a stable long-horizon model for fleet-wide inference and incremental learners at the edge that update thresholds or lightweight classifiers with vehicle-specific data. Drift-aware policies include contextual thresholds keyed to operating regimes, self-calibration using rolling quantiles of health indicators, and trigger hysteresis to prevent alarm flapping in stop-and-go cycles. Cloud–edge cooperation supports shadow training, where new models learn online while legacy models continue making decisions, with promotion only after A/B safety checks against ground-truth maintenance and warranty outcomes [,].

Digital twins provide a framework for safe adaptation. By simulating operating envelopes and fault progression, twins generate counterfactual data to pretrain or stress-test online learners and probe alarm policies before deployment. Coupling twins with deep models has been shown to improve detection and prognostics while retaining interpretability for engineers and safety managers []. In EV battery health prognostics, advanced sequence models have demonstrated extremely low error rates. One LSTM-based hybrid model (DCRNN + SVM-RFE) kept battery SOH prediction error < 0.02%, with mean RMSE ~0.014 and MAE ~0.011 (in normalized capacity units), representing an accuracy improvement of roughly 64.9% over a benchmark approach []. Together, these practices create PdM stacks that learn continuously while remaining governable, with alarms and RUL estimates evolving across the fleet while preserving traceability from signal to decision to maintenance action.

5.5. Key Takeaways

Table 4 summarizes the advanced processing techniques, their input requirements, and deployment advantages. The findings of this review support a layered diagnostic and prognostic strategy. Physics-guided features combined with classical machine learning enable explainable and low-latency decision-making at the edge. Compact convolutional neural networks and hybrid CNN–LSTM architectures are well suited for identifying subtle or masked faults, where the benefits of end-to-end learning justify the higher computational demand. Remaining useful life models extend these detections into actionable maintenance planning with calibrated uncertainty, supporting proactive decision-making.

Table 4.

Different machine learning approaches for vibration diagnostics, with their inputs, strengths, and use cases for PdM.

The analysis also highlights the importance of addressing limited labeled data and class imbalance through techniques such as transfer learning, data augmentation, and few-shot similarity metrics. Model robustness can be improved through contextual thresholds, rolling self-calibration, and cloud–edge shadow training prior to deployment.

Finally, the review underscores the need for architectures and monitoring frameworks that ensure full traceability from raw signal acquisition to diagnostic decision and subsequent maintenance action. Such traceability enhances confidence in automated analytics and supports continuous validation throughout the system lifecycle.

6. Case Studies and Physical Implementations

Methodological choices only gain credibility when they withstand real vehicle environments that include shock loads, thermal excursions, variable mounting, and contested bandwidth. This section examines how pipelines are instantiated on ICE, HEV, and BEV platforms as well as heavy-duty and defense vehicles, emphasizing sensor placement, bandwidth budgets, and human-in-the-loop validation.

6.1. Automotive Platforms

Across internal combustion engine platforms, OEM PdM deployments usually start with narrow pilots targeting well-known faults such as misfires, injector or valvetrain anomalies, and gear or bearing wear. These faults have well-characterized signatures that transfer across engine families. Fielded systems combine envelope analysis, band-limited kurtosis, and order-tracked spectra to separate combustion-induced content from rotating artifacts. Rule-based or lightweight machine learning classifiers then support on-board decisions [,]. On-vehicle constraints, including limited compute, variable mounting, and acoustic masking, favor compact feature sets and interpretable models that technicians can validate. When failures are rare, bench-rig campaigns generate high-SNR exemplars to anchor fleet thresholding and warranty analytics [,]. In one large-scale fleet dataset spanning 10 vehicle models, a deep Symptoms-Based Model (Deep-SBM) improved diagnostic accuracy to 60–80%, significantly outperforming legacy rule-based checks, which averaged below 50%, and leading in 6 out of 10 model categories [].

Battery-electric vehicles emphasize electromagnetic and inverter-induced patterns as primary diagnostic targets. Motor harmonics, including slot, pole, and eccentricity effects, interact with gearbox meshing and inverter pulse-width modulation, producing mid-to-high frequency bands that vary with torque and control strategy []. Production-ready stacks implement context-aware preprocessing, synchronous resampling to electrical order, speed and torque conditioning, and switching-state tagging to stabilize features across drive cycles. Studies demonstrate that CNN backbones trained on spectrograms or order maps have demonstrated automotive-grade inference budgets while reliably detecting demagnetization, eccentricity, and winding faults despite overlapping gear harmonics [].

Hybrid electric vehicles introduce additional complexity with mode switching. Transitions between ICE and electric drive create torque reversals, clutch synchronization, and bidirectional power flow that can mask or mimic faults. OEM strategies segment data by operating mode and apply transfer learning to share representations across modes and platforms, reducing the need for repeated relabeling after calibration changes []. Commercial-vehicle programs show that pairing PdM with telematics adds value. Route profiles and duty cycles inform baseline normalization, while fleet dashboards translate anomaly scores and health indices into actionable maintenance decisions, improving availability and reducing roadside events [,]. Multi-modal stacks that combine vibration, current, and CAN signals outperform single-sensor solutions, particularly for early low-SNR faults, as redundancy improves precision without increasing false alarms.

Real-world deployments highlight the importance of human-in-the-loop analytics. NVH engineers review flagged events using order-tracked plots and envelope spectra to confirm physical plausibility before issuing service bulletins. Studies combining acoustic wavelet packet transform features with PCA-tuned classifiers show that adding an explainability layer, such as feature importance or order markers, accelerates root-cause analysis and reduces model rollback risk during software updates []. Fleet experience confirms that combining physics-guided preprocessing with machine learning and deep learning achieves the best balance of robustness and maintainability across ICE, EV, and HEV platforms.

6.2. Military and Heavy-Duty Vehicles

Heavy-duty and defense vehicles operate in severe environments with shock loads, wide thermal ranges, abrasive contaminants, and persistent misalignment from rough terrain. Case studies on agricultural and off-road equipment show that low-cost embedded nodes can provide actionable monitoring if the signal chain is hardened. Oversampled MEMS accelerometers, rugged mounts, and in-node denoising or envelope detection reduce false positives when structures experience repeated impacts []. Transmitting compressed features or alarm metadata minimizes bandwidth while preserving fidelity for cloud analysis, a pattern readily applicable to military vehicles with constrained or contested communications [,].

Legacy rotating assets, such as transfer cases, final drives, and auxiliary power units, benefit from prognostics frameworks that model uncertainty and operational variability. System-theoretic approaches link health indicators, remaining useful life, and mission risk, which is critical when maintenance deferral affects sortie planning or convoy readiness []. In high-utilization bus and logistics fleets, edge-first AI boards demonstrate that local feature extraction, classification, and rule enforcement can prevent cascading failures, such as isolating a degrading wheel hub or differential bearing before thermal runaway, while the cloud aggregates fleet-wide evidence to refine thresholds and parts-life policies []. For instance, in a targeted suspension fault case study, applying transfer learning from pre-trained CNN backbones yielded 98.3% classification accuracy, substantially outperforming earlier classifiers like Bayesian and tree-based models, which typically ranged between 88% and 95% [].

Robustness under extreme loads requires models resilient to spectral smearing and intermittent saturation. Practical deployments implement operating-region maps, gating models by speed, gear, and torque zones, and adapting alarm thresholds to the zone’s nominal distribution. Sparse sensing coverage can be mitigated with ensembles that combine demodulated gear mesh features and low-frequency structural modes, capturing looseness or lug-bolt issues more effectively than single-band detectors. Fielded heavy-duty systems reinforce three design rules: prioritize mounting repeatability and cable management; evaluate models under worst-case excitations, including potholes and sharp turns; and calibrate alarms to catch early faults without causing mission aborts, a balance formalized through system-level safety frameworks [,,].

6.3. Comparative Performance of Techniques

Comparative studies consistently find that physics-guided preprocessing (envelope detection, order tracking) plus either classical ML or compact CNNs offers the best accuracy–latency trade-off for rotating drivetrain faults. In controlled wear experiments with contaminated lubricants, transmission-error–assisted vibration features detect gear wear earlier and more reliably than raw-spectrum baselines, indicating that targeted demodulation and sideband analysis remain strong foundations for any downstream learner []. Prognostic pipelines that fuse spectral indicators with wear progression models deliver earlier and more stable health indexing than purely discriminative detectors, which can fluctuate with duty-cycle shifts [].

From a computational standpoint, classical models (SVM, random forests) and shallow CNNs achieve real-time budgets on low-power ECUs, whereas deeper nets (ResNet-like backbones) often require either pruning/quantization or an edge accelerator to meet on-vehicle constraints [,]. Implementation cost scales with labeling effort and sensor count: deep models reduce feature-engineering burden but demand curated datasets; conversely, feature-rich classical stacks can run with limited labels yet require domain expertise to maintain. Complementing vibration-based indicators, machine learning has also been used to estimate gear safety margins directly from ISO-based simulations. Molaie et al. trained neural networks on over 5000 synthetic gear conditions to estimate safety factors with high fidelity, demonstrating that learning-based models can bridge simulation outputs and physical indicators such as transmission error or dynamic loads []. Studies on statistical feature learning demonstrate that judicious dimensionality reduction (e.g., deep statistical features or PCA) can preserve accuracy while shrinking model footprints, a key lever for retrofits and cost-sensitive platforms [,].

Fault coverage and data scarcity drive architecture choice. GAN-based augmentation and few-shot learners broaden coverage for rare failure modes without inflating fleet data collection, improving recall at the long tail while keeping false positives in check []. However, when failures progress slowly (e.g., mild pitting), order-synchronous indicators paired with lightweight classifiers often match or beat heavy DL in precision at far lower power and integration complexity, particularly when sensor placement or mounting varies between trims and model years [,,]. In sum, the most effective deployments adopt a tiered strategy: (i) efficient, interpretable detectors on the vehicle for fast, trusted alerts; (ii) cloud-side DL for hard cases, cross-fleet learning, and what-if analysis; and (iii) ongoing A/B evaluation against maintenance outcomes to tune thresholds and justify incremental cost [,,,,,].

6.4. Key Takeaways

This review found that fielded systems with strong performance tend to share three characteristics. First, they employ hardened signal chains that protect data integrity through repeatable sensor mounting, the selective use of oversampled MEMS sensors, and on-node denoising and enveloping. Second, they integrate context-aware analytics, including operating region maps, mode segmented features, and baselines informed by telematics, which align interpretation with real operating conditions. Third, they maintain governance practices in which alarms are explainable and reviewed by noise, vibration, and harshness experts, thresholds reflect risk, and updates are validated through A/B testing.

The review also observed that multimodal sensing, combining vibration with current or CAN signals, consistently outperforms single sensor approaches for early faults with low signal to noise. Fleet dashboards further translate anomaly scores into prioritized maintenance actions, improving operational efficiency.

Across internal combustion, battery electric, heavy duty, and defense applications, these patterns suggest that robustness arises as much from disciplined systems engineering and process control as from any single diagnostic algorithm.

7. Challenges and Future Directions

A persistent challenge in automotive vibration diagnostics is signal overlap in multi-component systems. Modern powertrains, particularly e-axles and hybrid transaxles, co-locate multiple rotating groups and power-electronics sources, causing characteristic orders, sidebands, and modulations to interfere. Classical band-pass envelope pipelines often underperform when meshing frequencies, bearing fault orders, electromagnetic harmonics, and inverter-switching artifacts coincide. Blind source separation and demixing strategies use statistical independence or sparsity to recover latent components. However, their assumptions are strained by operating-point drift and intermittent cyclostationarity in on-road data []. Resonance- and sparsity-based decompositions improve weak-fault observability, yet adaptive band selection under inverter-driven wide-band content remains an open problem [].

Nonstationarity from driving style, environment, and energy mode magnifies these challenges. In electric vehicles, torque commands, PWM schemes, and regenerative braking reshape the spectral canvas in real time; in hybrids, mode transitions introduce transients and rapidly varying orders []. Such variability produces domain shift: models trained on proving-ground cycles degrade on urban or mountainous routes, and platform revisions can trigger covariate shift. Transfer learning and domain adaptation help map between sensors, speeds, and platforms. However, stability under compounded shifts, driver behavior, climate, and software updates requires continual adaptation policies and uncertainty-aware inference [,,].

Concept drift over fleet life further complicates modeling. Baseline vibration envelopes evolve with wear, maintenance, aftermarket modifications, and software updates. Static thresholds or one-time labels misalign with present-day distributions, causing alert fatigue or missed faults. Research priorities include formalizing drift taxonomies and embedding drift detectors with recalibration, feature re-weighting, or human-in-the-loop adjudication to maintain detection performance while preserving rare, safety-critical signatures [,,].

Data limitations remain structural barriers. Label scarcity and class imbalance are endemic, as catastrophic failures are rare and warranty databases provide coarse, delayed, or biased supervision. Traditional resampling is brittle, and synthetic oversampling risks unphysical features. Generative modeling and domain adaptation help create minority-class exemplars and transfer knowledge across platforms, but validation against real failures is essential [,]. Few-shot and meta-learning approaches allow rapid specialization to new platforms or sensors, though their reliability under heavy nonstationarity and multi-sensor heterogeneity is still under study [].

Integration of digital twins and multi-sensor fusion represents a key frontier. High-fidelity twins of powertrains and drivelines provide physics-consistent priors, meshing stiffness maps, electromagnetic force models, and mount transmissibility to constrain feature extraction and synthesize counterfactuals for training and what-if analysis []. Fusing vibration with complementary modalities—acoustic emissions, thermography, and phase current—can disambiguate overlapping signatures and improve early-fault detection []. Hybrid digital twins coupling reduced-order physics with neural operators show promise for real-time inference and RUL forecasting, but balancing numerical stability with data-driven flexibility and quantifying uncertainty remain open questions [,]. Fusion techniques such as CFAM represent candidate directions to address these challenges. By jointly attending to spatial–temporal dependencies across sensor modalities, these frameworks enable more robust decision making even under noisy or incomplete input conditions [].

Fleet-scale deployment requires cloud/edge co-design. On-vehicle inference must meet latency, bandwidth, and power constraints while satisfying safety and cybersecurity requirements. Edge analytics can denoise, order-track, and extract compact features, transmitting only health indicators or compressed embeddings to the cloud for aggregation, drift monitoring, and model governance [,]. Field studies demonstrate feasibility on resource-constrained platforms, but model lifecycle management, versioning, rollback, and A/B validation across heterogeneous hardware and software remain practical bottlenecks [,]. Incorporating multibody dynamics into lightweight edge models can reduce data demands without sacrificing physical fidelity [].

Real-time adaptability introduces additional challenges. Incremental learners and adaptive thresholds can track slow drift, but frequent updates risk inconsistent alerts and complicate warranty adjudication. Governance is required: guardrails on adaptation, audit trails linking data shifts to threshold revisions, and human review for high-impact decisions. Hybrid schemes that combine slowly changing, physics-grounded features with adaptive embeddings, paired with uncertainty estimates, balance responsiveness and robustness while preserving safety [,,].

Progress also depends on standardized datasets, benchmarks, and evaluation protocols. Many studies rely on stationary rigs or narrow datasets, overestimating generalization. Benchmarks incorporating variable speed/load, energy-mode transitions, mounting variations, and cross-sensor/domain splits are essential to reveal failure modes before deployment []. Metrics should capture time-to-detect at fixed false-alarm rates, fleet-level alert stability, and cost impact []. Transparent reporting of preprocessing, label provenance, and leakage controls remains critical, and NLP-assisted meta-analyses can harmonize taxonomy and identify literature gaps.

Data sharing and privacy further limit progress. OEMs and suppliers collect vast telemetry, but contractual, competitive, and regulatory constraints restrict open release. Federated and split learning may enable cross-organization model training without raw data exchange, but introduce calibration drift and reproducibility challenges. De-identified or synthetic-but-validated twins could accelerate method development if fidelity is audited against real incidents [,].

Methodologically, EV/HEV-specific excitations require renewed attention. Inverter PWM patterns and magnetic saliency create cyclostationary and impulsive structures poorly captured by stationary filters. Adaptive cyclostationary analysis, time–frequency sparse coding, and nonnegative factorization applied to order-tracked spectrograms are promising [,]. Robust band-selection strategies that co-optimize mechanical and electromagnetic fault observability, rather than treating one as noise for the other, can reduce false interactions during regenerative braking and torque blending [].

Handling rare events responsibly is critical. GAN-based augmentation and contrastive pretraining improve minority-class separability but must be physics-anchored to avoid shortcut learning. Pairing augmentation with physics constraints, such as order relationships or resonance maps from twins, regularizes models toward causal mechanisms [,]. Few-shot adaptation should be stress-tested under shifting sensors, mounts, and firmware, with episodic benchmarks reflecting real commissioning or mid-cycle refresh [,].

Operationalization is as important as algorithmic innovation. End-to-end PdM pipelines must integrate explainability artifacts—fault maps, order traces, and envelope bands—into technician workflows to shorten triage and build trust. Cloud governance should track dataset lineage, model versions, and performance under domain shifts. Edge software should expose health and calibration states to prevent silent degradation. Shared implementation playbooks translating research-grade methods into automotive-grade systems with safety, cybersecurity, and lifecycle economics explicitly addressed would accelerate adoption [,,].

Addressing source separation, variability, data scarcity, digital-twin fusion, scalable cloud/edge deployment, and rigorous standardization will enable vibration-based diagnostics to evolve from pilot systems into reliable, fleet-wide capabilities for next-generation intelligent vehicles.

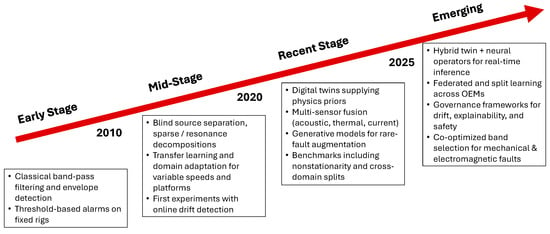

Figure 3 summarizes the evolution of vibration diagnostics for complex automotive powertrains, highlighting how methods have advanced alongside hardware and data practices. Early approaches focused on band-pass filtering and envelope detection, followed by blind source separation and sparse decompositions to address overlapping signatures. More recent work integrates digital twins, multi-sensor fusion, and generative models to manage nonstationarity and data scarcity, while benchmarks and governance frameworks support reliable deployment. Emerging directions, such as hybrid twin–neural operators, federated learning, and co-optimized band selection for mechanical and electromagnetic faults, point toward scalable, safety-aware diagnostics for next-generation vehicles.

Figure 3.

Timeline illustrating the progression of vibration diagnostics for complex automotive powertrains.

8. Conclusions

This review has synthesized the state of the art in vibration-based PdM for automotive powertrains, spanning conventional internal combustion engines, hybrid systems, and electrified architectures. Vibration analysis remains the most versatile modality for fault detection across rotating and reciprocating components because it is non-intrusive, cost-effective, and sensitive to early-stage degradation. Advances in sensing, edge data acquisition, and high-resolution signal processing have extended its reach to modern drivetrains characterized by increasingly complex mechanical–electrical interactions. In parallel, machine learning and deep learning frameworks now provide tools for disentangling overlapping excitations, predicting remaining useful life, and adapting to nonstationary operating conditions.