Abstract

This study explores the synergistic potential of ladle slag (LS) and sunflower shell fly ash (SSFA) in alkali-activated binder systems, focusing on their chemical and mineralogical characteristics and the influence of SSFA addition on the mechanical performance of LS-based pastes. X-ray fluorescence and XRD analysis revealed that LS is rich in CaO and latent hydraulic phases such as γ-belite and mayenite, while SSFA is dominated by K2O, SO3, and KCl/K2SO4 phases, reflecting its biomass origin. Infrared spectroscopy and thermal analysis confirmed the presence of carbonate, hydroxide, and hydrate phases, with SSFA exhibiting more complex thermal behavior due to volatile-rich composition. When used alone, LS produced weak binders; however, a 10 wt% SSFA addition tripled compressive strength to nearly 30 MPa, indicating a significant activation effect. Further increases in SSFA content led to strength reduction, likely due to increased porosity and excess salts. Microstructural analysis showed that SSFA promotes the formation of AFm phases such as Friedel’s salt and hydrocalumite, altering hydration pathways and enhancing early strength through chemical activation and carbonation processes. The findings highlight the potential of combining LS and SSFA as a sustainable binder system, offering a waste-derived alternative for low-carbon construction materials.

1. Introduction

The iron and steel industry is a pillar of the worldwide economy and an energy-intensive consumer. In 2021, the global crude steel production reached 1958.4 million metric tons (Mt), of which the European Union accounted for 152.8 Mt []. The production of iron and steel is accompanied by large amounts of metallurgical slag generated during smelting []. According to different steelmaking methods, steel slag can be subdivided into the following: conversion slag or basic oxygen furnace slag resulting from the refinement of crude iron; electric arc furnace slag from recycled scrap and/or crude iron; argon oxygen decarburization slag derived from the decarburization and desulfurization of stainless steel; ladle furnace slag from the refinement of steel in a ladle furnace; and other secondary metallurgical slags []. Each slag type possesses specific properties and potential applications. Certain slags are well-utilized, such as ground granulated blast furnace slag as a supplementary cementitious material [] or aggregated slags utilized in road base construction and asphalt mixtures [,]. Other low-reactive slags such as ladle slag hardly find application outside the steel industry and consequently are stockpiled outside []. The ladle slag annual output has exceeded 20 Mt [].

The ladle metallurgy furnace is part of a secondary steelmaking process of high-alloyed steel and an additional refining step after the basic oxygen furnace or electric arc furnace process []. The production of steel generally includes primary steelmaking and secondary treatment procedures. After the primary treatment process, the generated molten steel is cast into a ladle furnace. The ladle furnace heats the steel using graphite electrodes []. The ladle slag commonly consist of dicalcium silicate (C2S), mayenite (C12Al7), periclase (MgO), bredigite (C12MgS4), free lime (CaO), etc. []. Since the ladle slag is produced from a slow cooling process, the dicalcium silicate is transformed from β-C2S to γ-C2S. This transformation is accompanied by volume expansion and self-powdering, which means that ladle slag is unsuitable to be used as an aggregate []. Moreover, the γ-C2S is considered as scarcely reactive with water at normal conditions []. Still, ladle slag implies a certain potential as construction material, despite rather weak hydration and along with other difficulties (inconsistent chemical composition, potential leaching problems, volume stability due to MgO content) in being used as binding material. However, it was found that the binding properties of ladle slag, in particular γ-C2S, can be greatly enhanced through alkaline activation [,,].

Alkaline activation is based on the reaction between solid aluminosilicate precursors under alkaline conditions []. The alkaline activation of slags has been widely discussed and promoted as a component of the toolkit of ‘sustainable cementing binder systems’ []. However, several authors used different ladle slags to obtain alkali-activated materials. The most common activators used are a mixture of sodium silicate and sodium hydroxide [,,]; sodium silicate and potassium hydroxide []; and potassium silicate []. The alkali-activated ladle slag showed high compressive strength (up to about 65 MPa) and durability []. However, some authors reported rather ineffective activations of ladle slag with NaOH, Na2SO4, and/or sodium silicate [,]. However, despite the relatively respectable results using alkali silicates activators, the latter are expensive and have significant environmental impact []. This triggers the need for extensive research into alternative alkaline activators based on waste or by-products []. The effective replacement of commercial sodium silicates was achieved by the hydrothermal dissolution of waste glass [], rice husk ash [], silica fume [], sugarcane straw ash [], etc. Direct usage of alkaline waste solution as an activator by utilizing aluminum anodizing etching solution [] and Bayer liquor [] is also possible. Another approach is using dry activators and to design a one-part alkali-activated cement []. In this method the activator solution is replaced by solid materials consisting of alkali or alkali–earth components in a reactive form. Among the dry activators derived from waste products, different types of biomass ash are suitable as activators due to their high alkaline character []. For example, several biomass ashes were used as dry activators, such as maize stalk and cob ashes [], olive stone ash [], almond-shell ash [], wood ash [], and coffee husk ash []. Additionally, one-part cement formulations are considerably more user-friendly, requiring only the addition of water similar to conventional Portland cement. To the best of our knowledge, the use of sunflower shell fly ash as an alternative activator in alkali-activated binders has not been previously reported.

The present study aims to explore the potential of sunflower shell fly ash (SSFA) as a dry alkali activator for one-part alkali-activated cement based on ladle slag. Given the high alkalinity and reactive silica content of biomass ashes, SSFA is investigated as an alternative to conventional liquid activators, which are often costly and environmentally damaging. This study evaluates the physicochemical interactions between ladle slag and SSFA, assessing the phase evolution, microstructure, and mechanical properties of the resulting cementitious material. The findings contribute to the development of cost-effective one-part alkali-activated binders, promoting the valorization of industrial and agricultural waste in sustainable construction applications.

2. Materials and Methods

The main raw material for the preparation of alkali-activated material was ladle slag (LS). The ladle slag is a by-product of secondary refinement steel, produced in the industrial complex of Stomana Industries, S.A, Bulgaria, and provided by Aeiforos Bulgaria S.A, Pernik, Bulgaria. The LS was temporarily stored in stockpiles at a steel plant yard. A representative sample of 10 kg ladle slag was collected, dried to constant mass at 80 °C, and grinded via steel ball milling for 1 h. The role of the dry activator in the present study was taken by biomass fly ash from sunflower shells (SSFA) generated from the combustion of sunflower shell cake in a boiler producing water steam. The SSFA was collected from a bag cyclone filter at the Biodiesel Plant of the company Astra Bioplant EOOD company in the town of Slivo Pole, Ruse region, Bulgaria. The SSFA was dried to a constant mass at 80 °C and milled for 1 h in a ceramic ball mill. The SSFA exhibited a bright white color, which is associated with minimal residual carbon (see Supplementary Materials—Figure S1). The alkali-activated mixtures were obtained by using tap water.

The chemical composition of the precursors was determined by XRF using pressed pellets, analyzed on Rigaku Supermini 200WD apparatus, Rigaku Corporation, Osaka, Japan. The powder X-ray diffractograms were obtained on Empyrean (Malvern Panalytical, Almelo, The Netherlands) diffractometer using CuKα radiation at 40 kV and 30 mA. The infrared spectra were measured using the Zn-Se ATR accessory and Tensor 37 (Bruker, Berlin, Germany) spectrometer, averaging over 128 scans with ±2 cm−1 spectral resolution. The thermal analyses were carried out on the DSC-TG analyser SETSYS2400 (SETARAM, Caluire, France) under the following conditions: temperature range from 20 to 1000 °C, in a static air atmosphere, with a heating rate of 10 °C min−1, and 10–15 mg sample mass.

Compressive strength was measured on 3 cubic specimens with one side area of 10 cm2. The density of each series was calculated using dry mass and measuring the dimensions of three specimens per series by digital caliper with a resolution of 0.01 mm.

3. Results

3.1. Characterization of the Precursors

The chemical compositions of the two raw materials (LS and SSFA) used in the presented study are shown in Table 1. The dominant oxides in the LS sample were CaO, SiO2, and Al2O3. Additionally, the magnesium oxide (MgO) content was measured at 6.5 wt%. A certain amount of sulfur was also detected, calculated as sulfate (SO3).

Table 1.

Chemical composition of ladle slag (LS) and biomass fly as from sunflower shells (SSFA), determined by XRF, in wt%.

On the other hand, the SSFA exhibits a distinct chemical profile, being exceptionally rich in potassium (K2O), which accounts for over 61 wt%. This is in line with the composition of sunflower shells ash reported by Lokare at al. [] and Vassilev et al. [], with K2O content of = 45,1%, and 49,8%, respectively. They also report a significant amount of P2O5 content (7–10%), a fraction of which is discarded in the fly ash. Some authors report high content of SiO2 for SSA, which is probably due to contamination with sand and dust during the harvesting and processing of the sunflowers [,]. Notable quantities of alkaline–earth oxides, such as CaO (15.43 wt%) and MgO (2.33 wt%), were identified in SSFA. Sulfur and chlorine were also present in significant amounts, with SO3 reaching 14.02 wt% and Cl reaching 4.78 wt%. Elements such as S, Cl, and K are enriched in fly ashes due to their significant volatile nature during biomass combustion and often are transported by flue gases and the subsequent condensation in fly ashes [].

The high calcium content in LS, combined with the alkali and alkali–earth nature of SSFA, suggests their potential for synergistic interactions in cementitious or geopolymer applications.

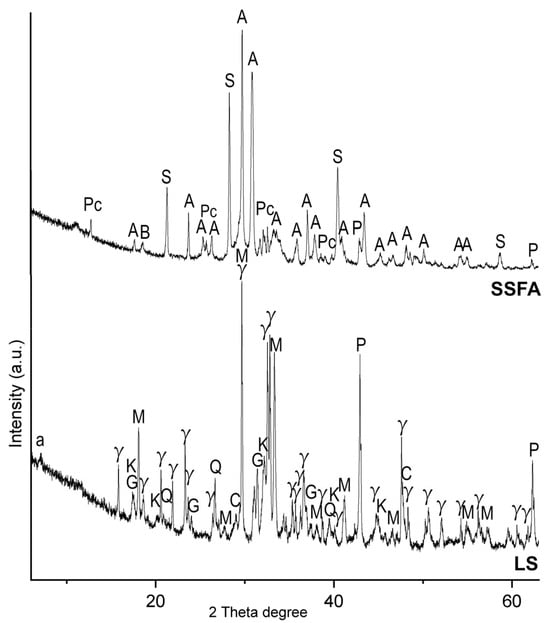

The mineral composition of the precursors is presented in Figure 1. The LS exhibited a well-crystalline structure, indicative of slow cooling during its formation. The dominant crystalline phase in LS was γ-belite (Ca2SiO4), a calcium disilicate phase that forms under slow cooling conditions and contributes to the material’s latent hydraulic properties []. The second major phase identified was mayenite (Ca12Al14O33), a calcium aluminate phase known for its high reactivity and rapid setting []. Additionally, periclase (MgO) was detected, often regarded for its role in volume stability on hydration []. Gehlenite (Ca2Al2SiO7), which is active phase in hydration, was also presented to enhance the reactivity of the slag in cementitious systems. Minor amounts of strätlingite (Ca2Al2SiO7·8H2O), katoite (Ca3Al2(SiO4)(OH)8), and brucite (Mg(OH)2) were also detected, probably as a product of natural hydration due to outside pile storage of the LS at the steel producing plant. Calcite was also detected, probably as a product of natural carbonation.

Figure 1.

Powder XRD of the raw materials: biomass fly ash from sunflower shells (SSFA) and ladle slag (LS). Legend: A—arcanite, a—strätlingite, B—brucite, C—calcite, G—gehlenite, K—katoite; Pc—potassium carbonate hydrate (K2CO3.1.5H2O), P—periclase, Q—quartz, M—mayenite, S—sylvite, γ—γ-belite (Ca2SiO4).

In contrast, the mineral composition of biomass fly ash from sunflower shells (SSFA) was dominated by arcanite (K2SO4) and sylvite (KCl). The high potassium content in SSFA promotes natural carbonation processes, resulting in the formation of potassium carbonate hydrate (K2CO3·1.5H2O). The strong hygroscopic nature of sylvite accelerates carbonation, further facilitating the transformation to potassium-bearing carbonate phases. Despite the dominance of crystalline potassium salts, the chemical and mineral composition results suggest that a certain amount of the potassium remains in an amorphous phase, as inferred from the high K2O content determined by XRF. A minor amount of brucite was also detected.

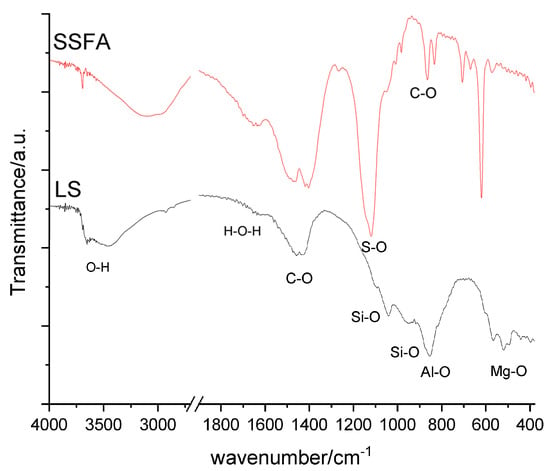

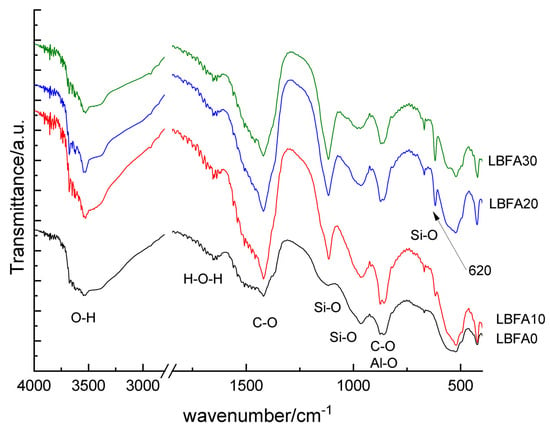

The infrared spectra of raw materials LS and SSFA are presented in Figure 2. The two starting materials have a complex phase composition, whereby the peaks in the spectra overlap and make interpretation difficult. However, some conclusions can be drawn and contribute to the description of the source materials.

Figure 2.

Infrared spectra of the raw materials: biomass fly ash from sunflower shells (SSFA), and ladle slag (LS).

The most intensive absorption peak of the LS is centered at 855 cm−1, which is in the range of the Al-O stretching vibrations of AlO4 tetrahedra in mayenite []. The asymmetric Al-O stretching of other aluminosilicates presented in the ladle slag (LS) also contribute in the range of 800-870 cm−1. Silicate minerals already detected by powder diffraction data are γ-belite—(γ-Ca2SiO4), gehlenite (CaAl(AlSiO7)), katoitite (Ca3Al2SiO4 OH8) and strätlingite (Ca2Al2SiO7·8H2O). In general, minerals containing silicate groups exhibit characteristic infrared absorption bands due to stronger Si–O stretching and less intensive bending vibrations. These bands typically appear in the range of 800–1200 cm−1 for stretching vibrations and 400–600 cm−1 for bending vibrations. Bands due to Si–O stretching are visible near 960 and 1040 cm−1. At such frequencies one would expect the intense absorption bands of belite, gehlenite, and other silicate phases present in the sample [,]. Strätlingite is a hydrated calcium aluminum silicate hydrate (also called gehlenite hydrate) that forms in hydrated cement systems and is important in cement chemistry. The infrared spectrum shows peaks related to water molecules at 3450 and 1640 cm−1, which could be attributed to this phase. Strong peaks in the range of the carbonate stretching region at 1458 and 1429 cm−1 indicate the presence of carbonate minerals. Calcite is confirmed by the infrared absorption at 2926w, 2860w, 1429s, and a shoulder at 870 cm−1 []. Brucite (MgOH2) is detected by the strong and sharp peak at 3660 cm−1 due to O-H stretching vibrations [].

The most intensive sharp peaks in the infrared spectrum of SSFA (Figure 2) at 1119 cm−1 and 620 cm−1 are indicative of potassium sulfate arcanite (K2SO4) []. The strong absorption at 1400-1470 cm−1 and at 830-870 cm−1 correspond to asymmetric stretching (ν3) and out-of-plane bending (ν2) modes of the carbonate ion, respectively. These carbonate peaks and characteristic absorption bands of water at 3100–2967 cm−1 and at 1630 cm−1 confirm the presence of potassium carbonate sesquihydrate []. The strong and sharp peak at 3690 cm−1 is characteristic of hydroxyl group stretching in brucite.

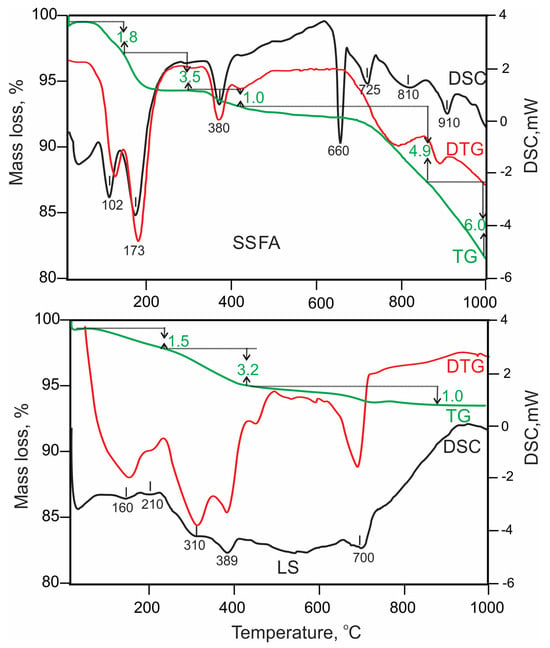

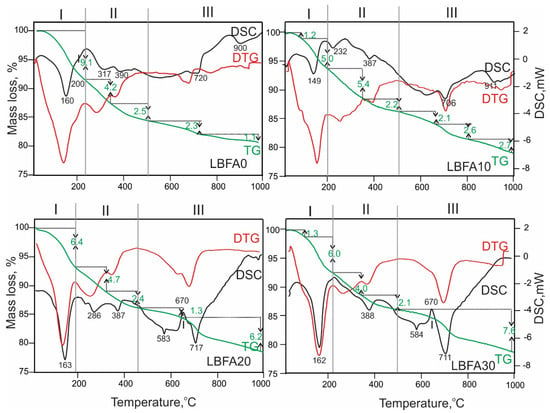

The thermal behaviors of both precursors LS and SSFA are shown in Figure 3. The LS exhibits insignificant mass losses on the TG curve and endothermic effects on the DSC curve within the temperature range of 25–400 °C, indicating the presence of a minor amount of hydrate phases due to weathering of the ladle slag. Minor endo-effects around 160 °C and 210 °C were related to strätlingite [], while katoite decomposed at about 310 °C []. The distinct endothermic peak at 389 °C is characteristic for brucite dehydration []. The endothermal event at about 700 °C is due to the presence of a carbonate mineral (calcite), the amount of which, calculated from the TG curve, is below 0.5%. The major mineral phases identified by PXRD such as γ-belite, mayenite, gehlenite, and periclase are thermally stable in this temperature region without expressions on the registered curves. In contrast to LS, SSFA shows more complicated thermal behavior. The only identified hydrate phase by PXRD was KCO3·1.5HO, which during heating from 25 to 300 °C dissociates to anhydrous form. The decomposition endo-effect of K2CO3 is around 900 °C, accompanied by mass loss. It is known that the suitable sintering temperature for this compound should be below the decomposition temperature []. The endothermal peak at about 380 °C is related to brucite dehydration. The sharp endo-effect at 660 °C and 725 °C are probably attributed to the two-step melting of KCl []. The melting point of pure KCl is 776 °C, but when this potassium salt is presented together with other salts, this temperature is considerably lower due to possible eutectics []. The KCl decomposition starts immediately after its melting. In the temperature range of 350–600 °C, SSFA showed no significant mass loss or exothermic peaks, indicating a very low content of unburned carbon.

Figure 3.

DSC-TG(DTG) curves of both precursors—LS and SSFA.

3.2. Influence of Sunflower Shells Fly Ash Addition to Ladle Slag

The influence of different amounts of SSFA addition (from 0 up to 30%) to ladle slag was investigated. The composition design of the prepared series is presented in Table 2. The ladle slag and SSFA were placed in a laboratory planetary mixer to obtain a homogenous dry mixture. The water-to-solid ratios of all series were fixed to 0.35. The fresh alkali-activated paste was stirred for 2 min and poured in steel molds wrapped in polyethylene foil. The samples were demolded after one day and stored under laboratory conditions. The properties of the obtained alkali-activated materials were examined on the 28th day.

Table 2.

Composition design and physical properties of the prepared pastes.

3.2.1. Physical Properties

The hydration of ladle slag (LS) alone resulted in the formation of a relatively weak material, achieving a compressive strength of approximately 10 MPa (Table 2). This indicates that LS, when used independently, exhibits limited self-cementing properties. However, the incorporation of 10 wt% SSFA significantly enhanced the compressive strength, increasing it by approximately threefold to 29.6 MPa. This remarkable improvement suggests that the presence of SSFA contributes to enhanced reaction kinetics and possibly the formation of additional binding phases. Further increasing the SSFA content to 20 wt% led to a decrease in strength (22.4 MPa), although the material still exhibited a notable improvement compared to the reference LS paste. A more pronounced reduction in mechanical performance was observed at 30 wt% SSFA, where the compressive strength dropped to 11.6 MPa, approaching the strength of the pure LS system. This decline may be attributed to an excessive sulfates and chlorides, or increased porosity associated with higher SSFA content.

In addition to mechanical properties, density measurements revealed that the alkali-activated pastes had relatively low bulk density, which further decreased with the progressive addition of SSFA. The reference paste (LBFA0) exhibited a density of 1.591 g/cm3, and the density decreased to 1.569 g/cm3, 1.560 g/cm3, and 1.548 g/cm3 for LBFA10, LBFA20, and LBFA30, respectively. This trend suggests that the incorporation of SSFA introduces a degree of porosity or reduces the packing density of the solid matrix, likely due to the physical and chemical nature of SSFA and reactions with LS.

The results demonstrate that a moderate substitution of 10 wt% SSFA optimally enhances strength, while excessive replacement leads to a decline in mechanical performance.

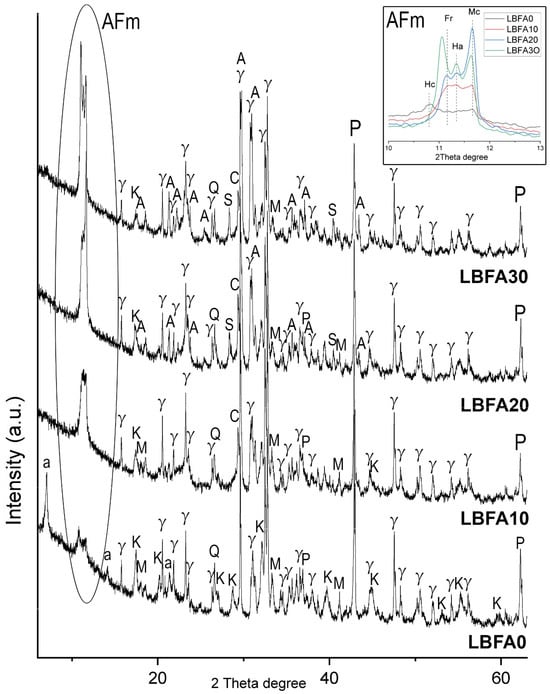

3.2.2. Microstructural Characterization

The primary reactive phases within the ladle slag were identified as mayenite (Ca12Al14O33) and gehlenite (Ca2Al2SiO7). Upon hydration of the ladle slag, strätlingite [(Ca2Al2SiO7)·8H2O] was formed as a dominant phase (LBFA0), followed by the relative increase in katoite phase (Figure 4). Hemicarboaluminate (Hc) [3CaO·Al2O3·Ca(OH)(CO3)0.5·xH2O] and monocarboaluminate (Mc) [3CaO·Al2O3·CaCO3·xH2O] were also formed as products of natural carbonation.

Figure 4.

Powder XRD of the alkali-activated material based on ladle slag and biomass ash from sunflower shells. Legend: A—arcanite (PDF 00-044-1414), a—strätlingite (PDF 00-029-0285), AFm—family of hydrated calcium aluminate phases, C—calcite (PDF 01-076-2713), Fr—Friedel’s salt(PDF 00-028-0207), Ha—hydrocalumite (PDF 00-031-0245), Hc—hemicarboaluminate (PDF 00-041-0221), Mc—monocarboaluminate (PDF 00-014-0083), K—katoite (PDF 01-074-3033), M—mayenite (PDF 00-048-1882), P—periclase (PDF 00-087-0651), Q—quartz (PDF 01-070-2517), S—sylvite (PDF 00-000-0587), γ—γ-belite (dicalcium silicate) (PDF 01-080-4279).

The incorporation of SSFA altered the formation of strätlingite and katoite. Instead, the presence of chloride ions in SSFA promoted the crystallization of AFm phases—a family of hydrated calcium aluminate phases representing a layered double hydroxide with a representative formula [Ca2(Al,Fe)(OH)6]·X·nH2O, where X equals an exchangeable single charged anion (such as chloride) or half of a double charged one (sulfate, carbonate). The AFm phases exhibit variable compositions and significantly influence cement performance, including strength, durability, and chemical stability []. The main phases detected in the LS activated by SSFA were hydrocalumite [3CaO·Al2O3·Ca(OH)2·10H2O], Friedel’s salt [3CaO·Al2O3·CaCl2·10H2O], and Mc. The amount of Mc increased, suggesting enhanced carbonation due to SSFA addition. Presence of sylvite and arcanite in the system increased the hygroscopicity of the material, which accelerated the natural carbonation []. Ettringite and monosulfoaluminate phases were not detected. The formation of hydrotalcite phase is also possible but its main peak overlaps with monocarboaluminate []. The presented AFm phases (Friedel’s salt, hydrocalumite, Hc, Mc) are referred as stable at normal conditions and contribute to the mechanical strength of the obtained material [,].

The γ-belite (2CaO·SiO2) and periclase (MgO) remained relatively inert even after the addition of SSFA, indicating their lack of hydration under the given conditions. Periclase (MgO) is often negatively associated with the volume stability of cementitious systems due to its potential late-stage hydration. The potassium-rich environment did not significantly promote the periclase hydration. The stability of periclase in this system can be attributed to its “dead-burned” nature. Dead-burned periclase refers to MgO that has undergone high-temperature sintering—typically around 1500 °C—within the molten mass of the kiln, resulting in a highly crystalline, dense, and refractory phase with significantly reduced reactivity []. Dead-burned MgO exhibits minimal hydration in conventional cementitious systems due to its low solubility and slow reaction kinetics []. Periclase and γ-belite stayed relatively inert even at SSFA addition.

The FTIR measurements were conducted to investigate the effect of varying SSFA additions (0–30%) to ladle slag. Infrared spectra of the alkali-activated material based on LS and SSFA are shown in Figure 5. The main phases already detected in LBFA0 upon hydration and carbonation of LS are strätlingite (Ca2Al2SiO7·8H2O), katoite (Ca3Al2SiO4OH8), hemicarboaluminate [3CaO·Al2O3·Ca(OH)(CO3)0.5·xH2O], and monocarboaluminate [3CaO·Al2O3·CaCO3·xH2O]. In a mixture containing these phases, the IR spectrum displays overlapping bands in the O-H stretching range at around 3400 cm−1 due to hydroxyl groups and water molecules, carbonate stretching, and bending near 1420 and 870 cm−1, as well as peaks in the range 1100–500 cm−1 due to Si-O and Al-O stretching and bending vibrations. The addition of SSFA leads to a clear trend: the appearance of peaks at 1117 and 620 cm−1 in LBFA10, which intensify progressively up to LBFA30, corresponding to the vibrations of the sulfate group. This is a main spectral indication of the increasing amount of arcanite (K2SO4) with the increasing amount of added SSFA, since the mineral remains stable.

Figure 5.

Infrared spectra of the alkali-activated material (LBFA) based on ladle slag (LS) and biomass ash from sunflower shells (SSFA).

The thermal behavior of alkali-activated material based on ladle slag and biomass ash from sunflower shells is presented in Figure 6. As was mentioned, the hydration of LS alone and especially in combination with SSFA promotes the crystallization of AFm phases—a family of hydrated calcium aluminate phases and hemi-, monocarboaluminates. This provokes the manifestation of a number of processes during heating. The data concerning the mass losses and the related endothermal events could be, in general, separated into three temperature regions: (I) from 25 to 200 °C; (II) from 200 to 500 °C; and (III) from 500 to 1000 °C. This grouping depends on the specific thermal behavior of the series compounds under study and therefore it is not exactly fixed. In the first temperature region, a dehydration process occurs. In the second one, along with the completion of the dehydration, a dehydroxylation process also proceeds. While in the third region, mainly a decarbonation of the carbonate-containing phases and likely desulfation takes place. Such observations have also been noted by other authors [,]. In the first temperature region, the dehydration processes are manifested by a well-defined endothermal effect at about 150–160 °C, which is related to strätlingite dehydration the and AFm phases []. The small shoulder at 200 °C observed in series LBFA0 is characteristic for strätlingite []. In the second region, the endothermal events are more complicated due to the existence of dehydroxylation. The endo-effects around 317 °C are related to katoite dehydration, which is most pronounced at series LBFA0 []. All of the series showed endo-effects at about 387 °C, which is related to brucite dehydraton. The endothermal effect at about 286 °C, most pronounced in series LBFA20, is related to Friedel salt dehydration. The Friedel salts recrystallize to calcium chloroaluminate at about 670 °C []. It becomes clear that the presence of hydrated calcium aluminate minerals is quite diverse, especially since a hydrated component is also present in the carbonate or semi-carbonate phases. In the third temperature region, decarbonation and desulfation mainly occur, displayed by an endothermal effect at around 700 °C and beyond. For both series, LBFA20 and LBFA30, where arcanite was identified, an endothermal peak at 583–584 °C has been observed due to β to α phase transformation [].

Figure 6.

DSC-TG(DTG) curves of LBFA0, LBFA10, LBFA20, and LBFA30.

The presented thermal data for the LBFA series in Table 3 show a decreasing amount of hydrate components in the direction from LBFA0 to LBFA30. However, in the same direction, the carbonate component increases and, in general, there is an increase in total mass loss with the increasing presence of biomass fly ash into the ladle slag.

Table 3.

Mass loss during dehydration–dehydroxylation and decarbonation processes.

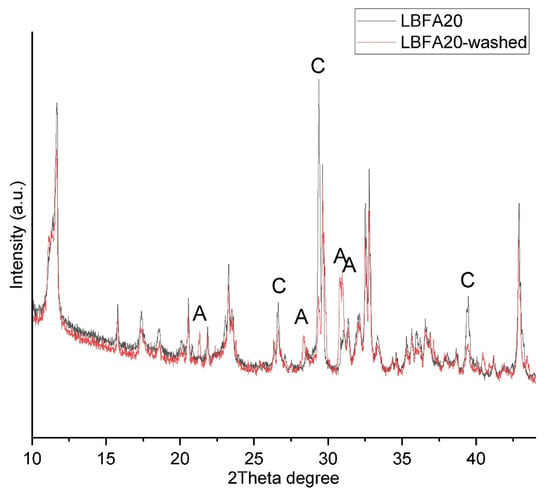

3.3. Leaching Experiments

The leaching behavior of sulfates, chlorides, and alkali is a crucial aspect in evaluating the environmental impact and durability of blended cementitious materials. In the ladle slag–biomass fly ash (LBFA) system, the release of sulfate, chloride, and potassium ions into a pore solution is governed by phase formation and stability, solubility equilibria, and external exposure conditions. To evaluate the leaching behavior ladle slag–biomass fly ash (LBFA), hardened material samples of LBFA20 were ground to powder and washed several times with distilled water. The washed powder was dried and chemical compositions were determined by XRF (Table 4). The results revealed a significant reduction in sulfur, chlorine, and potassium concentrations, indicating that these elements were not strongly bonded into stable crystalline phases and were instead present in soluble or weakly bound amorphous phases. Only a partial amount of chlorine (~26%) and sulfate (~12%) stayed after the washing test. Interestingly, potassium bearing phases were not detected at any stage of the analysis, suggesting that potassium was primarily presented in an amorphous phase or in soluble ionic form. X-ray diffraction analysis of the washed sample confirmed that AFm phases in LBFA20 remained stable (Figure 7). The remaining sulfur and chlorine are likely incorporated into the AFm phases, which play a crucial role in binding chlorides and sulfates, thereby enhancing the material’s ability to prevent steel corrosion [,]. However, most of the soluble components in the SSFA do not participate in the formation of any or enough stable phases, thus we can state that the full potential of SSFA was not achieved at the current addition levels.

Table 4.

Leaching of sulfates and chlorides after washing with water.

Figure 7.

Powder XRD diffraction of series LBFA20 before and after washing experiments. Legend showing the difference phases: A—Arcanite, C—calcite.

4. Conclusions

This study explored the potential of sunflower shell biomass fly ash (SSFA) as a dry alkali activator for one-part alkali-activated ladle slag binder. The chemical and mineralogical analysis of the precursors revealed that ladle slag (LS) is primarily composed of γ-belite, mayenite, and periclase, while SSFA is rich in potassium-bearing phases such as arcanite and sylvite.

The results showed that addition of SSFA to ladle slag mixtures improved the early hydration processes and contributed to higher compressive strength compared to normal hydration of the ladle slag. The optimal addition of SSFA was 10%, at which the compressive strength reached 30 MPa, indicating the effectiveness of SSFA as an alternative activator.

The high alkalinity of SSFA facilitated the partial dissolution of the LS phases, leading to the formation of cementitious reaction products. The presence of chorine and sulfur contribute to formation of more AFm phases such as hydrocalumite, Friedel’s salt, hemicarboaluminate, and monocarboaluminate, which contributed to higher mechanical strength.

However, most of the soluble components in the SSFA do not participate in the formation of any or enough stable phases, thus we can state that the full potential of SSFA as alkali activator was not achieved at higher proportions of SSFA addition.

By valorizing both industrial and agricultural waste materials, this study supports the development of environmentally friendly cement alternatives, contributing to circular economy principles and sustainable construction practices. Future research should focus on evaluating the long-term stability, durability, and potential leaching of heavy metals to further assess the material’s suitability for sustainable construction applications

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/ceramics8030079/s1, Figure S1. Images of raw materials: LS, SSFA.

Author Contributions

Conceptualization, A.N.; methodology, A.N., V.K., N.P., L.T., S.V.V. and R.T.; software, A.N., V.K., N.P., L.T. and R.T.; validation, A.N., V.K., N.P., L.T., S.V.V. and R.T.; formal analysis, A.N., V.K., N.P., L.T. and R.T.; investigation, A.N., V.K., N.P., L.T., S.V.V. and R.T.; resources, A.N.; data curation, A.N., V.K., N.P., L.T., S.V.V. and R.T.; writing—original draft preparation, A.N., V.K., N.P., L.T. and R.T.; writing—review and editing, A.N., S.V.V. and R.T.; visualization, A.N., V.K., N.P., L.T. and R.T.; supervision, A.N. and R.T.; project administration, R.T.; funding acquisition, R.T. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been carried out in the framework of the National Science Program “Critical and strategic raw materials for a green transition and sustainable development”, approved by the Resolution of the Council of Ministers No. 508/18 July 2024 and funded by the Ministry of Education and Science (MES) of Bulgaria.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article/Supplementary Material. Further inquiries can be directed to the corresponding author(s).

Acknowledgments

The team acknowledge Stomana Industry, S.A, Bulgaria, Aeiforos Bulgaria S.A., and Astra Bioplant EOOD, Bulgaria, companies for provision of the raw materials.

Conflicts of Interest

The authors declare no conflicts of interest. Stomana Industry, S.A, Bulgaria, Aeiforos Bulgaria S.A., and Astra Bioplant EOOD, Bulgaria, companies provided the raw materials. These companies had no role in design of the study; in the collection, analyses or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| AFm | A family of hydrated calcium aluminate phases |

| SSFA | Sunflower shells fly ash |

| LS | Ladle slag |

References

- World Steel Association. Steel Statistical Yearbook 2022: A Cross-Section of Steel Industry Statistics 2012–2021; World Steel Association: Brussels, Belgium, 2022. [Google Scholar]

- Chen, J.; Xing, Y.; Wang, Y.; Zhang, W.; Guo, Z.; Su, W. Application of iron and steel slags in mitigating greenhouse gas emissions: A review. Sci. Total Environ. 2022, 844, 157041. [Google Scholar] [CrossRef] [PubMed]

- Baalamurugan, J.; Kumar, V.G.; Chandrasekaran, S.; Balasundar, S.; Venkatraman, B.; Padmapriya, R.; Raja, V.B. Recycling of steel slag aggregates for the development of high density concrete: Alternative & environment-friendly radiation shielding composite. Compos. Part B Eng. 2021, 216, 108885. [Google Scholar] [CrossRef]

- Raut, S.R.; Saklecha, P.; Kedar, R. Review on ground granulated blast-furnace slag as a supplementary cementitious material. Int. J. Comput. Appl. 2015, 975, 8887. [Google Scholar]

- Aiban, S.A. Utilization of steel slag aggregate for road bases. J. Test. Eval. 2006, 34, 65–75. [Google Scholar] [CrossRef]

- Kumar, H.; Varma, S. A review on utilization of steel slag in hot mix asphalt. Int. J. Pavement Res. Technol. 2021, 14, 232–242. [Google Scholar] [CrossRef]

- Pinheiro, C.; Rios, S.; da Fonseca, A.V.; Fernández-Jiménez, A.; Cristelo, N. Application of the response surface method to optimize alkali activated cements based on low-reactivity ladle furnace slag. Constr. Build. Mater. 2020, 264, 120271. [Google Scholar] [CrossRef]

- Wu, L.; Li, H.; Mei, H.; Rao, L.; Wang, H.; Lv, N. Generation, utilization, and environmental impact of ladle furnace slag: A minor review. Sci. Total Environ. 2023, 895, 165070. [Google Scholar] [CrossRef]

- Brand, A.S.; Fanijo, E.O. A review of the influence of steel furnace slag type on the properties of cementitious composites. Appl. Sci. 2020, 10, 8210. [Google Scholar] [CrossRef]

- Najm, O.; El-Hassan, H.; El-Dieb, A. Ladle slag characteristics and use in mortar and concrete: A comprehensive review. J. Clean. Prod. 2021, 288, 125584. [Google Scholar] [CrossRef]

- Shi, C. Steel slag—Its production, processing, characteristics, and cementitious properties. J. Mater. Civ. Eng. 2004, 16, 230–236. [Google Scholar] [CrossRef]

- Serjun, V.Z.; Mirti, B.; Mladenovič, A. Evaluation of ladle slag as a potential material for building and civil engineering. Mater. Technol. 2013, 47, 543–550. [Google Scholar]

- Taylor, H. Cement Chemistry; Thomas Telford Publishing: London, UK, 1997. [Google Scholar]

- Yan, Z.; Jiang, Y.; Yin, K.; Wang, L.; Pan, T. Enhancement of Hydration Activity and Microstructure Analysis of γ-C2S. Materials 2023, 16, 6762. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Yang, J.; Yan, P. Influence of initial alkalinity on the hydration of steel slag. Sci. China Technol. Sci. 2012, 55, 3378–3387. [Google Scholar] [CrossRef]

- Shi, C. Characteristics and cementitious properties of ladle slag fines from steel production. Cem. Concr. Res. 2002, 32, 459–462. [Google Scholar] [CrossRef]

- Krivenko, P.V. Alkaline cements. In Proceedings of the 1st International Conference on Alkaline Cements and Concretes, Kiev, Ukraine, 11–14 October 1994; pp. 11–129. [Google Scholar]

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Wang, W.-C.; Wang, H.-Y.; Tsai, H.-C. Study on engineering properties of alkali-activated ladle furnace slag geopolymer. Constr. Build. Mater. 2016, 123, 800–805. [Google Scholar] [CrossRef]

- Murri, A.N.; Rickard, W.; Bignozzi, M.; Van Riessen, A. High temperature behaviour of ambient cured alkali-activated materials based on ladle slag. Cem. Concr. Res. 2013, 43, 51–61. [Google Scholar] [CrossRef]

- Adesanya, E.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Alkali activation of ladle slag from steel-making process. J. Sustain. Metall. 2017, 3, 300–310. [Google Scholar] [CrossRef]

- Češnovar, M.; Traven, K.; Horvat, B.; Ducman, V. The potential of ladle slag and electric arc furnace slag use in synthesizing alkali activated materials; the influence of curing on mechanical properties. Materials 2019, 12, 1173. [Google Scholar] [CrossRef]

- Adesanya, E.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Properties and durability of alkali-activated ladle slag. Mater. Struct. 2017, 50, 255. [Google Scholar] [CrossRef]

- Xu, B.; Yi, Y. Use of ladle furnace slag containing heavy metals as a binding material in civil engineering. Sci. Total Environ. 2020, 705, 135854. [Google Scholar] [CrossRef] [PubMed]

- Lancellotti, I.; Ponzoni, C.; Bignozzi, M.C.; Barbieri, L.; Leonelli, C. Incinerator bottom ash and ladle slag for geopolymers preparation. Waste Biomass Valor. 2014, 5, 393–401. [Google Scholar] [CrossRef]

- Passuello, A.; Rodríguez, E.D.; Hirt, E.; Longhi, M.; Bernal, S.A.; Provis, J.L.; Kirchheim, A.P. Evaluation of the potential improvement in the environmental footprint of geopolymers using waste-derived activators. J. Clean. Prod. 2017, 166, 680–689. [Google Scholar] [CrossRef]

- Adesanya, E.; Perumal, P.; Luukkonen, T.; Yliniemi, J.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Opportunities to improve sustainability of alkali-activated materials: A review of side-stream based activators. J. Clean. Prod. 2021, 286, 125558. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass as a precursor in alkaline activation: Chemical process and hydration products. Constr. Build. Mater. 2017, 139, 342–354. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H.; Kong, S.; Kamseu, E.; Leonelli, C. Geopolymer binders from metakaolin using sodium waterglass from waste glass and rice husk ash as alternative activators: A comparative study. Constr. Build. Mater. 2016, 114, 276–289. [Google Scholar] [CrossRef]

- Billong, N.; Oti, J.; Kinuthia, J. Using silica fume based activator in sustainable geopolymer binder for building application. Constr. Build. Mater. 2021, 275, 122177. [Google Scholar] [CrossRef]

- Moraes, J.; Font, A.; Soriano, L.; Akasaki, J.; Tashima, M.; Monzó, J.; Borrachero, M.V.; Payá, J. New use of sugar cane straw ash in alkali-activated materials: A silica source for the preparation of the alkaline activator. Constr. Build. Mater. 2018, 171, 611–621. [Google Scholar] [CrossRef]

- Nikolov, A.; Nugteren, H.; Rostovsky, I. Optimization of geopolymers based on natural zeolite clinoptilolite by calcination and use of aluminate activators. Constr. Build. Mater. 2020, 243, 118257. [Google Scholar] [CrossRef]

- Jamieson, E.; van Riessen, A.; McLellan, B.; Penna, B.; Kealley, C.; Nikraz, H. Introducing Bayer Liquor-Derived Geopolymers; Elsevier: Amsterdam, The Netherlands, 2017; pp. 159–189. [Google Scholar]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Peys, A.; Rahier, H.; Pontikes, Y. Potassium-rich biomass ashes as activators in metakaolin-based inorganic polymers. Appl. Clay Sci. 2016, 119, 401–409. [Google Scholar] [CrossRef]

- Font, A.; Soriano, L.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. One-part eco-cellular concrete for the precast industry: Functional features and life cycle assessment. J. Clean. Prod. 2020, 269, 122203. [Google Scholar] [CrossRef]

- Soriano, L.; Font, A.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Bonifácio, T.; Payá, J. Almond-shell biomass ash (ABA): A greener alternative to the use of commercial alkaline reagents in alkali-activated cement. Constr. Build. Mater. 2021, 290, 123251. [Google Scholar] [CrossRef]

- Hassan, H.S.; Abdel-Gawwad, H.; Vásquez-García, S.; Israde-Alcántara, I.; Flores-Ramirez, N.; Rico, J.; Mohammed, M.S. Cleaner production of one-part white geopolymer cement using pre-treated wood biomass ash and diatomite. J. Clean. Prod. 2019, 209, 1420–1428. [Google Scholar] [CrossRef]

- Lima, F.S.; Gomes, T.C.F.; de Moraes, J.C.B. Novel one-part alkali-activated binder produced with coffee husk ash. Mater. Lett. 2022, 313, 131733. [Google Scholar] [CrossRef]

- Lokare, S.S.; Dunaway, J.D.; Moulton, D.; Rogers, D.; Tree, D.R.; Baxter, L.L. Investigation of ash deposition rates for a suite of biomass fuels and fuel blends. Energy Fuels 2006, 20, 1008–1014. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Baxter, D. Trace element concentrations and associations in some biomass ashes. Fuel 2014, 129, 292–313. [Google Scholar] [CrossRef]

- Amin, M.; Zeyad, A.M.; Agwa, I.S.; Heniegal, A.M. Effect of peanut and sunflower shell ash on properties of sustainable high-strength concrete. J. Build. Eng. 2024, 89, 109208. [Google Scholar] [CrossRef]

- Shahbazpanahi, S.; Faraj, R.H. Feasibility study on the use of shell sunflower ash and shell pumpkin ash as supplementary cementitious materials in concrete. J. Build. Eng. 2020, 30, 101271. [Google Scholar] [CrossRef]

- Nikolov, A.; Kostov-Kytin, V.; Tarassov, M.; Tsvetanova, L.; Jordanov, N.B.; Karamanova, E.; Rostovsky, I. Characterization of cement kiln dust from Bulgarian cement plants. J. Chem. Technol. Metall. 2025, 60, 455–463. [Google Scholar] [CrossRef]

- Lyu, H.; Hao, L.; Zhang, S.; Poon, C.S. High-performance belite rich eco-cement synthesized from solid wastes: Raw feed design, sintering temperature optimization, and property analysis. Resour. Conserv. Recycl. 2023, 199, 107211. [Google Scholar] [CrossRef]

- He, Z.; Li, Y. The influence of mayenite employed as a functional component on hydration properties of ordinary Portland cement. Materials 2018, 11, 1958. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Cordonnier, B.; Zhu, W.; Renard, F.; Jamtveit, B. Effects of confinement on reaction-induced fracturing during hydration of periclase. Geochem. Geophys. Geosyst. 2018, 19, 2661–2672. [Google Scholar] [CrossRef]

- Tolkacheva, A.; Shkerin, S.; Plaksin, S.; Vovkotrub, E.; Bulanin, K.; Kochedykov, V.; Ordinartsev, D.; Gyrdasova, O.; Molchanova, N. Synthesis of dense ceramics of single-phase mayenite (Ca12Al14O32)O. Russ. J. Appl. Chem. 2011, 84, 907–911. [Google Scholar] [CrossRef]

- Horgnies, M.; Chen, J.; Bouillon, C. Overview about the use of Fourier transform infrared spectroscopy to study cementitious materials. WIT Trans. Eng. Sci. 2013, 77, 251–262. [Google Scholar]

- Fernández Carrasco, L.; Torrens Martín, D.; Morales, L.; Martínez Ramírez, S. Infrared Spectroscopy—Materials Science, Engineering and Technology; InTech: Rijeka, Croatia, 2012; pp. 357–372. [Google Scholar] [CrossRef]

- Gunasekaran, S.; Anbalagan, G.; Pandi, S. Raman and infrared spectra of carbonates of calcite structure. J. Raman Spectrosc. 2006, 37, 892–899. [Google Scholar] [CrossRef]

- Braterman, P.S.; Cygan, R.T. Vibrational spectroscopy of brucite: A molecular simulation investigation. Am. Mineral. 2006, 91, 1188–1196. [Google Scholar] [CrossRef]

- Chukanov, N.V. The Application of IR Spectroscopy to the Investigation of Minerals. In Infrared Spectra of Mineral Species: Extended Library; Springer: Dordrecht, The Netherlands, 2014; pp. 1–19. [Google Scholar]

- Schutte, C.; Buijs, K. The infra-red spectra of K2CO3 and its hydrates. Spectrochim. Acta 1961, 17, 921–926. [Google Scholar] [CrossRef]

- Okoronkwo, M.U.; Glasser, F.P. Stability of strätlingite in the CASH system. Mater. Struct. 2016, 49, 4305–4318. [Google Scholar] [CrossRef]

- Litwinek, E.; Madej, D. Structure, microstructure and thermal stability characterizations of C3AH6 synthesized from different precursors through hydration. J. Therm. Anal. Calorim. 2020, 139, 1693–1706. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, T.; Fang, H.; Li, S.; Yao, Y.; He, Y. A novel preparation of nano-sized hexagonal Mg(OH)2. Procedia Eng. 2015, 102, 388–394. [Google Scholar] [CrossRef]

- Sabzevari, M.; Sajjadi, S.A.; Moloodi, A. Physical and mechanical properties of porous copper nanocomposite produced by powder metallurgy. Adv. Powder Technol. 2016, 27, 105–111. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Vassileva, C.G. An overview of the behaviour of biomass during combustion: Part I. Phase-mineral transformations of organic and inorganic matter. Fuel 2013, 112, 391–449. [Google Scholar] [CrossRef]

- Broström, M.; Enestam, S.; Backman, R.; Mäkelä, K. Condensation in the KCl–NaCl system. Fuel Process. Technol. 2013, 105, 142–148. [Google Scholar] [CrossRef]

- Matschei, T.; Lothenbach, B.; Glasser, F. The AFm phase in Portland cement. Cem. Concr. Res. 2007, 37, 118–130. [Google Scholar] [CrossRef]

- Rai, R.K.; Serra-Maia, R.; Shi, Y.; Psarras, P.; Vojvodic, A.; Stach, E.A. Enhanced mineral carbonation on surface functionalized MgO as a Proxy for mine tailings. Environ. Sci. Nano 2025, 12, 2630–2646. [Google Scholar] [CrossRef]

- Khan, M.; Kayali, O.; Troitzsch, U. Chloride binding capacity of hydrotalcite and the competition with carbonates in ground granulated blast furnace slag concrete. Mater. Struct. 2016, 49, 4609–4619. [Google Scholar] [CrossRef]

- Damidot, D.; Glasser, F. Thermodynamic investigation of the CaO—Al2O3—CaSO4—CaCO3-H2O closed system at 25 °C and the influence of Na2O. Adv. Cem. Res. 1995, 7, 129–134. [Google Scholar] [CrossRef]

- Damidot, D.; Glasser, F. Investigation of the CaO-Al2O3-SiO2-H2O system at 25 °C by thermodynamic calculations. Cem. Concr. Res. 1995, 25, 22–28. [Google Scholar] [CrossRef]

- Landy, R.A. Magnesia refractories. Mech. Eng. 2004, 178, 109. [Google Scholar]

- Thomas, J.J.; Musso, S.; Prestini, I. Kinetics and activation energy of magnesium oxide hydration. J. Am. Ceram. Soc. 2014, 97, 275–282. [Google Scholar] [CrossRef]

- Madej, D. Hydration, carbonation and thermal stability of hydrates in Ca7−xSrxZrAl6O18 cement. J. Therm. Anal. Calorim. 2018, 131, 2411–2420. [Google Scholar] [CrossRef]

- Petkova, V.; Stoyanov, V.; Pelovski, Y. TG–DTG–DTA in studying white self-compacting cement mortars. J. Therm. Anal. Calorim. 2012, 109, 797–806. [Google Scholar] [CrossRef]

- Gartner, E.; Walenta, G.; Morin, V.; Termkhajornkit, P.; Baco, I.; Casabonne, J. Hydration of a belite-calciumsulfoaluminate-ferrite cement: Aether™. In Proceedings of the 13th International Congress on the Chemistry of Cement, Madrid, Spain, 3–8 July 2011. [Google Scholar]

- Birnin-Yauri, U.; Glasser, F. Friedel’s salt, Ca2Al(OH)6(Cl, OH)·2H2O: Its solid solutions and their role in chloride binding. Cem. Concr. Res. 1998, 28, 1713–1723. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, W.; Liu, H.; Jin, H.; Chen, H.; Su, K.; Tu, Y.; Wang, W. Thermochemical behavior of three sulfates (CaSO4, K2SO4 and Na2SO4) blended with cement raw materials (CaO-SiO2-Al2O3-Fe2O3) at high temperature. J. Anal. Appl. Pyrolysis 2019, 142, 104617. [Google Scholar] [CrossRef]

- Lv, Z.; Tan, H.; Liu, X.; Chen, P.; Wang, Y.; Liang, W.; Hong, J. Chloride binding of AFm in the presence of Na⁺, Ca2⁺ and Ba2⁺. Constr. Build. Mater. 2023, 364, 129804. [Google Scholar] [CrossRef]

- Jun, Y.; Yoon, S.; Oh, J.E. A comparison study for chloride-binding capacity between alkali-activated fly ash and slag in the use of seawater. Appl. Sci. 2017, 7, 971. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).