Abstract

This paper addresses the problem of ensuring the continuous operation of cyber–physical systems (CPS) under conditions of component degradation and wear. To achieve this goal, a transition to the concept of Proactive Prognostics and Health Management (PPHM) is proposed, focused on proactive control of the technical condition of equipment. A key stage of PPHM is the generation of control actions aimed at extending the remaining useful life by adapting the operational parameters of the system. This paper proposes an intelligent support method for generating control actions to optimize the operational conditions. The proposed method integrates an RUL prediction model with optimization procedures based on genetic algorithm. The method was experimentally validated using XJTU-SY Bearing test rig and a bearing-degradation dataset. The obtained results demonstrate its effectiveness and confirm its applicability for extending the service life of technical systems. The proposed method is general and can be adapted to any CPS where controllable parameters affect the degradation rate

1. Introduction

Modern manufacturing systems, which are cyber–physical systems (CPS), face increasing demands for reliability due to growing automation and digital technologies. Unexpected failures in these systems and their parts can cause production slowdowns, disrupt important processes, and large economic losses. Moreover, the reliability of a cyber–physical system is considered in close connection with the reliability of the both physical and digital components.

Traditional maintenance methods, whether they react to failures (reactive) or follow fixed schedules (preventive), are not enough for CPS that often degrade irregularly and operate under dynamically changing conditions. The development of predictive maintenance marks a major change, moving from fixing problems after they happen to preventing failures before they occur. This progress is made possible by combining prediction models with intelligent control methods aimed at improving reliability of the whole CPS and extending their remaining useful life (RUL).

This framework is known as prognosis and predictive health management(PPHM) and constitutes a critical domain within contemporary systems engineering and reliability sciences. Nowadays, the theoretical foundations and practical implementations of PPHM is an open discussion in engineering literature, highlighting its significance for Industry 4.0 and beyond [1,2,3].

The PPHM framework is based on a three-stage structure: (1) data acquisition (observation stage)—collecting and preprocessing information on the CPS’s technical condition; (2) state assessment and prognostics (analysis stage)—determining the current state of the CPS, estimating its RUL, and predicting potential failures; (3) decision-making and action implementation (action stage)—developing and executing corrective measures [4].

The second stage includes the following tasks: (1) calculation and prediction of the health index over a given horizon; (2) estimation of RUL; (3) faults or failures prediction.

In the decision-making stage (action stage), two main problems are addressed: (1) selecting and applying maintenance activities, such as checks, unit replacement, CPS maintenance, and CPS repair; (2) generating control actions to optimize the operational conditions (or regimes) towards extension of the lifetime until the next preventive maintenance interval.

Most studies on the PPHM domain focus on the observation and analysis stages, leaving the decision-making aspect, or adjusting operational modes to extend the predicted life, underexplored. Moreover, predictive analytics and the generation of control actions are often considered separately, limiting the potential for closed-loop proactive management of technical states.

Despite advances in predictive maintenance and PPHM, a fundamental limitation endures: existing methodologies are predominantly diagnostic rather than prescriptive. The capability not only RUL calculation of a certain CPS, but also to autonomously generate and implement control actions that actively increase this lifespan, via continuous, lifecycle-wide optimization of operational parameters, represents a critical unsolved challenge in achieving truly proactive CPS management.

We hypothesize that an intelligent support system, architected around an evolutionary algorithm guided by a machine learning prognostic model, can effectively generate control actions to modify CPS operating conditions. This mechanism allows for the dynamic change of environmental parameter, thereby deliberately prolonging the RUL while respecting predefined safety and performance boundaries.

The scientific contribution lies in developing a method for generating control actions to optimize the operational conditions towards the proactive maintenance of CPS. The proposed approach integrates an RUL prediction model with optimization procedures to generate control actions that extend equipments lifetime. This method provides a foundation for proactive control systems that deliberately prolong the operational lifecycle of equipment under uncertain conditions.

2. Problem Statement

Within the paradigm of prognosis and predictive health management (PPHM), Remaining Useful Life (RUL) prediction is typically treated as a forward problem: given past and current condition-monitoring data, estimate the time to failure under a fixed operating regime. In this work, we address a complementary, inverse problem: given a current state estimate and a target extension of RUL, determine how to adjust controllable operating parameters so that the predicted RUL attains a prescribed level while respecting technological constraints.

Let the set of considered assets (CPS units) be denoted by . Each asset is characterized by

- A time series of condition-monitoring data , where contains diagnostic features (e.g., vibration RMS and other statistics);

- A vector of controllable operating parameters (e.g., rotational speed and load in the bearing case);

- A failure time (or an associated RUL trajectory) observed under the historical operating regime.

Assume that, for each asset (or class of assets), an RUL prediction model is available, which maps preprocessed condition data and operating parameters to a predicted remaining life:

where denotes data up to the current time , u is a (possibly time-aggregated) vector of controllable parameters, and are model parameters (e.g., Weibull parameters).

At a given decision time , the operator specifies a desired RUL level

where represents the current operating conditions, and is the requested extension. The admissible control space is constrained by technological and safety limits:

where encodes inequality constraints (e.g., bounds on speed, load, temperature).

The core optimization problem is then formulated as follows:

that is, find admissible operating parameters u that make the predicted RUL as close as possible to the target value. In the bearing-study case considered later, , where is rotational speed and F is radial load.

The objective of this research is to develop an intelligent decision-support method that

- Integrates RUL forecasts with models describing the influence of operating parameters on degradation rates;

- Solves the inverse problem of generating control actions (parameter adjustments) that achieve a prescribed increase of RUL by at least N time units, subject to admissible bounds;

- Remains robust under incomplete, noisy and heterogeneous industrial data conditions.

3. Literature Review

3.1. Approaches to Optimize the Operating Conditions

The generation of control actions is a central element of proactive equipment state management. Control actions are deliberate measures intended to extend asset life, reduce failure probability, and optimize operating parameters. Modern approaches have evolved from simple scheduled operations to intelligent strategies based on RUL forecasting and optimization algorithms.

Historically, the primary approaches were as follows [5]:

- Corrective Maintenance—intervention only after failure, which results in high downtime risks and economic losses.

- Preventive Maintenance—intervention at fixed time intervals, reducing the frequency of failures but often causing excessive costs.

- Predictive Maintenance—intervention based on RUL forecasts and the actual condition of the asset. This approach has advanced recently due to integration of RUL prediction algorithms and intelligent decision-support systems [6].

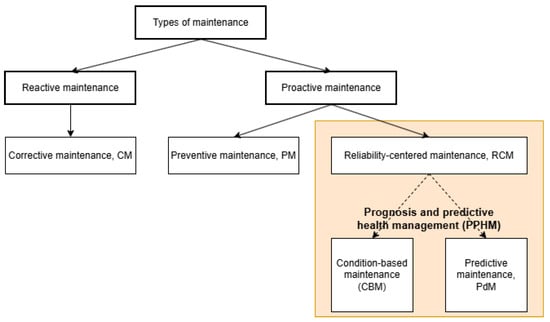

Figure 1 illustrates maintenance strategies. The PPHM concept unites diagnostics, prognostics and action generation methods, enabling a transition from passive monitoring to active management of technical condition.

Figure 1.

Classification of maintenance and repair strategies and the place of proactive approaches within the PPHM system.

Optimization methods for operating conditions’ definition. One important direction is the application of mathematical optimization methods to select the optimal timing and type of control actions [7].

Recently, optimizing operating conditions without halting equipment has been actively investigated. It has been shown that adjusting pump operating regimes via PSO can extend service life while preserving performance [8]. For energy-intensive installations, integrating RUL forecasts with decision-support architectures also demonstrates risk reduction through adaptive load regulation [9,10].

Evolutionary algorithms. Evolutionary methods such as Genetic Algorithm, Particle Swarm Optimization and Differential Evolution are widely used for maintenance planning and parameter optimization. Their advantage is the capability to find quasi-optimal solutions in high-dimensional, multi-criteria problems.

Models for optimizing maintenance plans based on PSO have been developed, reducing total repair and downtime costs compared to classical scheduling [7]. Evolutionary methods have been shown to produce effective replacement policies under reliability and availability constraints [11]. Integration of RUL prognostics with evolutionary optimization underpins adaptive action schemes responsive to changing production conditions [6,9].

Generative algorithms and scenario analysis. Generative methods are used to model possible degradation scenarios and assess the effectiveness of control actions. This approach enables exploration of a wide range of operating regimes without risking real equipment. Using generative models for RUL forecasting allows incorporation of uncertainty and formulation of strategies with confidence intervals [12].

Adaptive real-time interventions. Recent studies show that control actions are not limited to component replacement or repair. Increasing attention is paid to dynamic regulation of operational parametersaimed at extending lifetime. This approach is crucial for systems where shutdown is not feasible (energy, transport, aviation). Cases in the context of Industry 5.0 indicate that decision-support systems can modify production-line parameters in real time, extending component life and reducing unplanned failures [13,14].

Contemporary approaches to generating control actions reveal a shift from rigidly regulated procedures to intelligent adaptive strategies. The most promising directions include the following:

- Integration of RUL predictive models with evolutionary algorithms to select optimal actions;

- Application of generative models for operational scenario analysis and risk assessment;

- Use of digital twins to test actions and adjust operating parameters in real time;

- Development of adaptive control algorithms that extend equipment life without stopping operation.

Consequently, generation of control actions becomes a core instrument of intelligent lifecycle management within predictive and proactive maintenance frameworks.

3.2. Methods for Remaining Useful Life Prediction

Forecasting Remaining Useful Life is one of the key tasks in lifecycle management of CPS. RUL is defined as the time until the onset of a critical equipment state or failure moment at which further operation becomes impossible or economically infeasible. RUL prediction enables a shift from reactive and schedule-based maintenance strategies towards proactive management in which operational actions are formed with consideration of the predicted condition of the asset.

Contemporary studies classify RUL prediction methods into three major groups:

Physics-based models. A classical direction remains models founded on the mathematical description of wear processes. Well-known approaches include Weibull distributions, gamma processes, as well as Markov and semi-Markov processes [6,15]. Their advantage lies in high interpretability and the possibility of verification using expert knowledge. The main limitation, however, is the need for deep understanding of the physical degradation mechanisms, which complicates their application in complex multivariate systems. For example, gas turbine engines require simultaneous accounting of thermomechanical, vibrational, and aerodynamic phenomena, resulting in overly complex models [16,17,18].

Data-driven methods. With the development of the Internet of Things and widespread industrial sensing, data-driven methods have gained increasing attention. Their key advantage is the ability to train models on streams of operational data without full knowledge of physical mechanisms.

Current research demonstrates the effectiveness of recurrent architectures—Long Short-Term Memory (LSTM) and Gated Recurrent Unit (GRU)—which are capable of capturing long-term dependencies in data [19,20]. Studies also show that transformer models can improve prediction accuracy compared to traditional recurrent networks [21]. Transformers, thanks to the self-attention mechanism, scale well for multivariate signals (temperature, vibration, current, rotational speed).

Examples include works employing attention mechanisms for RUL prediction of aero-engine components [21]. Other studies use convolutional neural networks (CNN) to process time series cast as spectrograms [20].

Hybrid methods. Considering the shortcomings of purely physics-based and purely data-driven approaches, hybrid techniques are actively developed. In these, physics-based models provide constraints or guiding priors during neural network training, improving interpretability and robustness of predictions. Solutions with physically interpretable prototypes and incorporation of prior constraints have been demonstrated [22], as well as integration with digital twins and end-to-end industrial loops [14].

A distinct direction concerns generative algorithms—Variational Autoencoders and Generative Adversarial Networks—which can generate synthetic degradation scenarios and mitigate the lack of training data. It has been shown that generative models enhance the ability of RUL algorithms to account for uncertainty and to produce predictive confidence intervals [12], which is particularly important for industries with rare failures (aviation, nuclear energy).

Substantial attention is paid to building degradation simulators and digital twins that replicate equipment behavior in virtual environments. Studies indicate that digital twins form a basis for real-time condition forecasting and can be embedded into decision-support loops [14,23,24]. Within such frameworks, operational parameters (load, temperature, rotational speed) may be varied, enabling not only RUL forecasting but also optimization strategy testing.

Evolutionary algorithms (genetic algorithms, particle swarm optimization) are applied both for maintenance planning and for tuning RUL models. For instance, using particle swarm optimization (PSO) for hyperparameter and control parameter tuning yields robust RUL predictions under varying operating conditions for pumping units [8]. These methods are also used for automated search of optimal prognostic models when data are limited.

A related line of research considers state assessment in complex mission-oriented networks under incomplete and scarce data. Liang et al. [25] propose a state evaluation method for complex task network models of avionics and naval systems, where multivariate heterogeneous state features are mined, virtual samples are generated via an overall diffusion trend technique, and a neuro-fuzzy network with parameters tuned by a modified particle swarm optimization algorithm is used to assess mission/task availability under non-complete states. Their framework addresses few-shot and noisy data by combining virtual sample generation, kernel-based modelling and metaheuristic optimization, focusing on real-time estimation of available system capacity rather than explicit RUL prediction.

In the domain of electrified transportation, Guo et al. [26] developed an improved adaptive linear neuron (ADALINE) filter with phase compensation to mitigate current measurement errors in surface-mounted permanent magnet synchronous motors (SPMSM), thereby reducing speed pulsations, dq-axis current ripple, and phase-current imbalance while preserving fast dynamic response. Their approach enhances conventional ADALINE to compensate multiple harmonic components and dc offsets, exploits the orthogonality of dq-axis current errors to decouple periodic load disturbances, and introduces a phase-shift unit inspired by resonant controllers; experimental studies demonstrate accurate error compensation with low computational burden and robustness across different SPMSM platforms.

Taken together, the works of Liang et al. and Guo et al. illustrate the maturity of advanced data-driven, neuro-fuzzy, and adaptive control techniques for condition assessment and performance optimization in complex CPS. However, they primarily address state evaluation and dynamic performance (mission/task availability or current-measurement-error compensation), whereas the present study focuses on the explicit closed-loop generation of control actions integrated with RUL-based optimization for proactive lifetime extension.

3.3. Intelligent Decision Support

Intelligent decision support systems (DSS) for management of complex systems integrate predictive models, optimization techniques, and intelligent selection mechanisms based on fuzzy logic, semantic analysis, and cognitive modeling. The primary objective of a DSS is to provide operators or automated controllers with justified recommendations under uncertainty, multiple criteria, and dynamically changing operational conditions.

Early DSS implementations were rule-based and provided decisions according to pre-defined scenarios, but they poorly adapted to changing operating conditions. Modern DSS incorporate machine learning algorithms, neural prognostic models, and cognitive analysis elements. Transitioning to intelligent approaches allows for capturing forecast uncertainty and forming more flexible control action strategies [27,28].

Probabilistic methods are widely used to represent the stochastic nature of degradation processes. Bayesian networks enable construction of probabilistic dependencies between component states and failure probabilities [28]. Fuzzy-logic methods are applied to formalize expert knowledge especially where precise mathematical models are lacking, providing high interpretability and operator usability.

With the advent of digital-twin technologies, DSS capabilities have expanded. Integration of DSS with digital twins permits simulation of various operating scenarios and prior assessment of the consequences of control actions [23,24]. For power systems, such DSS allow for testing load-change scenarios, identifying optimal operating regimes, and preventing overloads; inclusion of operational safety assessments has been shown to reduce the risk of accidents [29].

Evolutionary methods are also implemented within DSS. Genetic algorithms help build optimal replacement and repair strategies accounting for cost, downtime, and risk [11]. DSS with evolutionary components can find compromise solutions in multi-criteria optimization, which is vital for industrial enterprises where decisions affect technical and economic indicators.

Generative models in DSS enable construction of probable degradation trajectories [12]. Generative-based DSS provide probabilistic forecasts with confidence intervals, improving the reliability of decisions.

Modern DSS increasingly operate online, using streaming sensor data. Applications within the Industry 5.0 concept demonstrate real-time adaptation of operating parameters based on RUL forecasts, extending component life without halting processes [9,13]. Additionally, planning and machine-learning aspects of predictive maintenance have been formalized [10].

DSS have evolved significantly from simple expert systems to cognitive platforms integrated with digital twins and RUL predictors. Systems of greatest interest are those that

- Integrate RUL forecasts with optimization algorithms (evolutionary and generative);

- Allow for real-time adjustment of operating parameters without stopping equipment;

- Provide scenario analysis and account for uncertainty.

Intelligent decision support is a key element in building proactive management systems for complex assets, providing not only enhanced reliability and safety but also extending equipment life through timely and adaptive correction of control actions. Such approaches have also been discussed in works focused on cognitive DSS and cyber–physical system integration [30,31,32].

4. Proposed Method

Overall Description

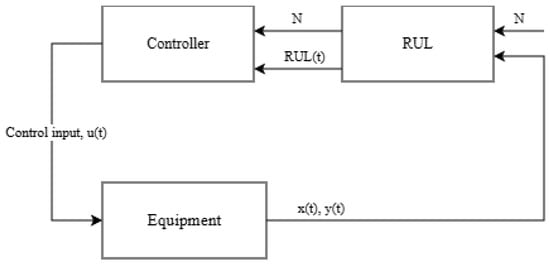

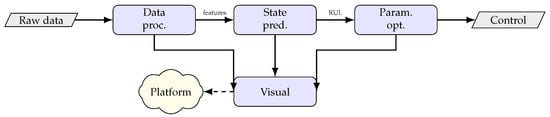

The proposed intelligent support method for generating control actions in proactive maintenance of CPS is based on a sequence of analytical and optimization procedures that form a closed-loop proactive control cycle. Figure 2 shows the functional structure of the proactive control loop. The controlled object receives control actions for optimizing the operational conditions. The RUL prediction block evaluates the current object state and transmits the forecast to the controller. Based on the forecast and the required lifetime extension N, new control actions are generated to prolong the equipment lifetime. Thus, a closed loop is realized that adapts operating regimes according to the object state and the predicted remaining useful life.

Figure 2.

Functional scheme of the proactive control loop. Here, and denote system input and output signals (e.g., operational and diagnostic variables), represents control actions generated by the controller, is the predicted remaining useful life at time t, N is the target lifetime increment, and the controller computes control inputs to adjust equipment operating parameters accordingly.

The method implements integration of monitoring, RUL prediction, and generating control actions aimed at extending CPS lifetime. The method comprises steps described below.

- Step 1. Data acquisition and preprocessing.

In the first stage, initial data on the CPS condition and its operating parameters are prepared. A set of preprocessing approaches, such as noise filtering, timestamp synchronization, and data normalization, are performed. The output of this stage is a set of diagnostic features that reflect the current CPS state and the dynamics of degradation processes. Typically, data on the operation of cyber–physical systems is high-frequency data. So, instead of the original values, the root mean square (RMS) might be used as follows:

where represents instantaneous data, and N is the number of samples in the observation window.

- Step 2. RUL prediction

Based on preprocessed data, the RUL is evaluated by the appropriate model. Various approaches exist for RUL estimation, such as statistical and physics-based methods, complex neural networks and hybrid models. For interpretability and analytical simplicity, this study employs a model based on the Weibull distribution. This approach describes the changes in failure intensity and provides not only an expected RUL value but also confidence intervals, thus accounting for uncertainty and variations in operating conditions.

In modern RUL prediction practice, various approaches are applied: physics-based, statistical, data-driven (including deep neural networks), and hybrid models that combine elements of both paradigms. Each approach has advantages: data-driven methods provide high accuracy given large training datasets, whereas physics-based and statistical models preserve interpretability and enable analytical verification.

Since the objective of this research is not to develop a new RUL model but to construct an interpretable decision-support loop, a parametric statistical approach based on the Weibull distribution is selected. This choice ensures simplicity of analysis, transparency of parameter relationships, and the ability to compare results with classical reliability theory. Thus, RUL prediction in this context serves an auxiliary role; it is an instrument for generating control actions rather than the subject of separate optimization.

In practice, the Weibull assumption is most appropriate for components dominated by a single wear-out mechanism with approximately monotonic degradation and an increasing or nearly constant hazard rate; in such settings, it provides a compact and interpretable description of failure behavior even from relatively small samples. Conversely, strongly multi-modal or non-monotonic degradation patterns (for example, mixtures of early-life (burn-in) failures and wear-out failures, or assets whose dynamics change abruptly across operating modes) can deviate substantially from the Weibull family and require more flexible RUL models. In these situations, the proposed control-action generation framework can be combined with advanced data-driven or hybrid RUL predictors, including recent deep-learning-based PHM architectures [19,20,21,22,33], while preserving the optimization and decision-support logic unchanged.

To model time-to-failure T, we use the two-parameter Weibull distribution, whose reliability function is as follows:

where is the shape parameter, and is the scale parameter.

The corresponding probability density function is as follows:

Parameters and are estimated from accumulated failure statistics by the maximum likelihood method:

where indicates observed failure times.

The conditional mean residual life at known current operating time (mean residual life, MRL) is computed as:

Substituting the Weibull reliability function yields

where denotes the upper incomplete gamma function.

In the proposed optimization loop, the Weibull parameters are estimated once for a given bearing and its current operating regime using historical degradation data. For candidate operating points generated by the evolutionary search, these parameters are not re-estimated from data; instead, the effective scale parameter is adjusted analytically via operating-condition scaling laws (e.g., using factors of the form , cf. Section 5). This choice avoids repeated statistical fitting inside the optimization loop while still capturing the dominant influence of speed and load on the predicted RUL.

- Step 3. Generation of control actions to optimize the operational conditions.

The control action generation step is the key element of the proposed method and embodies its scientific novelty. At this stage, an intelligent search is performed for generating operating parameters that provide an increase in the forecast RUL by a prescribed amount N. It is formulated as an optimization problem, where the objective function aims at extending RUL while satisfying technological and organizational constraints. The output of this step are recommended corrective parameter values.

Unlike traditional rule-based or linear-dependency methods, this study employs a genetic algorithm—an evolutionary optimization method capable of efficiently finding quasi-optimal solutions in problems with nonlinear and implicit dependencies between inputs and the objective function.

Consider a class of CPS for which regulation of operating parameters that determine degradation dynamics is feasible. Let, the set of two features is considered as a control actions: , F.

For the current observation time and known Weibull parameters , the optimization problem is formulated as follows:

subject to:

Thus, the deviation of the predicted RUL from the target value is minimized, enabling generating the control actions that extend equipment lifetime.

To solve (7), a modified Genetic Algorithm is used, where each individual encodes a pair and the fitness of an individual is given by . The genetic algorithm is represented in Algorithm 1; it enables us to generate the control actions targeted at extending equipment lifetime.

| Algorithm 1 Genetic algorithm for generating control actions |

|

The optimization process consists of standard evolutionary stages:

- Population initialization. An initial population of individuals—admissible combinations —is generated uniformly within the bounds. Population size M is chosen according to problem dimensionality.

- Fitness evaluation. For each individual, the predicted RUL is computed using the Weibull-based model, and the fitness is evaluated as follows:Smaller indicates closer proximity to the target increase.

- Selection. Individuals with smaller fitness values are selected with probability proportional to their quality (tournament or roulette selection), ensuring survival of better solutions.

- Crossover. Selected pairs exchange parts of parameters using a mixing coefficient :This generates novel combinations of control actions.

- Mutation. To avoid premature convergence, random perturbations are applied:where are zero-mean Gaussian deviations.

- Boundary enforcement. After each iteration, parameters are clipped to bounds:

- Termination. The algorithm stops when a preset number of generations G is reached or whenwhere is an admissible tolerance.

Applying a Genetic Algorithm in this context provides the following:

- Capability to search for optimal actions under a complex, nonlinear and implicit relation ;

- Robustness to noise and uncertainty typical for industrial data;

- Generation of multiple alternative solutions, important in multi-criteria control;

- High interpretability, since each solution can be analytically related to physical operating parameters.

- Step 4. Verification and implementation of control actions.

Applicability of the obtained solutions is assessed with regard to current operating conditions, safety constraints, and production requirements. After verification, the action can be implemented in the control system or proposed to an operator for approval.

Effectiveness was assessed using three metrics:

With fixed , relative measures and provide normalized gains that depend solely on the baseline prediction .

- Step 5. Feedback and adaptation.

After execution of control actions, monitoring data are updated and RUL is re-computed. This ensures a closed-loop operation, in which the system continuously adapts operating parameters to extend equipment lifetime and prevent failures.

5. Experimental Setup

5.1. Experiment Design

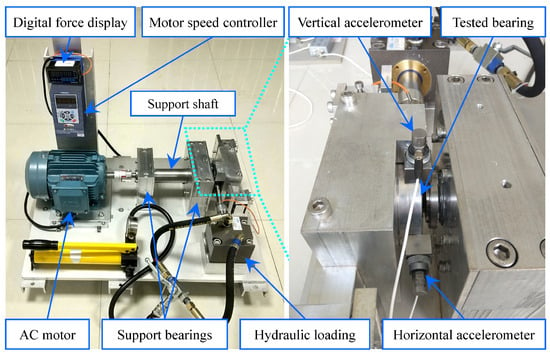

The experiment aimed to evaluate the effectiveness of the proposed intelligent support method for generating control actions in proactive equipment management. To verify the proposed intelligent support method for generating control actions, the XJTU-SY Bearing test rig is used. Figure 3 shows the XJTU-SY Bearing test rig [34].

Figure 3.

XJTU-SY Bearing test rig. The picture was originally published in [34].

For demonstration, the algorithm is applied here to regulate bearing parameters , where is rotational speed (rpm), and F is radial load (kN).

However, the proposed approach is general and can be adapted to any equipment type where controllable parameters (e.g., temperature, pressure, current, flow rate, etc.) affect the degradation rate.

The experiment consisted of two sequential stages. In the first stage, the Weibull-based RUL model was validated. For each bearing, the model parameters were estimated, and degradation curves were constructed for different operating regimes. This verified the model correctness and its stability with respect to operating-parameter variations.

In the second stage, the effect of control actions was assessed. For each bearing instance, the optimization module computed alternative operating parameters that increased the predicted RUL by a prescribed amount while respecting technological constraints. This quantified how changes in rotational speed and load influence degradation dynamics and lifetime.

The generating control actions algorithm proceeds as follows:

- Obtain the current forecast and diagnostic features;

- Create a population of candidate combinations ;

- Iteratively perform selection, crossover and mutation;

- Choose the optimal combination ensuring the required extension N;

- Transmit the selected action to the controller or operator.

5.2. Data

As the primary data source, the public XJTU-SY Bearing dataset is used [34]. XJTU-SY bearing datasets are provided by the Institute of Design Science and Basic Component at Xi’an Jiaotong University (XJTU), Shaanxi, China, and Changxing Sumyoung Technology Co., Ltd. (SY), Changxing, China. The dataset contains accelerated-degradation test results for rolling bearings. Experiments were conducted in three operating modes, differing by shaft rotational speed and radial load F. Table 1 contains parameters for different modes.

Table 1.

Experimental setup.

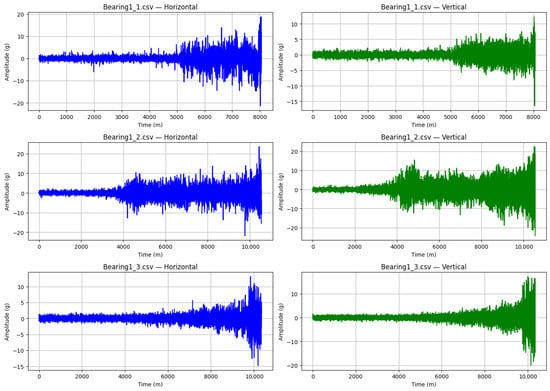

Vibration signals were recorded by accelerometers in two axes: horizontal and vertical . The sampling frequency is kHz. The dataset contains 15 test runs (5 runs per mode), each comprising recordings from several hours up to several days of continuous bearing operation until failure. Figure 4 shows vibration signals obtained from the XJTU-SY Bearing dataset.

Figure 4.

Visualization of vibration signals from the XJTU-SY Bearing dataset.

5.3. Preprocessing

Data preprocessing is a critical stage that determines the quality and reliability of modeling outcomes. Since raw XJTU-SY Bearing data are high-frequency vibration signals that include noise and artifacts, particular attention was paid to denoising, normalization, and extraction of informative features that characterize the bearing condition.

Raw data are time series sampled at 25.6 kHz with lengths ranging from to samples per test. Processing was performed in sliding windows of length samples (100 ms), which balances temporal resolution and computational efficiency. For each window, a set of diagnostic features describing vibration level and signal dynamics was computed.

The processing pipeline included the following procedures:

- Noise filtering. A low-pass filter with cutoff frequency 5 kHz was applied to remove high-frequency distortions. This step reduces parasitic harmonics introduced by rotor–housing interactions and preserves spectral components related to physical wear mechanisms.

- Segmentation and feature extraction. For each window, common bearing diagnostic statistics were computed [6]: root mean square (RMS), mean value, peak amplitude, kurtosis, crest factor and variance. The key diagnostic indicator is RMS, which serves as a universal measure of vibration level and correlates directly with wear severity.

- Feature normalization. All features were scaled to the range by the following normalization operator:which standardizes feature scales and prevents domination of large-valued features.

- Smoothing. A moving average with window was applied to suppress random fluctuations, improving robustness of trend estimation and visual interpretability of degradation curves.

- RUL labeling. For each time instant t, the remaining useful life was computed as follows:where is the time when RMS reaches a threshold associated with failure ( g). This constructs a degradation curve describing resource depletion over time.

In addition, spectrograms and correlation plots were used to check data consistency and detect anomalous runs. These procedures produced a clean, representative dataset suitable for statistical degradation modeling and optimization experiments.

5.4. Software Implementation

The method was implemented in Python 3.12.7 using standard scientific libraries (NumPy 2.3.3, Pandas 2.3.3, SciPy 1.16.2, Scikit-learn 1.8.0, Matplotlib 3.10.7) [35,36,37,38,39]. The system is modular and supports the full analysis cycle—from raw data ingestion to generation of control actions and visualization. Figure 5 shows the general architecture of the proposed modular architecture.

Figure 5.

Compact modular architecture.

Main components of the software.

- Data-processing module. Handles loading, filtering, and feature extraction from vibration signals. Implements segmentation, computation of statistical features (RMS, variance, kurtosis), and normalization to provide uniform inputs for later stages.

- State-prediction module. Implements the Weibull-based statistical degradation model for RUL estimation and confidence interval calculation. Model parameters are adapted to current operating conditions (load and rotational speed) to improve forecast reliability.

- Operational-parameter optimization module. Searches for combinations that produce an increase in predicted RUL by at least N. In the numerical experiments reported in Section 5, this module is instantiated with a genetic algorithm (GA): each individual encodes a pair , the fitness function is defined as , and crossover/mutation operators are applied under technological bounds. Other evolutionary optimizers such as Particle Swarm Optimization (PSO) can be integrated into the same framework, but their empirical evaluation is left for future work.

- Visualization module. Produces plots of degradation trajectories, RMS evolution, RUL before and after intervention, and the impact of parameter adjustment. Visualization supports interpretation and verification of system behavior.

Inter-module data exchange is performed through internal interfaces that preserve a sequential processing flow. Each module can operate independently, which makes the system flexible and extensible. The modular design enables use in both offline analysis of historical data and near-real-time integration with industrial monitoring platforms.

From an operational perspective, the software can be used in two main modes. First, an offline model-calibration mode, in which historical degradation data for a given class of assets are preprocessed, Weibull parameters are estimated, and optimization settings are tuned; this stage is computationally more demanding and is executed when new equipment types are introduced or substantial amounts of new data become available. Second, an online inference mode, in which incoming condition-monitoring data are transformed into RUL estimates and corresponding control actions via a single pass through the state-prediction and optimization modules. In this inference mode, computation times are negligible compared to typical sampling intervals, so the system can support near-real-time adjustments in industrial environments, while periodic offline recalibration keeps the models up to date.

6. Results and Discussion

This section describes obtained results on the XJTU-SY Bearing dataset. The target RUL increment N is a tunable parameter defined by the operator according to operational priorities and production constraints. For demonstration and comparability, we selected min.

6.1. Results Analysis

A comparison of the baseline and adjusted RUL values for all XJTU-SY instances is presented in Table 2. Each bearing is shown in two rows: the upper row contains the original operating parameters and baseline RUL, and the lower row (bold) reports the recommended adjusted parameters and the resulting RUL. Columns list rotational speed (, rpm), radial load (F, kN), and remaining useful life (, min).

Table 2.

Results for XJTU-SY bearings: original and adjusted operating modes. Bold values in the lower row of each bearing pair indicate the recommended adjusted operating mode and its corresponding RUL.

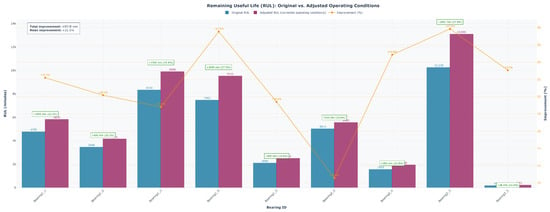

Table 2 shows RUL increases in all cases after adjustment. For example, Bearing1_1 exhibits a min gain () owing to a moderate reduction in and decrease in F. For Bearing2_4, the same absolute improvement corresponds to a relative increase. The largest relative effect is observed for Bearing3_5: RUL increases from 165 to 644.68 min when moving to a more conservative regime, which is typical for units with very low baseline life.

Practically, the bold rows indicate recommended control actions that extend lifetime without structural modification. These results align with the degradation model (Section 3.2 and Section 3.3) and demonstrate the applicability of the proposed closed-loop intelligent support cycle for lifetime extension.

A graphical comparison of baseline and adjusted RUL for each instance is shown in Figure 6. The visualization highlights both absolute and relative gains. The extension effect is most pronounced for bearings with low baseline RUL, where operational-parameter adjustment produces a large relative improvement.

Figure 6.

Comparison of predicted RUL before and after operating-mode adjustment for XJTU-SY bearings.

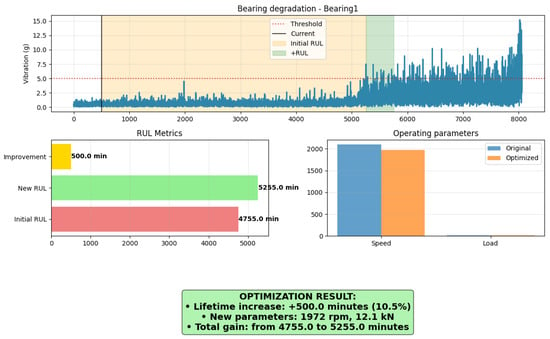

Figure 7 illustrates a representative result for bearing Bearing1_1: RMS evolution, RUL forecasts before and after parameter adjustment, and the effect of the modified operating mode on the time-to-failure.

Figure 7.

Method results for bearing Bearing1_1: RMS evolution and predicted RUL before and after parameter adjustment.

Experimental results demonstrate that the proposed method achieves the required RUL and confirm the applicability of evolutionary algorithms for generating control actions from real operational data.

6.2. Influence of Operating Factors on Bearing RUL

To validate the prediction model and RUL transfer across operating conditions, median time-to-failure estimates were computed for the three modes (five runs per mode). Table 3 summarizes median times-to-failure and equivalent revolutions-to-failure.

Table 3.

Summary of operating modes (median values over five runs per mode).

Based on the obtained values of the lifetime expressed in revolutions (), a regression model of the following form was fitted:

analogous to the Lundberg–Palmgren power law (ISO 281). The exponent p reflects sensitivity of life to load. Classical theory for deep-groove ball bearings suggests . However, empirical fitting on the three modes yielded

indicating an anomalously weak (and inverted sign) dependence on nominal load within the tested range (10–12 kN). The negative estimate is caused by correlated changes in rotational speed. Speed exerts a dominant influence on wear and in these experiments compensates the load effect. Therefore, using a fixed would substantially misestimate life.

To assess the adequacy of the adaptive model, we evaluated three methods for mapping the estimated lifetime from the Bearing 1 operating regime to the conditions of Bearing 3:

- Weibull-based scaling using ;

- ISO-281 with fixed ;

- adaptive model with empirically estimated .

Table 4 shows results.

Table 4.

Comparison of predicted failure times under transferred operating conditions. Bold values indicate the lowest absolute and relative errors among the compared methods.

The ISO-281 law () overestimates life nearly twofold (120% error), whereas the adaptive identification of from experimental data yields a prediction accuracy below 2%. This demonstrates that the real wear kinetics in these tests depend on an interplay of speed, lubrication, and thermal conditions, necessitating adaptive coefficient estimation. Within the proactive-management methodology, this result supports using data-driven identification of degradation parameters to improve RUL forecast accuracy and enable more effective lifetime extension.

It should be emphasized that the present study does not attempt to exhaustively characterize all possible fault types, defect sizes, or root causes in the bearing system. Instead, we work under the realistic constraint of limited and noisy information: the degradation state is represented by a chosen health indicator (vibration RMS), and the RUL model captures the aggregate effect of underlying uncertainties. In this setting, the proposed method treats RUL prediction as a tool for forming external operating conditions rather than as the primary object of optimization. Even under these uncertainties and incomplete knowledge about the exact nature of defects, the experiments show that adjusting controllable parameters according to the proposed optimization scheme consistently increases the predicted lifetime, indicating that the approach is robust enough to be useful in practice.

7. Conclusions and Future Work

This research proposes an intelligent support method for generating control actions in proactive management of CPS. The method integrates a Weibull-based RUL predictor with a corrective-action generation module and achieves a prescribed RUL increment by adjusting operating parameters inside admissible bounds.

Experimental validation on the XJTU-SY Bearing dataset demonstrated that the method reliably attains the requested increase in predicted RUL across units with different baseline conditions. The relative extension is inversely proportional to the baseline RUL, consistent with analytical considerations on normalized gains.

Results indicate that the method can be integrated into industrial monitoring and control systems to systematically extend maintenance intervals and improve equipment availability.

Planned directions of further research include the following:

- Integration with adaptive machine-learning models—development of modules for online adaptation of RUL prediction parameters and action generation using incoming operational data to improve real-time accuracy and robustness.

- Economic-oriented control layer—inclusion of cost metrics, downtime losses, and economic impact to support decisions that balance technical and financial objectives.

- Analysis of performance trade-offs—study of the compromise between RUL extension and reduction in equipment throughput or productivity.

- Expansion of experimental base—validation on multiple public and industrial datasets to confirm universality and reproducibility of results.

Implementation of these directions will increase the practical value of the proposed method, broaden its applicability, and provide comprehensive decision support for managing the condition of complex technical assets.

Author Contributions

Conceptualization, V.A., M.S. and K.D.; methodology, M.S.; visualization, K.D. and V.A.; validation, M.S.; data curation, V.A.; writing—original draft preparation, V.A.; writing—review and editing, M.S., A.K. and K.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the grant from the Russian Science Foundation (RSF) No. 24-21-00483 https://rscf.ru/en/project/24-21-00483/ (accessed on 16 December 2025). The APC was funded by the authors.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CPS | Cyber–Physical Systems |

| PPHM | Prognosis and Predictive Health Management |

| RUL | Remaining Useful Life |

| RMS | Root Mean Square |

| MRL | Mean Residual Life |

| DSS | Decision Support System |

| GA | Genetic Algorithm |

| PSO | Particle Swarm Optimization |

References

- Gálvez, A.; Diez-Olivan, A.; Seneviratne, D.; Galar, D. Fault Detection and RUL Estimation for Railway HVAC Systems Using a Hybrid Model-Based Approach. Sustainability 2021, 13, 6828. [Google Scholar] [CrossRef]

- Mishra, M. Prognostics and Health Management of Engineering Systems for Operation and Maintenance Optimization. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2018. [Google Scholar]

- Huang, C.; Bu, S.; Lee, H.H.; Chan, C.H.; Kong, S.W.; Yung, W.K.C. Prognostics and health management for predictive maintenance: A review. J. Manuf. Syst. 2024, 75, 78–101. [Google Scholar] [CrossRef]

- Van Tung, T.; Yang, B.-S. Machine fault diagnosis and prognosis: The state of the art. Int. J. Fluid Mach. Syst. 2009, 2, 1–26. [Google Scholar] [CrossRef]

- de Santis, R.B.; Gontijo, T.S.; Costa, M.A. Condition-based maintenance in hydroelectric plants: A systematic literature review. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2022, 236, 631–646. [Google Scholar] [CrossRef]

- Gupta, S.; Kumar, A.; Maiti, J. A critical review on system architecture, techniques, trends and challenges in intelligent predictive maintenance. Saf. Sci. 2024, 177, 106590. [Google Scholar] [CrossRef]

- Abidi, M.H.; Mohammed, M.K.; Alkhalefah, H. Predictive maintenance planning for industry 4.0 using machine learning for sustainable manufacturing. Sustainability 2022, 14, 3387. [Google Scholar] [CrossRef]

- Aliyu, R.; Mokhtar, A.A.; Hussin, H. Prognostic health management of pumps using artificial intelligence in the oil and gas sector: A review. Appl. Sci. 2022, 12, 11691. [Google Scholar] [CrossRef]

- Rosati, R.; Romeo, L.; Cecchini, G.; Tonetto, F.; Viti, P.; Mancini, A.; Frontoni, E. From knowledge-based to big data analytic model: A novel IoT and machine learning based decision support system for predictive maintenance in Industry 4.0. J. Intell. Manuf. 2023, 34, 107–121. [Google Scholar] [CrossRef]

- Hector, I.; Panjanathan, R. Predictive maintenance in Industry 4.0: A survey of planning models and machine learning techniques. PeerJ Comput. Sci. 2024, 10, e2016. [Google Scholar] [CrossRef]

- Bai, R.; Noman, K.; Feng, K.; Peng, Z.; Li, Y. A two-phase-based deep neural network for simultaneous health monitoring and prediction of rolling bearings. Reliab. Eng. Syst. Saf. 2023, 238, 109428. [Google Scholar] [CrossRef]

- Kraus, M.; Feuerriegel, S. Forecasting remaining useful life: Interpretable deep learning approach via variational Bayesian inferences. Decis. Support Syst. 2019, 125, 113100. [Google Scholar] [CrossRef]

- Van Oudenhoven, B.; Van de Calseyde, P.; Basten, R.; Demerouti, E. Predictive maintenance for industry 5.0: Behavioural inquiries from a work system perspective. Int. J. Prod. Res. 2023, 61, 7846–7865. [Google Scholar] [CrossRef]

- Abd Wahab, N.H.; Hasikin, K.; Lai, K.W.; Xia, K.; Bei, L.; Huang, K.; Wu, X. Systematic review of predictive maintenance and digital twin technologies challenges, opportunities, and best practices. PeerJ Comput. Sci. 2024, 10, e1943. [Google Scholar] [CrossRef]

- Badihi, H.; Zhang, Y.; Jiang, B.; Pillay, P.; Rakheja, S. A comprehensive review on signal-based and model-based condition monitoring of wind turbines: Fault diagnosis and lifetime prognosis. Proc. IEEE 2022, 110, 754–806. [Google Scholar] [CrossRef]

- Jantunen, E.; Hooghoudt, J.-O.; Yang, Y.; McKay, M. Predicting the remaining useful life of rolling element bearings. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 19–22 February 2018; pp. 2035–2040. [Google Scholar] [CrossRef]

- Wang, B.; Lei, Y.; Li, N.; Li, N. A Hybrid Prognostics Approach for Estimating Remaining Useful Life of Rolling Element Bearings. IEEE Trans. Reliab. 2020, 69, 401–412. [Google Scholar] [CrossRef]

- Zadiran, K.; Shcherbakov, M. New Method of Degradation Process Identification for Reliability-Centered Maintenance of Energy Equipment. Energies 2023, 16, 575. [Google Scholar] [CrossRef]

- Li, H.; Wang, Z.; Li, Z. An enhanced CNN-LSTM remaining useful life prediction model for aircraft engine with attention mechanism. PeerJ Comput. Sci. 2022, 8, e1084. [Google Scholar] [CrossRef] [PubMed]

- Afridi, Y.S.; Hasan, L.; Ullah, R.; Ahmad, Z.; Kim, J.-M. LSTM-based condition monitoring and fault prognostics of rolling element bearings using raw vibrational data. Machines 2023, 11, 531. [Google Scholar] [CrossRef]

- Chen, X. A novel transformer-based DL model enhanced by position-sensitive attention and gated hierarchical LSTM for aero-engine RUL prediction. Sci. Rep. 2024, 14, 10061. [Google Scholar] [CrossRef]

- Wang, D.; Hou, B.; Yan, T.; Shen, C.; Peng, Z. New statistical learning perspective for design of a physically interpretable prototypical neural network for machine condition monitoring. Mech. Syst. Signal Process. 2023, 188, 110041. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital twin: Enabling technologies, challenges and open research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- He, B.; Liu, L.; Zhang, D. Digital twin-driven remaining useful life prediction for gear performance degradation: A review. J. Comput. Inf. Sci. Eng. 2021, 21, 030801. [Google Scholar] [CrossRef]

- Liang, X.; Bao, D.; Yang, Z. State evaluation method for complex task network models. Inf. Sci. 2024, 653, 119796. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, Q.; Liu, Y.; Zhou, M.; Liang, X.; Liu, S.; Zeng, Y. A Current Measurement Error Compensation Strategy for SPMSM Based on An Improved Adaline Filter. IEEE Trans. Transp. Electrif. 2025, 11, 11644–11657. [Google Scholar] [CrossRef]

- Pandit, R.K.; Astolfi, D.; Durazo Cardenas, I. A review of predictive techniques used to support decision making for maintenance operations of wind turbines. Energies 2023, 16, 1654. [Google Scholar] [CrossRef]

- Zhuang, L.; Xu, A.; Wang, X.-L. A prognostic driven predictive maintenance framework based on Bayesian deep learning. Reliab. Eng. Syst. Saf. 2023, 234, 109181. [Google Scholar] [CrossRef]

- Oropallo, E.; Piscopo, P.; Centobelli, P.; Cerchione, R.; Nuevo, E.; Rodríguez-Prieto, Á. A decision support system to assess the operational safety and economic benefits of risk-based inspection implementation strategies. Saf. Sci. 2024, 177, 106570. [Google Scholar] [CrossRef]

- Shcherbakov, M.; Groumpos, P.P.; Kravets, A. A Method and IR4I Index Indicating the Readiness of Business Processes for Data Science Solutions. In Creativity in Intelligent Technologies and Data Science (CIT&DS 2017); Kravets, A., Shcherbakov, M., Kultsova, M., Groumpos, P., Eds.; Communications in Computer and Information Science; Springer: Cham, Switzerland, 2017; Volume 754. [Google Scholar] [CrossRef]

- Kravets, A.G.; Orudjev, N.Y.; Salnikova, N.A. Software for Predictive Maintenance and Repair of the Enterprise Office Equipment. In Proceedings of the 2019 International Multi-Conference on Industrial Engineering and Modern Technologies (FarEastCon), Vladivostok, Russia, 1–4 October 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Kravets, A.G.; Borzin, R.Y.; Rogozhnikov, E.D. Industrial Cyber-Physical Systems: Control Problems and Solutions. A Bibliometric Analysis Approach. In Cyber-Physical Systems. Studies in Systems, Decision and Control; Bolshakov, A.A., Ed.; Springer: Cham, Switzerland, 2024; Volume 554. [Google Scholar] [CrossRef]

- Shcherbakov, M.; Sai, C. A hybrid deep learning framework for intelligent predictive maintenance of cyber-physical systems. ACM Trans. Cyber-Phys. Syst. 2022, 6, 1–22. [Google Scholar] [CrossRef]

- Wang, B.; Xie, C.; Zhang, L.; Cui, H. XJTU-SY Bearing Datasets for Prognostics and Health Management; Xi’an Jiaotong University: Xi’an, China, 2023; Available online: https://github.com/WangBiaoXJTU/xjtu-sy-bearing-datasets (accessed on 11 November 2025).

- NumPy Developers. NumPy: The Fundamental Package for Scientific Computing with Python. Available online: https://numpy.org (accessed on 19 November 2025).

- Pandas Development Team. Pandas: Python Data Analysis Library. Available online: https://pandas.pydata.org (accessed on 19 November 2025).

- SciPy Developers. SciPy: Scientific Computing Tools for Python. Available online: https://scipy.org (accessed on 19 November 2025).

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Matplotlib Developers. Matplotlib: Visualization with Python. Available online: https://matplotlib.org (accessed on 19 November 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.