Abstract

In the context of Industry 4.0, Total Productive Maintenance (TPM) is undergoing a major shift driven by digital technologies such as the IoT, AI, cloud computing, and Cyber–Physical systems. This study explores how these technologies reshape traditional TPM pillars and practices through a two-phase methodology: bibliometric analysis, which reveals global research trends, key contributors, and emerging themes, and a systematic review, which discusses how core TPM practices are being transformed by advanced technologies. It also identifies key challenges of this transition, including data aggregation, a lack of skills, and resistance. However, despite the growing body of research on digital TPM, a major gap persists: the lack of a standardized model applicable across industries. Existing approaches are often fragmented or too context-specific, limiting scalability. Addressing this gap requires a structured approach that aligns technological advancements with TPM’s foundational principles. Taking a cue from these findings, this article formulates a systematic and scalable framework for TPM 4.0 deployment. The framework is based on four pillars: modular technological architecture, phased deployment, workforce integration, and standardized performance indicators. The ultimate goal is to provide a basis for a universal digital TPM standard that enhances the efficiency, resilience, and efficacy of smart maintenance systems.

1. Introduction

Today, equipment maintenance has become crucial to increasing the overall performance of any manufacturing organization [1], especially in this increasingly competitive environment, where every company is seeking to maintain or even expand its market position. Actually, maintenance is no longer merely about correcting breakdowns [1,2], but has become a crucial tool for optimizing processes, reducing downtime costs, and even improving quality [3]. As such, efficient maintenance management has a direct impact not only on equipment condition, but also on business productivity, flexibility, and competitiveness [4].

Meanwhile, the fourth industrial revolution, also known as Industry 4.0, is changing conventional production models [5]. Thus, this transformation goes beyond manufacturing processes and has a significant effect on how maintenance tasks are conceived and managed. Based on the integration of new and advanced technologies, such as the Internet of Things (IoT), Cyber–Physical Systems (CPSs), artificial intelligence (AI), real-time connectivity, cloud computing, and predictive analytics [6,7], this new trend allows for better machine interconnection, automated decision-making, failure anticipation, and the continuous optimization of operations [8]. However, while these technologies offer substantial improvements in efficiency and productivity, they also create a reliance on interconnected systems, which can introduce vulnerabilities. Furthermore, the rapid pace of technological change may exceed an organization’s capacity to adequately train its workforce, potentially resulting in a skills gap that obstructs the full utilization of these innovations [3,5,9].

In this new challenging environment, traditional approaches must also be improved and adapted to the context of Industry 4.0. When it comes to maintenance, we find that Total Productive Maintenance (TPM), which, since its emergence in the 1970s, has played a major role in the continuous improvement of industrial performance in companies [9,10,11]. Thanks to its principles of Continuous Improvement; Autonomous Maintenance; Preventive Maintenance; Quality Maintenance; Training and Education; and Safety, Health and the Environment, and the TPM office, companies that adopt it have been able to achieve high levels of reliability and availability [9]. However, in the current context, these principles must also be adapted to the new requirements and opportunities of the new industrial era [12]. This has given rise to a new term, TPM 4.0 or digital TPM [6,12], in which new technologies are integrated into the development of traditional principles, enabling the continuous monitoring of equipment, shifting from preventive maintenance to data-driven predictive maintenance, while ensuring real-time management and better integration between production and maintenance [6].

Consequently, a central question stands out: “How does TPM evolve in the era of Industry 4.0, and what foundations can be used to build a digital implementation standard”?

In order to effectively address this issue, this article proposes an in-depth analysis based on a systematic literature review (SLR) preceded by a bibliometric study, with a dual objective:

- Firstly, to map scientific production on digital TPM by identifying trends, studies, publication sources, and dominant themes;

- Secondly, to structure the conceptual and technological contributions in order to propose the foundations of a standard for the implementation of TPM in the era of Industry 4.0.

Consequently, the results of this study will allow us to establish a better understanding of the current dynamics of TPM 4.0 research, to clarify the technological facilitators identified in the literature, and to lay the foundations for a structured framework that can be used as a practical reference point for companies.

To conduct this study, the following plan will be followed: Following the introduction, Section 2 will present the theoretical background of the paper, where we will briefly define TPM with its pillars, as well as Industry 4.0 and its technologies. Next, Section 3 will introduce the research methodology used, detailing the different research steps followed with the tools adopted. Afterwards, another section will present the results obtained, both from the bibliometric and systematic studies. And just before the Conclusions and Perspectives section, a final section will summarize the main findings of our analysis to build a set of requirements that will form the basis for the development of a standard model for the implementation of digital TPM.

2. Theoretical Background

2.1. Total Productive Maintenance

Total Productive Maintenance, or TPM, is a maintenance strategy first created in 1971 in Japan at Nippondenso, a Toyota supplier, and later standardized by the Japan Institute of Plant Maintenance (JIPM) [9,13]. TPM has been influenced by the American preventive maintenance idea and follows lean manufacturing philosophy with a basic principle: achieving sustainable industrial performance requires collective responsibility for equipment management [9].

Unlike conventional methods that are based on corrective maintenance carried out by specialists, TPM focuses on the proactive and preventive engagement of all employees [9]. Its key focus is to maximize Overall Equipment Effectiveness (OEE) by reducing breakdowns, unplanned downtime, quality defects, and performance losses [14,15].

TPM is based on eight basic pillars [16], including Autonomous Maintenance, where operators are directly responsible for performing fundamental equipment maintenance, creating a sense of responsibility [17]; Preventive Maintenance through scheduled examinations to avoid failure [18]; and Focused Improvement, where efforts are aimed at the cause of losses, specifically the sixteen major categories [18]. The Education and Training pillar also focuses on developing a skilled and multidisciplinary workforce making active contributions towards TPM [17].

These pillars carry TPM over to office work, development management, and the critical areas of environment, health, and safety, underpinning the commitment to a safe and sustainable workplace [17,18]. Altogether, these pillars promote a sense of discipline and responsibility, and a spirit of continuous improvement, which encourage organizations to strive towards the ideal of “zero breakdowns, zero defects, zero accidents” [19].

2.2. Industry 4.0

Industry 4.0 (I4.0) refers to the digital transformation of manufacturing [20]. Popularized in Germany in the early 2010s [20,21], this concept brings together a set of emerging technologies aimed at making production systems more intelligent, flexible, and autonomous [22].

The main technological building blocks of I4.0 include the Internet of Things (IoT), which facilitates real-time data acquisition via connected sensors [23,24]; artificial intelligence (AI), used for predictive analysis and automatic anomaly detection [25,26]; Cyber–Physical Systems (CPSs), which ensure the interconnection between the physical and digital worlds [22]; or cloud computing, facilitating the storage and distributed exploitation of data [20,25]. In addition, there are tools such as digital twins, which allow virtual simulation of the behavior of machines [27,28], or augmented reality, used for training or assistance with interventions [29,30].

These technologies are profoundly transforming traditional industrial models. They enable the transition from static and hierarchical management to a connected, responsive, data-driven organization. Maintenance, in particular, becomes a particular area of application of these innovations [25,31,32].

3. Research Methodology

The principal aim of this study is to provide a holistic analysis of how TPM has been influenced by the context of I4.0, this new era in which digital technology convergence, advanced automatization, and vast data exploitation have driven the traditional paradigms of maintenance and, at the same time, created new unforeseen opportunities. As a consequence, in contrast to these changes, there is a vital necessity to analyze how the fundamentals of TPM are reinterpreted, expanded, or combined to suit the technological requirements of the Fourth Industrial Revolution.

To address this, a two-phased methodological framework was used. The first phase involved a bibliometric analysis to chart dominant research patterns over TPM within the I4.0 context. This quantitative method was applied to identify top publications, dominant publication sources, and thematic development in the field over time. Notably, data treatment and graph generation were carried out using Python 3.10 in Google Colab, thereby offering dynamic and reproducible computational analysis.

In the second phase, a systematic analysis of a set of significant publications was performed. This qualitative process involved extracting, interpreting, and synthesizing conceptual and empirical observations on integrating I4.0 technologies into TPM practice. Through this process, the analysis revealed primary directions for TPM development, new emerging ideas, frameworks outlined in the literature, and opportunities and constraints identified by researchers.

Together, these findings contribute to a better understanding of how TPM is transitioning in the context of smart manufacturing systems and offer informative insights into future research on TPM and its effective application in industry.

3.1. Identification of Research and Selection of Studies

The literature search was conducted using two major academic databases, Scopus and Web of Science (WoS), due to their wide coverage of the fields of digital technology, production, and industrial engineering.

Two search queries were defined to capture the body of literature intersecting the themes of TPM and I4.0 technologies:

Query 1:

TITLE-ABS-KEY ((“Total Productive Maintenance” OR “TPM”) AND (“Industry 4.0” OR “Smart Manufacturing” OR “Digitalization”) OR “TPM 4.0”).

Query 2:

TITLE-ABS-KEY ((“Total Productive Maintenance” OR “TPM”) AND (“Predictive Maintenance” OR “Condition-based Maintenance” OR “IoT” OR “Artificial Intelligence” OR “Big Data”)).

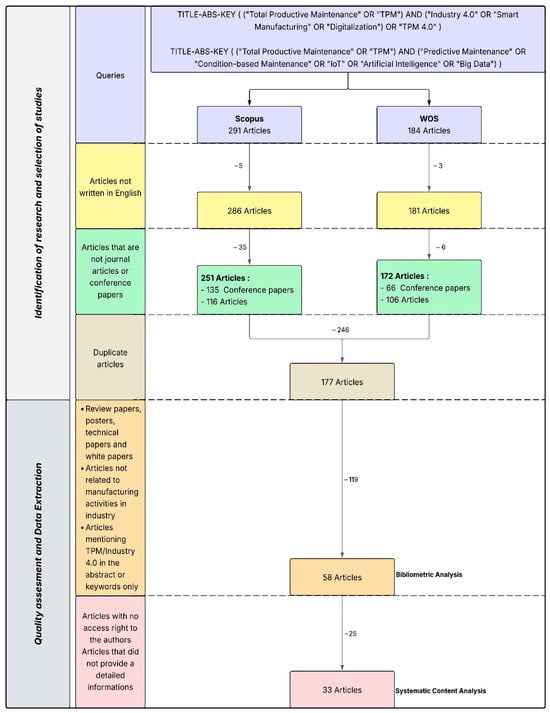

The analysis was restricted to the period from 2017 to March 2025, selected based on the availability of relevant publications for Query 1. As mentioned in the Figure 1 below, this search resulted in the identification of a total of 475 documents (143 for Query 1 and 332 for Query 2), distributed across both Scopus and WoS.

Figure 1.

Analysis methodology inspired by [33].

Then a rigorous selection process was applied. The initial filters resulted in the exclusion of articles

- Not written in English;

- Not classified as journal articles or conference proceedings.

Subsequently, duplicates (137 documents) were removed. The remaining publications were assessed using additional exclusion criteria:

- Review papers, posters, white papers, or technical reports;

- Studies not related to manufacturing contexts;

- Documents mentioning TPM/I4.0 only in the keywords or abstract, without further elaboration in the main text.

This first phase resulted in a final corpus of 58 articles retained for bibliometric analysis.

3.2. Quality Assessment and Data Extraction

A second filtering stage was carried out to refine the process by targeting publications that demonstrated clear technical or conceptual contribution to the research goals. During this stage, a set of inclusion criteria was used to ensure the quality and depth of the studies selected. First, articles that were not available in full-text form were eliminated, because they could not allow the formulation of a detailed analysis. Secondly, papers that did not offer deep discussions pertaining to implementation frameworks, architectures, or conceptual models that targeted TPM specifically in the digital context were eliminated from the process. After the application of the criteria, a list of 33 articles was left and was subjected to a systematic content analysis.

3.3. Research Questions

This study is guided by eight research questions that explore how TPM is changing in the digital age. These questions look at both the academic and practical sides of TPM in the context of Industry 4.0. They cover trends in research, key technologies, challenges, and ways to successfully use digital TPM in industry.

Q1. What are the spatio-temporal trends in TPM research in the era of I4.0?

This question aims to chart the spatial and chronological spread of digital TPM studies. It examines which countries or regions are most actively contributing to the field and how the volume of related publications has progressed over time, thereby offering a perspective on the global momentum and maturity of the subject.

Q2. What are the most influential works and publication sources in the field of digital TPM?

The aim here is to identify the scientific contributions that have influenced the formation of digital TPM. This involves determining the most-cited papers, as well as the leading journals or conferences, in order to define the intellectual structure of the field.

Q3. What are the dominant and emerging research themes related to digital TPM?

This question explores the central and emerging themes that characterize the digital TPM research space. Using keyword co-occurrence and clustering analysis, it traces the thematic development and highlights areas of growing interest or potential directions for future research.

Q4. What are the main technological enablers of digital TPM?

This question seeks to identify the core technologies, such as the IoT, artificial intelligence, Big Data, and predictive maintenance, that are instrumental in driving TPM’s transition toward a digital paradigm.

Q5. How does I4.0 transform the traditional foundations of TPM?

This question investigates the reinterpretation and redefinition of TPM’s foundational pillars in light of contemporary technological advancements and evolving organizational practices.

Q6. What are the challenges and opportunities associated with the implementation of digital TPM?

This question aims to map out technical, human, and organizational barriers as well as expected or observed benefits. This question aims to map the spectrum of barriers, technical, human, and organizational, as well as to highlight the potential benefits and opportunities that accompany the adoption of digital TPM.

Q7. How can enterprises successfully integrate digital TPM?

This question explores the critical success factors, methodological approaches, and practical best practices that facilitate the effective and sustainable implementation of TPM in smart manufacturing environments.

Q8. How can a standardized framework for digital TPM be developed, based on existing research and industrial needs?

The aim here is to synthesize academic insights in order to formulate a reference model that is both theoretically robust and practically applicable within real-world industrial contexts.

4. Results

4.1. Bibliometric Analysis

This section aims to emphasize the most prominent research trends concerning TPM evolution within the I4.0 context. The analysis relies on 58 articles carefully chosen based on the strict procedure outlined above. There are two overall purposes of the analysis: (i) to discover how the research on the subject has progressed over time, geographically, and scientifically, and (ii) to identify central contributions and arising thematic trends within the area.

4.1.1. Q1. What Are the Spatio-Temporal Trends in TPM Research in the Era of I4.0?

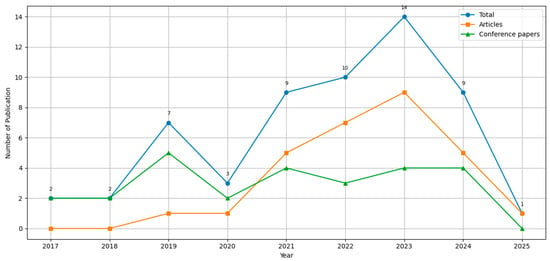

In the context of I4.0, as shown in Figure 2 below, research on TPM has increased gradually over time and is widespread worldwide. Between 2017 and 2025, the number of publications has increased, reflecting stronger interest in smart maintenance approaches.

Figure 2.

Trend graph for publications by year.

From 2017 to 2020, publication levels were low but consistent, ranging between two and seven articles annually. This period likely focused on early explorations and establishing foundational ideas. A clear growth phase began in 2020. The number of studies increased rapidly, from 3 in 2020 to 9 in 2021, peaking at 14 in 2023. This upward trend mirrors the wider adoption of I4.0 technologies such as predictive maintenance, smart monitoring, and IoT-based systems. Since 2021, journal publications have become more frequent than conference papers, suggesting a shift toward more in-depth and mature research outputs.

A drop in the number of publications was observed in 2024 and early 2025, with only one article recorded in the first quarter of 2025. This decline is likely linked to typical publishing delays and should not be interpreted as declining interest. It may also indicate a shift toward more specialized research areas.

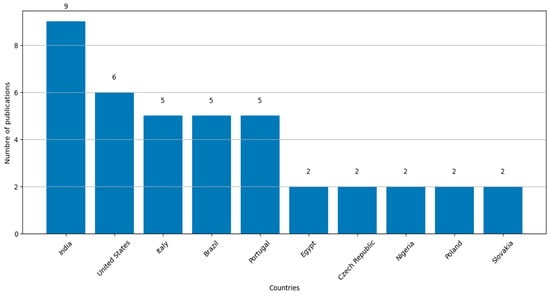

Geographically, publication output is standardized. The next Figure 3 demonstrates that India leads with nine contributions, likely supported by national initiatives like “Make in India” aimed at advancing smart manufacturing [34]. The United States follows with six publications, benefiting from its strong tech ecosystem and industrial collaborations [35]. Italy and Portugal each produced five studies, likely driven by EU-funded digital innovation programs [36]. Brazil also contributed five articles, showing growing participation from emerging economies [37].

Figure 3.

Top 10 countries contributing to publications.

Meanwhile, countries such as Egypt, the Czech Republic, Nigeria, Poland, and Slovakia each published two studies. Although these numbers are modest, they signal rising interest, possibly tempered by challenges such as limited funding or infrastructure capacity [38,39,40].

4.1.2. Q2. What Are the Most Influential Works and Publication Sources in the Field of Digital TPM?

The field of digital TPM has been shaped by a small number of highly cited papers and well-known publication venues. The most cited publications are mentioned in Table 1 below:

Table 1.

Most cited publications.

Starting first with publications, the most cited article is Tortorella et al. [6], which has received 193 citations and created the foundation for combining digital technologies with traditional TPM methods. Other key contributions include the study of Poor et al. [41] on predictive maintenance as a major step in modern maintenance, with 114 citations, and another by Mohan et al. [42] on machine learning for zero downtime in industrial equipment, with 106 citations. These works have helped define the main directions of research, especially in areas like AI, predictive analytics, and intelligent systems. In addition, some papers have also explored cybersecurity [47] and digitalization in small businesses [48], showing that the field is expanding into diverse topics.

At this stage, and after presenting the most cited publications, it is equally important to examine the most dominant publication sources in this research field. The Figure 4 below highlights the most frequent publication sources, offering insights into the journals and conferences that serve as key platforms for advancing research in this domain.

Figure 4.

Top 10 publication sources.

Research in this field is published in a mix of journals and conference proceedings. The International Conference on Industrial Engineering and Operations Management stands out as the most common source, with 10 papers. It serves as a platform for applied studies in industrial maintenance. Several journals also appear frequently, including Sustainability, Procedia Manufacturing, Computers and Industrial Engineering, Processes, Electronics, and Applied Sciences. These journals reflect the interdisciplinary nature of the field, touching on topics from automation to sustainability. In addition, specialized outlets like the Journal of Quality in Maintenance Engineering underline the practical and industrial focus of TPM 4.0 research.

4.1.3. Q3. What Are the Dominant and Emerging Research Themes Related to Digital TPM?

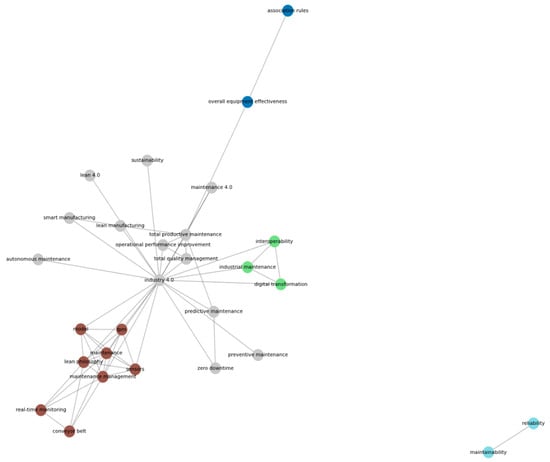

Research on digital TPM shows a clear blend of traditional maintenance goals with new digital technologies. Our analysis of author keywords and their relationships, present in the Figure 5 below, highlights both established and emerging themes shaping the field today and in the future.

Figure 5.

Word cloud of the author keywords.

At the center of the research landscape is the strong link between “Total Productive Maintenance” and “Industry 4.0”. This connection shows that TPM is no longer seen just as a maintenance method, but also as a key part of smart manufacturing systems [6]. Keywords like “predictive maintenance”, “digital transformation”, “operational performance improvement”, and “management” highlight a major focus on using digital tools to improve efficiency, reliability, and asset management. Terms like “maintenance”, “improvement”, “quality”, and “performance” confirm that traditional TPM goals, such as reducing downtime and driving continuous improvement, remain essential but are now pursued in a digital context.

Newer research areas are forming around advanced technologies. Keywords like “IoT”, “learning”, “smart”, “monitoring”, and “system” point to growing interest in connected, intelligent, and data-driven maintenance. This shift moves TPM from being reactive or proactive toward real-time and predictive models, enabled by artificial intelligence and smart sensors. Words like “digital”, “philosophy”, and “4.0” suggest that researchers are also exploring broader ideas, combining technical innovation with changes in management practices and organizational culture.

As shown in the Figure 6 above, several main clusters of themes emerge from the keyword analysis. A strong core around “Industry 4.0”, “TPM”, “predictive maintenance”, and “digital transformation” focuses on boosting performance and aligning maintenance with digital strategies. Another cluster deals with technological integration, where ideas like “interoperability”, “industrial maintenance”, and “digital transformation” show efforts to connect IT systems and physical operations. A third cluster, linked to “lean maintenance” and “real-time monitoring”, reflects ongoing interest in applying lean methods to digital environments. Smaller but important topics such as “association rules”, “reliability”, “maintainability”, and “OEE” suggest growing attention to data analysis and performance measurement.

Figure 6.

Keyword co-occurrence network.

Looking ahead, the field is moving toward a full model of smart maintenance, with AI, cybersecurity, digital twins, and human–machine collaboration expected to play key roles. There is also more interest in adapting TPM 4.0 for specific applications, such as small businesses, airport logistics, and complex manufacturing, showing the wide reach of digital maintenance strategies.

4.2. Systematic Analysis

Having outlined the main bibliometric trends, it is clear that research on TPM in the I4.0 era is both growing and diversifying. Key works, influential authors, active collaborations, and emerging themes provide a strong foundation for understanding how the field is evolving. However, while our bibliometric analysis offers a broad overview, it does not capture the depth and specific content of the studies.

To address this, this section presents a systematic analysis. It aims to explore how digital TPM is being conceptualized, implemented, and assessed in practice, providing deeper insights into the strategies, technologies, and challenges highlighted across the literature.

4.2.1. Q4. What Are the Main Technological Enablers of Digital TPM?

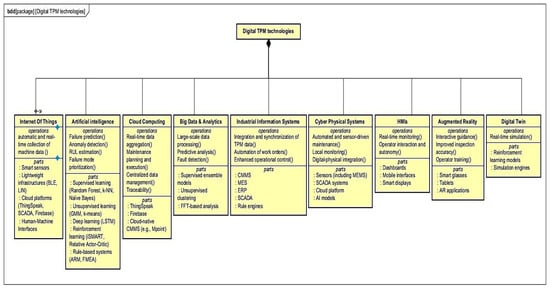

The transformation of TPM in the Industry 4.0 context is driven by several key digital technologies. These technologies combine to make TPM more connected, predictive, and data-driven [49,50]. From the analysis of 33 articles, nine major categories of technologies stand out: IoT, AI, cloud computing, Big Data Analytics, Industrial Information Systems, CPSs, human–machine interfaces, augmented reality, and digital twins.

The IoT is at the forefront of digital TPM. It is the main technology that allows machines to automatically and in real time collect data such as temperature, vibration, pressure, and lubrication. This data helps with condition-based and predictive maintenance strategies [51,52]. Moreover, smart sensors, connected via lightweight infrastructures like BLE (Bluetooth Low Energy) and LIN (Local Interconnect Network) to cloud platforms such as ThingSpeak [53], SCADA (Supervision Control and Data Acquisition) [54], or Firebase [55], allow for the real-time visualization of machine status on mobile devices and HMIs (Human–Machine Interfaces) [53]. This connectivity enables key functionalities such as automated part counting, fault classification, and proactive alert generation, which have contributed to measurable performance improvements, including increased availability, reduced MTTR (Mean Time To Repair), and enhanced OEE [52,56,57,58]. Furthermore, the IoT is frequently integrated with AI models, cloud services, and digital twins to anticipate failures and facilitate data-driven decision-making [43,58,59]. Additionally, it supports circular traceability in sustainable manufacturing practices [60] and reinforces interoperability with legacy systems [61]. However, its success is largely dependent on operator training and successful organizational integration; without these, the anticipated benefits might be minimal or even detrimental [49,50].

At the same time, AI is considered complementary to the IoT by enabling smart, adaptive maintenance. Random Forest, k-NN (K-Nearest Neighbors), and Naïve Bayes are examples of supervised learning methods that have been able to predict failures with up to 96% accuracy [62]. Also, rule-based approaches like Association Rule Mining (ARM) combined with FMEA (Failure Modes and Effects Analysis) help prioritize failures according to their criticality, supporting TPM strategies and increasing OEE by up to 10% [63]. Meanwhile, even in the absence of labeled datasets, deep learning architectures (such as LSTM—Long Short-Term Memory) and unsupervised techniques (such as GMM (Gaussian Mixture Model) and k-means) enable precise anomaly detection and RUL (Remaining Useful Life) prediction [43,58]. Notably, reinforcement learning techniques, such as iSMART and Relative Actor–Critic, have enabled real-time, self-optimizing maintenance policies without relying on probabilistic models [64].

Moreover, Big Data and cloud computing together form the digital core of modern TPM systems [50,51]. The real-time aggregation of data is enabled through cloud computing platforms such as ThingSpeak and Firebase [55], while Cloud-native CMMS (Computerized Maintenance Management System) services like Mpoint support the planning, execution, and traceability of maintenance activities [65]. At the same time, Big Data analytics enables the large-scale processing and analysis of equipment data [50], with practical applications including supervised ensemble models to forecast reliability [62], unsupervised clustering techniques to analyze sensor data [43], and FFT-based vibration analysis on MEMS (Micro Electro-Mechanical Systems) sensors for early fault detection [66].

Another key enabler consists of Industrial Information Systems (IISs), including CMMS, MES (Manufacturing Execution System), ERP (Enterprise Resource Planning), and SCADA, essential in the integration and control of TPM data and processes [45,51,65]. In practical applications, these systems have been used to process work orders automatically [45], coordinate maintenance and operational information [65], and enhance OEE through rule engines and MES platforms [67]. Supporting these digital infrastructures, CPSs help to close the loop of digital intelligence and physical assets [50]. Through the integration of sensors, SCADA systems, cloud platforms, and AI models, CPSs support dynamic, computerized maintenance responses [58]. Even with decreased-scale implementations, such as those based on the combination of MEMS sensors with FFT analysis, CPSs are effective in enabling local monitoring [66]. Despite their potential, some studies still refer to IISs only conceptually, without reporting actual deployment [68].

Alongside these technologies, HMIs, particularly when enhanced with augmented reality (AR), enable a considerable amount of operator autonomy and real-time decision-making [69]. Through AR applications, procedures may be walked through interactively by a person wearing intelligent glasses or using tablet devices, improving inspection accuracy and making process training easier [69]. Concurrently, cloud-based dashboards and mobile platforms are gaining popularity as means to facilitate proactive TPM monitoring [70]. Complementing these tools, digital twins represent a high-potential yet still underutilized technology. When integrated with reinforcement learning, they enable real-time, simulation-based planning, making predictive maintenance more precise and responsive [59].

To synthesize the various technologies discussed throughout this section, Figure 7 below provides an overview of all the technologies contributing to the digitalization of TPM. It outlines their respective roles and key components, as identified in the literature, offering a comprehensive mapping of how each technological element supports the transformation of traditional TPM practices in the context of Industry 4.0.

Figure 7.

Digital TPM technologies.

4.2.2. Q5. How Does Industry 4.0 Transform the Traditional Foundations of TPM?

Industry 4.0 technologies have profoundly transformed the core pillars of TPM, embedding digital intelligence into processes that were traditionally manual, reactive, and document-driven. The analysis of the 33 articles reveals that this transformation extends beyond technology itself, it reshapes practices, decision-making timelines, and operator roles.

In the Autonomous Maintenance pillar, connected sensors, SCADA systems, and Cyber–Physical architectures now automate routine inspections and continuously monitor equipment conditions [45,60]. Instead of executing predefined manual tasks, operators interact with intelligent interfaces, receiving real-time alerts and decision support. For example, Lucantoni et al. [51] present a four-layer system, from data acquisition to real-time visualization, that allows operators to prioritize interventions through smart HMIs rather than merely report anomalies. Moreover, AR, delivered via smart glasses or tablets, further enhances autonomy by guiding users through procedures hands-free, improving both inspection accuracy and responsiveness [69].

From another perspective, the Planned Maintenance pillar is shifting from static scheduling to dynamic, predictive planning [58]. AI-powered models, including LSTM and ensemble forecasting, leverage real-time machine data to anticipate failures and trigger maintenance only when needed [58,62]. This transition is exemplified by the iSMART model proposed by Encapera and Gosavi [64], which uses reinforcement learning in a semi-Markovian framework to optimize maintenance policies. Supporting this, cloud-based CMMS platforms such as Mpoint enable the automation of task planning, tracking, and the full traceability of maintenance activities [65].

In the Focused Improvement pillar, digitalization has turned reactive problem-solving into a continuous, data-driven loop [51]. The IoT and SCADA systems feed live operational data into machine learning algorithms that detect inefficiencies and support rapid root cause analysis [58]. Gosavi and Encapera [59] further illustrate this with a digital twin that simulates production scenarios and identifies improvement opportunities before losses materialize. FP-Growth algorithms, as shown by Lucantoni et al. [51], reveal hidden correlations between events and unplanned downtime, refining continuous improvement strategies. Real-time dashboards also enhance cross-functional collaboration and allow for a measurable impact on KPIs (key performance indicators) such as OEE [48,51,55].

The Training and Education pillar has evolved into an immersive learning environment [69]. AR provides real-time procedural guidance, reducing onboarding time and human error [69]. Operators are not passive recipients of training anymore, but active participants interacting directly with machine data via mobile dashboards and cloud-based platforms, reinforcing their skills through real-world feedback [53,55]. This shift also makes the traditional lines between training, quality, and safety less clear, encouraging a more unified performance culture [51].

In the Quality Maintenance pillar, sensors and analytics tools detect deviations before defects occur [51]. Predictive models analyze patterns in operational data, enabling early interventions, while MES systems ensure traceability throughout the production chain [51,57]. Root cause analysis is increasingly supported by algorithmic insights rather than relying solely on human experience.

The Safety, Health, and the Environment pillar also benefits from digital integration [49]. Embedded sensors identify hazards such as overheating or abnormal vibrations and automatically trigger alerts or shutdowns [66]. In parallel, AR guides operators through high-risk tasks while keeping their hands free, improving safety without compromising productivity [69].

Taken together, this transformation marks a broader paradigm shift from a human-centered TPM to a data-augmented TPM [51]. While human expertise remains essential, the operator’s role is evolving toward validation, supervision, and exception management [41]. TPM is no longer a static, document-based system but a dynamic, self-learning ecosystem powered by sensors, algorithms, and simulation tools, advancing toward integrated, resilient, and intelligent maintenance strategies [49].

4.2.3. Q6. What Are the Challenges and Opportunities Associated with the Implementation of Digital TPM?

The digitalization of TPM in the era of I4.0 offers undeniable transformative potential, both in terms of equipment performance and organizational agility [61]. However, integrating this new generation of TPM depends on technical, human, and systemic conditions that generate significant opportunities but pose substantial challenges. A cross-analysis of the 33 studies highlights this dual reality, where performance gains are counterbalanced by implementation constraints.

Among the most compelling opportunities, operational performance improvements stand out. Numerous studies report significant gains in OEE, increased equipment availability, and reduced downtime, largely enabled by real-time monitoring and predictive capabilities [53,55,58,64,65,67]. Furthermore, intelligent analytics and decision-support systems based on machine learning enhance diagnostic precision, fault prediction, and maintenance planning [58,62,64,67,71].

Digital TPM also contributes to sustainability and quality through reduced emissions, improved product consistency, fewer defects, and better energy and material efficiency [12,60,69]. From a workforce perspective, the use of AR, mobile HMIs, and IoT interfaces enhances operator autonomy and accuracy, supporting faster onboarding and reducing training errors [69]. Economically, digital TPM enables better resource efficiency by minimizing unnecessary interventions, extending asset lifespan, and lowering maintenance costs [55,62].

Lastly, integration and traceability are greatly improved through the adoption of CMMS, MES, and cloud platforms that connect maintenance and production data, providing end-to-end visibility and supporting standardized workflows [45,51,55].

Yet, despite these benefits, digital TPM faces several persistent challenges [50]. Technically, data-related issues are widespread, ranging from poor data quality and heterogeneity to difficulties in threshold setting and system initialization [51,58,62]. Sensor management and integration with legacy systems also remain complex and resource-intensive [66]. Moreover, technological maturity and scalability remain problematic. Many digital TPM models suffer from limited generalizability or rely on configurations that are not easily transferable across different industrial environments.

On the human and skills front, the lack of technical expertise, insufficient operator training, and resistance to change hinder adoption [68,72], especially in small and medium-sized enterprises (SMEs), where digital literacy gaps are more pronounced [48,53,63].

Organizationally, challenges include cultural resistance, weak data governance, and siloed departments [12,50]. These factors limit the alignment of TPM with broader operational strategies and often result in isolated, short-lived initiatives. And finally, the cost of implementation, especially for advanced techniques, represents a major barrier, particularly in developing contexts or budget-sensitive industries [57].

Looking beyond these findings, it becomes clear that while the digitalization of TPM offers clear and measurable advantages across performance, sustainability, and workforce efficiency, its success depends on the ability to overcome significant technical, human, and organizational barriers. The path forward requires investment not only in technologies but also in skills, culture, and cross-functional coordination. Therefore, bridging these gaps is essential to unlock the full potential of a truly integrated and resilient TPM 4.0 framework.

4.2.4. Q7. How Can Enterprises Successfully Integrate Digital TPM?

After defining the main technologies driving the digitalization of TPM, and examining how the traditional pillars of TPM have evolved through this digital shift, along with the opportunities and challenges it brings, it is time to look at how companies can successfully navigate this digitalization process. In order to accomplish this successfully, organizations require a coherent and systematic approach, combining technological readiness, human resource development, and strong organizational strategies.

To begin with, companies must establish a clear digital maintenance strategy aligned with their overall business goals [73]. Digital TPM should not be treated as an isolated initiative, but rather as an integral part of a broader I4.0 roadmap [41]. Defining key performance indicators such as OEE, MTBF (Mean Time Between Failures), and maintenance cost reduction targets allows companies to measure progress and demonstrate the value of their initiatives [51,55].

Once the strategic vision is defined, attention must turn to assessing the company’s technological infrastructure. This infrastructure rests on four key components. First, the IoT serves as the technical foundation and backbone of digital TPM [12]. The deployment of smart sensors capable of collecting real-time data, such as temperature, vibration, and pressure, is essential [61,66]. These sensors must be connected to cloud platforms like ThingSpeak, Firebase, or SCADA via lightweight communication networks such as BLE or LIN [53,55,58]. This configuration enables the continuous monitoring of machines, and it triggers automated alerts for proactive maintenance [53]. To support a smooth and progressive transition, companies must also ensure interoperability with legacy systems by establishing communication bridges through appropriate gateways [61].

Second, AI forms the analytical core of the system. AI transforms raw sensor data into actionable insights through a range of algorithms. Supervised methods such as Random Forest and k-NN [62]; unsupervised techniques like k-means and GMM [43]; and deep learning models such as LSTM [58] enable accurate anomaly detection, failure prediction, and estimation of RUL for equipment.

In addition, cloud computing and Big Data technologies provide the scalable analytical infrastructure needed for digital TPM. Cloud platforms offer a flexible and adaptable architecture [74], while Big Data Analytics enables the detection of hidden patterns and trends within vast volumes of equipment data, enhancing both decision-making and predictive capabilities [51].

Furthermore, Industrial Information Systems represent the organizational structure that supports TPM operations. Systems such as CMMS, MES, and ERP are critical for organizing, automating, and tracking maintenance processes [51,65]. These tools allow for the automatic generation of work orders, synchronization of operational and maintenance data, and integration of decision-making rules within production workflows [45].

However, the success of digital TPM is dependent not entirely on technology, but also, critically, on human factors and effective leadership [41,61]. Employees must be equipped with more than just basic digital skills; they need to understand predictive maintenance models, interpret complex data, and confidently use digital tools such as mobile maintenance applications and AR systems [41,51,53,69]. This shift calls for continuous investment in workforce development through e-learning platforms, practical workshops, and long-term training programs. These initiatives help reduce resistance to change and support smoother adoption across all levels of the organization.

Equally vital is the role of leadership in driving and sustaining the transformation. Top management must actively champion digital TPM by allocating sufficient resources, setting clear priorities, and consistently communicating the strategic importance of modernizing maintenance [53,75]. In parallel, cross-functional collaboration between departments, such as maintenance, production, IT, and data science, is essential to ensure a unified and effective implementation [41]. When leadership and workforce are aligned, the organization is well-positioned to fully realize the benefits of digital TPM.

Another critical pillar is the establishment of strong data governance. As sensor networks generate large volumes of data, companies must ensure that this data is accurate, standardized, and interoperable across platforms [55,61]. Without consistent and reliable data, predictive models lose effectiveness. To address this, organizations should implement centralized data lakes or structured maintenance databases that enable efficient analytics and informed decision-making.

In terms of execution, a gradual and iterative approach is recommended. Instead of launching a full-scale transformation all at once, companies should begin with pilot projects targeting critical machines or production lines [51,53]. These early initiatives act as proof of concept, generating quick wins that build momentum and strengthen organizational buy-in [51].

Lastly, to ensure sustainability and long-term impact, companies must cultivate a culture of continuous improvement. Feedback loops should be embedded into maintenance processes, allowing teams to regularly analyze performance data, identify gaps, and update predictive models as needed [69,70]. By fostering a mindset of learning and innovation, organizations ensure that their digital TPM systems evolve in step with future challenges and technological advancements.

4.2.5. Q8. How Can a Standardized Framework for Digital TPM Be Developed, Based on Existing Research and Industrial Needs?

The emergence of Industry 4.0 and the increasing digitalization of production environments have profoundly transformed maintenance management approaches. Among the 33 studies analyzed, six of them propose digital TMP frameworks. Despite their different models, they all converge on the idea that a standardized framework for digital TPM must be based on the systemic integration of data collection, advanced analysis, and proactive decision-making while preserving the human and organizational foundations of traditional TPM.

The first pillar of such a framework is modular structuring in functional layers, widely adopted in several articles. Whether it is the four-layer model proposed by Lucantoni et al. [51], combining acquisition, preprocessing, analysis, and decision support, or the three-part architectures integrating sensors, communication gateways, and the cloud [53,55], a clear hierarchy is essential to organize information flows and make the system scalable and interoperable. This approach is reinforced by the use of open and accessible tools like Arduino, Raspberry Pi, or ThingSpeak, making solutions feasible even for SMEs with limited resources [74].

The second key area lies in advanced data exploitation, notably through ARM [51,63,67,74], as well as FMEA [63] and multivariate statistical analyses [67]. These methods allow for the automatic detection of root causes of failures, the prioritization of issues, and the proposal of targeted corrective actions, thus reducing full dependence on human expertise. The combined use of ARM and network analysis, as in the works of Lucantoni and Mendes [51,74], helps map complex relationships between events and OEE factors, facilitating both tactical and strategic decision-making.

System responsiveness and its ability to support real-time maintenance are also key components of a digital standard. Mendes et al., [53,55] highlights the importance of instant visualization, automatic alerts, and prioritized incident reporting. This enables coordinated involvement across all organizational levels (operators, team leaders, management) and reinforces TPM culture by fully integrating maintenance into daily operations.

However, these technological systems cannot yield lasting results without the human and organizational integration of TPM principles. All high-performing models reviewed include continuous training, autonomous maintenance, standardized routines, and active operator participation in anomaly detection and resolution. This coexistence of human and digital intelligence is particularly emphasized by Lucantoni et al. [51] and Mendes et al. [53,74], who combine traditional TPM with Industry 4.0 tools in a structured continuous improvement cycle based on the PDCA (Plan–Do–Check–Act) model.

Lastly, sustainability and flexibility emerge as complementary requirements for any standardized framework. The MMSO approach (Modified MultiStep Outflow) [74] is exemplary in this regard, integrating Lean principles, low-impact and modular technologies, and a strong focus on energy performance.

5. Towards a Standardized Framework for Digital TPM Implementation

The purpose of this study is not limited to the bibliometric and thematic mapping of digital TPM literature. Rather, it aims to extract and consolidate the constitutive elements of a standardized implementation framework for TPM4.0. In a rapidly evolving digital industrial environment, the absence of a common reference model leads to inconsistent practices, limited scalability, and uneven performance outcomes, particularly among SMEs, which often lack the resources for extensive technological integration. Establishing a shared standard would provide a coherent structure to guide organizations in aligning technological innovations with the historical pillars of TPM while preserving its foundational philosophy of collective responsibility and continuous improvement.

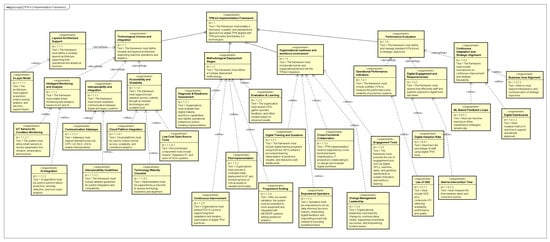

Based on the analysis in the previous section, a robust framework must integrate four complementary dimensions: (i) technological choices and integration logic; (ii) methodological deployment stages; (iii) organizational readiness and workforce involvement; and (iv) performance evaluation using standardized metrics. These dimensions constitute the backbone of a practical, adaptable, and scalable reference model for digital TPM implementation.

5.1. Technological Choices and Integration Logic

Starting first with the technological level, a standardized framework should be built on a modular and layered architecture that supports both real-time operations and advanced analytics. In most cases, as reported in the literature, implementations follow a four-layer model comprising data acquisition, preprocessing, analysis, and decision support. This structure enables the seamless integration of several critical technological enablers.

First, IoT devices and smart sensors play a central role by enabling condition monitoring through measurements of vibration, temperature, and pressure. Next, communication gateways ensure interoperability with existing legacy systems by supporting widely adopted protocols such as OPC-UA, BLE, and LIN. In addition, cloud platforms contribute by offering remote access, scalability, and centralized data analytics capabilities. Furthermore, AI algorithms enhance the framework’s intelligence, enabling functions such as failure prediction, anomaly detection, and root cause analysis. Finally, digital twins and simulation models provide tools for virtually testing maintenance strategies and conducting scenario planning

To ensure broader accessibility, especially for SMEs, particular emphasis must be placed on low-cost and open-source solutions such as the Arduino, Raspberry Pi, and open-source SCADA systems. Moreover, the framework should incorporate interoperability guidelines and include technology maturity checklists to support consistent and reliable implementation across different contexts.

5.2. Methodological Deployment Stages

Another critical factor for the successful implementation of TPM 4.0 is the adoption of a structured and phased deployment strategy. Drawing on empirical findings and industrial case studies, the proposed framework outlines five key stages to guide this transformation:

The first stage involves a Diagnosis and Readiness Assessment, during which organizations identify existing bottlenecks, evaluate the digital maturity of their systems, and assess the digital competencies of their workforce. This foundational step ensures that subsequent actions are tailored to the current context.

Following this, the Pilot Implementation phase focuses on the initial deployment of IoT technologies and monitoring tools, typically applied to selected critical equipment or production lines. This controlled setup allows for manageable experimentation and early validation.

Next, the Evaluation and Learning phase centers on measuring key performance indicators, such as OEE and MTTR, alongside collecting user feedback and refining digital models based on operational results.

Once early successes have been validated, organizations move to Progressive Scaling, which involves expanding the solution to additional assets, integrating it with existing MES or ERP systems, and incorporating more advanced analytics capabilities.

The final stage, Continuous Improvement, institutionalizes the use of PDCA cycles, enabling organizations to adapt to shifting conditions and embed feedback loops for ongoing optimization.

5.3. Organizational Readiness and Workforce Involvement

While technology is a key enabler of TPM 4.0, it cannot, on its own, guarantee successful implementation. To achieve a meaningful and lasting impact, the human and organizational dimensions must be fully integrated into the standardized framework. This integration reinforces the foundational values of TPM, namely, operator involvement, shared ownership, and structured discipline.

First, digital training programs must go beyond traditional instruction by incorporating tools such as augmented reality for procedural guidance, interpreting predictive maintenance outputs, and navigating performance dashboards. This ensures that operators are equipped to engage with digital tools confidently and effectively.

In parallel, the concept of autonomous maintenance must evolve. Rather than serving as passive executors, operators should be empowered as data-informed decision-makers, capable of interpreting system feedback and acting proactively.

Equally important is the establishment of collaborative structures. Cross-functional TPM teams, comprising maintenance, IT, and production personnel, should work together to co-design and evaluate digital workflows. Such collaboration fosters alignment and breaks down operational silos.

To support this shift, change management must be actively led by organizational leadership. Clear communication, a focus on incremental successes, and the empowerment of frontline teams are essential to driving cultural transformation and ensuring buy-in at all levels.

Finally, practical success stories highlight the effectiveness of tools such as standardized digital One-Point Lessons (OPLs), real-time alert systems, and gamified dashboards in boosting operator engagement, reinforcing learning, and sustaining motivation.

5.4. Performance Evaluation Using Standardized Metrics

Ultimately, the effectiveness of any TPM 4.0 initiative lies in its ability to demonstrate tangible impact through clearly defined performance metrics. To this end, the standardized framework must incorporate a core set of indicators that align operational outcomes with strategic objectives. Key among these is OEE, a synthetic KPI that captures availability, performance, and quality in a single measure. Complementing this, MTBF and MTTR provide insights into equipment reliability and maintainability. The Digital Adoption Rate, which reflects the percentage of staff actively using digital TPM tools, offers a measure of cultural integration and user engagement. In addition, Alert-to-Intervention Time is essential for evaluating real-time responsiveness and operational agility.

These metrics should be continuously monitored via digital dashboards and directly connected to broader business goals. Furthermore, integrating feedback loops, especially those powered by machine learning, enables the dynamic refinement of maintenance policies and operational strategies over time. Beyond their evaluative function, these standardized indicators also serve as a communication tool, fostering alignment across departments and improving transparency with external stakeholders.

Bringing these elements together, the successful implementation of TPM 4.0 requires more than the adoption of advanced technologies, it demands a holistic, structured, and inclusive approach. A robust digital TPM framework must integrate modular technological architectures, a phased deployment methodology, active workforce involvement, and performance monitoring grounded in standardized metrics. By aligning these four dimensions, organizations can ensure not only technical efficiency but also cultural integration, strategic coherence, and long-term adaptability. Ultimately, such a framework positions TPM 4.0 as a catalyst for operational excellence in the digital era, particularly when tailored to the constraints and opportunities of diverse industrial contexts, including SMEs.

To support this framework, a SysML requirements diagram was developed to formalize and structure the key elements of TPM 4.0 implementation. As demonstrated in the Figure 8 below, the diagram organizes the four main dimensions into hierarchical requirements, highlighting their internal structure and interdependencies. This model enhances clarity and traceability, and provides a foundation for system design and implementation alignment.

Figure 8.

Structured representation of TPM 4.0’s implementation requirements.

Although the proposed framework brings together the essential components for standardizing digital TPM implementation, certain limitations must be considered to better understand the potential constraints and challenges that may arise in its practical applications. First, industrial requirements vary significantly across sectors, which may affect the direct applicability of the framework without contextual adaptation. What works in the automotive industry, for example, may not be fully suitable for the food or chemical sector due to different regulatory, operational, and technical constraints. Second, human factors and resistance to organizational change remain critical challenges in the adoption of digital practices. Even well-designed technical solutions can face significant barriers if the workforce is not adequately engaged or trained. Third, the limited willingness of some industrial companies to collaborate with academic research poses a barrier to the empirical validation and iterative improvement of the model. Without access to real-world case studies and implementation environments, the framework cannot yet be tested or refined in practice. However, these limitations do not diminish the relevance of the framework, but rather, emphasize the importance of future efforts to tailor and test it through stronger industry–academia partnerships.

6. Conclusions and Perspectives

In an increasingly digitalized industrial landscape, maintenance has evolved from a reactive support function into a strategic lever for performance, flexibility, and competitiveness. This shift is particularly significant in the era of Industry 4.0, where the convergence of CPSs, AI, and real-time data analytics is fundamentally reshaping traditional production and maintenance paradigms. Within this changing environment, TPM must now be redefined to align with new technological and organizational imperatives.

To address this issue, this article adopted a two-phase methodology: a bibliometric analysis to map the scientific landscape of digital TPM, followed by a systematic literature review to identify and synthesize key technological and conceptual contributions. The analysis of 58 relevant publications highlighted the main enablers of digital TPM, including the IoT, AI, digital twins, and augmented reality, and demonstrated how these technologies are transforming the foundational TPM pillars. In parallel, the study outlined both the opportunities offered by digital TPM (improved OEE, predictive maintenance, enhanced operator autonomy) and the persistent challenges (technological integration, training gaps, cultural resistance).

Despite the growing interest in this topic, the current literature remains fragmented and primarily focused on isolated or sector-specific implementations. A clear theoretical and practical standard is still lacking, limiting the scalability and consistency of TPM 4.0 adoption—particularly among small and medium-sized enterprises. To bridge this gap, this study proposed a foundation for a standardized implementation framework, structured around four key dimensions: (i) modular technological integration; (ii) a phased deployment methodology; (iii) organizational readiness and cross-functional collaboration; and (iv) performance evaluation through standardized indicators such as OEE, MTBF, and MTTR.

These dimensions together form the conceptual basis for a scalable and operational reference model that is both academically grounded and industrially applicable. They provide a roadmap for organizations seeking to align traditional TPM principles with the demands of smart manufacturing while also enhancing adaptability and resilience in the face of ongoing digital transformation.

As a continuation of this research, future work will focus on the detailed development and validation of a generalized framework for digital TPM, grounded in the dimensions identified here and enriched through empirical case studies. This next phase will aim to fill the gap between theoretical modeling and practical deployment, contributing to both academic knowledge and industrial excellence in smart maintenance.

Author Contributions

Conceptualization, Z.M. and M.G.; methodology, Z.M.; validation, M.G., S.M., and A.S.; formal analysis, Z.M., M.G., and A.S.; investigation Z.M. and M.G.; resources, Z.M. and M.G.; data curation, Z.M.; writing—original draft preparation, Z.M.; writing—review and editing, Z.M., M.G., and M.D.N.; visualization, M.G., S.M., and A.S.; supervision, Z.M. and M.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ahuja, I.P.S.; Khamba, J.S. Total Productive Maintenance: Literature Review and Directions. Int. J. Qual. Reliab. Manag. 2008, 25, 709–756. [Google Scholar] [CrossRef]

- Gackowiec, P. General Overview of Maintenance Strategies—Concepts and Approaches. Multidiscip. Asp. Prod. Eng. 2019, 2, 126–139. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Introna, V.; Santolamazza, A.; Cesarotti, V. Maintenance Transformation through Industry 4.0 Technologies: A Systematic Literature Review. Comput. Ind. 2020, 123, 103335. [Google Scholar] [CrossRef]

- Eddarhri, M.; Adib, J.; Hain, M.; Marzak, A. Towards Predictive Maintenance: The Case of the Aeronautical Industry. Procedia Comput. Sci. 2022, 203, 769–774. [Google Scholar] [CrossRef]

- Geary, R.; Cosgrove, J. Manufacturing Reliability and Cost Improvements through Data Analytics: An Industry Case Study. Procedia Comput. Sci. 2023, 217, 395–402. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fogliatto, F.S.; Cauchick-Miguel, P.A.; Kurnia, S.; Jurburg, D. Integration of Industry 4.0 Technologies into Total Productive Maintenance Practices. Int. J. Prod. Econ. 2021, 240, 108224. [Google Scholar] [CrossRef]

- Meindl, B.; Mendonça, J. Mapping Industry 4.0 Technologies: From Cyber-Physical Systems to Artificial Intelligence. arXiv 2021, arXiv:2111.14168. [Google Scholar]

- Rødseth, H.; Schjølberg, P.; Marhaug, A. Deep Digital Maintenance. Adv. Manuf. 2017, 5, 299–310. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Saurin, T.A.; Fogliatto, F.S.; Mendoza, D.T.; Moyano-Fuentes, J.; Gaiardelli, P.; Seyedghorban, Z.; Vassolo, R.; Vergara, A.F.M.C.; Sunder, V.M.; et al. Digitalization of Maintenance: Exploratory Study on the Adoption of Industry 4.0 Technologies and Total Productive Maintenance Practices. Prod. Plan. Control 2024, 35, 352–372. [Google Scholar] [CrossRef]

- Nakajima, S. Introduction to TPM: Total Productive Maintenance; Productivity Press: Cambridge, MA, USA, 1988. [Google Scholar]

- Ahuja, I.P.S.; Khamba, J.S. Justification of Total Productive Maintenance Initiatives in Indian Manufacturing Industry for Achieving Core Competitiveness. J. Manuf. Technol. Manag. 2008, 19, 645–669. [Google Scholar] [CrossRef]

- Jain, A.; Bhatti, R.; Singh, H. Total Productive Maintenance (TPM) Implementation Practice: A Literature Review and Directions. Int. J. Lean Six Sigma 2014, 5, 293–323. [Google Scholar] [CrossRef]

- Agustiady, T.K.; Cudney, E.A. Total Productive Maintenance: Strategies and Implementation Guide; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- San, S. A Systematic Literature Review of Total Productive Maintenance on Industries. Performa 2021, 20, 97. [Google Scholar] [CrossRef]

- Reis, M.D.O.D.; Godina, R.; Pimentel, C.; Silva, F.J.G.; Matias, J.C.O. A TPM Strategy Implementation in an Automotive Production Line through Loss Reduction. Procedia Manuf. 2019, 38, 908–915. [Google Scholar] [CrossRef]

- Singh, J.; Singh, H. Justification of TPM Pillars for Enhancing the Performance of Manufacturing Industry of Northern India. Int. J. Product. Perform. Manag. 2019, 69, 109–133. [Google Scholar] [CrossRef]

- Hanged, W.S.; Kumar, S. TPM—A Key Strategy for Productivity Improvement in Medium Scale Industry. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 485–492. [Google Scholar]

- Parikh, Y.; Mahamuni, P. Total Productive Maintenance: Need & Framework. Int. J. Innov. Res. Adv. Eng. 2015, 2, 126–130. [Google Scholar]

- Sharma, A.K. Manufacturing Performance and Evolution of TPM. Int. J. Eng. Sci. Technol. 2012, 4, 854–866. [Google Scholar]

- Tortorella, G.L.; Fettermann, D. Implementation of Industry 4.0 and Lean Production in Brazilian Manufacturing Companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Serpanos, D.; Wolf, M. Industrial Internet of Things. In Internet-of-Things (IoT) Systems; Springer International Publishing: Cham, Switzerland, 2018; pp. 37–54. [Google Scholar]

- Prinz, C.; Kreimeier, D.; Kuhlenkötter, B. Implementation of a Learning Environment for an Industrie 4.0 Assistance System to Improve the Overall Equipment Effectiveness. Procedia Manuf. 2017, 9, 159–166. [Google Scholar] [CrossRef]

- Chang, T.-W.; Cho, E.; Jun, J.-H.; Ahn, H. Implementation of Smart Factory for SME: Focusing on Data Acquisition and Monitoring. ICIC Express Lett. Part B Appl. 2019, 10, 551–558. [Google Scholar]

- Wang, T.-Y.; Pan, H.-C. Improving the OEE and UPH Data Quality by Automated Data Collection for the Semiconductor Assembly Industry. Expert Syst. Appl. 2011, 38, 5764–5773. [Google Scholar] [CrossRef]

- Toro, C.; Wang, W.; Akhtar, H. Implementing Industry 4.0; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar]

- Bonada, F.; Echeverria, L.; Domingo, X.; Anzaldi, G. AI for Improving the Overall Equipment Efficiency in Manufacturing Industry. In New Trends in the Use of Artificial Intelligence for the Industry 4.0; Romeral Martínez, L., Osornio Rios, R.A., Delgado Prieto, M., Eds.; IntechOpen: London, UK, 2020. [Google Scholar]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Chia, B.C.L.; Yuen, K.Y.; Woon, K.S. Digital Twin for Overall Equipment Effectiveness in Intelligent Production Planning. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Rosales, J.; Deshpande, S.; Anand, S. IIoT Based Augmented Reality for Factory Data Collection and Visualization. Procedia Manuf. 2021, 53, 618–627. [Google Scholar] [CrossRef]

- Bellalouna, F. Digitization of Industrial Engineering Processes Using the Augmented Reality Technology: Industrial Case Studies. Procedia CIRP 2021, 100, 554–559. [Google Scholar] [CrossRef]

- Di Bona, G.; Cesarotti, V.; Arcese, G.; Gallo, T. Implementation of Industry 4.0 Technology: New Opportunities and Challenges for Maintenance Strategy. Procedia Comput. Sci. 2021, 180, 424–429. [Google Scholar] [CrossRef]

- Rahman, M.; Chakrabartty, S. GPS-free synchronized pseudo-random number generators for internet-of-things. Front. Comput. Sci. 2023, 5, 1157629. [Google Scholar] [CrossRef]

- Abdel-Aty, T.A.; Negri, E. Conceptualizing the Digital Thread for Smart Manufacturing: A Systematic Literature Review. J. Intell. Manuf. 2024, 35, 3629–3653. [Google Scholar] [CrossRef]

- Goswami, M.; Daultani, Y. Make-in-India and Industry 4.0: Technology Readiness of Select Firms, Barriers and Socio-Technical Implications. TQM J. 2022, 34, 1485–1505. [Google Scholar] [CrossRef]

- Scott, T.; Walsh, A.; Anderson, B.; O’Connor, A.; Tassey, G. High-Tech Infrastructure and Economic Growth: The Materials Genome Initiative. Sci. Public Policy 2021, 48, 649–661. [Google Scholar] [CrossRef]

- Georgescu, A.; Tudose, M.B.; Avasilcăi, S. Digital Innovation Hubs: SMEs’ Facilitators for Digital Innovation Projects, Marketing Communication Strategies and Business Internationalization. In Marketing and Smart Technologies: Proceedings of ICMarkTech 2022; Springer Nature: Singapore, 2023; Volume 2, pp. 307–330. [Google Scholar]

- Carrasco, E.R.; Williams, S. Emerging Economies after the Global Financial Crisis: The Case of Brazil. Nw. J. Int’l L. Bus. 2012, 33, 81. [Google Scholar]

- Maimbo, S.M.; Faye, I.; Triki, T. Financing Africa: Through the Crisis and Beyond; World Bank Publications: Washington, DC, USA, 2011. [Google Scholar]

- Xhala, N.C. Challenges and Lessons Learnt in the Financing of Public Infrastructure in South Africa, Czech and Slovak Republics: A Comparative Study. Ph.D. Thesis, University of the Free State, Bloemfontein, South Africa, 2017. [Google Scholar]

- Estache, A. Emerging Infrastructure Policy Issues in Developing Countries: A Survey of the Recent Economic Literature; World Bank Publications: Washington, DC, USA, 2004; Volume 3442. [Google Scholar]

- Poór, P.; Basl, J.; Zenisek, D. Predictive Maintenance 4.0 as Next Evolution Step in Industrial Maintenance Development. In Proceedings of the 2019 International Research Conference on Smart Computing and Systems Engineering (SCSE), Colombo, Sri Lanka, 28 March 2019; pp. 245–253. [Google Scholar]

- Mohan, T.R.; Roselyn, J.P.; Uthra, R.A.; Devaraj, D.; Umachandran, K. Intelligent Machine Learning Based Total Productive Maintenance Approach for Achieving Zero Downtime in Industrial Machinery. Comput. Ind. Eng. 2021, 157, 107267. [Google Scholar] [CrossRef]

- Amruthnath, N.; Gupta, T. Fault Class Prediction in Unsupervised Learning Using Model-Based Clustering Approach. In Proceedings of the 2018 International Conference on Information and Computer Technologies (ICICT), DeKalb, IL, USA, 23–25 March 2018; pp. 5–12. [Google Scholar]

- Koenig, F.; Found, P.A.; Kumar, M. Innovative Airport 4.0 Condition-Based Maintenance System for Baggage Handling DCV Systems. Int. J. Product. Perform. Manag. 2019, 68, 561–577. [Google Scholar] [CrossRef]

- Hardt, F.; Kotyrba, M.; Volna, E.; Jarusek, R. Innovative Approach to Preventive Maintenance of Production Equipment Based on a Modified TPM Methodology for Industry 4.0. Appl. Sci. 2021, 11, 6953. [Google Scholar] [CrossRef]

- Tripathi, V.; Chattopadhyaya, S.; Bhadauria, A.; Sharma, S.; Li, C.; Pimenov, D.Y.; Giasin, K.; Singh, S.; Gautam, G.D. An Agile System to Enhance Productivity through a Modified Value Stream Mapping Approach in Industry 4.0: A Novel Approach. Sustainability 2021, 13, 11997. [Google Scholar] [CrossRef]

- Zarreh, A.; Wan, H.; Lee, Y.; Saygin, C.; Al Janahi, R. Cybersecurity Concerns for Total Productive Maintenance in Smart Manufacturing Systems. Procedia Manuf. 2019, 38, 532–539. [Google Scholar] [CrossRef]

- Klimecka-Tatar, D.; Ingaldi, M. Digitization of Processes in Manufacturing SMEs—Value Stream Mapping and OEE Analysis. Procedia Comput. Sci. 2022, 200, 660–668. [Google Scholar] [CrossRef]

- Tortorella, G.; Saurin, T.A.; Fogliatto, F.S.; Tlapa, D.; Moyano-Fuentes, J.; Gaiardelli, P.; Seyedghorban, Z.; Vassolo, R.; Mac Cawley, A.F.; Sunder, M.V.; et al. The Impact of Industry 4.0 on the Relationship between TPM and Maintenance Performance. J. Manuf. Technol. Manag. 2022, 33, 489–520. [Google Scholar] [CrossRef]

- Mouhib, Z.; Naciri, L.; Gallab, M.; Merzouk, S.; Soulhi, A.; Bhiri, B.E.L.; Dinardo, M. TPM and TQM: What Connections and How They Are Changing Through Industry 4.0 Technologies? In Smart Mobility and Industrial Technologies: The Quality of Life in Sustainable Cities; International Conference on Advanced Technologies for Humanity; Springer Nature: Cham, Switzerland, 2022; pp. 125–134. [Google Scholar]

- Lucantoni, L.; Antomarioni, S.; Ciarapica, F.E.; Bevilacqua, M. A Data-Driven Framework for Supporting the Total Productive Maintenance Strategy. Expert Syst. Appl. 2025, 268, 126283. [Google Scholar] [CrossRef]

- Aranda-Gonzales, K.; Sanchez-Gutierrez, A.; Saenz-Moron, M. Increase in Operational Availability in Agricultural Fertilizer Production: A TPM Approach with Internet of Things (IoT). In Proceedings of the LACCEI International Multi-Conference for Engineering, Education and Technology, San Jose, Costa Rica, 17–19 July 2024. [Google Scholar]

- Mendes, D.; Gaspar, P.D.; Charrua-Santos, F.; Navas, H. Integrating TPM and Industry 4.0 to Increase the Availability of Industrial Assets: A Case Study on a Conveyor Belt. Processes 2023, 11, 1956. [Google Scholar] [CrossRef]

- Mohan, R.; Roselyn, J.P.; Uthra, R.A. LSTM Based Artificial Intelligence Predictive Maintenance Technique for Availability Rate and OEE Improvement in a TPM Implementing Plant through Industry 4.0 Transformation. J. Qual. Maint. Eng. 2023, 29, 763–798. [Google Scholar] [CrossRef]

- Mendes, D.; Gaspar, P.D.; Charrua-Santos, F.; Navas, H. Enhanced Real-Time Maintenance Management Model—A Step toward Industry 4.0 through Lean: Conveyor Belt Operation Case Study. Electronics 2023, 12, 3872. [Google Scholar] [CrossRef]

- Tripathi, V.; Chattopadhyaya, S.; Mukhopadhyay, A.K.; Sharma, S.; Li, C.; Singh, S.; Hussan, W.U.; Salah, B.; Saleem, W.; Mohamed, A. A Sustainable Productive Method for Enhancing Operational Excellence in Shop Floor Management for Industry 4.0 Using Hybrid Integration of Lean and Smart Manufacturing: An Ingenious Case Study. Sustainability 2022, 14, 7452. [Google Scholar] [CrossRef]

- Torre, N.; Leo, C.; Bonamigo, A. Lean 4.0: An analytical approach for hydraulic system maintenance in a production line of a steel-making plant. Int. J. Ind. Eng. Manag. 2023, 14, 186–199. [Google Scholar] [CrossRef]

- Roosefert Mohan, T.; Preetha Roselyn, J.; Annie Uthra, R. LSTM Based Predictive Maintenance Approach for Zero Breakdown in Foundry Line Through Industry 4.0. In Recent Advances in Intelligent Manufacturing: Select Proceedings of ICAME 2022; International Conference on Advancement in Manufacturing Engineering; Springer Nature: Singapore, 2022; pp. 29–51. [Google Scholar]

- Gosavi, A.; Gosavi, A. A Simulation-Based Digital Twin for Data-Driven Maintenance Scheduling of Risk-Prone Production Lines via Actor Critics. Flex. Serv. Manuf. J. 2024, 1–30. [Google Scholar] [CrossRef]

- Venâncio, A.L.A.C.; de Freitas Rocha Loures, E.; Deschamps, F.; dos Santos Justus, A.; Lumikoski, A.F.; Brezinski, G.L. Technology Prioritization Framework to Adapt Maintenance Legacy Systems for Industry 4.0 Requirement: An Interoperability Approach. Production 2022, 32, e20210035. [Google Scholar] [CrossRef]

- Samadhiya, A.; Agrawal, R.; Luthra, S.; Kumar, A.; Garza-Reyes, J.A.; Srivastava, D.K. Total Productive Maintenance and Industry 4.0 in a Sustainability Context: Exploring the Mediating Effect of Circular Economy. Int. J. Logist. Manag. 2023, 34, 818–846. [Google Scholar] [CrossRef]

- Braglia, M.; Castellano, D.; Frosolini, M.; Marrazzini, L.; Padellini, L. An Ensemble-Learning Model for Failure Rate Prediction. Procedia Manuf. 2020, 42, 41–48. [Google Scholar] [CrossRef]

- Antomarioni, S.; Lucantoni, L.; Ciarapica, F.E.; Bevilacqua, M. A Preliminary Implementation of Data-Driven TPM: A Real Case Study. In 16th WCEAM Proceedings; World Congress on Engineering Asset Management; Springer International Publishing: Cham, Switzerland, 2022; pp. 14–22. [Google Scholar]

- Encapera, A.; Gosavi, A.; Murray, S.L. Total Productive Maintenance of Make-to-Stock Production-Inventory Systems via Artificial-Intelligence-Based iSMART. Int. J. Syst. Sci. Oper. Logist. 2021, 8, 154–166. [Google Scholar] [CrossRef]

- Pannu, N.; Chawla, A.; Tewari, P.C. Computerized Maintenance Management System for Thermal Power Plant, Hisar. J. Phys. Conf. Ser. 2019, 1240, 012012. [Google Scholar] [CrossRef]

- Wszołek, G.; Czop, P.; Słoniewski, J.; Dogrusoz, H. Vibration Monitoring of CNC Machinery Using MEMS Sensors. J. Vibroeng. 2020, 22, 735–750. [Google Scholar] [CrossRef]

- Lucantoni, L.; Antomarioni, S.; Ciarapica, F.E.; Bevilacqua, M. A Rule-Based Machine Learning Methodology for the Proactive Improvement of OEE: A Real Case Study. Int. J. Qual. Reliab. Manag. 2023, 41, 1356–1376. [Google Scholar] [CrossRef]

- Okokpujie, I.P.; Tartibu, L.K.; Omietimi, B.H. Improving the Maintainability and Reliability in Nigerian Industry 4.0: Its Challenges and the Way Forward from the Manufacturing Sector. Int. J. Sustain. Dev. Plan. 2023, 18, 2489. [Google Scholar] [CrossRef]

- Grajzova, L.; Janik, S.; Cambal, M.; Mlkva, M. Analysis of the Current Application of AR in the Context of TPM in Slovakia Organizations. Ann. DAAAM Proc. 2021, 32. [Google Scholar] [CrossRef]

- Medyński, D.; Bonarski, P.; Motyka, P.; Wysoczański, A.; Gnitecka, R.; Kolbusz, K.; Dąbrowska, M.; Burduk, A.; Pawelec, Z.; Machado, J. Digital Standardization of Lean Manufacturing Tools According to Industry 4.0 Concept. Appl. Sci. 2023, 13, 6259. [Google Scholar] [CrossRef]

- Encapera, A.; Gosavi, A. A New Reinforcement Learning Algorithm with Fixed Exploration for Semi-Markov Control in Preventive Maintenance. In Proceedings of the ASME 2017 12th International Manufacturing Science and Engineering Conference, Los Angeles, CA, USA, 4–8 June 2017; ASME: New York, NY, USA, 2017; Volume 50749, p. V003T04A061. [Google Scholar]

- Tortorella, G.L.; Silva, E.; Vargas, D. An Empirical Analysis of Total Quality Management and Total Productive Maintenance in Industry 4.0. In Proceedings of the International Conference on Industrial Engineering and Operations Management (IEOM), Johannesburg, South Africa, 29 October–1 November 2018; pp. 742–753. [Google Scholar]

- Rakyta, M.; Bubenik, P.; Binasova, V.; Gabajova, G.; Staffenova, K. The Change in Maintenance Strategy on the Efficiency and Quality of the Production System. Electronics 2024, 13, 3449. [Google Scholar] [CrossRef]

- Mendes, D.; Gaspar, P.D.; Charrua-Santos, F.; Navas, H. Synergies between lean and Industry 4.0 for enhanced maintenance management in sustainable operations: A model proposal. Processes 2023, 11, 2691. [Google Scholar] [CrossRef]