A Study of the Response Surface Methodology Model with Regression Analysis in Three Fields of Engineering

Abstract

1. Introduction

+ b23x2x3 + b24x2x4 + b34x3x4 + ε

2. Materials and Methods

2.1. Data Sources for the Equations of the Response Surface Methodology

2.2. Model Building for the Response Surface Methodology

2.3. Basic and Complete Regression Analyses

2.4. Assumptions Involved in the Regression Analysis

2.5. Establishment of the Model

2.6. Criteria for the Evaluation of RSM Equations

3. Results

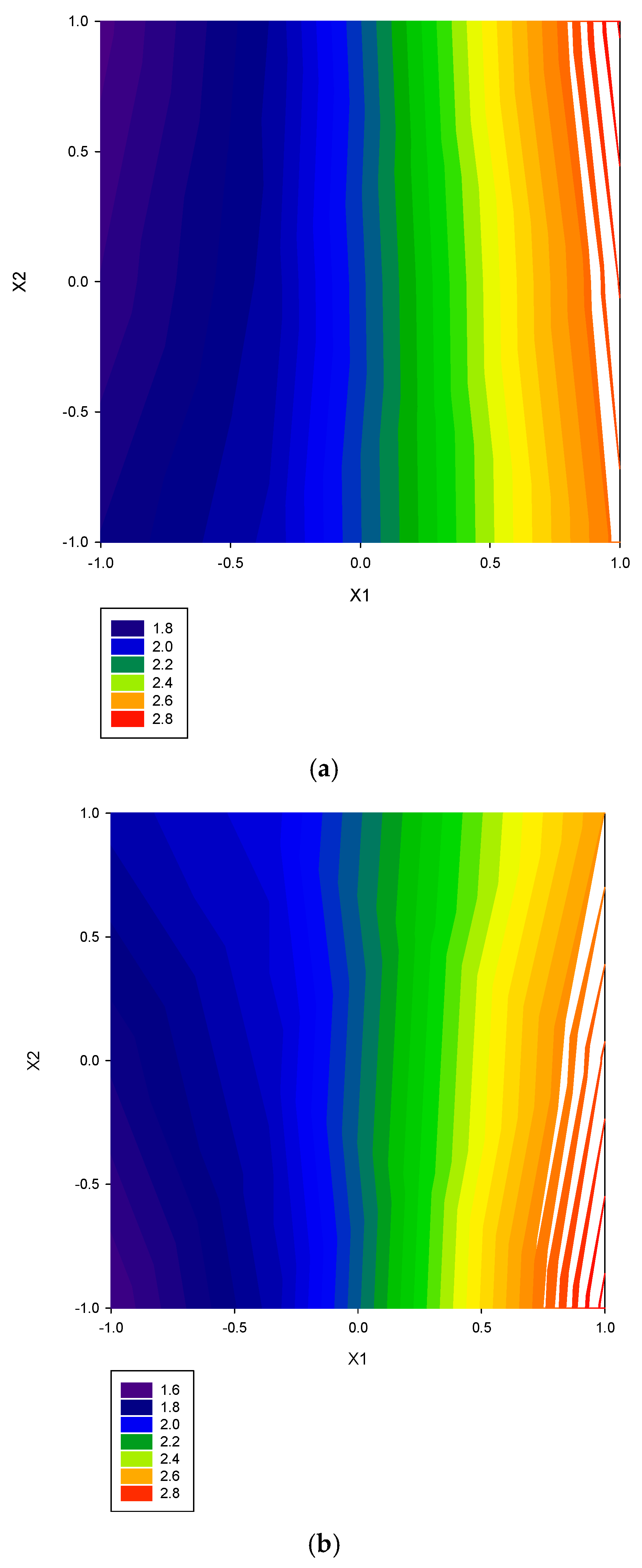

3.1. Semiconductor Manufacturing

(<0.001) (<0.001) (<0001) (0.317) (0.481)

−29.061x33 + 66.033x1x2 + 75.458x1x3 + 43.583x2x3

(0.363) (0.008) (0.003) (0.064)

R2 = 0.927, R2adj = 0.888, s = 76.111, PRESS = 337,737.94

(<0.001) (<0.001) (<0.001) (0.310) (0.356)

+ 66.033x1x2 + 75.458x1x3 + 45.583x2x3

(0.007) (0.003) (0.006)

(<0.001) (<0.001) (<0.001) (0.308) (0.007)

+ 75.458x1x3 + 43.458x2x3

(0.002) (0.058)

(<0.001) (<0.001) (<0.001) (0.006) (0.002)

+ 47.583x2x3

(0.0058)

R2 = 0.916, R2adj = 0.891, s = 75.068, PRESS = 288,457.9

(0.280) (0.156) (0.012) (0.818) (0.942)

−16.772x33 + 7.717x1x2 + 5.117x1x3 + 14.075x2x3

(0.362) (0.550) (0.691) (0.281)

R2 = 0.454, R2adj = 0.615, s = 43.817, PRESS = 93,044.256

(0.007)

R2 = 0.256, R2adj = 0.227, s = 42.171, PRESS = 52,441.283

(<0.001) (0.464) (0.027) (0.084) (0.931)

+ 0.223x32 + 0.0711x1x2 − 0.128x1x2 + 0.00125x2x3

(0.098) (0.302) (0.095) (0.985)

R2 = 0.958, R2adj = 0.882, s = 0.172, PRESS = 1.299

(<0.001) (0.007) (0.030) (0.037) (0.044)

R2 = 0.941, R2adj = 0.909, s = 0.154, PRESS = 0.646

(<0.001) (0.006) (0.011) (0.001) (0.008)

+ 0.00815x32 − 0.0325x1x2 + 0.425x1x3 + 0.000150x2x3

(0.038) (0.661) (0.029) (0.919)

R2 = 0.974, R2adj = 0.928, s = 0.140, PRESS = 1.559

(<0.001) (<0.001) (0.002) (<0.001) (0.002)

+ 0.00815x32 + 0.425x1x3

(0.014) (0.010)

R2 = 0.973, R2adj = 0.946, s = 0.121, PRESS = 0.603

R2 = 0.813, R2adj = 0.763, s = 6.755, PRESS = 2307.945

−22.265x1x2

R2 = 0.922, R2adj = 0.886, s = 162.678, PRESS = 948,709.4

−8.908x32 − 1.204x1x3

R2 = 0.768, R2adj = 0.633, s = 15.875, PRESS = 13,369.7

R2 = 0.721, R2adj = 0.698, s = 138.318, PRESS = 328.601

R2 = 0.688, R2adj = 0.636, s = 14.801, PRESS = 4.068

(<0.001) (<0.001) (<0.001) (<0.001) (0.842) (0.376)

+ 1.192x32 − 0.258x42 + 0.825x1x2 + 1.800x1x3 − 0.925x1x4 + 0.425x2x3

(0.147) (0.731) (0.364) (0.062) (0.311) (0.635)

−0.400x2x4+ 1.350x3x4

(0.655) (0.148)

R2 = 0.975, R2adj = 0.945, s = 1.748, PRESS = 211.08

R2 = 0.962, R2adj = 0.95, s = 1.659, PRESS = 100.206

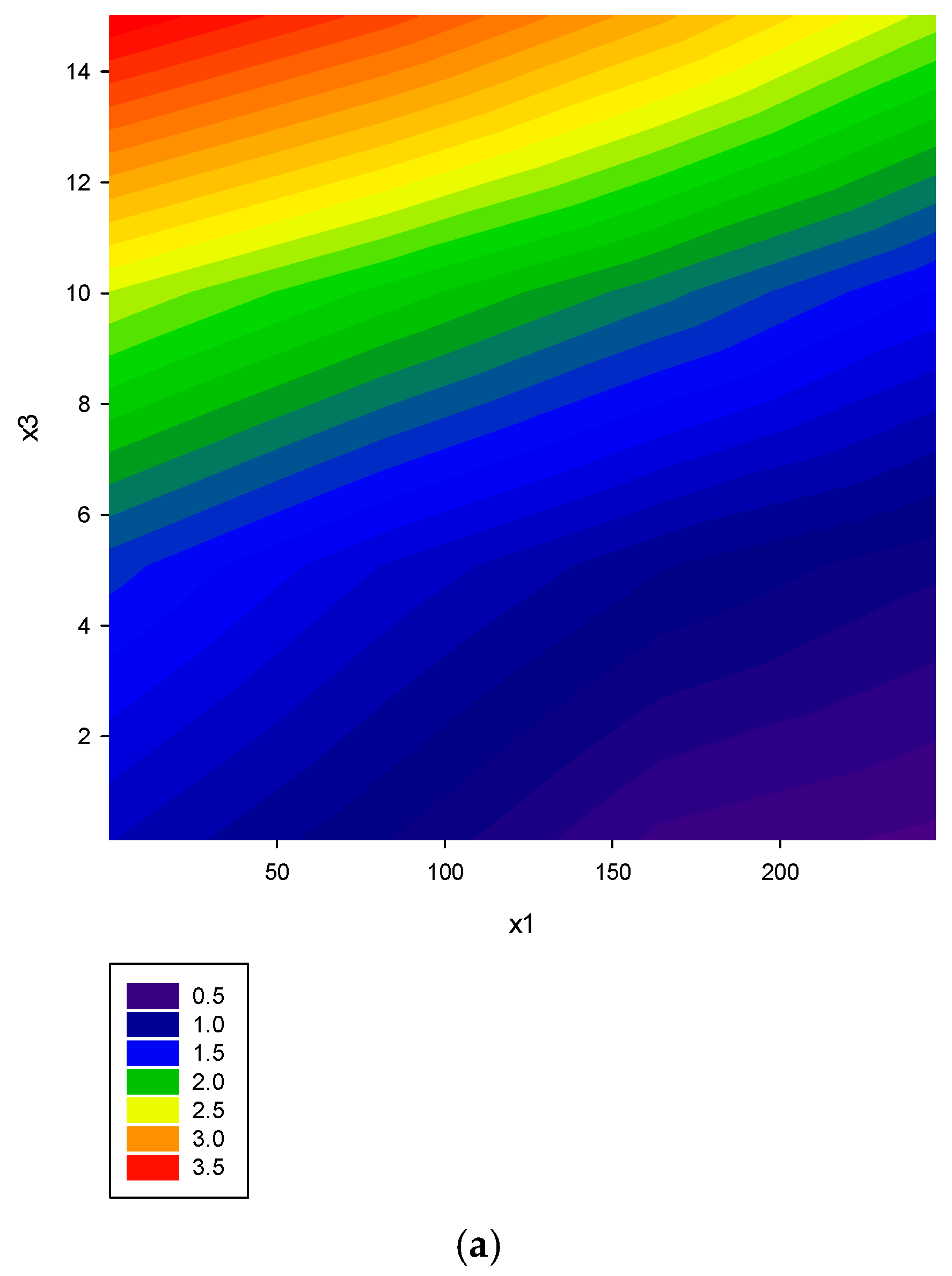

3.2. Steel Materials

R2 = 0.991, R2adj = 0.989, s = 0.018, PRESS = 0.0115

R2 = 0.986, R2adj = 0.982, s = 0.139, PRESS = 0.676

R2 = 0.993, R2adj = 0.990, s = 0.079, PRESS = 0.220

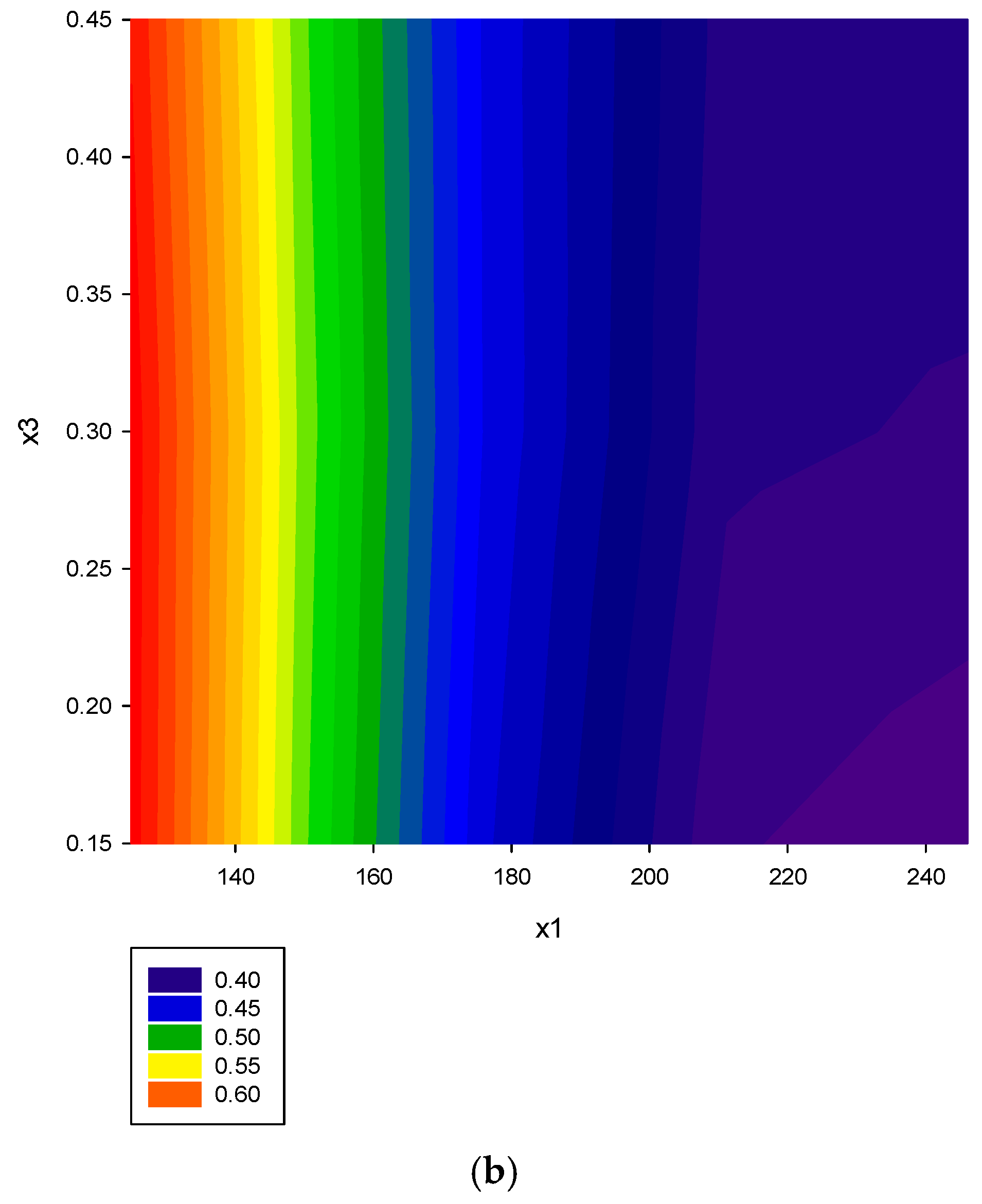

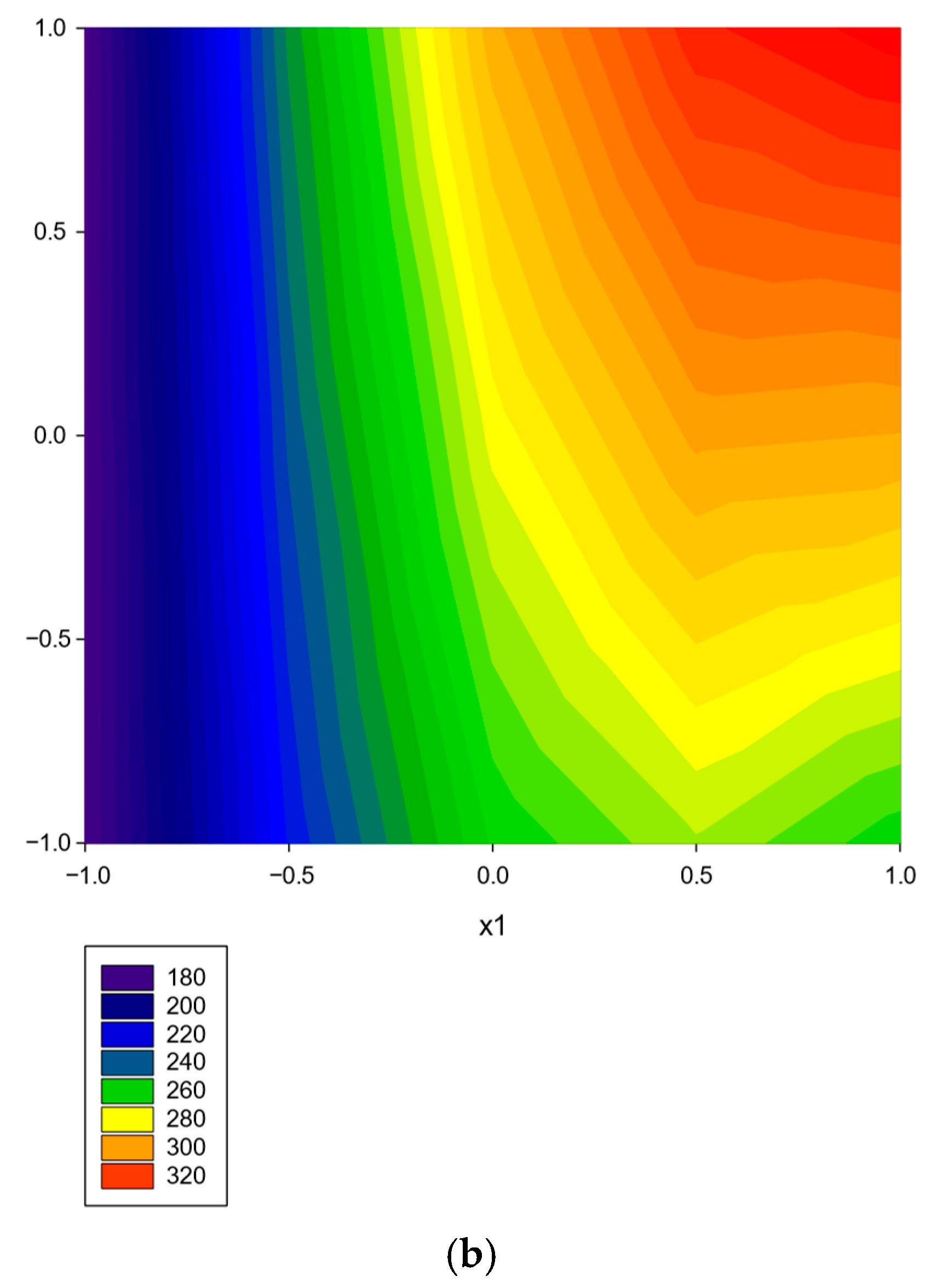

3.3. Nanomaterials

+ 17.501x1x2

−0.0000299x2x4 − 0.0000643x3x4

R2 = 0.86, R2adj = 0.797, s = 0.169, PRESS = 1.18

(0.629) (0.970) (0.985) (0.565) (0.997)

−0.432x32 − 0.00871x1x2 + 0.0113x1x3 + 0.0897x2x3

(0.739) (0.733) (0.566) (0.932)

R2 = 0.768, R2adj = 0.351, s = 7.154, PRESS = 6124.736

R2 = 0.651, R2adj = 0.592, s = 5.668, PRESS = 639.412

R2 = 0.814, R2adj = 0.789, s = 4.017, PRESS = 515.04

−0.000406x2x4

R2 = 0.984, R2adj = 0.979, s = 0.171, PRESS = 1.419

−0.0000171x2x3 + 0.000328x2x4 − 0.0000258x3x4

R2 = 0.979, R2adj = 0.970, s = 0.119, PRESS = 0.666

−0.00158x1x3 + 0.0000196x2x3

R2 = 0.998, R2adj = 0.997, s = 0.068, PRESS = 0.175

4. Discussion

- For engineers using RSM, receiving complete regression analysis training will help them in their research work. Engineers not only need to be able to use commercial software programs to calculate the estimated values of parameter coefficients but also need to be familiar with screening influencing variables, checking the conditions of regression analysis assumptions, and examining all possible influencing data points. Training in complete regression techniques can enhance researchers’ ability to establish appropriate RSM equations.

- Ask a statistician for help with the experimental design and verify the validity of the regression calculation.

- Many commercial software programs can calculate RSM models and create precision contour and response surface plots. The backward elimination technique is beneficial in finding an adequate equation. It is recommended to integrate this backward elimination method into commercial software to assist researchers in developing suitable RSM equations.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix A.1. Data from the Coating Experiment [49]

| Run | Speed | Pressure | Distance | Mean, y1 | Standard Deviation, y2 |

| 1 | −1 | −1 | −1 | 24 | 12.5 |

| 2 | 0 | −1 | −1 | 120.3 | 8.4 |

| 3 | +1 | −1 | −1 | 213.7 | 42.8 |

| 4 | −1 | 0 | −1 | 86 | 3.5 |

| 5 | 0 | 0 | −1 | 136.6 | 80.4 |

| 6 | +1 | 0 | −1 | 340.7 | 16.2 |

| 7 | −1 | +1 | −1 | 112.3 | 27.6 |

| 8 | 0 | +1 | −1 | 256.3 | 4.6 |

| 9 | +1 | +1 | −1 | 271.7 | 23.6 |

| 10 | −1 | −1 | 0 | 81 | 0.0 |

| 11 | 0 | −1 | 0 | 101.7 | 17.7 |

| 12 | +1 | −1 | 0 | 357.0 | 32.9 |

| 13 | −1 | 0 | 0 | 171.3 | 15.0 |

| 14 | 0 | 0 | 0 | 372.0 | 0.0 |

| 15 | +1 | 0 | 0 | 501.7 | 92.5 |

| 16 | −1 | +1 | 0 | 264.0 | 63.5 |

| 17 | 0 | +1 | 0 | 427.0 | 88.6 |

| 18 | +1 | +1 | 0 | 730.7 | 21.1 |

| 19 | −1 | −1 | +1 | 220.7 | 133.8 |

| 20 | 0 | −1 | +1 | 239.7 | 23.5 |

| 21 | +1 | −1 | +1 | 422.0 | 18.5 |

| 22 | −1 | 0 | +1 | 199.0 | 29.4 |

| 23 | 0 | 0 | +1 | 485.3 | 44.7 |

| 24 | +1 | 0 | +1 | 673.7 | 158.2 |

| 25 | −1 | +1 | +1 | 176.7 | 55.5 |

| 26 | 0 | +1 | +1 | 501.0 | 138.9 |

| 27 | +1 | +1 | +1 | 1010.0 | 142.4 |

Appendix A.2. Evaluation of the RSM Models for yRa, Ra Surface Roughness [28]

(0.403) (0.490) (0.541) (0.245) (0.468)

+ 0.419x32 − 0.0268x1x2 + 0.000110x1x3 + 1.375x2x3

(0.059) 0.192) (0.773) (0.031)

R2 = 0.982, R2adj = 0.954, s = 0.174, PRESS = 2.470

(0.358) (0.457) (0.559) (0.210) (0.433)

+ 0.0418x22 − 0.0268x1x2 + 1.375x2x3

(0.041) (0.159) (0.020)

(0.222) (<0.001) (0.652) (0.115) (0.018)

−0.0268x1x2 + 1.375x2x3

(0.147) (0.015)

(0.120) (<0.001) (0.680) (0.137) (0.023)

+ 1.372x2x3

(0.020)

(0.181) (0.001) (0.979) (0.004) (0.020)

(<0.001) (0.0199) (0.005) (0.003)

R2 = 0.958, R2adj = 0.942, s = 0.195, PRESS = 1.013.

Appendix A.3. Evaluation of the RSM Models for yRc, Tangent Force [28]

(0.725) (0.858) (0.481) (0.736) (0.143)

+ 2.668x32 − 0.0707x1x2 + 0.00244x1x3 + 62.058x2x3

(0.029) (0.943) (0.244) (0.051)

R2 = 0.994, R2adj = 0.985, s = 9.039, PRESS = 3864.088

(0.675) (0.857) (0.444) (0.715) (0.112)

+ 2.6688x32 + 0.0277x1x3 + 62.050x2x3

(0.018) (0.205) (0.034)

(0.490) (0.943) (0.445) (0.062) (0.007)

+ 0.0243x1x3 + 62.050x2x3

(0.178) (0.024)

(0.027) (0.950) (0.905) (0.072) (0.008)

+ 62.050x2x3

(0.027)

(0.046) (<0.001) (0.544) (0.002) (0.046)

R2 = 0.988, R2adj = 0.982, s = 9.654, PRESS = 2279.002

Appendix A.4. Evaluation of the RSM Models for yAfd, Average Fiber Diameter [37]

(<0.001) (<0.014) (0.019) (0.002) (0.535)

+ 34.792x32 + 6.000x1x2 + 9.750x1x3 − 17.501x1x3

(0.004) (0.402) (0.197) (0.044)

R2 = 0.982, R2adj = 0.95, s = 13.099, PRES S = 1,113,250

(<0.001) (<0.014) (0.019) (0.002) (0.535)

+ 6.001x1x2 + 9.750x1x3 − 17.501x2x3

(0.373) (0.169) (0.031)

(<0.001) (<0.006) (0.009) (<0.001) (0.001)

+ 9.750x1x3 − 17.501x2x3

(0.160) (0.026)

R2 = 0.97, R2adj = 0.947, s = 13.502, PRESS = 675,548

References

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Anderson, M.J.; Whitcomb, P.J. RSM Simplified: Optimizing Processes Using Response Surface Methods for Design of Experiments; Productivity Press: University Park, IL, USA, 2016. [Google Scholar]

- Asoo, H.R.; Alakali, J.S.; Ikya, J.K.; Yusufu, M.I. Historical background of RSM. In Response Surface Methods-Theory, Applications and Optimization Techniques; IntechOpen: London, UK, 2024. [Google Scholar]

- Baş, D.; Boyacı, İ.H. Modeling and optimization I: Usability of response surface methodology. J. Food Eng. 2007, 78, 836–845. [Google Scholar] [CrossRef]

- Chelladurai, S.J.S.; Murugan, K.; Ray, A.P.; Upadhyaya, M.; Narasimharaj, V.; Gnanasekaran, S. Optimization of process parameters using response surface methodology: A review. Mater. Today Proc. 2021, 37, 1301–1304. [Google Scholar] [CrossRef]

- De Oliveira, L.G.; de Paiva, A.P.; Balestrassi, P.P.; Ferreira, J.R.; da Costa, S.C.; da Silva Campos, P.H. Response surface methodology for advanced manufacturing technology optimization: Theoretical fundamentals, practical guidelines, and survey literature review. Int. J. Adv. Manuf. Technol. 2019, 104, 1785–1837. [Google Scholar] [CrossRef]

- Veza, I.; Spraggon, M.; Fattah, I.R.; Idris, M. Response surface methodology (RSM) for optimizing engine performance and emissions fueled with biofuel: Review of RSM for sustainability energy transition. Results Eng. 2023, 18, 101213. [Google Scholar] [CrossRef]

- Boshagh, F.; Rostami, K. A review of application of experimental design techniques related to dark fermentative hydrogen production. J. Renew. Energy Environ. 2020, 7, 27–42. [Google Scholar]

- Mäkelä, M. Experimental design and response surface methodology in energy applications: A tutorial review. Energy Convers. Manag. 2017, 151, 630–640. [Google Scholar] [CrossRef]

- Mishra, P.; Mohapatra, T.; Sahoo, S.S.; Padhi, B.N.; Giri, N.C.; Emara, A.; AboRas, K.M. Experimental assessment and optimization of the performance of a biodiesel engine using response surface methodology. Energy Sustain. Soc. 2024, 14, 28. [Google Scholar] [CrossRef]

- Pais-Chanfrau, J.M.; Núñez-Pérez, J.; del Carmen Espin-Valladares, R.; Lara-Fiallos, M.V.; Trujillo-Toledo, L.E. Uses of the response surface methodology for the optimization of agro-industrial processes. In Response Surface Methodology in Engineering Science; IntechOpen: London, UK, 2021. [Google Scholar]

- Boublia, A.; Lebouachera, S.E.I.; Haddaoui, N.; Guexxout, Z.; Ghriga, A.A.; Hasanzadeh, M.; Benguerba, Y.; Drouiche, N. State-of-the-art review on recent advances in polymer engineering: Modeling and optimization through response surface methodology approach. Polym. Bull. 2023, 80, 5999–6031. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Ferreira, S.L.C.; Novaes, C.G.; Dos Santos, A.M.P.; Valasques, G.S.; da Mata Cerqueira, U.M.F.; dos Santos Alves, J.P. Simultaneous optimization of multiple responses and its application in Analytical Chemistry—A review. Talanta 2019, 194, 941–959. [Google Scholar] [CrossRef]

- Dejaegher, B.; Vander Heyden, Y. Experimental designs and their recent advances in set-up, data interpretation, and analytical applications. J. Pharm. Biomed. Anal. 2011, 56, 141–158. [Google Scholar] [CrossRef]

- Szpisják-Gulyás, N.; Al-Tayawi, A.N.; Horváth, Z.H.; László, Z.; Kertész, S.; Hodúr, C. Methods for experimental design, central composite design and the Box–Behnken design, to optimise operational parameters: A review. Acta Aliment. 2023, 52, 521–537. [Google Scholar] [CrossRef]

- Olabinjo, O.O. Response surface techniques as an inevitable tool in optimization process. In Response Surface Methods—Theory, Applications and Optimization Techniques; IntechOpen: London, UK, 2024. [Google Scholar]

- Myers, R.H. Classical and Modern Regression with Applications, 2nd ed.; Duxbury Press: Monterey, CA, USA, 1990. [Google Scholar]

- Berger, D.E. Introduction to Multiple Regression. Master’s Thesis, Claremont Graduate University, Claremont, CA, USA, 2008. [Google Scholar]

- Meloun, M.; Militký, J. Detection of single influential points in OLS regression model building. Anal. Chim. Acta. 2001, 439, 169–191. [Google Scholar] [CrossRef]

- Bhattacharya, S. Central composite design for response surface methodology and its application in pharmacy. In Response Surface Methodology in Engineering Science; IntechOpen: London, UK, 2021. [Google Scholar]

- Rodrigues, A.C. Response surface analysis: A tutorial for examining linear and curvilinear effects. Rev. Adm. Contemp. 2021, 25, e200293. [Google Scholar] [CrossRef]

- Reza, A.; Chen, L.; Mao, X. Response surface methodology for process optimization in livestock wastewater treatment: A review. Heliyon 2024, 10, e30326. [Google Scholar] [CrossRef]

- Won, J.K.; Lee, J.H.; Lee, J.T.; Lee, E.S. The selection on the optimal condition of Si-wafer final polishing by combined Taguchi method and respond surface method. Trans. Korean Soc. Eng. A. 2008, 17, 21–28. [Google Scholar]

- Lee, E.S.; Hwang, S.C.; Lee, J.T.; Won, J.K. A study on the characteristic of parameters by the response surface method in final wafer polishing. Int. J. Precis. Eng. Manuf. 2009, 10, 25–30. [Google Scholar] [CrossRef]

- Zhang, H.; Jiang, Z.; Guo, C. Simulation-based optimization of dispatching rules for semiconductor wafer fabrication system scheduling by the response surface methodology. Int. J. Adv. Manuf. Technol. 2009, 41, 110–121. [Google Scholar] [CrossRef]

- Seo, J.; Kim, J.H.; Lee, M.; You, K.; Moon, J.; Lee, D.H.; Paik, U. Multi-objective optimization of tungsten CMP slurry for advanced semiconductor manufacturing using a response surface methodology. Mater. Des. 2017, 117, 131–138. [Google Scholar] [CrossRef]

- Saleem, M.M.; Somá, A. Design of experiments based factorial design and response surface methodology for MEMS optimization. Microsyst. Technol. 2015, 21, 263–276. [Google Scholar] [CrossRef]

- Noordin, M.Y.; Venkatesh, V.C.; Sharif, S.; Elting, S.; Abdullah, A. Application of response surface methodology in describing the performance of coated carbide tools when turning AISI 1045 steel. J. Mater. Process. Technol. 2004, 145, 46–58. [Google Scholar] [CrossRef]

- Bouacha, K.; Yallese, M.A.; Mabrouki, T.; Rigal, J.F. Statistical analysis of surface roughness and cutting forces using response surface methodology in hard turning of AISI 52100 bearing steel with CBN tool. Int. J. Refract. Met. Hard Mater. 2010, 28, 349–361. [Google Scholar] [CrossRef]

- Elbah, M.; Aouici, H.; Meddour, I.; Yallese, M.A.; Boulanouar, L. Application of response surface methodology in describing the performance of mixed ceramic tool when turning AISI 4140 steel. Mech. Ind. 2016, 17, 309. [Google Scholar] [CrossRef]

- Campos, d.S.P.H.; de Carvalho Paes, V.; de Carvalho Gonçalves, E.D.; Ferreira, J.R.; Balestrassi, P.P.; Davim, J.P. Optimizing production in machining of hardened steels using response surface methodology. Acta Sci. Technol. 2019, 41, e38091. [Google Scholar] [CrossRef]

- Khalil, K.; Mohd, A.; Mohamad, C.O.C.; Faizul, Y.; Ariffin, S.Z. The optimization of machining parameters on surface roughness for AISI D3 steel. J. Phys. Conf. Ser. 2021, 1874, 012063. [Google Scholar] [CrossRef]

- Pajaie, H.S.; Taghizadeh, M. Optimization of nano-sized SAPO-34 synthesis in methanol-to-olefin reaction by response surface methodology. J. Indust. Eng. Chem. 2015, 24, 59–70. [Google Scholar] [CrossRef]

- Jourshabani, M.; Badiei, A.; Lashgari, N.; Mohammadi Ziarani, G. Application of response surface methodology as an efficient approach for optimization of operational variables in benzene hydroxylation to phenol by V/SBA-16 nanoporous catalyst. J. Nanostructures 2016, 6, 107–115. [Google Scholar]

- Sheng, X.; Cheng, Y.; Yao, Y.; Zhao, Z. Optimization of synthesizing upright ZnO rod arrays with large diameters through response surface methodology. Processes 2020, 8, 655. [Google Scholar] [CrossRef]

- Rakhmanova, A.; Kalybekkyzy, S.; Soltabayev, B.; Bissenbay, A.; Kassenova, N.; Bakenov, Z.; Mentbayeva, A. Application of response surface methodology for optimization of nanosized zinc oxide synthesis conditions by electrospinning technique. Nanomaterials 2022, 12, 1733. [Google Scholar] [CrossRef]

- Pakolpakçıl, A.; Kılıç, A.; Draczynski, Z. Optimization of the centrifugal spinning parameters to prepare poly (butylene succinate) nanofibers mats for aerosol filter applications. Nanomaterials 2023, 13, 3150. [Google Scholar] [CrossRef]

- Sreekumar, S.; Chakrabarti, S.; Hewitt, N.; Mondol, J.D.; Shah, N. Performance prediction and optimization of nanofluid-based PV/T using numerical simulation and response surface methodology. Nanomaterials 2024, 14, 774. [Google Scholar] [CrossRef]

- Rawlings, J.O.; Pantula, S.G.; Dickey, D. Applied Regression Analysis; Springer: New York, NY, USA, 1998. [Google Scholar]

- Allen, M.P. Understanding Regression Analysis; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Dielman, T.E. Applied Regression Analysis for Business and Economics, 4th ed.; Duxbury/Thomson Learning: Pacific Grove, CA, USA, 2005. [Google Scholar]

- Mendenhall, W.; Sincich, T. Regression Analysis. A Second Course in Statistics, 12th ed.; Pearson: London, UK, 2012. [Google Scholar]

- Montgomery, D.C.; Peck, E.A.; Vining, G.G. Introduction to Linear Regression Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Ryan, T.P. Modern Regression Methods; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Wilcox, R.R.; Keselman, H.J. Modern regression methods that can substantially increase power and provide a more accurate understanding of associations. Eur. J. Pers. 2012, 26, 165–174. [Google Scholar] [CrossRef]

- Marinoiu, C. Classic and modern in regression modelling. Econom. Insights Trends Chall. 2017, 69, 41–50. [Google Scholar]

- Rowley, E.K. Comparison of Variable Selection Methods. Ph.D. Thesis, The University of North Carolina at Chapel Hill, Chapel Hill, NC, USA, 2019. [Google Scholar]

- Chowdhury, M.Z.I.; Turin, T.C. Variable selection strategies and its importance in clinical prediction modelling. Fam. Med. Community Health 2020, 8, e000262. [Google Scholar] [CrossRef]

- Box, G.E.P.; Draper, N.R. Response Surface, Mixtures, and Ridge Analysis; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Yang, K.; Tu, J.; Chen, T. Homoscedasticity: An overlooked critical assumption for linear regression. Gen. Psychiatry 2019, 32, e100148. [Google Scholar] [CrossRef]

- Wang, G.C.; Akabay, C.K. Heteroscedasticity: How to handle in regression modeling. J. Bus. Forecast. 1994, 13, 11. [Google Scholar]

- Agunbiade, D.A.; Adeboye, N.O. Estimation of heteroscedasticity effects in a classical linear regression model of a cross-sectional data. J. Pro. Appl. Math. 2012, 4, 18–28. [Google Scholar]

- Kumar, N.K. Autocorrelation and heteroscedasticity in regression analysis. J. Business Soc. Sci. 2023, 5, 9–20. [Google Scholar] [CrossRef]

- Stevens, J.P. Outliers and influential data points in regression analysis. Psychol. Bull. 1984, 95, 334. [Google Scholar] [CrossRef]

- Chatterjee, S.; Hadi, A.S. Regression Analysis by Example; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Snee, R.D. Validation of regression models: Methods and examples. Technometrics 1977, 19, 415–428. [Google Scholar] [CrossRef]

- Green, S.B. How many subjects does it take to do a regression analysis? Multivar. Behav. Res. 1991, 26, 499–510. [Google Scholar] [CrossRef]

- Khamis, H.J.; Kepler, M. Sample size in multiple regression: 20 + 5k. J. Appl. Stat. Sci. 2010, 17, 505–517. [Google Scholar]

| Year | Full Factorial Design (CFD) | Box–Behnken Design (BBD) | Central Composite Design (CCD) |

|---|---|---|---|

| 2019 | 145,000 | 7250 | 218,000 |

| 2020 | 151,000 | 8450 | 235,000 |

| 2021 | 147,000 | 9860 | 224,000 |

| 2022 | 132,000 | 12,400 | 207,000 |

| 2023 | 114,000 | 13,600 | 159,000 |

| 2024 | 88,300 | 16,500 | 113,000 |

| Study | Targets | Number of Data Points and Experimental Design | Software | Model Evaluation | Criteria for Parameter Selection | Reported Model | Optimization |

|---|---|---|---|---|---|---|---|

| I. Semiconductor | |||||||

| Won et al. [23] ySR = surface roughness x1 = applied pressure x2 = platen speed x3 = slurry ratio | Si-wafer polishing | 15 CCD | Not reported | Not reported | Not reported | Not reported | Contour plot, response surface plot |

| Lee et al. [24] ySR = surface roughness x1 = pressure x2 = wheel speed x3 = time | Final wafer polishing | 15 BBD | MINITAB | R2 | Not reported | Full models | Contour plot, response surface plot |

| Zhang et al. [25] yCT = CT yWTP = WTP yTP = TP x1 = Ub x2 = C1 x3 = C2 | Wafer fabricating | 20 CCD | Design Expert, version not mentioned | ANOVA lack of fit, PRESS, R2, R2adj | Not reported | Full models | Contour plot, response surface plot |

| Seo et al. [26] yw (WAPR) yoxide (Oxide MRR) x1 = Free concentration x2 = H2O2 x3 = SiO2 | 15 CCD | MINITAB | ANOVA R2, R2adj | t-value p-value | Full models | Contour plot, response surface plot | |

| Saleem and Soma [27] yPV = pull-in voltage x1 = TEL x2 = TEN x3 = TSL x4 = TSW | MEMS | 27 BBD | Not reported | R2, R2adj | F-value p-value | Full models | Contour plot, response surface plot |

| II. Steel materials | |||||||

| Noordin et al. [28] yRa = surface roughness yRc = tangential force x1 = cutting speed x2 = SCEA | Coated carbide tools AISI 1045 steel | 16 CCD | Design Expert Ver. 6.0 | ANOVA R2, R2adj Lock of First, PRESS | p-value backward elimination | YRa = f(x2, x3, x2x3, x32) YRc = f(x1, x2, x3, x2x3, x32) | Contour plot, response surface plot |

| Bouacha et al. [29] yRa = Ra yRt = Rt yRz = Rz x1 = VC x2 = f x3 = ap | Surface roughness, cutting forces AISI 52100 steel | 27 Taguchi orthogonal array | Not reported | ANOVA R2 R2adj | F-value p-value At once delete variance | YRa = f(x1, x2, x3, x1x2) YRt = f(x1, x2, x1x2, x22) YRz = f(x1, x2, x1x2, x22) | Contour plot, response surface plot |

| Elbah et al. [30] yFa = Fa yFr = Fr yFt = Ft yRa = Ra x1 = depth of cut x2 = feed rate x3 = cutting speed | Mixed ceramic tool, AISI 4140 steel | 27 CCD | Design Expert 8.0.7 | ANOVA R2 R2adj | F-value Some variables are not significant in ANOVA | full model | Contour plot, response surface plot |

| Campos et al. [31] yTime = Time yRa = Ra yRt = Rt x1 = VC x2 = f x3 = ap | Machining of hardened steel | 19 CCD | Design Expert, version not mentioned | ANOVA R2 R2adj | Sequential model for some terms | full model | Contour plot, response surface plot |

| Khalil et al. [32] yRS = surface roughness x1 = cutting spend x2 = feed rate x3 = depth of cut | Surface roughness AISI D3 steel | 20 CCD | Design Expert, version not mentioned | Lack of fit | F-value p-value (cutoffs p < 0.1) | Full model | Contour plot, response surface plot |

| III. Nanomaterials | |||||||

| Pajaie and Taghizadeh [33] yEthylene = ethylene yPropylene = propylene x1 = MW aging time x2 = US aging time x3 = HT time | Yield | 15 BBD | Design Expert ver. 6 | R2 R2adj | F-value p-value ANOVA Table. | Full model | Contour plot, response surface plot |

| Jourshabani et al. [34] yphenol yield = phenol yield x1 = temperature x2 = H2O2 content x3 = Catalyst | Benzene hydroxylation | 20 CCD | Design Expert Ver. 7.1.3 | R2 R2adj | F-value p-value | Full model | Contour plot, response surface plot |

| Sheng et al. [35] yTC002 = TC002 yAspect ratio = Aspect ratio yD = D x1 = concentration x2 = temperature x3 = catalyst | 27 CCD | MOODE Ver. 10 | ANOVA lack of fit | Not reported | Not reported Not reported log () of f(x1, x2, x3, x4, x1x2, x2x3, x2x4, x3x4, x32) | Contour plot, response surface plot Contour plot, response surface Contour plot, response surface plot | |

| Rakhmanova et al. [36] yZinc Oxide = zinc oxide synthesis x1 = applied potential x2 = distance x3 = temperature | 15 BBD | Design Expert ver. 8.0.7.1 | R2, R2adj Lack of fit, PRESS | Not reported | Not reported | Contour plot, response surface plot | |

| Pakolpakcil et al. [37] yAfd = Average fiber diameter x1 = concentration x2 = Rotational speed x3 = Needle size | Poly nanofiber mats | 15 BBD | Design Expert ver. 13 | ANOVA sequential model, quadratic, and interaction | F-value p-value | Full model | Contour plot, response surface plot |

| Sreekumar et al. [38] yNth = Nth ynele = nele ynex,th = nex,th ynex,ele = nex,ele x1 = φ% x2 = m x3 = I x4 = Ti | Nanofluid-based PV/T | 27 CCD | Design Expert, version not mentioned | ANOVA R2, R2adj | F-value p-value | Full model | Contour plot, Response surface plot |

| Criterion | Description | Cutoffs |

|---|---|---|

| R2 | The coefficient of determination is used to determine the relationship between the response and the independent variable. | R2 value near 1.0 |

| Adjusted R2 | This value takes into account the impact of the number of independent variables on the R-squared value. The closer the adjusted R-squared (R2adj) is to 1.0, the better the descriptive ability of the regression equation. | R2adj value closer to 1.0 |

| s | This represents the actual variability in the equation regarding the data distribution between the response and independent variables. It indicates the precision of those estimates. It reflects the variability in the estimates across different random samples from the same population. | A smaller s suggests a more precise estimate, meaning the estimated coefficient is likely closer to the actual population value. |

| t-value | The t-value is used to test the null hypothesis that the coefficients of the independent variables are significantly different from zero. | A large t-value for the independent variable indicates that the coefficient is statistically significant and not equal to zero. |

| p-value | The variable coefficient is calculated from its t-value and used to test the null hypothesis that the coefficients of the independent variables are significantly different from zero. | The p-value represents the probability of incorrectly determining whether the coefficient of the variable is not zero. A smaller p-value represents a greater probability of the validity of the variable. |

| PRESS, predicted residual error sum of squares | This evaluates the predictive ability of the regression model | The smaller, the better |

| Normality test | The normality test is used to evaluate whether the dataset is normally distributed. The normality test technique used in this study is the Kolmogorov–Smirnov method. | The p-value calculated with this method compares the preset value (p = 0.05). |

| Constant variance test | This assesses whether the dependent variable (response) has constant variance across its overall sources. The testing technique used in this study is the Spearman rank correlation method. | The cutoff value is p = 0.05. |

| ti, externally studentized residuals | This computes the standard error of the residual of the estimated value, and this data is not used in model building. | Values of are usually used to indicate the possibility of an outlier. |

| DFFITSi | This evaluates the prediction effect for a data point. It is used to compare the estimated standard errors when the observed value is removed. | The cutoffs of DFFITSi are . |

| Source | Reported Equations | Contour and Surface Response Plot | Adequate Equations | Normality Test | Constant Variance Test | Influential Data |

|---|---|---|---|---|---|---|

| Won et al. [23] | Not reported | Curve surface | ySR = f(x1, x3, x1x3, x12, x32) | Passed | Passed | 2, 15 |

| Lee et al. [24] | Full models | Curve surface | ySR = f(x1, x2, x3, x1x3, x22, x32) | Passed | Passed | 4, 6, 7, 12 |

| Zhang et al. [25] | Full models | Curve surface | yCT = f(x1, x2, x12, x22) yWTD = f(x1, x2, x3, x1x2, x22, x32) yTP = f(x1, x2, x3, x12, x22, x32, x1x2) | Passed Failed Failed | Passed Passed Failed | 5, 13, 17 13 5, 14, 18 |

| Seo et al. [26] | yW = full model | Curve surface | yW = f(x2) | Passed | Passed | 12, 14 |

| yOxide = full model | yOxide = (x1, x3) | Passed | Passed | no | ||

| Saleem and Soma [27] | Full model | Curve surface | yPV = f(x1, x2, x3, x4, x1x3, x32) | Failed | Passed | 27 |

| Source | Reported Equations | Contour and Surface Response Plot | Adequate Equations | Normality Test | Constant Variance Test | Influential Data Points |

|---|---|---|---|---|---|---|

| Noordin et al. [28] | ySR = f(x2, x3, x2x3, x32) yTF = f(x1, x2, x3, x2x3, x32) | Curve surface | ySR = f(x2, x3, x1x2, x2x3, x32) yTF = f(x1, x2, x3, x2x3, x32) | Passed | Passed | 7, 12, 13 |

| Bouacha et al. [29] | yRa = f(x1, x2, x3, x1x2) | Curve surface | yRa = f(x1, x2, x1x2, x12, x22) | Passed | Passed | 6, 13 |

| yRt = f(x1, x2, x1x2, x22) | Curve surface | yRt = f(x1, x2, x1x2, x12, x22) | Passed | Passed | 1, 4 | |

| yRz = f(x1, x2, x1x2, x22) | Curve surface | yRz = f(x1, x2, x3, x1x2, x1x3, x12, x22) | Failed | Passed | 5, 6 | |

| Elbah et al. [30] | Full models for yFa, yFr, yFt, yRa | Curve surface | yFa = f(x1, x2, x3, x1x3, x2x3) | Passed | Passed | 26 |

| yFr = f(x1, x2, x3, x1x2, x1x3) | Passed | Passed | 24 | |||

| yFt = f(x1, x2, x3, x1x2, x1x3, x2x3) | Passed | Passed | 27 | |||

| yRa = f(x1, x2, x1x2) | Passed | Passed | No | |||

| Campos et al. [31] | Full models | Curve surface | yTime = full equation | Passed | Passed | 1, 8, 16, 17 |

| yRa = f(x1, x2, x3, x1x2, x1x3, x2x3, x12, x32) yRt = f(x1, x12) | Passed Passed | Passed Passed | 1, 3 4, 6 18 | |||

| Khalil et al. [32] | Full model | Curve surface | ySR = f(x1, x2, x3, x1x2, x1x3, x32) | Passed | Passed | 1, 7, 17, 20 |

| Source | Reported Equations | Contour and Surface Response Plot | Adequate Equations | Normality Test | Constant Variance Test | Influential Data |

|---|---|---|---|---|---|---|

| Pakolpakcil et al. [37] | Full model | Curve surface | yAfd = f(x1, x2, x3, x2x3, x12, x32) | Passed | Failed | 12 |

| Pajaie and Taghizadeh [33] | Full model | Curve surface | yEthylene = full model yPropylene = f(x1, x2, x3, x1x3, x12, x22) | Passed | Passed | 3, 5, 8, 9, 11 |

| Jourshabani et al. [34] | Full model | Curve surface | yphenol yield = f(x1, x2, x3, x12, x22, x32) | Passed | Passed | 9 |

| Sheng et al. [35] | log () = f(x1, x2, x3, x4, x1x2, x2x3, x2x4, x3x4, x32) | Curve surface | yD = f(x1, x2, x3, x4, x1x2, x2x4, x3x4, x32) | Passed | Passed | None |

| Rakhmanova et al. [36] | Not reported | Curve surface | yZine oxide = f(x2, x3) | Passed | Passed | 6, 14 |

| Sareekumar et al. [38] | Full models for ynth-ynex,ele | Curve surface | Ynth = f(x1, x2, x4) | Passed | Passed | 18 |

| Curve surface | ynele = f(x1, x2, x3, x4, x2x3, x2x4) | Passed | Passed | 7, 24, 25 | ||

| Curve surface | ynex,th = f(x1, x2, x3, x2x3, x2x4, x3x4) | Passed | Passed | 3, 25 | ||

| Curve surface | ynex,ele = f(x1, x2, x3, x4, x1x3, x2x3, x22) | Passed | Failed | 3, 14 |

| Issue | Literature |

|---|---|

| [24,25,26,27,30,32,33,34,38] |

| [36] |

| [29] |

| [31,37] |

| [25,27,29] |

| [25,37,38] |

| [23,24,25,26,27,28,29,30,31,32,33,34,36,37,38] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.-Y.; Chen, C. A Study of the Response Surface Methodology Model with Regression Analysis in Three Fields of Engineering. Appl. Syst. Innov. 2025, 8, 99. https://doi.org/10.3390/asi8040099

Chen H-Y, Chen C. A Study of the Response Surface Methodology Model with Regression Analysis in Three Fields of Engineering. Applied System Innovation. 2025; 8(4):99. https://doi.org/10.3390/asi8040099

Chicago/Turabian StyleChen, Hsuan-Yu, and Chiachung Chen. 2025. "A Study of the Response Surface Methodology Model with Regression Analysis in Three Fields of Engineering" Applied System Innovation 8, no. 4: 99. https://doi.org/10.3390/asi8040099

APA StyleChen, H.-Y., & Chen, C. (2025). A Study of the Response Surface Methodology Model with Regression Analysis in Three Fields of Engineering. Applied System Innovation, 8(4), 99. https://doi.org/10.3390/asi8040099