Abstract

Aluminium composite panels (ACPs) have been used in almost every high-rise building because of their aesthetic and thermal properties. However, due to the nature of the combustibility of polymeric core materials, the fire issue is the main concern throughout the world. Several fire occurrences have been noticed in different countries. The ignition of combustible core materials used in ACP cladding is mainly responsible for spreading fire. Building-safety regulatory authorities have enforced new obligations to ban combustible ACP panels in high-rise buildings, especially in Australia and the UK. This is now considered as one of the critical components in these buildings. This study aims to comprehensively overview different types of cladding panels, core filler materials, flame-retardant mechanisms, their preparation methods, and recent developments. The PRISMA method has been used to conduct a systematic literature review. From the Scopus and Google scholar databases, a total of 180 documents have been selected using two relevant keywords through the screening process. This study reviews existing studies, covering cladding panel classifications based on standard codes, and existing ACP panels’ flammability, thermal, and mechanical properties. Following an in-depth recent literature review, the study outlines the combustibility and energy efficiency challenges and offers recommendations for future research to develop non-combustible cladding panels.

1. Introduction

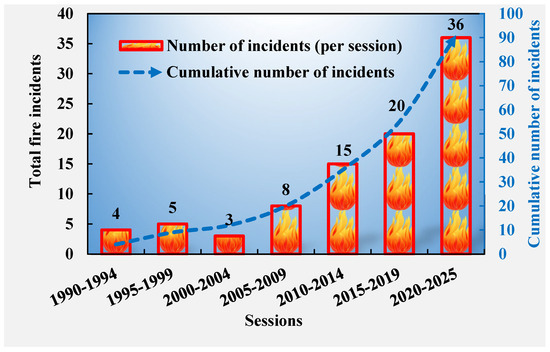

Cladding panels are one of the most important protective envelopes in high-rise buildings. The main purposes of this cladding system are to protect the building from wind damage and wet weather conditions and to provide thermal comfort inside the building [1,2]. Combustible composite cladding panels, i.e., aluminium composite panels (ACPs), are commonly used due to their lower cost, lightweight properties, improved energy efficiency, and readily available polymeric core materials [3]. As the construction of high-rise buildings has expanded persistently in recent decades, the application of combustible ACP panels has also increased noticeably [4]. However, several fire incidents have occurred in different countries. Since 2010, the number has been increasing rapidly (Figure 1). Recent fire incidents such as the Lacrosse Building fire in Melbourne in 2014 [5], the Grenfell Tower fire in 2017 [6], the Dwelling Building in South Korea in 2017 [7], the Milan tower block in Italy in 2021 [8], and the apartment building in Dubai in 2023 [9], involved combustible ACP cladding panels. The polymeric core materials of the combustible cladding panels are highly flammable, which is considered the main reason for fire spreading [10]. Most of the current combustible cladding panels contain highly flammable polymeric core materials such as polyethylene (PE), polyurethane (PU), polyisocyanurate (PIR), extruded polystyrene (XPS), and expanded polystyrene (EPS) [6,11,12]. The use of combustible cladding systems has been restricted in high-rise buildings by different authorities [10,13,14,15]. Building-safety authorities worldwide are now changing the requirements for applying cladding panels in high-rise buildings [16]. Consequently, building construction authorities now mandate using non-combustible cladding for high-rise buildings [10]. In Australia, the National Construction Code (NCC) has tightened the use of combustible cladding panels in buildings [17]. The update performed in 2019 and 2022 to volume 1, Section C, reflects the restrictions on the combustible cores in ACPs in building classes 2 to 9. In New South Wales and Victoria, the states have already implemented the ban on ACPs with more than 30% PE core [18]. In the UK, noticeable changes have also occurred. UK building regulations (2018) banned the use of ACPs containing a PE core in the external wall of buildings taller than 18 m [19]. They also enforced a requirement for buildings taller than 18 m to use materials in the external wall to achieve Euroclass A2-s1, d0. The BS 8414 standard [19] has also been updated by testing the whole cladding system instead of individual components. In the USA, the International Building Code (IBC) has also been updated due to the recent fire incidents; IBC section 1403 and chapter 26 (plastics) have been modified, which control the use of cladding materials [20]. In Europe, regulatory changes have also taken place. In high-rise buildings now, Class A2 or better ACPs need to be used. The testing following EN 13501-1 [21] has also been stringent for the reaction-to-fire classification of the materials.

Figure 1.

Building fire incident number involving ACP cladding.

Several non-combustible composite panels have been developed, such as solid aluminium panels [9,22], honeycomb panels [23,24], fibre–cement-based boards [25,26,27], etc. The major drawback of the solid aluminium panel is its higher thermal conductivity (237 W/mK) [28]. This property is directly related to the heat transfer. The disadvantages of the existing fibre–cement-based non-combustible composite panels are heavy weight [29], higher price [30], difficulty in installation due to heavy weight [29] and manpower requirements, and higher water absorbency [31] compared to honeycomb panels or solid aluminium cladding panels. The bonding of the aluminium skin with the core material is crucial in honeycomb panels and ACP cladding panels. At elevated temperatures, the bonding becomes weaker, leading to the delamination of the metal skin from the core materials of the honeycomb panel and ACP panel. This phenomenon was observed during testing regardless of the use of combustible [10] or non-combustible panels [32]. Although there is no ignition of the non-combustible materials at higher temperatures, the aluminium skin falls due to the delamination process, which stimulates the fire risk and spreads the fire due to the melting of the aluminium skin and cracking of core materials [32]. A few techniques [33] have been applied to develop strong bonds between core materials and outer metal sheets by applying adhesive film or mechanical joints. Still, these techniques also have several disadvantages, such as the melting of adhesive film at higher temperatures and crack formation [33].

Researchers have widely conducted small-scale tests using cone calorimeter and intermediate-scale test methods to understand the heat of combustion and ignitability properties of the materials and classify the cladding materials as categories A1, A2/B, C, D, E, or F for regulatory control according to the European fire classification standard EN 13501-1 [21] test. Non-combustible materials are classified as A1, while A2 is for limited combustible materials. Classes B, C, and D refer to materials that are very limited, limited, and acceptable flammable materials, respectively. Class E is for materials that are acceptable for only short period and small exposure where class E is for materials that fail to meet the categories or have never been tested. The small-scale and intermediate-scale tests provide fundamental data for assessing fire-related material properties. The full-scale fire test is a direct method to evaluate the fire performance of the cladding system [16]. However, this full-scale fire test approach is costly compared to the small-scale or intermediate fire test approaches. It is less feasible to conduct full-scale fire tests for each material and cladding system before being used in each project during high-rise building construction. Hence, the numerical investigation of full-scale testing of the facade using a Fire Dynamics Simulator (FDS) has recently become the choice of researchers for assessing fire hazards relative to the standard test, which includes (1) facade system design influence and (2) the fire performance of the facade.

Though there are several research studies available on ACP panels investigating the fire performance and flammability properties, there is still a lack of comprehensive research exploring the existing cladding panel’s core materials, flame-retardant fillers, and the mechanical and thermal properties of non-combustible ACP panels. The primary objective of this research study is to obtain a clear view of the current state of the art in cladding materials and filler materials and figure out the existing research gaps towards non-combustible cladding panels. This study also aims to bridge that gap by reviewing the current state of cladding research, focusing on classifications, material properties, filler types, flame-retardant mechanisms, preparation methods, and recent advancements, and outlines future directions for developing safe, non-combustible cladding panels.

2. Research Method

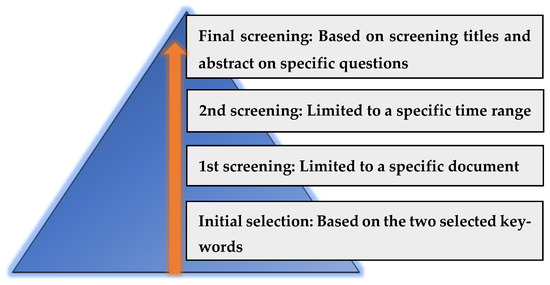

The methodology used in this research for selecting and processing articles is depicted in Figure 2. Four screening stages are employed for the selection and processing of research articles from the Scopus and Google scholar databases. In the initial stage, two primary keywords (keyword 1—“aluminium composite panels”; keyword 2—“ACP cladding panels”) are utilised to gather all relevant published documents. The first screening takes place to narrow down the specific document types for each topic and to pinpoint the relevant documents. A second screening is performed using the time range from 2005 to 2025 to select the last two decades of documents. The final screening occurs in the next stage, focusing on specific questions to sort out the relevant documents. The questions are as follows:

Figure 2.

Research items selection process for this study.

- Is the document relevant to the topic of this research study?

- Is the document relevant to the objectives of this research paper?

- Has the document already been screened through other keywords or other databases during the screening process for this study?

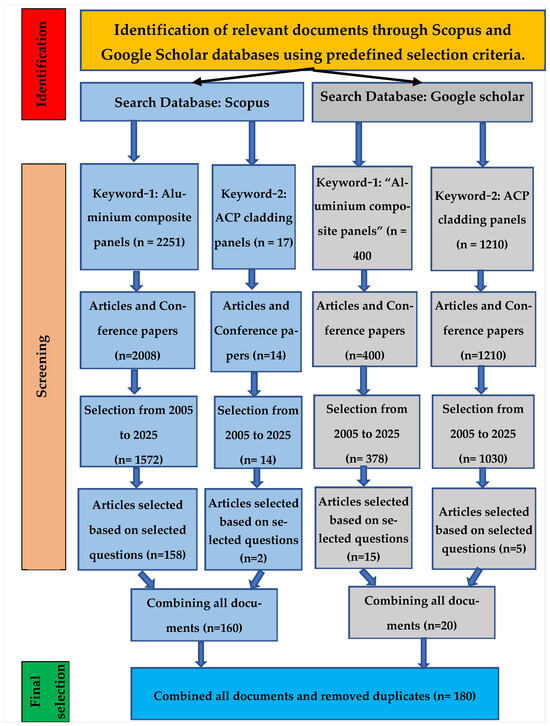

After screening based on the questions, all of the sorted articles are finally combine. All of the selected articles have been analysed in this comprehensive literature review study to achieve the research objectives. The details of the article selection process are illustrated in Figure 3 with a flowchart. From Scopus, 2239 articles were found for keyword 1, and then for keyword 2, 17 articles were found. After sorting through the screening process, a total of 160 articles were selected for comprehensive study based on suitability and relevancy. Similarly, article screening and selection was performed using both keywords from Google Scholar. As most documents were already selected from Scopus, only 15 articles from keyword-1 and 5 articles from keyword-2 were chosen from Google Scholar. Finally, 20 articles were selected from the Google Scholar database for this study. In addition, several ACP panel patents were listed from the Google patents database for a comprehensive understanding of the current cladding products. Including patents, additional research reports/web links (total: 54) have been referenced in this paper to discuss material types, properties, recent fire incidents, etc. All articles and research reports/conference papers/web links (234) are analysed, synthesised, and summarised regarding the key information related to cladding systems, core material types, flammability, thermal and mechanical properties, filler materials, flame-retardant mechanisms, preparation methods, recent developments, current challenges, and future research directions, which are discussed in the sections below.

Figure 3.

Flowchart illustrating the steps for selecting documents.

3. Cladding Systems

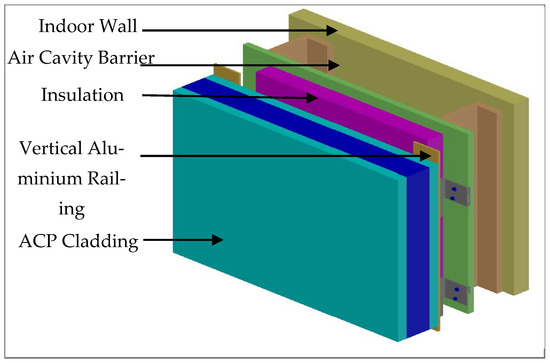

A cladding system is a combination of different parts used to form the outer covering of a building (Figure 4). It includes cladding panels, insulation, moisture barriers, ventilation systems, and any necessary structures or supports for attaching them to the building [15]. The cladding system has a dual purpose: it provides functional benefits by shielding the building from environmental elements and enhancing its overall design and visual appeal [34]. For this purpose, the cladding materials must be novel, thermally resistant, and environmentally friendly [35,36]. Many researchers believe that fire accidents and fatalities have increased due to the recent incorporation of flammable materials into aluminium composite cladding panels and their wide application [16,37]. Non-combustible (NC) cladding panels play a vital role in reducing the aftermath of fire incidents [34]. Therefore, further research on non-combustible cladding panels is required to provide fire-risk-free cladding systems for high-rise buildings.

Figure 4.

A cladding system’s simple illustration.

3.1. Cladding Panels

Cladding panels are non-loadbearing components used as an element of the external wall for protection [1] and aesthetic purposes [34]. Cladding panels can be classified into two general groups: combustible and non-combustible cladding panels. When a cladding panel contains any combustible material, the cladding panel is considered a combustible cladding panel [1,38]. The most common cladding panels available on the market are aluminium composite panels (ACPs), which contain a combustible polymeric core with or without inorganic mineral fillers. Some common industry names for specific types of ACP include ACP PE (using 100% combustible PE), ACP fire-rated also refer as ACP FR (using 30–70% combustible PE and flame-retardant fillers), and ACP NC/A1 (using no polymer at all) [39]. The non-combustible material also includes glass, plasterboard, fibre-reinforced cement sheeting, concrete, and metals. The classification of cladding panels based on different standards has been summarised in Table 1. According to the Building Code of Australia (BCA) clause C1.12, the non-combustibility of a material is determined by conducting the AS1530.1 standard [40] combustibility test using a furnace held steady at 750 °C. According to the Insurance Council of Australia, ACP products have been classified into four categories based on core composition (A, B, C, and D, see Table 1). EN 13501-1 [21] defines the categories based on testing using a burner imposing heat flux ranging from 30 to 35 kW/m2 at the peak moment [41]. The UK & BRE follows ISO 1716 [42] to determine the heat of combustion (HOC) using a bomb calorimeter, whereas ASTM uses a standard similar to AS 1530.1, a vertical furnace tube [43]. Based on the current Approved Document B (ADB) classification, cladding panels can be classified into four groups: A, B, C, and D. Class A is for non-combustible materials where class B is for limited-combustible materials as listed in Table 2 [44]. Class C is for combustible materials, and the materials those have not been determined fall under class D. Each cladding panel type has different drawbacks and limitations when used in the buildings, which have been listed in Table 3.

Table 1.

Classification of cladding panels in different standards.

Table 2.

According to ADB classification of material combustibility [44].

Table 3.

Different cladding panel types based on their combustibility, use restrictions, and drawbacks.

3.2. Types of Cores Used in Cladding Panels

Based on the nature of the combustibility of core materials used in ACP cladding, the ACP cladding panels are defined as either combustible, limited-combustible, or fire-rated, non-combustible cladding panels. The combustibility of core materials depends on the type of materials used in the core materials to fabricate the ACP panels. ACPs are one of the most common sandwich panels containing a combustible, fire-rated, and non-combustible core. A brief summary of combustible and non-combustible core materials is discussed below.

Combustible cores: The core materials of ACP panels prepared using combustible polymer are known as combustible cores. Most of the combustible core materials currently available on the market contain combustible polymers like polyethylene, polystyrene, phenolic foam (PF), and polyurethane (PU) [1]. The two most common types of PE used in composite panels are high-density polyethylene (HDPE) and low-density polyethylene (LDPE). The density range for LDPE and HDPE are around 905 kg/m3 and 952 kg/m3, respectively, and the melting points for these types are around 102 °C and 125 °C, respectively [50]. Most ACP cladding panels contain polymers because of the polymer’s availability, lower cost, and lightweight properties [6,11,51]. But after the Grenfell Tower fire accident (2019), Melbourne (2014, 2019), and Lacrosse (2014), which involved ACPs in fire spread, all around the world, different building-safety regulatory authorities put restrictions on the use of combustible cladding in high-rise buildings. Burning and dripping of the polymeric core is one of the major reasons for fire spread in high-rise buildings during fire accidents. The core materials used in ACP cladding panels are tested following AS 1530.1 [40] to assess whether the material is combustible or not. According to this test method, a single object will be exposed to 750 °C for a minimum of 30 min to observe any smoke or flame. The material will be considered combustible if the flame is sustained for 5 s at any time during the test.

Limited combustible cores and fire-rated cores: According to the European fire classification of building materials EN-13501-1 [21], between combustible and non-combustible core materials, there are two other types of core materials, including limited-combustible cores and fire-rated or flame-resistant cores [21]. This type of core makes a very low contribution to the spread of fire. This core type contains 1% and 29% polymers; the remaining core is flame-retardant filler material [52]. Depending on the quantity of the filler materials, the variation ranges from limited-combustible to fire-rated core materials. For limited-combustible cores, the polymer content is 8% to 29%, and the remainder is fire-retardant filler. In the case of fire-rated core materials, the polymer content in the core is 1% to 7% [52].

Non-combustible cores: If the materials satisfy the criteria stated in the test method in AS 1530.1 [40], the materials are deemed as non-combustible. For a cladding product, whether it is “not deemed” to be combustible is determined by Clause C1.12(f) of BCA as each layer must be tested by AS 1530.1 [40] as well as meeting all of the other requirements of Clause C1.12(f) of the BCA. According to the AS 1530.1 standard of combustibility test, there are three criteria: (1) the material is combustible if flaming sustains for 5 s or longer during the test for any of the five samples tested; (2) the mean furnace thermocouple temperature rise exceeds 50 °C; (3) the mean specimen surface thermocouple temperature rise exceeds 50 °C. The details of cladding panels using non-combustible cores are discussed in Section 5.1.

3.3. Insulation

Insulation in a cladding system is typically placed between the cladding panels and the building’s structure. It acts as a barrier, reducing heat transfer through the walls and reducing thermal bridging [53]. This helps to maintain a consistent indoor temperature and reduces the need for excessive heating or cooling [54]. Insulation materials commonly used in cladding systems are listed in Table 4, along with their properties. These materials have a high thermal resistance and are designed to minimise heat loss or gain. The specific choice of insulation material depends on many factors, such as the climate, building regulations, energy efficiency requirements, budget constraints, and insulating efficiency [54]. Insulation plays a crucial role in enhancing the energy performance and thermal comfort of buildings with cladding systems. The current insulation products can be classified as either highly combustible B3, normal or low-combustible (B1, B2), limited-combustible (A2), or non-combustible (A1) according to the German fire classification system DIN 4102 [55].

Table 4.

List of commonly used insulation materials and their important properties.

3.4. Cavity and Cavity Barriers

The cavity is one of the important components of the cladding system. It functions as a supplement to the insulation layer to provide greater insulating effects to the total cladding system. Air flows through the cavities, creating an additional insulation layer between the cladding panel and the main insulation layer [10]. Cavity barriers are used in cladding systems to obstruct fire and smoke, preventing their spread through cavities [10,57,58]. It is important to note that cavity barriers should not be mistaken for fire stops, which fill gaps between fire-rated elements and have different performance requirements. Cavity barriers can be classified as either open-state or closed-state. Open-state cavity barriers allow for ventilation within a cavity during normal conditions but close off the cavity during a fire. Typically, open-state barriers consist of intumescent materials that activate at high temperatures (usually around 120–200 °C) [59]. These materials expand continuously, sealing the gaps in the cavity and remaining in place to withstand the fire for a significant period. In normal conditions, ventilated cavities require vertical air circulation and allow moisture drainage. As a result, horizontal cavity barriers must be in an open state. It is worth noting that no relevant Australian standard specifically addresses open-state cavity barriers [60,61].

4. Fire-Rated Combustible Cladding Panel’s Filler Types, Mechanism, and Fabrication Process

Fire-rated combustible cladding panels contain a 7% to 30% polymer content and are classified as ICA category B cladding panels. There are many FR-rated core materials developed with various flame-retardant mineral fillers. The flame-retardant filler types and mechanisms are discussed in the following sub-sections.

4.1. Types of Flame-Retardant Fillers

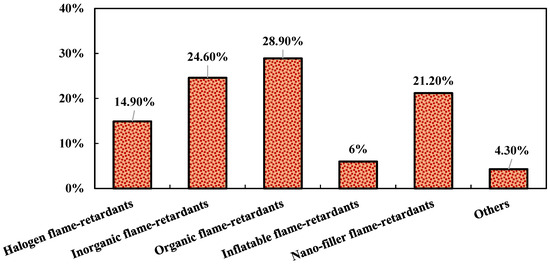

Flame-retardants can be categorised into two main categories: additive and reactive flame-retardants [62]. During the transformation process, additive flame-retardants are generally incorporated but do not react at this stage with the polymer. These usually react at the start of the fire at high temperatures. On the other hand, reactive flame-retardants are introduced into the polymer during the synthesis process. In some cases, these flame-retardants are incorporated during the post-reaction process. Due to the high flammability of the polymer, flame-retardants are frequently mixed with a combustible polymer to prepare a fire-rated polymer composite, which can meet fire-safety regulations. Flame-retardant materials have vast applications in construction, electronics, and transportation [63]. One of the general applications of flame-retardant fillers in the construction and building sector is to provide fire-resistance properties and insulation to the building materials. In the ACP panel, flame-retardant fillers are mixed with polymer cores in various percentages to prepare a fire-rated composite panel. Different flame-retardant fillers include halogen, inorganic, and organic flame-retardants (Figure 5). An example of each flame-retardant with its working mechanism is listed in Table 5.

Figure 5.

Different flame-retardant materials’ proportion of applications [63].

Table 5.

Different types of flame-retardant fillers and their working mechanisms [64].

4.1.1. Halogen-Containing Flame-Retardants

The flame-retardancy of this flame-retardant material potentially depends on the variety of the halogen. Due to the lower energy requirement of bromine and chlorine for binding with carbon atoms, the halogen radicals are released quickly and participate in the combustion process. Though these flame-retardants have a few benefits, such as lower cost, easy dispersion and high efficiency, these materials produce a large amount of toxic gases during combustion, potentially harming the environment and human survival [70]. Therefore, these materials are now replaced by non-halogen flame-retardants in case of sustainable development and environmentally friendly applications [70,71,72]. For instance, in Europe, some countries restrict the use of halogen-flame-retardants, and hence, research on high-efficiency, non-toxic flame-retardants has been significantly accelerated [73].

4.1.2. Inorganic Flame-Retardants

These flame-retardant materials contain high-temperature-resistant solutions and ultrafine inorganic metal oxides. These materials are mixed in a polymer matrix in a physical dispersion state. The flame-retardancy mechanism involves chemical or physical changes in a gas or condensed phase. These flame-retardants generally include metal hydroxides, inorganic phosphorous series, nitrogen-based, silicon-based compounds, etc. Flame-retardant fillers’ energy absorption involves four segments: (i) heat absorbed by the filler to raise its temperature from ambient to decomposition temperature, (ii) heat absorbed to raise the temperature from decomposition to the final residue temperature of the condensed phase, (iii) heat absorbed by endothermic decomposition calculated by using the DSC instrument, (iv) heat absorbed from filler decomposition temperature to the maximum flame temperature [74].

- Metal Hydroxides: Aluminium tri-hydroxide (ATH) and magnesium hydroxide (MH) are the most common inorganic metal hydroxides used for flame-retardancy applications. The decomposition of ATH starts at 200 °C, which is generally suitable for many polymers. It transforms into Al2O3 (see Equation (1)), which is a thermally stable material that works as a heat barrier and reduces heat transfer through the material. On the other hand, MH decomposition begins at around 300 °C and ranges from 340 °C to 490 °C (Equation (2)), which makes it more applicable than ATH as a flame-retardant [74]. This metallic hydroxide, during combustion, decomposes and releases water, which absorbs heat from the surroundings [75,76,77,78,79]. This heat-absorbing tendency greatly helps when these filler materials have been used in the ACP core materials. Both MH and ATH have numerous advantages as flame-retardant materials, such as non-toxicity, no toxic gas being generated during decomposition, good stability, cheapness, and wide availability. One of the drawbacks of these metal hydroxides is that they require a high load content (40% to 60%) in the polymer matrix for optimum flame-retardant effects [80].

- Inorganic phosphorous flame-retardants: These types of flame-retardants contain red phosphorous, coated red phosphorous, and ammonium polyphosphate (APP) [81]. APP and red phosphorous are good flame-retardants because of their remarkable properties [81,82]. There are some drawbacks, such as red phosphorous absorbing water in the air producing phosphoric acid, phosphite, and other substances [83]. Another disadvantage is its poor compatibility with resin and its dispersion complexity, leading to segregation settlement [57,84]. Red phosphorous also releases PH3 gas, which is highly toxic. Coated red phosphorous and polyphosphoric acid are good inorganic flame-retardants because of their low toxicity, good thermal stability, and better dispersion in the polymer matrix. APP has some disadvantages, such as absorbing humid air [85]. The important fact about APP is that the mentioned drawbacks can be overcome by microencapsulating with a coating of melamine-formaldehyde resin, poly-plus, epoxy resin, amino resin, etc. [63].

There are boron-containing inorganic flame-retardants [70,71,72]. Among these, zinc borate (ZB) is widely used. At around 260 °C, ZB decomposes and releases water by absorbing large amounts of heat, remarkably reducing the combustor’s temperature. In addition, during material combustion, ZB assists in generating porous carbon layers. It also produces hard porous residues like glass and ceramic with ATH. Nitrogen-based flame-retardants also have several applications as flame-retardant materials because of their low corrosiveness, strong thermal stability, reduced smoke generation during fire, and higher thermal decomposition temperature. Due to its limited nitrogen content, the flame-retardant effect and compatibility are poor, which led the researchers to focus on reducing the thermal conductivity of the nitrogen flame-retardants and improving compatibility through modification [86,87,88,89,90].

4.1.3. Organic Flame-Retardants

Some commonly used organic flame-retardants are organophosphorus, silicone-based, and intumescent materials. The advantage of organophosphorus flame-retardants is that the preparation of organophosphorus flame-retardants containing sulphur elements in polymer polymerisation rapidly enhances the flame-retardant effects of the polymer by synergistic effects of the chemical reaction between phosphorus and sulphur elements in the polymer materials [91,92,93,94]. Silicone-based flame-retardants also have several advantages. These materials exhibit good mechanical properties and better heat, burn, and oxidation resistance. Silicone-based flame-retardant materials come across the surface of the polymer and form a silicone-enriched layer, which turns into polysiloxane of Si and characteristic SI-C bonds during burning. This protective layer helps the polymer to inhibit thermal decomposition. In addition, this also keeps the combustion decomposition materials within the polymer matrix, which is an environmentally friendly process [95,96,97,98].

4.2. Fabrication Methods of Flame-Retardant Composite

In this section, polymer composites with inorganic flame-retardants are discussed. The primary focus of this study is on inorganic metal hydroxide flame-retardants. Research has been conducted on flame-retardant polymer composites containing inorganic metal hydroxide fillers as flame-retardants. Recently, researchers have been actively addressing challenges related to the elevated loading content (approximately 60% ATH or MH) required for better flame-retardancy performance in filler materials. This high load content of filler material negatively impacts the mechanical properties of polymer composites, reducing tensile strength and impact resistance [65,99]. To tackle this issue, scientists are exploring various approaches, including modifying the surface of magnesium hydroxide (MH), adjusting its particle size, and investigating the synergistic effects of MH [100,101,102].

Numerous studies have focused on enhancing the compatibility of MH with polymer composites through surface modifications, such as encapsulating elements like polyphosphazene [103], vinyltriethoxysilane [104], and grafted maleic anhydride [105]. One notable example is the work of Huang [100], who employed stearic acid surface modification on MH. This technique proved effective in improving the flame-retardancy, rheological properties, and mechanical characteristics of the composites. Notably, the Limiting Oxygen Index (LOI) value decreased by 4 when applying 7 to 15% stearic acid coating. While the tensile strength of the composites decreased with a stearic acid coating content of up to 15 wt%, the elongation at break increased significantly by up to 500%.

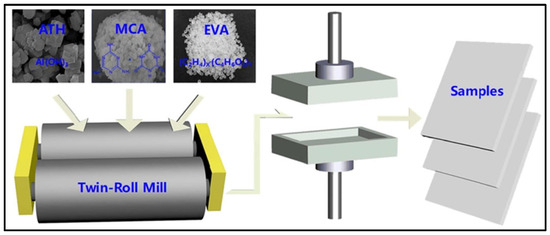

Kalali et al. [106] developed an innovative flame-retardant system for wood polymer composites (WPCs) using a combination of APP and phytic acid-modified layered double hydroxides (Ph-LDH) as raw materials. The inclusion of Ph-LDH resulted in the early degradation of WPCs, leading to more thermally stable products and improved carbon formation. The combustion performance of the WPCs was assessed using LOI, UL-94, and cone calorimetry. The study demonstrated that the addition of Ph-LDH had a synergistic effect on the combustion performance of WPCs, thus making them suitable for applications in buildings or furniture requiring high flame resistance. In another study, Xu et al. [107] addressed the high flammability issue associated with ethylene vinyl acetate (EVA), a commonly used material. They developed highly flame-retardant EVA composites through a combination of melt blending and template methods (as depicted in Figure 6). The combustion tests revealed that EVA-60-40, consisting of 60 wt.% ATH and 40 wt.% monochloroacetic acid (MCA) formed the most effective thermal insulation layer, enhancing its flame resistance. Furthermore, EVA-60-40 exhibited the highest LOI value of 27.5% and attained the UL-94 V-0 grade, indicating its non-flammability. These findings demonstrated that the synergistic effect of ATH and MCA had significant benefits, making the EVA-ATH-MCA composite widely applicable in the construction industry.

Figure 6.

EVA-ATH-MCA composite preparation using melt blending and template methods [63].

Cinausero et al. [108] investigated the synergistic effects of nano-oxide and APP when combined with polymers such as polystyrene (PS) and polymethylmethacrylate (PMMA). Through cone calorimetry, it was observed that the combined application of silicon and an APP flame-retardant reduced the peak heat release rate, minimised the production of opaque smoke, and improved the LOI value. Another study by Nazare et al. [109] examined the synergistic effects of APP, melamine phosphate (MP), and an ATH silicate layer for polyethylene terephthalate (PET). The results showed that MP had the most significant peak heat release rate (pHRR) reduction, followed by APP and ATH.

The main focus of current research on fire-rated combustible cladding panels has been on improving fire resistance through optimised filler types, flame-retardant mechanisms, and fabrication processes. Common fillers, such as aluminium hydroxide (ATH), magnesium hydroxide (MH), and ammonium polyphosphate (APP), work by releasing water or forming protective char layers during decomposition to inhibit flame spread; mechanistically, these fillers reduce heat release, delay ignition, and suppress smoke generation through endothermic reactions and barrier formation. Fabrication techniques such as co-extrusion, lamination, and surface modification are being improved to enhance filler dispersion and bonding between the core and skin layers. Despite these advancements, there are still difficulties in striking a balance between fire performance, mechanical strength, weight, and energy efficiency, indicating the need for sophisticated multifunctional filler systems and scalable, cost-effective manufacturing processes.

5. Non-Combustible Cladding Panel’s Binders, Fillers, and Fibres

Several non-combustible cladding panels [9] have been developed by manufacturers worldwide. Among these, the solid aluminium panel is widely used and accepted as a non-combustible cladding panel, though researchers have recently argued about the testing standard of aluminium panels’ non-combustibility [110]. There are some other non-combustible cladding panels available, which are made of cement-based materials and inorganic minerals [111], which will be discussed in the following sections.

5.1. Filler Types Used in Non-Combustible Cladding

In non-combustible cladding, most of the composite core materials contain inorganic mineral fillers. Among these, ATH, MH, calcium carbonate (CaCO3), calcium hydroxide (Ca(OH)2), and magnesium (MgCO3) have been used by manufacturers worldwide [112,113,114,115]. During testing following AS 1530.1: 1994 [40], few brands received the non-combustible classification for the composite panels listed in Table 6. It is evident that few brands clearly stated their filler details along with their content. Some non-combustible cladding panels contain no filler type, such as PROMINIUM, ALUCOBOND® PLUS, VITRACORE G2, etc., which solely have solid aluminium. PROCOREliteA1 and PROCORE-A1 contain profiled aluminium sheets as the core layer. Some ACPs contain aluminium honeycomb structures as a core material, such as aluminium honeycomb panels, LARCORE, LARCORE A2, etc. Equitone contains a fibre–cement mixer as the core material. Cement-based core materials sometimes contain coarse and/or fine aggregates that also function as insulators.

Table 6.

List of different non-combustible ACPs available in market with their filler types.

5.2. Binders Used to Develop Non-Combustible Cladding Materials

The most common binders used in combustible and fire-rated combustible cladding panels are polymeric materials such as polyethylene [51,127,134,135,136]. As the polymers are highly flammable and pose a high fire risk, polymeric binders have been replaced with cementitious materials to prepare non-combustible cladding panels. Cement, gypsum, and fly ash are the common binders currently used in cement-based cladding panels [137,138]. These cementitious binders are non-combustible [47,139] and have better mechanical properties [47,140,141]. Very few fibre cement-based non-combustible cladding panels, such as Cimentel, Swisspearl, and Equitone, are currently available.

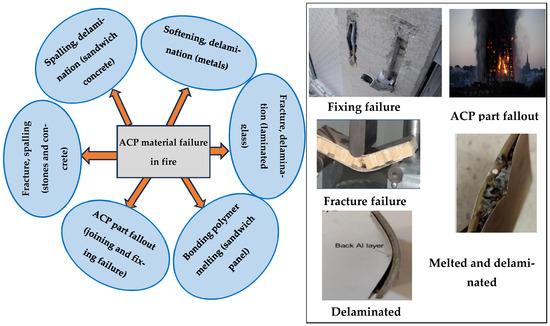

5.3. Bonding Mechanisms

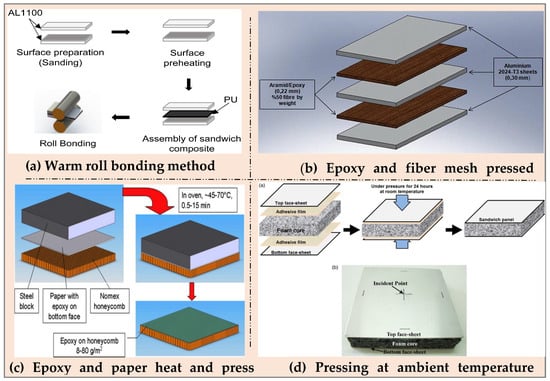

Bonding between the aluminium sheet and core material of ACP panels is of the utmost importance in preventing delamination. There has been a notable occurrence of substantial debris resulting from the separation of aluminium sheets from the core of ACP panels during fire incidents [46]. These separated components also contribute to the spread of fire. Maintaining the attachment of the core materials to the solid aluminium sheet is very important. Manufacturers employ various bonding mechanisms in composite structures to prevent this delamination issue [142,143,144,145]. These techniques include adhesive bonding, bolted joining, clinching, self-piercing riveting, and laser-assisted welding. Each method has its own set of advantages and disadvantages, as detailed in Table 7. Among these options, adhesive bonding and clinching systems are particularly relevant in the context of ACPs. Polymeric materials, such as synthetic rubber adhesive film [146], are commonly used to secure aluminium sheets to the core [28]. The thickness of this bonding film typically ranges from 0.02 mm to a maximum of 0.10 mm. Figure 7 provides a visual representation of the different types of bonding techniques for bonding in ACPs using adhesive films.

Figure 7.

Different bonding mechanism of core materials with aluminium skin. (a) Bonding using warm roll; (b) bonding using fibre mesh and epoxy; (c) bonding using heat press; (d) bonding by pressing at room temperature. Images were reprinted with permission [147,148,149,150].

Table 7.

List of different bonding techniques applied in composite structures with their advantages and disadvantages [33].

Table 7.

List of different bonding techniques applied in composite structures with their advantages and disadvantages [33].

| Bonding Techniques | Joining Mechanism | Advantages | Disadvantages |

|---|---|---|---|

| Adhesive bonding | Inter-atomic and inter-molecular forces at interface, mechanical keying led the adhesives to fill cavities, pores, and asperities of adjacent surface | (i) Widely available materials (ii) Flexible with material arrangements (iii) The only effective method to join two element surfaces which have a substantial thickness difference | (i) Requires significant pre-treatment of adherent surfaces (ii) Requires good wettability with surfaces (iii) Cracking failure is very common |

| Bolted joining | Screwing bolts into nuts on either side | (i) Joining components can be tightened at the required tension (ii) Bolts do not plastically deform | (i) Bearing-mode failure is common (ii) Requires drilling operation on the elements which develop stress and sometimes crack near the hole |

| Clinching | Aluminium sheets are compressed with a punch and die, which helps to interlock within the core segment | (i) Can be joined two dissimilar materials which cannot be welded. (ii) Requires less surface preparation for joining (iii) Improves fatigue performance [142,143,144,145] | (i) Failure can occur due to a lack of sufficient undercut (ii) Initial investment required to set up the die and punch system (iii) Lower bonding strength than self-piercing rivet joining |

| Self-piercing rivet | Semi-tubular rivet joins the elements by plastic deformation of joint components. The compression force creates a mechanical interlock | (i) Requires no surface preparation for joining (ii) No need for proper alignment (iii) Improves fatigue performance [142,143,144,145] | (i) Debonding of composites occur due to discontinuity in joints by adding rivets (ii) Tendency of rivets to bend increases failure chances |

| Laser-assisted welding | Melting and joining parts using a laser beam heat source | (i) Requires less surface preparation (ii) Laser beam conduction welding is suitable for high reflective materials like Al with polymers [151] | (i) High porosity and welding defects reported (ii) Laser beam with high energy is not suitable for highly reflective metals such as Al and concrete |

There is an opportunity to enhance the bonding mechanism within the clinching system through further research to refine the clinching process. Interlocking, a method that has recently gained the attention of manufacturers, serves as an approach to prevent delamination in composite panels. This approach bears similarities to the clinching method.

5.4. Fibres Used to Develop Bendable Cementitious Materials

Bendable cementitious materials or bendable concrete, referred to as engineered cementitious composite (ECC), can bend and withstand a high bending pressure [152]. As these composites contain approximately 2% of fibres [153], the ductility of the cementitious materials is greatly enhanced, and the immediate collapse from cracks is also deferred. Researchers have studied the effect of adding different fibres on developing bendable cementitious materials [153]. To develop bendable cementitious materials, the most common fibres are steel fibres, carbon fibres, polypropylene fibres, polyethylene fibres, basalt fibres, polyvinyl alcohol fibres, jute fibres, coir fibres, etc. Most fibres can be categorised into three categories based on the material type, such as metallic, polymeric, and inorganic fibres. The mechanical and physical properties of different fibres are presented in Table 8 [154].

Table 8.

List of different fibres used to develop bendable cementitious composite.

The fibre content used in concrete plays a crucial role in enhancing its ductility, thereby reducing crack propagation and increasing its impact resistance [152]. In a study conducted by Zhang et al. [170], it was noted that fibre-reinforced cementitious composites with high-modulus nanofibres like carbon and steel exhibited limited strain capacity but high tensile strength. Conversely, low-modulus fibres like PVA displayed the opposite characteristics. The incorporation of PVA fibres into ECC significantly improved the tensile strain, flexural strength, and tensile strength properties [171]. The most significant improvement was a 116.4% increase in flexural strength with a 1.5% PVA fibre content and a 100% enhancement in ultimate strain with a 1.2% PVA fibre content.

In another investigation by Wang and Li et al. [172], the combination of PVA and SF fibres was explored. It was determined that a combination of 1.5% PVA and 0.5% SF fibres resulted in the highest levels of strength, strain, and ductility for ECC. Wang and Li [173] conducted a study on PVA and steel fibres in ECC composites to examine their mechanical properties. The research revealed that ECC with steel fibres demonstrated optimal outcomes in the 0.5% to 0.75% fibre content range. It was also observed that when the steel fibre volume is below 0.5%, there is a risk of rupture failure, while a fibre volume exceeding 0.75% may result in tensile failure. For thermal insulation applications, in another study [174], it was noticed that polypropylene was the most suitable fibre among the various fibres investigated. Another study examined a mixture of steel microfibres and PP fibres with a ratio of 4:1, respectively [175]. In fly ash type C geopolymer concrete, varying dosages of 0%, 0.5%, and 1% were used. The research focused on compressive and flexural strength, revealing enhanced mechanical properties at higher temperatures (250 °C) [175]. In a separate investigation, the impact of different fibre types and percentages on the density of the composites was studied [165,176,177,178]. Steel fibre-reinforced geopolymer concrete (FRGC) was specifically examined, demonstrating that FRGC containing steel fibre exhibited a higher density compared to composites without fibre. Additionally, an increase in fibre content led to a decrease in composite density due to the presence of pores among the fibre clusters in their initial state [154]. While there are several advantages to incorporating fibres in specific proportions, it is worth noting that some fibres may require treatment to improve their dispersion properties, especially when used in polymer composites [179].

It can be seen that superior fire retardancy and structural integrity are achieved by non-combustible cladding panels using high-performance fibres, mineral fillers, and inorganic binders. Current systems frequently have limitations in terms of weight, durability, and environmental effect, despite the thermal and mechanical advantages of these components. Future studies should concentrate on creating sustainable, lightweight composite compositions for advanced facade applications that perform better over the long run.

6. Thermal, Flammability, and Mechanical Properties of Cladding Materials

For sustainable energy-efficient cladding materials, it is crucial to examine the thermal, flammability, and mechanical characteristics of cladding materials. To enhance the fire resistance of materials under elevated temperatures, researchers have devoted extensive efforts to study mechanical and flammability properties [46,180,181,182].

6.1. Thermal Properties of Cladding Materials

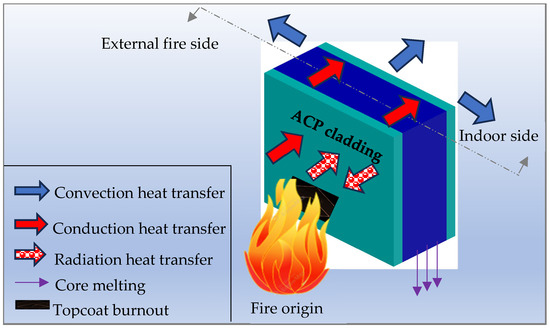

Heat transfer through cladding panels controls the overall thermal performance of the building. A schematic view of the usual heat transfer modes is presented in Figure 8. The thermal conductivity of a material is directly connected to the heat conduction through the material [183]. It is one of the most important thermal properties widely studied in developing thermally insulated construction materials [6]. The thermal conductivity property is crucial for better cladding performance [4]. Table 9 presents some cladding brands’ thermal conductivity and weight per square meter (kg/m2) and thermal resistance (m2·K/W). It can be seen from Table 9 that the cladding panels containing flame-retardant fillers have a lower thermal conductivity than the solid aluminium panels and honeycomb panels. This is due to the high heat transfer ability of the aluminium metal lattice [28]. A high amount of heat energy transfers through the lattice when a high temperature difference exists on aluminium surfaces. In addition, due to the weak metallic bonding in aluminium, its heat transfer is very high as electrons can freely move throughout the material [28]. Flame-retardant fillers have a very low thermal conductivity compared to aluminium because the basic function of these materials is to interrupt heat transfer during combustion by producing barriers or absorbing heat during chemical reactions [184]. Due to aluminium’s high heat conductivity, aluminium composite panels typically have a very low thermal resistance, making them inadequate insulators in and of themselves. Nonetheless, the thermal resistance of products such as PROCORE-A1, ALPOLIC A2, and LARCORE A2 is somewhat increased by the addition of fire-rated or mineral-filled cores. The fibre–cement-based cladding panels exhibit higher thermal resistance, indicating them as better insulating materials.

Figure 8.

A schematic illustration of heat transfer modes involved in fire incidents through ACP panels.

Table 9.

Thermal properties of different cladding products.

Recent research examining the thermal characteristics of aluminium composite panels (ACPs) has provided important new information about how these panels behave in hot environments, especially with regard to their function in fire safety and building energy efficiency. According to research, the kind of core material utilised has a significant impact on the thermal conductivity of ACPs. The energy efficiency of buildings is compromised by the thermal bridging effect and increased heat transfer caused by traditional polyethylene (PE) cores’ high thermal conductivity [185]. On the other hand, more recent mineral-filled cores that are fire-retardant and designated as A2 or non-combustible have a significantly lower thermal conductivity, enhancing thermal resistance and lowering the chance of a fire spreading. The integration of nano-fillers, such as nano-scale SiO2 fillers, into the core or resin matrix offers a significant advancement in thermal performance. This approach enhances heat dissipation across the panel, thereby mitigating issues related to thermal bridging and overheating. The considerable surface area of SiO2 nanoparticles promotes stronger adhesion with the polymeric core, thereby improving structural integrity and reducing thermal resistance at the interfaces.

In addition to SiO2 nanoparticles, some other nano-fillers such as Boron nitride nanosheets, carbon nanotubes, graphene oxide, and nano-clay can contribute to enhanced thermal stability and fire resistance by serving as a barrier that slows heat transfer while inhibiting the release of flammable gases during exposure to fire. This synergistic effect not only optimises the energy efficiency of aluminium composite panels (ACPs) through improved heat flow management but also increases fire safety. Consequently, ACPs become more appropriate for use in sustainable, high-performance building facades, facilitating the development of resilient and efficient architectural solutions. They have also been evaluated in a variety of climatic conditions using finite element simulations and real-time performance monitoring, demonstrating how well air gaps, panel thickness, and orientation reduce heat gain [186]. Nevertheless, despite these developments, little is known about how non-combustible ACPs behave thermally overall in practical settings, indicating the urgent need for more experimental and simulation-based studies.

6.2. Flammability Properties of Cladding Materials

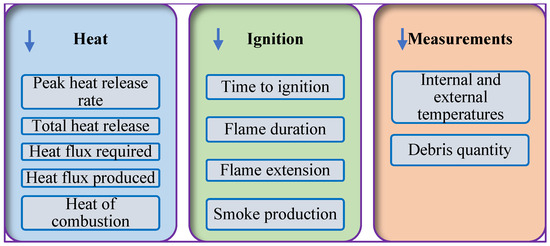

Flammability testing of a cladding system is very important for a building to identify the materials’ combustibility and potential to contribute to fire spread in buildings. The testing for the cladding system, which contains combustible materials, is more sensitive as the materials can melt at higher temperatures, though the surface sheets are non-combustible [187]. Different tests [6,39,135,188,189] have been conducted to study flammability properties, ranging from small-scale individual component tests to full-scale cladding system tests. Different performance criteria are considered to assess the flammability, see Figure 9 [187].

Figure 9.

Different performance criteria considered in flammability testing.

Hossain et al. [39] studied the reaction-to-fire properties of cladding panels with conventional and alternative testing approaches using a cone calorimeter at 50 kW/m2 heat flux. In conventional cone calorimeter testing, only the ACP-1 specimen containing 100% PE ignited, while the other samples did not. However, both ACP-2 and ACP-3 specimens were ignited when tested using alternative testing approaches using the same cone calorimeter at 50 kW/m2 heat flux (see Table 10) [39]. Another study was conducted on various ACP panels’ cores containing different polymers and minerals with varying heat fluxes, such as 35, 50, and 60 kW/m2, and it was observed that with the increase in heat flux, ignition occurred earlier (ignited at 252 s, 202 s, and 106 s, respectively) and the total heat release and peak heat release rate per unit area (pHRRPUA) also increased [46]. The results also provide insight into the effectiveness of the flame-retardant fillers. Specimen ACP-2 and specimen ACP-7 contain ATH filler with 28% EVA and 27% PE polymer, respectively. At 50 kW/m2 heat flux, the PE-containing specimen ignited 9 sec earlier, and the total heat release was much higher than that of the EVA specimen (73.41 MJ and 56.9 MJ, respectively). This indicates the effectiveness of the ATH filler with EVA rather than PE. In the case of the ACP-3 and ACP-5 specimens, CaCO3 filler was used with 99% PE and 78% PE, respectively. It was observed that though the filler content was increased, the flammability properties did not improve significantly as ignition occurred earlier. Similar behaviour was observed in the case of specimens ACP-6 and ACP-8, where MgOH filler was added to the PE-EVA composites at 86% and 70%, respectively. With increased filler, the flammability properties did not enhance significantly. For specimen ACP-2 and ACP-7, it can be seen that ATH filler showed a better flame-retardancy with EVA polymer, though a similar amount of filler (around 72%) was used in those two specimens containing EVA and PE. The results show that the high amount of the polymer in the specimen influences the ignition time, total energy release, and pHRRPUA. With the increase in the mineral content, the ignition time was delayed, and the total heat release was also lower. It is also evident that, with the increase in heat flux, ignition occurred earlier, and the total heat release and pHRRPUA also increased (see Table 10). The performance of fire-retardant fillers depends not only on the filler percentage but also on the polymer element of the composite.

Table 10.

Reaction-to-fire properties of ACP core samples with different compositions tested using a small-scale test at 50 kW/m2 heat flux [39,46].

6.3. Mechanical Properties of Cladding Materials

The mechanical behaviour of ACP panels decreases very quickly due to the rapid heat transfer of aluminium and quick degradation of the core materials [32]. The common mechanical properties of cladding materials studied by researchers and manufacturers are bending strength [190,191,192], tensile strength [193], impact loading [194], and peel strength [195]. Ahcene et al. studied the bending strength of ACP honeycomb under cyclic loading (90%, 80%, and 70%), where it was observed that the ideal load for maximising the service resistance of the tested sandwich panel is 70% of the material’s elastic limit (720 N) [190]. Usually, the 0.2% proof stress of a typical ACP panel is around 130 N/mm2 [129], whereas the flexural elasticity is around 38.5 KN/mm2. The tensile strength of a typical ACP panel is around 130 to 150 N/mm2 [121,129]. Recently, glass fibre has been used to improve the mechanical properties of the ACP panel, such as impact resistance [196]. E. Simsir studied the impact-resistance behaviour of ACP panels with reinforced glass fibre composite weighing 200 g/m2 and 400 g/m2. A low-velocity impact test was also conducted, and it was observed that the 400 g/m2 glass fibre showed a better resistance with less displacement (5 mm), whereas it was 15 mm for the 200 g/m2 composite. The displacement for the ACP without glass fibre was 20 mm and the damage was severe [196]. When cladding panels are heated, the mechanical properties of most materials degrade, and eventually, some materials burn (combustible materials) or melt (metal, glass, and thermoplastic polymers). Several changes occur during the degradation process, such as changes in microstructure and weakening of the atomic bonding. In Figure 10, several modes of material failure methods have been illustrated, which mainly occur during fire exposure. There is limited data provided by the manufacturers about the mechanical properties of the cladding products and not much available in the literature either. However, in Table 11, a list of different cladding products with their mechanical properties is presented. The specified cladding materials’ flexural strengths vary greatly; PROBOND-FACADE-FR has the strongest resistance at 60 MPa, while CEMINTEL BARESTONE and SWISSPEARL have lesser resistances at 18 MPa and 26 MPa, respectively. Some products, such as PROMINIUM, PROCORE-A1, and PROBOND extreme FR, have an impact resistance of 50 kg/cm2, but data is unavailable for others. Indicating notable variations in material resilience, tensile strength ratings range from 5 MPa for SWISSPEARL to 160 MPa for PROCORE light A1 and PROMINIUM. The tensile strength of aluminium-based panels is generally higher than that of fibre cement panels, like SWISSPEARL, which have a relatively lower tensile capacity.

Figure 10.

Different failure modes due to thermal expansion. Thermal degradation of mechanical properties in fire: some figures are reprinted with permission [10,135,197,198].

Table 11.

Mechanical properties of different cladding brands.

7. Survey on the Patents of ACP Cladding Panels

Numerous patents relevant to aluminium composite panels (ACPs) demonstrate significant advancements in the structure, fire resistance, and surface treatment of these panels since their inception. In the 1970s, the first ACP patent was owned by Alusingen (now 3A Composites), leading to the launch of the popular ALUCOBOND® trademark. Numerous innovations, including enhanced fire-retardant cores, UV-printed surfaces, and mechanically reinforced constructions like corrugated aluminium stiffeners, have since been patented by manufacturers like Chinalco (China), Yaret (China), as well as companies in Korea, Germany, and the US. As a step towards safer and more environmentally friendly building materials, new international patents also look into sustainable cores like magnesium oxide with reinforcing mesh. These patents show how performance, safety, and aesthetics are becoming increasingly important in the ACP sector. In Table 12, a list of patents on ACP cladding panels have been presented from the Google patents database by searching the term “non-combustible aluminium composite panels”. Relevant patents have been included in the table. A variety of panels, such as honeycomb, corrugated, non-combustible, and fire-retardant designs, have been developed by manufacturers in the USA, China, Germany, and Japan. Notable businesses with patented technology for safer and more resilient building materials include Mitsubishi Chemical, Alcoa, and Novelis. Additionally, Chinese producers have been engaged, particularly in the production of non-flammable, A2-grade panels that adhere to stringent fire-safety regulations. The global endeavour to improve the functionality and security of ACP systems in contemporary building is reflected in all of these patents.

Table 12.

List of notable patents of ACP cladding panels around the world.

8. Economic Viability of Non-Combustible Panels

Fire-safety performance, material cost, installation, maintenance, and lifespan benefits must all be balanced for non-combustible cladding options to be economically viable. Even though non-combustible materials—like fibre cement, mineral-based composites, and solid aluminium—are frequently more expensive initially than combustible alternatives, they provide substantial long-term savings due to their increased durability, decreased risk of fire, cheaper insurance rates, and regulatory compliance [212]. Even while fire-rated non-combustible panels can cost 20–40% more up front, according to recent studies, they frequently outperform combustible systems in terms of lifespan cost-effectiveness, particularly in public or high-rise buildings where fire risk is a major concern [213]. Additionally, cost competitiveness is steadily increasing due to advancements in prefabricated systems and lightweight, sustainable core materials. Nevertheless, there are still study gaps in assessing the following:

- Comparing different cladding systems using full life-cycle cost analysis (LCCA).

- Scalability and supply chain viability of new non-flammable materials.

- Incorporating the concepts of the circular economy to enhance reuse and decrease waste.

Thus, when long-term safety, compliance, and sustainability are given priority, non-combustible cladding options become more economically viable even though they may currently have higher capital costs.

9. Recycling Challenges of ACP Panels in Circular Economy

Aluminium composite panels (ACPs) pose substantial challenges for recycling within a circular economy due to their complex multi-material structure. Comprising two aluminium skins bonded to a polymeric or mineral core, ACPs are difficult to disassemble, leading to inefficient and energy-intensive material recovery processes. While fire-retardant additives enhance safety, they complicate recycling by altering thermal properties and generating potentially hazardous by-products. Coatings on aluminium skins may also introduce contaminants during remelting, reducing the quality of the recovered metal.

There is a lack of specialised recycling infrastructure and scalable technologies, coupled with high processing costs and low economic returns, which deters investment in effective recovery solutions. Additionally, significant variability in panel composition and the absence of standardised designs limit batch processing and secondary use opportunities. Regulatory constraints, particularly in the construction sector, also restrict the reuse of recycled ACP components due to compliance issues with fire safety and structural performance standards.

To overcome these challenges, future ACP designs should focus on recyclability by incorporating standardised components, using non-toxic and separable materials, and applying design-for-disassembly principles. These strategies will improve alignment with circular economy initiatives and promote sustainable lifecycle management.

10. Recent Research on Cladding Panels

Recently, several research studies have been conducted to investigate the fire safety [6,9,39,214,215], thermal properties [216,217,218], and energy efficiency [219,220] of ACP panels. A list of recent studies on cladding panels is presented with details in Table 13 and Table 14. Due to convenience and cost-efficiency, a small-scale test is widely used to determine the flammability and fire hazard properties of the materials. As the number of fire incidents in high-rise buildings has remarkably increased, the significance of testing cladding materials for flammability has also increased. Mckenna et al. [6] conducted experiments on different cladding materials available on the market, ranging from combustible to non-combustible, after the Grenfell Tower fire incident. A micro-scale combustion calorimeter and cone calorimeter were used. ACPs with a higher polymeric core had the maximum heat of combustion, while in the case of the non-combustible core, there was very low or no heat of combustion [46]. Another study was conducted on polymer-based ACP with different core compositions using a cone calorimeter for 35, 50, and 60 kW/m2 heat fluxes [46]. The results showed that the time to ignition generally decreases with the increase in polymer content. At 60 kW/m2 heat flux, the influence of the polymer was evident. The time to ignition for the specimen with 99% PE was only 26 s, while for the specimen containing 7% polymer, it was 106 s. For a 99% PE core ACP, the peak HRRPUA was 725 kW, while with 7% polymer, it was 99 kW. Another finding was that in the case of a 99% PE core, the peak was very sharp instead of burning in a steady state, and with an increase in the thickness of the core, the peak HRRPUA increased significantly for the same core composition. Mckenna et al. [6] conducted another study on ACP samples, removing some of the aluminium skin to ignite the core materials. The results from the cone calorimeter test show that there are significant variations in the heat release rate and total heat release for different ACP samples, which are greatly influenced by the polymer content and the mineral filler types and contents. The tests were conducted with 50 kW/m2 heat flux and the results showed that the high polymer content panels ignited earlier than the other panels. In addition, for high polymer content specimens, the heat release rates were also significantly high (up to 1300 kW/m2). A study on aluminium composite panels reinforced with jute, sisal, kenaf, and flax fibres in an epoxy matrix reveals the promising potential of developing sustainable, lightweight ACPs using natural fibres [221]. It effectively highlights the favourable mechanical properties of these materials. However, to enhance their applicability in fire-safe contexts, future research could focus on evaluating their fire performance, addressing an important aspect for their overall suitability in construction applications. In another study, the full-scale fire performance of curtain wall systems demonstrates that non-combustible assemblies, when equipped with properly installed firestops, significantly exceed the performance of combustible systems in containing fire spread and safeguarding adjacent compartments [215].

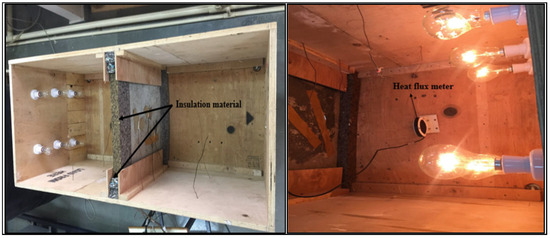

For energy-efficient cladding material, it is crucial to investigate thermal performance and evaluate the energy consumption of the cladding panels. A list of some recent studies on the energy consumption of external cladding is presented in Table 1 with key findings. Sravani et al. [222] studied the inclusion of phase change material in composite external wall cladding to improve energy efficiency. A wooden experimental setup was fabricated (Figure 11) to observe the change in air temperature with 60 W, 100 W, and 200 W heat fluxes. TGA analysis was conducted to observe the PCM’s thermogravimetric properties. It was found that lauric acid started losing mass very consistently between 140 and 210 °C. Three types of cladding were studied: concrete with perlite cladding, aluminium box cladding with PCM and coarse aggregate, and composite wall cladding. The highest air temperature difference was for composite wall cladding (20.96% at 100 W), whereas the minimum temperature difference was in the case of aluminium box cladding with PCM and coarse aggregate (3.20% at 60 W). The drop in heat flux was highest in the case of aluminium box cladding with PCM and coarse aggregate (98.61% at 60 W and 100 W), but at a higher heat flux (200 W), the drop in heat flux was 97.17% for concrete cladding containing perlite.

Figure 11.

Wooden experimental setup by K. Sravani et al., reprinted with permission [222].

Table 13.

List of recent research on ACP cladding panels.

Table 13.

List of recent research on ACP cladding panels.

| Sl No | Title | Source Title | Year | Test Category | Ref. |

|---|---|---|---|---|---|

| 1 | Alternative fire performance screening method of cladding system using cone calorimeter | Construction and Building Materials | 2024 | Cone calorimeter | [39] |

| 2 | Establishing pyrolysis kinetics for fire modelling and thermal analysis of polymeric cladding materials used in high-rise buildings | Case Studies in Construction Materials | 2023 | Small-scale test | [223] |

| 3 | Manufacturing of aluminum composite panels based on aluminum with jute/sisal/kenaf flax natural fibre reinforced epoxy | Journal of Environmental Protection and Ecology | 2023 | Mechanical properties testing | [221] |

| 4 | Full-Scale Fire Performance of Combustible and Non-combustible Curtain Wall Systems with Firestops | Fire Technology | 2023 | Full-scale test | [215] |

| 5 | Assessing the combustibility of claddings: A comparative study of the modified cone calorimeter method and cylindrical furnace test | Fire and Materials | 2022 | Cone calorimeter test | [224] |

| 6 | Experimental and simulation study on the combustion fire spreading characteristics of aluminium composite panels with different thicknesses | Fire and Materials | 2022 | - | [225] |

| 7 | Numerical Investigations on the Influencing Factors of Rapid Fire Spread of Flammable Cladding in a High-Rise Building | Fire | 2022 | Full-scale test | [226] |

| 8 | Effect of different building facade systems on thermal comfort and urban heat island phenomenon: An experimental analysis | Building and Environment | 2022 | - | [219] |

| 9 | Facade Fire Hazards of Bench-Scale Aluminum Composite Panel with Flame-Retardant Core | Fire Technology | 2021 | Cone calorimeter test | [135] |

| 10 | Testing of aluminium composite panels in a cone calorimeter: A new specimen preparation method | Polymer Testing | 2021 | Cone calorimeter | [2] |

| 11 | Evaluating the fire risk associated with cladding panels: An overview of fire incidents, policies, and future perspective in fire standards | Fire and Materials | 2021 | Cone calorimeter | [10] |

| 12 | Quantification of Enhanced Fire Severity in Modern Buildings | Advances in Energy and Combustion | 2021 | Quantitative analysis (full scale) | [227] |

| 13 | An experimental study on effect of aluminum composite panel waste on performance of cement concrete | Ain Shams Engineering Journal | 2021 | Mechanical properties of concrete | [228] |

| 14 | Fire behaviour of modern facade materials—Understanding the Grenfell Tower fire | Journal of Hazardous Materials | 2019 | Full-scale test | [6] |

| 15 | Study of fire behaviour of facade mock-ups equipped with aluminium composite material-based claddings, using intermediate-scale test method | Fire and Materials | 2018 | Intermediate-scale test | [37] |

| 16 | Flammability and multi-objective performance of building Facades: towards optimum design | International Journal of High-Rise Buildings | 2018 | - | [229] |

| 17 | Fire Spread Caused by Combustible Facades in Japan | Fire Technology | 2016 | Intermediate-scale test, full-scale test | [230] |

Table 14.

Recent experimental studies of the energy analysis of composite cladding.

Table 14.

Recent experimental studies of the energy analysis of composite cladding.

| Sl No | Title | Cladding Types | Key Findings | Ref. |

|---|---|---|---|---|

| 1 | Experimental Study on PCM-Based External Wall Cladding for Energy Efficient Buildings | (i) Concrete with perlite cladding (ii) Aluminium box cladding with PCM and coarse aggregate (iii) Composite wall cladding | (i) 20.96% reduction in air temperature with composite wall cladding at 100 W heat flux. (ii) Heat flux dropped 98.61% for aluminium box cladding at 60 W and 100 W. | [222] |

| 2 | Experimental Study on the Thermal Performance of Ventilation Wall with Cladding Panels in Hot and Humid Area | (i) Higher-density fibre-reinforced calcium silicate board | (i) 4.9 °C lower air temperature with proposed cladding. (ii) Increase in building thermal resistance. (iii) Need mechanical ventilation to dissipate heat. | [231] |

| 3 | Innovative PCM-incorporated foamed concrete panels for walls’ exterior cladding: An experimental assessment in real-weather conditions | (i) PCM-FC cladding | (i) The average daily fluctuations of the temperatures decreased by 3.59 °C, 7.39 °C, and 6.02 °C, respectively, for the external wall surface, internal wall surface, and room inside temperature, respectively. (ii) The intensity of overheating also decreased by 32.1%, 29.4%, 24.4%, and 21.1% for the south, east, west, and north orientations. | [232] |

| 4 | Several facade types for mitigating urban heat island intensity | (i) ACP panels | (i) Best UHI mitigation: green walls and reflective coatings. (ii) Reflective coatings: avg. temp reduction of 0.53 °C, max reduction of 1.89 °C, effective during low sun angles. (iii) Green walls: avg. temp reduction of 0.65 °C, max reduction of 0.99 °C, cooling via evapotranspiration. | [233] |

| 5 | Investigating the Influence of Thermal Conductivity and Thermal Storage of Lightweight Concrete Panels on the Energy and Thermal Comfort in Residential Buildings | (i) Lightweight concrete panels with PCM (ii) Normal concrete panel | (i) The influence of thermal mass is higher than that of thermal resistance on discomfort hours. (ii) The position of insulation layer has a significant impact on the energy savings rate. (iii) Heating energy consumption depends on thermal resistance much more than on thermal mass, while cooling energy consumption is influenced more by thermal mass. | [234] |

| 6 | Energy consumption to cool and heat experimental modules for the energy refurbishment of facades. Three case studies in Madrid | (i) Precast concrete panel (M1 model) (ii) Extruded, high-pressure laminate (HPL) ceramic tile ventilated facade (VF) with thermal insulation layer and cavity (M2) (iii) ETIS panel (M3) | (i) Maximum 15.4% energy savings were achieved for south-facing ETISs, while for the standard non-insulated cavity wall it was 13.3%. (ii) For different seasons of the year, energy consumption varied significantly. | [235] |

| 7 | A New Method for Energy Efficiency Design of Building Facade and Its Thermodynamic Evaluation | (i) Cement–rockwool facade | (i) Presented calculation methods for the coefficient of building shape, the resistance of heat transfer, and thermal inertia. (ii) Proposed a thermodynamic evaluation method for assessing the energy-saving efficiency of the facade. | [236] |

| 8 | Ventilated facades energy performance in summer cooling of buildings | (i) Copper plates (ii) Brick slabs (iii) Asbestos cement panels (iv) Slabs of ceramics (v) Brick hollow flat blocks (vi) Polyester panels | (i) With an air duct width increase, the energy savings also increased. (ii) It was suggested to position the insulating layers close to the inner masonry walls. (iii) With increasing solar radiation, the ventilated facades performed more efficiently. (iv) The wall’s outer surface thermal resistance significantly influenced the energy savings of the model. | [237] |

| 9 | Effect of different building facade systems on thermal comfort and urban heat island phenomenon: An experimental analysis | (i) ACP panels (ii) Clear glass (iii) Brick (iv) Concrete | (i) ACP: When combined with brick, it reduces the indoor air temperature significantly; however, it may raise the outdoor air temperature, potentially worsening UHI. (ii) Brick facades absorb and store heat during solar exposure, and re-emit heat to indoor and outdoor environments, contributing to UHI. | [219] |

In another study by Zhu et al. [231], experiments were conducted in a test room on a sunny day and a cloudy day. The test room is surrounded by an external ventilated wall and cladding panel made of a higher-density fibre-reinforced calcium silicate board. It was identified that with the cladding and the wall, the indoor maximum temperature was 4.9 °C lower and 4 h later than the outside temperature, whereas the external wall temperature was 5.9 °C lower and 1 h later than the cladding board surface. It was also observed that the heat absorbed during the daytime did not dissipate at night on cloudy days due to the ventilated cavity. Mechanical ventilation was recommended to remove the heat from the wall, and an indoor natural ventilation system was recommended to reduce the structure’s thermal resistance and dissipate heat due to indoor thermal waves on cloudy days and at night [231]. Al-Absi et al. [232] studied the thermal performance of wall cladding containing PCM and foamed concrete. It was observed that due to the inclusion of PCM in foamed concrete, the thermal performance was significantly improved. An experimental setup was prepared to measure the temperature inside the cell (Ti), on the external wall outside surface (TSe), and on the inside surface (TSi). It was found that the internal temperature was decreased by 5.50 °C with the PCM-FC cladding, and the temperature reduction at the inside surface was 6.75 °C. The average daily temperature fluctuations also reduced by 3.59 °C, 7.39 °C, and 6.02 °C for TSe, TSi, and Ti, respectively. The intensity of overheating was also decreased by 32.1%, 29.4%, 24.4%, and 21.1% for the south, east, west, and north orientations. Ornam et al. conducted research on different facades and identified that green walls and reflective coatings effectively reduce the intensity of urban heat islands (UHIs), lowering surface temperatures by 0.65 °C and 0.53 °C, respectively [233]. In contrast, heavy materials like brick tend to retain heat and exacerbate UHI effects. By integrating field data with simulations, the research emphasises the potential of these facade strategies to enhance thermal comfort and guide sustainable urban design.

Several research studies have been conducted using full-scale testing methods to study the fire performance of ACP cladding panels. Gandhi et al. [238] studied the fire performance of PE containing ACP cladding panels in a full-scale test setup where it was observed that the cladding panel started to shrink at around 275 °C, while the panel’s polyethylene core delaminated at 600 °C and combustion initiated. In addition, the aluminium skin and the insulation polymer melted, which created a secondary fire. Another full-scale fire performance study on ACP panels with LDPE core material was investigated by G. Srivastava et al. [134]. Within 5 min of the test run, the temperature of the cladding system increased to 740 °C, and the cladding panels failed due to the ignition of the core materials. J. E. Mendez et al. [12] investigated the flame-spreading behaviour of ACP cladding panels, PE-core, and FR-rated core. The ignition temperature was 321 °C for ACP panels with PE core, while the ignition temperature for the core with FR materials was 423 °C. The maximum peak heat release rate was also 615 kW/m2 and 175 kW/m2, respectively. Hence, it is evident that the composition of core materials greatly influences the fire performance of cladding panels.

Upon discussing the current research studies on ACP cladding panels’ flammability properties, fire performance, thermal and mechanical properties, and energy consumption analysis, several factors have been identified that require further investigation for fire-safe non-combustible cladding panels, such as non-combustible core materials, alternative bonding mechanisms, and improvement of the thermal performance of the ACP cladding panels, which are briefly discussed in the following section.

11. Conclusions and Future Research Directions

Cladding panel research has increased significantly in investigating the flammability and fire-resistant performance of combustible and fire-rated cladding panels. After thoroughly studying the literature on cladding panels, several research scopes have been identified where significant research can be conducted for sustainable energy-efficient fire-resistant ACP panels. The following conclusions can be drawn based on this literature review.