Abstract

This article discusses the current problem of industrial waste disposal and its use in the production of building materials, which corresponds to the global concept of sustainable development. Attention is mainly paid to the development of a gruntosilicate composite (concrete) based on a mineral slag binder using drilling sludge from the mining industry, ashes from thermal power plants and electrothermophosphoric slag. Physico-chemical studies of man-made raw materials have been carried out, including analysis of chemical and mineralogical composition, granulometric characteristics, radiation safety and other parameters. It has been established that drilling mud, thermal power plant ash and electrothermophosphoric slag meet the requirements for use in building materials and belong to non-hazardous waste. The optimal ratios of the components in the composition of gruntosilicate concrete have been experimentally determined. The highest compressive strength (3.0–3.5 MPa) is achieved with a drilling mud content of 15–23% and a mineral slag binder of 10–20%. It is shown that the introduction of these wastes improves the structure of the material, reduces shrinkage deformations and ensures compliance with the requirements of road surfaces of the II–III classes. The use of industrial waste in construction will reduce the cost of raw materials by approximately 10–30%, reduce the environmental burden and solve the problem of waste disposal. The results of the study demonstrate the prospects of creating a waste-processing industry capable of processing up to 40% of industrial waste into building materials.

1. Introduction

Saving energy and natural material resources are two interrelated tasks that underlie the concept of “Sustainable Development” of humanity [1,2,3,4,5]. It was first put forward at the UN conference in Rio de Janeiro in 1992 in the presence of 178 heads of state, and became decisive in the development strategy of civilized countries [3,4,5,6,7]. It involves both preserving the environment by reducing the harmful effects of humanity on water, air, soil, flora and fauna, and maximizing the conservation of irreplaceable natural resources [8,9,10,11,12].

In March 2006, the World Council for Sustainable Development in Building (WBCSD), led by the world’s largest manufacturers and suppliers of building materials, United Technologies Corp. and Lafarge Group, proposed that the largest developed and developing countries (USA, EU, China, India and Brazil), by 2050, minimize energy consumption and eliminate emissions of harmful substances during the construction process, while maintaining economic feasibility and competitiveness.

The return of waste to the general production material circulation as secondary raw materials is an inevitable and progressive trend for all countries in the world [12,13,14,15,16,17], and, therefore, in the third millennium all regions “should and will be able” to use the potential of secondary resources [18,19,20,21,22,23,24,25]; there is a real possibility that “recycling” will reach 55% [24,25,26,27,28,29,30,31].

The problem of waste generation has two interconnected parts: environmental and resources [30,31,32,33,34,35].

The problem of environmental safety in the Republic of Kazakhstan remains acute and is directly related to the growing accumulation of industrial, household and agricultural waste and the problem of handling and processing it. The complexity of the latter lies in the intersectoral nature of waste and objective contradictions in the sphere of its processing as secondary material resources (SMRs). The complexities are as follows: waste producers are not interested in processing waste into other, non-core products if there is no possibility of recycling (return to the original technological process), because we need new technologies, new personnel, material and financial resources; and manufacturers of other (in particular construction) products are not interested in replacing standard (standard) raw materials with waste-secondary raw materials that are unstable in composition, since this is associated with the complication of an already-proven technology caused by the additional preparation of secondary raw materials.

The creation of such an industry in the Republic of Kazakhstan will ensure the return of waste in the form of secondary raw materials into the general production material circulation, which corresponds to the inevitable and progressive global trend of general “recycling”.

Construction is the most material-intensive sector of the national economy, which consumes up to 50% of the volume of natural raw materials, the extraction of which causes inevitable damage to the natural environment. The shortage and cost of non-metallic construction raw materials are increasing every year (for example, according to Rosstat, prices for crushed stone from dense rocks have increased by 100% over the past 5 years). At the same time, construction, especially civil construction within urban areas, associated with the demolition of old and unsafe buildings and structures, is accompanied by the production of large amounts of construction waste: scrap brickwork, wooden products, broken glass, concrete and reinforced concrete structures, facing materials, metal, etc. The construction industry enterprises themselves also produce waste in the form of defective materials and products, and technological waste. Therefore, the problem of handling construction waste and its disposal has its own specifics, associated with their large volume and practical safety (sanitary and toxicological), which leads to unauthorized landfills within the city limits.

The Republic of Kazakhstan is an industrially developed region with a powerful construction complex, which also experiences a shortage of affordable and high-quality raw materials for the construction industry, in the products of which the share of material and fuel costs traditionally exceeds 50%. In terms of the variety and volume of products produced and the consumed raw materials, the construction materials industry surpasses all others and is therefore a unique industry capable of recycling the bulk of waste from almost all other industries of the Republic of Kazakhstan: oil production and oil refining, organic and inorganic chemistry, mechanical engineering, light and even food industries, and also waste from the construction and agro-industrial complex itself.

To create a waste processing industry, or “Ecocomplex”, we need new enterprises with new technologies for processing industrial waste from the Republic of Kazakhstan into building materials and their functional components: binders and fillers, chemical additives, fillers, hardening accelerators and many others.

In 2020 in Kazakhstan, the volume of waste generated amounted to 914,135.3 thousand tons, including industrial waste at 909,491.6 thousand tons (99.4%) and solid waste at 9.947 thousand tons (0.6%). In total, 182,807.8 thousand tons (19.9%) were processed and reused, and 726,683.8 thousand tons (79.9%) were placed in controlled landfills. Trans-boundary transportation of waste in 2020 amounted to 9.947 thousand tons. The volume of accumulated industrial waste as of 01/01/2022 amounted to 23,609,272.937 thousand tons.

The end result of the activities of NPEK “Ekostroymat” should be a number of new building materials and products produced at the enterprises of the complex from waste from the Republic of Kazakhstan using new and improved traditional technologies, as well as new functional components of known building materials.

One of the most promising areas for recycling industrial waste is its use in the production of building materials, which will reach up to 40% to satisfy the needs for raw materials in this most important industry.

The use of industrial waste will reduce the cost of producing building materials by 10–30% compared to their production from natural raw materials, with capital investment savings in this case of 35–50%.

The use of man-made industrial waste would cover up to 50% of the country’s needs for raw materials [36,37,38,39,40,41], reduce the costs for the production of building materials by 10–30% [40,41,42,43,44,45,46,47] and reduce man-made loads on the environment [48,49,50,51,52,53].

The aim of this scientific work is to study the production of a ground silicate composite based on a mineral slag binder with the disposal of industrial waste.

2. Materials and Methods

During the research work on the project, we took samples of drill cuttings from the uranium mining industry to obtain soil silicate concrete based on mineral slag binder and drill cuttings. The studies used gray drill cuttings from the mining industry of Semizbay LLP, ash from a thermal power plant (Stepnogorsk), electrothermophosphorus slag from Kazphosphate LLP (Taraz) and local raw materials (wood chips, crushed stone and sand).

Sampling was carried out manually. Six point samples were taken along the perimeter of the sludge ponds, ash ponds and dumps, which were then combined into a common sample. Pool samples consisting of an appropriate number of point samples (each 3 kg) were numbered according to the accounting system and delivered to the laboratory for sample preparation, where further processing was carried out.

The remaining part of the pooled sample (after selecting a portion to determine the moisture content) was prepared for physicochemical analysis. The sample was averaged and reduced to obtain a mass of at least 0.2 kg. The sample was reduced manually using the reduction and squaring method [54].

After reduction, at least 0.2 kg of the sample was crushed into the final sample for physicochemical analysis, in particular, the sample was crushed in a porcelain mortar and sifted through a 008 mm sieve [54]. From this large number of samples, several samples were prepared for physicochemical studies.

Ash from a thermal power plant is a product of fuel combustion, which is carried away by flue gases from the boiler furnace and collected by ash collectors. The Stepnogorsk CHPP consumes about 950 thousand tons of Ekibastuz coal in 1 year, which generates 421 thousand tons of ash and slag waste (ASW). ASW at the enterprise is formed as a result of coal combustion. Stepnogorsk CHPP LLP (StCHPP) uses the technology of a reverse hydraulic ash and slag removal system as BAT. Ash is transported by hydraulic transport through an ash pipeline and placed in an ash dump.

Depending on the quality of the phosphate rock, when receiving 1 ton of finished yellow phosphorus products, 10–12 tons of electrothermophosphorus slag are formed under the conditions of the Novodzhambul phosphorus plant (Taraz, Kazakhstan). The main part of the electrothermophosphorus slag consists of silicon oxides (40–41%) and calcium (47–49%), and also contains small amounts of aluminum and iron oxides. The content of these oxides gives electrothermophosphorus slag valuable qualities as a raw material for the production of binding materials.

Liquid glass and sodium disilicate were used as alkaline components. Local raw materials (wood chips, quartz sand and crushed stone) were used as coarse and fine aggregates in soil silicate concrete.

Determination of the moisture of technogenic raw materials was carried out as follows: a sample weighing 1 g was placed in a weighing bottle previously dried to a constant weight, placed in a drying cabinet heated to a temperature of (105 ± 5 °C), dried for 1.5–2 h and then cooled in a desiccator and weighed on an analytical balance that ensures a random measurement error of no more than ±0.01% of the mass of the weighed sample; after drying, the sample was weighed, and the moisture content of the drill cuttings sample was determined based on the difference in mass, which in our case was 2.54%.

Particle size distribution, content of dust and clay particles, true density, bulk density, humidity, water absorption, frost resistance, strength and other characteristics were determined using standard methods in accordance with the requirements [55,56]. Technogenic raw materials were subjected to chemical composition determination and X-ray phase analysis using a general-purpose diffract meter DRON-3 (USSR, Moscow).

3. Results and Discussion

The chemical composition of drill cuttings is represented by the following compounds, wt.%: SiO2-63.20; Al2O3-18.55; CaO-1.53; FeO-8.96; MgO-1.85; K2O-2.69; Na2O-1.10; TiO2-0.91; SO3-0.95; p.p.p.-0.26. Drilling cuttings are technogenic waste from the mining industry and are not dangerous according to the level of waste hazard. They have a density of 1.65 t/m3.

The names of the waste components included in drill cuttings and their mineralogical composition are given in Table 1.

Table 1.

Mineralogical composition of drill cuttings.

In addition, it was found that, in terms of effective specific activity, gray drill cuttings and the proposed samples of local brown soils belong to the first radiation hazard group (<370 Bq/kg) and can be used in construction without restrictions (Table 2).

Table 2.

Study of radiation hazard of drill cuttings.

The granulometric composition of thermal power plant ash is as follows: mass%: more than 0.25 mm–6.88; 0.05–0.25 mm–22.84; 0.01–0.05 mm 51.67; 0.005–0.01 mm–11.90; 0.001–0.005 mm–3.69; less than 0.001 mm–3.00. The ash from StCHPP has the following characteristics: content of SiO2–57.7%, Al2O3–25.1%, CO–3.65%, MgO–1.30%, Fe2O3–5.89%, Stot–0.15%. The organic carbon content, depending on the size of the source material, ranges from 0.232 g/kg to 6.65 g/kg. The presence of petroleum-like products from 0.175 g/kg to 3.30 g/kg is observed. Among the impurity elements, copper (20 g/t), lead (30 g/t), and zinc (20 g/t) were identified. The crystalline phase consists of mullite, quartz (glass) and the remains of unburnt carbonaceous material. Petrographic analysis data showed that groups of glassy, amorphous, crystalline and organic matter can be found in the ash. The ash catcher has a high glass phase content (up to 70%).

According to the results, the content of grains of electrothermophosphorus slag passing through sieve No. 0.14 (pulverized and clay fractions) should not exceed 10% by weight, and 0.5% for larger 10 mm grains. If these conditions are met, the grain composition of the sand is suitable for use. Bulk density was determined according to GOST 22733-77- “Soils. Laboratory method for determination of maximum density”. It is 1450–1460 kg/m3. The humidity of electrothermophosphorus slag is 5–6% (GOST 5180-75—“Soils. Laboratory methods for determination of physical characteristics”). Water absorption was determined according to GOST 7025-78—“Soils. Laboratory methods for determination of strength and deformability characteristics” by the water saturation method for 48 h. The indicator is 3–5%. The void content of electrothermophosphorus slag is 42–45%. The angle of internal friction was determined according to GOST 12248-78 using a planar cut device, φ = 40°. The solubility of electrothermophosphorus slag in water does not exceed 0.3–0.5% by weight. Frost resistance was determined according to GOST 10060-76, “Methods for determining frost resistance”, using the freezing and thawing method. The frost resistance index is 75–100 cycles. True density was determined according to GOST 2211-85 by the pycnometric method. The chemical composition of ETF slags is represented by the following mass compounds, %: SiO2–42.71; Al2O3–2.54; Fe2O3–0.25; CaO–45.92; MgO–3.24; P2O5—2.25; SO3–0.5; p.p.p.–0.07. Electrothermophosphorus slags are resistant to silicate decomposition, which were determined according to GOST 9758-77, “Porous inorganic fillers for concrete”. According to XRF, the mineralogical composition of dense electrothermophosphorus slag was as follows: pseudo-wollastonite CaSiO3 70–80%, (d/n) = 2.87; 2.79; 2.55; 2.34; 2.18; 2.02; 1.82·10–10 m, phosphorus-containing phases (cuspidine) 3CaO·2SiO·CaF2 5–10(d/n) = 3.30; 3.06; 2.55; 2.30·10–10 m, melilite CaAl2SiO6 5–7(d/n) = 3.06; 2.86; 2.47; 2.30; 1.98; 1.88 · 10–10 m.

Based on physical and chemical studies of drill cuttings and local raw materials, it is obvious that the studied technogenic raw materials meet all the requirements for raw materials for use in the composition of soil silicate concrete based on mineral slag binder [57,58,59,60,61,62].

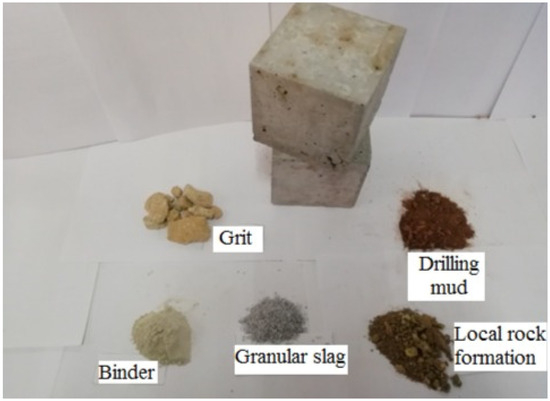

In the course of exploratory and experimental studies, the dependences of the consumption of drill cuttings and local raw materials on the strength characteristics of soil silicate concrete were established, from which it follows that their introduction in an amount of 15–23% should be considered rational and quite sufficient, ensuring a significant increase in the strength of soil silicate concrete at compression of 3.0–3.5 MPa, i.e., compliance with the requirements for road pavement bases for class II and III roads. In addition, the introduction of this mixture helps to reduce shrinkage deformations, which are significantly manifested during the hardening of soil silicate concrete. That is, the presence of drill cuttings and local raw materials in the composition of soil silicate concrete, when strengthened with a mineral slag binder, significantly improves its structure and performance characteristics. A general view of technogenic and mineral raw materials and the samples of soil slice concrete obtained from them is shown in Figure 1.

Figure 1.

General view of technogenic and mineral raw materials and samples of soil slice concrete obtained from them.

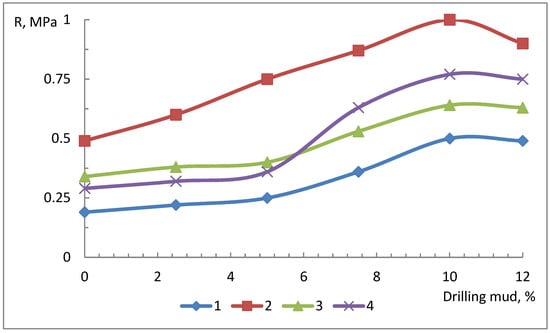

The next stage in obtaining soil silicate concrete that meets the requirements was to find the optimal amount of waste drill cuttings. Figure 2 shows the dependence of waste consumption in the form of drill cuttings and ash from thermal power plants on the strength of soil silicate concrete in compression and bending. Figure 2 shows the maximum strength indicators for drill cuttings consumption in the range of 20 to 40%. It is also obvious that a further increase in the drill cuttings content does not lead to an increase in bending strength, because in this case, aggregation of micro-reinforcing fragments is observed, which leads to an increase in defects and deterioration of the structure of soil silicate concrete. In addition, the increased (more than 40%) content of drill cuttings contributes to a significant increase in the water demand of soil silicate concrete to ensure the required plasticity and workability of the soil mass, and this, in turn, leads to a sharp decrease in the strength indicators [63,64,65,66,67,68,69,70,71]. Thus, the rational consumption of waste drill cuttings, which acts as dispersed micro-reinforcement, can be considered 10 ± 1%, which makes it possible to obtain soil silicate concrete with a tensile strength in bending of at least 0.6 MPa, i.e., meeting the requirements for class II roads.

Figure 2.

The influence of the consumption of drill cuttings and ash from a thermal power plant mixture on the bending strength of soil silicate concrete with the introduction of additives: 1-mineral slag binder (10%) + drill cuttings (20%) + ash from a thermal power plant (10%); 2-mineral slag binder (10%) drill cuttings (20%) + thermal power plant ash (20%); 3-mineral slag binder (20%) + drill cuttings (30%) + thermal power plant ash (10%); 4-mineral slag binder (30%) + drill cuttings (40%) + thermal power plant ash (20%).

The next stage of research established the influence of the consumption of mineral slag binder, drill cuttings and ash from thermal power plants on the strength of soil silicate concrete, depending on recipe changes and the characteristics of the composition of composite soil silicate concrete. The main task was to obtain soil silicate concrete with specified properties that meet the requirements, with minimal consumption of mineral slag binder and maximum consumption of drill cuttings and thermal power plant ash.

For this purpose, a series of samples with different formulations and different ratios of components were tested. The consumption of mineral slag binder, thermal power plant ash and drill cuttings in soil silicate concrete mixtures varied between 10 to 30% wt., 20–40% wt. and 10–20% wt. accordingly, which ensured wide coverage of the studied formulations.

The dependences of the strength properties of soil silicate concrete with thermal power plant ash, drill cuttings and mineral slag binder on their ratio in the component mixture were also obtained. It is noted that the introduction of mineral slag binder has a positive effect on the strength of soil silicate concrete in compression and tension in bending; however, the degree of influence of the amount of mineral slag binder on the strength in bending is more pronounced compared to the compressive strength. This fact is explained by the high dispersion of soil silicate concrete and high deformability; therefore, the mineral slag binder introduced into its composition does not affect the strength indicators effectively enough. When strengthening a soil silicate concrete mixture containing drill cuttings, thermal power plant ash and mineral slag binder, it becomes the center of crystallization of not only soil particles, but also drill cuttings and thermal power plant ash in the mixture, which, in turn, are structure-forming components. Therefore, the strength characteristics of such a mixture are much higher, and the role of the mineral slag binder is enhanced throughout the entire range of formulations; however, as the most optimal approach, it can be reduced by an interval equal to 10–20%.

4. Conclusions

Based on the research conducted, the following findings and conclusions can be drawn in particular:

- -

- It has been established that, in terms of effective specific activity, gray drill cuttings and the proposed samples of local brown soils belong to the first radiation hazard group (<370 Bq/kg) and can be used in construction without restrictions;

- -

- It was experimentally determined that the introduction of brow sludge and local raw materials in an amount of 15–23% ensures the production of soil silicate concrete with a compressive strength of up to 3.0–3.5 MPa, which meets the requirements for road pavement bases of classes II and III;

- -

- With the help of exploratory and experimental studies, it was established that, regarding the dependence of the consumption of drill cuttings and local raw materials on the strength characteristics of soil silicate concrete, in particular, the strength indicators were maximized when the consumption of drill cuttings was in the range of 20 to 40%.

Author Contributions

Conceptualization, S.A., B.S., A.K., O.K. and E.K.; Methodology, S.A. and M.B.; Validation, B.T. and V.L.; Formal analysis, V.L.; Resources, B.T.; Data curation, M.B., B.T., G.S., O.K. and Z.Z.; Writing—original draft, S.A.; Writing—review & editing, S.A., B.T., A.K. and Z.Z.; Visualization, M.B. and G.S.; Supervision, S.A., A.K., V.L. and G.S.; Project administration, B.S., E.K., Z.Z. and O.K.; Funding acquisition, B.S., E.K. and O.K. All authors have read and agreed to the published version of the manuscript.

Funding

The research was carried out according to the Program. This research was funded by the Committee of Science of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. BR21882292—“Integrated development of sustainable construction industries: innovative technologies, optimization of production, effective use of resources and creation of technological park”).

Data Availability Statement

The data used to support the findings of this study are included within the article.

Acknowledgments

The authors express their gratitude to K.I. Satpayev Kazakh National Research Technical University, V.G. Shukhov Belgorod State Technological University, M. Auezov South Kazakhstan University and Tashkent University of Architecture and Civil Engineering for the opportunity to conduct research in their scientific laboratories.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Petrenko, E.S.; Vechkinzova, E.A.; Urazbekov, A.K. Context Analysis and Prospects of Development of the Mining and Metallurgical Industry of Kazakhstan. Ekon. Otnos. 2019, 9, 2661–2676. [Google Scholar] [CrossRef]

- Zharmenov, A.A. (Ed.) Waste: Ways of Minimization and Prevention; National Academy of Sciences of the Republic of Kazakhstan: Almaty, Kazakhstan, 2002; p. 132. [Google Scholar]

- Komarov, M.A.; Aliskerov, V.A.; Kusevich, V.I.; Zavertkin, V.L. Mining and Industrial Waste as an Additional Source of Mineral Raw Materials. Miner. Resour. Russ. Econ. Manag. 2007, 4, 3–9. [Google Scholar]

- Stolboushkin, A.Y.; Berdov, G.I. Resource-Saving Complex Processing of Mineral Technogenic Raw Materials in the Production of Building Materials. Izv. Vuzov. Constr. 2011, 1, 46–53. [Google Scholar]

- Berdov, G.I.; Mashkin, N.A. Promising Directions for Improving the Compositions and Technology of Building Materials Based on Mineral Binders. Izv. Vuzov. Constr. 2015, 4, 45–56. [Google Scholar]

- Evgeniev, I.E.; Karimov, B.B. Highways in the Environment; Transdornauka: Moscow, Russia, 1997; pp. 88–122. [Google Scholar]

- Amran, M.; Fediuk, R.; Murali, G.; Vatin, N.; Karelina, M.; Ozbakkaloglu, T.; Krishna, R.S.; Kumar, S.A.; Kumar, D.S.; Mishar, J. Rice Husk Ash-Based Concrete Composites: A Critical Review of Their Properties and Applications. Crystals 2021, 11, 168. [Google Scholar] [CrossRef]

- Andreev, E.E.; Tikhonov, O.N. Crushing, Grinding and Preparation of Raw Materials: Textbook; Publishing House of SPGGU: St. Petersburg, Russia, 2007; pp. 156–182. [Google Scholar]

- Donayev, A.; Kolesnikov, A.; Shapalov, S.; Sapargaliyeva, B.; Ivakhniyuk, G. Studies of waste from the mining and metallurgical industry, with the determination of its impact on the life of the population. News Natl. Acad. Sci. Repub. Kazakhstan Ser. Geol. Tech. Sci. 2022, 4, 55–68. [Google Scholar] [CrossRef]

- Kulikova, E.Y.; Balovtsev, S.V.; Skopintseva, O.V. Complex estimation of geotechnical risks in mine and underground construction. Sustain. Dev. Mt. Territ. 2023, 15, 7–16. [Google Scholar] [CrossRef]

- Skopintseva, O.V.; Ganova, S.D.; Buzin, A.A.; Fedotova, V.P. Measures to reduce dusting during loading and transportation of solid mineral resources. Gorn. Zhurnal 2019, 12, 76–79. [Google Scholar] [CrossRef]

- Bedov, A.I.; Gabitov, A.I.; Domarova, E.V.; Kolesnikov, A.S. Investigation of the stress-strain state of domical masonry vaults. Constr. Mater. Prod. 2023, 6, 6. [Google Scholar] [CrossRef]

- Kolesnikov, A.S.; Zhanikulov, N.N.; Syrlybekkyzy, S.; Kolesnikova, O.G.; Shal, A.L. Utilization of Waste from the Enrichment of Non-Ferrous Metal Ores as Secondary Mineral Raw Materials in the Production of Cement Clinker. Ecol. Ind. Russ. 2023, 27, 19–23. [Google Scholar] [CrossRef]

- Zhanikulov, N.N.; Khudyakova, T.M.; Taimasov, B.T.; Sarsenbayev, B.K.; Dauletiarov, M.S.; Kolesnikov, A.S.; Karshygayev, R.O. Receiving Portland Cement from Technogenic Raw Materials of South Kazakhstan. Eurasian Chem.-Technol. J. 2019, 21, 333–340. [Google Scholar] [CrossRef]

- Ibragimov, R.A.; Shakirzyanov, F.R.; Kayumov, R.A.; Korolev, E.V. Evaluation of the Influence of an Aggressive Environment on the Durability of the Cement Stone. Constr. Mater. Prod. 2024, 7, 4. [Google Scholar] [CrossRef]

- Zhangabay, N.; Suleimenov, U.; Utelbayeva, A.; Buganova, S. Experimental research of the stress-strain state of prestressed cylindrical shells taking into account temperature effects. Case Stud. Constr. Mater. 2022, 18, e01776. [Google Scholar] [CrossRef]

- Taimasov, B.T.; Sarsenbayev, B.K.; Khudyakova, T.M.; Kolesnikov, A.S.; Zhanikulov, N.N. Development and testing of low-energy-intensive technology of receiving sulphate-resistant and road portlandcement. Eurasian Chem.-Technol. J. 2017, 19, 347–355. [Google Scholar] [CrossRef]

- Ji, Y.; Li, E.; Zhu, G.; Wang, R.; Sha, Q. Influence of Solid Waste Material Content on the Properties of Steel Slag-Waste Clay Brick Ceramic Bricks. Coatings 2024, 14, 434. [Google Scholar] [CrossRef]

- Pukharenko, Y.V.; Khrenov, G.M.; Klyuev, S.V.; Khezhev, T.A.; Eshanzada, S.M. Design of Steel Fiber-Reinforced Concrete for Slip Forming. Constr. Mater. Prod. 2024, 7, 2. [Google Scholar] [CrossRef]

- Kim, A.S.; Akberdin, A.A.; Sultangaziev, R.B. Using Basalt Rocks for Agglomeration of Refractory Chromite Ores of Kazakhstan. Metallurgist 2020, 63, 1005–1012. [Google Scholar] [CrossRef]

- Kolesnikov, A.S.; Sergeeva, I.V.; Botabaev, N.E.; Al’zhanova, A.Z.; Ashirbaev, K.A. Chemical and phase transitions in oxidized manganese ore in the presence of carbon. Steel Transl. 2017, 47, 605–609. [Google Scholar] [CrossRef]

- Kulikova, A.A.; Kovaleva, A.M. Use of tailings of enrichment for laying of the developed space of mines. Mining Inf. Anal. Bull. 2021, 2-1, 144–154. [Google Scholar] [CrossRef]

- Fediuk, R. High-strength fibrous concrete of Russian Far East natural materials. IOP Conf. Ser. Mater. Sci. Eng. 2016, 116, 012020. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Beskopylny, A.N.; Shcherban’, E.M.; Mavzolevskii, D.V.; Drukarenko, S.P.; Chernil’nik, A.A.; Elshaeva, D.M.; Shilov, A.A. Influence of Corn Cob Ash Additive on the Structure and Properties of Cement Concrete. Constr. Mater. Prod. 2024, 7, 2. [Google Scholar] [CrossRef]

- Bulanov, P.E.; Vdovin, E.A.; Stroganov, V.F. Increasing the level of aging stability of bitumes modified by kaolinite. Mag. Civ. Eng. 2023, 8, 12413. [Google Scholar]

- Klyuev, S.V.; Slobodchikova, N.A.; Saidumov, M.S.; Abumuslimov, A.S.; Mezhidov, D.A.; Khezhev, T.A. Application of Ash and Slag Waste from Coal Combustion in the Construction of the Earth Bed of Roads. Constr. Mater. Prod. 2024, 7, 3. [Google Scholar] [CrossRef]

- Al-Kinani, A.M.; Thajeel, J.K.; Al-Umar, M.H.; Fattah, M.Y. Utilizing seismic techniques and dynamic field tests for soil dynamic response prediction in clay soils. Mag. Civ. Eng. 2024, 17, 12504. [Google Scholar]

- Teker Ercan, E.E.; Cwirzen, A.; Habermehl-Cwirzen, K. The Effects of Partial Replacement of Ground Granulated Blast Furnace Slag by Ground Wood Ash on Alkali-Activated Binder Systems. Materials 2023, 16, 5347. [Google Scholar] [CrossRef]

- Volokitina, I.; Bychkov, A.; Volokitin, A.; Kolesnikov, A. Natural Aging of Aluminum Alloy 2024 After Severe Plastic Deformation. Metallogr. Microstruct. Anal. 2023, 12, 564–566. [Google Scholar] [CrossRef]

- Fediuk, R.S.; Lesovik, V.S.; Vavrenyuk, S.V.; Zaiakhanov, M.Y.; Bituyev, A.V.; Klyuev, S.V.; Yu, K.; Lesovik, Y.R.; Bakatov, K.A. Composite cement materials for structures foundation strengthening. Mag. Civ. Eng. 2024, 17, 12701. [Google Scholar]

- Sapargaliyeva, B.; Suleimenov, U.; Abshenov, K.; Utelbayeva, A.; Baibolov, K.; Fediuk, R.; Arinova, D.; Duissenbekov, B.; Seitkhanov, A. Analysis of Stress-Strain State for a Cylindrical Tank Wall Defected Zone. Materials 2022, 15, 5732. [Google Scholar] [CrossRef]

- Yessengaliev, D.; Mukhametkhan, M.; Mukhametkhan, Y.; Zhabalova, G.; Kelamanov, B.; Kolesnikova, O.; Shyngysbayev, B.; Aikozova, L.; Kaskataeva, K.; Kuatbay, Y. Studies of the Possibility of Improving the Quality of Iron Ores and Processing of Technogenic Composite Iron-Containing Waste of Metallurgical Production. J. Compos. Sci. 2023, 7, 501. [Google Scholar] [CrossRef]

- Samuratov, Y.; Kelamanov, B.; Akuov, A.; Zhumagaliyev, Y.; Akhmetova, M. Smelting standard grades of manganese ferroalloys from agglomerated thermo-magnetic manganese concentrates. Metalurgija 2020, 59, 85–88. [Google Scholar]

- Yessenbayev, B.A.; Naukenova, A.S.; Shapalov, S.K.; Ramatullaeva, L.I.; Ivakhniyuk, G.K. Analysis of the impact of bauxite dumps on the environment and public health. MIAB Mining Inf. Anal. Bull. 2024, 3, 55–69. [Google Scholar]

- Kolesnikov, A.S.; Sapargaliyeva, B.O.; Bychkov, A.Y.; Alferyeva, Y.O.; Syrlybekkyzy, S.; Altybaeva, Z.K.; Nurshakhanova, L.K.; Seidaliyeva, L.K.; Suleimenova, B.S.; Zhidebayeva, A.E.; et al. Thermodynamic modeling of the formation of the main minerals of cement clinker and zinc fumes in the processing of toxic technogenic waste of the metallurgical industry. Rasayan J. Chem. 2022, 15, 2181–2187. [Google Scholar]

- Khudyakova, T.M.; Kolesnikova, O.G.; Zhanikulov, N.N.; Ashirbaev, H.A.; Kolesnikova, V.A. Low-Basicity Cement, Problems and Advantages of its Utilization. Refract. Ind. Ceram. 2021, 62, 369–374. [Google Scholar] [CrossRef]

- Naizabekov, A.B.; Latypova, M.A.; Fedorova, T.D.; Mamitova, A.D. Current Trends to Obtain Metals and Alloys with Ultrafine-Grained Structure. Prog. Phys. Met. 2022, 23, 629–657. [Google Scholar]

- Kulikova, E.Y.; Balovtsev, S.V. Risk control system for the construction of urban underground structures. IOP Conf. Ser. Mater. Sci. Eng. 2020, 962, 042020. [Google Scholar] [CrossRef]

- Muratov, B.A.; Shapalov, S.; Syrlybekkyzy, S.; Volokitina, I.; Zhunisbekova, D.; Takibayeva, G.; Nurbaeva, F.; Aubakirova, T.; Nurshakhanova, L.; Koishina, A. Physico-Chemical Study of the Possibility of Utilization of Coal Ash by Processing as Secondary Raw Materials to Obtain a Composite Cement Clinker. J. Compos. Sci. 2023, 7, 234. [Google Scholar] [CrossRef]

- Zhangabay, N.; Giyasov, A.; Bakhbergen, S.; Tursunkululy, T.; Kolesnikov, A. Thermovision study of a residential building under climatic conditions of South Kazakhstan in a cold period. Constr. Mater. Prod. 2024, 7, 1. [Google Scholar] [CrossRef]

- Filin, A.; Kolbina, I.; Seidaliyev, A.; Koibakova, S.; Mankesheva, O. Comparison of the Quality of Gas Equipment at Metallurgical and Coke-Chemical Enterprises and Production Plants. Pol. J. Environ. Stud. 2024, 33, 2999–3008. [Google Scholar] [CrossRef]

- Zhangabay, N.; Giyasov, A.; Ybray, S.; Tursunkululy, T.; Kolesnikov, A. Field thermovision study of externsl enclosure for multi-storey residential building under climatic conditions of Northern Kazakhstan. Constr. Mater. Prod. 2024, 7, 1–21. [Google Scholar] [CrossRef]

- Yessengaliyev, D.; Kelamanov, B.; Sariev, O.; Kuanalin, Y. Research of thermal analysis of nickel ore and mixture with carbon-containing reducing agents by non-isothermal method. Metalurgija 2024, 64, 344–346. [Google Scholar]

- Filin, A.E.; Kurnosov, I.Y.; Kolesnikova, L.A.; Ovchinnikova, T.I. Description of The Methodology for Conducting an Experiment on Dust Deposition of Mining and Metallurgical Production. Ugol 2022, 9, 67–72. [Google Scholar] [CrossRef]

- Razorenov, Y.I.; Yatsenko, E.A.; Goltsman, B.M. Building materials based on manmade waste of the mining industry and solid fuel energy—An environmental trend of the modern time. Gornyi Zhurnal. 2021, 11, 95–98. [Google Scholar] [CrossRef]

- Levitsky, I.A.; Pavlyukevich, Y.G.; Bogdan, E.O.; Kichkaylo, O.V. Production of ceramic gravel by using of galvanic wastewater sludge. Glass Ceram. 2013, 7, 23–27. [Google Scholar]

- Volokitina, I.E.; Volokitin, A.V.; Latypova, M.A.; Chigirinsky, V.V.; Kolesnikov, A.S. Effect of Controlled Rolling on the Structural and Phase Transformations. Prog. Phys. Met. 2023, 24, 132–156. [Google Scholar]

- Ufimtsev, V.M. Structural fired porous fillers based on technogenic raw materials. Constr. Mater. Equip. Technol. XXI Century 2013, 5, 25–29. [Google Scholar]

- Leismann, A. Utilization of hard-coal mining wastes and red mud for the production of expanded clay granulate. Keram. Z. 1999, 51, 26–31. [Google Scholar]

- Sigachev, N.P.; Konovalova, N.A.; Konnov, V.I.; Pankov, P.P.; Efimenko, N.S. Efficiency of using of ash and slag wastes from the Trans-Baikal Territory in the production of road cement soils. Ecol. Ind. Russ. 2015, 19, 24–27. [Google Scholar]

- Ying, P. Granulation and drying of fly-ash considered with the aid of a mathematical model. ZKG Int. Ed. 1984, 37, 72–79. [Google Scholar]

- Mousavi, M.; Bengar, H.A. Investigation of the effect of internal curing as a novel method for improvement of post-fire properties of high-performance concrete. Comput. Concr. 2024, 33, 309–324. [Google Scholar]

- Abdrakhimov, V.Z.; Abdrakhimova, E.S. Use of oil production wastes in expanded clay production. Ecol. Prod. 2012, 8, 52–55. [Google Scholar]

- Andreev, E.E. Crushing, Grinding, and Raw Material Preparation: Textbook; Publishing House of SPGGU: St. Petersburg, Russia, 2007; 439p, pp. 156–182. [Google Scholar]

- GOST 1532-81; Viscometers for Determination of Conditional Viscosity. Technical Specifications. Introduced 1982-01-01; Standards Publishing House: Moscow, Russia, 1981; 12p.

- Lazarev, A.N. Vibrational Spectra and Structure of Silicates; Nauka: Leningrad, Russia, 1968; p. 347. [Google Scholar]

- Vasilenko, T.A.; Saleh-Zhafer, A.Z. Physico-mechanical properties of expanded clay gravel obtained by using of calcium-containing technogenic materials. Mod. Probl. Sci. Educ. 2015, 1, 85. Available online: https://science-education.ru/en/article/view?id=19899 (accessed on 14 February 2025).

- Bolondi, A.; Andreoli, R. Expanded Inorganic Insulating Materials: Production, Characteristics and Application Areas. Termotec. Milano 1987, 41, 55–61. [Google Scholar]

- Knatko, M.V.; Scherbakova, E.V. Use perspectives for recycled raw material resources. Mag. Civ. Eng. 2009, 7, 55–56. [Google Scholar] [CrossRef]

- Tanutrov, I.N.; Sviridova, M.N.; Savenya, A.N. New technology of joint processing of technogenic wastes. News Univ. Non-Ferr. Metall. 2013, 1, 21–26. [Google Scholar]

- Starostina, I.V.; Simonov, M.M.; Pendyurin, E.A.; Besedina, I.N. Assessment of the toxicological properties of expanded clay gravel by using of ferrovanadium production sludge. Mod. Probl. Sci. Educ. 2014, 5. Available online: https://science-education.ru/en/article/view?id=14533 (accessed on 15 February 2025).

- Lebedev, M.S.; Strokova, V.V.; Karatsupa, S.V.; Dmitrieva, T.V. Designing of soil-concretes using the kursk magnetic anomaly technogenic raw and waste-lime-based binder for reinforcing of road pavements subgrades. World Appl. Sci. J. 2014, 30, 970–982. [Google Scholar]

- Gao, Z.; Yuan, B.; Qi, C.; Liu, J.; Zhu, Y.; Wu, S.; Wang, P.; Kong, Y.; Jin, H.; Mu, B. Multi-stage releasing water: The unique decomposition property makes attapulgite function as an unexpected clay mineral-based gas source in intumescent flame retardant. Compos. Part A Appl. Sci. Manuf. 2024, 178, 108014. [Google Scholar] [CrossRef]

- Marsh, A.T.; Velenturf, A.P.; Bernal, S.A. Circular Economy strategies for concrete: Implementation and integration. J. Clean. Prod. 2022, 362, 132486. [Google Scholar] [CrossRef]

- Martínez-García, R.; Jagadesh, P.; Fraile-Fernández, F.J.; Morán-del Pozo, J.M.; Juan-Valdés, A. Influence of design parameters on fresh properties of self-compacting concrete with recycled aggregate—A review. Materials 2020, 13, 5749. [Google Scholar] [CrossRef]

- An, S.; Wang, B.; Chen, W.; Yu, Z.; Fan, C. Preparation of geopolymer based on municipal solid waste incineration fly ash-phosphorus slag and its function for solidification of heavy metals. Waste Manag. 2024, 178, 186–198. [Google Scholar] [CrossRef]

- Ding, Y.; Dai, J.G.; Shi, C.J. Mechanical properties of alkali-activated concrete: A state-of-the-art review. Construct. Build. Mater. 2016, 127, 68–79. [Google Scholar] [CrossRef]

- Klyuev, S.V.; Kashapov, N.F.; Radaykin, O.V.; Sabitov, L.S.; Klyuev, A.V.; Shchekina, N.A. The Reliability Coefficient for Fibre Concrete Material. Constr. Mater. Prod. 2022, 5, 51–58. [Google Scholar] [CrossRef]

- Ameri, F.; Shoaei, P.; Zareei, S.A.; Behforouz, B. Geopolymers vs. alkali-activated materials (AAMs): A comparative study on durability, microstructure, and resistance to elevated temperatures of lightweight mortars. Constr. Build. Mater. 2019, 222, 49–63. [Google Scholar] [CrossRef]

- Provis, J.L. Alkali-activated materials. Cement Concr. Res. 2017, 114, 40–48. [Google Scholar] [CrossRef]

- Collins, F.G.; Sanjayan, J.G. Workability and mechanical properties of alkali activated slag concrete. Cement Concr. Res. 1999, 29, 455–458. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).