Abstract

The electro-discharge (ED) drilling of precision boreholes in difficult-to-machine materials, particularly with respect to the cost-effectiveness of the overall process, is still a challenge. Flushing is one key factor for the precise machining of boreholes, especially with high aspect ratios. Therefore, the influence of internal and external flushing geometries for six types of brass tool electrodes with a diameter of 3 mm with and without a helical groove was analyzed experimentally and numerically. Using this helical external flushing channel, drilling experiments in X170CrVMo18-3-1 (Elmax Superclean) with an aspect ratio of five revealed a material removal rate (MRR) that was increased by 112% compared with a rod electrode, increased by 28% for a single-channel tool electrode and decreased by 8% for a multi-channel tool electrode. Signal analyses complemented these findings and highlighted correlations between classified discharge event types and the experimental target parameters. Amongst others, it was verified that the arcing frequency ratio drove the electrode wear rate and the beneficial frequency ratio correlated with the MRR and the surface roughness Ra. Sophisticated 3D computational fluid dynamics (CFD) models of the liquid phase were introduced and evaluated in great detail to demonstrate the validity and further elucidate the effect of the external flushing channel on the evacuation capability of debris and gas bubbles. The presented methods and models were found to be suitable for obtaining in-depth knowledge about the flushing conditions in the ED drilling working gap.

1. Introduction

Electrical discharge machining (EDM) is an established manufacturing process for machining metal and electrically conductive ceramic materials. It enables the manufacturing of precise holes with high surface quality and small tolerances, independent of the hardness and strength of the material. However, in addition to the physical limitation of the minimum electrical conductivity of σ > 0.01 S/cm of the material [1] (p. 3), the production of high aspect ratios, which refer to the ratio of machining depth dm to hole diameter dh, is a limiting factor in electro-discharge (ED) drilling [2]. With the decreasing diameter of the tool electrode, the maximum achievable aspect ratio of the hole and the material removal rate (MRR) decrease and the electrode wear rate (EWR) increases [3,4,5]. This is caused by the deterioration of the process conditions in the working gap between the electrodes with increasing machining depth since removed particles can no longer be efficiently evacuated [6,7]. Today, it is generally agreed that the EWR is primarily associated with the material properties. However, both the EWR and the MRR result from overlapping discharge crater geometries and increase with an increased discharge energy We [8]. The latter is generally influenced by the generator that acts as a source of charge carriers and its main parameters, which depend on the generator type. More theoretically, at the micro level, the system of tool and workpiece electrode and dielectric fluid can be interpreted as a capacitor. Its energy depends on the capacity and voltage applied, resulting in an electric field strength that influences the energy density in a quadratic manner or the surface charge density in a linear manner, respectively [9]. This is why one can say that the process target parameters of MRR and EWR are directly connected to the process parameters of open-circuit voltage ûi and discharge capacity Ce by means of the surface charge density σS. Other process parameters, such as the charge current iL and the pulse duration ti or the pulse interval time t0, instead affect the charging process of the capacitor or the time interval available for flushing. Apart from the electrical parameters and the charge carrier source, the dielectric itself also contributes to increasing the energy density by constricting the discharge channel [10].

The flushing conditions therefore play a decisive role, but in practice are often underrated regarding improved process stability and the removal of debris particles, and hence, an increased MRR and a decreased machining time and EWR. The dielectric can be supplied or removed either by positive or negative pressure in one or more flushing channels of the tool or workpiece electrode or by lateral flushing from the outside by means of an articulated hose. Flushing holes in the tool or workpiece electrode allow for direct flushing of the discharge area between the electrodes. Amongst others, Uhlmann et al. gave an overview of different flushing approaches, like the inverted pressure flushing, an external automated flushing unit, a multi-fluidic spindle, oscillating tool electrode segments and alternative dielectric fluids, as well as a first introduction of the tool electrodes with external flushing channels discussed in detail in the present work [11]. Rod and tube electrodes as single- or multi-channel electrodes are predominantly used in ED drilling. However, previous studies mainly focused on drastically simplified numerical models and single aspects of the flushing conditions. Generally, improvement of the material removal characteristics can be observed when as little dielectric as possible flows in the working gap. However, if the volume flow rate is too low, the material removal process comes to a standstill because removal products are no longer removed from the gap [10] (p. 42).

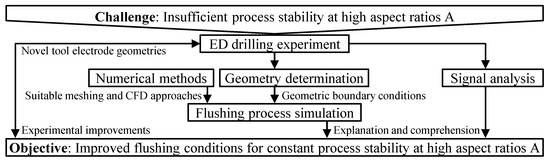

The aim of this study was to comprehensively investigate the influence of flushing conditions during ED drilling using tool electrodes with different internal and external geometries, as well as their interactions. The authors intended to address the research question of whether the improvements in process target parameters accomplished by several authors are actually due to the provision of additional space for the evacuation of debris and gas bubbles in the form of external flushing channels and what impact superimposed active flushing has. In comparison with the literature on similar topics, active flushing is not only considered but also given a special focus, as it promises further process improvements. Also, sophisticated transient numerical calculations are presented that go beyond steady-state results. From a numerical point of view, no holistically generated insights are available. Existing publications on this topic by the same authors will be considerably extended by much more detailed explanations of the numerical modeling approaches, with the objective of enabling accurate comprehensibility and reproducibility, as well as by a considerably improved and more elaborate discussion of the signal analyses [11,12,13,14]. The fluid mechanical phenomena in the working gap, the effects on the process target parameters and the process stability with increasing machining depth were analyzed. Figure 1 illustrates the overall investigation approach to maintain the process stability at high aspect ratios due to improved flushing conditions.

Figure 1.

Overall approach of improving the flushing conditions by use of tool electrodes with external flushing channels.

Following a state-of-the-art discussion in Section 2 and a detailed description of the materials and methods in Section 3, this paper presents the processing results of the ED drilling in Section 4.1, as well as corresponding numerical results of the fluid flow field for novel tool electrode geometries based on the standard tool rod (R), single-channel (1C) and multi-channel (4C) electrodes without and with a helical external flushing channel (prefix H, i.e., HR, H1C and H4C). In this way, commonly used tool electrode types, like 1C and 4C, can serve as references. In Section 4.2, a generic, numerical computational fluid dynamics (CFD) model created with ANSYS Fluent 2020R1 from ANSYS Inc., Canonsburg, PA, USA, with sufficient complexity was used to compare different meshing techniques and to find the trade-off between the mesh resolution and the accuracy of the solution. A complex 3D CFD model was developed on the basis of these findings to enable detailed numerical investigations of the fluid flow within the working gap in general and an evaluation of the external flushing channel’s influence on the flow field in particular in Section 4.3. This was done for all six types of tool electrodes with and without internal and external flushing channels, respectively. In addition, signal analyses of the gap voltage u and current i are used for evaluation in Section 4.4, utilizing a signal analysis system combining sophisticated measurement hardware and a Raspberry Pi 4 single-board computer from the Raspberry Pi Foundation, Cambridge, UK [15]. Performance-enhancing algorithms for the event classification using vector calculations, multithreading and multiprocessing techniques enabled a substantial reduction in the runtime and are also presented. Finally, the Supplementary Materials not only contain detailed experimental and numerical data of this work but also additional flow visualizations in the form of transient multi-phase CFD simulation animations.

2. State of the Art

An intuitive approach to avoid destabilization of the process conditions is the use of partially electrically insulated tool electrodes applying coatings or oxidation to drill holes with high aspect ratios. This, however, implies persisting challenges regarding delamination and fracturing of the insulation layers, as well as a loss of strength or deviations in straightness [11] (p. 628) and [16,17]. Nevertheless, Ferraris et al. improved the shape quality and the achievable aspect ratio by 30% to a maximum of A = 126 in micro-ED drilling [17]. Major improvements of the process characteristics or at least maintaining decent process stability while increasing the aspect ratio are prevalently assured by influencing the flushing conditions.

Takeuchi and Kunieda verified relations between an analytically obtained debris concentration and the measured frontal working gap width sF under given working conditions and for different volume flow rates. They found that the frontal working gap width sF is reduced by an increasing volume flow rate but increases with increasing debris concentration in the gap. However, the authors also state that these findings might differ for other discharge energies We or frontal areas Ae of the tool electrodes since both affect the probability of discharges or particle size. Nevertheless, universally it was found that electrophoresis plays a neglectable role, and the average velocities of the dielectric and the debris particles are the same [18,19].

Kliuev et al. supplemented contradictory works by Yilmaz and Okka and Bozdana and Ulutas by investigating the use of multi-channel tool electrodes and stated that the flushing efficiency is dependent on the tool electrode length and geometry, the machining depth and the flushing pressure [20,21,22]. Kliuev et al. also used experimental and numerical calculations of the volume flow rates and the flow field for comparative purposes. They concluded that single-channel tool electrodes provide the best flushing efficiency and also reduce the recast layer thickness, which is important in ED drilling applications in aerospace [20].

Beyond internal geometries, other authors investigated external geometric modifications of tool electrodes in ED drilling, like D-shaped or elliptic tool electrodes [23,24], rotating graphite tool electrodes with eight different cross sections [25], a stirrer-shaped tool electrode [26], internal or external inclined pathways through rod tool electrodes [27,28,29], eccentric micro-slots in tool electrode tips [30], a rectangular tool electrode cross-section [31], or radially arranged straight and helical slots [7,32,33,34,35]. Yadav et al., Nastasi and Koshy, and Natsu et al. compared straight-slotted and helical external flushing channels with cylindrical or rod tool electrodes in near-dry or conventional ED drilling, and all achieved improvements in the process target parameters but with different rankings of the tool electrodes. In the case without active flushing, single deep-slot or multi-slot tool electrodes performed better than helical external geometries, which in turn were better than the standard rods [7], whereas the performance ranking was different with active flushing of a glycerin-air mist [33]. In micro-ED drilling using deionized water, all geometrical adaptions led to an improvement by a factor of 2.8 in terms of the achievable depth [34]. The process improvements observed in all these works were mainly attributed to the additional space as a result of the geometric modifications, as well as the evacuation of gas bubbles and debris directly along the modified geometry features reducing the hydrodynamic resistance of the working gap and, therefore, increasing the volume flow rate [36].

Tools with external helical geometries in general are almost without exception used in conventional drilling or milling, e.g., twist drill geometries or axial slots for chip flow. In the field of EDM, however, only a few works dedicated to the use of helical external geometries exist so far [2,7,27,33,37,38,39]. In addition, the so-called helical electrodes have found their way into research on electrochemical machining (ECM) [40,41,42,43], as well as hybrid processes [44,45]. All of these research activities followed the objective of providing additional space in the lateral working gap for the evacuation of debris and gas bubbles with the aid of the external flushing channels. Actually, the use of tool electrodes with external flushing channels, especially with external helical geometries, shows great potential for improving the flushing conditions in ED drilling [12]. Plaza et al. conducted an experimental study with helical electrodes for machining the titanium alloy Ti6Al4V. They investigated the influence of helix geometries on the evacuation of particles removed in the case of micro-bores with high aspect ratios. Using a rotational speed of n = 40 min−1, they were able to confirm that helical grooves help to improve the flushing conditions. The optimal combination of pitch and groove depth led to a reduction in the machining time of 37% compared with conventional rod electrodes. However, process instabilities occurred above the aspect ratio of A = 5.6. Tip regenerations following the primary hole helped to compensate for the loss of helix geometry at the tip of the tool electrode due to wear and to increase the achievable aspect ratio by 60% [2]. Nastasi and Koshy used external flushing channels to improve the removal of particles during the machining of the aluminum alloy 6061. They optimized the geometries of the flushing channels of copper tool electrodes with outer diameters of do = 15.8 mm. With a single, deep groove, they were able to achieve a 300% higher MRR compared with conventional rod electrodes and a 38% higher MRR compared with the equal-area quadruple-grooved tool electrode. Numerical simulations showed that for helical electrodes, the evacuation and supply of fluid occur through the helical groove and the lateral working gap separately, while for axially grooved electrodes, both the evacuation and the supply of fluid occur within the vertical groove [7]. Wang et al. investigated the use of tool electrodes with outer diameters of do = 0.07 mm with axial and double helical grooves in the area of micro-ED drilling in steel 1.0503. They observed slightly reduced hole diameters and increased process stability with the double helix electrode. Applying a rotational speed of n = 300 min−1, the maximum aspect ratio achieved with the double helix was A = 13, which was about 30% higher than that of the bore produced with the axially grooved tool electrode. The numerical investigations showed that the fluid undergoes vertical convection movements within the helices and has opposite inflow or outflow areas in the case of helical electrodes, while the vertical fluid movement is absent with axially grooved electrodes [37]. Wang et al. used helical electrodes with increased rotational speeds of 1000 min−1 ≤ n ≤ 8000 min−1 to machine the titanium alloy Ti6Al4V. Increasing the rotational speed resulted in an increase in the MRR by 75% to 95% depending on the direction of rotation and reductions in the EWR by at least 60% and taper or hole conicity α by up to 50% [38]. Kumar and Singh also confirmed the advantages of helical electrodes in the same material. Amongst others, a groove or flute angle of αg = 60° led to the helix-induced evacuation of the particles removed in such a way that according to the authors, active flushing can be omitted. With multiple grooved electrodes, it was possible to increase the maximum aspect ratio by 300% [27]. Hu et al. conducted very similar but more in-depth studies than Uhlmann et al., and like the works discussed so far, they did not apply active flushing. Both author groups found a groove or flute angle of αg = 60° to be optimal in intervals of 30° ≤ αg ≤ 75° or 15° ≤ αg ≤ 60°, respectively [12,39]. Hu et al. stated that in most cases, the larger groove width and groove depth allow for higher machining speeds and lower EWR while avoiding severe bore shape and surface defects. However, basic numerical simulations using a rather simple mesh without dissolving the boundary layer and no further information about the model or software used led to the conclusion that the dielectric is sucked into the helical groove at the bottom of the bore and moves upward in a spiral path [39]. Uhlmann et al., however, more generally pointed out that minimum groove depths dg ≥ 0.3 mm and groove angles αg ≥ 45° are needed for tool electrodes with an outer diameter of do = 3 mm to improve the ED drilling process. Similar to Plaza et al., this is explained by a loss of the helical geometry at the tool electrode tips but, furthermore, with the possibility of clogging of the groove geometry with removed and re-solidified tool and workpiece material [13] (p. 17). Using rod tool electrodes, with the deepest groove of dg = 1.0 mm, they reduced the machining time by 39% in MAR-M247 or by 64% in X170CrVMo18-3-1 with a groove depth of dg = 0.5 mm [11,12,13].

Tool electrodes with external flushing channels were also successfully used in ECM, where electrolysis was used as the fundamental working principle [10]. The renewal of the electrolyte is critical for improving the process stability and dissolution rate and reducing form defects at high aspect ratios [43]. Increasing the rotational speed of the rotating helical tool electrode had a reducing effect on the working gap in both electrochemical micro-drilling [12] and electrochemical contouring, allowing for precise manufacturing of gap contours in quartz glass with an aspect ratio of A = 6.8 [43] and complex structures in steel 1.4301 [42]. Studies by Tsui et al. showed that the use of helical electrodes resulted in a significant reduction in the hole conicity by 42.4% compared with conventional cylindrical electrodes [40]. Hung et al. were able to achieve a significant reduction in the hole diameter by 45.6% using helical tool electrodes with insulating layers of epoxy and ceramic [41]. Supposedly as the first, Hung et al. specifically investigated the influence of helical external geometries on the process target parameters of a material removal process, in this case, a hybrid process of ED drilling and ultrasonic-assisted ED sinking. Using specially manufactured helical tungsten carbide tool electrodes, they were able to manufacture holes with a maximum aspect ratio of A = 10, achieving a reduction in machining time, working gap and roughness characteristics [44].

The literature focuses on manufacturing aspects when using helical tool electrodes, but usually excludes detailed considerations of the fluid mechanical processes in the working gap. On the other hand, the numerical fluid simulations performed are mostly single-phase and steady-state. Hinduja and Kunieda gave a major and in-depth overview of the phenomena and several corresponding models to simulate these different phenomena occurring during EDM but also ECM, and they introduced a generalized model for EDM processes [46].

Generally, numerical simulations, especially fluid mechanical analyses using CFD, have contributed to improving the understanding of the phenomena in the working gap. The increased possibilities in terms of available hardware and modeling approaches have made a decisive contribution to this. The extremely fast physical processes in the working gap, the severely limited optical accessibility due to the very small dimensions, and challenges with flow visualization make CFD an indispensable tool and is especially helpful for the investigation of multi-phase interactions, as well as for compressible phenomena, like in the case of dry-ED milling or drilling [44,47,48].

While in the beginning, in-house codes or the first CFD software, like Star-CD from CD adapco group, Melville, NY, USA, were used [6,49], today only a few authors do this, e.g., in order to exploit the potentials of fully resolved particle simulations that accurately resolve all relevant fluid scales and the fluid flow around each debris particle [50,51]. Today, only the use of so-called supercomputers allows for the fully resolved simulation of the two-phase flow of particles and fluid, e.g., as performed by Brito Gadeschi et al. [51] based on the method by Schneiders et al. [52], or even three-phase flow including gas bubbles. Various authors analyzed the flushing conditions during ED processes using Reynolds-averaged Navier–Stokes (RANS) approaches within commercial software, such as CFX [7,38,48,53,54] or Fluent [37,40,55,56,57,58,59,60,61], both by ANSYS, Inc., Canonsburg, PA, USA, but also COMSOL Multiphysics by COMSOL, Inc., Burlington, VT, USA [35,62,63,64,65], or STAR-CCM+ by Siemens Industry Software Inc., Plano, TX, USA [66]. The degrees of complexity of the RANS modeling approaches are equally crucial but quite different in the existing works. Detailed information on the boundary conditions, meshing or models used can be found in a minority of works. It can be assumed that many numerical analyses are greatly simplified calculations, e.g., by neglecting a resolution of the wall boundary layer by so-called inflation layers.

For the purpose of closing the gap between the averaged results from ED drilling experiments and insights into the fluid mechanic processes within the working gap using sophisticated CFD simulations, the analysis of voltage and current signals over the entire machining depth of a borehole is a well-established method. Experimentally validated CFD models allow researchers to match directions or absolute values of physical properties, like the velocity, the fluid flow or turbulence characteristics, from the local or global flow field with process target parameters, which are typically single, averaged values representing a specific case based on three experiments for statistical validation. These kinds of process target parameters, like the MRR or EWR, are strongly affected by the type of appearing discharges [67]. In addition to the process-averaged quantities, signal analyses possess a temporal component since measurements, and thus, event classifications are possible over the entire machining depth or parts of it. This allows for online control, as well as global and time-dependent evaluations of the process stability to be made [67,68]. Dauw et al. already developed a pulse discriminator, not just for the basic four pulse type classification of normal sparks, short circuits, arcs and open circuits but also for the subdivision of fifteen pulse types, e.g., ignition-delay-free discharges or less effective normal spark discharges [67]. Other authors used thresholds [15,69,70,71,72,73,74], discharge-energy-based approaches [68,75] or field programmable gate arrays (FPGAs) for real-time signal processing [76,77]. Nirala and Saha observed the distribution of energy in micro-ED drilling while studying online responses, such as the pulse frequency and the pulse type density, as well as offline responses, such as the MRR or volume removal per discharge. They defined the share of effective discharges in the removal as the discharge energy and state where the effective discharges have 50% of the discharge energy of the normal discharges. Therefore, they defined the number of effective discharges as the number of normals plus half of the number of effectives and noted that the number of effective discharges increases, whereas the number of normals decreases with the drilling depth [69] (p. 11). The evaluation of the process stability is determined by the decrease in volume per discharge over the drilling depth [69] (p. 15). Yeo et al. applied a similar approach, also for micro-EDM signals based on RC generators, but used the fixed pulse cycle time as one discrimination parameter and counted the number of current peaks in it to distinguish between short circuits and groups of arcs. The comparison of the peak current enabled them to detect normal and delayed discharges [73]. Chu et al. used FPGA logical circuits with adjustable thresholds for the discrimination of normal, short-circuit and open-circuit pulses, and finally improved the machining efficiency and the feed rate stability in wire EDM [78]. The same authors later used this classification method to evaluate the discharge statistics during the visual observation of ED drilling on an inclined surface [79]. Amongst others, Schneider investigated the energy input in the continuous erosion process and, therefore, also applied an FPGA-based real-time signal processing that was originally developed by Schwade and later evolved for the realization of online process monitoring by Küpper et al. [76,77,80,81].

3. Materials and Methods

The materials and methods used to accomplish the results presented in Section 4 are deliberately described in great detail in the following. In particular, the descriptions of numerical models often lack information and are not well or not at all suited to be fully understood, adapted, or replicated by other researchers or research groups. These numerical models are mostly regarded as tools for obtaining evaluable numerical results without clearly demonstrating their validity and origins, although sophisticated numerical models themselves should be considered as results of development processes. In particular, Section 3.2, Section 3.3 and Section 3.4 are intended to go beyond the content of other literature to facilitate replication and allow others to build on these methods as part of the results. This is especially the case, as the numerical models presented here enqueue in a history of experimentally validated CFD modeling ([11,47], [48] (pp. 16–17)).

3.1. Experimental Setup for ED Drilling

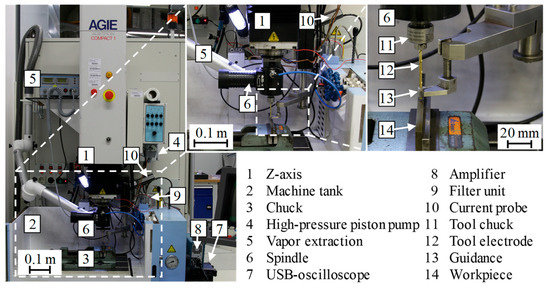

For the purpose of machining blind holes to a machining depth of dm = 15 mm and with a process-dependent hole diameter of dh > 3 mm, the die-sinking machine tool AGIETRON compact 1 from GF Machining Solutions, Losone, Switzerland, was used, offering a generator that is capable of generating both transistor and resistance–capacitance (RC)-type pulses (Figure 2). The process parameters given in Table 1 were selected based on preliminary experiments with capacitor discharges. The latter generally not only allows for very low discharge energies We ≤ 0.1 µJ in micro-EDM but also enables levels of the discharge current ie that exceed those of static discharges on the same machine tool. The spindle that enabled rotation was the Jet Injektion-H.S.2000 from Schleinkofer GmbH, Rödermark, Germany, allowing for a rotational speed 0 min−1 ≤ n ≤ 2000 min−1 with an age-related run-out error of er ≤ 0.016 mm.

Figure 2.

Experimental setup on the machine tool AGIETRON compact 1.

Table 1.

Process parameters used for the experiments.

Following Equation (1), the selected parameters led to high theoretical discharge energies of We ≤ 21.4 mJ and adverse process conditions in the form of a high particle load in the working gap due to the short pulse interval time t0 = 2.4 µs and high discharge currents ie < 125 A. This helps to emphasize the effects of the lateral working gap that might result from improved flushing conditions.

We = 0.5 × Ce × ûi2

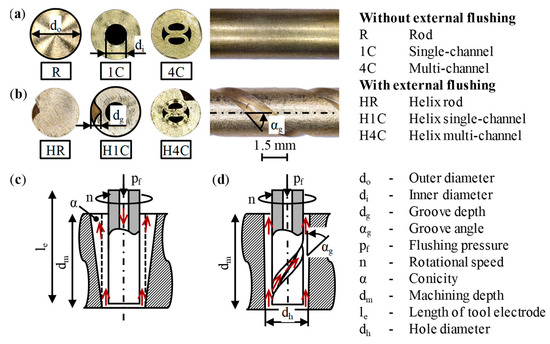

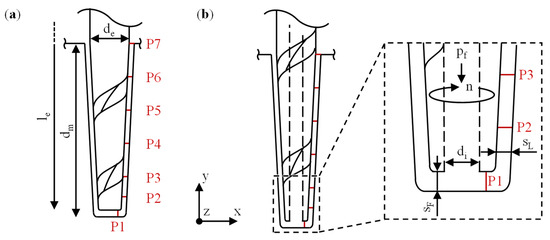

Brass tool electrodes in the form of rod, single-channel and multi-channel electrodes manufactured by EDM-Deutschland, Kahl am Main, Germany, were used as tool electrodes for the ED drilling process. In addition to these, tool electrodes with helical external flushing channels were prepared with a groove angle of αg = 60° and a groove depth of dg = 0.5 mm using an automatic CNC lathe Cincom B12E by Citizen Machinery Europe GmbH, Esslingen, Germany [12]. Figure 3 visualizes the tool electrode variants that were manufactured and their geometrical specifications, as well as a comparison of the flushing conditions with the established internal flushing and an additional external flushing channel in the form of schematic diagrams.

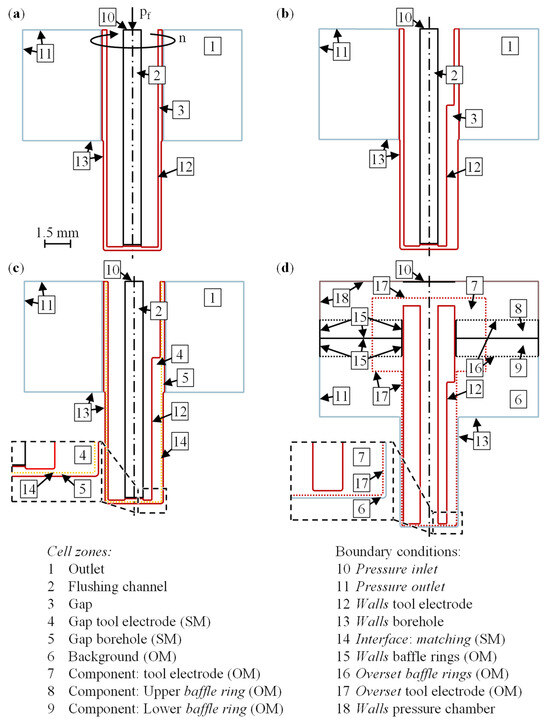

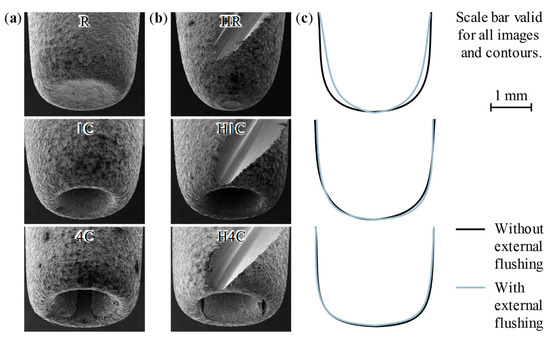

Figure 3.

Tool electrodes used for the ED drilling experiments: (a) without external flushing channel; (b) with external flushing channel; (c) schematic of conventional flushing with internal flushing; (d) schematic of flushing with additional external flushing channel.

All tool electrodes had a nominal outer diameter of do = 3 mm and a length of le = 60 mm, resulting in a total of six different tool electrodes that were analyzed with three experiments each in a workpiece made of the powder-metallurgy-based high-performance steel web from Uddeholms AB, Hagfors, Sweden. In cases of internal flushing, the dielectric IME63 from oelheld GmbH, Stuttgart, Germany, was supplied with an average flushing pressure pf = 2 MPa. The combination of this relatively high flushing pressure pf and internal flushing cross-sections of Af,1C = 1.07 mm2 for the 1C type and Af,4C = 0.74 mm2 for the 4C type led to volume flow rates = 0.69 L/min and 4C = 0.58 L/min. With a displacement volume of VHP = 0.0092 L for one double stroke, these flow rates could hardly be supplied by the M22 DVE double-acting high-pressure piston pump from Maximator GmbH, Nordhausen, Germany, in a constant manner. This was why the double stroke led to flushing pressure fluctuations in the range pf = 1.6 MPa to pf = 2.2 MPa.

3.2. Geometry Determination for Sophisticated 3D CFD Model

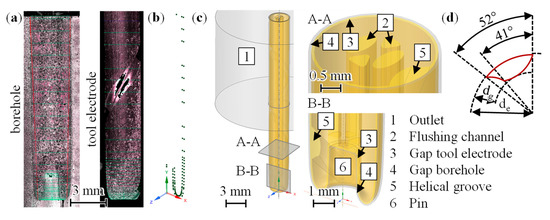

Then, in order to accurately simulate the internal and external flushing process, it was obligatory to determine the final tool and workpiece geometries subsequent to the ED drilling experiments. By cutting the bores in half using wire EDM and measuring the contour polygons of the bores and the associated tool electrodes using an InfiniteFocus G4 digital microscope from Alicona Imaging GmbH, Raaba, Austria, it was possible to design a digital representation of the tool and workpiece geometries and, therefore, gain the geometric boundary conditions after the ED drilling experiments for the six types of tool electrodes defined in Figure 3a,b. Figure 4 visualizes this sequence of the geometry determination. In Figure 4c, the sliding mesh approach, which split the working gap in two, is shown and is explained in the following section.

Figure 4.

Sequence of geometry determination, which was exemplary for the H4C tool electrode as a multi-channel tool electrode with helical external flushing channel: (a) images obtained using digital microscope, including measurement lines (green); (b) contour polygons of bore and associated tool electrode; (c) 3D fluid domain in ANSYS SpaceClaim 2022R2 with details from sectional views; (d) design of the helical groove in top view. Table S1 contains all original data.

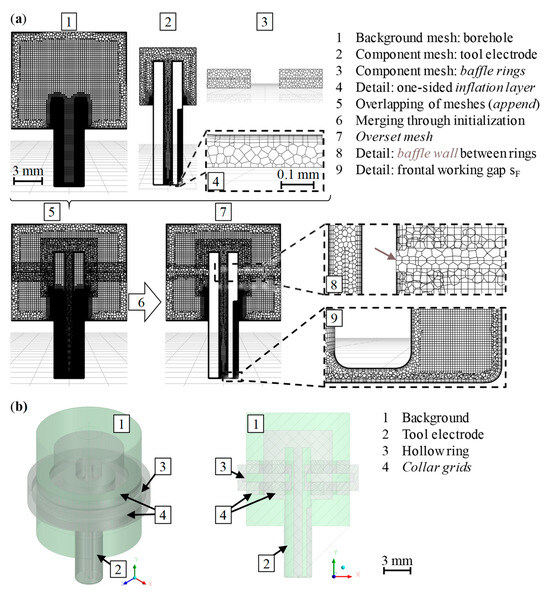

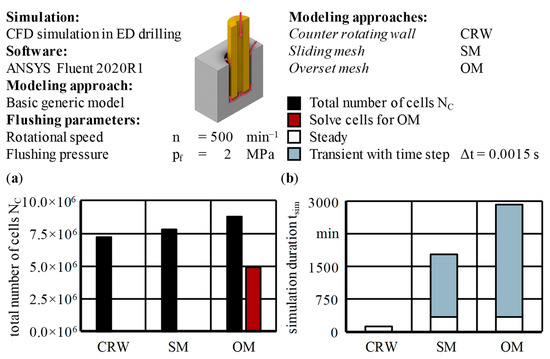

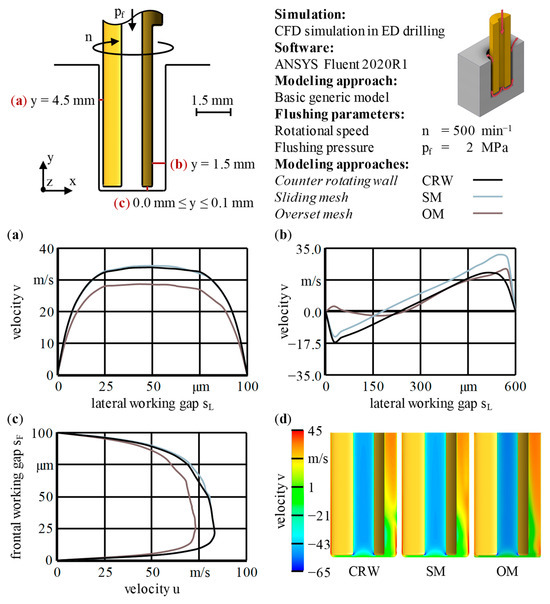

3.3. Generic Numerical Model and Approaches for Rotating Asymmetric Domains

Preliminary investigations focused on determining suitable meshing approaches, as well as a trade-off between the accuracy of the solution and the resolution of the wall boundary layer. For this purpose, as discussed in Section 4.2, the number of inflation layers nIL and the height of the first layer h1L were studied and three methods to model the rotating fluid domain, namely, counter-rotating wall (CRW), sliding mesh (SM) and overset mesh (OM), were compared. This section introduces these three meshing approaches, gives the theoretical background and motivates the settings. From here on, specific software or numeric-related terms are written in italics to clarify and highlight related terminology. Figure 5 shows the basic generic model that was used for the mesh analyses, as well as the three generic models derived from it to model the rotation of the asymmetric tool electrode geometry. It can be seen that the latter three encompassed a straight slot that worked as a simplified groove with a groove length lg = 8 mm, a groove depth dg = 0.5 mm and a groove width of wg = 0.5 mm. All four models shared the same geometrical specifications, which included an outer diameter do = 3 mm and a length le = 12 mm of the tool electrode, an inner diameter di = 1 mm and a hole diameter dh = 3.2 mm, resulting in a working gap width s = 0.1 mm and a machining depth dm = 6 mm, giving an aspect ratio A = 2, as well as physical boundary conditions, namely, a rotational speed n = 500 min−1 and a flushing pressure pf = 2 MPa. All radii were to R1 = 0.1 mm, except the bottom radius inside the borehole, which was R2 = 0.2 mm.

Figure 5.

Cell zones and boundary conditions of the generic models: (a) basic model for mesh analyses; (b) counter-rotating wall; (c) sliding mesh (SM); (d) overset mesh (OM).

With the help of the generic model given in Figure 5a, relevant mesh parameters of the inflation layer at the walls were varied with the objective of correctly resolving the wall boundary layer. Across a discrete span, the distances of the wall parallel prism cells were steadily increased in the normal direction to the wall to resolve the usually high gradients of any fluid mechanic property. The most important example is the velocity |c|, which is |c| = 0 m/s at any wall with a no-slip boundary condition. Regions that are outside of the wall’s influence are meshed with selected cell types, like ted-, hex- or polyelements.

In addition, the global mesh was divided into three cell zones with the option share topology in ANSYS SpaceClaim for the basic model in Figure 5a. These cell zones were linked with each other at their contact areas, which acted as interfaces, as they were set to internal. In this way, the generation of conformal meshes in ANSYS Fluent with individual element sizes for each cell zone was possible, increasing the control over the mesh resolution at relevant locations, like the working gap. The theory of wall boundary layers uses dimensionless parameters, like the dimensionless wall distance y+ and the dimensionless velocity u+, to describe fluid mechanical quantities; see Equations (2)–(4):

with y being the coordinate normal to the wall, ν the kinematic viscosity, ρ the density, the average wall-parallel velocity and uτ the friction velocity as the characteristic velocity for turbulent flows with given shear stress . This notation arises from the examination of the Couette flow, whose velocity distribution is of a universal character, especially for large Reynolds numbers, and results in the logarithmic law of the wall [82]. The velocity distribution u+(y+) is divided in the three regions viscous sublayer for y+ < 5 with the approximation u+ = y+, the buffer layer for 5 < y+ < 70, and the log law region for y+ > 70 with u+ = 1/κ × ln y+ + C+, κ = 0.41 and C+ = 5.0 [82]. The influence of the dynamic viscosity µ is dominant in the viscous sublayer but drastically decreases toward the log law region, which is nearly fully turbulent. The aforementioned wall functions are usually applied with turbulence models, like the k-ε turbulence model, on meshes with distances of y+ ≥ 30 to the cell closest to the wall. This is only acceptable for cases where the turbulence production k and the dissipation ε are in balance but not for cases with strongly three-dimensional flow structure; tangential upstream oriented pressure gradients; or missing far away flow, like in the case of narrow gaps [83]. As a solution, low-Re turbulence models help to describe the transition from the fully turbulent core flow to the boundary layer by introducing damping functions to correct the turbulence production k and dissipation ε. Unfortunately, this advantage comes with the necessity of a higher mesh resolution and increased numerical effort, which results from the recommendation of applying a dimensionless wall distance in the order of y+ = 1 for the cell closest to the wall [83]. This is why, in common cases of free external flows, like the flow around airfoils, the viscous sublayer and the buffer layer of the boundary layer are to be resolved with several inflation layers nIL ≥ 10 [83,84].

The enhanced wall treatment method within ANSYS Fluent is a direct consequence and combines a classical two-layer model with enhanced wall functions to determine the dissipation ε and the turbulent viscosity µt. Therefore, the whole fluid domain is divided into a fully turbulent and a viscous region, which are delimited by a characteristic Reynolds number Rey:

where y is the wall-normal distance to the respective cell centers. In fully turbulent regions with Rey ≥ 200, the standard k-ε turbulence model is used, whereas in the viscous layer, the turbulent viscosity µt is derived with a turbulent length scale lµ. A blend function is then used to determine the turbulent viscosity μt as a function of the characteristic Reynolds number Rey [84]. For the sake of completeness, it should be noted that a y+-insensitive wall treatment is used by default in the case of turbulence models based on the ω-equation for the specific rate of dissipation ω.

As a result of these considerations, the number of inflation layers nIL and the height of the first layer h1L were varied according to Table 2. First, the number of inflation layers nIL was analyzed with a fixed height of the first layer h1L = 2.0 µm regarding the axial velocity profiles and an inspection of the mesh elements, which were colored with the corresponding values of the wall-parallel velocity. Afterward, the most appropriate number of inflation layers nIL was used to vary the height of the first layer h1L and analyze it accordingly.

Table 2.

Relevant parameters of the boundary layer that were varied.

As mentioned before, the recommendation of applying a dimensionless wall distance in the order of y+ = 1 comes with increased numerical effort. For transient calculations, this also may result in a very small time step Δt. Additional objectives for the inflation layer analyses were as follows:

- NV = 5 volume cells between opposite inflation layers across a gap, amongst others, was a necessary condition for the overset mesh approach;

- The inflation layer volume fraction amounted to about 50% of the working gap;

- The total number of cells NC needed to be as low as possible to enable a transfer of the meshing parameters to the even bigger mesh of the full numerical model;

- The dimensionless wall distance of the first cell should be in the order of y+ = 1.

For all these numerical calculations, a global mesh using poly-hexcore elements, two peel layers, a transition ratio between the last inflation layer cell and the first volume cell of TR = 0.4, and an inflation gap factor of IGF = 1 were applied and the option keep layer height was activated. The inflation gap factor ensured that the cells between both inflation layers and the inner volume cells had the same volume ratio as the inflation layers on both sides. The pressure-based SIMPLE solver was selected for the sequential pressure–velocity coupling, as it is recommended for steady-state incompressible flows. The PISO solver should be used for transient calculations, especially with skewed meshes. A coupled scheme includes the advantages of robust and efficient solutions of steady-state flows and the use of a large time step Δt, in conjunction with meshes of low quality for transient calculations [85]. To study the mesh, in addition to the standard SIMPLE algorithm, a first-order upwind method was used to discretize the momentum equation, and the warped-face gradient correction was activated to improve the accuracy of the gradient. The latter is recommended for three-dimensional simulations on poly-hexcore meshes, as these do not have perfectly planar faces [85].

The counter-rotating wall (CRW) approach shown in Figure 5b is the simplest way to model the rotation of the asymmetric tool electrode geometry. This approach works based on the assumption of a change in the reference position, originating from the stationary workpiece to the rotating tool electrode. As seen from this moving reference point, the tool electrode is at rest and the wall of the workpiece electrode moves in the direction opposite to the actual direction of rotation. The volume forces on the fluid are generated by the rotation of the whole fluid domain or cell zone respectively by applying frame motion on the cell zone ‘gap’ with a rotational speed of n = 500 min−1 (see Figure 5). The walls of the ‘electrode’ are walls moving relative to an adjacent cell zone, whereas the walls of the ‘borehole’ are absolute moving walls, both with a rotational speed of n = 0 min−1. The difference between these definitions becomes apparent when the proximity to a stationary or rotating cell zone is considered. The aforementioned relative specification implies a resting wall in the moving reference frame and, at the same time, a moving wall in the absolute reference frame. The absolute specification means that the wall rests in the absolute reference frame and moves in the opposite direction in the moving reference frame. Frame motion only allows for capturing steady-state flow phenomena within the CRW approach. The steady-state solution is reached after a number of iterations of nI = 1000 iterations. A transient calculation would need a mesh motion or dynamic mesh approach instead and a respective interface to the stationary domain. This is exactly what a sliding mesh offers.

The sliding mesh (SM) approach, as shown in Figure 5c, allows for calculating even transient behavior of at least two cell zones that move relative to each other. In other words, during the simulation, one cell zone slides along the connecting surface within a discrete time step Δt. The former cell zone ‘gap’ is now split into a moving cell zone ‘gap tool electrode’ and a stationary cell zone ‘gap borehole’, which are connected via a mesh interface with the option matching, which tries to match the element nodes on both sides of the interface to reduce the oscillations of the solution. A reason for this might lie in the interpolation of the mass flow from the interface to the sliding surfaces that might locally influence the mass balance. The meshes of the rotating and stationary parts are created separately and brought back together inside the setup of ANSYS Fluent 2020R1 via append case. The interface boundary conditions of both sides will be merged and interpreted again as internal. The PISO solver is used because, in the long run, multiple rotations of the tool electrode are supposed to be considered, and hence, a bigger time step Δt is needed but also supported by that algorithm. When using frame motion for the rotating cell zones during the steady-state calculation, a number of iterations of nI = 1000 was again computed for comparability reasons. This solution acts as the initial solution or flow field for the transient calculation, now using mesh motion. Bounded second-order implicit was selected for the time integration since this allowed for improved accuracy and stability compared with the standard settings by maintaining limits regarding the time discretization of the variables [85]. The transient calculation was performed with a fixed time step of Δt = 0.0015 s, which corresponded to an incremental angle passed of β = 4.5° as the result of the rotational speed of n = 500 min−1. In the center of the working gap in the tangential direction, this equaled a swept arc with an arc length of about la = 0.12 mm. By specifying the number of time steps nΔt = 160 and the number of iterations nI/Δt = 20 per time step Δt, a maximum of nI = 3200 iterations were calculated. During this period, the tool electrode performed two full rotations.

The overset mesh (OM) approach has the advantage of allowing for arbitrary movements of the component meshes on the background mesh and, therefore, translation movements of the tool electrode are possible. This is visualized in Figure 5c and involves additional boundary conditions. The background and component geometries have to be designed and meshed independently. Merging of those overset regions happens during the initialization of the flow field within the setup and is not only highly complex and numerically expensive but also subject to numerous and strict requirements [85]:

- Component meshes of an overset interface may overlap arbitrarily, allowing them to be combined into a complex object, provided that physical boundary conditions, such as walls, an inlet or an outlet, do not intersect;

- However, component and background meshes can be placed in such a way that the physical boundary conditions lie on top of each other, and thus, e.g., wall boundary conditions can be coincident with each other;

- Overset boundary conditions, on the other hand, can intersect other overset boundary conditions, as well as physical boundary conditions;

- The calculation has to be performed with double precision;

- The time step selection for dynamic meshes must be based on the relative mesh motion per time step Δt, which should be below the smallest volume cell size lc of the overset interface.

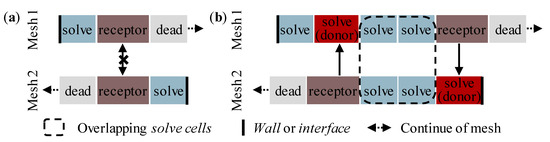

The merging process includes the following steps (see Figure 6) [85]:

- Hole cutting: The process of marking mesh elements as dead cells that are outside of the fluid domain of interest, e.g., on the inside of bodies. Excessive overlap of component meshes and the background mesh is numerically inefficient. The transition of both meshes ideally occurs in areas with similar resolution. Large deviations between the overlapping meshes influence the interpolation, and thus, impair the quality of the solution.

- Overlap minimization: The process of converting solve cells to receptor cells, as well as unnecessary receptor cells in dead cells, between component meshes and the background mesh. A solve cell is converted into a receptor cell if a suitable donor cell with a higher donor quality can be found for this cell. The specification of a donor priority method influences this cell replacement procedure depending on the local mesh resolution.

- Donor search: A solve cell containing the centroid of a receptor cell of the overlapping mesh is used together with the adjacent solve cells as a donor for the selected receptor. Within the search, each receptor cell must be associated with at least one eligible donor or solve cell. Four or more cells must be present in the overlap zone of both meshes to ensure a successful donor search. Orphan cells are generated during initialization wherever this routine fails.

The avoidance of orphan cells is the major challenge when using the OM approach because even fairly simple geometry configurations involve numerous potentially problematic combinations and overlaps of boundary conditions and components, especially with additional use of the bodies of influence meshing method or other auxiliary bodies.

Figure 6.

Overlapping of two meshes to form an overset interface: (a) invalid overlap creating orphan cells; (b) valid overlap with sufficient cells in the overlap zone [85].

The specific third requirement for the donor search motivates the first objective concerning the inflation layer analyses below Table 2. The OM approach was already introduced for CFD simulations in the field of ED drilling without internal flushing, also providing detailed visual insights into modeling, meshing and merging [14]. In addition, Figure 7a shows the overset mesh for the present case with internal flushing, which was generated with the procedure described above and on the basis of Figure 5d. The working gap was successfully resolved with a number of cells of NC = 18, which was divided into NV = 6 volume cells between the two inflation layers. The little detail of an inlet, which could not be placed at the boundary of the mesh (see the first OM requirement), led to the necessity of adding some kind of pressure chamber domain around the tool electrode’s top pressure inlet and sealing this chamber on the outside walls of the tool electrode to prevent perpendicular bypass fluid flows. This fact resulted in many additional geometries for the implementation of baffle walls (Figure 7a) or collar grids (Figure 7b), which, in turn, caused the heavy occurrence of orphan cells and, therefore, diverging solutions. These additional geometries were also multiplied by additional auxiliary bodies, namely, the bodies of influence, for the purpose of local mesh refinements because the latter cannot be set up by the cell sizes inside the cell zones in the case of the OM approach. The idea of applying a hollow ring instead of the two baffle rings holds the advantage of generating more dead cells and, therefore, reducing the numerical effort. Nevertheless, additional components with respective meshes have to be generated and increase the complexity, not only for the user but also for the merging algorithm. During initialization, the flood filling of dead cells in areas where no fluid is supposed to be starts with placing seed cells. Complexities in the topology or mesh resolution issues can cause the algorithm to unintentionally identify seed cells inside fluid regions and end up marking entire fluid regions or cell zones as dead. Different variants and arrangements of component meshes led to incorrectly identified seed cells and, as a consequence, dead regions, which is why the approach of using baffle walls is preferred.

Figure 7.

Creation of the overset mesh by overlapping and merging different components: (a) final OM domain with baffle walls; (b) geometries of overlapped background and components for the use of collar grids.

Identical transient settings were used compared with the SM approach and were supplemented by a frozen flux formulation for the implicit discretization of the convective terms to improve convergence. The underlying steady-state solution with frame motion was achieved with a number of iterations of nI = 500 this time because the coupled scheme used accelerated convergence. Table 3 summarizes the most significant models and solver settings of the three generic models for reproduction purposes.

Table 3.

Models, solver settings and mesh characteristics of the generic models.

The most accurate and effective meshing approach and respective CFD setup were identified by means of the generic models described here (see upcoming Section 4.2). Using the resulting recommendations and the realistic geometric boundary conditions obtained as described in the previous Section 3.2, the fluid flow in the working gap was simulated on those realistic, greater domains, as introduced in the following Section 3.4. The numerical results gained with these sophisticated models of all six tool electrode types finally allowed for deriving analogies to the experimental results of Section 4.1.

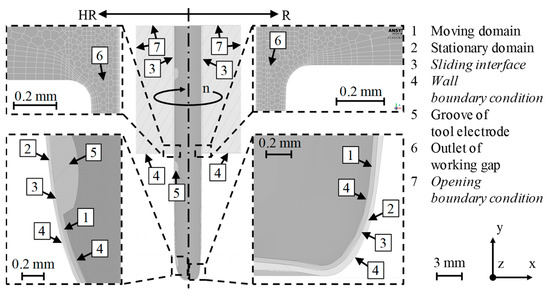

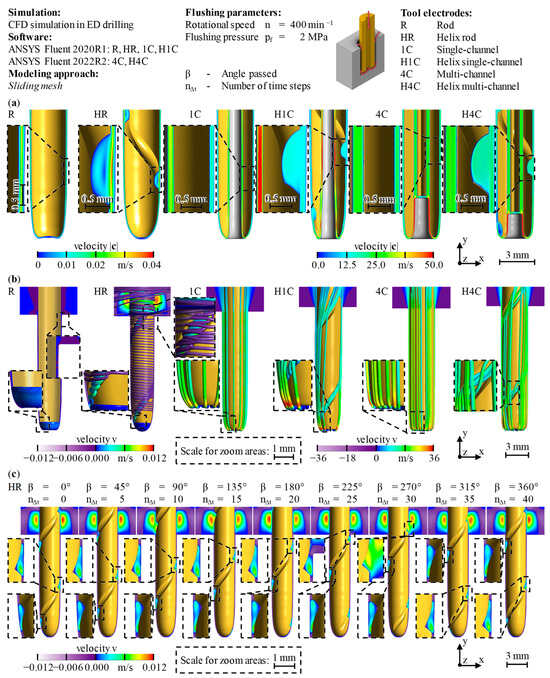

3.4. Sophisticated 3D CFD Model

Fluid simulations of the tool electrodes introduced in Figure 3 were carried out with ANSYS Fluent 2020R1 in the case of R, HR, 1C and H1C, as well as ANSYS Fluent 2022R2 in the case of 4C and H4C from ANSYS Inc., Canonsburg, PA, USA. Rod, single-channel and multi-channel electrodes were compared with their equivalent helix geometries to examine the influences of the internal and external flushing channels. Figure 8 exemplarily shows both fluid domains for the R types. A sliding mesh approach was used to model the rotation of the tool electrodes, dividing the working gap into a moving and a stationary domain via a sliding interface.

Figure 8.

Numerical model, exemplary for the type R and HR tool electrodes, with details of the mesh and the sliding mesh approach.

This model was built using measured contour polygons of the bores and the associated tool electrodes as depicted in Figure 4 ensuring realistic values of the frontal and lateral working gap width sF and sL. The groove geometry, as well as an enlarged hole conicity α, increased the number of polyhedral cells NC, especially orthogonally across the lateral working gap (see the hole entrance areas in Figure 8).

The fluid properties for all CFD simulations that are presented in this paper can be found in Table 4. Data for the dielectric IME63 was taken from the manufacturer oelheld GmbH. The properties of air were needed for the supplemental multi-phase simulations, as mentioned at the end of Section 4.3 and linked in the Supplementary Materials section.

Table 4.

Material properties for CFD simulations.

The most important boundary conditions, as well as assumptions and additional details, supplemental to the information in Table 5, are listed hereafter:

- 50% of the cells across the working gap were volume cells;

- RANS modeling for the single-phase flow;

- Reference and operating pressure: pref = 0 MPa, pop = 0.1 MPa;

- Inlet pressure equaled the flushing pressure pf = 1.9 MPa;

- Moving domains rotated with rotational speed n = 400 min−1;

- Liquid only: neglected the presence of debris and gas bubbles;

- Steady-state solution after a number of iterations nI = 1000 iterations was followed by nR = 11 transient revolutions being calculated;

- Adaptive time step Δt for the first revolution to ensure CFL ≤ 1 (see Section 4.2);

- Last ten revolutions: fixed time step Δt = 0.00375 s; incremental angle passed: β = 9°; simulation durations tsim = 35 h for HR and tsim = 96 h for H1C.

It has to be stated that ANSYS Fluent internally uses a subtraction of the absolute pressure pabs and the operating pressure pop to avoid roundoff errors [85]. The result following Equation (6), namely, the gauge pressure pgauge, is what is manually specified within the software; this is why the gauge pressure needs to be set to pgauge = 1.9 MPa to ensure a flushing pressure of pf = 2.0 MPa at the pressure inlet:

pabs = pop + pgauge.

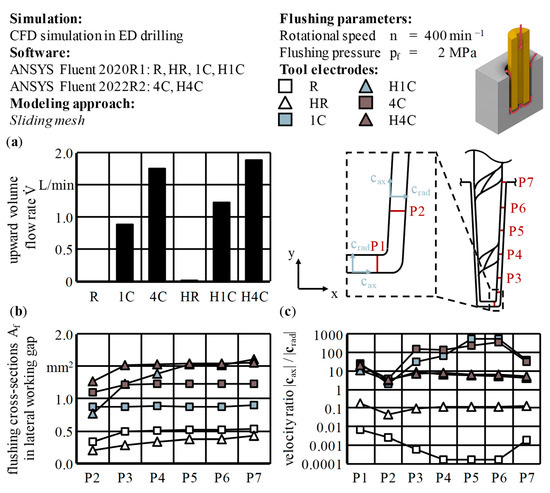

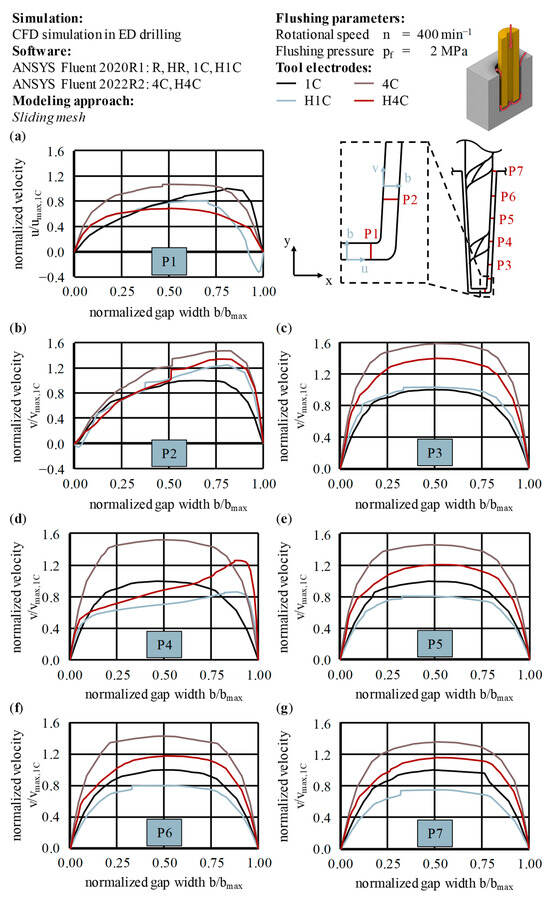

Schematic sketches of the rod and single-channel geometries are illustrated in Figure 9, which also details positions P1 to P7 for later evaluations. The multi-channel geometries are equivalent to Figure 9b, except for the internal channels. The geometrical and physical parameters of all fluid flow simulations are consistent with the experiments and correspond to an aspect ratio of A = 5.

Figure 9.

Schematic sketch of the tool electrodes and definition of evaluation positions and velocity components: (a) R and HR types; (b) 1C, H1C, 4C and H4C types.

Table 5.

Models, solver settings and mesh characteristics of the sophisticated models.

Table 5.

Models, solver settings and mesh characteristics of the sophisticated models.

| Mesh Characteristic | Value or Setting |

| Type of mesh | Poly-hexcore |

| Cell size in working gap | 20 µm ≤ lc ≤ 30 µm |

| Number of inflation layers | nIL = 6 |

| Height of the first layer | 0.5 µm ≤ h1L ≤ 10.0 µm |

| Total number of cells | 9.33 mil. ≤ NC ≤ 11.65 mil. |

| Model/Setting | Value or Setting |

| Turbulence | Realizable k-ε model, enhanced wall treatment |

| Pressure–velocity coupling | R, HR: SIMPLE; 1C, H1C, 4C, H4C: coupled |

| Spatial discretization | |

| Gradients | Least squares cell-based with warped-face gradient correction |

| Pressure | Second order |

| Momentum | Second-order upwind |

| Turbulent kinetic energy | First-order upwind |

| Turbulent dissipation rate | First-order upwind |

| Transient formulation | Steady: pseudo-time method global Transient: bounded second-order implicit |

| Time step | Δt = 0.00375 s |

| Iterations per time step | nI/Δt = 20 |

The qualitative and quantitative evaluations in Section 4.3 were based on these evaluation positions, which are further specified in Table 6.

Table 6.

Geometrical parameters and evaluation positions for simulated tool electrodes.

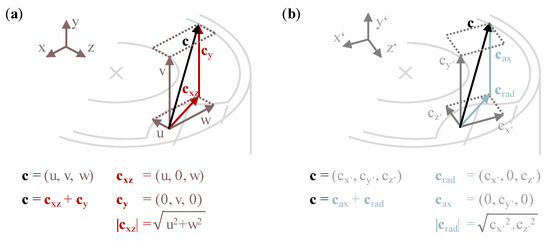

Comparative quantitative and qualitative evaluations and analyses of results gained by using CFD simulations are usually based on common tools like streamlines, vector plots or contour plots of the parameters of interest. One advantage of numerical results besides an infinite spatial resolution arises from the possibility of calculating nearly any physical or non-physical parameter and, by using it, its average value or sum on auxiliary geometries or any other mathematical construct with it for explanatory approaches. In 3D CFD simulations, the components of the velocity vector c in the global Cartesian coordinate system are frequently used to reveal local flow field characteristics. Figure 10 visualizes and defines the velocity vector c on cross-sectional views of the H1C type tool electrode for the cases of a global Cartesian coordinate system and a slightly rotated coordinate system, marked with apostrophes, where the radial velocity vector crad is the vector resulting from the velocity components cx’ and cz’ being perpendicular to the vector of the axial velocity cax. The latter in this work will always be aligned in the main flow direction. Vector quantities are written in bold. The evaluation positions and velocity components defined this way are used in Section 4 for the detailed evaluation of the calculated 3D flow fields.

Figure 10.

Visualization and vector quantities of the velocity in the example of the H1C-type tool electrode in a cross-sectional view: (a) stationary, global Cartesian coordinate system; (b) moving consideration with the vectors cax and crad giving the axial and radial components of the main flow, respectively.

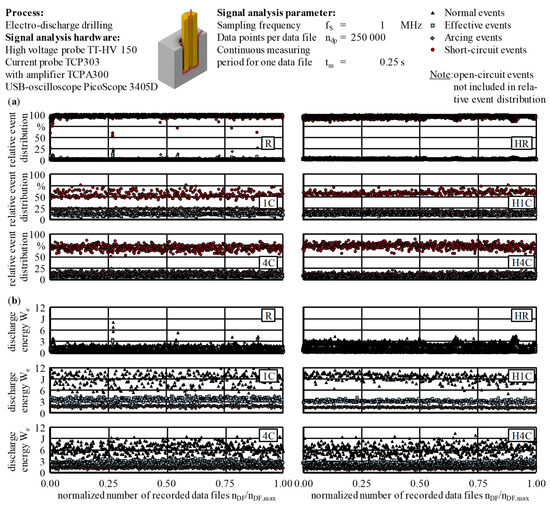

3.5. Signal Analysis

In order to ensure a good EDM process, discharge conditions must be created in the working gap that largely exclude the occurrence of short-circuit, false discharge and open-circuit pulses. A short-circuit pulse in this context occurs when the electrodes are touching or when bridging takes place due to removed particles [10] (p. 12). The task of the feed control is, therefore, to feed the tool electrode according to the material removal, the wear and the respective gap conditions [10] (p. 41). A detailed signal analysis of the current i and gap voltage u by detecting rising and falling flanks allowed for explanations and further quantification of the influence of internal and external flushing geometries on the process stability. The general approach of using rising and falling flanks in combination with threshold crossing points was inspired by the pulse classification algorithms proposed by Zhou et al., Janardhan and Samuel, and Nirala et al. [69,70,71,72]. Janardhan and Samuel described a method to detect rising and falling signal flanks by detecting and storing the sampling data points just before and after a voltage or current threshold is crossed [71]. Nirala et al. solely used voltage thresholds for the pulse discrimination and rightly stated that the corresponding threshold values should be determined empirically (Table 7). Therefore, they are hardly transferable from one parameter setting to another. This is why the thresholds have to be adapted to every machine tool and generator type. They also measured the current signal and utilized this additional information to calculate the average energy to further obtain an implication of the process stability. This was based on the understanding that an early discharge originates from a locally increased electrical conductivity σ, e.g., as a consequence of process residues, like debris or a too-small working gap. Due to those early discharges, only partially charged capacitors are ignited and contribute a maximum of half of the discharge energy We per pulse to the material removal process, following their thresholds and Equation (1) [69,70].

Table 7.

Thresholds for differentiation of discharge event types following Nirala et al. [70].

Other authors utilized the ignition delay time for classification purposes. Since the ignition delay time is the time from the voltage pulse being applied until the ignition of the discharge, i.e., until the current rises, this is only possible for static pulse generators [10]. For RC generators, switching on the voltage pulse does not necessarily initiate the ignition of the discharge, but instead the charging of the capacitor first, necessitating other strategies for event classification.

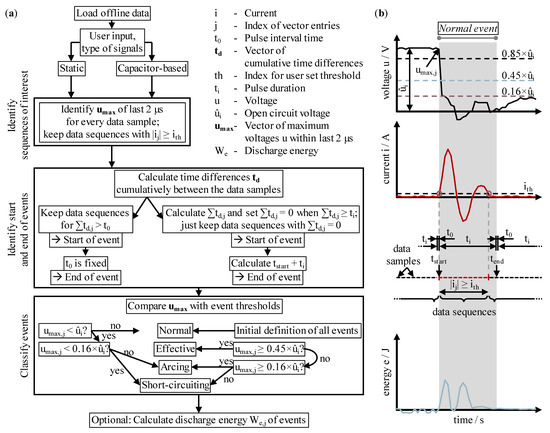

The basis of the signal analysis for the purpose of a classification of discharges proposed in this work is a semi-automated software tool written in the Python programming language and utilizing the Qt toolkit for the graphical user interface (GUI). It was introduced as the first version in prior work, enabling data acquisition and signal analysis based on lists and nested loop iterations to perform classification [15,86]. In this way, the classification was very slow and the raw data had to be split 50 times to achieve an improvement of more than 90% in runtime and disk space. Nevertheless, the time to be spent on signal analysis was in the order of hours rather than minutes for each case and parameter setting, thus hindering the search for an adequate benchmark of the signal analysis parameters. As stated above, this empirical determination of thresholds implies a user-dependent character and threshold evaluation at random that both led to a general underestimation of events by nearly 40%, mainly short circuits, compared with previous results [11].

For performance reasons, these algorithms have now been further enhanced and the discharge energy We can be used as an additional indicator for a sophisticated threshold determination. In particular, the implementation of vector calculations with Numpy, in combination with multithreading and multiprocessing techniques enabled a substantial reduction of the runtime. By substituting the use of loops and entirely adopting Numpy-based computations, the runtime could thus be reduced from 200 times the machining time down to just 0.1 times the machining time of an actual drilling process. These combined methods now allow for real-time signal analysis in principle [68]. Table 8 specifies the thresholds for the gap voltage u that were manually adapted to the signals resulting from the process parameters given in Table 1 and were finally used for the offline signal analysis. The classification algorithm implemented not only utilized the gap voltage u but also the current i for the detection and characterization of discharge events. The combination with edge detection whenever a certain voltage threshold uth = 0.16×ûi = 28.8 V was undercut (falling edge) allowed for the discrimination between different types of events and their assignment to any interval of the pulse cycle time tp. If a falling voltage edge fell from above a gap voltage u = 0.85×ûi to below the voltage threshold uth in close temporal proximity to a rising current edge that exceeded the current threshold ith = 5.9 A, this event was registered as normal. In the same way, the classification of the event types effective and arcing was enabled, only using different voltage thresholds. Current edges occurring at voltage values u < uth were counted as short circuiting.

Table 8.

Adapted thresholds for the differentiation of discharge event types.

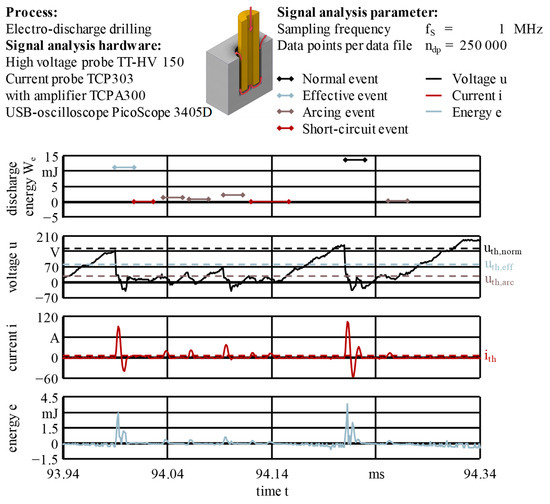

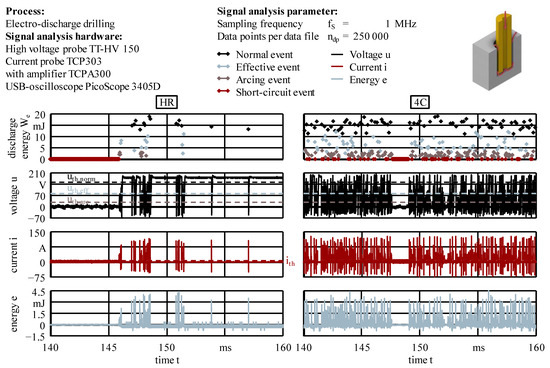

Figure 11 details the classification algorithm for the analysis of static, as well as capacitor-based process signals of the gap voltage u and the current i. In this work, capacitor-based process signals were analyzed, which is why the focus was on these data.

Figure 11.

General algorithm to identify and classify discharge events: (a) flow chart; (b) visualization of the data analysis on the example of a capacitor-based normal event.

The measurement system for signal acquisition involved a TT-HV 150 high-voltage probe from Testec Elektronik GmbH, Frankfurt, Germany, and a TCP303 current probe in combination with a TCPA300 current probe amplifier from Tektronix, Inc., Beaverton, OR, USA, which were both connected to a PicoScope 3405D USB-oscilloscope from Pico Technology, Cambridgeshire, UK. The data were recorded using a Raspberry Pi 4 single-board computer from Raspberry Pi Foundation, Cambridge, UK. Considering the times for buffering tb, transfer tt and saving ts of each data file, a measurement ratio of around rmeas = 0.65 of the ED drilling process was captured for every type of tool electrode within the machining depth 12 mm ≤ dm ≤ 15 mm. The sampling frequency was set to fS = 1 MHz; the number of data points was set to ndp = 250,000 for each data file; and scaling factors of Fu = 100 and Fi = 50 were used for the voltage and current signals, respectively. The first two parameters resulted in a continuous measuring period of tm = 0.25 s for each data file. This period, as well as the internal processing time, for the data handling between two measurement intervals directly affected the measurement ratio rmeas [15], following Equation (8), and the measuring duration tmeas by multiplying it with the number of recorded data files nDF, as seen in Equation (7):

tmeas = nDF × tm

rmeas = tm/(tm + tb + tt + ts)

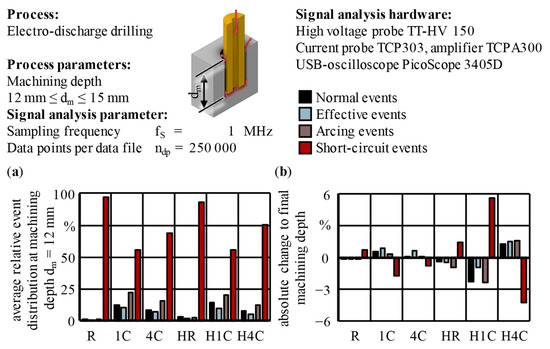

In addition to the absolute values of the classification results, the event pulse frequency, which is the number of discharge events of a certain type occurring in the working gap per unit time, and the frequency ratio λ, which is calculated as the ratio with the pulse frequency fp, were used for the process evaluations in Section 4.4 [10]. The combination of sophisticated numerical modeling and signal analyses allowed for explanations and to attest to the improved process stability when using helical external flushing channels.

4. Results and Discussion

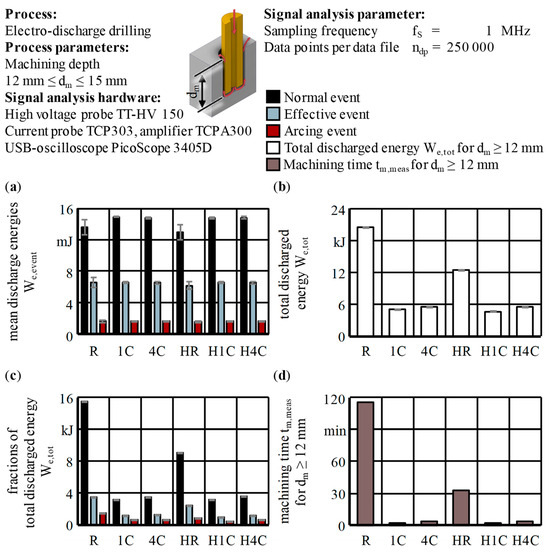

4.1. Experimental Results

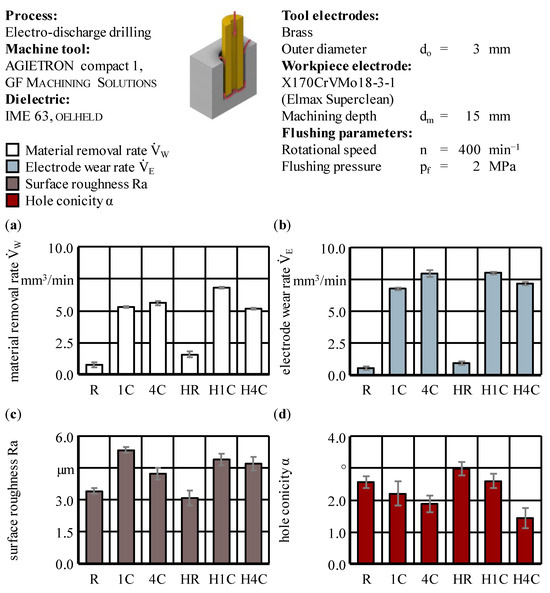

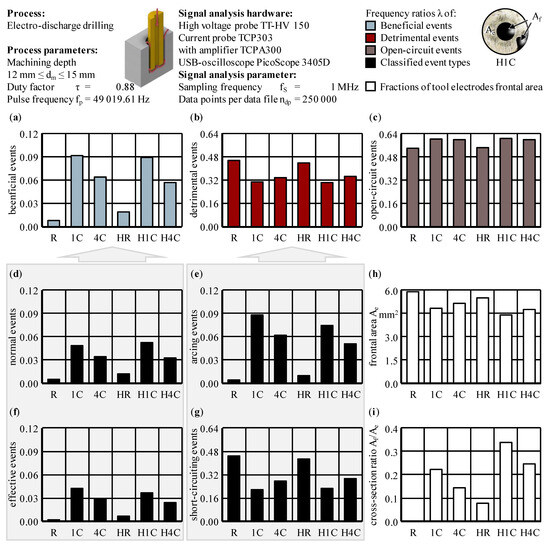

Figure 12 presents the machining results, comparing the process target parameters of MRR, EWR, surface roughness Ra and hole conicity α for the six types of tool electrodes, which are further referred to with the abbreviations given in Figure 3. The standard deviation sD gives the statistical error. The surface roughness Ra represents the surface quality on the hole’s lateral surfaces. Table 9 summarizes in detail all comparisons of interest between the six types of tool electrodes, e.g., the sum of the internal and external flushing channels cross-sectional areas and the flushing cross-sections Af. In addition to Figure 12, the changes in the frontal area Ae, which resulted from the subtraction of the internal and external flushing channels, as well as the machining time tm, are given. These seemingly minor geometric differences were also taken into account for the calculations of the MRR and EWR.

Table 9.

Numeral comparison of process target parameters of the tool electrode types studied [11].

In general, the common target parameters of the EDM process cannot be influenced independently of each other. The results presented in Figure 12 and Table 9 mirror the complex correlations between the target parameters and the fact that they cannot all be improved together.

The influence of the external flushing channel with respect to the MRR and EWR was most obvious for the comparison of the rods. Due to the improved debris removal from the frontal working gap, the MRR and EWR were increased by 112% and 75%, respectively. The latter results from the flushing through the external flushing channel greatly decreasing the machining time tm by 64% by increasing the volume per unit time that was eroded from both electrodes. In fact, the absolute value for the relative linear wear of ϑl = 71.2% for the HR type showed only a minor difference compared with the R type with ϑl = 75.5%. Generally, the additional external flushing channel favored improvements in terms of MRR and surface roughness Ra, but deteriorations of the EWR and the conicity α for the R and 1C types. Surprisingly, it was the complete opposite for the 4C types.

The vastly increased values of the MRR and EWR when using single- and multi-channel tool electrodes instead of one of the rod types resulted from the application of pressure flushing through the internal channels and the direct evacuation of the process residues. The activation of pressure flushing in all cases led to an increase in the surface roughness Ra and a stepwise decrease in the conicity α, as well as the lateral working gap width sL, when comparing R, 1C and 4C or HR, H1C and H4C. In contrast, adding the additional helical flushing channel increased the hole conicity α when comparing R and HR or 1C and H1C. Nonetheless, when comparing 4C and H4C, an improvement of 24% could be stated for the hole conicity α.

Further advancements resulting from the supplementary space for debris and gas bubbles within the external flushing channel could be stated in terms of the MRR with the 1C type, as well as the EWR with the 4C type. In the case of H1C, an improvement of 28% from = 5.3 mm3/min to = 6.8 mm3/min could be stated, but the helical groove caused a slight increase in the relative linear wear from ϑl = 138.7% to ϑl = 144.5%, corresponding to an increase in the EWR by 19%. A similar behavior could be found for the 4C electrodes, where the values were ϑl = 155.0% for 4C and ϑl = 164.3% for H4C, indicating an increase. Nevertheless, the EWR dropped by 10%, which underlines the need to take the geometries of the boreholes and the tool electrodes into account in a precise and detailed manner. The process-effective frontal areas Ae of the tool electrodes were decreased by the inner diameter di of the tool electrodes, as well as the cross-section of the external flushing channel or groove, in terms of the variants with additional passive flushing. Therefore, simplified methods for determining the values of the MRR and EWR, like using the aspired machining depth dm of the holes and the linear wear of the tool electrode ΔlE alone, were not applicable for systematical analyses of the influence of internal and external flushing geometries.

The theoretical effect that a reduced effective cross-section due to subtraction of those geometries led to a decrease in the MRR and an increase in the EWR for reaching a specified machining depth dm of the holes was superseded by the effects of fluid mechanics and thermodynamics when using a flushing pressure and a rotational speed.

When applying an external flushing channel with the particular groove geometry chosen for these experiments, the frontal areas Ae of the tool electrodes were decreased by 7% to 9%. The utilization of internal flushing channels reduced the frontal area Ae by 12% to 20%, resulting in pins with a diameter dp in the order of dp = di − 2s that remained in the blind holes. In the cases of 1C and H1C, the pin kept its full pin height of hp = 15 mm and the pin diameters were dp,1C = 1.00 mm and dp,H1C = 1.05 mm, respectively. Also, in the cases of 4C and H4C, a small pin remained, with pin heights of hp,4C = 3.04 mm and hp,H4C = 2.19 mm and pin diameters of dp,4C = 1.19 mm and dp,H4C = 1.17 mm, respectively. These different pin geometries helped to explain the counterintuitive comparison between 1C and 4C, showing an increase in the MRR, EWR and machining time. Risto et al. already stated that changes in the tool electrodes cross-section combined with the pin formation reduces the effective flushing cross-section Af, hence resulting in increased hydraulic resistance and a decreased volume flow rate for constant flushing pressures pf [36]. Yilmaz and Okka did not explicitly discuss pin formation issues, but just like Bozdana and Ulutas, applied brass multi-channel tool electrodes whose flushing cross-sections Af, unlike in the present study, exceeded those of the single-channel tool electrodes by up to 144% and 34%, respectively. These investigations led to contradictory results concerning a considerable reduction or increase in the MRR but an increased EWR in both cases [21,22]. These results, which are partly contradictory to the present study and each other, underline the fact that generalized findings on internal flushing channels are difficult to deduce and are always case and geometry dependent. Consequentially, the same applies to external flushing channels.

Figure 13 shows the electrode tips on the scanning electron microscope (SEM) images, which were measured using an SEM of type JCM-5000 NeoScope from Jeol Ltd., Akishima, Japan. In the case of the rod electrodes without internal flushing, a small cavity evolved at the tips of R and HR. Only for negatively polarized tool electrodes, as in the present case, Li et al. revealed similar concave contours of the electrode tip and explained this fact with the skin effect and a decreased discharge probability in the center [87]. The authors did not attribute this concavity to the ejection of debris, but from their SEM images, it can be supposed that the center concavity deepened as a result of the increasing rotational speed [87] (p. 9). It can therefore be further concluded that the concave tip contour was also a consequence of accumulated debris in the frontal working gap due to the absence of pressure flushing, supporting the formation of a stationary vortex. The helical geometry of HR reduced this effect, but instead led to an increased relative edge wear ϑIK and, therefore, a more conical tip, relocating the beginning of the groove upward (see Figure 13b,c). The unevenly distributed areas of discharge craters with predominant directions on the lateral surfaces were probably caused by a combination of spindle run-out and pressure flushing, resulting in fluctuating lateral low-pressure regions, with both leading to vibrations of the tool electrode and promoting those irregularities (see Ferraris et al. [17] (p. 193)).

Figure 13.

SEM images and contours of worn tool electrode tips: (a) without external flushing; (b) with external flushing; (c) comparison of contours [11].

The contours of the tool electrodes shown in Figure 13, as well as the bores that were drilled with them, were digitized by using the digital microscope mentioned in Section 3.2. The data obtained in this way enabled fluid dynamic simulations with geometries and working gap dimensions as close as possible to realistic conditions of the ED drilling process, providing explanatory approaches for the process behavior discussed.

Section summary:

- The additional external flushing channel geometry applied favored improvements in terms of MRR and surface roughness, but deteriorations in the EWR and the conicity for the R and 1C types while exhibiting the opposite behavior for the 4C types.

- The MRR increased by 112% when adding an external flushing channel to the R type, by 28% when adding it to the 1C type, but decreased by 8% in the case of the 4C type.

- Due to the relative frontal wear ϑIF, the beginning of the groove, and thus, its beneficial effect, were shifted upward for the HR type. Nevertheless, the bubble-flushing effect most probably generated sufficient additional lift from the tool electrode tip to push and pull removal products in the impact area of the groove.

- A precise comparison of the MRR and EWR between the six tool electrode types necessitated considering geometric differences in the greatest possible detail.

- The resulting pin geometries explained the comparison between 1C and 4C.

- Nevertheless, the effects of the altered frontal areas and flushing cross-sections on the process target parameters were superseded by the effects of cooling and direct ejection of the removal products as a result of the active high-pressure flushing.

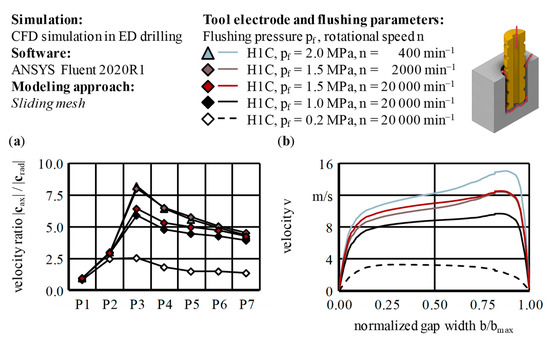

4.2. Preliminary Numerical Results with the Generic Models

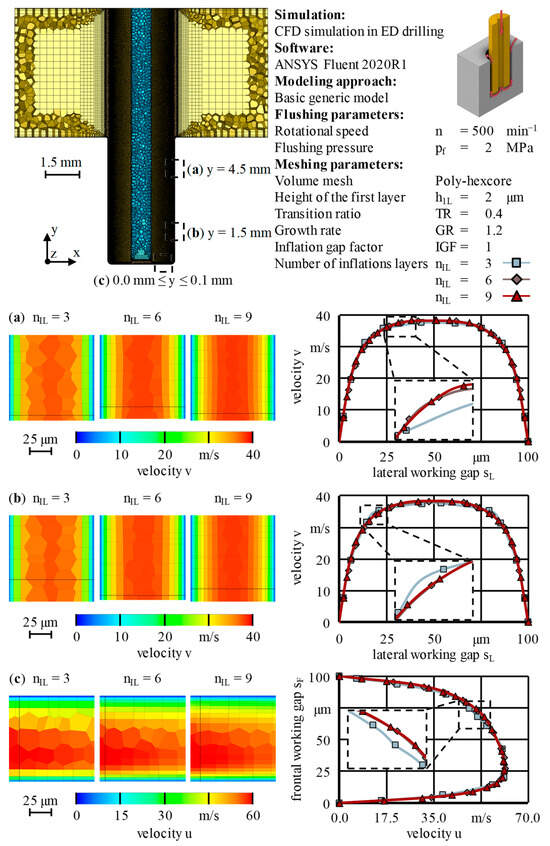

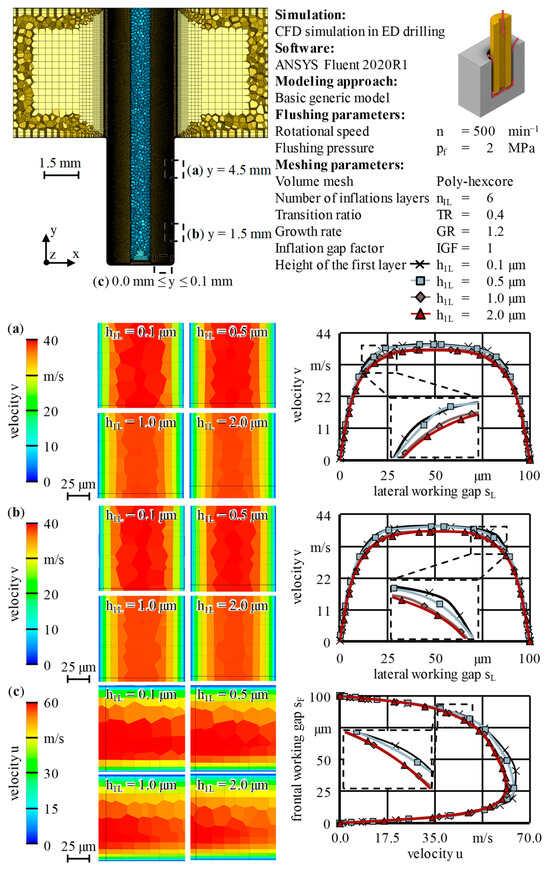

With the objective of maximizing the numerical robustness and physical validity and likewise minimizing the numerical effort, a generic model with all characteristic properties of the liquid domain of an ED drilling process was introduced, as described in Section 3.3. Figure 14 and Figure 15 show the results of the inflation layer analyses for the number of inflation layers nIL with a fixed height of the first layer h1L and vice versa (see Table 2).

Figure 14.

Variation in the number of inflation layers nIL with fixed height of the first layer h1L = 2 µm. Cells of the mesh are colored according to the velocity downstream of the respective velocity profiles on the right side. Positions: (a) y = 4.5 mm; (b) y = 1.5 mm; (c) 0.0 mm ≤ y ≤ 0.1 mm. Basic generic model, see Figure 5.

Figure 15.

Variation in the height of the first layer h1L with fixed number of inflation layers nIL = 6. Cells of the mesh colored according to the velocity downstream of the respective velocity profiles on the right side. Positions: (a) y = 4.5 mm; (b) y = 1.5 mm; (c) 0.0 mm ≤ y ≤ 0.1 mm. Basic generic model, see Figure 5.

The velocity profiles with nIL = 3 differed from those with nIL = 6 or nIL = 9, which were nearly identical. This also indicates that a further increase in the number of inflation layers nIL would bring no benefit. For both of the latter, when looking at those cells that were colored according to the dominant velocity component, it can be seen that nearly the full gradients in the direction orthogonal to the wall occurred inside the inflation layer. In contrast, a number of inflation layers nIL = 3 was not capable of resolving the velocity gradients. This is also suggested by the fact that in the last inflation layer, the velocity u or v amounted to just 50% to 70% of its maximum value. Finally, the total number of cells generated was strongly influenced by the number of inflation layers nIL (see Table 10). Based on the first three objectives for the inflation layer analyses below Table 2, nIL = 6 was set for all further analyses.

Table 10.

Total number of cells NC for varying the number of inflation layers nIL and maximum values of y+ in dependence of the height of the first layer h1L.