Abstract

In this work, we propose a sensor based on Tamm plasmonic resonance; the structure is composed of gold nanoribbons deposited on a Distributed Bragg Reflector (DBR) (SiO2/Si3N4)6. We have enhanced the sensitivity of our sensor from 40 nm/RIU to 200 nm/RIU for a refractive index change of 1% by replacing the last layer of Si3N4 in contact with gold with porous Si3N4 with a porosity of p = 40%.

1. Introduction

Tamm plasmons are confined modes that propagate between the metal and the DBR, characterized by a fine peak that appears in the photonic band gap [1]. But Tamm sensors have low sensitivity compared to delocalized plasmons due to the energy confinement between the metal and the DBR. Ferrier et al. [2] theoretically and experimentally studied a structure that generates Tamm plasmons, constituted of gold nanoribbons deposited on a DBR (SiO2/Si)4. The advantage of our structure over the metal layer is that the spacing between the nanoribbons will allow us to introduce the analyte into the pores of a porous layer between the metal and the DBR.

2. Materials and Methods

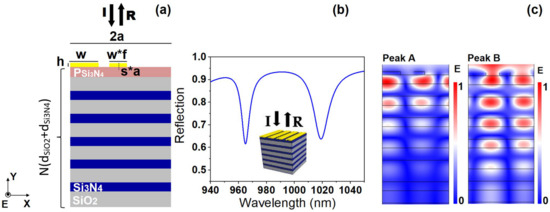

In this work, we used the numerical calculation by COMSOL Multiphysics software Version 5.6 which is based on the finite element method. Perfectly matched layers (PML) are used at the top and bottom of the structure proposed in Figure 1a to ensure accurate modeling of wave propagation and avoid electromagnetic wave reflections outside the calculation domains.

Figure 1.

(a) Schematic representation of the Tamm plasmon structure constituted of double period Tamm structure, with p = 0%. (b) Reflection spectrum of Tamm structure. (c) Norm of the electric field of peaks A and B.

The refractive index of the porous nitride is calculated from the Burgmann relation as follows:

where εP1 is the permittivity of the porous nitride, P is the porosity, ε1 is the permittivity of nurture and εP2 is the permittivity of the material filling the pores.

−2εP12 + εP1[2ε1−εP2 + 3P (εP2 − ε1)] + ε1εP2 = 0

3. Results and Discussion

The structure is composed of a nanostructured grating constituted of two different nanoribbons per period 2*a deposited on a DBR of (SiO2/Si3N4)6, as shown in Figure 1a.

Indeed, the porous nitride allows us to reach a porosity of p = 40% without losing the quality of the Tamm modes. The parameters of the structure are dSiO2 = 182 nm, dSi3N4 = 133 nm, a = 480 nm, w = 260 nm, s = 0.16, f = 0.6, h = 50 nm.

The excitation of the Tamm structure without the porous layer allows us to observe two modes that are located in the band gap of the DBR; the field intensity maps of peaks A and B Figure 1c show that mode A is a metal mode and mode B is an air mode. We are interested in the air mode because it is more sensitive than the metal mode to the change in the refractive index of the detection medium.

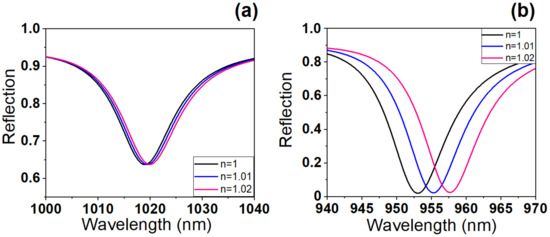

From the reflection spectra of the Tamm structure without a porous layer (Figure 2a), we calculate the sensitivity to detect an index change of 1%, S = 40 nm/RIU. The use of a porous nitride layer allows us to increase the sensitivity of the structure 5 times, S = 200 nm/RIU.

Figure 2.

Reflection spectra as a function of wavelength for different refractive indices of the double period Tamm structure (a) without a porous layer and (b) with a porous Si3N4 layer of porosity p = 40%.

4. Conclusions

In this work, we have proposed an efficient Tamm sensor to be fabricated and used. Indeed, it is not necessary to use porous DBR structures to improve the sensitivity of Tamm sensors [3]. A single porous layer at the location where the electric field is high and is largely sufficient.

Author Contributions

Conceptualization, O.H., A.T., A.A. and Y.D.; methodology, O.H., A.T., A.A. and Y.D.; software, O.H.; validation, B.M., M.E.B. and G.L.; formal analysis, O.H.; investigation, A.T.; writing—original draft preparation, O.H.; writing—review and editing, A.T., A.A., Y.D., B.M. and M.E.B.; visualization, O.H., A.T. and B.M.; supervision, A.T., A.A., A.M. and Y.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [PHC TOUBKAL 2021] grant number [TBK/22/151].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kaliteevski, M.; Iorsh, I.; Brand, S.; Abram, R.A.; Chamberlain, J.M.; Kavokin, A.V.; Shelykh, I.A. Tamm plasmon-polaritons: Possible electromagnetic states at the interface of a metal and a dielectric bragg mirror. Phys. Rev. B 2007, 76, 165415. [Google Scholar] [CrossRef]

- Ferrier, L.; Nguyen, H.S.; Jamois, C.; Berguiga, L.; Symonds, C.; Bellessa, J.; Benyattou, T. Tamm plasmon photonic crystals: From bandgap engineering to defect cavity. APL Photonics 2019, 4, 106101. [Google Scholar] [CrossRef]

- Juneau-Fecteau, A.; Savin, R.; Boucherif, A.; Fréchette, L.G. A practical Tamm plasmon sensor based on porous Si. AIP Adv. 2021, 11, 065305. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).