Abstract

Okara, which is used in the production of tofu and soy milk, is rich in dietary fibers (DFs) and phytochemicals such as soy isoflavones and soyasaponins. Despite its nutritive value, okara is scarcely used as a food source, as the DFs in okara are mostly insoluble. Thus, improving the physicochemical properties of okara for various food applications is of great importance. Here, okara were atomized using a wet-type grinder (WG) that is used to produce nanocelluloses (NC). We treated 2 wt% okara with the WG by different passages (1, 3, and 5 times). The particle size distribution (PSD) and viscosity of WG-treated okara decreased and increased, respectively, with different passages. The five time-WG treated okara also dispersed in water homogeneously after 24 h, whereas untreated okara did not. The breaking stress and strain of soybean-protein-isolate gels increased upon the addition of WG-treated okara. This effect increased as the number of WG treatments increased. These results suggest that NC technology can improve the physicochemical properties of okara and is useful in the development of protein gel-based foods.

1. Introduction

Within the last decade, nanocellulose (NC) has attracted great attention as a novel green nanomaterial, and commercial NC-based products are currently available. These NC products have high specific surface area, dispersion performance, and viscosity. It is common to use mechanical methods (e.g., homogenization and grinding) to produce biopolymer-based nanofibers from various agricultural waste, such as rice straw, cotton stalk, and soy pods [1].

The wet-type grinder (WG) is commonly used to produce NCs. In this grinder, cellulose dispersed in water is passed between two grinding stone-disks, where the distance between two disks can be adjusted. The zero position between the two disks is the contact position, and a negative gap (~−0.15 mm) between two disks can be set under wet conditions to increase the fibrillation efficiency. The cellulose slurry is delaminated by the shearing forces generated between the two disks. An advantage of this system is its ability to avoid the clotting that often occurs in a high-pressure homogenizer [2].

Soy protein isolate (SPI) has high nutritional value and functional properties, such as gel and emulsion forming abilities [3]. In this study, we examined (1) okara atomization using a WG and (2) the effects of WG-treated okara on SPI gel properties.

2. Materials and Methods

2.1. Materials

Defatted okara (Newproplus 1000) and SPI (Fujipro F) were obtained from Fuji Oil Co., Ltd. (Izumisano, Japan).

2.2. Preparation of WG-Treated Okara

Dispersion of 2 wt% okara was pulverized with the Supermasscolloider (MKCA6-2; Masuko Sangyo Co., Ltd., Kawaguchi, Japan) using a −0.15 mm gap and 1540 rpm revolution.

2.3. Viscosity

The viscosity was measured using a B type viscometer (Toyo Keiki Inc., Tokyo, Japan), with a No. 1 rotor at a shear rate of 0.5 s−1 at 25 °C. The data represent the averages of three measurements of each sample.

2.4. Particle Size Distribution (PSD)

The particle size distribution (PSD) was measured by a laser scattering PSD analyzer (LA-960, Horiba, Kyoto, Japan) using 1.60 as a relative refractive index. The data represent the averages of two measurements of each sample.

2.5. Gel Preparations

SPI powder (6 wt%) was hydrated by mixing with a WG-treated okara slurry and dispersed using a homogenizer (IKA Ultra-Turrax T8 Disperser, IKA Works, Inc., Staufen im Breisgau, Germany). After adding 0.25% magnesium chloride and 1% sodium chloride, the slurry was poured into a stainless mold (inner diameter 20 mm and height 20 mm), whose inside surface was covered with silicon grease. A silicon rubber sheet and a polycarbonate plate (25 × 25 mm) were put on both the top and bottom of the mold, and then, the plates were tightly sealed using two rubber bands. The molds were heated at 80 °C for 30 min in a water bath (FSGPD05, Fisher Scientific International Inc., Hampton, NH, USA).

2.6. Compression Measurements

Compression measurements were performed with a Texture Analyzer (TA-XT2iHR, Stable Micro Systems) attached to a 5 kg loadcell at 25 °C. A cylindrical plunger with a diameter of 50 mm was used, and the compression speed was 1 mm/s. In each experiment, at least six gels were examined for each point.

2.7. Statistical Analyses

The data represent the mean ± standard deviation (SD). Statistical significance was calculated using a one-way analysis of variance (ANOVA) followed by the Tukey’s post-hoc test, using the Origin 2020b software (Origin Lab, Northampton, MA, USA). The data were considered statistically significant at p < 0.05.

3. Results

3.1. PSD, Viscosity, and Dispersion Ability of WG-Treated Okara

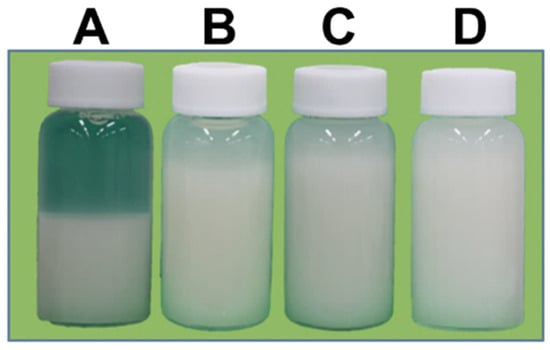

We treated 2 wt% okara dispersed in water with the WG using different passages. The PSD of okara decreased with increasing passages. In contrast, the okara viscosity increased with increasing passages (Table 1). The WG-treated okara dispersed in water homogeneously with increasing passages after 24 h (Figure 1).

Table 1.

Median sizes from particle size distributions and apparent viscosities of wet-type grinder treated okara after different passages.

Figure 1.

Wet-type grinder (WG)-treated okara in water after 24 h. Okara (2 wt%) was treated with the WG at different passages. (A) untreated; (B) one passage; (C) three passages; (D) five passages.

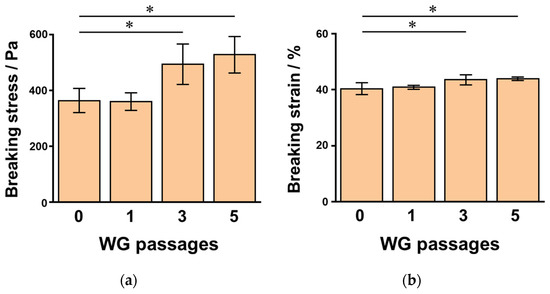

3.2. Effects of Adding WG-Treated Okara on SPI Gels

We next examined the breaking stress and strain of SPI gels with 1 wt% okara treated with the WG after different passages. The breaking stress of SPI gels to which untreated okara and WG-treated okara after one, three, and five passages were added were 398 ± 21 Pa, 360 ± 32 Pa, 470 ± 22 Pa, 561 ± 46 Pa, respectively (Figure 2a). The breaking strain of SPI gels to which untreated okara and WG-treated okara after one, three, and five passages were added were 41.2 ± 0.9%, 40.9 ± 0.7%, 43.6 ± 1.9%, 44.2 ± 0.6%, respectively (Figure 2b).

Figure 2.

The breaking stress (a) and strain (b) of 6% soybean protein isolate (SPI) gels to which 1% wet-type grinder-treated okara was added after different passages. * p < 0.05.

4. Discussion

The results of this study show that the WG can be a useful technology to improve the physicochemical properties of okara, such as dispersion ability and viscosity. In addition, the WG-treated okara improves the gel-forming properties of SPI.

In the present study, the median PSD size decreased with increasing passages up to three, and there was little difference in the median sizes of WG-treated okara after three and five passages. Iwamoto, et al. investigated pulp fibers delamination using the WGsystem. The photographs of a scanning electron microscope showed many micro-sized fibers by one passage, and the size of the fibers reduced with further treatments. Most fibers became nano-sized fibers after five passages, but further passages did not change fiber morphology. Our present results are in line with the study by Iwamoto et al. [4].

Liu et al. applied ultra-high pressure homogenization (UHPH) to soy flour for tofu making. UHPH reduced the particle size of soy flour, and the hardness of tofu made from UHPH-treated soy flour was similar with the control tofu [5]. Our study showed that the addition of WG-treated okara increased the breaking stress and strain of SPI gels. This effect became higher as the number of treatments by the WG increased. This could be attributed to the fact that WG-treated okara has high dispersion ability and viscosity. However, the underlying mechanism for this was not clear from this study and warrants further investigation.

Author Contributions

Conceptualization, T.N. and K.N.; methodology, T.N.; validation, Y.A., K.N., and T.N.; formal analysis, T.N.; investigation, Y.A.; data curation, T.N.; writing—original draft preparation, T.N.; writing—review and editing, T.N.; visualization, T.N.; supervision, K.N.; project administration, T.N.; funding acquisition, T.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Salt Science Research Foundation, grant number 1945 and the Fuji Foundation for Protein Research.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rajinipriya, M.; Nagalakshmaiah, M.; Robert, M.; Elkoun, S. Importance of agricultural and industrial waste in the field of nanocellulose and recent industrial developments of wood based nanocellulose: A review. ACS Sust. Chem. Eng. 2018, 6, 2807–2828. [Google Scholar] [CrossRef]

- Nagano, T.; Arai, Y.; Yano, H.; Aoki, T.; Kurihara, S.; Hirano, R.; Nishinari, K. Improved physicochemical and functional properties of okara, a soybean residue, by nanocellulose technologies for food development—A review. Food Hydrocoll. 2020, 109, 105964. [Google Scholar] [CrossRef]

- Nishinari, K.; Fang, Y.; Nagano, T.; Guo, S.; Wang, R. Soy as a food ingredient. In Proteins in Food Processing, 2nd ed.; Yada, R.Y., Ed.; Woodhead Publishing: Sawston, UK, 2018; pp. 149–186. [Google Scholar]

- Iwamoto, S.; Nakagaito, A.N.; Yano, H. Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl. Phys. A. 2007, 89, 461–466. [Google Scholar] [CrossRef]

- Liu, H.H.; Chien, J.T.; Kuo, M.I. Ultra high pressure homogenized soy flour for tofu making. Food Hydrocoll. 2013, 32, 278–285. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).