Abstract

Thin films from double hydrophilic copolymer of complex branched structures containing poly(N,N-dimethyl acrylamide) and poly(ethylene oxide) blocks were used as humidity sensitive media, and two types of Bragg reflectors with different optical contrast and operating wavelengths were implemented as transducers of humidity changes. The required film thickness was pre-optimized through theoretical modelling in order to achieve the highest sensitivity. Single films and Bragg reflectors were characterized by transmittance measurements at different humidity levels in the range from 5% to 95% relative humidity. The influence of the number of the layers in the stack, the operating wavelength and optical contrast on sensitivity was studied. The potential and advantages of using top-covered Bragg reflectors as humidity sensors with simple optical read-out are demonstrated and discussed.

1. Introduction

Bragg reflectors are multilayered systems comprising layers with alternating low and high refractive index and quarter-wavelength optical thickness, i.e., the film thickness multiplied by the film’s refractive index equals a quarter of the operating wavelength of the Bragg reflectors (λBR). Due to the quarter-wavelength thickness of all layers in the reflectors, all multiple reflected waves are in phase, interfere constructively and a band of high reflectance centered at λBR appears in the spectra. Simultaneously, a stop band of low transmittance is generated that is also centered at λBR. If Bragg reflectors are designed in such a way that the operating wavelength is in the visible part of the spectra, then a distinctive color called structural color is observed, although transparent and colorless layers are used for building the reflector [1,2]. The position of λBR and the reflector’s color depend strongly on refractive index and thickness of the layers, and change when one or both of these parameters change [3,4]. Thus, the optical behavior of Bragg reflectors could be controlled by external stimuli, for example vapors of volatile organic compounds or humidity [5,6,7,8]. The concept of optical sensing has already been demonstrated for multilayered structures comprising diverse materials such as oxide nanoparticles [1,8], mesoporous films [4,5], zeolite nanoparticles [9,10], metal organic frameworks [11,12], polymers [13,14,15] and 2D-materials [16,17], etc. However, the reflectance band also depends on the direction of the incident light and shifts toward smaller wavelengths when the incident angle increases [7]. It is obvious that this will be a problem when visual inspection of color is used as a detection approach, because the observer will not be able to distinguish properly the real reason for the color change. We have already demonstrated [10,15] that a possible solution is to prepare structures with omnidirectional reflection that have high reflectance in all directions and polarization of light. In this case, the same color will be observed at all viewing angles.

In this paper, we consider a different approach. Instead of measuring or observing reflectance, we use transmittance. Undoubtedly, measuring transmittance is simpler, more accurate and less expensive compared to reflectance measurement. Moreover, observing the sample color in the transmittance configuration, i.e., using the light transmitted through the sample, could overcome to a great extent the problem related to the angle-dependence of the color, because it is easy for the sample color to be observed at normal light incidence when transmittance is considered. In order to further simplify the sensing approach, we deposited the sensitive film on top of specially designed Bragg reflectors, instead of incorporating it in the reflector, thus overcoming possible issues of incompatibility that may arise when organic and inorganic materials are used for Bragg reflectors.

In this study, we proved the concept of implementing top-covered Bragg reflectors as optical sensors for humidity. As humidity sensitive media, we used thin films of previously developed poly(N,N-dimethyl acrylamide) (PDMA)-poly(ethylene oxide) (PEO) block copolymer with a branched macromolecular architecture that were deposited on top of two types of Bragg reflectors, with different optical contrast and operating wavelengths. The humidity sensing ability was demonstrated through (i) transmittance measurements at relative humidity levels of 5% and 95%, and (ii) the color change of the sensor in transmitted light at different humidity levels. The influence of the number of layers in the stack, the operating wavelength, and optical contrast on the sensitivity was studied.

2. Materials and Methods

PDMA/PEO copolymer of branched macromolecular architecture was synthesized by means of redox polymerization of N,N-dimethylacrylamide (DMA) in deionized water using ammonium cerium (IV) nitrate as initiator, poly(ethylene oxide) (PEO; Mn 2000 g mol−1; Fluka) as a hydroxyl functionalized initiating moiety and poly(ethylene glycol) diacrylate (av. Mn 575 g mol−1; Sigma-Aldrich) as cross-linker, according to the previously described synthetic procedure [18]. The polymerization was carried out in a nitrogen atmosphere for 3 h at 35 °C under vigorous stirring, and terminated by diluting the reaction mixture with methanol (1:1 volume ratio). The diluted reaction mixture was used for thin polymer film deposition without further polymer isolation or purification.

Thin polymer films with thickness in the range 140–550 nm were deposited by the spin-coating method (4000 min−1, 60 s) both on the silicon substrate and Bragg reflectors using polymer solutions with different concentrations. All films were annealed at 180 °C for 30 min in air. Five- and seven-layered Bragg reflectors were prepared on glass substrates by alternating the deposition of sol–gel Nb2O5 [19] and SiO2 [20] films or dense and porous Nb2O5 films [21]. The optical thickness of the films in the reflectors was calculated so that their stop bands would be at 550 and 450 nm.

Optical constants (refractive index and extinction coefficient) and the thickness of the films were calculated using previously developed two-stage nonlinear curve fitting of the reflectance spectra measured with a UV-VIS-NIR spectrophotometer (Cary 5E, Varian) [19]. The sensing behavior was tested by measuring the transmittance spectra at low and high levels of relative humidity, realized using a homemade bubbler system that generates vapors from liquids [10].

3. Results and Discussion

The sensor under investigation consisted of polymer film as a sensitive element that is spin-coated on top of a multi-layered stack (Bragg reflector) regarded as a transducing element. The detection was performed by measuring the transmittance (T) of the stack or by visual inspection of its color. When the relative humidity in the environment changed, the thickness and refractive index of the polymer film also changed. This led to the alteration of T and subsequent change of the reflector’s color. The implementation of the Bragg reflectors enabled the monitoring of transmittance instead of reflectance when detecting humidity, because Bragg reflectors are transparent, in contrast to the previously used silicon wafer, which is opaque [18,22]. Measuring transmittance is simple, accurate and inexpensive and therefore it is always preferable to measure reflectance. Further, Bragg reflectors provide an additional opportunity for the visual inspection of the sensor’s color as a method for detecting humidity that is not possible in the case of a bare glass substrate, because the polymer film/glass system is colorless.

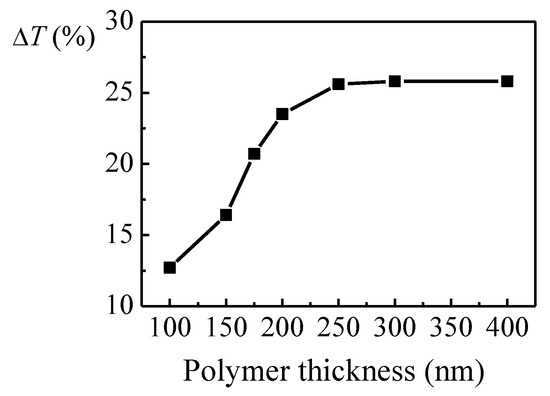

In order to achieve the highest sensitivity to humidity, we optimized the thickness of the polymer film through theoretical modelling. We calculated the humidity induced change in the transmittance (ΔT) of Bragg reflectors covered with polymer films with different thicknesses in the range 100–400 nm. In the first modelling step, we calculated transmittance (T1) using a particular thickness of polymer film and refractive index that equaled 1.5. Then, in the second step we increased the polymer film thickness by 30% and decreased its refractive index by 7% [22], thus simulating high humidity, and again calculated the transmittance (T2). The absolute value of the difference T1–T2, which could be regarded as a change in transmittance due to the change of humidity from 5% RH to 95% RH, is plotted in Figure 1 as a function of the thickness of polymer film deposited on top of Bragg reflector comprising five layers.

Figure 1.

Calculated humidity-induced change of transmittance ΔT (=T95%RH – T5%RH) of five layered Bragg reflector covered with polymer film with different thicknesses.

It is seen that ΔT increased with the thickness of the polymer film reaching steady state for thickness higher than 250 nm. Therefore, in the next step of our investigation we decided to use polymer film with a thickness of 290 nm and deposit it on four different Bragg stacks. Thicker films were not suitable because the time response of the sensor would increase due to the longer diffusion path length in thicker polymer films. Moreover, there was no enhancement of the sensitivity when films thicker than 250 nm were used (Figure 1).

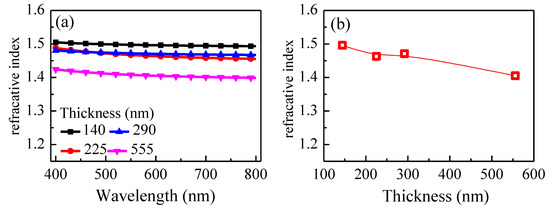

It is interesting to see how the thickness of branched polymer film influences its refractive index. Polymer films with different thicknesses in the range 140–550 nm were deposited on a silicon substrate using polymer solutions with different concentrations. The refractive index (n), extinction coefficient (k) and thickness (d) of the films were determined simultaneously using a previously developed two-step algorithm [19]. Briefly, nonlinear minimization of the discrepancies between the measured and calculated reflectance spectra was used for the determination of n, k and d [19]. The calculated dispersion curves of the refractive index of polymer films with thicknesses in the range 140–550 nm are presented in Figure 2a. The thickness-dependence of n at 600 nm is plotted in Figure 2b. All the studied samples obeyed normal dispersion, i.e., the refractive index decreased slightly with each wavelength, which could be expected because polymer films are transparent in the studied spectral range. The calculated values of the extinction coefficient were smaller than 0.003, thus confirming the good quality and transparency of the studied polymer films. The refractive index was almost the same for films with thickness values up to 300 nm and decreased for thicker films. It is likely that when d increased the influence of the substrate adhesion weakened and as a result less dense films were deposited.

Figure 2.

(a) Dispersion curves of the refractive index of polymer films with the denoted thicknesses; (b) thickness-dependence of the refractive index (the values were taken at a wavelength of 600 nm).

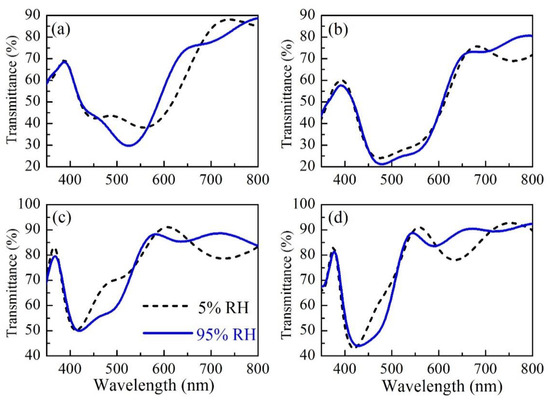

To study the sensing behavior toward humidity, branched polymer film with thickness of 290 nm was deposited on four Bragg reflectors consisting of five and seven alternating layers of Nb2O5/SiO2 and dense/mesoporous Nb2O5. The top-covered reflectors were put in the measuring cell and their transmittance spectra were taken at low (5%) and high (95%) relative humidity. The transmittance spectra of all Bragg reflectors are shown in Figure 3. The stop band, i.e., the band with low transmittance, is well distinguished even after polymer film deposition. The optical contrast of the constituent layers in the stacks (the difference between the refractive index of Nb2O5 and SiO2 on the one hand and the dense and mesoporous Nb2O5 films on the other) is different, which explains the different widths of the stop bands (Figure 3). The dissimilarity of the wavelength positions of the bands can also be seen. This originates from the different optical thicknesses of the layers of the studied Bragg reflectors.

Figure 3.

Transmittance spectra at low (5%) and high (95%) relative humidity of branched polymer film with thickness of 290 nm deposited on top of Bragg reflectors consisting of 5 (a,c) and 7 (b,d) alternating layers of Nb2O5 and SiO2 (a,b) and dense and mesoporous Nb2O5 (c,d).

The thickness and refractive index of polymer films were strongly affected by the humidity, and the film thickness increases and refractive index decreases at high humidity levels. These alterations in the n and d of the polymer film also modified the optical behavior of the entire Bragg reflector and its transmittance spectra changed with humidity (Figure 3).

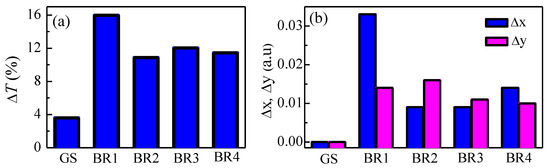

Figure 4a presents the humidity-induced changes in transmittance for a single polymer film with a thickness of 290 nm deposited on a bare glass substrate (GS) and on Bragg reflectors (BR). The advantage of using Bragg reflectors over bare glass is obvious: a fourfold increase in ΔT was obtained when Bragg reflectors were used. Besides, in Figure 4a it can also be seen that the characteristics of a reflector, such as operating wavelength, number of layers, optical contrast etc., do not substantially influence the measured signal. The average sensitivity (Sav) and the accuracy/resolution (ΔRH) of detection were calculated using Equations (1) and (2), respectively, and are presented in Table 1:

Figure 4.

Humidity-induced changes in transmittance (a) and CIE (International Commission on Illumination) color coordinates x and y (b) for single polymer film with thickness of 290 nm deposited on bare glass substrate (GS) and on Bragg reflectors (BR) (BR1-5 layers, BR2-7 layers—Nb2O5 and SiO2; BR3–5 layers, BR4-7 layers—dense and mesoporous Nb2O5).

Table 1.

Average sensitivity in (%/% RH) and accuracy ΔRH in (% RH) for single layer deposited on bare glass substrate (GS) and on Bragg reflectors (BR).

ΔT is the humidity-induced change of the film’s transmittance and errT is the measuring error in transmittance, which in this study was assumed to be 0.2%.

It can be seen in Table 1 that the implementation of the Bragg stack as a sensor transducer enhanced the sensitivity more than four times compared to the glass substrate. The sensitivity of 0.18%/% RH is comparable with that of a single film on a silicon substrate (0.16%/%RH) [18], but due to the smaller experimental error of the transmittance measurement, the accuracy of the humidity detection (1.1% RH for T-measurements) was smaller than in the case of reflectance measurement.

In our previous investigations [22], we have demonstrated the possibility of color sensing of humidity using a single film on an opaque (silicon) substrate. For example, the color of film with a thickness of 215 nm changes substantially from yellow to dark magenta. The main problem when color is sensing in reflection mode is the dependence of color on the viewing angle. This means that the sample color changes not only with humidity but also with the angle of the observation and it is difficult to unambiguously distinguish for the real reason for a color change. This problem could be overcome to a great extent if color sensing in the transmittance mode is used, that is, monitoring the color of the sensor using the transmitted light instead of reflected light.

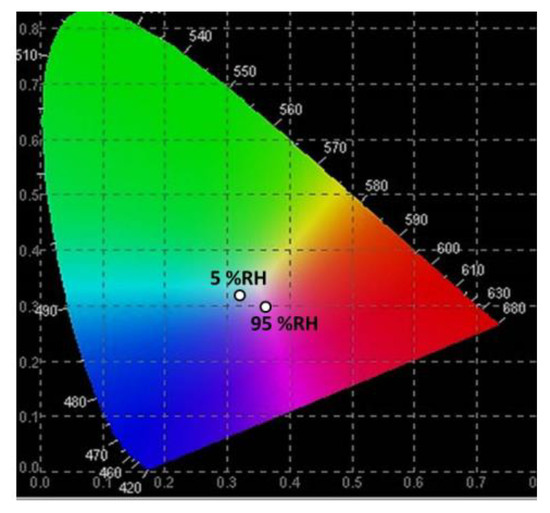

To check this we calculated x, y and z CIE color coordinates using transmittance spectra measured at low and high humidity with previously developed computer code [22]. The humidity-induced changes in the CIE color coordinates x and y for a single polymer film with a thickness of 290 nm deposited on a bare glass substrate and on Bragg reflectors are shown in Figure 4b. As can be expected, there was no color change for the film on the glass substrate, while of all the Bragg reflectors, the color changes were most pronounced for the five-layered Bragg stacks with SiO2 and Nb2O5 films (BR1).

Figure 5 presents the calculated CIE color coordinates for BR1 at the low and high humidity levels. It can be seen that the color of the sample observed using transmitted light changed from blueish to magenta. The separation of colors in the color scheme is necessary for the visual color detection of humidity to take place.

Figure 5.

CIE color coordinates for polymer films with a thickness of 290 nm deposited on five-layered Bragg stacks with SiO2 and Nb2O5 films at denoted values of relative humidity.

4. Conclusions

The concept of using Bragg reflectors covered at the top with polymer film for the optical sensing of humidity was verified and confirmed. Thin films of branched poly(N,N-dimethylacrylamide)-based copolymer with optimized thickness were used as the humidity-sensitive media, while five- and seven-layered Bragg reflectors comprising SiO2 and dense and porous Nb2O5 films were used as transducing elements. The detection of the humidity was performed both by measuring the transmittance spectra and monitoring the change of the sensor’s color in transmission mode. It was demonstrated that the implementation of Bragg reflectors as a sensor transducer element enhanced the sensitivity more than four times compared to the case of a glass substrate. The obtained sensitivity of 0.18%/% RH is comparable with that of a single film on a silicon substrate (0.16%/% RH), while the accuracy of the humidity detection, using transmittance measurement (1.1% RH), was higher than accuracy by reflectance measurement, due to the smaller experimental error of transmittance measurement. Although the change of color is comparable to that of film deposited on Si-substrate, the transmittance measuring approach has the advantage of experimental convenience and overcomes the ambiguity related to the dependence of the color on the viewing angle. Top-covered Bragg reflectors are promising sensing platforms and after proper optimization could be used for sensitive optical detection of humidity and vapors.

Author Contributions

Conceptualization, D.C. and T.B.; Investigation, K.L. and R.G.; Theoretical modelling, T.B.; Writing—original draft, T.B. and D.C.

Funding

This research received no external funding.

Acknowledgments

The financial support of the Bulgarian National Science Fund, grant number DN08-15/14.12.2016 is highly appreciated. R. Georgiev acknowledges the World Federation of Scientists for a fellowship and the project DFNP-17-97/28.07.2017 of the BAS program for the career development of young scientists.

Conflicts of Interest

The authors declare no conflict of interest

References

- Puzzo, D.; Bonifacio, L.; Oreopoulos, J.; Yip, C. Manners, I.; Ozin, G. Color from colorless nanomaterials: Bragg reflectors made of nanoparticles. J. Mater. Chem. 2009, 19, 3500–3506. [Google Scholar] [CrossRef]

- Kurt, P.; Banerjee, D.; Cohen, R.; Rubner, M. Structural color via layer-by-layer deposition: Layered nanoparticle arrays with near-UV and visible reflectivity bands. J. Mater. Chem. 2009, 19, 8920–8927. [Google Scholar] [CrossRef]

- Anaya, M.; Rubino, A.; Calvo, M.; Mıguez, H. Solution processed high refractive index contrast distributed Bragg reflectors. J. Mater. Chem. C 2016, 4, 4532–4537. [Google Scholar] [CrossRef]

- Ghazzal, M.; Deparis, O.; Errachid, A.; Kebaili, H.; Simonis, P.; Eloy, P.; Vigneron, J.P.; De Coninck, J.; Gaigneaux, E.M. Porosity control and surface sensitivity of titania/silica mesoporous multilayer coatings: Applications to optical Bragg resonance tuning and molecular sensing. J. Mater. Chem. 2012, 22, 25302–25310. [Google Scholar] [CrossRef]

- Fuertes, M.; López-Alcaraz, F.; Marchi, M.; Troiani, H.; Luca, V.; Míguez, H.; Soler-Illia, G. Photonic Crystals from Ordered Mesoporous Thin-Film Functional Building Blocks. Adv. Funct. Mater. 2007, 17, 1247–1254. [Google Scholar] [CrossRef]

- Bonifacio, L.; Lotsch, B.; Puzzo, D.; Scotognella, F.; Ozin, G. Stacking the Nanochemistry Deck: Structural and Compositional Diversity in One-Dimensional Photonic Crystals. Adv. Mater. 2009, 21, 1641–1646. [Google Scholar] [CrossRef]

- Choi, S.; Mamak, M.; Freymann, G.; Chopra, N.; Ozin, G. Mesoporous Bragg Stack Color Tunable Sensors. Nano Lett. 2006, 6, 2456–2461. [Google Scholar] [CrossRef]

- Lee, D.; Rubner, M.; Cohen, R. All-Nanoparticle Thin-Film Coatings. Nano Lett. 2006, 6, 2305–2312. [Google Scholar] [CrossRef]

- Babeva, T.; Awala, H.; Vasileva, M.; Fallah, J.E.; Lazarova, K.; Thomas, S.; Mintova, S. Zeolite films as building blocks for antireflective coatings and vapor responsive Bragg stacks. Dalton Trans. 2014, 43, 8868–8876. [Google Scholar] [CrossRef]

- Lazarova, K.; Awala, H.; Thomas, S.; Vasileva, M.; Mintova, S.; Babeva, T. Vapor responsive one-dimensional photonic crystals from zeolite nanoparticles and metal oxide films for optical sensing. Sensors 2014, 14, 12207–12218. [Google Scholar] [CrossRef]

- Dalstein, O.; Ceratti, D.; Boissière, C.; Grosso, D.; Cattoni, A.; Faustini, M. Submicrometric, MOF-Based 2D Photonic Structures: Toward Easy Selective Vapors Sensing by a Smartphone Camera. Adv. Funct. Mater. 2016, 26, 81–90. [Google Scholar] [CrossRef]

- Ranft, A.; Niekiel, F.; Pavlichenko, I.; Stock, N.; Lotsch, B. Tandem MOF-Based Photonic Crystals for Enhanced Analyte-Specific Optical Detection. Chem. Mater. 2015, 27, 1961–1970. [Google Scholar] [CrossRef]

- Lova, P.; Manfredi, G.; Boarino, L.; Comite, A.; Laus, M.; Patrini, M.; Marabelli, F.; Soci, C.; Comoretto, D. Polymer Distributed Bragg Reflectors for Vapor Sensing. ACS Photonics 2015, 2, 537–543. [Google Scholar] [CrossRef]

- Georgaki, M.-I.; Oikonomou, P.; Botsialas, A.; Papanikolaou, N.; Raptis, I.; Argitis, P.; Chatzichristidi, M. Powerless and Reversible Color Humidity Sensor. Procedia Eng. 2011, 25, 1177–1180. [Google Scholar] [CrossRef]

- Lazarova, K.; Georgiev, R.; Vasileva, M.; Georgieva, B.; Spassova, M.; Malinowski, N.; Babeva, T. One-dimensional PMMA-V2O5 photonic crystals used as color indicators of chloroform vapors. Opt. Quantum Electron. 2016, 48, 310. [Google Scholar] [CrossRef]

- Yao, C.; Zhao, J.; Ge, H.; Ren, J.; Yin, T.; Zhu, Y.; Ge, L. Fabrication of dual sensitive titania (TiO2)/graphene oxide (GO) one-dimensional photonic crystals (1DPCs). Colloids Surf. A Physicochem. Eng. Asp. 2014, 452, 89–94. [Google Scholar] [CrossRef]

- Szendrei-Temesi, K.; Sanchez-Sobrado, O.; Betzler, S.; Durner, K.; Holzmann, T.; Lotsch, B. Lithium Tin Sulfide—A High-Refractive-Index 2D Material for Humidity-Responsive Photonic Crystals. Adv. Funct. Mater. 2018, 28, 1705740. [Google Scholar] [CrossRef]

- Lazarova, K.; Vasileva, M.; Ivanova, S.; Novakov, C.; Christova, D.; Babeva, T. Influence of Macromolecular Architecture on the Optical and Humidity-Sensing Properties of Poly(N,N-Dimethylacrylamide)-Based Block Copolymers. Polymers 2018, 10, 769. [Google Scholar] [CrossRef]

- Lazarova, K.; Vasileva, M.; Marinov, G.; Babeva, T. Optical characterization of sol-gel derived Nb2O5 thin films. Opt. Laser Technol. 2014, 58, 114–118. [Google Scholar] [CrossRef]

- Lazarova, K.; Awala, H.; Fallah, J.E.; Vasileva, M.; Mintova, S.; Babeva, T. Optimization of optical and sensing properties of sol-gel oxides through zeolite doping. Bulg. Chem. Commun. 2017, 49, 88–94. [Google Scholar]

- Georgiev, R.; Christova, D.; Todorova, L.; Georgieva, B.; Vasileva, M.; Babeva, T. Generating porosity in metal oxides thin films through introduction of polymer micelles. Opt. Quantum Electron. 2018, 50, 156. [Google Scholar] [CrossRef]

- Lazarova, K.; Todorova, L.; Christova, D.; Babeva, T. Color Sensing of Humidity Using Thin Films of Hydrophilic Cationic Copolymers. In Proceedings of the 40th International Spring Seminar on Electronics Technology (ISEE), Sofia, Bulgaria, 10–14 May 2017; pp. 1–6. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).