Abstract

The growing decrease of traditional fuels leads to the development of a new energy model. Biomass poses as an energy alternative that can substitute fossil fuels. In this context, this work aims to study the necessities and possible solutions in biomass production for conventional energy systems in populated-industrial environments. The methodology applied evaluates the use of biomass by collecting both the integrity of the management process and the transformation of the existing resources to start up bioenergy plants for domestic and industrial markets. The results show both the energetical and environmental importance that biomass shows in said locations in terms of reducing Greenhouse Gasses (GHG) and the development of future environmentally sustainable systems through energy-renewable projects.

1. Introduction

In Spain, as in Europe, the use of biomass material represents a good alternative to other fuels by energy transition [1]. Reduction of the emissions of greenhouses gases (GHG), increasing the share of wood biomass in the energy balance, increasing energy production from autochthonous sources and decreasing energy dependency represent the key goals [2]. This is due to its large amount of forests, which need to be maintained. More advanced and efficient conversion technologies now allow the extraction of biofuels from materials such as wood, crops and waste material. It gives rise to different wood residues that can be turned into fuel by means of either physical or chemical transformations for an industrial or domestic final use [3].

All fuels produce CO2, but what really matters is its origin [4]. Industrial and domestic sectors are consumers of fossil fuels. Burning fossil fuels means an active increase in the amount of CO2 in the environment. This produced gas is not processed by the actual plants, so it just adds up to the existing one. On the contrary, the CO2 resulting from burning biomass can be considered “neutral”. This is because the plants and woody material used consumed CO2 from the atmosphere not long before they were collected, so it can be said that the amount of CO2 in the atmosphere has not been negatively affected [5]. The pollution problem and GHG emitted into the atmosphere add to the necessity to increase energy production every year, due to the development and population increase. The main proposal and the ultimate goal to reduce the impact of pollutants are finding the balance between renewable and non-renewable fuels. For the development and progress of technologies, the need to set objectives that have already indicated the way forward has been made clear from the well-known Kyoto Protocol. Currently, bearing in mind the Summit of Paris, the paramount objective is the well-known 2020 horizon, whose basis establishes several social, economic and energy requirements [6]. In this context, industrial environments have unique demand needs in terms of quantity and flexibility of supply. Aboño (Gijón) in Asturias, North of Spain, has a significant energy, cement, steel industry. This work aims to evaluate the potential of wood biomass for a biofuel plant in the industrial environment of Aboño as an alternative to traditional fuels for energy domestic and industrial applications.

2. Methodology

There are different types of biomass and ways to transform them. The goal of the energy transition is to achieve a sustainable supply of energy [7]. Forest production generates a large amount of wood residues ranging from wood chips and sawdust to stumps from felling trees. The industrial activity of preparing planks and different construction and decoration products, as well as the enabling and cleaning of forests to maximize the production and fire protection are some of the processes that generate all this amount of waste.

The total amount of available matter is calculated by Geographic Information Systems (GIS), which will give data about the amount, energy and cost of available biomass [8]. The evaluation of the amount of resource is done with the BIORAISE GIS software belonging to the Centre for Energy, Environment and Technological Research (CIEMAT) [9]. It calculates the available mass of the residues by taking into account the forest management operations of the collection area under techno-economical and environmental constraints. The residues are based on dry mass basis (dry t) [9].

For this study, forest residues have been considered as the best source of biomass since there is the great availability of the resource in the location of the supposed biofuel plant. To select the amount of resource available in the area of study, a 100 km radius has been chosen from Aboño Valley (Asturias), where available forest residues are evaluated. Techno-economical constraints derive from ground conditions to access to raw material and environmental constraints come from ground nature. The calorific value of the materials collected is lower than 17 GJ/dry t, which is one step behind the materials commonly used.

The biofuel plant will produce primary biofuels, such as fuelwood, wood chips and pellets, organic materials are used in an unprocessed form, primarily for heating or electricity production. The production process by fuel type consists of a combination of grinding and drying, balling and induration followed by screening and handling. The biofuels plant includes the complete machinery for industrial purposes. The valuation is presented in economic terms, together with the comparison of CO2 emissions as an alternative to traditional fuels. The economic factors of the Net Present Value (NPV) and Internal Rate of Return (IRR) have been evaluated.

3. Results

The available biomass is 192 dry kt/year equivalent to 3302 TJ/year for a 100 km radius from Aboño (Gijón). The average total cost of the available biomass carried to the plant is 63 €/dry t. The supply of available biomass allows to build a biofuels plant. Once factors such as personnel, maintenance and energy consumption have been taken into account and compared with the possible revenues from the sale of the final fuel, as approach the values of VAN and IRR are 48 M€ and 11%, respectively. The development of biofuel production is expected to offer new opportunities to diversify industrial activities.

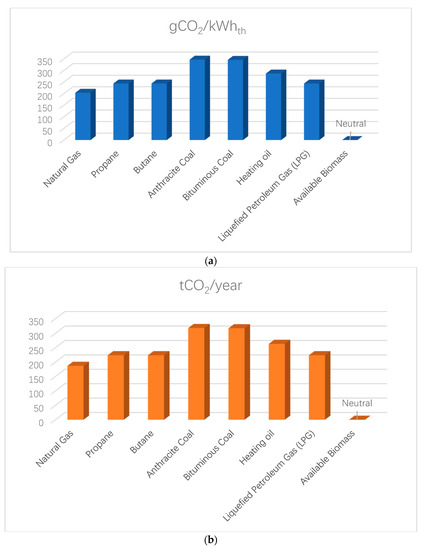

Additionally, the CO2 emissions produced by traditional fuels with equivalent energy to the biofuel production capacity are shown in Figure 1 [10].

Figure 1.

Comparison of CO2 emissions by fuel type in energy applications: (a) emission of CO2 per kWhth produced, (b) tones of CO2 produced with each type of fuel.

4. Conclusions

The amount of resource and the advantages derived from its use make it one of the best options in the energy panorama, an important point to be taken into consideration in the domestic energy production. The work shows the profitability of a biofuel plant in industrial environments, being it possible to recover the initial investment, producing the necessary quantity of renewable clean fuel for its final use. The study carried out in Aboño (Spain) indicates that the total amount of wood residue is 192 dry kt/year equivalent to 3302 TJ/year. The economic results show the biofuel plant viability and future emissions reduction in CO2 by substitution of traditional fuels in energy applications. The energy-renewable projects are supporting biofuels with the objectives of reducing GHG emissions, boosting the decarbonisation, diversifying fuel supply sources and developing long-term replacements for fossil fuels.

Author Contributions

C.U.L. performed the experiments; C.U.L., J.P.P.S., G.L.C., J.X.B. analyzed the data and wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ghaffariyan, M.R.; Brown, M.; Acuna, M.; Sessions, J.; Gallagher, T.; Kühmaier, M. An international review of the most productive and cost effective forest biomass recovery technologies and supply chains. Renew. Sustain. Energy Rev. 2016, 74, 145–158. [Google Scholar] [CrossRef]

- Montoya, F.G.; Aguilera, M.J.; Manzano-Agugliaro, F. Renewable energy production in Spain: A review, Renew. Sustain. Energy Rev. 2014, 33, 509–531. [Google Scholar] [CrossRef]

- Tsalidis, G.A.; Joshi, Y.; Korevaar, G.; De Jong, W. Life cycle assessment of direct co-firing of torrefied and/or pelletised woody biomass with coal in the Netherlands. J. Clean. Prod. 2014, 81, 168–177. [Google Scholar] [CrossRef]

- Rokni, E.; Ren, X.; Panahi, A.; Levendis, Y.A. Emissions of SO2, NOx, CO2, and HCl from Co-firing of coals with raw and torrefied biomass fuels. Fuel 2018, 211, 363–374. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Lainez, M.; Manuel, J.; Aguilar, A.; Vela, C. Spanish strategy on bioeconomy: Towards a knowledge based sustainable innovation. New Biotechnol. 2017. [Google Scholar] [CrossRef] [PubMed]

- Ellabban, O.; Abu-Rub, H.; Blaabjerg, F. Renewable energy resources: Current status, future prospects and their enabling technology, Renew. Sustain. Energy Rev. 2014, 39, 748–764. [Google Scholar] [CrossRef]

- Romero-García, J.M.; Sanchez, A.; Rendón-Acosta, G.; Martínez-Patiño, J.C.; Ruiz, E.; Magaña, G.; Castro, E. An olive tree pruning biorefinery for co-producing high value-added bioproducts and biofuels: Economic and energy efficiency analysis, Bioenerg. Res. 2016, 9, 1070–1086. [Google Scholar] [CrossRef]

- BIORAISE. Biomass GIS Database. 2014. Available online: http://bioraise.ciemat.es/bioraise/ (accessed on 10 July 2018).

- IDAE. Factors of CO2 Emission and Coefficients of Passage to Primary Energy of Different Final Energy Sources Consumed in the Buildings Sector in SPAIN. 2014. Available online: http://www.mincotur.gob.es/energia/desarrollo/EficienciaEnergetica/RITE/Reconocidos/Reconocidos/Otros%20documentos/Factores_emision_CO2.pdf (accessed on 6 May 2018).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).