Abstract

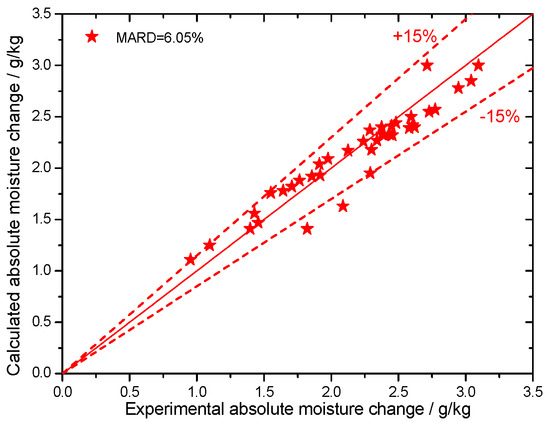

The present study intended to study the dehumidification performance of KCOOH solution both experimentally and numerically. The heat and mass transfer model for internal cooling dehumidifier was built. The influences of different parameters on dehumidification performance were identified by experiments. Results indicated that the air temperature and solution has negligible influence on dehumidification performance. However, the air humidity and solution temperature have significant influence on dehumidification due to its close relationship with mass transfer driving force. The proposed model can simulate the dehumidification performance in terms of absolute moisture change well with the MARD of 6.05%.

1. Introduction

Due to the fact that humans spend up to 70%~90% of their lifetime in indoor environmental [1], it is quite necessary and meaningful to maintain a comfortable indoor environmental with suitable temperature and humidity. Therefore, as a promising alternative for the traditional vapor compression cooling air conditioning system (VCS), the liquid desiccant cooling system (LDCS) is proposed in recent years.

In the early time, researchers adopted TEG as the liquid desiccant. Restricted by its inherent high viscosity and small volatility which may cause system instability and health problem for inhabitants [2], the TEG was given up later. Then, the saline solution, lithium chloride (LiCl) solution and lithium bromide (LiBr) solution for example, was widely adopted in the field of LDCS. It has proper viscosity and is unlikely to volatilize into the air. However, serious metal corrosion caused by the utilization of saline solution was revealed by investigators during such attempts. To overcome such a thorny problem, some research indicated the replacement of saline solution by potassium formate (KCOOH) solution recently. Compared with the saline liquid desiccant, the KCOOH solution has much less severe corrosion, lower price and high environmental compatibility [3]. Even though some researchers conducted relevant studies on KCOOH [3,4], more investigation is still necessary. Therefore, to fill up the research gap abovementioned for better understanding of dehumidification performance of KCOOH solution, the present study the dehumidification performance both experimentally and numerically.

2. Model Development for Falling Film Dehumidification/Regeneration

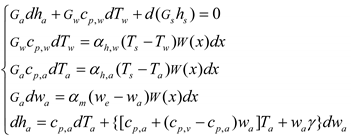

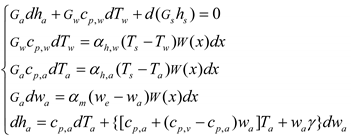

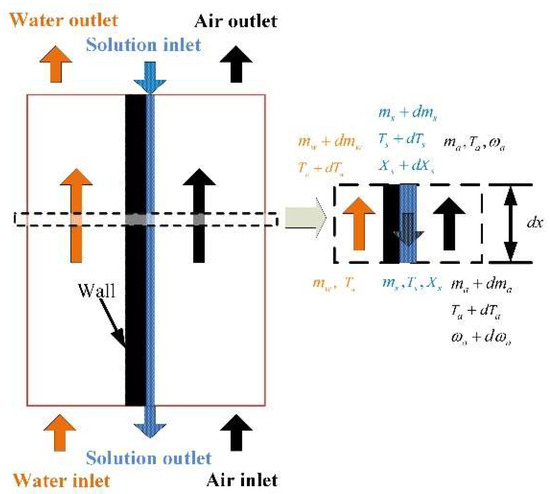

A microelement indicating the heat and mass transfer process during dehumidification is presented in Figure 1. Some widely used assumptions [5,6] are adopted during the modeling. Based on the above assumptions, energy and mass balance between solution, air and water can be formulated correspondingly by the following equations.

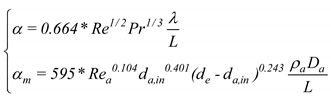

where α represents the corresponding heat transfer coefficient and is determined by the empirical correlation shown in Equation (4) [7]. αm is the mass transfer coefficient between air and solution and is determined by Equation (2).

where α represents the corresponding heat transfer coefficient and is determined by the empirical correlation shown in Equation (4) [7]. αm is the mass transfer coefficient between air and solution and is determined by Equation (2).

Figure 1.

Microelement for the heat and mass transfer.

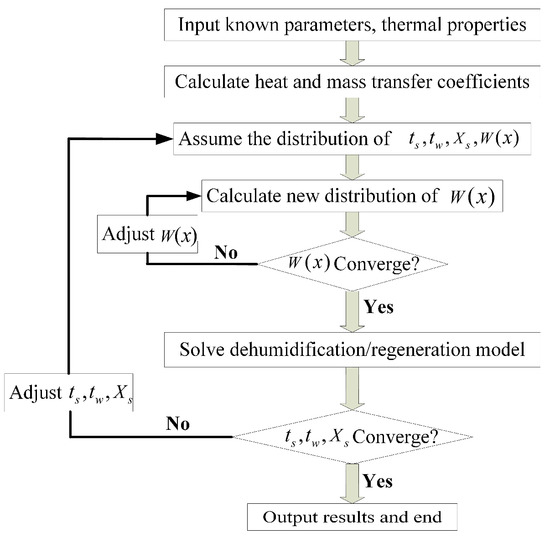

Integrating the set of equations from (1) and (2), the heat and mass transfer characteristics in an internal cooling dehumidifier can be acquired. The calculation flow chart for the models is presented in Figure 2.

Figure 2.

Calculation flow chart for solving the model.

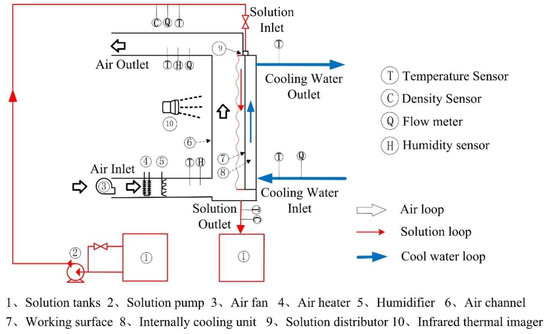

3. Experimental Methodology

An experimental system to study the influence of different parameters on the dehumidification/regeneration performance of KCOOH solution was designed and built. The schematic diagram of it is shown in Figure 3. It has three subsystems, namely air, solution and water subsystem, and corresponding measurement instruments. The detailed introduction of the experimental system could be found in our previous studies.

Figure 3.

Schematic diagram of the experimental system.

4. Experimental Results and Validation

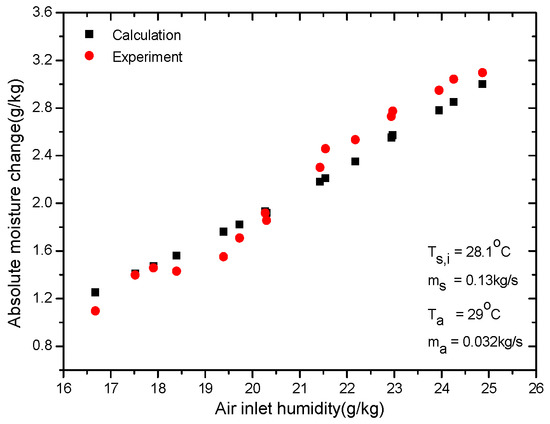

4.1. Influence of Air Humidity on Dehumidification Performance

Figure 4 presents the effect of air humidity on dehumidification performance. The concentration of KCOOH solution kept at 70.3%. It is obvious that the absolute moisture change increases with the increase the air humidity. The ascending tendency can be explained in the aspect of mass transfer driving force. When the air humidity increases from 15.7g/kg to 24.9g/kg, the partial water vapor pressure of air also increases from 2495 Pa to 3900 Pa and so does the vapor pressure difference between air and solution from 1414 Pa to 2819 Pa. Therefore, the increment of vapor pressure difference leads to the increment of mass transfer driving force and so does the absolute moisture removal.

Figure 4.

Influence of air humidity on dehumidification performance.

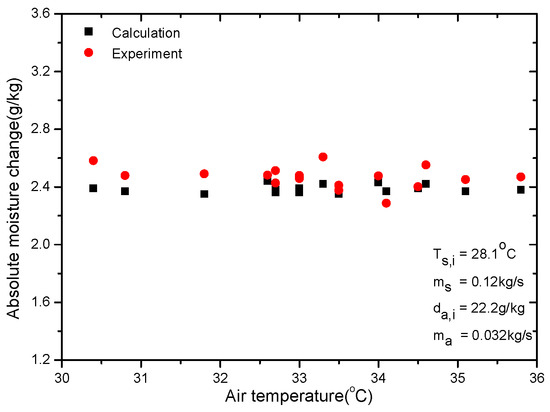

4.2. Influence of Air Temperature on Dehumidification Performance

The influence of air temperature on dehumidification characteristics is presented in Figure 5. As one can see, the air dry bulb temperature has negligible influence on the dehumidification performance resulted from their negligible effect on both mass transfer driving force and wettability of falling film on plate dehumidifier.

Figure 5.

Influence of air temperature on dehumidification performance.

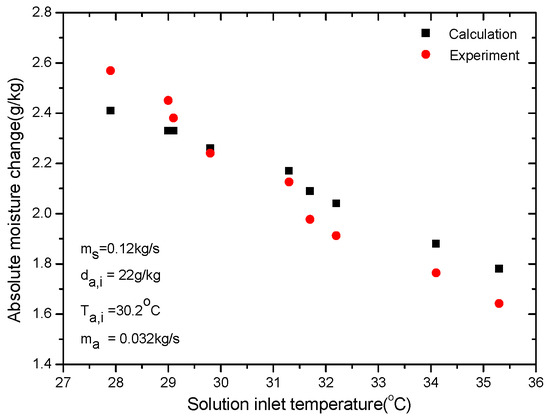

4.3. Influence of Solution Temperature on Dehumidification Performance

From Figure 6, the influence of solution inlet temperature on the water vapor absorption by KCOOH solution can be analyzed. Obviously, the absolute moisture change decreases with increase of solution temperature which can be also interpreted in terms of mass transfer coefficient. For the solution temperature, its increment from 28 °C to 35.3 °C leads to the increment of vapor pressure from 1067 Pa to 1657 Pa. The mass transfer force decreases from 2394 Pa to 1804 Pa correspondingly. As a consequence, the descending trend for solution temperature can be understood.

Figure 6.

Influence of solution temperature on dehumidification performance.

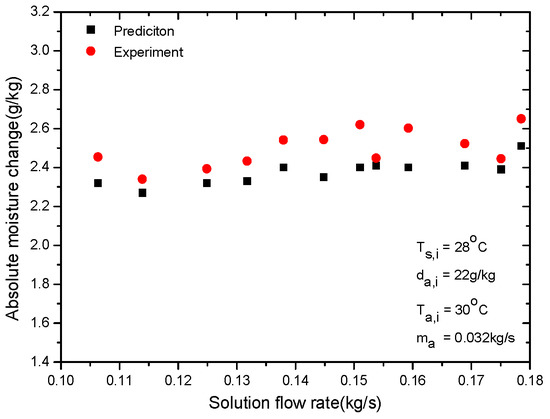

4.4. Influence of Solution Flow Rate on Dehumidification Performance

The experimental results for absolute moisture change during dehumidification are shown in Figure 7. Clearly, the dehumidification performance also keeps unchanged under various solution flow rate. This is due to the fact that the mass transfer driving force and wettability of falling film on plate dehumidifier almost keep constant at different solution flow rate. As a result, the nearly constant trends for absolute moisture change under various solution flow rates are presented.

Figure 7.

Influence of solution flow rate on dehumidification performance.

4.5. Validation of Mathematical Model

The absolute moisture change of dehumidification the simulated by the mathematical model was also indicted in Figure 4, Figure 5, Figure 6 and Figure 7. Comparing the experimental and calculated data in Figure 4, Figure 5, Figure 6 and Figure 7, we can see they match well with each other for both and variation trend and detailed magnitude of absolute moisture change. Figure 8 compares the experimental and numerical results for all data under various conditions. For all the data, the MARD is only 6.05% which demonstrates the prediction accuracy of the developed models adequately.

Figure 8.

Comparison of experimental and calculated absolute moisture change.

5. Conclusions

The dehumidification performance of an internal cooling dehumidifier were experimentally investigated. Mathematical models to describe the heat and mass transfer performance was also developed and validated. Some main conclusions from present study are drawn and listed as follows:

- (1)

- Dehumidification experiment for KCOOH solution indicated the negligible influence of air temperature and solution flow rate on mass transfer performance due to their negligible effect on mass transfer driving force. However, the air humidity and solution temperature are closely related with the mass transfer driving force and influence the absolute moisture change significantly.

- (2)

- The heat and mass transfer model for dehumidification were built. The new model can simulate the mass transfer performance precisely with the relative difference of 6.05% for dehumidification.

Author Contributions

T.W. and Y.L. conceived and designed the experiments; T.W. and K.Y. performed the experiments; Y.Z. and L.S. analyzed the data; T.W. and Y.L. wrote the paper.

Funding

The work described in this paper was supported by National Natural Science Foundation of China (Grant No. 51706003). The authors appreciated the financial supports.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Huang, Y.; Niu, J.L.; Chung, T.M. Energy and carbon emission payback analysis for energy-efficient retrofitting in buildings—Overhang shading option. Energy Build. 2012, 44, 94–103. [Google Scholar] [CrossRef]

- Rafique, M.M.; Gandhidasan, P.; Bahaidarah, H.M. Liquid desiccant materials and dehumidifiers—A review. Renew. Sustain. Energy Rev. 2016, 56, 179–195. [Google Scholar] [CrossRef]

- Longo, G.A.; Gasparella, A. Experimental and theoretical analysis of heat and mass transfer in a packed column dehumidifier/regenerator with liquid desiccant. Int. J. Heat Mass Trans. 2005, 48, 5240–5254. [Google Scholar] [CrossRef]

- Melinder, Å. Thermophysical Properties of Aqueous Solutions Used as Secondary Working Fluids. Ph.D. Thesis, KTH, Stockholm, Sweden, 2007. [Google Scholar]

- Mesquita, L.; Harrison, S.; Thomey, D. Modeling of heat and mass transfer in parallel plate liquid-desiccant dehumidifiers. Sol. Energy 2006, 80, 1475–1482. [Google Scholar] [CrossRef]

- Liu, X.; Chang, X.; Xia, J.; Jiang, Y. Performance analysis on the internally cooled dehumidifier using liquid desiccant. Build. Environ. 2009, 44, 299–308. [Google Scholar] [CrossRef]

- Patankar, S. Numerical Heat Transfer and Fluid Flow; CRC Press: Boca Raton, FL, USA, 1980. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).