Abstract

We present a valveless microfluidic pump utilizing an oscillating membrane made from a flexible printed circuit board. The microfluidic channel is fabricated by a 3D printing process and features diffuser/nozzle structures to obtain a directed flow; the flexible membrane is bonded to the channel. The membrane is actuated via Lorentz forces to accomplish out-of-plane motions and push the fluid through the channel. A permanent magnet provides the static magnetic field required for the actuation. The simple fabrication method can potentially be used for inexpensive mass fabrication for disposable devices.

1. Introduction

Microfluidic pumps are key elements in lab-on-a-chip devices (LOC) and micro total analysis systems (µ-TAS) to, e.g., transport an analyte to different analysis stages of the device. So called diffusor/nozzle pumps are commonly utilized for this task, which periodically push and pull the fluid through the channel. Complemented by a specific channel design, the periodic motion of the fluid is rectified resulting in a directed net flow.

Possible actuation approaches are diverse. Often oscillating membranes are utilized, which are actuated by piezo elements [1], magnets and electromagnetic coils [2,3,4], but also oscillating bubbles [5] are used for actuation. The diffusor/nozzle structures can be implemented via the channel geometry, but also open-porous foams with a gradient in pore size (which also adds a filtration function) are reported [6]. Our proposed design uses polyimide based flexible printed board (PCB) technology as one wall of the microfluidic channel, which is actuated using Lorentz forces to perform out-of-plane motions. The fabrication method is simple and cost effective, potentially enabling this setup to be used for disposable devices.

2. Materials and Methods

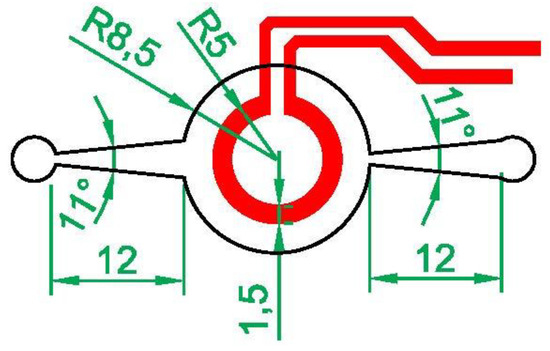

Diffusor/nozzle pumps are categorized as valveless pumps, as they do not require mechanical valves, which are usually complicated to fabricate in microfluidic systems. The flexible PCB performs periodically out-of-plane motions that squeeze the fluid through the channel during the downward motion of the membrane, and suck fluid through the channel during the upward motion. The periodic motion of the flow is rectified by diffusor/nozzle structures at the inlet and the outlet of the channel, which provide different hydraulic resistances depending on the flow direction generating a directed net flow in the course of the actuation cycles. Figure 1 shows a schematic of the microfluidic channel and its dimensions.

Figure 1.

Schematic of the diffusor/nozzle pump. Black outline: Microfluidic channel, the depth of the channel is 250 µm; dimensions in mm. Red: Copper traces of the PCB.

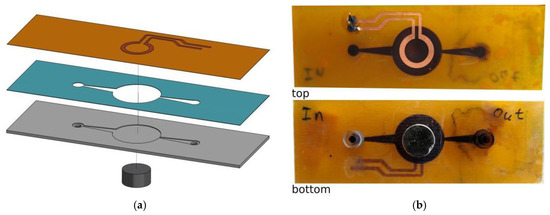

The 250 µm high microfluidic channel was fabricated by a 3D printing process (Stratasys Objet) and the flexible PCB (consisting of a 50 µm polyimide carrier and 35 µm thin copper traces) is bonded to the plastic channel using a double sided adhesive tape, where the outline of the channel was cut using a digital craft cutter. Figure 2a shows an explosion drawing of the whole assembly and Figure 2b the top and bottom view of the device (the microfluidic channel is filled with black ink).

Figure 2.

(a) Explosion drawing of the assembly. Orange: Flexible PCB. Blue: Double sided adhesive tape. Grey: Microfluidic polymer channel. Bottom: Permanent magnet. (b) Top and bottom view of the device. The microfluidic channel is filled with black ink for better visualization.

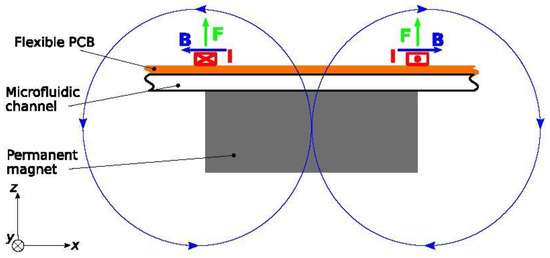

Figure 3 shows a cut-plane through the length dimension of the assembly to illustrate the actuation of the membrane. A NdFeB permanent magnet (radius of 5 mm) provides a static magnetic field (as illustrated by the blue field lines in Figure 3). The copper traces of the PCB are routed in a way that they run right around the edge of the permanent magnet (see also red traces in Figure 1). Since the traces are close to the magnet, the magnetic field at the edge of the magnet points mainly in the x-direction (see coordinate system in Figure 3). In conjunction with the current flowing in y-direction, a Lorentz force acts on the PCB traces in z-direction according to

where I is the electrical current, l the length of the traces and B the magnetic flux density. Since the setup is radial symmetric, the force acts all along the circumference mainly in z-direction.

F = I(l × B),

Figure 3.

Principle of actuation. A cut-plane through the length dimension is depicted. Red: Copper traces with indicated current direction. Blue: Magnetic field lines and direction of the magnetic induction (B) at the position of the traces. Green: Forces acting on the traces, F = I(l × B).

3. Results

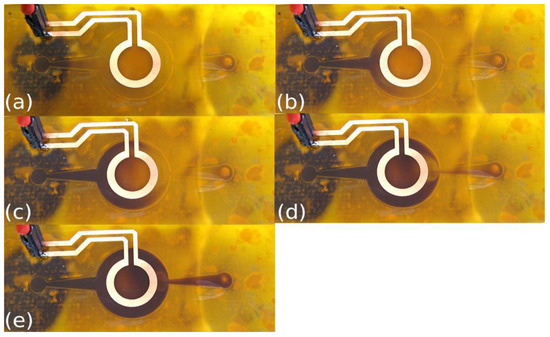

To test the device, pumping from one water filled reservoir to another was evaluated. To visualize the flow, the inlet connector was dipped into a basin filled with DI water and black ink (dark spot at the left side of Figure 4); the outlet connector was dipped into clear DI water. After applying a sinusoidal current with a peak value of 2 A and a frequency of 5 Hz, the black colored water is pumped from the left reservoir to the right one. Figure 4 shows snapshots of this process at different times after applying the current signal.

Figure 4.

Pumping action over time. (a) 0 s, (b) 60 s, (c) 120 s, (d) 180 s, (e) 240 s after applying a sinusoidal actuation current (2 A/5 Hz) to the copper traces. The dark spot on the left represents the inlet reservoir (filled with black ink).

4. Discussion

We presented a diffusor/nozzle pump that uses an oscillating membrane made from a flexible PCB that is actuated by oscillating Lorentz forces. First tests proof the functionality of the design. Due to the simple fabrication process, the proposed device could be potentially used for mass fabrication (especially since most major PCB manufactures offer solutions including flexible materials), accompanied by the reduction of manufacturing costs, this design can be suitable for disposable devices.

Nest steps will include the evaluation of the optimal actuation frequency with respect to flow rate, a full characterization of the pump performance and the downsizing of the setup.

Author Contributions

M.A.H. was responsible for the actuator design, fabrication, experiments and manuscript writing. B.J. contributed to the design idea, manuscript writing and project management.

Acknowledgments

This work has been supported by the COMET-K2 “Center for Symbiotic Mechatronics” of the Linz Center of Mechatronics (LCM) funded by the Austrian federal government and the federal state of Upper Austria.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wei, Y.; Torah, R.; Yang, K.; Beeby, S.; Tudor, J. A novel fabrication process to realize a valveless micropump on a flexible substrate. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Lederer, T.; Heinisch, M.; Hilber, W.; Jakoby, B. Electromagnetic membrane-pump with an integrated magnetic yoke. In Proceedings of the 2009 IEEE Sensors, Christchurch, New Zealand, 25–28 October 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 532–537. [Google Scholar]

- Kawun, P.; Leahy, S.; Lai, Y. A thin PDMS nozzle/diffuser micropump for biomedical applications. Sens. Actuators A Phys. 2016, 249, 149–154. [Google Scholar] [CrossRef]

- Yamahata, C.; Lotto, C.; Al-Assaf, E.; Gijs, M.A.M. A PMMA valveless micropump using electromagnetic actuation. Microfluid. Nanofluid. 2005, 1, 197–207. [Google Scholar] [CrossRef]

- Tsai, J.-H.; Lin, L. A thermal bubble actuated micro nozzle-diffuser pump. In Technical Digest, MEMS 2001, Proceedings of the 14th IEEE International Conference on Micro Electro Mechanical Systems (Cat. No. 01CH37090); Interlaken, Switzerland, 25 January 2001, IEEE: Piscataway, NJ, USA, 2001; pp. 409–412. [Google Scholar]

- Hilber, W.; Clara, S.; Jakoby, B. Microfluidic Pumping Utilizing a PDMS Membrane with an Integrated Nonuniform Open-Porous Foam. IEEE Sens. J. 2015, 15, 5109–5114. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).