Abstract

This paper presents the results recorded by upgrading and rehabilitating the pumping stations for an urban water network with a primary goal of diminishing the operation and maintenance costs and a secondary goal of reducing the water losses in the water distribution network. The adopted technical solutions within the structural and functional modifications of the pumping stations have led to both the improvement of hydraulic parameters of the pumping stations and also the improvement of registered energy consumption. The undertaken modifications and transformations within the pumping stations led to significant energy savings and at the same time to important water losses reductions within the distribution network.

1. Introduction

In Romania, the construction of distribution and wastewater systems begun as early as the end of the 19th century. Although currently at a national level there are water and wastewater systems in most of the urban areas and partially in the rural areas, not all the population benefits from these features. This fact makes the modernization and expansion works of these public utility systems to be in a continuously state of transformation both physically (by extending the service area) and technically (by introducing more performing equipment and materials). At the same time, the energy costs associated with the pumping of potable water represents approx. 60–70% of the operational costs so the rehabilitation and re-equipment of the pumping stations represents the proprietary objective of the water producers and distributors. The rehabilitation and refurbishing requirements of the pumping stations in the water and waste water systems involved in-depth structural and functional modifications such as: passing from sequential operation (pumps with constant speed) to continuous (pumps with variable speed) as well as creating the means of remote monitoring of pumps operating parameters.

Such transformations took place in Bucharest beginning in the early 90s and continued just as recently as 2013–2014. The focus of this paper is a specific network zone that is representative for the entire water system of Bucharest in terms of the end results.

In order to better understand the impact of these large scale transformations in the water systems a brief description is given of the common practices used regarding the design and operation of the pumping stations prior to the commencement of modernization works.

2. Pumping Stations Characteristics in Water and Wastewater Systems Operation

Within the existing centralized water and wastewater systems in Romania, the pumping stations share some similar characteristics, such as:

- The pumping groups within the pumping stations are in most part composed of pumps coupled in parallel;

- The pumped water volume is variable in the course of the day and differs from one day to the other, depending on random factors (holidays traditions, week-ends etc.) or restricted by objective factors (exaggerated consumption, restrictions for pumps or motors operation);

- The daily flow variation is done within a limit of maximum and minimum pressure in the discharge pipes, the pressure being imposed by starting/stopping of pumps;

- Pumps were chosen based on nominal flow and head, these values being determined based on approximate data that take into account a specific consumption for every type of consumer;

- Based on the role played within the water or wastewater systems, the pumping stations may be equipped with fixed or variable speed pumps, but only after 1990.

The construction of the pumping stations was done in several steps in a period when the ratio of energy costs from the total operational costs was relatively low compared to today tariffs and the water consumption was very high, at the end of the 20th century registering specific consumptions of 500 L/day/pers. Today, when the energy price tends to align with the price in most of UE countries, a fundamental requirement that pumping station within distribution systems have to accomplish is to ensure a flow variation in correlation with the consumer needs at a constant pressure, and this is done by adjusting the operating parameters of the pumps.

3. Methods of Adjusting the Pumping Stations Operating Parameters within Water and Wastewater Systems

Depending on the role of the pumping station within the water and wastewater system, on the type of pumps, on the characteristic parameters of the pumps and on the variable consumer demands, the possibilities for pump adjustment can be one of the following:

- External adjustment—changing the network characteristic, but keeping the pump characteristic unchanged;

- Internal adjustment—changing the pump characteristic, but keeping the network characteristic unchanged;

- Mixed adjustment—simultaneously changing both characteristics (pumps characteristic and network characteristic).

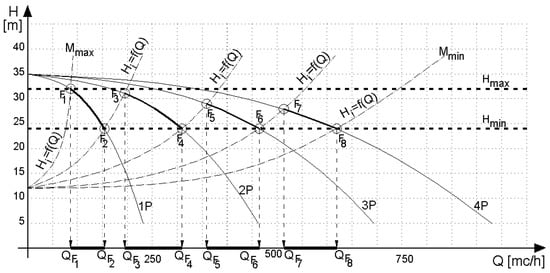

Initially the pumping stations intended to serve the water and wastewater systems in Romania were designed based upon the available technology at the time, where the pumps were actuated by constant speed motors and the adjustment of the operating parameters was sequential. The sequential adjustment involves starting and stopping the pumps based on the pressure variation in the pump station discharge pipe; the pressure variation which is caused by the increase and decrease of demands in the distribution network (see Figure 1).

Figure 1.

Sequential adjustment for a pumping stations when the water demand is increasing.

For such type of operating regime, in order to ensure the necessary pressure within the imposed limits (Hmin and Hmax), it is noted that as the demand is increasing the pumps are started one by one until the pump station reaches the maximum load (F8). The projection of resulted the duty points in order to reach the desired pressures on the flow axis leads to discrete or sequential variation intervals of the total pumped flow. This particular operating regime generates time periods where the pumped flow is higher than the demanded flow for the consumers, immediately after a pump starts. This phenomenon is similar in operating situations where the demand is decreasing (according to night periods) but in this case the operating sequence stops the pumps and generates periods where the pumped flow is insufficient for the consumer’s demands [1].

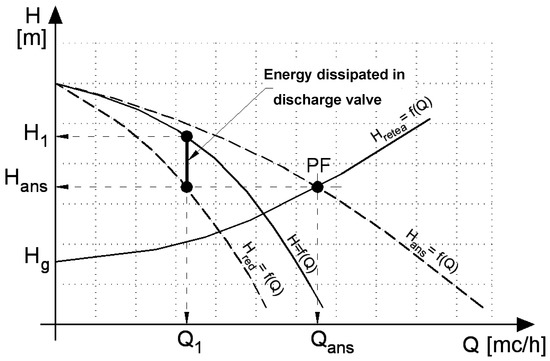

The second widely used type of sequential adjustment for correlating the pumping station operating parameters with the demands of the consumers from the distribution network is by throttling the discharge valve. This adjustment method for the operating parameters of the pumping station is applied in cases where the operating personnel typically have to address certain operating restrictions, such as: avoiding electric motor currents past a certain maximum value and avoiding opening the discharge valves past the limit where cavitation may appear. For two identical pumps in parallel with throttled discharge valves (illustrated in Figure 2) the resulted duty point obtained by coupling the two modified pump characteristics in parallel (with the resulting flowrate Qans and pumping head Hans) one can determine the useful power of the entire pumping station as

Figure 2.

Operating sequence for a pumping stations with variable speed.

By rationing the useful power with the sum of total powers of the two pumps, one can obtain the efficiency of the entire pumping station, which is in fact the quality factor of the pumping process. In Equation (2), the flow rate for one pump is denominated as Q1 and the pumping head is denominated as H1 since both pumps are identical.

The conclusion is that the pumping station efficiency depends on the H1/Hans ratio. If this value is high, then the pumping station efficiency is low and consequently the energy consumptions are higher and depend on the throttling of the discharge valves. The difference between H1 and Hans represents the dissipated (lost) energy by closing the valves [2].

This adjustment method of the operating parameters is the simplest to be put in practice because of the low investments, but on the other hand presents a huge disadvantage because of the significant energy losses.

The progresses made in time, as well as the new EU regulations regarding the manufacturing of electrical motors (specifying that starting with 2017 all electrical motors up to 375 kW should be fitted with frequency converters), made it that the concept of variable speed pumps be applied also in the water and wastewater systems.

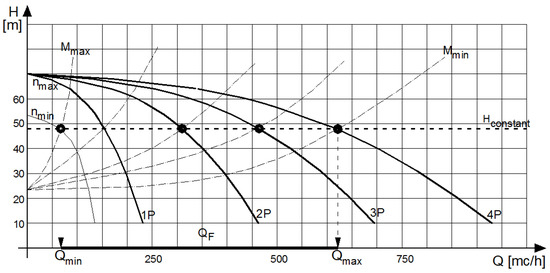

This approach represented an important step in operating the pumping stations, because by modifying the speed the pump is capable of continuously adjusting the pressure in order to optimally adapt itself to the consumer’s demands, at the same time ensuring important economy savings without compromising the operating life time of the pump. The analysis of such pumping station with four pumps coupled in parallel connection, in which one pump presents variable speed drive and the other three have fixed speed drives, is illustrated in Figure 3. The goal of this operating sequence is to maintain a constant pressure in the discharge pipe of the pumping station [3].

Figure 3.

Operating sequence for a pumping stations with variable speed.

One can observe that by varying the speed, the pumping station operates at a constant head and the resulting duty points migrates on the horizontal corresponding with H = constant. The variation of the pumps parameters is done according to the affinity laws.

When the variable speed pump reaches the nominal operating parameters, a second fixed speed pump is started within the pumping station simultaneously with a decreasing of the variable speed. It can be noted that by this particular method, when projecting the duty points on the flow axis, the pumping station is capable to ensure any flow rate within the given interval, without discontinuities in the pumped flow.

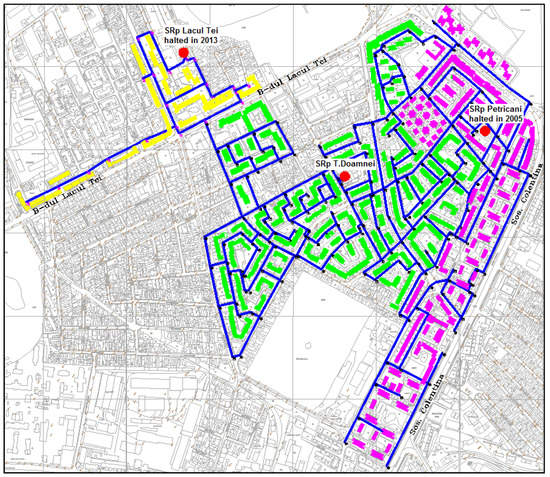

4. Case Study. Transformations in Pumping Optimization in High Pressure Networks within Tei-Colentina District

The district Tei-Colentina is situated in north-eastern part of Bucharest and it is supplied by a water distribution system that was built in several construction phases based on the occupancy in the area. Simultaneously with construction of apartments blocks, in this particular area begun the construction of water networks capable of ensuring the operating parameters for water supply of 8 and 10 story buildings. Consequently, between 70s and 80s, in separate construction phases, three new pumping stations were built (Teiul Doamnei, Petricani and Lacul Tei) in this district as seen in Figure 4.

Figure 4.

Localization of the initial three pumping stations and their supply areas in Tei-Colentina district.

Initially, the booster stations Teiul Doamnei and Petricani were designed and built to operate like a classical pumping station, that is taking the water from a battery of reservoirs and pump it in the high pressure distribution system. The pumping station Lacul Tei receives the water directly from the low pressure water network and then discharges the water in the appropriate high pressure area. All of these three pumping stations were equipped with locally manufactured pumps type NDS, DN/TN with fixed speed drive [4,5].

The operating regime adjustment for these pumping stations was sequential by manually starting/stopping of pumps. This task was accomplished by the local personnel that took into considerations two important factors: the discharge pressure and the water level in the reservoirs. In time, the operating regime of the pumping stations suffered major transformations and their effect was a modification in the operational parameters, in a sense that the actual parameters of the pumping groups were significantly different from the nominal pump parameters and as a consequence the power consumptions were extremely high [6].

The first modification phase began in early 90s when, due to the new social and economical transformations, the water consumptions decreased. As a consequence the pressure in the low-pressure network begins to increase so the pumping stations Petricani and Teiul Doamnei by-passed the reservoirs and took the water directly from the low-pressure network. In this new operational manner, the pressure from the distribution network (which varied between 15–25 mH2O) was used by the pumping stations. At first glance this solution appeared to bring some added value, but in reality, because the original pumps parameters were in the vicinity of 360 m3/h nominal flow rate and 60 m head, led to a throttled valve operation so that the discharge pressure will not surpass the maximum admissible pressure in the network (6 bars). The result was that the pumps were working at very low efficiencies and with high energy costs [6].

The second major phase in modifying the operational regime of the pumping stations began as a result of a vast measurement campaign for the pumps operational parameters and it was decided that the existing pumps will be replaced with new variable speed pumps. At the same time, a hydraulic study was conducted in order to understand how the high-pressure distribution networks are behaving and one of the conclusions was the pumping station Petricani should be closed and all the corresponding consumers should be supplied from Teiul Doamnei. So, at the beginning of 2005, all the connections in the initial high-pressure zone were supplied exclusively from the newly refurbished and modernized Teiul Doamnei and Lacul Tei pumping stations.

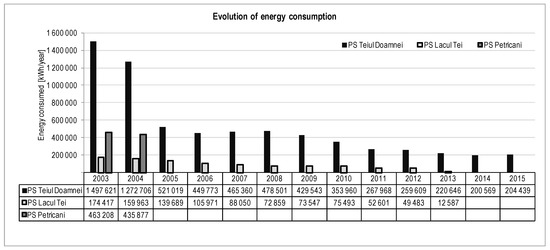

The third and final phase (to date) in optimizing the pumping process for the high-pressure distribution networks in Tei-Colentina district begun as a result of large leaks detection and repairing program. Using an updated version the hydraulic models from the previous phase, the simulations done in January 2013 revealed that the new upgrades for the distribution network can lead to also permanently closing the Lacul Tei pumping station, and this task was accomplished in March 2013. The progresses made by optimizing the three pumping stations from the initial area led to substantial energy savings, as seen in Figure 5.

Figure 5.

Evolution of energy consumption for the booster stations in Tei-Colentina district.

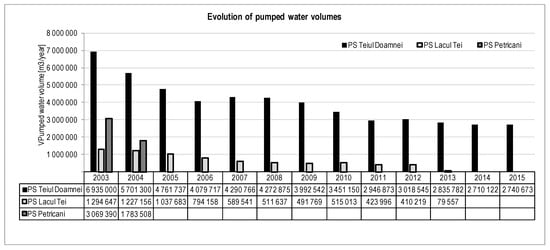

At the same time, the pumped water volume showed a continuously decreasing trend until it reached relatively constant values which proved that the network leakages were significantly diminished (see Figure 6).

Figure 6.

Evolution of pumped water volume for the booster stations in Tei-Colentina district.

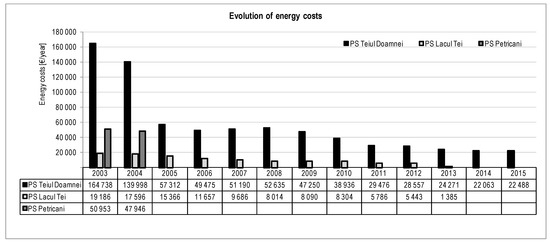

Upon acknowledging the end results, the technical solutions implemented in operation of the water distribution system for this particular district proved to be economically reliable. Considering the energy price as 0.11 euro/kWh, the increase in the energy efficiency within the pumping stations collaborated with the decrease of the water losses led to a significant financial gain as a direct benefit of the lower energy consumption (only 10% in 2015 compared to the energy costs in 2003—see Figure 7).

Figure 7.

Evolution of energy costs for the booster stations in Tei-Colentina district.

In this context, the amortization of the investment, by refurbishing the pumping station Teiul Doamnei with pumps fitted to the actual network demands, was achieved in about 12 months only by energy savings, without taking into consideration other costs related with operational personnel, spare parts, maintenance works for the pumps and electrical motors.

5. Conclusions

The pumping stations have an essential role in transportation and distribution of drinking water and also in collection and transportation of wastewater. The progresses made in the technology of pump and electrical motors manufacturing and also the advanced technical solutions from the field of operational parameters measurements, of data acquisition and processing made possible a more efficient pumping process and created new operational possibilities in order to ensure a continuous water supply without producing bursts in the distribution network.

Fitting the pumping stations with variable speed pumps, designing the pumping stations in such a way that no energy losses exits within their perimeter, switching to an automated operation, introducing means of surveillance an control of the pumps parameters by measurements taken “in situ” are essential elements in order to optimize the operational costs and in 1 particular the energy costs.

From a social perspective, the reduction of both water losses and energy consumption within the distribution systems must be a priority for both the water operators and their consumers.

Author Contributions

S.P. provided the technical solution for the water supply system by modelling the water network and A.A. provided the analysis of the energy costs over the studied time period.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Perju, S. Statii de Pompare in Sistemele de Alimentary cu apa si Canalizari; Editura Conspress: Bucharest, Romania, 2009; ISBN 978-973-100-059-6. [Google Scholar]

- Perju, S.; Hasegan, L.V. Reducing Energy consumption by upgrading pumping stations in water distribution systems. Environ. Eng. Manag. J. 2013, 12, 735–740. [Google Scholar]

- Anton, A.; Perju, S. Alegerea pompelor in sisteme de apa municipale. In Proceedings of the Technical and Scientific Conference “Serviciile de apa si Noile Exigent Energetice”, Bucharest, Romania, 10–12 June 2013; pp. 9–16, ISBN 978-606-8284-66-8. [Google Scholar]

- Masuratori Parametri Hidroenergetici si Analize de Retea la 24 Statii de Repompare. Available online: mmut.mec.upt.ro/mh/Conferinta_MH/301_AntonA.pdf (accessed on 6 August 2018).

- Perju, S.; Aldea, A.; Mihailovici, M.; Zaharia, V. Challenges in the assessment of water loss KPIs in large distribution systems. Case study of Bucharest water supply system. In Proceedings of the 16th International Scientific GeoConference SGEM, Albena Resort, Bulgaria, 28 June–7 July 2016. [Google Scholar]

- Perju, S.; Mihailovici, M.; Stanescu, I. Simulation of two high pressure distribution network operation in one-network connection. Sci. J. Math. Model. Civ. Eng. 2014, 3, 31–40. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).