Abstract

Packaging waste that is not recycled or reused has a negative environmental effects and presents serious concern. At the same time, various secondary raw materials, which were used to produce packaging from recycled materials, can affect human health and the environment because they can contain harmful chemical substances. For this reason, it is necessary to investigate the existence of hazardous chemicals in recycled materials. This paper analyzes issues related to the production of packaging by using materials from recycled packaging waste with a focus on the influence of the hazardous substances that the waste may contain. This paper presents the results of a survey interviewing packaging manufacturers who use recycled materials in packaging, revealing problems that packaging manufacturers face in the manufacturing of packaging from recycled materials.

1. Introduction

The concept of the circular economy (CE) is getting more and more attention, various materials are highly valued and perceived as a source of resources, unlike in the traditional, linear economy model [1,2]. When a product reaches the end of its life cycle recycling provides an opportunity to extend keeping of materials in the economy. However, packaging recycling as well as the use of recycled materials for packaging production face a variety of challenges related to technical, economic, environmental, social and legal issues. Increasing recycling costs, a lack of raw materials, the availability of technologies to separate different materials, and increasing numbers of legal acts are just a few examples of them. One of the barriers faced by operators who want to use secondary raw materials is uncertainty as to their quality. Among the causes which may compromise its purity are substances used in packaging production or added to raw materials in order to make the production processes easier or improve the properties of the packaging. Many problems occur in packaging recycling when attempts to solve the issue of hazardous substances in packaging are shifted to the end of the process, instead of eliminating them at the outset of the product cycle. Contamination of collected packaging materials with chemicals hinders their further processing and handling. This can happen either due to the use of certain raw materials and additives in the packaging, or because of what was packaged and stored [3,4,5].

The purpose of current research is to overview the issue related the use of recycled materials in the production of new packaging, concentrating on the potential presence of hazardous chemical substances in recycled packaging waste flow, and on traceability of these substances.

2. Materials and Methods

An overview of recycling and barriers to recycling was based on the analysis of scientific literature, study reports, and a survey. It was conducted with companies that manufacture packaging in Lithuania. In total, 82 such companies were identified, which manufacture packaging from glass, plastic, polyethylene terephthalate (PET), paper and cardboard, metal, wooden, composite, and other (textile) materials. The questionnaire included questions on the use of recycled materials: does the company use recycled raw materials, why and how much, what share of production is made of recycled materials, what has inspired the production of packaging made from recycled materials, what are the disadvantages of packaging produced from recycled materials, etc.

3. Results

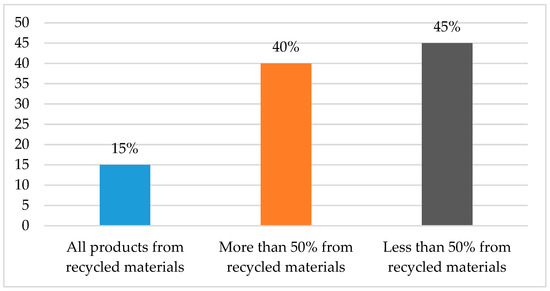

The survey of packaging manufacturers in Lithuania revealed that 60% of those who participated in the survey use recycled raw materials in their production processes. Nevertheless, the percentage varied for various packaging materials. It was 100% for metal and glass packages, as well as for other packages. It must be noted that the group of “other” packages consisted of one single company, producing “eco-friendly textile bags”, as they call them, and therefore is a specific and not representative case. For paper and cardboard packaging, 75% of manufacturers confirmed the use of recycled raw material. Manufacturers of plastic and PET packaging were divided into two separate groups. However, it appeared that there was no difference between PET and other plastics. The share of those who use recycled raw materials made 68% in both cases. In the case of composite packaging, companies using recycled and only primary materials were equally divided: 50% and 50%. Surprisingly, only 25% of wooden packaging produced from the recycled materials. Only a small proportion, 15%, of manufacturers produce their entire production from recycled raw materials. This means that manufacturers of packaging, who replied that they are producing from recycled materials, in fact also have packages produced from primary raw materials only. The proportion of those who produce less than half, and those who produce over half of their production using secondary raw materials, was similar, respectively 45% and 40%. Results are presented in Figure 1.

Figure 1.

Part of the packaging production that is made from recycled raw materials in companies (%).

Companies have listed the following reasons which encourage them to use secondary raw materials: willingness to be competitive with other companies, environmental policy in the company, a possibility to use it as a marketing measure, and trends in legislation.

Lithuanian companies are facing problems with the implementation of the circular economy concept and manufacturing packaging from recycled materials. In the survey, manufacturers of packaging for recycled materials revealed several problems, including: unclear composition of the recycled raw materials, insufficient amounts of secondary material, and rising prices for secondary raw materials. From these answers, we can conclude that the traceability of harmful substances in the supply chain is inadequate and that the requirements for safe secondary raw materials are too low to produce a larger quantity of packaging from a secondary substance free from hazardous chemical additives to human health and the environment.

4. Conclusions

(1) The survey reveals that in Lithuania, only a small number of packaging manufacturers are using 100% secondary raw materials for their production. Forty percent of packaging manufacturers from the survey indicated that in their companies more than 50% of the packaging is made from recycled materials and 45% indicated that less than 50% of their packaging is from recycled materials.

(2) The survey clarified an important problem which packaging manufacturers from recycled materials face; unclear composition of secondary materials and their traceability in the supply chain. A complicated traceability process of hazardous substances in packaging materials presents a problem for waste operators seeking to increase the share of recycled materials in packaging production.

(3) Circular economy documents formulate goals and strategic targets, such as recycling of used packaging materials placed to market and closing circular economy loops (reuse, recycle, renew) at 100%, but recommendations and guidelines on how to implement them are still under preparation. As a result, packagers and processors are facing problems which they cannot solve on their own due to the limited knowledge, information and resources they possess.

Author Contributions

Authorship is limited to the one author—K.R.

Conflicts of Interest

The author declare no conflict of interest. The founding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Reike, D.; Vermeulen, J.V.; Vitjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. J. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Geisendorf, S.; Pietrulla, F. The circular economy and circular economic concepts—A literature analysis and redefinition. Thunderbird Int. Bus. Rev. 2018, 60, 1–12. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. J. R. Soc. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Pennarun, P.Y.; Dole, P.; Feigenbaum, A. Functional barriers in PET recycled bottles. Part I. Determination of diffusion coefficients in bioriented PET with and without contact with food simulants. J. Appl. Polym. Sci. 2004, 92, 2845–2858. [Google Scholar] [CrossRef]

- Pivnenko, K.; Olsson, M.E.; Gotze, R.; Eriksson, E.; Astrup, T.F. Quantification of chemical contaminants in the paper and board fractions of municipal olid waste. J. Waste Manag. 2016, 51, 43–54. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).