Abstract

The pulsed polarization measurement technique applied on sensor devices based on yttria stabilized zirconia (YSZ) with porous platinum electrodes enables the detection of low ppm concentrations of NOx in exhaust gas applications with a simple device. Pulsed polarization is based on alternating voltage pulses with intermediate pauses for self discharging. The discharge characteristics after polarization depends strongly on NOx content in the low ppm range. Due to faster discharging in NOx containing atmospheres compared to base gas, the voltage difference between the discharge curves can act as a concentration dependent parameter. Sensor probes for usage in exhaust gas conditions have been built. The feasibility of NOx sensing in diesel exhaust gas by use of a planar cost-effective YSZ sensor element is evaluated in detail in comparison to commercial NOx exhaust sensors and referenced with gas analysis equipment.

1. Introduction

For active emission control in combustion engines, especially for control of SCR catalyst control in diesel engines, detection of oxides of nitrogen (NOx) in the low ppm range is required, while cross-sensitivities to other exhaust components has to be avoided. Numerous approaches for NOx sensors suitable for automotive exhaust monitoring have been investigated in the past years [1]. Nevertheless only one principle of NOx sensor is in use in series production. Due to the complex setup of this sensor incorporating two amperometric pumping cells [2] and with respect to the low sensitivities of the sensor raw signal of only a few nA/ppm NO [3], reduction in cost without diminution of the sensor performance is limited for this technology.

As shown in previous works, it is possible to operate simple planar YSZ based structures as a promising NOx sensor by applying the so-called pulsed polarization technique [4]. While the gas sensing characteristics of this technique have been deeply investigated in earlier studies using synthetic gas mixtures under controlled environments, the recent work now evaluates the detection capabilities of planar YSZ sensor elements operated in pulsed polarization mode for detection of NOx in real exhaust gas of a diesel combustion engine.

2. Materials and Methods

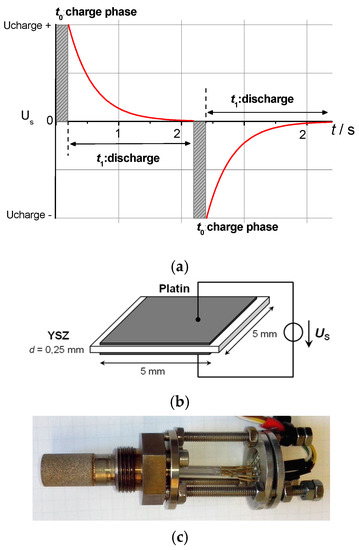

The pulsed polarization sequence is illustrated in Figure 1a. A charge voltage Ucharge is applied to the electrodes for a time t0 followed by an open circuit discharge phase t1 via the internal resistance of the sensor. The voltage transient during discharge shows a logarithmic dependency on the NO concentration. The same procedure is repeated with opposite polarity of the charging voltage to avoid unilateral charge effects. Typical values for the charge times are in the range of 0.1 s to 1 s, for discharge times in the range of 0.5 s to 3 s. For the evaluation shown in this work, the change in sensor voltage after 800 ms discharge has been used. Charge voltage has been set to ±1 V for all measurements.

Figure 1.

(a) schematic depiction of the charge and discharge phases during pulsed polarization; (b) schematic depiction of the YSZ based sensor element consisting of a YSZ substrate and screen printed Pt electrodes; (c) Sensor probe as used in the engine tests, overall length is 12 cm.

Sensor elements have been fabricated using 3% yttria doped zirconia substrates and screen printed platinum electrodes as depicted in Figure 1b. The electrodes were contacted with 100 µm Pt wires and bonding through Pt paste. In order to control the sensor temperature additional platinum heater elements has been deposited on a ceramic carrier. Sensor and heater elements have been integrated in a sensor probe suitable for usage in diesel exhaust (Figure 1c).

During the engine tests, sensors probes have been installed in the exhaust gas of a 6-cylinder V Diesel engine with 3l cubic capacity. The sensor temperature has been set in the range of 400 °C to 470 °C. Exhaust gas components have been characterized using a Horiba MEXA 7000 exhaust gas analyzing system. In addition, the response of a commercial amperometric NOx sensor (Continental) has been recorded simultaneously.

3. Results

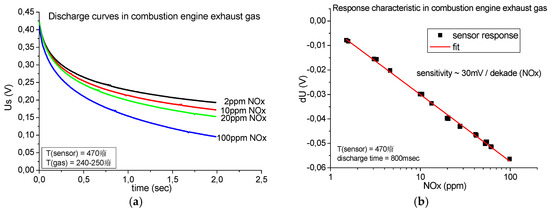

The effect of varying NOx concentrations in exhaust gas on the sensor discharge characteristics is shown in Figure 2a. With increasing NOx content, the self discharge of the sensor is increased causing lower voltage across the sensor electrodes over time. By evaluation of the sensor voltages as function of different NOx concentration, a semilogaritmic response curve can be derived (Figure 2b).

Figure 2.

(a) discharge curves at varying NOx concentrations in diesel exhaust gas; (b) Sensor response derived from discharge curves at NO concentrations from 2 ppm to 50 ppm. dU corresponds to the change in sensor voltage after 800 ms discharge time.

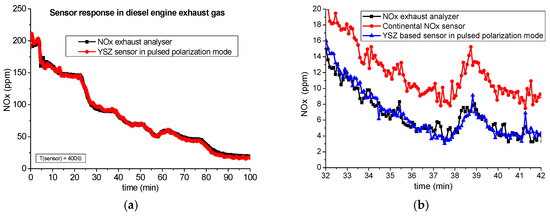

Using typical response characteristics as shown in Figure 2b for calibration, NOx concentrations have been estimated from the sensor response in diesel combustion exhaust. Figure 3a compares the response of a calibrated sensor using the pulsed polarization technique to a commercial exhaust gas analyzing system in the concentration range of 20 ppm up to 200 ppm NOx. Even at NOx concentrations below 20 ppm, the calibrated sensor response exhibits only minor deviations from the analyzer signal in the range of approx 1 ppm (Figure 3b). A offset of the commercial amperometric NOX sensor in the range of 1–2 ppm has been observed.

Figure 3.

(a) Comparison of the response of a commercial NOx exhaust analyzer and a calibrated YSZ sensor in pulsed polarization mode in diesel engine exhaust gas; (b) Comparison of the response of an NOx exhaust analyzer, a commercial amperometric NOx sensor and a calibrated YSZ sensor in pulsed polarization mode in diesel engine exhaust gas at low NOx levels.

4. Discussion

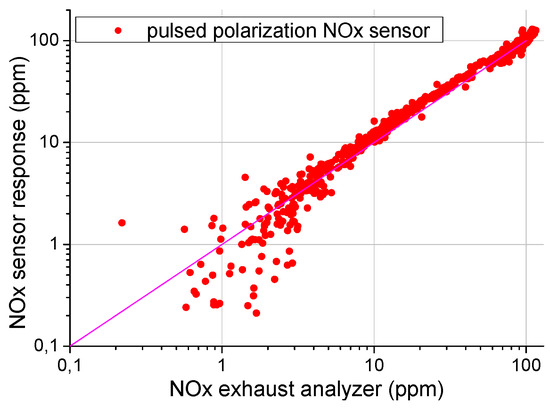

The response of the sensor operated in pulsed polarization mode has been assessed in comparison to the NOx concentrations given by the exhaust gas analyzing system. For NOx concentrations above 5 ppm, a highly linear response of the sensor can be observed as shown in Figure 4 in a double logarithmic scale. Below NOx levels of 5 ppm, a significant scattering of the sensor response is visible. This is mainly related to the fact that the pulsed polarization sensor is similarly to the commercial sensor also responding to ammonia, which is present in ppm concentrations mainly at low NOx levels due to the ammonia slip in the SCR catalyst. For the calculation of the measurement error summarized in Table 1, the ammonia content of the exhaust has been taken into account. The average measurement error of the sensor in pulsed polarization mode determined from different engine conditions is comparable to the average error obtained with the commercial sensor.

Figure 4.

Correlation of the response of a sensor in pulsed polarization moded calibrated to NOx to the concentrations provided by the NOx exhaust gas analyzer.

Table 1.

Comparison of the relative measurement error for NOx detection of a pulsed polarization sensor and a commercial Continental NOx sensor at different engine conditions.

5. Conclusions

Simple two-electrode YSZ based sensor elements have been exposed to exhaust gas of a diesel engine using pulsed polarization of the sensor electrodes and evaluation of the effect of NOx on the self-discharge behavior. The results of this study demonstrate that the measurement of relevant NOx concentrations in diesel exhaust gas can be achieved in a very cost effective manner using YSZ based sensor elements combined with a pulsed discharge operation and adequate signal evaluation. Since the accuracy in NOx measurements gained with prototype sensor probes has reached a level comparable to a commercial automotive NOx probe, an even higher accuracy can been envisioned, if the sensor probes will be further improved dedicated to the requirements of the pulsed polarization.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Guth, U.; Zosel, J. Electrochemical solid electrolyte gas sensors—Hydrocarbon and NOx analysis in exhaust gases. Ionics 2004, 10, 366–377. [Google Scholar] [CrossRef]

- Siegberg, D.; Kilinc, M. Thermal and Chemical Robustness of the Smart NOx-Sensor. In Proceedings of the 12th CTI International Conference Exhaust Systems—Euro VI and Beyond—Focus on CO2 Reduction, Mainz, Germany, 28–29 January 2014. [Google Scholar]

- Kato, N.; Nakagaki, K.; Ina, N. Thick Film ZrO2 NOx Sensor. 1996. Available online: http://papers.sae.org/960334/ (accessed on 8 August 2017). [CrossRef]

- Fischer, S.; Pohle, R.; Magori, E.; Fleischer, M.; Moos, R. Detection of NO by Pulsed Polarization of Pt YSZ. Solid State Ion. 2014, 262, 288–291. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).