Abstract

As urban areas exert profound pressures on the natural environment, driving significant resource consumption and waste production, designers need to rethink the way urban projects are being developed. Therefore, this article advances the operationalization of the Circular Urban Metabolism (CUM) framework by analyzing a design case study: the Promenade Nardal in Paris. While CUM integrates the systemic material flow analysis of Urban Metabolism with the restorative strategies of the Circular Economy, it remains limited in its spatial articulation and applicability at the scale of urban design. Through a mixed-methods approach combining Life Cycle Assessment, spatial analysis, and qualitative inquiry, the article compares two circular design strategies, associated with the reuse of paving stones and the recycling of glass to produce Misapor, with conventional alternatives. Results demonstrate that stone reuse reduced CO2 emissions, energy demand, and water use, while Misapor showed energy and water advantages but slightly higher CO2 emissions due to production and transport. Beyond quantitative metrics, the study reveals the distinct design efforts and institutional frictions induced by circular practices, especially reuse, which requires adaptive aesthetics, labor-intensive design, and negotiation with technical norms. By spatializing material flows and foregrounding design agency, the article refines CUM as a situated and scalable framework, highlighting the need for context-sensitive, materially differentiated strategies in circular urban design.

1. Introduction

Urban areas exert profound pressures on the natural environment, driving significant alterations in ecosystems, accelerating resource depletion, and amplifying climate change [1,2,3]. Though cities occupy merely three percent of the Earth’s terrestrial surface, they consume approximately seventy-five percent of global natural resources and generate up to eighty percent of greenhouse gas emissions, while producing roughly half of all solid waste [4]. As a result, achieving sustainable urbanization demands a systemic understanding of resources and waste flows within cities and the development of strategies to minimize environmental footprints [5].

The concept of Urban Metabolism (UM) offers such a systemic lens and provides a metaphor conceptualizing cities as living organisms that ingest resources and expel wastes [6]. First articulated by Abel Wolman in 1965, UM frames the urban environment in terms of inputs—such as water, energy, and building materials—and outputs, including emissions, wastewater, and solid waste [7]. Some of its theoretical foundations reside within industrial ecology, pioneered in the late 1960s by physicists and engineers such as Ayres and Kneese [8]. Industrial ecology is essentially a normative project that takes ‘nature’ as a model for analyzing industrial systems [9,10]. Building on Wolman’s work on urban metabolism, Ayres [11,12] further elaborated the notion of ‘industrial metabolism,’ framing industrial systems as analogous to organisms in their capacity to process matter, energy, and waste [13]. Kennedy et al. [14] summarized subsequent work on urban metabolism as a combination of energy production and waste elimination technologies, as well as socioeconomic development within the city. In this metaphor, resource flows are analogous to metabolic pathways, enabling the quantification and mapping of urban resource use patterns through tools such as Material Flow Analysis (MFA) [15] and Life Cycle Assessment (LCA), among others [16]. By tracing these flows from extraction to end-of-life, UM facilitates the identification of intervention points to improve efficiency and reduce environmental burdens [17], while acknowledging the socio-material processes involved in urban projects [18].

Parallel to developments in UM, the Circular Economy (CE) paradigm has gained traction as an alternative to the prevailing linear “extract-produce-use-dispose” model [19]. Championed by the Ellen MacArthur Foundation [20], CE promotes a “cyclical and restorative” model of resource use that prioritizes maintaining products, components, and materials at their highest utility and value through reuse, repair, and recycling. Over time, CE frameworks have evolved to articulate hierarchies of strategies: the original “3Rs”—reduce, reuse, recycle—expanded to the “4Rs” by adding recover [21]. Following these first developments, the EU adopted a plan for building a resource-efficient Europe, introducing the Circular Economy as a key measure to tackle raw material security as part of its Europe 2020 strategy [22]. More recently, the “9Rs”—refuse, rethink, reduce, reuse, repair, refurbish, remanufacture, repurpose, recycle, and recover—enriched the CE model, each tier reflecting a diminishing preference but broader strategic scope [23]. These R-frameworks guide policy and business models toward minimizing waste and closing material loops, thereby mitigating climate impacts by reducing CO2 emissions, conserving energy, and curbing water consumption associated with material extraction and production [24].

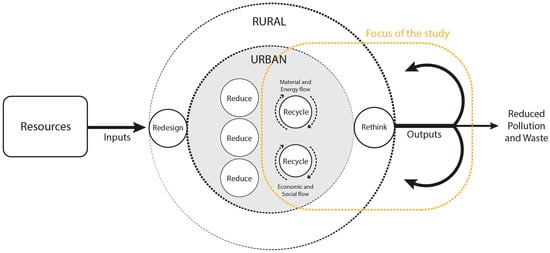

Recognizing the complementary strengths of UM and CE, Lucertini and Musco [4] introduced the Circular Urban Metabolism (CUM) framework to integrate the material-flow perspective of UM with the restorative principles of CE in practice (Figure 1). In their CUM framework, circularity entails reliance on renewable energy and material resources, as well as the systematic minimization, tracking, and eradication of waste through intentional design interventions. At the city scale, CUM rethinks and redesigns urban resource flows to prioritize reduction, reuse, and recovery, thereby enabling a cyclical and restorative urban model [25]. This hybrid approach leverages UM’s quantitative mapping of inflows and outflows with CE’s qualitative prescriptions for process redesign, offering a comprehensive methodology to guide sustainable urban planning and policy [26].

Figure 1.

Circular Urban Metabolism framework, adapted from Lucertini and Musco (2020) [4].

Despite its promise, Circular Urban Metabolism remains in its infancy and faces notable conceptual and practical limitations. One critical gap relates to its spatial dimension: most CUM studies treat the city as an isolated system, neglecting the geographic distribution and transportation routes of resource flows [27]. However, urban systems are inherently open and connected to broader regional and global networks and overlooking spatial boundaries can lead to misleading conclusions about a city’s true environmental footprint [17,28]. In addition, most interventions in urban design take place at much smaller scales—typically at the level of individual buildings, streetscapes, or public spaces—yet these meso- and micro-scale applications have not been thoroughly explored within the CUM literature. Designers working on plazas, or neighborhood projects, lack clear guidance on how to apply CUM principles to their specific contexts, as the majority of studies remain framed at the entire-city level [25,29] or are pertained to either UM or CE [30,31,32]. Moreover, existing literature rarely differentiates the metabolic impacts of distinct circular strategies—such as reuse versus recycling—across varied material types. For example, the transportation and processing requirements for reusing reclaimed stone may diverge substantially from those for recycling polymers, resulting in different CO2, energy, and water footprints that current CUM models do not adequately capture. These issues render the CUM framework less actionable for practitioners who need tailored, scale-sensitive tools to balance material flows, space constraints, and user needs in discrete urban interventions. To bridge this gap, CUM research must delve into localized analyses that align with the scope and decision-making processes of urban designers and architects.

In light of these considerations, this article proposes to respond to the calls of Lucertini and Musco and Ragazou et al. [4,27], to put the CUM framework to the test through a spatially explicit UM analysis of reuse and recycling strategies used for an existing urban design project: the Promenade Nardal in Paris, France. By leveraging LCA and qualitative research methods, the article aims to empirically compare the metabolic performances of several design scenarios using (1) virgin and reused stones for walls and paved areas and (2) new expanded polystyrene, produced through conventional means, and Misapor, an inert aggregate used for drainage layers and produced through the recycling of glass. This research, therefore, aims to discuss how material selection, transportation, and design and construction processes can enrich the theoretical foundations of CUM, and offer empirically grounded recommendations for embedding circularity in urban design.

2. Materials and Methods

2.1. The Promenade Nardal in Context

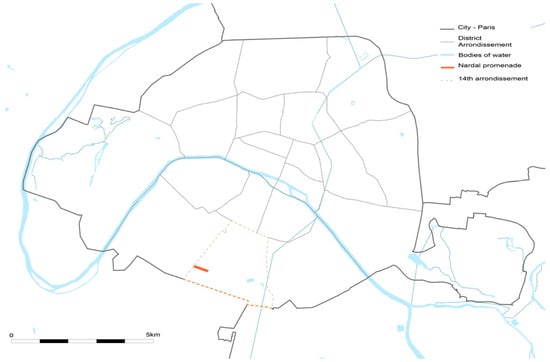

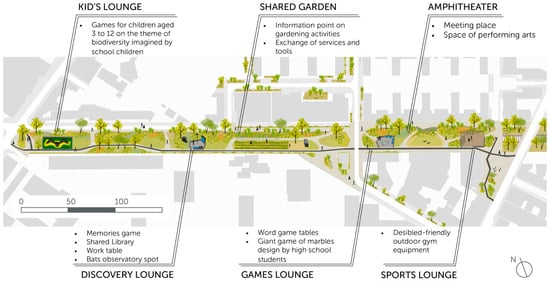

The Nardal promenade project is located in the 14th arrondissement of Paris, within the neighborhood “Plaisance portes de Vanves.” (Figure 2). This neighborhood faces several urban challenges, including a high concentration of social housing, precarious living conditions, inadequate public facilities, and spatial segregation resulting from the location of road and rail infrastructure. In this context, the promenade is part of a Parisian urban renewal strategy aimed at transforming an obsolete hospital block into a mixed-use neighborhood. Like a backbone, it unfolds over 1–2 hectares above a former railway corridor, housing a protected colony of pipistrelle bats. Its route offers a diversity of spaces (recreational, educational, sports, and urban agriculture) designed in collaboration with local stakeholders such as associations, residents, and school communities (Figure 3). Furthermore, the promenade constitutes the largest Parisian public space built, on the one hand, with reused stones, and on the other hand, with Misapor, a brand name for a type of foam glass aggregate made from 98% recycled glass and used primarily in construction and landscaping applications.

Figure 2.

Location of the Nardal promenade project in Paris.

Figure 3.

Presentation of the Nardal promenade project, Atelier NOUS.

Both these choices implied different CUM dynamics. First, to build the pathways and separating walls of the promenade’s different spaces, 1500 tons of reused stones were utilized, including 240,000 recovered pavers. These stones are exclusively sourced from local Paris city stocks, and the vast majority were destined for waste disposal. Furthermore, the dry-stone walls were manually constructed without the use of mechanical energy. The use of Misapor enabled the creation of 2000 m2 of lightweight fill above the railway tunnel, capable of supporting 23,843 new plants. It provides stable and draining support for vegetation while being reusable without treatment. In the context of the Nardal promenade, Misapor reconciles technical constraints (limited weight), environmental performance (low carbon footprint), and landscape functionality.

The study, therefore focuses on a specific series of steps associated with CUM, illustrated in Figure 1, and proposes a structured reflection around comparative design scenarios evaluating the impact of material choices on urban metabolism:

- -

- between 1500 tons of reused stones versus an equivalent supply of new materials;

- -

- between 175 tons of Misapor versus expanded polystyrene.

The study focuses on construction materials to render the CUM framework applicable at the scale of the urban project. Construction materials represent a concrete, measurable, and spatially locatable domain, providing a suitable field for testing the articulation between material flow analysis and circular strategies.

2.2. Data Collection

To analyze the various metabolic impacts of the Nardal promenade, this study draws on both quantitative and qualitative data sources.

Geometric and geographic characteristics of the materials—such as surface areas, volumes, material origins, and transport distances—were provided by the architecture and urban design agency Atelier Nous. Indicators related to CO2 emissions, energy consumption, and water use were extracted from the INIES database, managed by the Alliance HQE-GBC with the support of the French Ministry for the Ecological Transition. This database compiles environmental, health, and technical information on construction products and building equipment in accordance with the NF EN 15804 standard and its French national supplement, within the framework of Life Cycle Assessment (ISO 14040/14044) [33,34]. The data are published in the form of Environmental and Health Product Declarations (EHPD) for construction materials and Product Environmental Profiles (PEP) for technical equipment. These documents may be developed individually or collectively by manufacturers or professional trade unions. In the absence of specific declarations, average values are provided through Reference Environmental Data (RED) issued by public authorities. For this study, two EHPD (for stone paving and Misapor aggregate) and one RED (for expanded polystyrene drainage layer) were used to calculate the CO2 emissions, energy flows, and water consumption associated with the project. Distances associated with the transportation of materials were measured by our team using Google Map, except for the polystyrene drainage layer, for which we did not have a precise resource geographical origin. In that case, we took the distance value in its associated RED. Virgin stones were sourced from Anstrude, a locality situated southwest of Paris, while reused stones came from a dedicated logistics platform managed by the City of Paris and located in its suburbs; by contrast, Misapor aggregates were produced in Dagmersellen, Switzerland. All materials were transported by trucks, and carbon emission factors (gCO2/ton-km) for trucks were obtained from the Guidelines for Measuring and Managing CO2 Emissions from Freight Transport Operations by the European Clean Trucking Alliance (ECTA) [35].

Qualitative data collection was based on the project’s graphical documentation—plans, cross-sections, and photographs—obtained from the team of architects and urban designers responsible for the Nardal promenade. In parallel, site visits were conducted and informal discussions were held with these professionals to compare the quantitative data with on-site design and construction constraints, technical choices, and functional considerations identified during project implementation.

2.3. Data Analysis

The analysis employs a mixed-methods approach, combining quantitative and qualitative assessments to compare material reuse and recycling options within the context of the Nardal promenade project. This integrated methodology draws on the concept of UM to assess the impacts of material flows generated by each scenario, with a particular focus on CO2 emissions, energy consumption, and water use. This choice of environmental impacts relates to the resources generally analyzed in urban metabolism studies [7,14].

From a quantitative perspective, environmental data—specifically CO2 emissions, energy demand, and water consumption—are derived from the INIES database. Each INIES declaration presents these indicators according to Life Cycle Assessment (LCA) modules:

- -

- A1–A3 (Production phase): raw material extraction, transport to manufacturing facilities, and production processes.

- -

- A4–A5 (Construction phase): transport to the construction site and installation.

- -

- B1–B7 (Use phase): maintenance, repairs, and operational energy and water consumption.

- -

- C1–C4 (End-of-life phase): deconstruction, waste transport, and treatment processes.

- -

- D (Beyond the system boundary): recovery, recycling, and environmental credits or burdens that occur outside the studied system boundary.

System boundaries for each of the materials are as follows:

- -

- Stones: For the virgin stone scenario, we included all phases from cradle to grave (A1–A5, B1–B7, C1–C4), as given by its EHPD. For the reuse scenario, the boundary includes deconstruction (C1), re-installation (A5), and transport from storage to the site. B-modules are negligible for inert materials and set to zero. In both case scenarios, the functional unit ensures the function of 1 m2 of natural stone made of Anstrude and Bleu-de-Lignières stones, extracted from a quarry within 50 km of the project site, with a thickness of 2 cm, over a reference service life of 100 years.

- -

- Misapor: We also included all phases from cradle to grave (A1–A5, B1–B7, C1–C4), as given by its EHPD. Misapor production takes place in Switzerland, with transport distances tailored to the project context in Paris. The functional unit ensures that 1 m3 of loose lightweight backfill (non-compacted material), serving its function as lightweight backfill suitable for public works and civil engineering applications, based on a reference service life of 100 years.

- -

- Polystyrene: We also included all phases from cradle to grave (A1–A5, B1–B7, C1–C4), as given by the French State’s RED. If the geography of the boundary is not clearly indicated in the RED, it states a radius of 1000 km within the construction site, and transportation by truck without empty return. The functional unit ensures a drainage function over 1 m2 of garden roof terraces or green roofs, in the form of a rigid expanded polystyrene (EPS) board [thickness 25 to 40 mm], for a reference service life of 50 years.

Then, it is necessary to distinguish the mathematical approaches according to each scenario.

The total environmental cost of the solution related to the use of virgin stone and polystyrene is calculated by aggregating all life cycle modules from A1 to C4 (f1):

: total metabolic cost of the conventional solution, being associated either with virgin stone, polystyrene, or Misapor.

: cost in units associated with CO2 emission (kg eq CO2), energy (MJ PCI), and water (m3) consumption.

Even though Misapor is a recycled material, its production entails the same process and resources as virgin stones or polystyrene. We therefore adopted the same calculation approach, while adapting module A4 related to the transportation of the material to the project’s site, based on our own transportation distance measurements. In contrast, the “reuse” scenario involves a reduced scope, accounting only for modules and , as well as transport-related CO2 emissions (f2). The latter was obtained by measuring the transportation distances using Google Maps, and by multiplying such distances by the carbon emission factor of 62 gCO2/ton-km given by the ECTA guidelines [35]:

: total metabolic cost of the reused stones solution.

: cost in units associated with CO2 emission (kg eq CO2), energy (MJ PCI), and water (m3 consumption).

The relative benefit of reuse, denoted , is then obtained by subtracting the environmental cost of the reused solution from that of the virgin stone baseline (f3):

For the drainage layer solutions, the comparison protocol involved evaluating the full life cycle (modules A to C) for two reference materials: Misapor, derived from a recycled inert glass aggregate process, and expanded polystyrene. The recycling differential (f4), was then calculated as the difference between the environmental cost of the Misapor and that of the expanded polystyrene:

Several limitations of this analysis can be acknowledged here. First, module D was excluded from the analysis due to the difficulty of accurately integrating certain reuse-specific processes observed by the design team. In particular, for the reuse scenario, intermediate storage and potential reconditioning steps carried out at logistics platforms are not covered by the indicators provided in the INIES database. Consequently, the environmental impacts associated with additional off-site transport (e.g., detours to the platform before reaching the construction site) and with potential material reconditioning are not included in the standard LCA modules. Second, our team lacked sufficient data to quantify the manual construction energy associated with the project, particularly in relation to the wall built with reused stones. As a result, only mechanical construction energy was considered in the analysis. Third, due to limited data, we were unable to accurately assess the environmental impacts of reuse-specific processes such as storage and reconditioning. These limitations restrict the scope of the study and may result in an underestimation of the actual environmental burden of reuse. Given this constraint, the results should be interpreted as indicative rather than absolute values—useful for guiding design decisions toward more sustainable practices, while acknowledging the approximations involved.

This quantitative analysis is accompanied by diagrams based on the Baccini and Brunner [15] methodology and complements the qualitative analysis of the project. This qualitative analysis draws on graphical documentation (plans, sections, photographs) and feedback from the architect-urbanist team responsible for the Promenade Nardal. The design drawings were redrawn and spatially analyzed to identify constraints related to the integration of reused or recycled materials within the project.

In parallel, discussions with the design team allowed the numerical data to be cross-checked against the project’s operational realities. These included procedures for end-of-life stone collection and sorting, conditions for storage and reconditioning in the Île-de-France region, availability of reusable materials, mechanical compatibility of recovered elements, and the need for specialized labor.

3. Results

3.1. Quantitative Analysis

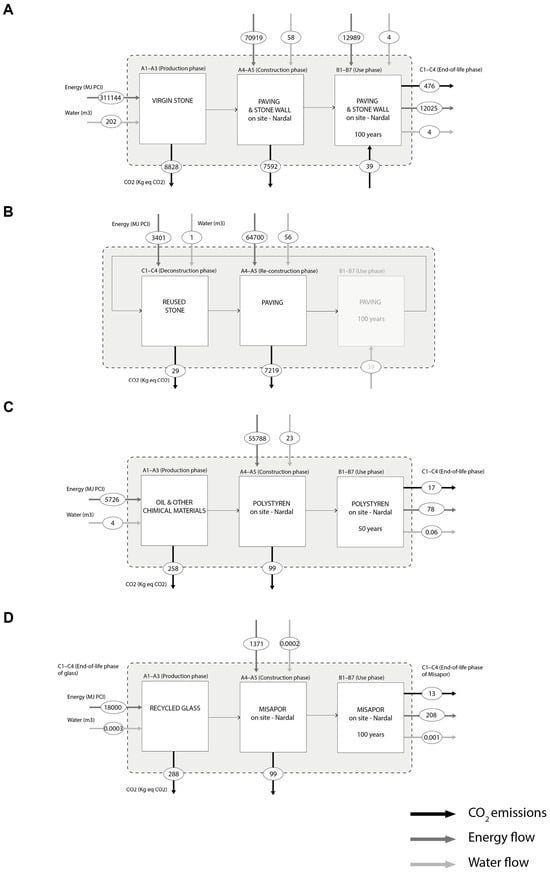

This section presents the quantified environmental performance of two CE strategies: reuse and recycling. By applying a spatially informed LCA, the environmental impacts of both strategies in terms of CO2 emissions, energy, and water consumption for each design scenario were compared (Figure 4).

Figure 4.

Metabolic analysis of the 4 scenarios. (A) For virgin stones. (B) For reused stones. (C) For polystyrene. (D) For Misapor.

The comparative LCA of stone materials demonstrated a substantial environmental advantage for the reuse scenario over the virgin-stone scenario (Table 1). Reclaimed stone yielded total CO2 emissions of 8078 kg CO2 eq, representing a 52% reduction relative to the 16,858 kg CO2 eq associated with newly quarried stone. Primary energy demand followed a similar trend: the reused material required an 83% decrease compared to the 407,079 MJ (PCI) embodied in virgin stone. Finally, water consumption was reduced from 268 m3 for new stone to 57 m3 for reclaimed stone, representing a 79% reduction. These findings confirm that, within the Île-de-France context, stone reuse can dramatically curtail carbon, energy, and water footprints when transport distances and processing steps remain limited.

Table 1.

Metabolic costs comparison between reuse and recycling scenarios.

By contrast, the comparison between conventional expanded polystyrene and Misapor aggregate revealed a more nuanced picture. Misapor exhibited slightly higher CO2 emissions—401 kg CO2 eq versus 374 kg CO2 eq for polystyrene (Δ = +26 kg CO2 eq)—due to its production processes located in Switzerland, and associated transportation. However, the recycled aggregate achieved a 68% reduction in primary energy demand and virtually eliminated water consumption (0.001 m3 vs. 28 m3). These results indicate that while Misapor’s closed-loop origin confers significant energy and water benefits, the life-cycle CO2 profile may be sensitive to logistical factors.

Overall, this spatially explicit assessment underscores that material- and context-specific conditions critically shape the metabolic performance of circular strategies. Stone reuse delivers unequivocal environmental gains across all indicators, whereas recycling outcomes depend on the balance between upstream production impacts and downstream resource savings.

3.2. Qualitative Analysis

When looking qualitatively at CUM and its impact on design, several observations can be made. The collected data show how the design process and technical constraints impact metabolism. Conversely, urban metabolism related to two circular economy strategies—reuse and recycling—requires fundamentally different design approaches.

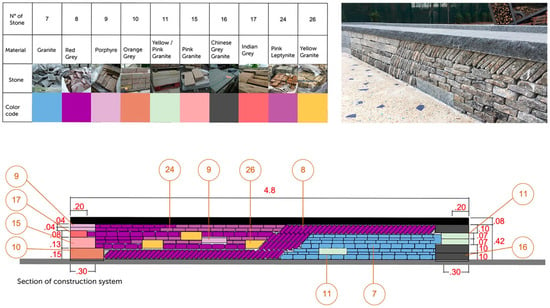

The process of reusing stone materials (Figure 5) demonstrates substantial environmental advantages. First, the project is fundamentally based on the fortuitous discovery of a deposit of eclectic stone pieces in the Paris City stocks (CMA) in Bonneuil. The design team identified 132 tons of recoverable materials composed of stone offcuts, including sandstone, granite, and other varieties from paver cutting operations, which did not require further energy and water-intensive processing. These “waste materials”—remnants from transforming 20 cm stone cubes into 8 or 12 cm pavers for Parisian roadways—represented a colossal and unexploited resource with tremendous potential for sustainable construction practices. For designers, this aberrant situation perfectly illustrates the fundamental dysfunctions of a linear economic system, where remnants of transformation using noble and durable materials are systematically sent to waste centers without consideration for their intrinsic value. Furthermore, the team chose dry stone construction, an ancestral technique that allows for the valorization of material heterogeneity. This traditional technique has the significant advantage of integrating elements of diverse dimensions, shapes, and natures in a coherent constructive logic, while being inherently ecological, requiring little energy, no additional materials, and no binder or water use. Therefore, the project’s construction phase consumes little water and energy while minimizing CO2 emissions.

Figure 5.

Reused stone process. The arrows show the flow of materials between stages A to B: The stones found at CMA are used to create a prototype, B to C: The amphitheater is constructed on site with the help of the French dry-stone federation, C to D: Construction of the amphitheater is finished, D to A: The amphitheater (D) could be disassembled and the stones could be reused.

However, using reused stones requires more energy from designers, generating additional work at each design stage. According to the designers, the remarkable diversity of stones, accumulated over decades of Parisian urban developments, constituted a considerable technical and aesthetic heritage that reflects the city’s architectural evolution, but this stone heterogeneity needed to be transformed into valuable design assets. They deliberately opposed the prevailing design modes of the “all concrete” era, where uniformity and standardization reigned supreme. This progressive stance required “inverted” and “very adaptable” design work that had to adjust to available resources rather than impose predefined specifications typical of conventional construction projects. Indeed, the comprehensive inventory of available materials is strategically placed at the heart of the conceptual approach, fundamentally altering traditional design methodologies. In this sense, for the designers of the Nardal promenade, the diversity of textures, formats, defects, and colors of stones was strategically used to develop the complete aesthetics of the project. To succeed in this ambitious undertaking, the designers had to create numerous detailed drawings so that all stone pieces could create sophisticated color games and harmonious dynamics throughout the space. Thus, all the retaining walls delimiting each space of the promenade are constructed with these reclaimed pieces and form an aesthetic whole that successfully unifies the entire project (Figure 6).

Figure 6.

Designing walls with reused stones, Atelier NOUS.

Furthermore, the use of a traditional and ancestral construction technique clashed with contemporary construction sector prejudices, dominated by industrial and normative logics. It was perceived by professionals as outdated and inefficient, creating significant resistance to adoption. This constituted an important obstacle for project implementation. Implementation also revealed deep institutional resistance to this constructive technique, manifesting at different levels of the decision chain. Despite encountering obstacles—initial refusal by the technical studies office due to insurance concerns, need for extremely precise documentation, lack of real mastery of the technique by the construction company, and necessary training by the French Dry-Stone Federation—the team transformed these challenges into valuable learning opportunities, developing a pedagogical dynamic enriching the metabolic approach of the project.

Despite these obstacles, this circular metabolism dynamic associated with stone reuse has generated significant economic and social impacts. From an economic perspective, the reutilization of stones resulted in substantial cost reductions while establishing a local circular economy framework that valorizes urban waste materials. This approach eliminated the need for quarry extraction, with its associated labor costs, and minimized material procurement expenses. Initially, the construction company had proposed an exceptionally high budget involving extraction, handling, and stone procurement from China. The reuse methodology also facilitated the creation of specialized employment opportunities in masonry, thereby contributing to the preservation and transmission of French heritage craftsmanship. From a social standpoint, the project strengthened the connection between residents and their territory by revealing the geological and architectural history of Paris through the diversity of stones utilized. This approach raised citizen awareness regarding circular economy challenges while fostering a sense of collective appropriation of public space.

Finally, these results are quite opposite to what could be observed for the design processes associated with Misapor. While the production of Misapor involved higher levels of CO2 emissions, as well as energy and water consumption (Table 1) than reused stones, it remains a “turnkey” product, which required minimal change in the conceptual process, and did not require specific implementation and construction strategies.

4. Discussion

4.1. Spatializing CUM: For a Nuanced Assessment of Reuse and Recycling Environmental Impact

The CUM framework promised a seamless integration of CE and UM principles, enabling cities to reconceptualize material and energy flows as closed-loop systems, and to guide urban planning toward resilient, low-impact futures. However, as originally noted by Lucertini and Musco [4] and subsequently emphasized by Ragazou et al. [27], the framework’s practical deployment remained challenged by its poor spatial articulation: most CUM applications continue to treat the city as an entity with vague, static boundaries, neglecting the precise geographies of resource flows and the localized contexts in which circular strategies must operate. In our study, we sought to advance the spatial dimension of CUM by focusing on two of the “9 R” of the CE model [23]—reuse and recycle—and examining how each manifests within defined urban project boundaries.

This spatialized analysis revealed that “reuse” often emerges as the more environmentally advantageous pathway, at least within the specific context of reused stones in the Paris region. Zeller and colleagues [36] highlight the techno-economic importance of matching CE initiatives to an appropriate geographic “right size,” wherein outputs from one process can be feasibly reintegrated as inputs elsewhere. Our analysis is scoped to the site-level (the Promenade Nardal and its immediate Parisian context). For the reuse scenario, we deliberately set the geographic boundary to the project area (within Île-de-France) to reflect local sources and typical transport distances. Expanding this boundary (e.g., to the entire city or region) would incorporate additional flows: longer supply routes, regional material stocks, and systemic waste loops. Conversely, contracting the boundary (e.g., only onsite) would omit upstream or downstream impacts [27]. Furthermore, the regional stone recovery center near Paris intramuros enables environmentally and economically viable reuse. Transport distances—and thus associated CO2 emissions and energy consumption—were substantially lower than those for virgin stones, which are typically sourced from more distant sites. However, the reuse pathway is not without its own hidden burdens. The reuse of stones involved intermediate steps of sorting, temporary storage, and occasional reconditioning. Crucially, these phases are not yet codified within any standardized INIES dataset, leading to a systematic under-reporting of reuse’s true metabolic cost. In other words, while our spatialized analysis shows reuse to be energetically and carbon-wise preferable, the absence of robust data for the storage and preparation stages suggests that the net environmental gains may be somewhat overstated. Accounting for these “invisible” handling operations would likely narrow the apparent advantage of reuse.

By contrast, the recycling strategy we examined demonstrated a higher metabolic footprint. Although Misapor nominally embodies the CE ideal of recycling, its production facility is located in Switzerland, which imposes significant cross-border transport distances. These long hauls dilute the circularity benefits by inflating CO2 emissions and energy consumption. Without local infrastructure, even well-intentioned recycling schemes may incur higher net emissions and resource demands than linear alternatives, as demonstrated by our comparison of CO2 emissions for the use of Misapor and expanded polystyrene. Therefore, despite closing the material loop by using Misapor, “recycling” per se does not guarantee lower metabolic impacts for all environmental indicators. The metabolic impact of expanded polystyrene is, however, higher for energy and water consumption, due to the nature of the material production processes. Our findings, therefore, suggest that material- and context-specific analyses are essential. Had we applied the same methodology to metallic elements—such as steel beams or aluminum cladding—the results might have diverged sharply, given these metals’ high embodied energies [37].

Our study also invites reflection on the larger question of scale and feasibility. Zeller et al. [36] remind us that circular loops only hold when markets reach a “critical mass,” a concept equally applicable to the spatial networks of CUM interventions. In the absence of sufficient local volume—be it stone, polystyrene, or metal—transport distances lengthen, energy costs rise, and the purported environmental benefits may be diminished. Such variability calls into question the assumption that CE strategies are universally “virtuous.” Instead, their environmental performance hinges upon three interrelated factors: resource spatial proximity, the availability of local processing and recovery facilities, and the intrinsic metabolic profile of the material itself.

4.2. Designing and Building Using CUM: A Diverse and Complex Endeavor

Faced with contemporary socio-environmental challenges, circular economy practices are progressively establishing themselves in urban design. In this sense, the European Commission has demonstrated its commitment through legislation that imposes a 70% valorization rate for construction waste [38]. This is reflected in France through the National Waste Prevention Program and the energy transition law for green growth, setting ambitious objectives to reduce construction sector waste by encouraging a circular economy. Thanks to earlier scholarly work on urban metabolism, especially on the Paris region [39,40], local development of circular economy charters and frameworks is being carried out by various public organizations such as Est Ensemble and the Greater Paris Metropolis. These documents define objectives to be achieved for urban development projects, with the goal of systematizing the use and recycling of materials. In this sense, approximately ⅔ of inert materials produced by the construction sector are now entering a reuse process [38].

However, this virtuous dynamic is accompanied by considerable challenges that question traditional design and construction methods, as well as institutional acceptance and maintenance requirements. Recent scientific research, particularly that of Knoth et al. [41], reveals that designers are forced to develop unprecedented autonomy. They must now research their own supply of reused or recycled materials, propose innovative technical experiments, and negotiate with often contradictory regulatory elements [42]. This complexity has been finely analyzed by [43], who categorizes the multiplicity of these challenges according to their nature and scales. This analysis aligns with our observations by identifying interconnected challenges concerning technical design, contextual constraints, regulatory issues, company knowledge and skills, temporalities, design aesthetics, as well as stakeholder awareness and perception. Therefore, advancing circular construction requires addressing social, technical, and material dimensions in an integrated manner. Social acceptance and institutional commitment are as decisive as technical and environmental factors. Moreau et al. [44] note that the social dimension is often overlooked in circular economy frameworks, and neglecting it limits the effectiveness of institutional reforms and the potential for higher circularity. Engaging individuals throughout the production chain, as exemplified by Berlin’s “House of Materialization,” provides a practical pathway to normalize circular practices [44,45]. Furthermore, architects must balance environmental performance with conceptual, aesthetic, and heritage requirements. Integrating reclaimed materials can reduce environmental impacts and enhance architectural quality while meeting heritage and environmental constraints, provided that implementation techniques are adapted [46]. This approach encourages an “aesthetics of imperfection,” valuing traces of prior use, and demands high conceptual adaptability [47], increasing design complexity, stakeholder negotiation, and awareness efforts. Finally, material durability remains a central consideration. In our case, stone as a material demonstrates exceptional longevity and minimal maintenance, with historical precedence for repeated reuse. Standardized tests by the Centre Technique de Matériaux Naturels de Construction [48] indicate that, with proper inspection, reused stone can match the performance of new stone. On the other hand, Misapor, being inert and rot-resistant, requires no maintenance [49]. Despite these insights, comparative studies on reclaimed and recycled material durability remain limited and call for further research. Therefore, our analysis reveals complexities in the socio-material processes of projects integrating reuse and recycling processes. These approaches require strong “conceptual adaptability”, which significantly increases workload and negotiation times, even sensitization of the various actors involved.

This study also highlights the structural fragilities of a reuse and recycling sector that is still poorly structured. Design teams had to coordinate everything: material counting, transport, etc. But this contributed to democratizing this approach at the city scale. This evolution reveals the capacity of a pilot project to transform the circular economy of a sector, but also underlines perverse effects. Today, the design team finds itself paradoxically penalized by its success, as the city now sells its reuse stocks to the detriment of its own projects. Furthermore, the particular Parisian case is not necessarily reproducible elsewhere, as other French cities do not have similar storage centers. Nevertheless, new sectors are emerging in other French regions, allowing the reuse of excavated soil for backfill or the development of storage facilities for materials from demolition sites. These sectors require new forms of solidarity between territories at institutional scales, going beyond existing construction waste management installations. It is now a question of developing innovative endeavors capable of integrating material transformation processes within local storage facilities in connection with each territorial context [38]. The benefits of reuse and recycling for local territories are manifold and largely dependent on institutional acceptance. These practices contribute to the creation of local employment, reduce material transportation costs, and foster the development of a territorial circular economy [50]. The commitment of local authorities, through incentive policies and resource-sharing mechanisms, is crucial for structuring these emerging sectors. However, this positive dynamic requires strong institutional support and coordination across different territorial levels to ensure the sustainability and effectiveness of these new construction practices.

5. Conclusions

By explicitly situating the comparative analysis of materials within the CUM framework, this study demonstrates how reuse and recycling strategies contribute to closing resource loops, reducing dependence on virgin extraction, and avoiding the generation of construction waste streams that would otherwise be landfilled or incinerated. The findings highlight that the reuse of stones embodies the most direct expression of CUM, as it prevents material downcycling and retains both the embodied energy and cultural value of resources within the urban system. Conversely, the Misapor case illustrates a more complex pathway within CUM: while it diverts glass waste from disposal and creates a functional lightweight aggregate, it also involves significant transformation processes and energy inputs, which partly re-open resource loops rather than fully closing them.

This study can also provide several guidelines for policymakers and practitioners, enabling them to design strategies using the CUM framework. Future applications of this approach should extend to a broader palette of construction materials, particularly metals and composites, whose high metabolic profiles and circularity pathways could contribute to reducing environmental impact more significantly. Furthermore, beyond conceptual and technical aspects, the success of CUM requires a profound shift in mindset and a dynamic of solidarity between territories. It is essential to foster a genuine culture of circularity and resource-sensitive design among all stakeholders in the design and construction sectors: project owners, architects, engineers, construction companies, as well as users and policymakers. This cultural transformation entails rethinking the criteria for urban design quality, embracing the aesthetic imperfections that may accompany reused materials, and valuing technical experimentation. Such a shift will help overcome current resistance and normalize circular practices in urban design. Incorporating detailed social and economic assessments—such as labor intensity, institutional acceptance, and cost implications—could also enrich the metabolic analysis by capturing the socio-material dynamics that condition the feasibility and durability of circular urban practices. Finally, this approach could be adapted to other scales to allow for a better understanding of how local loops interact with regional and global supply chains, thereby testing the scalability of the CUM framework.

Future research should also examine the deployment of human energy and consider the impact of human design activities on metabolic calculations, while developing more detailed social and economic assessments of design projects using the CUM framework. This will require innovative quantitative and qualitative analyses of a greater variety of projects, to further reduce the environmental impact of cities

Author Contributions

Conceptualization, C.D. and V.S.; methodology, C.D. and V.S.; validation, C.D., V.S., and P.D.; formal Analysis, C.D. and V.S.; investigation, C.D. and V.S.; writing—original draft preparation, C.D. and V.S.; writing—review and editing, P.D.; visualization, P.D. and Y.C.; project administration, C.D.; funding acquisition, C.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by a FACE Foundation grant, 2023.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Marshall, E.P.; Shortle, J.S. Urban Development Impacts on Ecosystems. In Land Use Problems and Conflicts; de Steiguer, J.E., Libby, L.W., Eds.; Routledge: London, UK, 2004; pp. 79–93. [Google Scholar]

- Collier, C.G. The Impact of Urban Areas on Weather. Q. J. R. Meteorol. Soc. 2006, 132, 1–25. [Google Scholar] [CrossRef]

- Ferreira, C.S.; Walsh, R.P.; Ferreira, A.J. Degradation in Urban Areas. Curr. Opin. Environ. Sci. Health 2018, 5, 19–25. [Google Scholar] [CrossRef]

- Lucertini, G.; Musco, F. Circular Urban Metabolism Framework. One Earth 2020, 2, 138–142. [Google Scholar] [CrossRef]

- Scoones, I.; Stirling, A.; Abrol, D.; Atela, J.; Charli-Joseph, L.; Eakin, H.; Ely, A.; Olsson, P.; Pereira, L.; Priya, R. Transformations to Sustainability: Combining Structural, Systemic and Enabling Approaches. Curr. Opin. Environ. Sustain. 2020, 42, 65–75. [Google Scholar] [CrossRef]

- Gandy, M. Urban Metabolism Redux. Urban Stud. 2025, 62, 1483–1511. [Google Scholar] [CrossRef]

- Wolman, A. The Metabolism of Cities. Sci. Am. 1965, 213, 178–190. [Google Scholar] [CrossRef]

- Ayres, R.U.; Kneese, A.V. Production, Consumption, and Externalities. Am. Econ. Rev. 1969, 59, 282–297. [Google Scholar]

- Jelinski, L.W.; Graedel, T.E.; Laudise, R.A.; McCall, D.W.; Patel, C.K.N. Industrial Ecology: Concepts and Approaches. Proc. Natl. Acad. Sci. USA 1992, 89, 793–797. [Google Scholar] [CrossRef]

- Frosch, R.A. Industrial Ecology: A Philosophical Introduction. Proc. Natl. Acad. Sci. USA 1992, 89, 800–803. [Google Scholar] [CrossRef]

- Ayres, R.U. Industrial Metabolism. In Technology and Environment; Ausubel, J.H., Sladovich, H.E., Eds.; National Academy Press: Washington, DC, USA, 1989; pp. 23–49. [Google Scholar] [CrossRef][Green Version]

- Ayres, R.U. Industrial Metabolism: Theory and Policy. In The Greening of Industrial Ecosystems; Richards, D.J., Allenby, B.R., Eds.; National Academies Press: Washington, DC, USA, 1994; pp. 23–37. [Google Scholar] [CrossRef]

- Newell, J.P.; Cousins, J.J. The Boundaries of Urban Metabolism: Toward a Political–Industrial Ecology. Prog. Hum. Geogr. 2015, 39, 702–728. [Google Scholar] [CrossRef]

- Kennedy, C.; Cuddihy, J.; Engel-Yan, J. The Changing Metabolism of Cities. J. Ind. Ecol. 2007, 11, 43–59. [Google Scholar] [CrossRef]

- Baccini, P.; Brunner, P.H. Metabolism of the Anthroposphere: Analysis, Evaluation, Design; MIT Press: Cambridge, MA, USA, 2023. [Google Scholar]

- Maranghi, S.; Parisi, M.L.; Facchini, A.; Rubino, A.; Kordas, O.; Basosi, R. Integrating Urban Metabolism and Life Cycle Assessment to Analyse Urban Sustainability. Ecol. Indic. 2020, 112, 106074. [Google Scholar] [CrossRef]

- Kennedy, C.; Pincetl, S.; Bunje, P. The Study of Urban Metabolism and Its Applications to Urban Planning and Design. Environ. Pollut. 2011, 159, 1965–1973. [Google Scholar] [CrossRef]

- Moss, T.; Becker, S.; Gailing, L. Energy Transitions and Materiality: Between Dispositives, Assemblages and Metabolisms. In Conceptualizing Germany’s Energy Transition; Gailing, L., Moss, T., Eds.; Palgrave Macmillan: London, UK, 2016; pp. 43–68. [Google Scholar] [CrossRef]

- Feiferytė-Skirienė, A.; Stasiškienė, Ž. Seeking Circularity: Circular Urban Metabolism in the Context of Industrial Symbiosis. Sustainability 2021, 13, 9094. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- Hom, K. Circular Economy: The 4Rs Reduce–Reuse–Recycle–Recover. IOP Conf. Ser. Earth Environ. Sci. 2024, 1402, 012042. [Google Scholar] [CrossRef]

- Barreiro-Gen, M.; Lozano, R. How Circular Is the Circular Economy? Analysing the Implementation of Circular Economy in Organisations. Bus. Strategy Environ. 2020, 29, 3484–3494. [Google Scholar] [CrossRef]

- Khaw-ngern, K.; Peuchthonglang, P.; Klomkul, L.; Khaw-ngern, C. The 9Rs Strategies for the Circular Economy 3.0. Psychol. Educ. 2021, 58, 1440–1446. [Google Scholar] [CrossRef]

- de Melo, T.A.; de Oliveira, M.A.; de Sousa, S.R.; Vieira, R.K.; Amaral, T.S. Circular Economy Public Policies: A Systematic Literature Review. Procedia Comput. Sci. 2022, 204, 652–662. [Google Scholar] [CrossRef]

- Cui, X. A Circular Urban Metabolism (CUM) Framework to Explore Resource Use Patterns and Circularity Potential in an Urban System. J. Clean. Prod. 2022, 359, 132067. [Google Scholar] [CrossRef]

- Van Broekhoven, S.; Vernay, A.L. Integrating Functions for a Sustainable Urban System: A Review of Multifunctional Land Use and Circular Urban Metabolism. Sustainability 2018, 10, 1875. [Google Scholar] [CrossRef]

- Ragazou, K.; Zournatzidou, G.; Sklavos, G.; Sariannidis, N. Integration of Circular Economy and Urban Metabolism for a Resilient Waste-Based Sustainable Urban Environment. Urban Sci. 2024, 8, 175. [Google Scholar] [CrossRef]

- Kissinger, M.; Stossel, Z. An Integrated, Multi-Scale Approach for Modelling Urban Metabolism Changes as a Means for Assessing Urban Sustainability. Sustain. Cities Soc. 2021, 67, 102695. [Google Scholar] [CrossRef]

- Fernandes, J.; Ferrão, P. Urban Metabolism-Based Approaches for Promoting Circular Economy in Buildings Refurbishment. Environments 2023, 10, 13. [Google Scholar] [CrossRef]

- Pistoni, R.; Bonin, S. Urban Metabolism Planning and Designing Approaches between Quantitative Analysis and Urban Landscape. City Territ. Archit. 2017, 4, 20. [Google Scholar] [CrossRef]

- Bortolotti, A.; Verga, G.C.; Khan, A.Z. Which Circularity for Urban Design and Planning? A Compass to Navigate Circular Economy Research Knowledge and Methods. Plan. Pract. Res. 2023, 0, 1–20. [Google Scholar] [CrossRef]

- Doussard, C.; Rowe, P.G.; Detavernier, P.; Guo, B. Metabolism and Urban Design: Insights from the Champs–Elysées, Paris. Sustainability 2024, 16, 603. [Google Scholar] [CrossRef]

- NF EN 15804; Contribution des Ouvrages de Construction au Développement Durable—Déclarations Environnementales sur les Produits—Règles Régissant les Catégories de Produits de Construction. Afnor: Saint-Denis, France, 2012.

- ISO14040/14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- ECTA. Guidelines for Measuring and Managing CO2 Emissions from Freight Transport Operations; European Chemical Industry Council & European Chemical Transport Association: Brussels, Belgium, 2011. [Google Scholar]

- Zeller, V.; Towa, E.; Degrez, M.; Achten, W.M.J. Urban Waste Flows and Their Potential for a Circular Economy Model at City-Region Level. Waste Manag. 2019, 83, 83–94. [Google Scholar] [CrossRef] [PubMed]

- Reck, B.K.; Graedel, T.E. Challenges in Metal Recycling. Science 2012, 337, 690–695. [Google Scholar] [CrossRef]

- Bastin, A. Towards a Circular Metabolism of Inert Materials Produced by Demolition and Public Works in the Paris Region: A Framework Combining Transition Thinking and a Territorial Approach. In Transition or Consolidation of the Dominant Regime: The Urban Metabolism in Question; Cahiers scientifiques internationaux Réseaux et territoires; Université Gustave Eiffel: Champs-sur-Marne, France, 2019; Volume 2, pp. 42–57. [Google Scholar]

- Barles, S. Urban Metabolism of Paris and Its Region. J. Ind. Ecol. 2009, 13, 898–913. [Google Scholar] [CrossRef]

- Barles, S. Territorial Ecology and Urban Metabolism: Some Issues at Stake in Socioecological Transition. Rev. D’écon. Rég. Urbaine 2017, 819–836. [Google Scholar]

- Knoth, K.; Fufa, S.M.; Seilskjær, E. Barriers, Success Factors, and Perspectives for the Reuse of Construction Products in Norway. J. Clean. Prod. 2022, 337, 130494. [Google Scholar] [CrossRef]

- Koźmińska, U. Circular Design: Reused Materials and the Future Reuse of Building Elements in Architecture—Process, Challenges and Case Studies. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012033. [Google Scholar] [CrossRef]

- Ghoz, L. A Multidisciplinary Categorization of Challenges of Reuse of Residential Buildings. Front. Sustain. Cities 2025, 7, 1576288. [Google Scholar] [CrossRef]

- Moreau, V.; Sahakian, M.; van Griethuysen, P.; Vuille, F. Coming Full Circle: Why Social and Institutional Dimensions Matter for the Circular Economy. J. Ind. Ecol. 2017, 21, 497–506. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017. [Google Scholar]

- Jensen, K.; Sommer, J. Building a Circular Future; GXN: Denmark, Copenhagen, 2016; 248p. [Google Scholar]

- Hebel, D.E.; Wisniewska, M.H.; Heisel, F. Building from Waste: Recovered Materials in Architecture and Construction; Birkhäuser: Berlin, Germany; Boston, MA, USA, 2014. [Google Scholar] [CrossRef]

- Sari, M.; Pestre, T. Réemploi des Matériaux de Terre Cuite ou de Pierre Naturelle Issus de la Déconstruction D’ouvrages: Retours D’expérience et Méthodologie D’accompagnement des Maîtres D’ouvrage et Maîtres D’œuvre. Construction21 France, 2022. Available online: https://www.construction21.org/france/articles/h/reemploi-des-materiaux-de-terre-cuite-ou-de-pierre-naturelle-issus-de-la-deconstruction-d-ouvrages-retours-d-experience-et-methodologie-d-accompagnement-des-maitres-d-ouvrage-et-maitres-d-oeuvre.html (accessed on 2 September 2025).

- Centre Scientifique et Technique du Bâtiment (CSTB). Avis Technique 3.3/16-910: Granulat de Verre Cellulaire MISAPOR; CSTB: Marne-la-Vallée Cedex, France, 2017; Available online: https://www.cstb.fr/pdf/atec/GS03-D/A160910.pdf (accessed on 2 September 2025).

- Pomponi, F.; Moncaster, A. Circular Economy for the Built Environment: A Research Framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).