Abstract

This paper presents research on the effects of the addition of various contents of graphene oxide and sintering temperature on the mechanical, tribological, and electrical characteristics of WC-ZrO2 composites. Wet processing and spark plasma sintering provided dense samples with simultaneous reduction of graphene oxide (rGO) during sintering. The obtained results showed that the best mechanical properties were observed at a sintering temperature of 1700 °C in samples with 0.5 vol.% rGO content; namely, indentation fracture toughness (5.8 ± 0.4 MPa·m1/2) and flexural strength (872 ± 43 MPa) increased by 9% and 24.3% compared with the sample without rGO. In addition to improved mechanical performance, rGO-reinforced composites exhibited lower wear rates and friction coefficients than non-rGO composites, due to the formation of a graphitic lubricating tribolayer on worn surfaces and counterbodies in a friction pair, which provided sufficient lubrication to reduce the coefficient of friction and wear rate. The resulting composites also showed low electrical resistivity, suggesting the possibility of using electrical discharge machining to manufacture ceramic products of complex shapes from them.

1. Introduction

The utilization of WC-Co cemented carbides is widespread in various demanding engineering applications, due to their exceptional mechanical and tribological properties [1,2,3,4,5,6,7,8]. However, their practical use as structural components requiring high temperature strength, oxidation resistance, and corrosion resistance is limited by the poor thermal stability of the cobalt (Co) binder [9,10,11]. Recently, scientists have increasingly been looking for alternatives to cobalt, due to its price volatility, toxicity, and the degeneration of its properties [12]. As a result, researchers have been focusing on the development of novel WC-based materials reinforced with ceramic phases such as zirconia (ZrO2), magnesium oxide (MgO), and alumina (Al2O3) [13,14,15,16]. These materials not only exhibit improved mechanical performance but also possess high tribological properties [17,18,19,20], making them promising for industrial applications like machining, mining, and others. The mechanical properties that have been reported for WC-ZrO2 differ depending on the composition and consolidation method used. Mukhopadhyay et al. reported that spark plasma-sintered (SPS) WC–6 wt.% ZrO2 and WC–10 wt.% ZrO2 nanocomposites showed 10.9 and 10.1 MPa·m1/2 and 1.3 and 0.9 GPa of fracture toughness and Vickers hardness, respectively [21]. Basu et al. demonstrated the dependence of fracture toughness of WC–6 wt.% ZrO2 composites on SPS temperature; values were in the range 5.6 MPa·m1/2 (1200 °C), 6.3 MPa·m1/2 (1250 °C), 5.9 MPa·m1/2 (1300 °C) [22]. In another paper, the effect of sintering temperature and time on the fracture toughness of WC–6 wt.% ZrO2 composites obtained via pressureless sintering was investigated. At temperatures of 1600 °C (3 h) and 1700 °C (1 h), the following values were obtained: 5.4 MPa·m1/2 and 4.4 MPa·m1/2, respectively [17]. Malek et al. studied the interrelationships between the dispersion of the secondary ZrO2 phase and the material properties of WC-based composites with up to 10 vol% of zirconia. The obtained fracture toughness values of the sintered composites ranged from 5.4 MPa·m1/2 (SPS temperature 1700 °C) to 6.2 (SPS temperature 1800 °C) [23]. Lancev et al. obtained a fracture toughness value of 4.4 MPa·m1/2 for WC–5 wt.% ZrO2 composites produced by the SPS method at a temperature of 1450 °C [24]. In that work [25], it was found that with the incorporation of 3 and 10 wt.% ZrO2 in the WC matrix, the fracture toughness values of SPS composites at 1600 °C were 7.4 and 8.7 MPa·m1/2, respectively.

Nevertheless, like many ceramic composites, WC–ZrO2 has some disadvantages, including low fracture toughness and flexural strength [26,27]. Thus, it is crucial to enhance these properties. Additionally, the processing of ceramic composites presents challenges due to their high hardness, making conventional mechanical methods impractical. Therefore, there is a need to explore new sintering methods and investigate approaches to reinforce ceramic composites. It is known that grain size directly affects the mechanical properties of the resulting products. To avoid undesirable grain growth, spark plasma sintering (SPS) technology was chosen as the method of consolidation. This method utilizes pulsed direct current along with simultaneous application of pressure to the material. Its primary technical advantages lie in the high speed of heating and cooling, enabling a reduction in processing time through the concurrent application of mechanical pressure and electrical impulses. This innovative approach enhances process efficiency and improves material processing quality. By synchronously applying pressure and electrical impulses, a more uniform distribution of heat across the material being processed is achieved, minimizing potential deformations and surface damage. Additionally, this method boasts high energy efficiency and cost-effectiveness as it reduces electricity and equipment expenses. These features make it highly appealing for industrial applications where material processing speed and quality are crucial. In recent years, the discovery of graphene has generated considerable interest due to its small size, unique two-dimensional structure [28], and excellent thermal [29], mechanical [30] and tribological properties [31]. Graphene oxide (GO) is considered more advantageous than graphene for the formulation of ceramic suspensions, owing to its capability for homogeneous dispersion within a liquid medium. In the subsequent process of spark plasma sintering conducted under vacuum conditions, graphene oxide undergoes reduction to form reduced graphene oxide (rGO). The thermal reduction of GO in sintered samples has been extensively validated in previous research using Raman spectroscopy [32,33,34,35,36]. Despite the fact that rGO has inferior properties compared with pure graphene, its higher availability and lower price are great advantages for industry. Due to the presence of oxygen-containing functional groups, rGO becomes more hydrophilic than pure graphene, enhancing the densification process during sintering and the rGO–matrix interface. Additionally, rGO is still characterized by high thermal and electrical properties. The authors of the present research have previously published articles in which the addition of graphene oxide to the ceramic matrix was shown to improve the mechanical and tribological properties [37,38,39] of sintered samples [40,41]. The addition of graphene oxide to the ceramic matrix also increases its electrical conductivity, enabling the processing of workpieces using electrical discharge machining (EDM). This eliminates the need for mechanical machining in the sample preparation process, which, as mentioned earlier, is nearly impossible when working with this class of materials.

In the present work, WC–ZrO2 composites were chosen as the ceramic matrix due to their potential mechanical and tribological applications. The aim of this study was to obtain WC–ZrO2 composites with varying (0.25 vol.%, 0.5 vol.%, 1 vol.%) graphene oxide (GO) content. Characteristics such as density, hardness, indentation fracture toughness, and flexural strength were investigated for the sintered samples, and the tribological properties were tested under different loads in a ball-on-disk experiment. The investigation revealed the dependencies of the mechanical and tribological properties on the sintering temperature and GO content. Optimal sintering conditions and graphene oxide content were identified.

2. Materials and Methods

2.1. Graphene Oxide Preparation

The production of graphene oxide from graphite powder utilized a modified Hummers method. Further elaboration on this process can be found in prior publications [42,43]. For this study, commercially sourced graphite powder (Plasmotherm, Moscow, Russia) with a median particle size d50 = 3 mm was employed.

2.2. Powder Processing and Sintering

Commercial t-ZrO2 (3Y-TZP, 3 mol% Y2O3; TZ-3YS-E, Tosoh Corp., Tokyo, Japan) and WC (Plasmotherm, Moscow, Russia) with average sizes 0.20 μm and 1.5 μm, respectively, were used in this work. The content of the powder mixture was 94 wt.% of WC and 6 wt.% ZrO2. The required quantity of powders was placed into a plastic receptacle along with ZrO2 balls (3 mm in diameter) and distilled water. The obtained mixture was wet mixed via ball mill (ML-1, Kaluga, Russia) for 24 h at 150 rpm and subsequently dried in a vacuum oven VO 400 (Memmert, Büchenbach, Germany) for 24 h. In order to achieve compositions with the specified graphene oxide content, the material was incrementally added to the suspensions and subsequently stirred for a duration of 1 h. Thereby, WC-ZrO2 powders with GO content of 0.25 vol.%, 0.5 vol.%, and 1 vol.% were prepared and labeled as 0.25-G, 0.5-G, and 1-G, respectively. The powder blends were subjected to sintering using an H-HP D 25 SD Spark Plasma Sintering machine (FCT Systeme GmbH, Rauenstein, Germany) under vacuum across a temperature range of 1600–1900 °C in 100 °C increments, with a heating rate of 100 °C/min and a pressure of 80 MPa. The holding time when the maximum sintering temperature was reached was 3 min. The manufactured samples had a diameter measuring 20 mm and were 3 mm in height. Thermal reduction of the GO occurred during sintering. In this study, the resulting carbon material following consolidation is denoted as reduced graphene oxide (rGO). WC-ZrO2 composites without the addition of GO (0-G) were used as reference samples.

2.3. Microstructural Characterization

Scanning electron microscopy (SEM) characterization of the sintered samples was carried out by VEGA 3 LMH (Tescan, Brno, Czech Republic). Prior to analysis, the samples underwent polishing with diamond slurries featuring grit sizes spanning from 9 μm to 1 micrometer, using a Tegramin 30 (Struers, Ballerup, Denmark) polishing machine and diamond suspensions. Following the polishing process, the samples underwent a 15 min ultrasound bath in ethanol and were subsequently dried with compressed air.

2.4. X-Ray Diffraction (XRD) and Raman Characterization

XRD analysis (Empyrean diffractometer, PANalytical, Almelo, The Netherlands, Cu-Kα radiation, wavelength 1.5405981 Å, accelerating voltage 60 kV, beam current 30 mA) of the sintered samples was conducted in step scanning mode at 2-theta diffraction angles ranging from 25 to 80 (step size 0.05). The Raman analysis was conducted using a Raman analyzer DXRTM2 (Thermo Fisher Scientific, Waltham, MA, USA), employing a 532 nm laser with a power output of 2.0 mW to examine the graphene-based mixtures and composites. This process involved the use of a 50× optical microscope objective to concentrate the laser beam onto the designated area, resulting in a 2 μm spot, with an accumulation time of approximately 10 s [44].

2.5. Density and Mechanical Properties Characterization

The sintered sample density (ρ) was determined in distilled water by employing Archimedes’ principle and was subsequently contrasted with the theoretical value computed in accordance with the rule of mixtures. The theoretical densities of the powder mixtures were calculated according to the rule of mixtures, using densities of 15.63 g/cm3 for WC and 6.05 g/cm3 for ZrO2, measured using an AccuPyc II 1340 helium pycnometer, (Micrometrics, Norcross, GA, USA). The density of graphene was assumed to be 2.2 g/cm3. Vickers hardness (Hv) was assessed on polished surfaces utilizing a Vickers diamond indenter (QNess A10 Microhardness Tester, Salzburg, Austria) with a 1 kg load and an indentation period of 10 s. To estimate the hardness values, the equation presented in previous works was used [39]. The reported values represent the average values of the data obtained from ten indentation tests. The Vickers indentation fracture toughness (K1C) was determined using formulas proposed by Miranzo and Moya [28]. The flexural strength (σf) was assessed using a biaxial bending test, where each sample was positioned on a device with three 3 mm hardened steel balls arranged at 120° angles on a 10 mm diameter holder. The load was applied with an AutoGraph AG-X universal testing machine (Shimadzu Corp., Kyoto, Japan), utilizing a 1.6 mm diameter plain head at a speed of 1 mm/min−1 until failure occurred. The specimen’s thickness was measured at the point of fracture. The strength value was determined by averaging the data obtained from testing 10 sintered disks of each composition, following the strength calculation equation outlined in a previous study [45].

2.6. Measurement of Electrical Resistance

Electrical conductivity was assessed by employing an RLC-78105G high-frequency meter (Good Will Instrument Co., Ltd., New Taipei City, Taiwan) across the frequency spectrum spanning from 20 Hz to 5 MHz. In order to ensure consistent electrical connection between the samples and the device electrodes, silver-based conductive adhesive Rexant Kontaktol-Avto (SDS-Group, Putilkovo, Russia) featuring a specific electrical resistance of 0.0 Ohm mm2 was utilized on the polished surfaces.

2.7. Wear Test Set-Up and Conditions

The tribological behavior of composites was investigated on a Ducom POD 4.0 tribometer (Ducom Instruments, Bangalore, India) according to the requirements of ASTM G99-23 [46], using the “ball-on-disk” scheme. The linear velocity and friction path were 0.1 m/s and 1 km, respectively. An alumina ball (Al2O3) with a diameter of 6 mm was used as a counterbody. The applied load (FN) was 10 or 15 N. Before each wear test, the specimens were washed with ethanol in an ultrasonic cleaner for 15 min and dried with compressed air. The tests were performed under conditions. The wear rate (W) was calculated using the following equation:

where ΔV is the volume loss of the specimen after testing (mm3), FN is the applied load (N), and S is the friction path (m). The volume loss of the specimens was measured using 3D images of the wear path profile, which were obtained using a Talysurf CLI 500 profilometer (Taylor Hobson, Leicester, UK). The average roughness (Ra) of the worn surface after the wear test was analyzed at five different points.

3. Results and Discussion

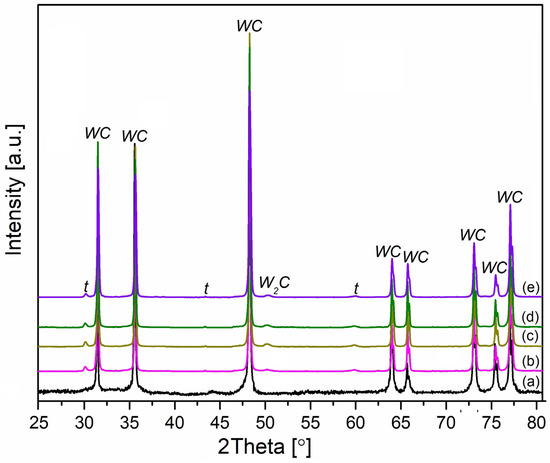

Figure 1 shows the X-ray diffraction patterns of the powder mixture and sintered compositions.

Figure 1.

X-ray radiographs of 1-G powder (a), 0-G (b), 0.25-G (c), 0.5-G (d) and 1-G (e) samples sintered at 1700 °C. “t” denotes tetragonal zirconia.

Analysis indicated that zirconia and WC were the main phases in all the studied samples, without the presence of any impurities. However, it was found that during the SPS processing of samples with graphene oxide, a small amount of W2C was formed (Figure 1c,e). Since only WC and ZrO2 were detected in the initial powder with the highest GO content (Figure 1a), we assume that the formation of W2C occurred as a result of the sintering reaction of compositions with graphene oxide. The peaks of reduced graphene oxide were not visible, due to its low content. The presence of a monoclinic phase of zirconia in the WC–ZrO2 powder was noted, along with its complete transformation into a tetragonal phase in the sintered samples. This suggested the presence of a t→m transformation toughening mechanism in the sintered samples.

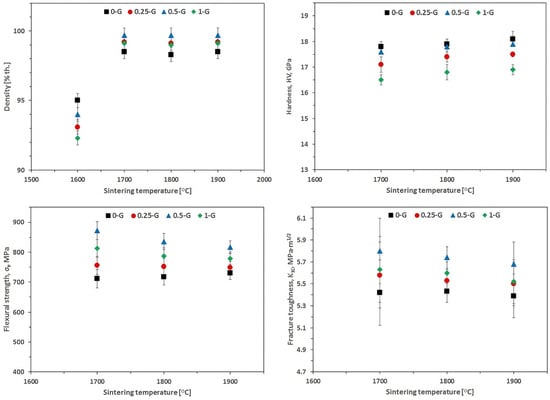

The relative density of the composites was then calculated as the ratio of bulk density to theoretical density. The density values (Figure 2) indicated that all the compositions were almost able to achieve full theoretical compaction (98.5–99.7%) by spark plasma sintering at all selected temperatures except the lowest. Therefore, the mechanical properties of the materials sintered at the lowest temperature were not further studied.

Figure 2.

Density and mechanical properties of all the studied specimens. The standard deviations of all measured values are presented in Appendix A.

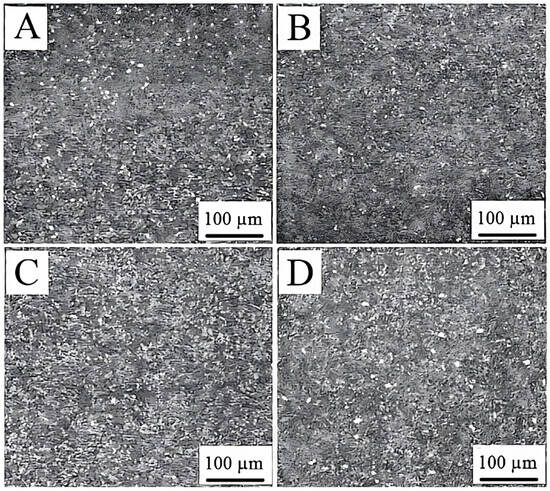

Figure 3 shows the microstructures of studied samples with different graphene oxide content sintered at 1700 °C. In the figure, white and dark phase represent ZrO2 and WC, respectively. The presence of closed pores can also be noted. The SEM micrographs indicate the homogeneous distribution of ZrO2 in the matrix.

Figure 3.

SEM images of 0-G (A), 0.25-G (B), 0.5-G (C) and 1-G (D) samples sintered at 1700 °C.

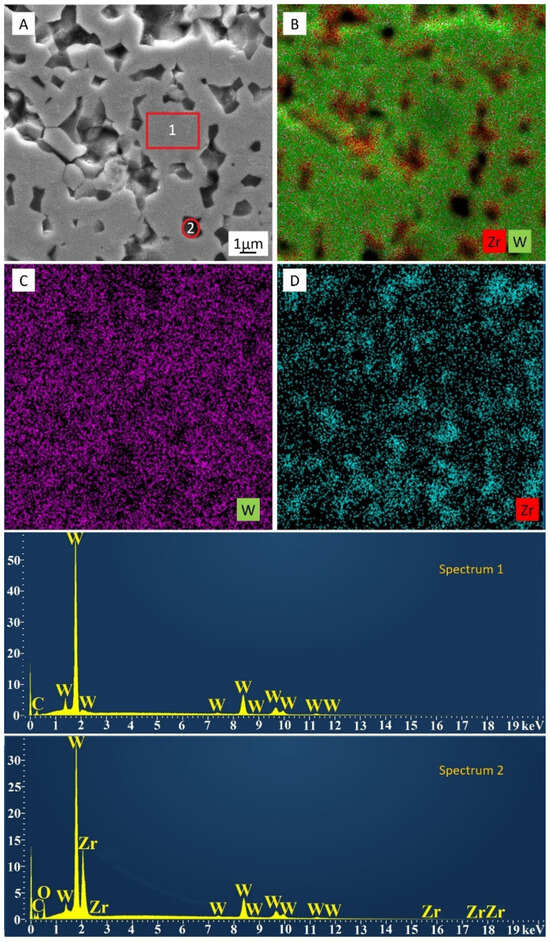

Figure 4 presents SEM images with EDS mapping, including distribution of basic (W and Zr) elements and spectra acquired from two points on the polished surface of the 0.5-G composite sintered at 1700 °C. Figure 4A shows the microstructure of the sintered composite, consisting of a matrix, inclusions, and sections of chips incurred during sample preparation. It can be seen that the basis of the material (matrix) was tungsten, inside of which there were inclusions of Zr (Figure 4B). These inclusions were evenly distributed in the microstructure of the matrix (Figure 4C,D).

Figure 4.

Representative SEM image of polished surface of 0.5-G composite sintered at 1700 °C (A), SED-EDS elemental map (B), and elemental mapping of W (C) and Zr (D). EDS spectra obtained at two points marked with figures on a polished surface.

The average contents of constituents in all samples were approximately as follows: W—84.75 wt.%, Zr—5.64 wt.%, C—6.29 wt.%, and O—3.33 wt.%. The content calculation was performed automatically using Aztec 2.0 software (Oxford Instruments, High Wycombe, UK), employing an EDS detector, based on counting the numbers of quanta with specific energies emitted by the atoms of the elements. The reported values represent the average concentrations of elements in the studied area, with a confidence interval of σ ≤ 0.3% by mass. The investigation was conducted on a polished surface, with an accelerating voltage of 20 kV to excite all characteristic lines of the elements. Due to the presence of light elements (carbon) in the composition, the results were semi-quantitative, which was sufficient for reliable comparison of samples against each other and for conclusions to be drawn about concentration changes and ongoing processes. However, these results may have been less reliable for determining absolute concentrations. In this context, the significance of deviations was lower. Since all samples were prepared and studied under identical conditions, the results were taken as reliable.

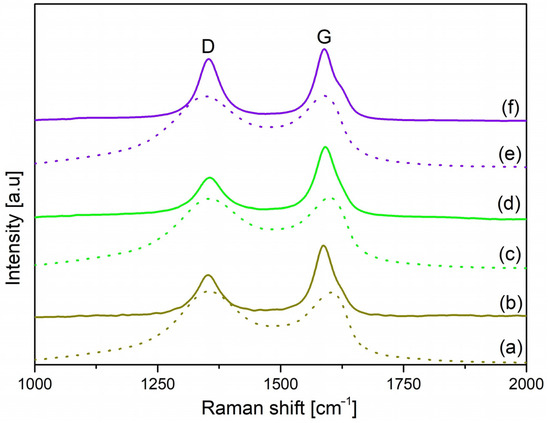

Figure 5 illustrates Raman spectra for powder mixtures and SPS composite samples prepared at 1700 °C with different rates of rGO loading.

Figure 5.

Raman spectra of powder mixtures (dot lines) and (solid lines) composites sintered at 1700 °C containing 0.25 vol.% (a,b), 0.5 vol.% (c,d), and 1 vol.% (e,f) GO, respectively. “D” and “G” denote GO peaks.

The wide G peak and slight second-order area in the spectra of the powder mixtures are features of sp1, sp2, and sp3 hybridized C-C bonds in graphene [47], and the D band (~1350 cm−1) indicates structural flaws such as lattice deformation [48]. Raman spectra for sintered composites show that GO was reduced in situ during spark plasma sintering. This is substantiated by the decline in the intensity ratio between the D and G bands (ID/IG). In the raw powder mixtures, the intensity ratios were measured to be 1.02, 0.97, and 0.98 for 0.25, 0.5, and 1 vol.% GO, respectively. However, in the sintered composites, the ID/IG values decreased to 0.38 and 0.50 for 0.5 and 1 vol.% rGO, respectively. This decrease indicates a lower level of defects in the rGO present in the thermally treated samples. Biaxial flexural strength, indentation fracture toughness, and Vickers hardness of the samples as a function of rGO content and sintering temperature is presented in Figure 2. All values represent averages of five measurements. Both the flexural strength and fracture toughness initially increased and then decreased with the increase in rGO content. As expected, the sample with 0.5 wt.% rGO showed the highest values for fracture toughness (5.8 ± 0.4 MPa·m1/2) and flexural strength (872 ± 43 MPa) among all the studied composites. Compared with WC–ZrO2 composites without addition of graphene oxide, the percentage increases for strength and fracture toughness in the 0.5-G composite were reported as 24.3% and 9%, respectively.

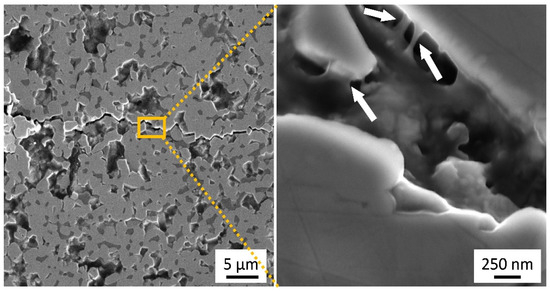

It has been stated in other sources [39,45,49,50,51] that small amounts (0.1–0.5 vol.%) of graphene can improve the mechanical properties of the matrix, while it is difficult to achieve good dispersion of high graphene content within the composite. The Vickers hardness of composites containing graphene oxide was slightly affected by the presence of rGO. The obtained hardness values were similar to that reported for the composite without GO, with the exception of the 1-G sample. This was due to the aggregation of a higher concentration of graphene in the composite matrix. Figure 6 shows the Vickers indentation cracks induced on the surface of the 0.5-G sample sintered at 1700 °C. The presence of rGO in the sintered composites created opportunities for deflection of cracks and bridging, which in turn increased the toughness of the material. In the picture, the crack is deflected and does not pass directly through the grains of tungsten carbide or zirconia. This pattern of crack propagation was typical of all the samples obtained during this study.

Figure 6.

Vickers indentation cracks induced on the surfaces of 0.5-G sample sintered at 1700 °C, under low (left) and high (right) magnification. The white arrows illustrate the presence of rGO in the microstructure.

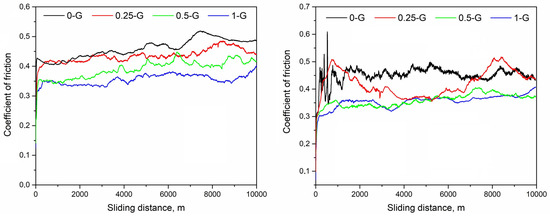

Figure 7 shows the dependence of the friction coefficient (COF) on the distance travelled, for loads of 10 N (left) and 15 N (right). Under the low load (Figure 7, left), all materials tested exhibited similar behavior. This can be explained by the fact that this load was insufficient for the appearance and formation of a protective tribolayer on the worn surfaces, which would have reduced the coefficient of friction and wear. At the same time, under the higher load (Figure 7, right), the behavior of the materials was different. Samples without rGO and with minimal rGO content showed higher values for their coefficient of friction, especially in the first meters. The friction coefficient underwent a rapid rise during the initial meters of sliding before subsequently declining. Following this early phase, the variations in the friction coefficient curves diminished, with a slight increase observed for the remainder of the testing period. This pattern was attributed to the polishing effect that occurred during the wear test, which resulted in a smoother surface on the wear track by eradicating surface asperities and roughness irregularities. On the other hand, composites with higher content of graphic structures had smoother friction coefficient curves. This may have been due to the presence of graphene plates adhering to the friction surface and forming a self-lubricating layer that provided sufficient lubrication to reduce both the wear rate and the coefficient of friction.

Figure 7.

Dependence of coefficient of friction on distance under 10 N (left) and 15 N (right) loads, for all studied composites sintered at 1700 °C.

From the surface topographies of the 3D wear tracks, the volume losses were estimated and wear rate was calculated using Equation (1). These results are summarized in Table 1.

Table 1.

Wear rate values under two loads, for all studied composites sintered at 1700 °C.

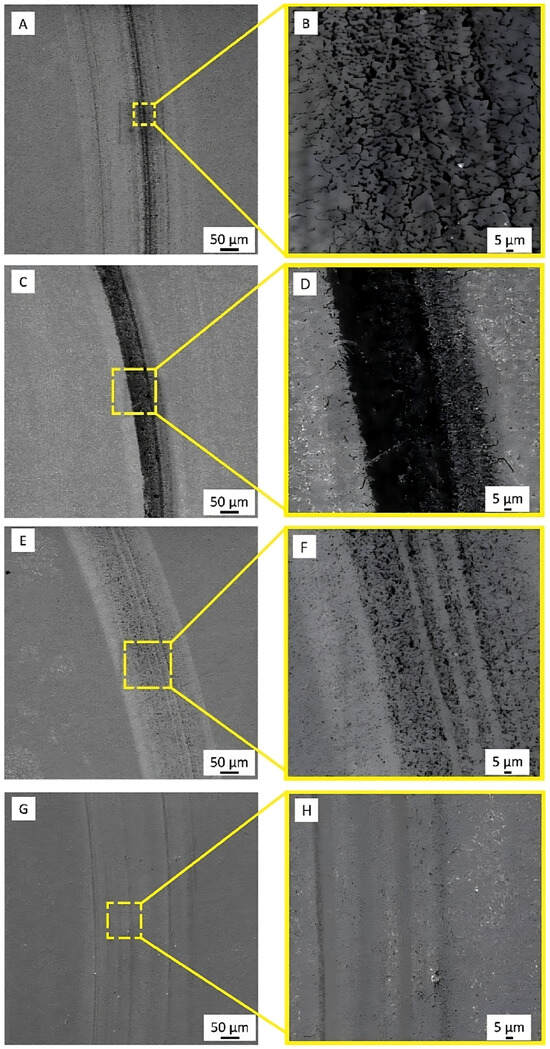

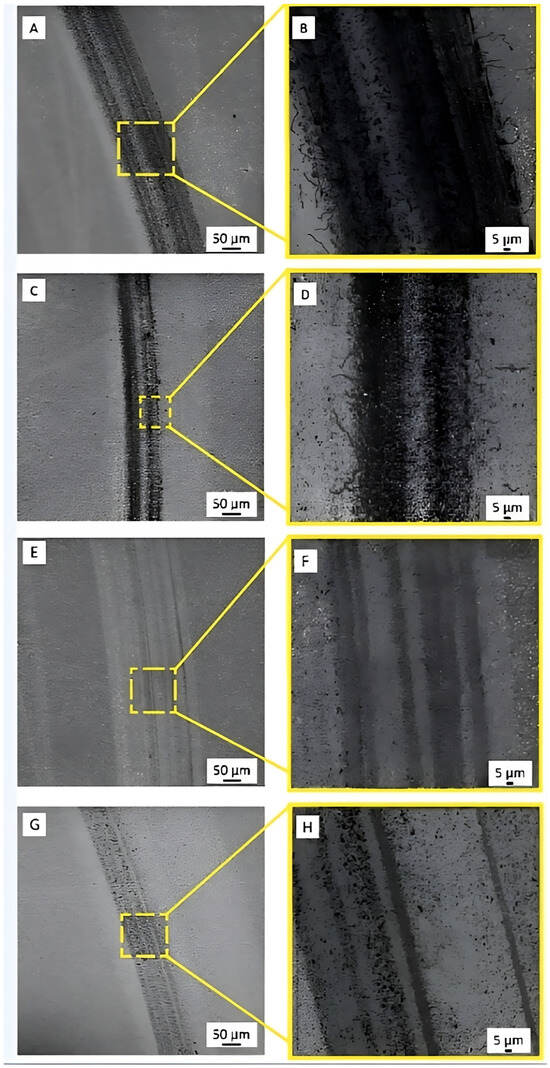

It can be seen from Table 1 that the wear rate decreased with increasing content of reduced graphene oxide. In addition, the wear rates of the graphene composites under a load of 15 N were lower than under a load of 10 N. Probably, for the studied materials, the applied load of 15 N served as an activating factor for graphene adaptation and formation of an auto-lubricating layer of graphene in the composites, which provided sufficient lubrication between the specimen and the alumina ball that acted as the counterpart material. Figure 8 shows the wear tracks of all studied composites under load of 10 N. As for the samples without additives (Figure 8A,B), it was observed that the track’s formation was due to a greater extent to abrasive wear when a layer of matrix material was present in the form of abrasive microscopic particles. In addition, the image includes a noticeable stripe in the center of the track, which was formed due to simultaneous abrasive and fatigue wear. As we know, more pressure is concentrated at the point of contact between the ball and the plane, which leads to cyclic wear. The close-up of this part of the worn surface confirms the fact that abrasion and fatigue wear occurred at the center of the track. Among the materials investigated, this material had the highest wear rate (Table 1) and coefficient of friction (Figure 7, left).

Figure 8.

SEM micrographs of the worn surfaces of 0-G (A,B), 0.25-G (C,D), 0.5-G (E,F), and 1-G (G,H) composites sintered at 1700 °C, under a load of 10 N.

Figure 8C,D shows the friction track of the 0.25-G specimen. Here, as in the case of the previous sample, a central track was formed from simultaneous abrasive and fatigue wear. Abrasive wear zones were noted on the sides of this track. Compared with the 0-G material, a 10% reduction in the wear rate and 13.3% reduction in the coefficient of friction were observed. Figure 8E,F shows the friction track of the 0.5-G specimen, with marks of abrasive wear across the width of the track. Despite the abrasive wear mechanism, the graphitic structure was able to adapt well to these conditions and its presence prevented intense material loss. Doubling the volume amount of rGO content resulted in 15% and 5% reductions in wear rate compared with the 0-G and 0.25-G composites, respectively. Figure 8G,H show the friction track of the 1-G sample, with shallow abrasion marks across the width of the track. The enlarged image of the wear track area shows that localized fatigue wear spots were present, but these were few. The presence of 1 vol.% reduced graphene oxide content in the material resulted in decreases of 32%, 24%, and 20% in wear rate compared with 0-G, 0.25-G, and 0.5-G, respectively. The worn surface of the 0-G composite under a 15 N load is presented in Figure 9A,B. It is evident that the track formation was predominantly influenced by abrasive wear, where microscopic abrasive particles were formed from the degradation of the matrix material. The tribosurface analysis also indicated the presence of adhesive wear in addition to abrasive wear. The combined effect of these wear mechanisms led to a wear rate value and friction coefficient of 17.8 × 10−9 mm3/N·m and 0.49, respectively, the highest among all the materials tested under either load. It was noted that abrasion occurred up to 1500 m, characterized by the penetration of abrasive particles leading to abrupt spikes in the friction coefficient. Once the friction track aligned with the profile of the ball (irregularities having been removed), the penetration of abrasive particles between the contacting surfaces became difficult, which stabilized the coefficient of friction without sudden fluctuations. Analysis of the worn surface on the 0.25-G sample under a load of 15 N (Figure 9C,D) indicated wear caused by a combination of abrasive and adhesive factors, leading to a wear rate of 7.16 × 10−9 mm3/N·m, 59% less than the wear rate of 0-G at 15 N and 50% less than the wear rate of the same material at 10 N. In addition, a decrease in the coefficient of friction by 10.6% compared with the 0-G samples was also noted. This decrease in the wear rate was directly related to the presence of reduced graphene oxide in the material. Probably, a load of 15 N was enough to form a graphitic tribolayer in the contact zone between the ball and the sample. Figure 9E,F shows the tribosurface of the 0.5-G sample at 15 N, with both adhesive and abrasive wear marks and abrasion marks along the entire width of the trace.

Figure 9.

SEM micrographs of the worn surfaces of 0-G (A,B), 0.25-G (C,D), 0.5-G (E,F) and 1-G (G,H) composites sintered at 1700 °C, under a load of 15 N.

An increase in the graphitic content to 0.5 vol.% led to a significant decrease in the wear rate, by 72% compared with the 0-G material at 15 N, and a significant reduction in the wear rate, by 65% compared with the same composition at 10 N. Figure 9G,H show the friction trace of the 1-G sample at 15 N, with polished shallow abrasion marks along the entire width of the track. Compared with the other samples, the enlarged image of the wear track shows local marks of fatigue wear, but these are few. The highest content of rGO in the material led to a decrease in the wear rate by 82% compared with 0-G at a load of 15 N, and by 78% compared with the wear rate of the same composition at a load of 10 N.

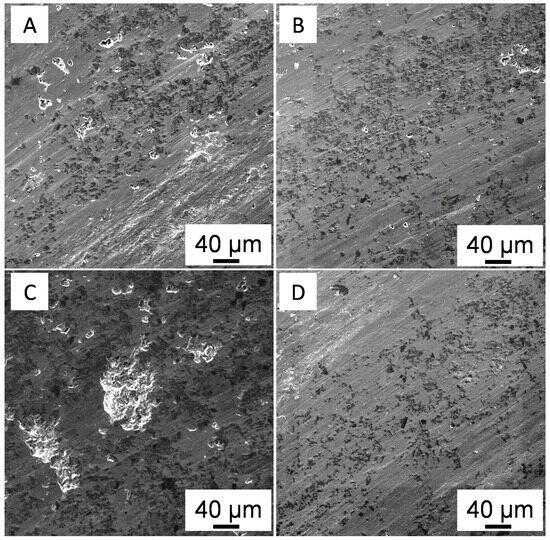

Figure 10 shows the worn surfaces of the alumina ball after tribological tests.

Figure 10.

The worn surfaces of an alumina ball sliding against 0-G (A,C) and 0.5-G (B,D) composites sintered at 1700 °C, under a load of 10 N (A,B) and 15 N (C,D).

After testing the 0-G and 0.5-G composites under a load of 10 N (Figure 10A and Figure 10B, respectively), the wear ball surfaces for each were relatively smooth. Areas with longitudinal grooves and adhered material from the composites were observed. Unlike the previous surfaces, those exposed to the wear test under 15 N had a completely different appearances from each other. The ball surface after the wear test with the 0.5-G composite (Figure 10D) was smoother compared with the one tested with the 0-G composite (Figure 10C) under the same conditions. All four surfaces showed longitudinal ploughing indicating abrasive wear of the surface during testing. This occurred because WC particles are much harder than alumina, which is why the abrasive mechanism arises. In addition, the presence of spalling on the worn surfaces was observed, except for surface used for testing the 0.5-G composite at 15 N. However, larger and deeper spalls were found only in the 0-G composite tested under a load of 15 N. These spalls were the result of subsurface fatigue, which caused fractures to form on the ball surface. After the spalls formed, they were removed from the ball surface due to the atomic bonding forces arising from the sample surface. Moreover, according to Figure 10A, the higher the applied force during testing, the larger was the size of the spalls. On the other hand, spalls were not present when the 0.5-G composite was tested at 15 N. This can be explained by the formation of a self-lubricating graphene layer between the ball and sample surfaces. It can be assumed that the effect of the self-lubricating graphene layer became apparent when the applied force was of the required value. In this study, it was noticeable that at 15 N, the graphene-based tribolayer was sufficiently compacted, thus providing enough lubrication for protection of the surfaces. However, when a force of 10 N was applied, the self-lubricating graphene layer was not compacted enough and attached to the surface of the ball; thus, its effective operation was not manifest. In this regard, the formation of several spalls can be observed in Figure 10B. Thus, based on the above observations, it can be said that the wear of the ball surfaces occurred due to the combined effects of abrasive, adhesive, and fatigue wear, except for the 0.5-G composite at 15 N, where abrasive wear was the primary active mechanism.

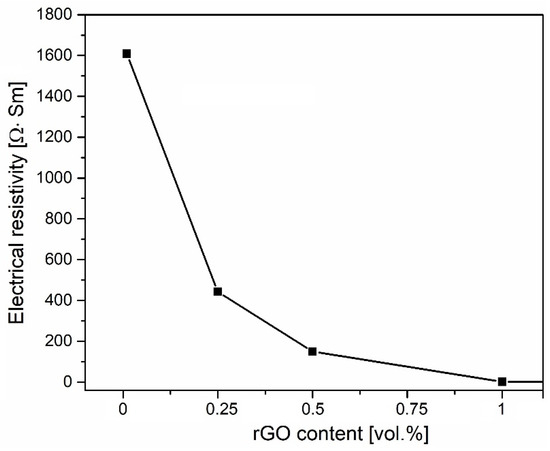

Figure 11 shows the dependence of the electrical resistivity of composites sintered at 1700 °C on the concentration of rGO. The composition without rGO exhibited extremely high resistivity. However, even with an rGO content of 0.5 vol.%, there was a significant decrease in resistivity (below 300 Ω·cm−1) [39,45], indicating the suitability of these samples for electrical discharge machining. This confirms that the simple introduction of 0.5% rGO was sufficient to create conductive pathways within the non-conductive matrix. As the rGO content increased further, the electrical resistance of the samples decreased.

Figure 11.

The change in electrical resistivity of samples sintered at 1700 °C depends on the content of rGO.

The increase in rGO content led to more inter-sheet bonds, thereby enhancing conductivity along the a–b planes; during spark plasma sintering, the a–b planes are oriented perpendicular to the applied pressure. Utilizing carbon nanotubes to produce composites has a significant drawback: their tendency to form agglomerates, hindering point-to-point contact. This heterogeneity contributes to a decline in the electrical conductivity of such composites. Conversely, the presence of rGO facilitates the formation of “area-to-area” contact among lamellated graphene particles. As a result, closely adjacent and interconnected carbon networks with high conductivity are formed, leading to reduced electrical resistivity. Furthermore, the thermal reduction of GO eliminates oxygen-containing groups and increases the material’s specific surface area, resulting in greater electron mobility and the formation of conductive pathways, thereby improving electrical conductivity.

4. Conclusions

WC–ZrO2 composites containing 0.25, 0.5, and 1 vol.% GO were fabricated using wet mixing and the SPS technique at four (1600, 1700, 1800, and 1900 °C) sintering temperatures. The lowest temperature did not enable the materials to achieve high theoretical density values. Thermal reduction of graphene oxide during sintering was confirmed by Raman spectroscopy. The effects of sintering temperature on density, hardness, flexural strength, and indentation fracture toughness were studied. It was found that the addition of 0.5 vol.% graphene oxide to the matrix was associated with an increase in the mechanical properties of the obtained materials, such as indentation fracture toughness (5.8 ± 0.4 MPa·m1/2) and flexural strength (872 ± 43 MPa), which increased by 9% and 24.3% compared with the sample without rGO. This mechanical upgrade occurred mainly due to the crack deflection and bridging reinforcement mechanisms in the composites with added graphene oxide. However, no significant improvement in the Vickers hardness of WC-ZrO2-rGO composites was observed. On the contrary, the hardness values of composites without rGO were slightly higher than those of materials with rGO; as a softer phase, it contributed to a decrease in hardness [52].

The addition of GO to the matrix significantly increased the wear resistance of the composites. The reason for this behavior may have been the presence of a self-lubricating graphene layer that provided sufficient lubrication between the sample and the aluminum oxide ball. However, it should be noted that at a load of 15 N, the lubricating effect was more noticeable than at a load of 10 N. Additionally, results suggest that the presence of graphene in sintered composites makes them suitable for processing using electrical discharge machining technologies, to make production process more economical and faster.

Author Contributions

Conceptualization, Y.P. and N.W.S.P.; methodology, A.S. and Y.P.; software, P.P. and Y.M.; validation, N.W.S.P., Y.P. and A.S.; formal analysis, P.P. and Y.M.; resources, S.G. and M.V.; data curation, Y.P., Y.M. and P.P.; writing—original draft preparation, Y.P. and N.W.S.P.; writing—review and editing, A.S. and N.W.S.P.; visualization, P.P. and M.V.; supervision, S.G.; project administration, A.S. and N.W.S.P.; funding acquisition, S.G. and M.V. All authors have read and agreed to the published version of the manuscript.

Funding

The research was financially supported by the Ministry of Science and Higher Education of the Russian Federation (project No. FSFS-2023-0003).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

This work was carried on the equipment of the Collective Use Center of MSUT “STANKIN” (project No. 075-15-2021-695).

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

The values of the physico–mechanical properties of all studied compositions sintered at different temperatures.

Table A1.

The values of the physico–mechanical properties of all studied compositions sintered at different temperatures.

| Sintering Temperature, °C | 0-G | 0.25-G | 0.5-G | 1-G |

|---|---|---|---|---|

| Density, %th. | ||||

| 1600 | 95.0 ± 0.5 | 93.1 ± 0.5 | 94.0 ± 0.5 | 92.3 ± 1.5 |

| 1700 | 98.5 ± 0.5 | 99.2 ± 0.5 | 99.7 ± 0.5 | 99.1 ± 0.5 |

| 1800 | 98.3 ± 0.5 | 99.1 ± 0.5 | 99.7 ± 0.5 | 99.0 ± 0.5 |

| 1900 | 98.5 ± 0.5 | 99.2 ± 0.5 | 99.7 ± 0.5 | 99.1 ± 0.5 |

| Hardness, HV, GPa | ||||

| 1600 | - | - | - | - |

| 1700 | 17.8 ± 0.2 | 17.1 ± 0.3 | 17.6 ± 0.1 | 16.5 ± 0.2 |

| 1800 | 17.9 ± 0.1 | 17.4 ± 0.2 | 17.8 ± 0.3 | 16.8 ± 0.3 |

| 1900 | 18.1 ± 0.3 | 17.5 ± 0.1 | 17.9 ± 0.1 | 16.9 ± 0.2 |

| Flexural strength, σf, MPa | ||||

| 1600 | - | - | - | - |

| 1700 | 711.0 ± 30 | 756.0 ± 30 | 872.0 ± 30 | 813.0 ± 30 |

| 1800 | 718.0 ± 27 | 751.0 ± 27 | 835.0 ± 27 | 787.0 ± 27 |

| 1900 | 730.0 ± 21 | 748.0 ± 21 | 817.0 ± 21 | 779.0 ± 21 |

| Fracture toughness, K1C, MPa·m1/2 | ||||

| 1600 | - | - | - | - |

| 1700 | 5.42 ± 0.3 | 5.58 ± 0.3 | 5.8 ± 0.3 | 5.63 ± 0.3 |

| 1800 | 5.43 ± 0.1 | 5.53 ± 0.1 | 5.74 ± 0.1 | 5.6 ± 0.1 |

| 1900 | 5.39 ± 0.2 | 5.5 ± 0.2 | 5.68 ± 0.2 | 5.52 ± 0.2 |

References

- Katiyar, P.K.; Singh, P.K.; Singh, R.; Kumar, A. Modes of failure of cemented tungsten carbide tool bits (WC/Co): A study of wear parts. Int. J. Refract. Metals Hard Mater. 2016, 54, 27–38. [Google Scholar] [CrossRef]

- Cramer, C.L.; Aguirre, T.G.; Wieber, N.R.; Lowden, R.A.; Trofimov, A.A.; Wang, H.; Yan, J.; Paranthaman, M.P.; Elliot, A.M. Binder jet printed WC infiltrated with pre-made melt of WC and Co. Int. J. Refract. Metals Hard Mater. 2019, 87, 105137. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Fedorov, S.V.; Hamdy, K. Materials, properties, manufacturing methods and cutting performance of innovative ceramic cutting tools—A review. Manufact. Rev. 2019, 6, 19. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Kuzin, V.V. Prospects for tools with ceramic cutting plates in modern metal working. Glass Ceram. 2011, 68, 253–257. [Google Scholar] [CrossRef]

- Pristinskiy, Y.; Peretyagin, N.; Solis Pinargote, N.W. Comparative studies on mechanical properties of WC-Co composites sintered by SPS and conventional techniques. MATEC Web Conf. 2017, 129, 0202. [Google Scholar] [CrossRef]

- He, J.; Schoenung, J.M. A review on nanostructured WC–Co coatings. Surf. Coat. Technol. 2002, 157, 72–79. [Google Scholar] [CrossRef]

- de Villiers Lovelock, H.L. Powder/Processing/Structure Relationships in WC-Co Thermal Spray Coatings: A Review of the Published Literature. J. Therm. Spray Technol. 1998, 7, 357–373. [Google Scholar] [CrossRef]

- Shao, G.; Duan, J.R.; Xie, X.; Yu, X.; Zhang, W.; Yuan, R. Sintering of nanocrystalline WC-Co composite powder. Rev. Adv. Mater. Sci. 2003, 5, 281–286. [Google Scholar]

- Park, C.; Kim, J.; Kang, S. Effect of cobalt on the synthesis and sintering of WC-Co composite powders. J. Alloys Compd. 2018, 766, 564–571. [Google Scholar] [CrossRef]

- Huang, S.; Vanmeensel, K.; Van Der Biest, O.; Vluegels, J. Sintering, thermal stability and mechanical properties of ZrO2-WC composites obtained by pulsed electric current sintering. Front. Mater. Sci. 2011, 5, 50–56. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, J.; Gong, F.; Ni, X.; Li, Z. Development and application of WC-based alloys bonded with alternative binder phase. Crit. Rev. Solid State Mater. Sci. 2018, 44, 211–238. [Google Scholar] [CrossRef]

- Xia, X.; Li, X.; Li, J.; Zheng, D. Microstructure and characterization of WC-2.8wt% Al2O3-6.8wt% ZrO2 composites produced by spark plasma sintering. Ceram. Int. 2016, 42, 14182–14188. [Google Scholar] [CrossRef]

- Zheng, D.; Li, X.; Li, Y.; Qu, S.; Yang, C. ZrO2 (3Y) toughened WC composites prepared by spark plasma sintering. J. Alloys Comp. 2013, 572, 62–67. [Google Scholar] [CrossRef]

- Radajewski, M.; Schimpf, C.; Krüger, L. Study of processing routes for WC-MgO composites with varying MgO contents consolidated by FAST/SPS. J. Eur. Ceram. Soc. 2017, 37, 2031–2037. [Google Scholar] [CrossRef]

- Oh, S.J.; Kim, B.S.; Yoon, J.K.; Hong, K.T.; Shon, I.J. Enhanced mechanicalproperties and consolidation of the ultra-fine WC–Al2O3 composites using pulsed current activated heating. Ceram. Int. 2016, 42, 9304–9310. [Google Scholar] [CrossRef]

- Kuzin, V.V.; Fedorov, S.Y.; Grigoriev, S.N. Features of Al2O3–TiC-Ceramic specimen edge morphology formation during diamond grinding. Refract. Ind. Ceram. 2017, 58, 319–323. [Google Scholar] [CrossRef]

- Basu, B.; Venkateswaran, T.; Sarkar, D. Pressureless sintering and tribological properties of WC–ZrO2 composites. J. Eur. Ceram. Soc. 2005, 25, 1603–1610. [Google Scholar] [CrossRef]

- Ouyang, C.; Zhu, S.; Li, D.Y. Experimental and simulation studies on the solid-particle erosion of WC-MgO composites. Tribol. Lett. 2013, 52, 501–510. [Google Scholar] [CrossRef]

- Ouyang, C.; Zhu, S.; Li, D.Y. Corrosion and corrosive wear behavior of WC–MgO composites with and without grain-growth inhibitors. J. Alloys Comp. 2014, 615, 146–155. [Google Scholar] [CrossRef]

- Su, Q.; Zhu, S.; Ding, H.; Bai, Y.; Di, P. Effect of the additive VC on tribological properties of WC-Al2O3 composites. Int. J. Refract. Metals Hard Mater. 2018, 75, 111–117. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Chakravarty, D.; Basu, B. Spark Plasma-Sintered WC-ZrO2-Co Nanocomposites with High Fracture Toughness and Strength. J. Am. Ceram. Soc. 2010, 93, 1754–1763. [Google Scholar] [CrossRef]

- Basu, B.; Lee, J.H.; Kim, D.Y. Development of WC-ZrO2Nanocomposites by Spark Plasma Sintering. J. Am. Ceram. Soc. 2004, 87, 317–319. [Google Scholar] [CrossRef]

- Malek, O.; Lauwers, B.; Perez, Y.; De Baets, P.; Vleugels, J. Processing of ultrafine ZrO2 toughened WC composites. J. Am. Ceram. Soc. 2009, 29, 3371–3378. [Google Scholar] [CrossRef]

- Lantsev, E.A.; Nokhrin, A.V.; Boldin, M.S.; Smetanina, K.E.; Blagoveshchenskii, Y.V.; Isaeva, N.V.; Murashov, A.A.; Chuvil’deev, V.N.; Terentev, A.V.; Tabachkova, N.Y. Preparation of Ultrafine-Grained WC–ZrO2 Ceramics by Spark Plasma Sintering. Inorg. Mater. 2023, 59, 537–543. [Google Scholar] [CrossRef]

- Golub, A.V.; Semenov, O.V.; Gurtovoy, V.N. Nanostructural Composites in the WC/ZrO2 (Y2O3) System. Key Eng. Mater. 2019, 822, 298–303. [Google Scholar] [CrossRef]

- Liang, Z.; Liu, X.; Zhao, Z.; Lu, H.; Wang, H.; Liu, C.; Wang, M.; Song, X. Enhancing hardness and toughness of WC simultaneously by dispersed ZrO2. Mater. Sci. Eng. A 2023, 870, 144905. [Google Scholar] [CrossRef]

- Venkateswaran, T.; Sarkar, D.; Basu, B. Tribological Properties of WC-ZrO2 Nanocomposites. J. Am. Ceram. Soc. 2005, 88, 691–697. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385. [Google Scholar] [CrossRef]

- Zhai, W.; Srikanth, N.; Kong, L.B.; Zhou, K. Carbon nanomaterials in tribology. Carbon 2017, 119, 150–171. [Google Scholar] [CrossRef]

- Grigoriev, S.; Smirnov, A.; Pinargote, N.W.S.; Yanushevich, O.; Kriheli, N.; Kramar, O.; Pristinskiy, Y.; Peretyagin, P. Evaluation of mechanical and electrical performance of aging resistance ZTA composites reinforced with graphene oxide consolidated by SPS. Materials 2022, 15, 2419. [Google Scholar] [CrossRef] [PubMed]

- Porwal, H.; Grasso, S.; Mani, M.K.; Reece, M.J. In situ reduction of graphene oxide nanoplatelet during spark plasma sintering of a silica matrix composite. J. Am. Ceram. Soc. 2014, 34, 3357–3364. [Google Scholar] [CrossRef]

- Xia, H.; Zhang, X.; Shi, Z.; Zhao, C.; Li, Y.; Wang, J.; Qiao, G. Mechanical and thermal properties of reduced graphene oxide reinforced aluminum nitride ceramic composites. Mater. Sci. Eng. A 2015, 639, 29–36. [Google Scholar] [CrossRef]

- Rincón, A.; Moreno, R.; Chinelatto, A.S.A.; Gutierrez, C.F.; Rayón, E.; Salvador, M.D.; Borrell, A. Al2O3-3YTZP-Graphene multilayers produced by tape casting and spark plasma sintering. J. Am. Ceram. Soc. 2014, 34, 2427–2434. [Google Scholar] [CrossRef]

- Broniszewski, K.; Wozniak, J.; Cygan, T.; Kostecki, M.; Moszczynska, D.; Chmielewski, M.; Dydek, K.; Olszyna, A. Effect of Anisotropy of Reduced Graphene Oxide on Thermal and Electrical Properties in Silicon Carbide Matrix Composites. Nanomaterials 2024, 14, 555. [Google Scholar] [CrossRef]

- Centeno, A.; Rocha, V.G.; Alonso, B.; Fernández, A.; Gutierrez-Gonzalez, C.F.; Torrecillas, R.; Zurutuza, A. Graphene for tough and electroconductive alumina ceramics. J. Am. Ceram. Soc. 2013, 33, 3201–3210. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, M.; Jin, L.; Li, L.; Mo, Y.; Su, G.; Tian, Y. Recent advances in friction and lubrication of graphene and other 2D materials: Mechanisms and applications. Friction 2019, 7, 199–216. [Google Scholar] [CrossRef]

- Nyholm, N.; Espallargas, N. Functionalized carbon nanostructures as lubricant additives—A review. Carbon 2023, 201, 1200–1228. [Google Scholar] [CrossRef]

- Tomanik, E.; Christinelli, W.; Souza, R.M.; Oliveira, V.L.; Ferreira, F.; Zhmud, B. Review of Graphene-Based Materials for Tribological Engineering Applications. Eng 2023, 4, 2764–2811. [Google Scholar] [CrossRef]

- Meleshkin, Y.; Solis, W.; Smirnov, A. Influence of graphene oxide content on the wear resistance of zirconia toughened alumina composites consolidated by spark plasma sintering. High Temp. Mater. Processes 2023, 28, 81–91. [Google Scholar] [CrossRef]

- Smirnov, A.; Peretyagin, P.; Bartolomé, J.F. Processing and mechanical properties of new hierarchical metal-graphene flakes reinforced ceramic matrix composites. J. Eur. Ceram. Soc. 2019, 39, 3491–3497. [Google Scholar] [CrossRef]

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Botas, C.; Perez-Mas, A.M.; Alvarez, P.; Santamaria, R.; Granda, M.; Blanco, C.; Menendez, R. Optimization of the size and yield of graphene oxide sheets in the exfoliation step. Carbon 2013, 63, 576–578. [Google Scholar] [CrossRef]

- Grigoriev, S.; Peretyagin, P.; Smirnov, A.; Solís, W.; Díaz, L.A.; Fernández, A.; Torrecillas, R. Effect of graphene addition on the mechanical and electrical properties of Al2O3-SiCw ceramics. J. Eur. Ceram. Soc. 2017, 37, 2473–2479. [Google Scholar] [CrossRef]

- Miranzo, P.; Moya, J.S. Elastic/plastic indentation in ceramics: A fracture toughness determination method. Ceram. Int. 1984, 10, 147–152. [Google Scholar] [CrossRef]

- ASTM G99-23; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2023.

- Guo, H.L.; Wang, X.F.; Qian, Q.Y.; Wang, F.B.; Xia, X.H. A green approach to the synthesis of graphene nanosheets. ACS Nano 2009, 3, 2653–2659. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef]

- Fan, Y.; Jiang, W.; Kawasaki, A. Highly conductive few-layer graphene/Al2O3 nanocomposites with tunable charge carrier type. Adv. Funct. Mater. 2012, 22, 3882–3889. [Google Scholar] [CrossRef]

- Liu, J.; Yan, H.; Jiang, K. Mechanical properties of graphene platelet–reinforced alumina ceramic composites. Ceram. Int. 2013, 39, 6215–6221. [Google Scholar] [CrossRef]

- Wang, K.; Wang, Y.; Fan, Z.; Yan, J.; Wei, T. Preparation of graphene nanosheet/alumina composites by spark plasma sintering. Mater. Res. Bull. 2011, 46, 315–318. [Google Scholar] [CrossRef]

- Nieto, A.; Huang, L.; Han, Y.H.; Schoenung, J.M. Sintering behavior of spark plasma sintered alumina with graphene nanoplatelet reinforcement. Ceram. Int. 2015, 41, 5926–5936. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).