Abstract

When accompanied by a rigorous in-depth risk assessment and management, the introduction of innovative technologies in underground construction activities can substantially contribute to the overall quality and the health and safety of workers. The aim of this study is to investigate the potential improvements resulting from the use of emerging systems within this challenging environment, in the current context of technological development. The results, obtained through an analysis of the available literature on the topic, are divided based on their characteristics into support in design, Industry 4.0 context, management phase, and personal systems. Next, we discuss the results of some field tests of different emerging technologies drawn from experience gained in TELT—Tunnel Euralpin Lyon Turin SAS construction sites. The literature review and the feedback from practical applications in some case histories provide an overview of the main technologies and trends for the improvement of Occupational Safety and Health, although a fully integrated system still seems a distant prospect in underground construction sites. This study can contribute to the dissemination of the culture of safety and stimulate further research on the topic.

1. Introduction

The effectiveness of the contribution of innovative technologies for the improvement of Occupational Safety and Health—OS&H in all production sectors has been widely discussed by numerous authors (e.g., [1,2]: a proper management of these aspects cannot today disregard technological progress, which is exponentially revolutionizing work and life scenarios. In particular, the concept is explored in specific studies on the application of technologies that can be traced as a whole to the various applications of Industry 4.0, databases, and the Internet of Things—IoT (based on the concepts of Cyber Physical System—CPS, in which connected devices, Cloud Storage Systems—CSS, and Application Systems—AP, are combined to implement an intelligent production process). In particular, not only system innovation, but also a radical change in the very figure of the underground worker can be expected [3,4,5].

The “Advanced robotics, artificial intelligence and the automation of tasks: definitions, uses, policies and strategies and Occupational Safety and Health” document published by the European Agency for Safety and Health at Work [6] constitutes a basic reference on the subject. Based on a bibliographic review of 183 titles selected through three separate systematic literature searches, with rigorous representativeness criteria, the paper summarizes an up-to-date point of view on systems based on artificial intelligence, human–robot interaction and task automation (cognitive and physical). The unavoidable need for OS&H risk assessment and management consistent with the changed scenario and thus characterized in particular by ever-increasing predictive insight is clearly underlined. Moreover, this is not an easy task, as expressed in ISO 31000:2018—Risk management-Guidelines [7], “The purpose of risk analysis is to understand the nature of the risk and its characteristics, including the level of risk. Risk analysis involves a detailed consideration of uncertainties, sources of risk, consequences, probability, events, scenarios, controls and their effectiveness. An event may have multiple causes and consequences and may affect multiple objectives”.

In the specific field of underground construction, the realization of large infrastructure works can refer to organizational models, advanced techniques and technologies, specialized personnel, surveillance and rescue systems, and to the widespread use of information technology, which overall make construction sites safer and healthier. Even today, however, the fundamental step to achieve further improvements in OS&H is the development and dissemination of an adequate “culture of safety”, which should be integrated into the design and management of operations, to support and govern the continuous updating of available techniques and technologies [8].

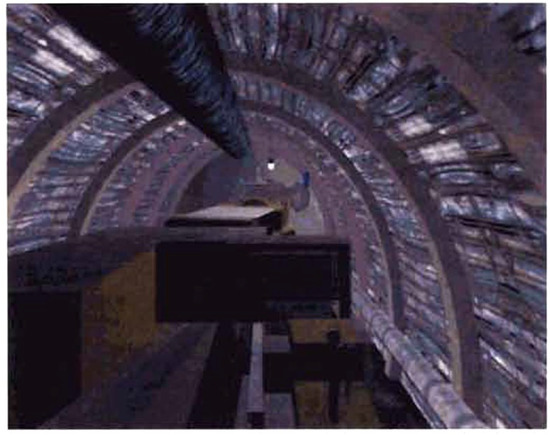

Underground construction sites certainly constitute a complex scenario (Figure 1) whose risks, which are also complex, require a system approach, due to the possible criticalities linked both to the nature and characteristics of the formations to be crossed, and to the excavation activities themselves. Typically, we should consider the presence of relatively restricted operating spaces with a high concentration of high-powered vehicles, the use of iterative work cycles and reduced excavation execution times, interacting operations in the same place, etc., which make it imperative to plan and schedule the activity with precision, taking into account the safety of workers. These issues are intertwined with aspects of occupational hygiene, becoming particularly critical in the case of excavation in the presence of harmful substances (asbestos, quartz, radioactive substances, etc.), bearing in mind that underground living conditions (lighting, air exchange, communications, water pumping, etc.) must be managed in a hierarchically logical approach: it follows that a design is necessary that takes due account of these aspects and to prepare dedicated technical and plant engineering countermeasures consistent with both normal operating and emergency conditions, the availability of which must be clearly determined [9,10].

Figure 1.

Underground construction site as a challenging work environment.

Understanding the complexity of such a scenario is crucial for the selection of the appropriate risk assessment and management method and/or techniques, a current reference being the ISO/IEC 31010:19 risk management–risk assessment techniques [11]. (The mentioned ISO and ISO/CEN standards cover general system risks and not only OS&H aspects, but in the prevention through design—PtD [12,13,14,15], and quality safety management approach [16,17], they can be a useful reference in the present case).

This study aims to “take stock” of the spread, use, OS&H implications, and the prospects for future dedicated development of the various emerging technologies that may be realistically foreseeable and applicable for the purpose of improving performance quality and safety also in the context of underground construction activities, starting with large infrastructure works that may constitute a starting point for the dissemination of a new “culture of safety”, and to provide some examples of practical applications activated in the TELT—Tunnel Euralpin Lyon Turin SAS construction sites, which has proposed itself from the beginning of its activity as a supporter of virtuous forms of innovation [18].

2. Materials and Methods

This research identified the main OS&H improvements through innovative technologies in underground construction sites to provide an overview of this topic, identifying main trends and discussing some case histories.

The study was carried out in two distinct directions:

- analysis of available literature on technological and organizational innovations capable of improving OS&H conditions in underground construction sites;

- critical discussion of some applications of the techniques and technologies highlighted above, mainly at TELT construction sites under development.

2.1. Analysis of the Literature

Based on the specific literature, a bibliographical study on the current situation was developed, and the search was conducted using the methods outlined in Table 1.

Table 1.

Bibliographic search process.

After defining the problem and the reasons for investigation, the scientific literature related to the subject was examined through the Scopus database.

The keywords used for the search were defined to include studies about underground construction sites, technological innovation, and occupational safety.

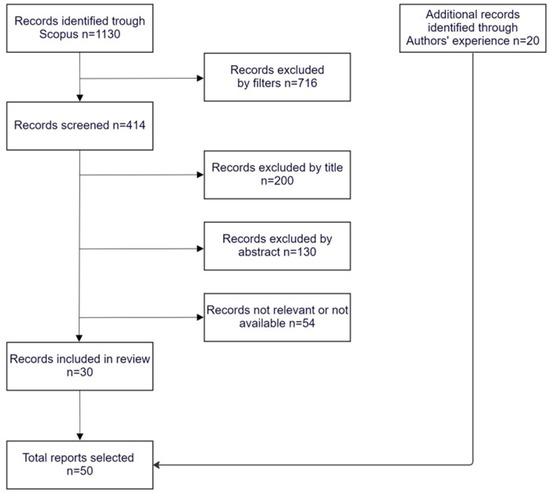

A total of 1130 records were identified (Figure 2). Since only one database was used, it was not necessary to use automated tools to eliminate any duplicates.

Figure 2.

Bibliographic search flowchart.

Subsequently, 716 records were eliminated through automatic filters because they did not comply with the inclusion criteria of publication date, language, document type, keywords limitations, and subject area. Studies strictly concerning coal mines were also excluded.

We manually screened 414 records, excluding 200 studies based on the title, then 130 based on the abstract, and ultimately 54 based on the full text, where available, because they were considered not relevant.

Finally, 30 articles were deemed pertinent to the research topics.

In addition, 20 records from the authors’ experiences were identified in order to discuss critically some test cases on the basis of the literature.

In conclusion, a total of 50 articles were included in the survey.

The aforementioned literature was supplemented by additional publications, international standards, and reports deemed appropriate for this study, all appropriately cited in the bibliographical references.

Criteria for Ascribing Results to Predefined Categories

The results considered to be consistent with the objective of the investigation were further processed with a breakdown into the following categories, which were also defined taking into account indications found in the literature [21]:

- Support in design: general design and specific operations with BIM, CAD 3D approaches, virtual simulations of future operations to optimize efficiency and workers health and safety;

- Industry 4.0: applications and potential of Industry 4.0 techniques, databases, and the Internet of Things in mining and underground construction;

- Management phase: system efficiency and quality management to reduce the probability of deviation and autonomous trigger corrective actions: stationary and mobile vehicles and equipment can now be fully or partially automated through geolocation, in-depth monitoring of operating parameters, and external interference detection;

- Personal systems for improvement of prevention through wearable technologies, smart PPE, workload reduction, virtual reality applications to support Information, Formation, Training—IFT.

2.2. The TELT Construction Sites, a Field of Experimentation of Practical Examples of the Innovative Techniques and Technologies Discussed

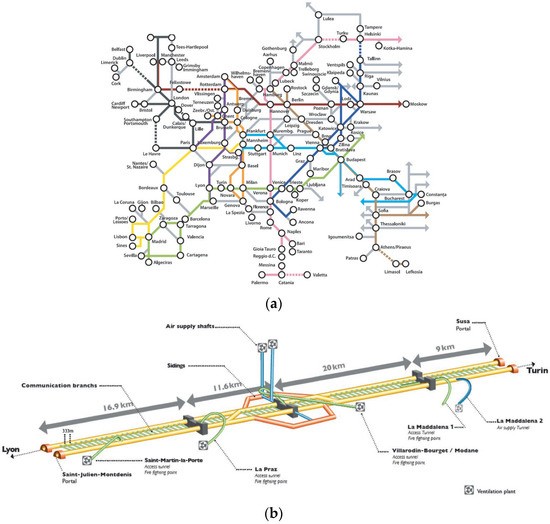

The Lyon–Turin is a new railway line for freight and passengers that stretches 270 km, 70% of which is in France and 30% in Italy. It constitutes the central link in the Mediterranean Corridor, one of the nine axes of the European TEN-T transport network, which stretches 3000 km connecting seven EU corridors from east to west (Figure 3).

Figure 3.

(a) Mont Cenis base tunnel; (b) Functional diagram of the tunnel.

The line is divided into three sections:

- the shared cross-border section between Italy and France, from Susa (Piedmont) to Saint-Jean-de-Maurienne (Savoie), under the responsibility of the French–Italian public promoter TELT, whose main work is the 57.5-km-long Mont Cenis base tunnel, currently under construction;

- the Italian part, from the Turin hub to Bussoleno (Susa Valley), under the responsibility of RFI;

- the French part, from Saint Jean de Maurienne to Lyon, under the responsibility of SNCF.

The cross-border section of the Lyon–Turin line is 65 km long, 89% of which is underground. Most of the above-ground facilities are located on domesticated areas.

The key element of the new line is the Mont Cenis base tunnel. The tunnel is a twin-tube, single-track tunnel, of 57.5 km of length (45 km of which on French territory and 12.5 on Italian territory) and connects the international stations of Saint Jean de Maurienne and Susa, where it connects to the existing line.

In France, the civil works for the construction of the tunnels were fully commissioned at the end of 2021 and work started on the three access adits and the St. Jean de Maurienne access. In Italy, the tender is ongoing, and work will start in 2023, while the preparatory work is being completed in the Maddalena exploratory tunnel.

The largest French and Italian companies are involved in the realization of these works, having passed an evaluation in the tender phase on the proposals for improving safety and health of workers and the approach to innovation. Then, TELT selected partners who shared its safety policy and signed a formal commitment to the OS&H objectives.

Technological and organizational innovation have been promoted since the exploratory works and have generated some shared standards on all construction sites [22,23,24,25,26,27].

The main themes, also studied in collaboration with the University of Turin (UniTo) and implemented, are summarized in Table 2.

Table 2.

Main innovations implemented in TELT construction sites.

3. Results

The methods described above made it possible to classify the main techniques, technologies, and organizational strategies for improving OS&H conditions in underground construction sites, as summarized in Table 3. The main trends derived from the literature analysis and the case histories obtained, mainly, from the applications in TELT are presented.

Table 3.

Classification of the results.

3.1. Support in Design

3.1.1. Online Databases

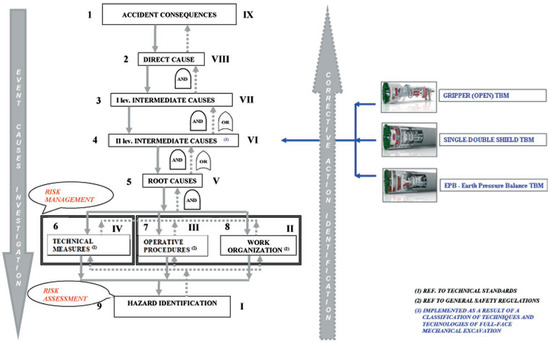

These are used to improve safety training and hazard factor identification, including virtual inspection applications to improve the effectiveness and quality of OS&H inspections. With regard to underground sites, artificial intelligence systems and data analysis software can be used to identify anomalies, data discrepancies, and criticalities [30]. Data analysis and visualization techniques can also be used to assess the causal factors of incidents and the corresponding corrective measures.

Case histories

An example of support that can also be used for in-depth analysis of accident events for prevention purposes is the Computer Aided Cause Consequence for Prevention—CCCP, an original model resulting from the combination of the FTA and ETA techniques, which can be used to identify prevention solutions resulting from an analysis of deviations in a system approach, cleansed of subjective interpretations [31,32]. In the case of the example [25]—collision between a person and a moving vehicle—from the analysis one can derive suggestions for the refinement of the risk analysis by means of the Functional Volumes method and deriving from the adoption of anti-collision systems, and the strengthening of the IFT action of the personnel [33,34].

Figure 4 illustrates the CCCP model implemented to make it specific for the analysis of accidents occurring during full-section mechanical excavation.

Figure 4.

CCCP accident data management model—developed as part of the TELT—UniTo study and research collaboration.

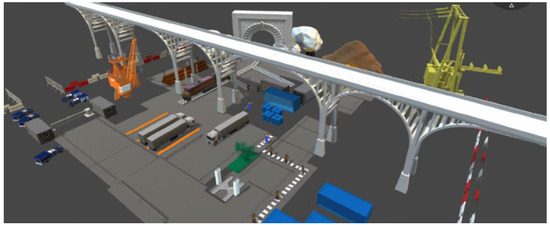

3.1.2. Building Information Modeling (BIM)

This consists of the creation of a set of digital information models to provide reliable and usable shared data from the initial design phase, throughout the entire lifecycle of the activity [35], and it can also serve as support for the design and management of OS&H aspects in open and underground construction sites. The implementation of BIM allows a visual representation of the construction site and the identification of potential hazard factors. By combining BIM and IoT technologies, the probability of deviations can be reduced and their consequences minimized. During construction, the model provides semi-automatic support for optimizing production efficiency and safety [36]. A further possibility is the development of videos for personnel IFT, aimed at fostering better knowledge of construction site conditions.

3.1.3. 3D CAD

3D CAD can be used in OS&H for design, safety management, and investigation of the causes of deviations and applied to simulate processes and visualize safety components and areas of major criticality in the design phase, in PtD logic. In construction sites, typically characterized by frequent spatial/temporal interference scenarios of workers and vehicles, it constitutes a basic support for analyses using the Functional Volumes technique.

Case histories

- a.

- 3D modeling applied in the TELT “La Maddalena” construction site (Chiomonte, Susa Valley, Turin) for proper interference management using the Functional Volumes technique (Figure 5).

Figure 5. Interference analysis and management: example of result [24].

Figure 5. Interference analysis and management: example of result [24]. - b.

- Computer Image Generation for Job Simulation—The CIJIS model, in PtD approach, makes possible a predictive simulation of the activities in a project hypothesis, extending the potential of Job Safety Analysis—JSA [37]. Information on foreseeable hazard factors can thus be obtained, and the effectiveness of the control measures can be validated. The result can also be used in the context of IFT, retaining the typical advantages of JSA.

3.2. Industry 4.0 Context

Currently, with the advancement of science and technology, numerous frontier computing techniques, such as big data, artificial intelligence, IoT, and vehicle automation, are progressively being integrated with underground construction technologies [38].

Geolocalization and Communication Systems

A critical aspect of underground activities is the difficulty of acquiring information—essential for production efficiency and OS&H—on the location of personnel and equipment over time. Seguel et al. proposed an exhaustive critical taxonomy of the main geolocalization techniques [39]. These techniques can increasingly be integrated with operational and emergency communication systems, and they constitute an essential element in the case of rescue operations [40,41].

Case histories

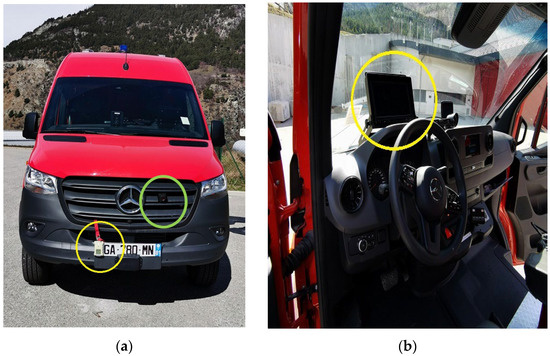

Due to the complexity of the structure, a typical rescue TSP cannot easily access all the underground constructions sites, so it is necessary to design an intervention machine according to the needs of the project. Figure 6 illustrates an example, meeting the operational expectations of the rescue services, with the following main characteristics: capacity of 14 persons, 4 firemen + 10 companions, fire fighting equipment, 360° zone lighting, audible and visual alarm for emergency evacuation of rescue personnel, front and rear obstacle detectors.

Figure 6.

(a) Thermal camera (green circle) and gas detection cell (yellow circle) integrated in the grille. (b) Report of the images on retractable screen in the cockpit.

3.3. Management Phase

3.3.1. Robotics and Automation

Robotics and automation can provide significant support, particularly when working in hostile environments. In recent years, robotics has undergone exponential technological advancement, gaining more and more space and interest, thanks to advances in computer vision, sensor technology, and human-machine communication [42,43]. With regard to the efficiency and safety of machine interaction with operators, so-called “cobots” have been developed, i.e., collaborative robots that can dynamically adapt to the operator’s task. Furthermore, the new automated systems can be applied not only to speed up and automate some tasks, but also to conduct operations in particularly dangerous areas. In the underground environment, the implementation of special robots can result in improvements in OS&H, and in general in the entire production cycle efficiency, thanks to the integration of various systems such as machine learning, remote control and IoT.

Case histories

- a.

- The AXEL rover (Figure 7), currently working on the Maddalena site. TELT entrusted WEBUILD and CSC (the construction of the Maddalena interchange niches was entrusted by TELT to the VINCI WEBUILD group) with the construction of 24 interchange niches along the 7 km tunnel. The last 3 km, due to the coverage of over 2000 m, present prohibitive microclimatic conditions with rock and water at over 45 °C. This section, closed since 2017, remained inaccessible for four years, which prevented checks on the structural condition of the supports. Through the CIM consortium, a prototype of a remotely guided electric rover, which can accommodate cameras, measuring instruments, and sensors, was developed, and successfully carried out environmental monitoring and site surveys.

Figure 7. (a,b) The Axel Rover for inspections used in the “Maddalena niches” construction site.

Figure 7. (a,b) The Axel Rover for inspections used in the “Maddalena niches” construction site. - b.

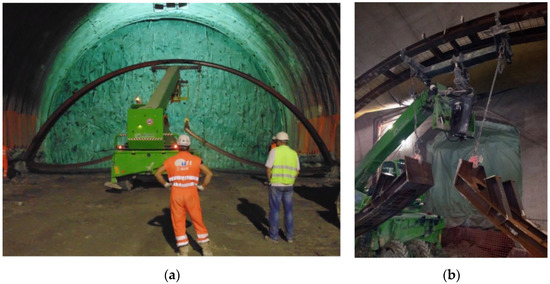

- An example of the application of advanced technology is the use of automatic ribs (Figure 8). These appeared at the turn of the 2000s on the sites of the Bologna–Florence high-speed railway line and were introduced to simplify the installation of supports at the front, reducing the workers’ exposure duration. Over time, the system has undergone significant evolutions in the adjustment and connections between structural parts, reducing the frequency of accidents associated with ribs installation [29].

Figure 8. (a) Lift laying rib; (b) release grippers [29].

Figure 8. (a) Lift laying rib; (b) release grippers [29]. - c.

- The construction site (the work in the S. Martin La Porte four site was carried out by the Spie Batignolles, Eiffage, Cogeis, CMC group of companies on behalf of TELT) in S. Martin La Porte (Figure 9): in the drill and blast sections, deformable TH ribs were installed, which required a study on gripping and lifting systems.

Figure 9. (a,b) Automatic ribs [44].

Figure 9. (a,b) Automatic ribs [44].

3.3.2. Sensors

The application of sensor-based technologies capable of automatically detecting potentially critical situations has become widespread in many industrial sectors. In particular, functional parameter sensors, localization, visual detection, and wireless sensor networks are now available for safety management [45].

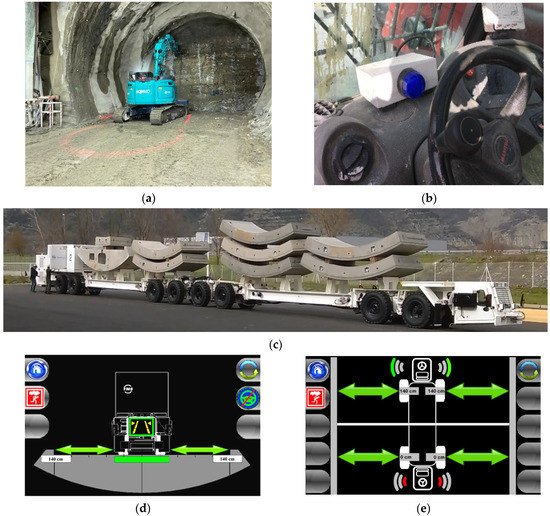

Sensors have also been the subject of experimentation in underground construction sites, in particular to reduce the risks of interference between free steering and personnel working in construction areas. Over the years, anti-collision systems capable of operating effectively even in hostile environments have been studied, including Radar, RFID, Ultrasound, Lidar, Infrared Cameras, Bluetooth Beacons, and GPS, or to manage plants and systems [25].

Case histories

- a.

- RFID systems: in the S. Martin La Porte construction site, the risk associated with forklifts and forklift trucks, which have some dangerous blind spots due to their conformation, was managed by providing personnel with RFID tags and installing detectors and acoustic/visual alarms for operators with a selectable range. After an experimental phase, the system was definitively adopted, with a substantial reduction in the frequency of collisions and accidents in the construction site.

- b.

- Infrared light, ultrasonic and radar anti-collision sensors used to detect the distance of a vehicle from the tunnel walls and from workers on foot: in the same site, reversible vehicles for transporting personnel, segments, and materials to the TBM with a double cab can operate in semi-autonomous driving mode with infrared detection of walls and obstacles (Figure 10); underground rescue vehicles available to the Public Emergency Services since 2017 have been equipped with ultrasonic and radar sensors that make them capable of operating even in reduced or zero visibility.

Figure 10. (a) Laser presence detection system in areas of possible interference; (b) Tag-based RFID system: light signal inside the vehicle cab; (c) TSP—concierge transport vehicle, and position control screen [28]; (d,e) Use of infrared sensors in the self-driving vehicle.

Figure 10. (a) Laser presence detection system in areas of possible interference; (b) Tag-based RFID system: light signal inside the vehicle cab; (c) TSP—concierge transport vehicle, and position control screen [28]; (d,e) Use of infrared sensors in the self-driving vehicle. - c.

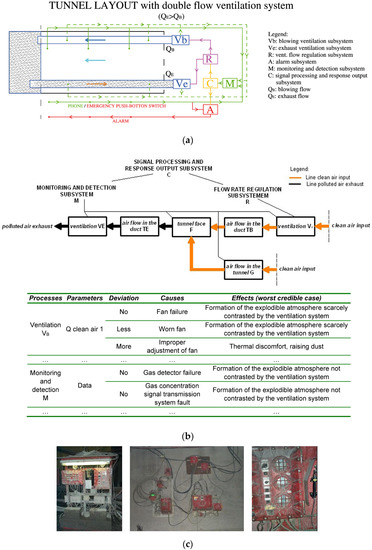

- Monitoring for the management of installations and systems (Figure 11): in the case of ventilation, detectors of air speed, presence/concentration of gases, airborne particulates (in some cases also capable of discerning the mineralogical nature and concentration of highly critical particles). These can be integrated with software capable of monitoring data and possibly implementing corrective measures by adjusting air flow rates [46].

Figure 11. (a,b) Layout of blowing/exhaust ventilation system for gassy tunnel management (the exhaust flow QE being usually higher than the blowing flow QB, clean air enters the main tunnel) and schematization for HazOP [9]; (c) Example of fixed gas monitoring instrument [47].

Figure 11. (a,b) Layout of blowing/exhaust ventilation system for gassy tunnel management (the exhaust flow QE being usually higher than the blowing flow QB, clean air enters the main tunnel) and schematization for HazOP [9]; (c) Example of fixed gas monitoring instrument [47].

3.4. Personal Systems

3.4.1. Exoskeletons

Exoskeletons are a wearable technology that can assist and support the human body to reduce musculoskeletal disorders resulting from the manual handling of loads. They are distinguished in

- active exoskeletons, which use actuators, mechanically driven components, to enhance human strength. For advantageous performance, they require an external energy supply;

- passive exoskeletons, which use elastic elements to store and release energy during the movement [48].

Currently, exoskeletons equipped with “intelligent sensors on the body”, aimed at monitoring and recognizing in real time—and avoiding—non-ergonomic movements and postures are increasingly being developed [49]. Their use remains, however, still very limited, especially in the underground environment.

3.4.2. Smart PPE

Personal Protection Equipment—PPE—are defined as intelligent when integrated with technological devices to provide workers with an additional, innovative system of protection. With the help of sensors, they are able to transmit feedback on the operator’s internal and external parameters, interacting with the surrounding environment [50]. This is particularly useful in the underground environment, where wearable devices (smartwatches and smartphones) connected to sensors capable of monitoring environmental hazards, temperature, humidity, position, heart rate, etc., are becoming more widespread.

A smart PPE capable of receiving information from sensors and communicating it to other IoT devices where it is stored, analyzed, and shared, could lead to [51] protection from invisible hazards in the work area (e.g., gas), localization of personnel, real-time data analysis, intelligent communication systems, warnings via smartphone apps, increased performance, and reduced errors through remote updates and communication (Figure 12). According to the findings of studies on PAPR [27], an implementation of such devices with communication and localization systems is an imminent prospect.

Figure 12.

(a) Prototype of an interconnected sensor system associated with PPE [51]; (b) Embedded wearable systems tested at the mine site [52]. From top left to top right: sensor-equipped mine safety vest; miner wearing Recon Jet Smart Eyewear; miner using Epson Moverio BT-2200. From bottom left to bottom right: sensor-equipped safety helmet; smartwatch.

3.4.3. Virtual and Augmented Reality

Virtual reality—VR—makes it possible for the user to be fully immersed in a digitally generated environment, whether real or imaginary. It can generate realistic images and sounds, making the user feel as if they are experiencing the simulated reality first-hand [42]. On the other hand, augmented reality—AR—uses computer-generated images to simulate real-life scenarios, modifying reality through technology, and can superimpose contextual information on a physical environment, merging digital elements with a real context [21]. These systems open great possibilities for training, simulation, planning, and modeling, allowing real-time visualization of critical scenarios, contributing—for example, during a training course—to workers’ awareness and knowledge of risk management. Virtual reality is also finding wide use in the planning of evacuation strategies during emergencies, e.g., following a fire, offering numerous advantages, and allowing a high degree of experimental control [53]. The subject of research for several years now, virtual reality offers enormous potential, from sharing data from excavation operations to reconstructing deviations for defining prevention strategies, etc. (Figure 13) [54].

Figure 13.

Image of virtual reality simulation model—AITEMIN roadheader simulation-operator’s view [54].

In the underground environment, AR/VR systems are already available and rapidly spreading, finding application for improvement in OS&H mainly through IFT procedures [55].

4. Discussion

The study, aimed at providing a general overview of the main innovations and strategies for the improvement of work health and safety conditions in underground, was based on the analysis of the literature and of the results of field tests carried out at TELT construction sites.

The bibliographic research, conducted through the Scopus search engine, enabled the identification of 30 reports suitable for the definition of four categories in which to classify the main technological innovations and trends for OS&H in underground construction sites:

- Support in design;

- Industry 4.0 context;

- Management phase;

- Personal Systems.

In addition, 20 documents obtained through the authors’ experiences, and regulatory and technical documentation relevant to the topic under investigation, were considered.

The Lyon–Turin railway, one of the nine axes of the European TEN-T transport network, has been used as a field for testing innovative strategies to improve workers’ health and safety conditions. Based on the defined classification, critical discussions were conducted on practical applications implemented in TELT underground construction sites.

The work carried out confirmed that underground mining and civil engineering activities are a stimulus for technological innovation [20], and that the efforts to make innovative technological solutions usable in these areas are considerable.

In the particular field of construction sites for large infrastructure works, the specific subject of this investigation, the documentation examined and the case histories discussed highlight some significant results deriving from the introduction of advanced technological solutions, both on specific systems (e.g., ventilation, communication and alarm, etc.) and on specific types of equipment, also for accident prevention and improvement of environmental conditions in underground workplaces.

New techniques for tele-monitoring of workers’ health and safety conditions, and advances in staff information, education, and training, are further examples of rapidly spreading improvements.

However, some other desirable transfers from solutions validated in different industrial sectors to underground construction sites are still in the process of evolution, due to the aforementioned peculiarities of both the context and the operations to be performed in underground. For example, alleviating manual effort in the handling of heavy parts by adopting exoskeletons—as is common in warehouse handling operations—is still not an immediate prospect due to the characteristics of the access routes and the available space.

The literature relating to field experiments aimed at the introduction, in the underground of articulated systems of exhaustive and integrated knowledge in real time, of the operational scenarios and their internal and external interconnections that are endowed with the capacity for direct self-correction of deviations resulting from various causes (including human error), is relatively limited. One of the greatest problems in this regard, linked to the very nature of the activity, is the objective impossibility of forecasting some critical parameters with the desired detail [23].

Similarly, A.I., Machine Learning, and Deep Learning experiments currently undergoing advanced development for the verification of the quality over time of the final lining of operating tunnels [56,57,58,59] can presumably find application in the construction of long tunnels as an evolution of the already consolidated techniques of discontinuity recognition and evolution [60], in particular where it is necessary to overcome sections characterized by asbestos-containing formations, to resume the activities under normal conditions, once the critical section has been overcome.

5. Limitations

A limitation of the study is that since only the Scopus database was considered as a source of data for the study, and only documents published in English were selected, future research using a mixture of databases including documents written in other languages may improve the present results. Furthermore, since inclusive search terms were used, it has been impossible to rule out the risk of failing to spot some relevant articles.

6. Conclusions

Underground construction activities still entail significant criticalities also in terms of Occupational Safety and Health. Considerable efforts are being made to take advantage of the emerging possibilities offered by the Industry 4.0 scenario in its general sense, although more difficult than in other industrial sectors due to the peculiar context.

The research, based on a structured analysis of the literature sources selected according to the discussed criteria, supplemented by the authors’ experiences, regulatory and technical documentation, and the criteria adopted for organizing the results, made it possible to draw a limited but representative overview of the current practical applicability of the main innovations and strategies that can contribute to improve workers’ health and safety conditions in underground construction sites for large infrastructures.

In general, the survey highlighted that many of the innovative technologies are now applied in several underground excavation activities, both on systems and fittings and on equipment, with significant returns in terms of Occupational Safety and Health. On the other hand, the introduction of articulated systems of comprehensive and integrated real-time knowledge of operating scenarios and their internal and external interconnections with direct self-correction of deviations seems at the moment less easy to envisage, due to the very nature of underground activity.

The ongoing experiments of safer new techniques and technologies at TELT—Tunnel Euralpin Lyon Turin SAS construction sites are highly significant. In some cases, these experiences also led to the identification of alternative approaches particularly suitable for the specific context.

Supported by the systematic organization of the field tests in a methodological framework, and conducted within a high-quality system, their results can be directly replicated in the various TELT sites, substantially improving the Occupational Safety and Health conditions, and contribute to the dissemination of the culture of safety in the TELT organization and in similar infrastructural projects.

Moreover, at least some innovations of confirmed feasibility and effectiveness, such as anticollision systems or personal systems, can gradually become a general reference also in less complex construction activities.

Author Contributions

Conceptualization, M.P. and A.S.; methodology and investigation, L.M.; resources, A.S.; writing—original draft preparation, L.M., M.P., A.S. and E.P.; supervision, M.P. and E.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Haupt, T.C.; Akinlolu, M.; Raliile, M.T. Emerging technologies in construction safety and health management. In Proceedings of the International Conference on Innovation, Technology, Enterprise, and Entrepreneurship (ICITEE), Bahrain, Saudi Arabia, 24–25 November 2019; pp. 413–420. [Google Scholar]

- Zhou, W.; Whyte, J.; Sacks, R. Construction Safety and Digital Design: A Review. Autom. Constr. 2012, 22, 102–111. [Google Scholar] [CrossRef]

- Lööw, J.; Abrahamsson, L.; Johansson, J. Mining 4.0—The Impact of New Technology from a Work Place Perspective. Min. Metall. Explor. 2019, 36, 701–707. [Google Scholar] [CrossRef]

- Aguirre-Jofré, H.; Vogt, D.; Eyre, M.; Valerio, S. Low-Cost Internet of Things (IoT) for Monitoring and Optimising Mining Small-Scale Trucks and Surface Mining Shovels. Autom. Constr. 2021, 131, 103918. [Google Scholar] [CrossRef]

- Yang, L.; Birhane, G.; Zhu, J.; Geng, J. Mining Employees Safety and the Application of Information Technology in Coal Mining: Review. Front. Public Health 2021, 9, 709987. [Google Scholar] [CrossRef]

- European Agency for Safety and Health at Work; Rosen, P.; Heinold, E.; Fries-Tersch, E.; Moore, P.; Wischniewski, S. Advanced Robotics, Artificial Intelligence and the Automation of Tasks: Definitions, Uses, Policies and Strategies and Occupational Safety and Health: Report; Publications Office of the European Union: Luxembourg, 2022; Available online: https://data.europa.eu/doi/10.2802/681779 (accessed on 6 December 2022).

- ISO Standard No. 31000:2018; Risk Management—Guidelines. International Organization for Standardization: Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/65694.html (accessed on 15 September 2022).

- Sorlini, A.; Patrucco, M.; Pentimalli, S.; Nebbia, R.; Todaro, C. Occupational Health and Safety Aspects. In Handbook on Tunnels and Underground Works; CRC Press: London, UK, 2022; pp. 119–138. ISBN 978-1-00-325617-5. [Google Scholar]

- Bersano, D.; Labagnara, D.; Patrucco, M.; Pellegrino, V. Affidabilità: La “Cenerentola” nella progettazione degli impianti di ventilazione in galleria. GEAM 2011, 133, 17–26. [Google Scholar]

- Labagnara, D.; Maida, L.; Patrucco, M. Firedamp Explosion during Tunneling Operations: Suggestions for a Prevention through Design Approach from Case Histories. Chem. Eng. Trans. 2015, 43, 2077–2082. [Google Scholar] [CrossRef]

- ISO Standard No. 31010: 2019; Risk Management—Risk Assessment Techniques. International Electrotechnical Commission: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/72140.html (accessed on 15 September 2022).

- Lingard, H.; Cooke, T.; Blismas, N.; Wakefield, R. Prevention through Design: Trade-Offs in Reducing Occupational Health and Safety Risk for the Construction and Operation of a Facility. J. Built Environ. Proj. Asset Manag. 2013, 3, 7–23. [Google Scholar] [CrossRef]

- National Institute for Occupational Safety and Health. The State of the National Initiative on Prevention through Design; U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, DHHS (NIOSH): Cincinnati, OH, USA, 2014. [Google Scholar]

- Gambatese, J. Prevention through Design (PtD) in the Project Delivery Process: A PtD Sourcebook for Construction Site Safety; Oregon State University: Corvallis, OR, USA, 2019; Available online: https://designforconstructionsafety.files.wordpress.com/2019/09/ptd-in-the-project-delivery-process.pdf (accessed on 17 January 2023).

- Labagnara, D.; Martinetti, A.; Patrucco, M. Tunneling operations, occupational S&H and environmental protection: A prevention through design approach. Am. J. Appl. Sci. 2013, 10, 1371–1377. [Google Scholar] [CrossRef]

- De Cillis, E.; Patrucco, M.; Borchiellini, R.; Fargione, P. Risk Assessment and Management: Easier said, perhaps with too many words, than done—The importance of the culture of prevention. In Proceedings of the International Symposium on Occupational Safety and Hygiene, Guimarães, Portugal, 23–24 March 2016. [Google Scholar]

- De Cillis, E.; Fargione, P.; Maida, L.; Sambuelli, L. Present and Future Contribution of Geophysics to the Prevention through Design and Quality Management Approaches for Tunneling Operations. First Break 2018, 36, 35–41. [Google Scholar] [CrossRef]

- TELT—Tunnel Euralpin Lyon Turin SAS. Mission-S. Available online: https://www.telt.eu/en/challenges/safety/mission-s/ (accessed on 25 March 2023).

- Large, D.; Ball, L.; Farstad, A. Radio Transmission to and from Underground Coal Mines—Theory and Measurement. IEEE Trans. Commun. 1973, 21, 194–202. [Google Scholar] [CrossRef]

- Patrucco, M.; Rostagnotto, A. La miniera come origine e Palestra dei Primordi della Meccanizzazione Moderna: Vestigia Storiche in Cornovaglia. In Proceedings of the Convegno De Re Metallica—Miniere e Materie Prime alle Soglie del 3° Millennio, (Politecnico di Torino, Ass. Min. Subalpina, Dip. Georisorse, Musep Attr. Per la didattica e la ricerca), Torino, Italy, 1–2 December 1994; pp. 149–164. [Google Scholar]

- Haupt, T.C.; Akinlolu, M.; Raliile, M.T. Applications of digital technologies for health and safety management in construction. In Proceedings of the 8th World Construction Symposium, University of Moratuwa, Moratuwa, Sri Lanka, 8 November 2019; pp. 88–97. [Google Scholar]

- Patrucco, M.; Sorlini, A. Mechanized tunnelling: Workers risk analysis and machine adjustment to the local situation. In Proceedings of the Safety Innovation Criteria inside Tunnels, Gijon, Asturias, Spain, 29 June–1 July 2005; pp. 29–37. [Google Scholar]

- Labagnara, D.; Patrucco, M.; Sorlini, A. Occupational Safety and Health in Tunnelling in Rocks Formations Potentially Containing Asbestos: Good Practices for Risk Assessment and Management. Am. J. Appl. Sci. 2016, 13, 646–656. [Google Scholar] [CrossRef]

- Labagnara, D.; Maida, L.; Patrucco, M.; Sorlini, A. Analysis and management of spatial interferences: A valuable tool for operations efficiency and safety. GEAM 2016, 16, 35–43. [Google Scholar]

- Patrucco, M.; Pira, E.; Pentimalli, S.; Nebbia, R.; Sorlini, A. Anti-Collision Systems in Tunneling to Improve Effectiveness and Safety in a System-Quality Approach: A Review of the State of the Art. Infrastructures 2021, 6, 42. [Google Scholar] [CrossRef]

- Pentimalli, S.; Nebbia, R.; Sorlini, A.; Pira, E.; Patrucco, M. Discussion on the Possible Approaches for the Management of Pollutants in Tunneling in Rock Formations Containing Asbestos Minerals. In Proceedings of the 31st European Safety and Reliability Conference—ESREL 2021, Angers, France, 19–23 September 2021; Castanier, B., Cepin, M., Bigaud, D., Berenguer, C., Eds.; Research Publishing: Singapore, 2021; ISBN 978-981-18-2016-8. [Google Scholar]

- Sorlini, A.; Patrucco, M.; Pira, E.; Nebbia, R.; Garzaro, G. Excavation mécanique dans des formations rocheuses susceptibles de contenir de l’amiante: Tests préliminaires et résultats des respirateurs à ventilation assistée THP3 dans une galerie de reconnaissance. In Proceedings of the XVIème Congrès International de L’association Française des Tunnels et de L’espace Souterrain, AFTES 2020 Posposte à AFTES 2021, Paris, France, 6–8 September 2021. [Google Scholar]

- Comin, G. Système de guidage des TSP. In Proceedings of the International Conference of Dissemination of the Culture of Safety and Occupational Health, Turin, Italy, 23–24 May 2018. [Google Scholar]

- Berry, P.; Calzolari, F.; Cormio, C. Workshop Nazionale NIR 2013—Note Interregionali Di Ingegneria Della Sicurezza Nello Scavo Di Gallerie: Origine, Evoluzione, Applicazioni e Futuri Sviluppi Del Nuovo Approccio Alla Progettazione Della Sicurezza; Scuola di Ingegneria e Architettura—Alma Mater Studiorum Università di Bologna: Bologna, Italy, 2014; p. 212. [Google Scholar] [CrossRef]

- Hyder, Z.; Siau, K.; Nah, F. Artificial Intelligence, Machine Learning, and Autonomous Technologies in Mining Industry. J. Database Manag. 2019, 30, 67–79. [Google Scholar] [CrossRef]

- Reason, J. Human Error, 1st ed.; Cambridge University Press: Cambridge, UK, 1990; ISBN 978-0-521-30669-0. [Google Scholar]

- Reason, J. Human Error: Models and Management. BMJ 2000, 320, 768–770. [Google Scholar] [CrossRef]

- Luzzi, R.; Passannanti, S.; Patrucco, M. Advanced Technique for the In-Depth Analysis of Occupational Accidents. Chem. Eng. Trans. 2015, 43, 1219–1224. [Google Scholar] [CrossRef]

- Luzzi, R.; Maida, L.; Martinetti, A.; Patrucco, M. Information, Formation and Training for the Maintenance Operations: The Lesson Learned from Fatal Accidents. Chem. Eng. Trans. 2013, 32, 229–234. [Google Scholar] [CrossRef]

- Liang, Y.; Liu, Q. Early Warning and Real-Time Control of Construction Safety Risk of Underground Engineering Based on Building Information Modeling and Internet of Things. Neural Comput. Applic. 2022, 34, 3433–3442. [Google Scholar] [CrossRef]

- Malomane, R.; Musonda, I.; Okoro, C.S. The Opportunities and Challenges Associated with the Implementation of Fourth Industrial Revolution Technologies to Manage Health and Safety. Int. J. Environ. Res. Public Health 2022, 19, 846. [Google Scholar] [CrossRef]

- Patrucco, M.; Bersano, D.; Cigna, C.; Fissore, F. Computer Image Generation for Job Simulation: An Effective Approach to Occupational Risk Analysis. Saf. Sci. 2010, 48, 508–516. [Google Scholar] [CrossRef]

- Li, P.; Cai, M. Challenges and New Insights for Exploitation of Deep Underground Metal Mineral Resources. Trans. Nonferrous Met. Soc. China 2021, 31, 3478–3505. [Google Scholar] [CrossRef]

- Seguel, F.; Palacios-Jativa, P.; Azurdia-Meza, C.A.; Krommenacker, N.; Charpentier, P.; Soto, I. Underground Mine Positioning: A Review. IEEE Sens. J. 2022, 22, 4755–4771. [Google Scholar] [CrossRef]

- Patri, A. Wireless Communication Systems for Underground Mines—A Critical Appraisal. Int. J. Eng. Trends Technol. 2013, 4, 3149–3153. [Google Scholar]

- Einicke, G.; Dekker, D.; Hainsworth, D. A review of underground communications systems. In Proceedings of the Technology Exchange Workshop in Coal Mine Productivity, Newcastle, NSW, Australia, 3–4 December 1997. [Google Scholar]

- Jacobs, J. A Technology Map to Facilitate the Process of Mine Modernization throughout the Mining Cycle. J. S. Afr. Inst. Min. Metall. 2017, 117, 636–648. [Google Scholar] [CrossRef]

- Pira, E.; Patrucco, M.; Nebbia, R.; Pineri, P.; Godono, A.; Gullino, A. Results of the implementation of a virtual control approach to improve the effectiveness and quality of Safety and Health inspections at workplaces. GIMLE 2015, 44, 41–50. [Google Scholar]

- Tallec, M. Innovations SMP4 2014-2022, Ouvrages de reconnaisance de Saint-Martin-La-Porte 4. In Proceedings of the Journées Techniques de l’AFTES, Chambéry, France, 26–27 October 2022. [Google Scholar]

- Zhang, M.; Cao, T.; Zhao, X. Applying Sensor-Based Technology to Improve Construction Safety Management. Sensors 2017, 17, 1841. [Google Scholar] [CrossRef]

- Shriwas, M.; Pritchard, C. Ventilation Monitoring and Control in Mines. Min. Metall. Explor. 2020, 37, 1015–1021. [Google Scholar] [CrossRef]

- Galleria di Base del Brennero. Piano di Sicurezza e Coordinamento, Allegato 3. Lavorazioni in Sotterraneo. 2016. Available online: https://va.mite.gov.it/File/Documento/180794 (accessed on 5 December 2022).

- Dempsey, P.; Kocher, L.; Nasarwanji, M.; Pollard, J.; Whitson, A. Emerging Ergonomics Issues and Opportunities in Mining. Int. J. Environ. Res. Public Health 2018, 15, 2449. [Google Scholar] [CrossRef]

- Romero, D.; Mattsson, S.; Fast-Berglund, Å.; Wuest, T.; Gorecky, D.; Stahre, J. Digitalizing Occupational Health, Safety and Productivity for the Operator 4.0. In Advances in Production Management Systems. Smart Manufacturing for Industry 4.0; Moon, I., Lee, G.M., Park, J., Kiritsis, D., Von Cieminski, G., Eds.; IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2018; Volume 536, pp. 473–481. ISBN 978-3-319-99706-3. [Google Scholar]

- Rosso, A. Machine Learning e Intelligenza Artificiale per la Valutazione Dinamica e Predittiva del Rischio di Infortunio: Applicazione Pilota ADAM—ITALFERR in un Cantiere Ferroviario. In Proceedings of the Le Grandi Infrastrutture in Sotterraneo del Prossimo Decennio e il Contributo dei Gruppi di Lavoro SIG per lo Sviluppo, l’ Innovazione e la Sicurezza del Tunnelling, Samoter 2023, Verona, Italy, 4–5 May 2023. [Google Scholar]

- Adjiski, V.; Despodov, Z.; Mirakovski, D.; Serafimovski, D. System architecture to bring smart personal protective equipment wearables and sensors to transform safety at work in the underground mining industry. MGPB 2019, 34, 37–44. [Google Scholar] [CrossRef]

- Mardonova, M.; Choi, Y. Review of Wearable Device Technology and Its Applications to the Mining Industry. Energies 2018, 11, 547. [Google Scholar] [CrossRef]

- Ronchi, E.; Kinateder, M.; Müller, M.; Jost, M.; Nehfischer, M.; Pauli, P.; Mühlberger, A. Evacuation Travel Paths in Virtual Reality Experiments for Tunnel Safety Analysis. Fire Saf. J. 2015, 71, 257–267. [Google Scholar] [CrossRef]

- Mallett, L.; Unger, R. Virtual Reality in Mine Training. In Proceedings of the 2007 SME Annual Meeting and Exhibit, Denver, CO, USA, 25–28 February 2007; Preprint 07-031. Society for Mining, Metallurgy, and Exploration, Inc.: Littleton, CO, USA, 2007; pp. 1–4. [Google Scholar]

- Australian Main Safety Journal (AMSJ). Augmented reality may transform mining safety, Emerging Issues in Mining Safety—Training & Education, 14 September 2018. Available online: https://www.amsj.com.au/augmented-reality-transform-mining-safety/ (accessed on 8 October 2022).

- Wang, W.L.; Wang, T.T.; Su, J.J.; Lin, C.H.; Seng, C.R.; Huang, T.H. Assessment of Damage in Mountain Tunnels Due to the Taiwan Chi-Chi Earthquake. Tunn. Undergr. Space Technol. 2001, 16, 133–150. [Google Scholar] [CrossRef]

- Lei, M.; Liu, L.; Shi, C.; Tan, Y.; Lin, Y.; Wang, W. A Novel Tunnel-Lining Crack Recognition System Based on Digital Image Technology. Tunn. Undergr. Space Technol. 2021, 108, 103724. [Google Scholar] [CrossRef]

- Kim, B.; Cho, S. Automated Vision-Based Detection of Cracks on Concrete Surfaces Using a Deep Learning Technique. Sensors 2018, 18, 3452. [Google Scholar] [CrossRef]

- Song, Q.; Wu, Y.; Xin, X.; Yang, L.; Yang, M.; Chen, H.; Liu, C.; Hu, M.; Chai, X.; Li, J. Real-Time Tunnel Crack Analysis System via Deep Learning. IEEE Access 2019, 7, 64186–64197. [Google Scholar] [CrossRef]

- Cina, A.; Fargione, P.; Patrucco, M.; Pira, E. Occupational Risk Assessment and Management in workplaces with possible presence of Asbestos Containing Materials: The substantial contribution of Image Analysis. GEAM 2019, 2, 47–55. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).