Abstract

The railway industry has shown a strong interest in utilizing sustainable materials, including recycled materials and composites, in construction. Bamboo, as a highly renewable natural resource, has been proposed as a construction material for the railway industry. This material offers several advantages, such as high strength and durability, sustainability, low embodied energy, and ease of handling. It has been used in various construction materials like plywood, scrimber, laminates, and fibers. This paper aims to review the application of bamboo as a material in the railway industry and provide suggestions for its future use as railway sleepers. The mechanical properties of bamboo and its desirable features for sleeper construction, such as versatility, durability, low embodied energy and carbon footprint, lightweight, and ease of handling, are discussed. Bamboo-based products like plywood and scrimber can offer higher mechanical properties compared to traditional timber sleepers. Moreover, due to its rapid growth rate, bamboo is considered an environmentally friendly material. However, there are certain factors that limit the widespread deployment of bamboo in the railway industry. For instance, the lightweight nature of bamboo can reduce the lateral resistance of sleepers. Additionally, long-term performance studies and its performance in regions with varying weather conditions need to be further investigated. This review paper aims to promote the increased utilization of bamboo in the railway industry, contributing to the development of sustainable railway tracks. By considering the mechanical properties and advantageous characteristics of bamboo, it is possible to explore its potential as a viable and eco-friendly material for railway sleepers.

1. Introduction

Recently, the demand for composite materials as an alternative to existing timber sleepers has risen due to the increasing resource requirements in today’s modern industrialized world [1]. However, the availability and quality of wood resources from forests have declined, necessitating the exploration of alternative construction materials to replace traditional wood utilization [2]. Consequently, there is growing interest in identifying promising alternatives to wood as a raw material [3]. In parallel, bamboo is being cultivated as a plantation crop in addition to its natural occurrence in various countries like China and India [4]. This cultivation provides significant benefits to local farmers, as they can process bamboo into diverse products, improving their livelihoods [5]. The large production of bamboo, for instance, in China, which produces approximately 10,000 types of bamboo products, can provide a long-term resource for railway sleeper manufacturing [6]. However, the bamboo culm does not meet the mechanical properties needed for railway sleeper manufacturing, but by developing recent technologies to produce bamboo products, this material is suggested for employment in the railway industry [7]. Those features of bamboo suitable for railway sleepers are listed and discussed in the following sections.

1.1. Versatility and Durability

Bamboo exhibits remarkable versatility and durability, making it an attractive material for various applications [8]. Bamboo can be utilized in construction for a wide range of applications, including structural elements, flooring, walls, roofs, and even entire buildings [9]. It can be used as a primary material or in composite forms with other substances [10,11]. Its natural beauty and flexibility allow for diverse design possibilities [12]. Bamboo fibers are used for producing paper and textiles [13]. Bamboo can also be utilized as a biomass fuel source, providing renewable energy in the form of heat and electricity [14]. Bamboo has an impressive strength-to-weight ratio, making it comparable to steel in terms of tensile strength [15]. It can withstand heavy loads and has excellent structural integrity [16]. Bamboo possesses inherent flexibility, allowing it to withstand bending and vibrations without breaking [17]. This flexibility helps it resist damage from wind, earthquakes, or other external forces [18]. Bamboo has natural resistance to water, making it less prone to rot or decay [19]. Additionally, it contains natural silica, which acts as a deterrent to pests such as insects and fungi [20]. When properly treated and maintained, bamboo products can have a long lifespan [21]. With appropriate preservation techniques, bamboo can withstand outdoor conditions and retain its durability for many years [22]. The versatility and durability of bamboo products are two of the features needed for railway sleeper manufacturing.

1.2. Low Embodied Energy and Carbon Footprint

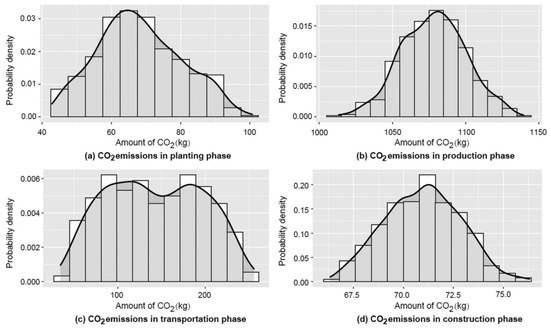

With appropriate preservation techniques, bamboo can withstand outdoor conditions and retain its durability for many years [23]. Bamboo is considered an environmentally friendly material due to its rapid growth rate, high yield per acre, and minimal need for pesticides or fertilizers [24]. It is a renewable resource that can be harvested without causing deforestation, as bamboo plants rapidly regenerate from their root systems [25]. However, bamboo cultivation practices such as irrigation, fertilization, and respiration during the planting stage contribute to emissions (Figure 1a). The production phase is the largest contributor to emissions, accounting for approximately 83% of carbon emissions (Figure 1b), which at its maximum is 1070 kg emissions, which is higher than concrete sleeper production with 420.26 kg emissions [26]. This is mainly due to the involvement of numerous complex processes that require high-power machinery (e.g., sanding machines, hot plate presses, and vacuum bumpers) and materials (e.g., antimold preservatives and adhesives). emissions during the transport phase primarily range between 100 and 200 kg and are significantly influenced by the distance of transportation (Figure 1c). These bamboo emissions are much lower than those of concrete sleepers because of the lower weight and size of bamboo products. The construction phase generates a lower amount of compared to the production and transport phases (Figure 1d). The emitted amount is significantly smaller compared to the uptake through manufacturing raw materials for concrete sleepers, which is about 306.4 kg [26].

Figure 1.

Bamboo emissions by phases in (a) planting phase, (b) production phase, (c) transportation phase, and (d) construction phase [27].

1.3. Lightweight and Easy to Handle

Bamboo possesses inherent characteristics and physical properties that make it lightweight and easy to handle [28]. Its unique hollow structure, consisting of interconnected chambers called “internodes” [29], separated by solid segments called “nodes,” significantly reduces its weight while maintaining strength [30]. This distinguishes bamboo as a much lighter material compared to others [31]. Additionally, bamboo has a low density relative to traditional building materials like wood, metal, or concrete, further contributing to its lightweight nature [32]. Despite its lightness, bamboo exhibits an impressive strength-to-weight ratio, enabling it to support heavy loads [33]. Bamboo can also be readily cut, drilled, or modified using standard tools, enhancing its convenience in various projects or installing fastening systems in railway tracks [34]. The lightweight nature of bamboo additionally contributes to its portability and ease of transportation [35]. It can be carried or loaded onto vehicles without the need for heavy machinery or specialized equipment [36]. This makes bamboo a practical choice for projects requiring mobility and efficient logistics, such as railway track construction.

1.4. Bamboo Life Cycle Assessment

Life cycle assessment (LCA) is a method used to assess the environmental impacts associated with all stages of a product or process, starting from raw material extraction to its end-of-life [37]. Numerous researchers have conducted LCA studies on bamboo products, examining their entire life cycle [38,39]. When comparing the emissions of bamboo products, timber is often chosen as a reference point [40]. During the growth phase of bamboo, carbon is absorbed through photosynthesis as the culms mature [38]. Fertilizers may be used to enhance biomass yield. The amount of stored in the aboveground bamboo biomass is calculated by multiplying the mass of the aboveground bamboo, the carbon content, and the molecular weight ratio between and carbon [41]. Harvested bamboo culms are transported to nearby processing facilities, where they undergo drying and cutting processes. They may also be further processed into composite materials using adhesives [42]. Air drying is the most common method, requiring minimal energy consumption, which is often overlooked in LCA assessments. However, the production of glued laminated composites involves energy-intensive drying and carbonization steaming treatments, in contrast to air drying [43]. In the disposal stage of bamboo products, three common scenarios are considered: landfill, incineration, and recycling [44]. In landfill scenarios, post-consumer waste is transported to landfills located at distances ranging from 20 to 60 km [45]. Incineration scenarios involve burning waste bamboo products, generating approximately 19 MJ of heat per kilogram, which can be recovered and used as a heat source, displacing the need for heat from other sources [42].

1.5. Limitations

Despite the presence of over 1200 bamboo species worldwide, the variations in geometric and mechanical properties of bamboo culms [46] show limitations to producing railway sleepers with sensitivity in material quality use [47]. Additionally, making connections and joints for round sections can be challenging, rendering the use of tubes impractical in certain applications; therefore, more treatment processes are needed for the application of bamboo [48]. Furthermore, some bamboo culms exhibit several other limitations, including small diameter, longitudinal variations in diameter, thin and hollow walls, and a susceptibility to corrosion and cracking [49]. Therefore, high conservation in choosing bamboo for construction applications is needed. As a result, bamboo has primarily been utilized in applications with low technological complexity and limited added value [50] until bamboo treatment and fabrication technologies have been developed [51]. Furthermore, bamboo standards are outdated, with the most recent publications occurring more than 10 years ago, lacking updates to incorporate new technologies in bamboo product manufacturing, for instance, JG/T 428 [52] for composite ply bamboo forms with steel frames, GB/T 30762 [53] for quality grading standards of main bamboo shoots, JG/T 199 [54] for testing methods of physical and mechanical properties of bamboo used in building, GB/T 2690 [55] for bamboo timber, and GB/T 15780 [56] for testing methods of physical and mechanical properties of bamboo [57].

1.6. Current Number of Research about Bamboo

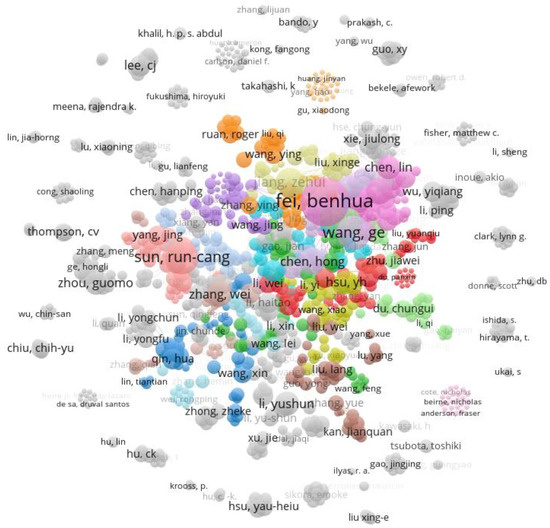

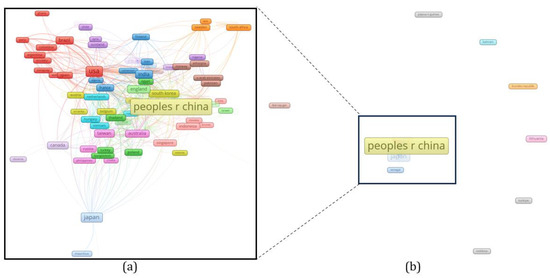

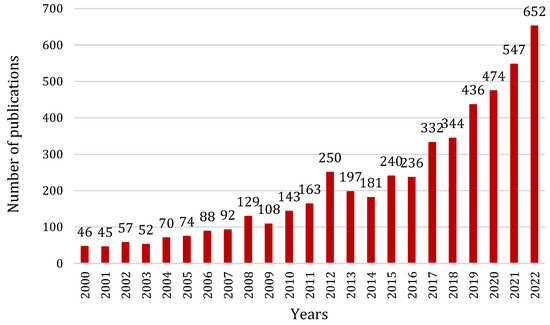

More than 1000 authors have written about bamboo applications in structures in more than 4119 papers (Figure 2). These authors co-authorship is divided into 82 clusters, which shows authors on this topic have contributed to a lot of joint projects. When it comes to categorization based on countries, we can see that more than 104 countries have contributed to bamboo publications (Figure 3). China has the highest co-authorship with other countries of any of these countries. These countries co-authorship is divided into 21 clusters. Figure 4 illustrates the trend of publications related to the application of bamboo in structures from 2000 to 2022. The graph demonstrates a steady and gradual increase in the number of publications over the course of 22 years. This upward trend indicates the growing popularity and interest among researchers in exploring and utilizing bamboo for structural applications. The most frequently mentioned keywords are species, forest, carbon, area, diversity, building, specimen, tensile strength, synthesis, and adsorption. More than 1710 publications about the application of bamboo in construction are published by Elsevier, 342 by MDPI, 649 by Springer Nature, 331 by Wiley, 193 by Taylor & Francis, and other publishers. The most publications in bamboo belong to the International Center for Bamboo and Rattan, with more than 353 publications, followed by Nanjing Forestry University, the Chinese Academy of Sciences, the Chinese Academy of Forestry, etc.

Figure 2.

Bibliometric analysis of 1000 researchers worked on bamboo application in structures extracted from VOSviewer from a Web of Science data source.

Figure 3.

Bibliometric analysis of 104 countries worked on the application of bamboo in structures extracted from VOSviewer from a Web of Science data source; (a) group of countries with joint collaboration, and (b) the connection between countries with joint colaboration.

Figure 4.

Number of publications about the application of bamboo in structures over 22 years.

1.7. Paper Outline

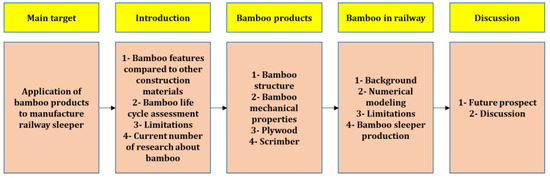

Here, in this section, a flowchart is presented to show the paper approach for a better understanding of how bamboo can be employed as a railway sleeper (Figure 5). Four steps are designed to provide enough information about new types of bamboo products suitable for sleeper construction. In the first step, the main target is to show that bamboo materials are gaining importance as an alternative to timber and other materials due to several compelling reasons. Afterwards, it is explained that, first, bamboo is an incredibly sustainable resource. It is one of the fastest-growing plants on Earth, with some species maturing in just a few years. In contrast, trees used for timber can take decades, or even centuries, to reach maturity. This rapid growth rate makes bamboo a highly renewable and eco-friendly option for construction and manufacturing. In comparison with other materials such as concrete and steel, bamboo possesses impressive strength and durability, making it a viable alternative to traditional materials like concrete or timber for railway sleepers. Bamboo has excellent load-bearing capacity and can withstand heavy weights and constant stress, making it suitable for the high pressure exerted by trains and maintaining track stability. Then, in the third section, bamboo products are introduced with related features. In the fourth section, the current application of bamboo is reviewed and limitations, numerical modeling, and some suggestions are presented. Finally, future prospects and studies needed for more employment of bamboo in the railway industry are discussed.

Figure 5.

Paper outline, including each step to review the potential of bamboo products for railway sleeper deployment.

2. Bamboo Construction Material Fabrication

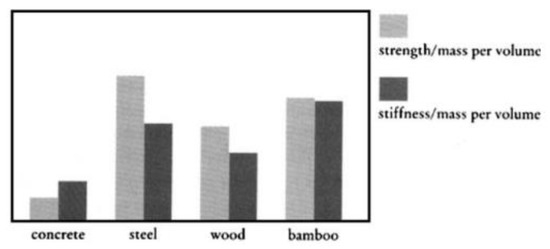

Bamboo culm has been treated before application as construction materials such as scrimber [58], plywood [59], panels [60], lumber [61], and laminated [33]. Bamboo products can compete with other railway sleeper materials such as concrete, wood, and steel because they have high strength and stiffness compared to their weight [62]. As shown in Figure 6, stiffness and strength divided by mass per volume of four common construction materials, such as concrete, steel, wood, and bamboo, are compared. Bamboo shows higher performance compared to concrete and wood in terms of stiffness/mass per volume and higher strength than concrete, steel, and wood in terms of strength/mass per volume. In the following sections, more specifications are presented about bamboo products.

Figure 6.

Stiffness and strength/mass per volume of various materials used for railway sleeper manufacturing [63].

2.1. Bamboo Structure

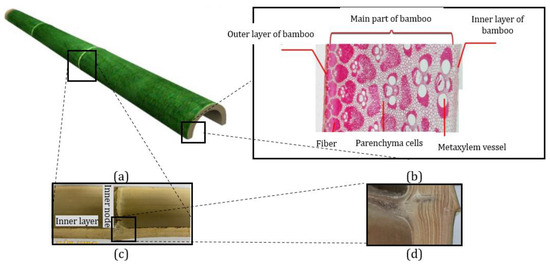

Bamboo exhibits a hollow internal structure with tube-like sections between the nodes, where longitudinal fibers are aligned within a matrix of lignin (see Figure 7a) [64,65]. The thickness of the culm wall gradually decreases from the base to the top of the bamboo culm [66]. The slender bamboo fibers, which are long, tapered at both ends, and sometimes forked, also vary in density within the culm wall, with a decrease in density from the outer wall to the inner wall [67]. A cross-section micrograph of bamboo is presented in Figure 7b. Based on the distribution density of longitudinal vascular bundles and corresponding chemical components, bamboo can be divided into four components: the outer layer, the fresh layer, the inner layer, and the nodal area (Figure 7c,d). The size of the vascular bundles gradually increases from the outer layer to the fresh layer, reaching its maximum size in the inner layer [68]. Consequently, the mechanical strength of bamboo gradually decreases from the outer to the inner regions [69]. The high density and hardness of the outer layer make it difficult to compress, while the softness of the inner layer makes it prone to stretching and cracking [70].

Figure 7.

Bamboo structure: (a) culm, (b) microstructure, (c) node, and (d) node structure [71,72].

2.2. Bamboo Mechanical Properties

Raw bamboo has significantly lower mechanical properties than treated bamboo products. Table 1 shows that each bamboo product has mechanical properties suitable for being used in construction. However, a wide range of differences in the mechanical properties of bamboo can be seen in this table. It can be a disadvantage to employ bamboo as a construction material for railway sleepers. Among all listed bamboo products, bamboo scrimber shows the highest mechanical properties, higher than wood.

Table 1.

Mechanical properties of different bamboo products [73,74,75,76,77,78,79,80].

2.3. Bamboo Plywood

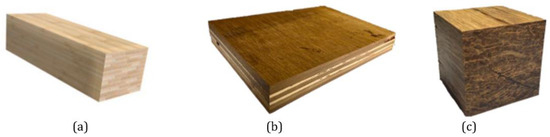

The development of the bamboo plywood production process stemmed from the need for a simple bamboo processing technology that could enhance the performance of bamboo products without altering their original thickness and width [81]. This process aimed to reduce costs and increase the added value of bamboo products [82]. Various methods have been proposed for bamboo plywood production, including the technique known as “bamboo fattening” [83]. This method involves constructing fattened bamboo boards to create strong and highly rigid bamboo plywood [84]. Examples of this type of plywood include curtain-ply, woven compressed wood, crisscross mat, bamboo curtain sheet, and compressed wood, among others [85]. Producing plywood from bamboo enhances its qualities, such as moisture-proofing, water resistance, corrosion resistance, and resistance to salt damage [86]. Bamboo plywood becomes significantly harder and stronger than standard wood, exhibiting a tensile strength that is 1.5 to 2 times greater than that of wood [87]. Another method for producing bamboo plywood is through bamboo lamination (Figure 8) [74]. In this process, bamboo culms are split into splits using a sizing and splitting machine [88]. These splits are then refined into strips, which are subsequently bonded together using resin to create a laminate [89]. These laminates can be further bonded together to produce bamboo plywood [90]. Hot pressing and the application of pressure are commonly employed to treat the laminates and ensure their cohesion [91].

Figure 8.

An overview of bamboo plywood with different laminate layers (a) laminated bamboo, (b) laminated flattened bamboo, (c) Bamboo scrimber [78].

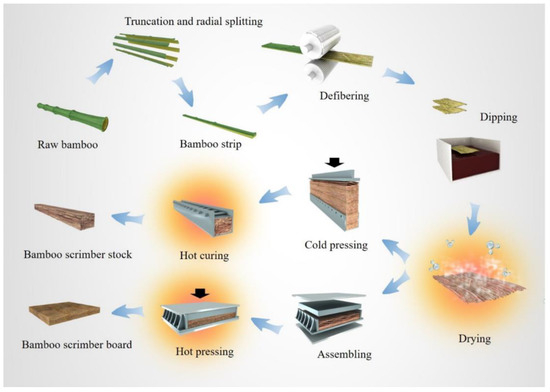

2.4. Bamboo Scrimber Fabrication

In response to the growing industry and demand for sustainable construction products, bamboo is being utilized to create engineered bamboo composites, which aim to standardize the shape and reduce material property variations [92]. One specific type of engineered bamboo composite is bamboo scrimber, which involves crushed bundles of bamboo fibers saturated in resin and compacted into a dense block [93]. This rectangular structural element possesses exceptional qualities, including a high bamboo utilization ratio (over 80%), an appealing grain pattern, and similar hardness and color to that of hardwood [94]. These characteristics make bamboo scrimber a competitive option among commonly used construction materials [95]. The production process of bamboo scrimber typically involves several steps, as illustrated in Figure 9. These steps include truncation and splitting of bamboo, softening, removal of the bamboo’s outer skin, drying, sizing, assembly, and hot-pressing [72]. However, with advancements in technology, certain steps have been omitted in the large-scale production of bamboo scrimber [96]. The main processes involved now include truncation and splitting, defibering, drying, dipping, assembly, cold-pressing, and heat curing or hot-pressing [97].

Figure 9.

Process of bamboo scrimber production line [72].

3. Application of Bamboo in the Railway Industry

3.1. Background

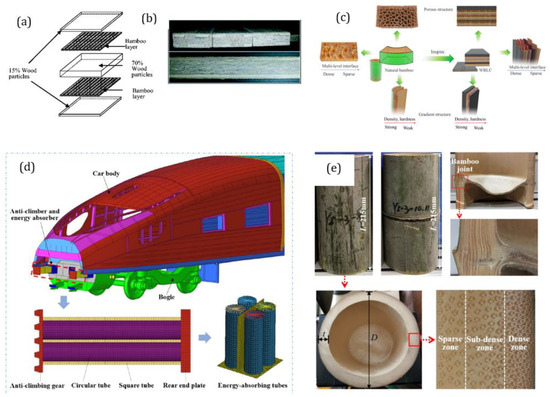

Bamboo has been increasingly applied in various aspects of the railway industry, showcasing its versatility and potential benefits. For instance, Erlangga et al. [98] used bamboo nets to improve soil density, offering an environmentally friendly alternative for soil enhancement (Figure 10a). The bamboo nets, measuring 10 cm in diameter and 5 m in length, achieved a density degree of 96.5% based on sand cone density tests. Xiao et al. [77] developed a composite railway sleeper using a combination of wood and bamboo (Figure 10b). Through their study, they found that by using a resin content of 15.5%, targeting a density of 0.8 g/cm3, applying a hot-pressing time of 0.65 min/mm, and setting a hot-pressing temperature of 170 °C, an optimal modulus of rupture value of 70.08 MPa was achieved. Sasmayaputra et al. [99] explored the use of bamboo mats as temporary reinforced soil retaining walls in railway beds. Bamboo mats were investigated as an alternative to geosynthetics for temporary mechanically stabilized earth (MSE) walls. These mats proved cost-effective and biodegradable, offering advantages for temporary MSE walls. Numerical simulations showed that the bamboo mat MSE walls were safe against internal and external collapses, with the lowest safety factor recorded at 1.53, primarily due to the potential of global slope stability leading to collapse. Wang et al. [76] conducted a theoretical evaluation to determine optimal material combinations for a newly developed composite railway sleeper. The composite material consisted of polyvinyl chloride, chalk, and bamboo fiber.

Figure 10.

(a) Preparation and (b) cross-section of a real composite sleeper, (c) process to produce a bamboo laminate composite for the flooring of railroad cars, (d) application of energy-absorbing CTs in rail vehicles, and (e) bamboo samples and the detailed structures [71,77,98,100].

In their research, Han et al. [71] investigated the use of a bamboo laminate composite for railroad car flooring. The study findings revealed that this laminated composite exhibited a low density of 0.73 g/cm3, resulting in a specific modulus of 13.03 GPa cm3/g. Moreover, it demonstrated a vibration damping ratio of 6.61% and an impact toughness of 14.16 J/cm2. These characteristics were significantly superior to those of other wood-based composites, such as Birch plywood (BP), which is commonly used for high-speed rail floors (Figure 10c). In a separate study, Xue et al. [60] developed laminated bamboo–wood composite lumber for railway applications. This composite lumber consists of two thin curtain boards with a thickness of 3–4 mm as the surface material, along with three layers of wood boards with a thickness of 10–15 mm forming the interior structure. This composite lumber offers several advantages over solid bamboo boards, including increased strength, improved resistance to abrasion, lower density, better nail holding capacity, and cost-effectiveness. Currently, the product is undergoing testing on railway flat wagons. Liu et al. [100] proposed a novel type of thin-walled circular tubes (CTs) inspired by the energy absorption capabilities of bamboo. The intention behind these bamboo-inspired bionic tubes (BT) was to use them as energy absorbers in rail vehicles (Figure 10d). The research results indicated that the BT specimens exhibited significantly enhanced energy absorption (EA) compared to the CT specimens. In experimental tests, the BT specimens showed an increase of 93.1% in EA, while simulated tests demonstrated an increase of 101.8% in EA. Additionally, the mean load values rose from 74.2 kN and 68.3 kN to 143.4 kN and 137.9 kN for the BT specimens, respectively, indicating a substantial improvement in crashworthiness (Figure 10e).

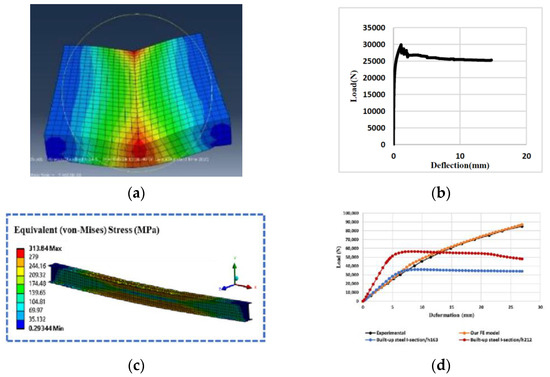

3.2. Numerical Modeling

Bamboo is composed of vascular bundles and ground tissues, both of which contribute to its mechanical properties, similar to unidirectional composites [101]. However, a notable distinction between wood and bamboo is the absence of horizontal tissue, such as rays, in bamboo [102]. As a result, bamboo is often simplified as a transversely isotropic material in modeling [103]. There are some standard methods for measuring the elastic constants of anisotropic materials [104]. However, bamboo presents challenges in determining the elasticity constants due to its inherent anisotropy, hollow culm structure, and gradient distribution [105]. Various mathematical models have been developed to predict the structural behavior of bamboo as a construction material, including analytical solutions [106] and finite element methods implemented by researchers using software such as ANSYS [107] and ABAQUS [108]. Iynkaran et al. [79] studied a hybrid reinforcement for concrete slabs, including steel and bamboo bars (Figure 11a). Reinforcement bamboos were modeled by two-node, three-dimensional truss elements. FEM results showed that hybrid slab behavior shows more flexibility to the load than steel reinforcement slabs and lower weight (Figure 11b). Al-Rukaibawi et al. [109] conducted an assessment of the mechanical behavior of a bamboo–steel composite beam subjected to pure bending. Bamboo was characterized as an anisotropic material, with greater tensile and compressive strengths in the longitudinal direction compared to the transverse directions. Using FEM, it was observed that the computational model developed closely predicted the experimental results, with an average difference as low as 3%.

Figure 11.

An overview of bamboo numerical modeling: (a) FEM modeling of bamboo slab, (b) load-deflection results of concrete slab reinforced by bamboo [79], (c) FEM study of a bamboo–steel composite beam, and (d) load-deflection results of different types of bamboo–steel composite [109].

3.3. Bamboo Sleeper Production

3.3.1. Background

Railway sleepers, also known as railroad ties or crossties, play a crucial role in the functioning and stability of railway tracks [110,111]. Their primary purpose is to provide support, stability, and secure alignment for the rails [112]. This railway track component has several roles, such as supporting rails, absorbing loads coming from trains, maintaining track alignment, reducing vibration, and maintaining track stability [1]. Railway sleepers are subject to train dynamic loads [113]. Bad ballast support conditions may cause ununified load support distribution for sleepers, which results in cracks in the rail seat and middle of the sleeper [114]. Track owners have tried to replace wood sleepers with different types of composite railway sleepers, such as TieTek, Axion, and KLP [115]. So far, the application of bamboo to construct railway sleepers has been studied [71,76]. This type of sleeper can be an alternative to timber railway sleepers. Xiao et al. [77] studied the manufacturing process of a wood–bamboo hybrid composite sleeper. Three parameters, including resin content, density, and hot-press time of the sleeper manufacturing process, are defined, and their relationship with the modulus of elasticity (MOE) is assessed. Results showed that more resin in bamboo composite sleepers increases MOE, while more density than 0.8 g/cm3 decreases sleeper MOE. Longer hot-press times slightly decrease MOE.

However, the authors have started a comprehensive study regarding the application of bamboo in railway sleeper production with different types of bamboo construction materials, such as bamboo plywood and fibers. Here are some examples of bamboo sleeper production: two different processes of using bamboo fibers mixed with concrete and using bamboo plywood are followed. These sleepers are studied under bending tests, and their mechanical results are compared with those of normal concrete and timber sleepers.

3.3.2. Bamboo Sleeper Application Challenges

Bamboo, despite its many advantages, may present several disadvantages when used as a sleeper on railway tracks. One notable drawback is its light weight, which can lead to reduced lateral resistance [116]. This can potentially affect the stability and integrity of the railway track, especially under heavy loads or during high-speed train operations [117]. Another concern related to bamboo sleepers is their durability, particularly in regions with variable weathering action [118]. Bamboo is susceptible to weather-induced deterioration, such as fungal decay, cracking, or rotting, which can compromise its structural integrity over time [119]. This vulnerability to weathering raises concerns about the long-term performance and reliability of bamboo sleepers on railway tracks. Furthermore, limited data exists on the long-term performance of bamboo sleepers in railway applications. Comprehensive studies and field trials assessing the durability, maintenance requirements, and overall performance of bamboo sleepers are relatively scarce. This lack of available data makes it challenging to accurately assess their suitability and longevity in railway track systems. It is crucial to address these disadvantages and thoroughly evaluate the feasibility and practicality of bamboo sleepers before incorporating them extensively in railway infrastructure. Table 2 shows a comparison between different types of sleepers. It can be seen that bamboo plywood sleepers have the lightest weight between 60 and 75 kg, and their middle bending strength is equal to that of high-quality timber sleepers by 100 MPa. The results for the fiber bamboo sleeper and the plywood sleeper are reported from the authors’ experiments. Application of bamboo fiber reduces the bending strength of concrete sleepers; however, it lightens the weight of concrete sleepers by 10%. The bamboo plywood sleeper is the cheapest among other types of sleepers. All prices are extracted from a sleeper-selling website [120].

Table 2.

A comparison of the flexural strength and total weight of different types of sleepers.

4. Future Prospects and Discussion

Bamboo products, such as plywood and bamboo scrimber, have shown promising mechanical features that make them potential alternatives to timber sleepers [123]. However, further studies are necessary to assess their long-term performance, resistance to temperature variance, and weathering effects. Additionally, more research, both numerical and experimental, is needed to explore the application of bamboo products in ballast mats and under sleeper pads, particularly in terms of their damping properties when combined with elastic materials like recycled tires. The use of bamboo in sleeper construction can provide benefits such as protecting the elastic layer from abrasion caused by ballast particles and contributing to vibration attenuation. However, when considering bamboo as a fiber mixed with conventional concrete or as laminates, certain concerns arise. The mechanical performance of railway concrete sleepers may be compromised when using bamboo fibers, as they are typically extracted from culms and may not provide sufficient reinforcement [124]. Moreover, the bonding and stress between laminate layers in bamboo plywood sleepers may lead to premature failure. To address these concerns, various methods have been suggested, including the use of high-strength resin and carbon fiber-reinforced polymer (CFRP) reinforcement in similar structures [1]. These approaches aim to enhance the bonding and stress distribution within bamboo laminates, ensuring the durability and longevity of bamboo sleepers. Therefore, while bamboo products offer potential as alternatives to timber sleepers in terms of their mechanical features and damping properties, further research is necessary to investigate their long-term performance, resistance to environmental factors, and bonding characteristics. Addressing these aspects will contribute to the successful incorporation of bamboo in railway sleeper construction.

5. Conclusions

This paper aims to study the potential and properties of bamboo products to manufacture a railway sleeper. Therefore, the mechanical properties of bamboo products and their manufacturing methods are discussed. The application of bamboo in the railway industry has been reviewed, and numerical modeling of bamboo is presented. A brief overview of the authors in bamboo sleeper production is also shown in this review paper. Bamboo sleepers’ static behavior is compared with current railway sleepers. The key findings of this paper are as follows:

- Bamboo has been considered a low-quality product for construction by emerging new technologies to manufacture bamboo products such as plywood, bamboo scrimber, and laminates. This material provides better properties than wood and composites with high stiffness, strength/mass per volume, and low carbon emission features.

- More than 104 countries have contributed to bamboo publications with around 4119 papers. These contributions have increased in recent years, which shows the attention given by researchers even in those countries without bamboo as a local plant.

- One of the main defects regarding the application of bamboo is the wide range of properties that can be found in the same bamboo products. However, the mechanical properties of bamboo products greatly increase, but the high difference between the mechanical properties of the elements of the structures may cause failure.

- Bamboo plywood and scrimber are the main products that are suitable for railway sleeper production in terms of their durability and mechanical performance. These products can provide moisture-proofing, water resistance, corrosion resistance, and resistance to salt damage.

- The application of bamboo in the railway industry has not been well extended compared with other parts of structural science. This material has mostly been used for soil improvement. However, considering its properties, it has the potential to be widely used in railway sleeper manufacturing, as has been studied so far. The shortcoming for more application of bamboo in the railway industry is the concerns about its weathering and long-term performance, as there are no such studies.

- To model bamboo, it is mostly characterized as an anisotropic material, with greater tensile and compressive strengths in the longitudinal direction compared to the transverse directions. The literature has proven that most FEM models can be validated with experimental results with low differences.

Author Contributions

Conceptualization, X.H., W.J., Y.D. and M.S.; methodology, X.H., W.J., Y.D. and M.S.; formal analysis, X.H., W.J., Y.D. and M.S.; investigation, X.H., W.J., Y.D. and M.S.; resources, X.H., W.J., Y.D. and M.S.; data curation, X.H., W.J., Y.D. and M.S.; writing—original draft preparation, X.H., W.J., Y.D. and M.S.; writing—review and editing, X.H., W.J., Y.D. and M.S.; visualization, X.H., W.J., Y.D. and M.S.; supervision, X.H., W.J., Y.D. and M.S.; project administration, W.J.; funding acquisition, W.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data generated or analyzed during this study are included in this published article.

Acknowledgments

The research was supported by the National Natural Science Foundation of China (No. 52027813).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Siahkouhi, M.; Li, X.; Han, X.; Jing, G. Improving the mechanical performance of timber railway sleepers with carbon fabric reinforcement: An experimental and numerical study. J. Compos. Constr. 2022, 26, 04021064. [Google Scholar] [CrossRef]

- Maulana, M.I.; Jeon, W.S.; Purusatama, B.D.; Kim, J.H.; Prasetia, D.; Yang, G.U.; Savero, A.M.; Nawawi, D.S.; Nikmatin, S.; Sari, R.K. Anatomical Characteristics for Identification and Quality Indices of Four Promising Commercial Bamboo Species in Java, Indonesia. BioResources 2022, 17, 1442–1453. [Google Scholar] [CrossRef]

- Yang, S.; Li, H.; Fei, B.; Zhang, X.; Wang, X. Bond quality and durability of cross-laminated flattened bamboo and timber (CLBT). Forests 2022, 13, 1271. [Google Scholar] [CrossRef]

- Rathour, R.; Kumar, H.; Prasad, K.; Anerao, P.; Kumar, M.; Kapley, A.; Pandey, A.; Kumar Awasthi, M.; Singh, L. Multifunctional applications of bamboo crop beyond environmental management: An Indian prospective. Bioengineered 2022, 13, 8893–8914. [Google Scholar] [CrossRef] [PubMed]

- Pamungkas, D.; Prasetyo, B.D.; Roshetko, J.M.; Sabastian, G.E.; Indartik, I.; Suryandari, E.Y.; Ekawati, D.; Ingram, W. Growth, yield and economic potential of Strobilanthes cusia (Nees) Kuntze in underutilized bamboo stands in Indonesia. Agrofor. Syst. 2023, 97, 1491–1509. [Google Scholar] [CrossRef]

- Dlamini, L.C.; Fakudze, S.; Makombe, G.G.; Muse, S.; Zhu, J. Bamboo as a valuable resource and its utilization in historical and modern-day China. BioResources 2022, 17, 1926. [Google Scholar] [CrossRef]

- Khong, S.; Yee, J.; Doh, S.; Chin, S. A review of agro-potential waste’s as constituent in railway sleepers. Phys. Chem. Earth Parts A/B/C 2022, 128, 103238. [Google Scholar] [CrossRef]

- Chaturvedi, K.; Singhwane, A.; Dhangar, M.; Mili, M.; Gorhae, N.; Naik, A.; Prashant, N.; Srivastava, A.; Verma, S. Bamboo for producing charcoal and biochar for versatile applications. Biomass Convers. Biorefinery 2023, 1–27. [Google Scholar] [CrossRef]

- Sharma, B.; van der Vegte, A. Engineered bamboo for structural applications. In Nonconventional and Vernacular Construction Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 597–623. [Google Scholar]

- Jain, S.; Kumar, R.; Jindal, U. Mechanical behaviour of bamboo and bamboo composite. J. Mater. Sci. 1992, 27, 4598–4604. [Google Scholar] [CrossRef]

- Adin, H.; Adin, M.Ş. Effect of particles on tensile and bending properties of jute epoxy composites. Mater. Test. 2022, 64, 401–411. [Google Scholar] [CrossRef]

- Garcia-Saenz, M. Social and cultural aspects of constructions with bamboo. In Proceedings of the Tenth LACCEI Latin American and Caribbean Conference, Panama City, Panama, 23–25 July 2012. [Google Scholar]

- Waite, M. Sustainable Textiles: The Role of Bamboo and a Comparison of Bamboo Textile Properties—Part 2. J. Text. Appar. Technol. Manag. 2010, 6. [Google Scholar]

- van Dam, J.E.; Elbersen, H.W.; Montaño, C.M.D. Bamboo production for industrial utilization. In Perennial Grasses for Bioenergy and Bioproducts; Academic Press: Cambridge, MA, USA, 2018; pp. 175–216. [Google Scholar] [CrossRef]

- Lakkad, S.; Patel, J. Mechanical properties of bamboo, a natural composite. Fibre Sci. Technol. 1981, 14, 319–322. [Google Scholar] [CrossRef]

- Jia, B.; Yu, Q.; Zhao, Y.; Qin, M.; Wang, W.; Liu, Z.; Lao, C.Y.; Liu, Y.; Wu, H.; Zhang, Z. Bamboo-like hollow tubes with MoS2/N-doped-C interfaces boost potassium-ion storage. Adv. Funct. Mater. 2018, 28, 1803409. [Google Scholar] [CrossRef]

- Han, S.; Chen, F.; Ye, H.; Zheng, Z.; Chen, L.; Wang, G. Bamboo-Inspired Renewable, High-Strength, Vibration-Damping Composites for Structural Applications. ACS Sustain. Chem. Eng. 2023, 11, 1146–1156. [Google Scholar] [CrossRef]

- Wei, X.; Zhou, H.; Chen, F.; Wang, G. Bending flexibility of moso bamboo (Phyllostachys edulis) with functionally graded structure. Materials 2019, 12, 2007. [Google Scholar] [CrossRef] [PubMed]

- Isa, A.; Minamino, J.; Mizuno, H.; Suzuki, S.; Kojima, Y.; Ito, H.; Makise, R.; Okamoto, M.; Hasegawa, T. Increased water resistance of bamboo flour/polyethylene composites. J. Wood Chem. Technol. 2013, 33, 208–216. [Google Scholar] [CrossRef][Green Version]

- Ding, T.; Zhou, J.; Wan, D.; Chen, Z.; Wang, C.; Zhang, F. Silicon isotope fractionation in bamboo and its significance to the biogeochemical cycle of silicon. Geochim. Cosmochim. Acta 2008, 72, 1381–1395. [Google Scholar] [CrossRef]

- Norhisham, A.; Faizah, A.; Zaidon, A. Effects of moisture content on the bamboo borer Dinoderus minutus . J. Trop. For. Sci. 2015, 27, 334–341. [Google Scholar]

- Van Der Lugt, P.; Van den Dobbelsteen, A.; Abrahams, R. Bamboo as a building material alternative for Western Europe? A study of the environmental performance, costs and bottlenecks of the use of bamboo (products) in Western Europe. J. Bamboo Ratt. 2003, 2, 205–223. [Google Scholar] [CrossRef]

- Nie, Y.; Ping, R.; Ji, C.; Li, L.; Bao, L.; Peng, J.; Li, X. Achieving superior high-life-stability and stable structure for flexible fiber electrodes inspired by Bamboo rice dumpling. Electrochim. Acta 2023, 452, 142352. [Google Scholar] [CrossRef]

- Emamverdian, A.; Ding, Y.; Ranaei, F.; Ahmad, Z. Application of bamboo plants in nine aspects. Sci. World J. 2020, 2020, 7284203. [Google Scholar] [CrossRef] [PubMed]

- Shah, K.N.A.K.A.; Yusop, M.Z.M.; Rohani, J.M.; Fadil, N.A.; Manaf, N.A.; Hartono, B.; Tuyen, N.D.; Masaki, T.; Ahmad, A.S.; Ramli, A. Feasibility study on biomass bamboo renewable energy in Malaysia, Indonesia, Vietnam and Japan. Chem. Eng. Trans. 2021, 89, 127–132. [Google Scholar]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Xu, X.; Xu, P.; Zhu, J.; Li, H.; Xiong, Z. Bamboo construction materials: Carbon storage and potential to reduce associated CO2 emissions. Sci. Total Environ. 2022, 814, 152697. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Shen, H.; Shan, W.; Han, T. Flexural behavior of lightweight bamboo–steel composite slabs. Thin-Walled Struct. 2012, 53, 83–90. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; Song, B.; Yao, Y.; Shi, Y. Bamboo-inspired, simulation-guided design and 3D printing of light-weight and high-strength mechanical metamaterials. Appl. Mater. Today 2022, 26, 101268. [Google Scholar] [CrossRef]

- Shao, Z.; Zhou, L.; Liu, Y.; Wu, Z.; Arnaud, C. Differences in structure and strength between internode and node sections of moso bamboo. J. Trop. For. Sci. 2010, 22, 133–138. [Google Scholar]

- Dauletbek, A.; Xue, X.; Shen, X.; Li, H.; Feng, Z.; Lorenzo, R.; Liu, K.; Escamilla, E.Z.; Yao, L.; Zheng, X. Lightweight bamboo structures-Report on 2021 International Collaboration on Bamboo Construction. Sustain. Struct. 2022, 3, 25. [Google Scholar] [CrossRef]

- Chaowana, K.; Wisadsatorn, S.; Chaowana, P. Bamboo as a sustainable building material—Culm characteristics and properties. Sustainability 2021, 13, 7376. [Google Scholar] [CrossRef]

- Mahdavi, M.; Clouston, P.; Arwade, S. Development of laminated bamboo lumber: Review of processing, performance, and economical considerations. J. Mater. Civ. Eng. 2011, 23, 1036–1042. [Google Scholar] [CrossRef]

- Arcos, P.; Tintín, K.; Calvo, J.; Avila, E.B. Golden Flower: Architectural Design Based on Bamboo Structure. Available online: https://www.researchgate.net/profile/Enrique-Barreno-Avila/publication/359109569_Golden_Flower_Architectural_design_based_on_bamboo_structure/links/63d67d86c97bd76a8246cda6/Golden-Flower-Architectural-design-based-on-bamboo-structure.pdf (accessed on 1 October 2023).

- Liu, Y.; Zhang, J.; Xu, J.; Wang, Y.; Li, B.; Zhang, S. Carbon emission-based life cycle assessment of rural residential buildings constructed with engineering bamboo: A case study in China. J. Build. Eng. 2023, 76, 107182. [Google Scholar] [CrossRef]

- Chen, X.; Chen, F.; Yang, Q.; Gong, W.; Wang, J.; Li, Y.; Wang, G. An environmental food packaging material part I: A case study of life-cycle assessment (LCA) for bamboo fiber environmental tableware. Ind. Crops Prod. 2023, 194, 116279. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Gan, J.; Chen, M.; Semple, K.; Liu, X.; Dai, C.; Tu, Q. Life cycle assessment of bamboo products: Review and harmonization. Sci. Total Environ. 2022, 849, 157937. [Google Scholar] [CrossRef]

- Zea Escamilla, E.; Habert, G.; Correal Daza, J.F.; Archilla, H.F.; Echeverry Fernández, J.S.; Trujillo, D. Industrial or traditional bamboo construction? Comparative life cycle assessment (LCA) of bamboo-based buildings. Sustainability 2018, 10, 3096. [Google Scholar] [CrossRef]

- Chang, F.-C.; Chen, K.-S.; Yang, P.-Y.; Ko, C.-H. Environmental benefit of utilizing bamboo material based on life cycle assessment. J. Clean. Prod. 2018, 204, 60–69. [Google Scholar] [CrossRef]

- Vogtländer, J.G.; van der Velden, N.M.; van der Lugt, P. Carbon sequestration in LCA, a proposal for a new approach based on the global carbon cycle; cases on wood and on bamboo. Int. J. Life Cycle Assess. 2014, 19, 13–23. [Google Scholar] [CrossRef]

- Ogawa, K.; Hirogaki, T.; Aoyama, E.; Taniguchi, M.; Ogawa, S. Sustainable Manufacturing System Focusing on the Natural Growth of Bamboo (Evaluation of Environmental Impact by LCA). J. Adv. Mech. Des. Syst. Manuf. 2010, 4, 531–542. [Google Scholar] [CrossRef]

- Vogtländer, J.; Van der Lugt, P.; Brezet, H. The sustainability of bamboo products for local and Western European applications. LCAs and land-use. J. Clean. Prod. 2010, 18, 1260–1269. [Google Scholar] [CrossRef]

- Caldas, L.; da Gloria, M.; Santos, D.; Andreola, V.; Pepe, M.; Toledo Filho, R. Carbon footprint of bamboo particles, rice husk and wood shavings-cement composites. Acad. J. Civ. Eng. 2017, 35, 499–506. [Google Scholar]

- Zhang, S.; Li, Y.; Singh, B.P.; Wang, H.; Cai, X.; Chen, J.; Qin, H.; Li, Y.; Chang, S.X. Contrasting short-term responses of soil heterotrophic and autotrophic respiration to biochar-based and chemical fertilizers in a subtropical Moso bamboo plantation. Appl. Soil Ecol. 2021, 157, 103758. [Google Scholar] [CrossRef]

- Harries, K.A.; Bumstead, J.; Richard, M.; Trujillo, D. Geometric and material effects on bamboo buckling behaviour. Proc. Inst. Civ. Eng.-Struct. Build. 2017, 170, 236–249. [Google Scholar] [CrossRef]

- Wang, J.; Siahkouhi, M.; Astaraki, F.; Uuganbayar, S.; Jing, G.; Movahedi Rad, M. Modification of Concrete Railway Sleeper Mix Design, Using a Hybrid Application of Steel Fibers. Acta Polytech. Hung. 2022, 19, 119–130. [Google Scholar] [CrossRef]

- Das, M.; Chakraborty, D. Evaluation of improvement of physical and mechanical properties of bamboo fibers due to alkali treatment. J. Appl. Polym. Sci. 2008, 107, 522–527. [Google Scholar] [CrossRef]

- Xiansheng, Q.; Feng, H.; Qiong, L.; Xin, S. Online defect inspection algorithm of bamboo strip based on computer vision. In Proceedings of the 2009 IEEE International Conference on Industrial Technology, Churchill, VIC, Australia, 10–13 February 2009; pp. 1–5. [Google Scholar]

- Satyanarayana, K.; Sukumaran, K.; Mukherjee, P.; Pavithran, C.; Pillai, S. Natural fibre-polymer composites. Cem. Concr. Compos. 1990, 12, 117–136. [Google Scholar] [CrossRef]

- Yuan, T.; Wang, X.; Lou, Z.; Zhang, T.; Han, X.; Wang, Z.; Hao, X.; Li, Y. Comparison of the fabrication process and macro and micro properties of two types of crack-free, flatten bamboo board. Constr. Build. Mater. 2022, 317, 125949. [Google Scholar] [CrossRef]

- Composite Plybamboo Form with Steel Frame. Available online: https://www.gbstandards.org/China_standard_english.asp?code=JG/T%20428-2014&id=86051 (accessed on 1 October 2023).

- Quality Grading Standards of Main Bamboo Shoot. Available online: https://www.chinesestandard.net/PDF.aspx/GBT30762-2014 (accessed on 1 October 2023).

- Testing Methods for Physical and Mechanical Properties of Bamboo Used in Building. Available online: https://www.chinesestandard.net/PDF/English.aspx/JGT199-2007 (accessed on 1 October 2023).

- Bamboos . Available online: https://www.chinesestandard.net/PDF/English.aspx/GBT2690-1981 (accessed on 1 October 2023).

- Testing Methods for Physical and Mechanical Properties of Bamboos . Available online: https://www.chinesestandard.net/PDF/English.aspx/GBT15780-1995 (accessed on 1 October 2023).

- Amede, E.A.; Hailemariama, E.K.; Hailemariam, L.M.; Nuramo, D.A. A review of codes and standards for bamboo structural design. Adv. Mater. Sci. Eng. 2021, 2021, 4788381. [Google Scholar] [CrossRef]

- Yu, Y.; Zhu, R.; Wu, B.; Hu, Y.a.; Yu, W. Fabrication, material properties, and application of bamboo scrimber. Wood Sci. Technol. 2015, 49, 83–98. [Google Scholar] [CrossRef]

- Van Hung, T.; Lien, H.D.; Antonov, S. A Design of Bamboo Plywood Pressing Machine. VNUHCM J. Eng. Technol. 2019, 3, SI143–SI150. [Google Scholar]

- Shen-xue, J.; Qi-sheng, Z.; Shu-hai, J. On Structure, production, and market of bamboo-based panels in China. J. For. Res. 2002, 13, 151–156. [Google Scholar] [CrossRef]

- Dauletbek, A.; Li, H.; Xiong, Z.; Lorenzo, R. A review of mechanical behavior of structural laminated bamboo lumber. Sustain. Struct. 2021, 1, 4. [Google Scholar] [CrossRef]

- Rathod, S.; Parab, A.; Tamkhane, A.; Neharkar, A.; Patil, A.; Gayake, P. A Comparative Study of Bamboo Reinforced Vs Steel Reinforced Concrete Structure. Int. J. Res. Appl. Sci. Eng. Technol. (IJRASET) 2022, 10, 973–976. [Google Scholar] [CrossRef]

- Van der Lugt, P.; Van den Dobbelsteen, A.; Janssen, J. An environmental, economic and practical assessment of bamboo as a building material for supporting structures. Constr. Build. Mater. 2006, 20, 648–656. [Google Scholar] [CrossRef]

- Sun, H.; Li, H.; Dauletbek, A.; Lorenzo, R.; Corbi, I.; Corbi, O.; Ashraf, M. Review on materials and structures inspired by bamboo. Constr. Build. Mater. 2022, 325, 126656. [Google Scholar] [CrossRef]

- Ma, R.; Chen, Z.; Du, Y.; Jiao, L. Structural Grading and Characteristic Value of the Moso Bamboo Culm Based on Its Minimum External Diameter. Sustainability 2023, 15, 11647. [Google Scholar] [CrossRef]

- Madhushan, S.; Buddika, S.; Bandara, S.; Navaratnam, S.; Abeysuriya, N. Uses of Bamboo for Sustainable Construction—A Structural and Durability Perspective—A Review. Sustainability 2023, 15, 11137. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, H.; Li, J.; Zhong, T.; Wang, H. Differences in dry shrinkage of bamboo rings with multiple heights and radians based on vascular bundle group. Holzforschung 2023, 77, 208–217. [Google Scholar] [CrossRef]

- Fang, C.-H.; Jiang, Z.-H.; Sun, Z.-J.; Liu, H.-R.; Zhang, X.-B.; Zhang, R.; Fei, B.-H. An overview on bamboo culm flattening. Constr. Build. Mater. 2018, 171, 65–74. [Google Scholar] [CrossRef]

- Amada, S.; Untao, S. Fracture properties of bamboo. Compos. Part B Eng. 2001, 32, 451–459. [Google Scholar] [CrossRef]

- Shao, Z.-P.; Fang, C.-H.; Tian, G.-L. Mode I interlaminar fracture property of moso bamboo (Phyllostachys pubescens). Wood Sci. Technol. 2009, 43, 527–536. [Google Scholar] [CrossRef]

- Han, S.; Chen, F.; Yu, Y.; Zheng, Z.; Chen, L.; Wang, G. Bamboo-Inspired Renewable, Lightweight, and Vibration-Damping Laminated Structural Materials for the Floor of a Railroad Car. ACS Appl. Mater. Interfaces 2022, 14, 42645–42655. [Google Scholar] [CrossRef]

- Huang, Y.; Ji, Y.; Yu, W. Development of bamboo scrimber: A literature review. J. Wood Sci. 2019, 65, 25. [Google Scholar] [CrossRef]

- Sumardi, I.; Alamsyah, E.M.; Suhaya, Y.; Dungani, R.; Sulastiningsih, I.M.; Pramestie, S.R. Development of bamboo zephyr composite and the physical and mechanical properties. J. Korean Wood Sci. Technol. 2022, 50, 134–147. [Google Scholar] [CrossRef]

- Kumar, D.; Mandal, A. Review on manufacturing and fundamental aspects of laminated bamboo products for structural applications. Constr. Build. Mater. 2022, 348, 128691. [Google Scholar] [CrossRef]

- Li, Z.; Xia, M.K.; Shi, J.J.; Wang, R. Shear properties of composite cross-laminated bamboo panels. Eur. J. Wood Wood Prod. 2022, 80, 635–646. [Google Scholar] [CrossRef]

- Wang, C.; Kondrashchenko, V.; Jing, G.; Adilhodzaev, A. Determination of material composition for composite sleepers based on polyvinyl chloride, chalk and bamboo fiber. In AIP Conference Proceedings; AIP Publishing: Semarang, Indonesia, 2023. [Google Scholar]

- Xiao, S.; Lin, H.; Shi, S.Q.; Cai, L. Optimum processing parameters for wood-bamboo hybrid composite sleepers. J. Reinf. Plast. Compos. 2014, 33, 2010–2018. [Google Scholar] [CrossRef]

- Nkeuwa, W.N.; Zhang, J.; Semple, K.E.; Chen, M.; Xia, Y.; Dai, C. Bamboo-based composites: A review on fundamentals and processes of bamboo bonding. Compos. Part B Eng. 2022, 235, 109776. [Google Scholar] [CrossRef]

- Iynkaran, S.; Bogoda, S. Performance Analysis of Concrete Slab Reinforced with Steel and Bamboo. Adv. Technol. 2022, 2, 114–123. [Google Scholar] [CrossRef]

- Javadian, A.; Smith, I.F.; Saeidi, N.; Hebel, D.E. Mechanical properties of bamboo through measurement of culm physical properties for composite fabrication of structural concrete reinforcement. Front. Mater. 2019, 6, 15. [Google Scholar] [CrossRef]

- Anwar, U.; Zaidon, A.; Paridah, M.; Razak, W. The potential of utilising bamboo culm (Gigantochloa scortechinii) in the production of structural plywood. J. Bamboo Ratt. 2004, 3, 393–400. [Google Scholar] [CrossRef]

- Kuian, W.; Qin, L.; Xiaohui, G. Present utilizational situation and deep exploitation of bamboo resources. J. Bamboo Res. 2000, 19, 72–75. [Google Scholar]

- Wang, Q.; Han, H.; Lou, Z.; Han, X.; Wang, X.; Li, Y. Surface property enhancement of bamboo by inorganic materials coating with extended functional applications. Compos. Part A Appl. Sci. Manuf. 2022, 155, 106848. [Google Scholar] [CrossRef]

- Chu, G.M.; Jung, C.K.; Kim, H.Y.; Ha, J.H.; Kim, J.H.; Jung, M.S.; Lee, S.J.; Song, Y.; Ibrahim, R.I.H.; Cho, J.H. Effects of bamboo charcoal and bamboo vinegar as antibiotic alternatives on growth performance, immune responses and fecal microflora population in fattening pigs. Anim. Sci. J. 2013, 84, 113–120. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y. Engineered Bamboo Structures; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Qiu, Z.; Zhu, W.; Fan, H. Anisotropy attenuation of reconstituted bamboo lumber by orthogonal layup process. Compos. Commun. 2023, 40, 101608. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Z.; Yang, Y.; Zhou, J. Acoustic emission characteristics of different bamboo and wood materials in bending failure process. J. Renew. Mater. 2022, 10, 527. [Google Scholar] [CrossRef]

- Lee, A.W.; Bai, X.; Bangi, A.P. Selected properties of laboratory-made laminated-bamboo lumber. Holzforschung 1998, 52, 207–210. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.; Yang, D.; Xiong, Z.; Sayed, U.; Lorenzo, R.; Corbi, I.; Corbi, O.; Hong, C. Bamboo node effect on the tensile properties of side press-laminated bamboo lumber. Wood Sci. Technol. 2021, 55, 195–214. [Google Scholar] [CrossRef]

- Dong, W.; Wang, Z.; Zhou, J.; Gong, M. Experimental study on bending properties of cross-laminated timber-bamboo composites. Constr. Build. Mater. 2021, 300, 124313. [Google Scholar] [CrossRef]

- Nugroho, N.; Ando, N. Development of structural composite products made from bamboo II: Fundamental properties of laminated bamboo lumber. J. Wood Sci. 2001, 47, 237–242. [Google Scholar] [CrossRef]

- Ghavami, K. Application of bamboo as a low-cost construction material. In Proceedings of the International Bamboo Workshop, Cochin, India, 14–18 November 1988; pp. 270–279. [Google Scholar]

- Chen, J.; Guagliano, M.; Shi, M.; Jiang, X.; Zhou, H. A comprehensive overview of bamboo scrimber and its new development in China. Eur. J. Wood Wood Prod. 2021, 79, 363–379. [Google Scholar] [CrossRef]

- Sun, X.; He, M.; Li, Z. Novel engineered wood and bamboo composites for structural applications: State-of-art of manufacturing technology and mechanical performance evaluation. Constr. Build. Mater. 2020, 249, 118751. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, R.; Huang, Y.; Meng, F.; Yu, W. Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Constr. Build. Mater. 2017, 157, 1032–1039. [Google Scholar] [CrossRef]

- Shangguan, W.; Gong, Y.; Zhao, R.; Ren, H. Effects of heat treatment on the properties of bamboo scrimber. J. Wood Sci. 2016, 62, 383–391. [Google Scholar] [CrossRef]

- Peng, R.; Yang, F.; Yin, W.; Du, C.; Liu, C.; Chen, S.; Shan, Y.; Shao, Y.; Wang, Y. Facile preparation, pyrolysis and pilot production a bamboo scrimber with halogen-free, flame-resistance and low-smoke. Ind. Crops Prod. 2023, 204, 117358. [Google Scholar] [CrossRef]

- Erlangga, A.W.; Priyanto, S.; Laynardo, D.C. Analysis of Soil Improvement Using Bamboo Net-System on Railway. J. Phys. Conf. Ser. 2019, 1273, 012079. [Google Scholar] [CrossRef]

- Sasmayaputra, N.A.; Adi, A.D.; Faris, F. Bamboo mat as a temporary reinforced soil retaining wall in a railway bed. In Proceedings of the International Conference on Technology and Vocational Teachers (ICTVT 2017), Yogyakarta, Indonesia, 28 September 2017; Atlantis Press: Amsterdam, The Netherlands, 2017; pp. 72–77. [Google Scholar]

- Liu, K.; Yu, Z.; Wang, K.; Jing, L. Crashworthiness of bamboo-inspired circular tubes used for the energy absorber of rail vehicles. Acta Mech. Sin. 2022, 38, 122014. [Google Scholar] [CrossRef]

- Grosser, D.; Liese, W. On the anatomy of Asian bamboos, with special reference to their vascular bundles. Wood Sci. Technol. 1971, 5, 290–312. [Google Scholar] [CrossRef]

- Liese, W.; Weiner, G. Ageing of bamboo culms. A review. Wood Sci. Technol. 1996, 30, 77–89. [Google Scholar] [CrossRef]

- Torres, L.; Ghavami, K.; Garcia, J. A transversely isotropic law for the determination of the circumferential young’s modulus of bamboo with diametric compression tests. Lat. Am. Appl. Res. 2007, 37, 255–260. [Google Scholar]

- García, J.J.; Rangel, C.; Ghavami, K. Experiments with rings to determine the anisotropic elastic constants of bamboo. Constr. Build. Mater. 2012, 31, 52–57. [Google Scholar] [CrossRef]

- Ramful, R. Evaluation of the Mechanical Properties of Bambusa Bamboo Laminates through Destructive Testing. J. Green Build. 2018, 13, 1–18. [Google Scholar] [CrossRef]

- Adhikari, R.; Wood, D.; Sudak, L. Low-cost bamboo lattice towers for small wind turbines. Energy Sustain. Dev. 2015, 28, 21–28. [Google Scholar] [CrossRef]

- Fu, Y.; Fang, H.; Dai, F. Study on the properties of the recombinant bamboo by finite element method. Compos. Part B Eng. 2017, 115, 151–159. [Google Scholar] [CrossRef]

- Chand, N.; Shukla, M.; Sharma, M.K. Analysis of mechanical behaviour of bamboo (Dendrocalamus strictus) by using FEM. J. Nat. Fibers 2008, 5, 127–137. [Google Scholar] [CrossRef]

- Al-Rukaibawi, L.S.; Károlyi, G. Nonlinear analysis of a bamboo plywood-steel composite I-section beam under bending. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Jing, G.; Siahkouhi, M.; Edwards, J.R.; Dersch, M.S.; Hoult, N. Smart railway sleepers—A review of recent developments, challenges, and future prospects. Constr. Build. Mater. 2021, 271, 121533. [Google Scholar] [CrossRef]

- Siahkouhi, M.; Han, X.; Wang, M.; Manalo, A.; Jing, G. Development and performance evaluation of self-healing concrete railway sleepers using different size PU tubes. Eng. Struct. 2023, 283, 115920. [Google Scholar] [CrossRef]

- Siahkouhi, M.; Li, X.; Han, X.; Kaewunruen, S.; Jing, G. Experimental and finite element assessments of the fastening system of fiber-reinforced foamed urethane (FFU) composite sleepers. Eng. Fail. Anal. 2022, 141, 106693. [Google Scholar] [CrossRef]

- Aela, P.; Zong, L.; Siahkouhi, M.; Bahari, Y.; Jing, G. Numerical and Experimental Analysis of Lateral Resistance of Single Y-Shaped Steel Sleeper on Ballasted Tracks. J. Mater. Civ. Eng. 2022, 34, 04021414. [Google Scholar] [CrossRef]

- Siahkouhi, M.; Li, X.; Markine, V.; Jing, G. An experimental and numerical study on the mechanical behavior of Kunststof Lankhorst Product (KLP) sleepers. Sci. Iran. 2021, 28, 2568–2581. [Google Scholar] [CrossRef]

- Jing, G.; Aela, P. Review of the lateral resistance of ballasted tracks. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2020, 234, 807–820. [Google Scholar] [CrossRef]

- Guo, Y.; Fu, H.; Qian, Y.; Markine, V.; Jing, G. Effect of sleeper bottom texture on lateral resistance with discrete element modelling. Constr. Build. Mater. 2020, 250, 118770. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.; Alothman, O.Y.; Abdullah, L.C. Accelerated weathering and soil burial effects on colour, biodegradability and thermal properties of bamboo/kenaf/epoxy hybrid composites. Polym. Test. 2019, 79, 106054. [Google Scholar] [CrossRef]

- Sonar, I.; Siddhaye, V. Theoretical and experimental investigation on single and double bolted bamboo joint under axial tension. J. Struct. Eng. 2009, 36, 164–171. [Google Scholar]

- Made in China. Railway Sleepers. Available online: https://www.made-in-china.com/productdirectory.do?subaction=hunt&style=b&mode=and&code=0&comProvince=nolimit&order=0&isOpenCorrection=1&org=top&keyword=&file=&searchType=0&word=railway+concrete+sleeper (accessed on 1 October 2023).

- Jing, G.; Fu, H.; Aela, P. Lateral displacement of different types of steel sleepers on ballasted track. Constr. Build. Mater. 2018, 186, 1268–1275. [Google Scholar] [CrossRef]

- Jing, G.; Yunchang, D.; You, R.; Siahkouhi, M. Comparison study of crack propagation in rubberized and conventional prestressed concrete sleepers using digital image correlation. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2022, 236, 350–361. [Google Scholar] [CrossRef]

- Bolin, C.A.; Smith, S.T. Life cycle assessment of creosote-treated wooden railroad crossties in the US with comparisons to concrete and plastic composite railroad crossties. J. Transp. Technol. 2013, 3, 30419. [Google Scholar] [CrossRef]

- Sharma, B.; Gatóo, A.; Ramage, M.H. Effect of processing methods on the mechanical properties of engineered bamboo. Constr. Build. Mater. 2015, 83, 95–101. [Google Scholar] [CrossRef]

- Dewi, S.M.; Wijaya, M.N. The use of bamboo fiber in reinforced concrete beam to reduce crack. AIP Conf. Proc. 2017, 1887, 020003. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).