Abstract

Spun piles adjacent to the pile cap need sufficient confinement to ensure the formation of plastic hinges during severe earthquakes. However, the high confinement ratio required for precast piles according to ACI 318-19 results in tightly spaced spirals, which are difficult to implement. Since higher confinement is only needed at specific regions of the pile, external transverse reinforcement using steel jacketing has been proposed as an alternative solution. An experimental and numerical study was conducted to evaluate the effectiveness. The experimental results showed that the jacket enhanced both the strength and energy dissipation of the connection, but had only a minor effect on its ductility. A parametric study using finite element analysis was performed to investigate the parameters influencing connection behavior. The results indicated that variations in jacket thickness did not significantly impact the connection’s performance. A jacket height equal to 1.53 times the pile diameter was found to be the maximum effective height. It was also observed that higher axial loads led to a sudden loss of connection strength, thereby reducing ductility. Partial bonding between the jacket, grout, and pile was found to be acceptable within a certain range. The numerical analysis found that the steel jacket increases the ductility.

1. Introduction

Spun piles are widely used in Indonesia for bridge and wharf foundations. The piles have been produced with limited confinement below the minimum standards since they are designed based on the elastic concept, where the damages are inhibited. The design code [1] for substructures still adopts the elastic method. However, in terms of concrete pile detailing, it refers to upper structure code [2], where at a potential plastic hinge, confinement should be fulfilled. Hence, the spun pile and pile cap connection requires adequate confinement, as it experiences the highest curvature. Post-severe-earthquake observations have reported several damages occurring in the pile close to the pile [3]. Therefore, the spun pile at this location must be equipped with adequate confinement. Since it refers to two different standards with different concepts, the requirement for confinement in spun piles in Indonesia is not strictly enforced. As a result, spun piles with low confinement have been widely used in bridges and pier infrastructures across Indonesia.

Recent seismic hazard assessments indicate an increase in seismic acceleration across many regions of Indonesia. Allowing inelastic behaviour in the piles in the future becomes a real concern when a major earthquake occurs. This highlights the need to implement performance-based design for substructures. Therefore, ensuring adequate confinement in spun pile connections becomes essential. Confinement plays a crucial role in restraining concrete, allowing it to develop confined concrete strength (f’cc), which enables the structure to sustain large displacement during a major earthquake. The provision of confinement in the plastic hinge area should correlate with the ductility of the structure and its energy dissipation capacity during an earthquake.

ASCE 7-16 [4] also provides confinement requirements for prestressed piles. Unlike ACI 318-19, the confinement demand is not only governed by the ratio of the gross area (Ag) of the pile to the core concrete (Ach), but also by the amount of axial load applied to the pile. A higher axial load requires a greater level of confinement. When compared, at relatively low axial load, the confinement ratio requirement specified in ASCE 7-16 is lower than that of ACI 318; however, it increases proportionally with the rise in axial load.

Several studies have been conducted in Indonesia to investigate the behavior of spun piles with limited confinement [5,6,7]. An experimental study on three spun pile specimens was performed [5]. All piles have a volumetric ratio of 0.097%, which is about 16% of the minimum requirement according to ASCE 7-16. The spun pile had a diameter of 400 mm, a wall thickness of 70 mm, and a concrete strength (f’c) of 54.4 MPa, with stirrups having a yield strength (fy) of 681 MPa. The bending test results showed that 3.2 mm diameter stirrups with 100 mm spacing were unable to prevent concrete spalling. Therefore, the research concluded that the existing spun pile configuration is not recommended in high-seismic-risk areas.

Another experimental study was conducted on the connection between spun piles and pile caps using a typical connection type commonly used in Indonesia [6,7]. A 450 mm diameter spun pile with an 80 mm wall thickness was connected to the pile cap with an anchorage length of 500 mm embedded into the pile cap, with an additional 200 mm bent at an angle of 30 degrees. There are three spun pile–pile cap connections in the experimental study: an empty spun pile (SPPC01) and two spun piles with concrete infill (SPPC02 and SPPC03), both reinforced with 6D19 bars. SPPC03 used expansive concrete to ensure better bonding between the infill concrete and the spun pile, and SPPC02 used regular concrete. All specimens have a spiral reinforcement of 4 mm in diameter with a space of 120 mm, which represents only 0.113% confinement and 19% of the minimum requirement of ASCE. 7-16 The infill concrete was confined by a stirrup of 8 mm diameter with a 75 mm pitch. All specimens were subjected to cyclic horizontal loading, with a constant vertical load of 0.1 f’cAg applied during testing.

The results indicated that the connections exhibited relatively ductile behavior, with a ductility value of 3.7 for the infilled spun pile connections and up to 5 for the empty spun pile. The strength of the spun pile with concrete infill and 6D19 reinforcement increased by 41% compared to the empty spun pile connection. However, despite its higher ductility, the empty spun pile failed to reach the target drift of 3.5%, failing at 2.75% drift instead. The test results also revealed a fracture in the prestressing strands at a location 30–50 mm outside the pile cap. Overall, the experimental study demonstrated that spun piles with limited minimum confinement performed reasonably well, although they exhibited limited ductility and pinched hysteretic curves. The spun pile with 6D19 reinforcement showed significant strength improvement and better energy dissipation compared to the empty spun pile.

On the other hand, an experimental study on spun pile–pile cap connections was also conducted in China with a better confinement ratio [8]. A total of six specimens with different connection configurations were tested, representing common connection types used in China. The 500 mm diameter spun piles with a 100 mm wall thickness were made of 62–65 MPa concrete and were connected to the pile cap using anchor bars welded to steel plates attached to the surface of the spun pile. Additionally, two specimens with different connection details where the spun pile was filled with reinforced concrete and the rebars were anchored 500 mm in length into the pile cap. These connections, labelled as CT4 and CT5, are similar to the connection type in Indonesia. Although the volumetric ratios were not specified, based on the data, the stirrup of A5 with a space of 45 mm is equivalent to a 0.436% confinement ratio, whereas the minimum requirement according to ASCE was 0.94%. All specimens were subjected to a constant vertical load of 0.1 f’cAg and cyclic horizontal loading. The results indicated that the displacement ductility of the connections ranged between 3 and 4. Specimen CT5 exhibited the best performance in terms of its strength and ductility. Overall, the hysteretic curves also showed pinching behavior. This study demonstrated that the performance of better confinement spun piles in China was not significantly different from the spun piles with poor confinement tested in Indonesia, in terms of ductility.

The experimental study on spun pile–pile cap connections in Korea, utilized spun piles with a diameter of 500 mm, a wall thickness of 80 mm, and f’c of 80 MPa [9]. The study compared three different pile head treatments. PHC-A and PHC-B were reinforced by nine PC bars with 9.2 mm diameter, meanwhile PHC-C had 12 PC bars of 8.3 mm diameter. The pile head treatment of the three connections was different. The pile of PHC-A was fully embedded in the pile cap with a 500 mm length. PHC-B was similar to the connection type in Indonesia by removing only the concrete of the pile without cutting the PC bars. The pile was filled with reinforced concrete of f’c 24 MPa and 9D19 deformed bars with an anchorage length of 920 mm. PHC-B uses a D13 spiral hoop as transverse reinforcement with a space of 150 mm, which was 70% of the minimum requirement of ASCE. PHC-C has a similar pile head treatment to PHC-B, with additional transverse reinforcement. The study found that different pile head treatments resulted in different connection performance. PHC-A has the highest initial rigidity but the lowest bending capacity. PHC-C, which has additional transverse reinforcement, has the highest energy dissipation and bending capacity. The ductility increased from 2.72 to 3.76 with the addition of confinement to the spun pile.

Sufficient transverse reinforcement is needed to ensure the concrete achieves f’cc at large deformation and hence, its strength could exceed the strength loss caused by concrete cover spalling. Due to the uncertainty of the hard soil position, ensuring confinement in the spun pile at the connection area can be achieved by providing external confinement. The confinement prevents spalling of the concrete cover, and hence the spun pile can maintain ductile behavior during a severe earthquake. This option is more efficient as it can be customized to suit the connection location rather than adding spiral reinforcement along the entire length of the pile. Concrete jacketing, steel jacketing, or FRP wrap are three common confinement methods that can be employed.

A 50 mm-thick concrete jacketing in the connection area of spun piles was conducted to strengthen the connection [10]. The spun pile had a diameter of 400 mm, a wall thickness of 95 mm, and a concrete strength of f’c 82 MPa. The spun pile was reinforced with seven 10.7 mm-diameter strands and D8 (50 mm) spiral reinforcement with a confinement ratio of 1.318%. The specimen was subjected to a constant vertical load of 0.1 f’cAg and cyclic horizontal loading. The experiment demonstrated a more robust hysteretic curve, with the ductility value increasing from 3.07 for specimens without strengthening to 4.31. Additionally, the connection strength increased twice compared to the unreinforced connection. The study concluded that concrete jacketing significantly improves connection performance. Nevertheless, the application of concrete jacketing as a strengthening technique is difficult to implement in foundation systems.

Yang conducted an experimental study on the spun pile–pile cap connection by applying three different strengthening methods at the pile, such as reinforcing with steel deformed bars, steel fibers, and CFRP (carbon fiber-reinforced polymer) [11]. The spun pile used had a diameter of 500 mm, a wall thickness of 100 mm, and a concrete strength of f’c 85 MPa. The piles use stirrups of 5 mm in diameter with 80 mm spacing, which leads to a confinement ratio of 0.245%; this is 25% of the minimum requirement of ASCE 7-16. The study found that the pile reinforced with steel fiber and deformed bars can improve the deformability and flexural bearing capacity of piles, which causes the displacement ductility of the connection to be better. However, the presence of CFRP had minimal effect on the connection ductility.

Research on steel jackets as a strengthening method has been widely conducted on column structures [12,13,14]. Steel jackets can provide confinement similar to continuous hoop reinforcement. Columns strengthened with steel jacketing exhibit higher strength and ductility. In conclusion, the study found that steel jackets significantly improve the initial stiffness, strength, ductility, and energy dissipation of columns. Engineered cementitious composites (ECC) is another alternative exterior jacketing material that can be utilized to the region of plastic hinge for enhancing the seismic performance of concrete column [15].

Recent seismic hazard assessments indicate an increase in seismic acceleration across many regions of Indonesia. The potential for damage to piles in the future during major earthquakes has become a serious concern. This highlights the need to implement performance-based design for substructures. Therefore, ensuring adequate confinement in spun pile connections is essential. It is necessary to find an external confinement solution that is customized to the diameter of the spun pile, easy to construct, and cost-effective.

A numerical study on the use of steel jackets as external confinement for spun piles in the connection area has been conducted [16]. The validation of the FE model using Abaqus was performed based on the experimental study conducted by Wang [8]. Parametric variations in steel jacket thickness demonstrated that steel jackets provide additional strengthening and also enhance the ductility of the connection. The use of concrete jacketing requires formwork during construction, making it less practical. Steel jacketing made from hot-formed steel has limitations in terms of diameter and thickness. FRP offers advantages in constructability, but it is relatively expensive.

This study proposes a steel jacket made from cold-formed steel as an alternative external confinement. Besides being cost-effective, its thin profile allows for customization of the diameter to match the spun pile. The innovation of the steel jacket and the associated construction methods have been registered with the Indonesian Patent [registration number P00202109462]. An experimental study has been conducted to ensure the construction process and the effect of steel jacketing on the spun pile connection behaviour [17]. The jacket improves the connection’s deformability, boosts the energy dissipation and increases the bending strength. Those results showed that the steel jacket can be used as a promising alternative solution to fulfill the confinement of the spun pile on the connection area. This paper reports a further numerical study based on finite element (FE) analysis to investigate parameters that affect the behavior of the connection. A brief description of a previous experimental study was reported.

2. The Experimental Programs

2.1. The Specimens

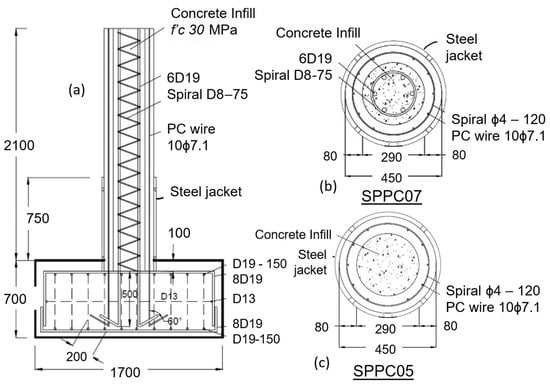

Three full-scale spun pile connections strengthened with a steel jacket were prepared to evaluate their seismic performance. The comprehensive discussion and results were reported [17]. The specimens SPPC05 was an empty spun pile, SPPC06 was filled with concrete, meanwhile SPPC07 had reinforced concrete infill. The steel jacket was a 0.7 mm thick cold-formed steel plate that was bent to match the diameter of the spun pile. Rivets were utilized to connect the ends. The height of the jacket was 850 mm, which was equal to the length of the concrete crack damage on the spun pile of the first series testing.

Figure 1 shows the details of the spun pile and the pile cap connection. A 450 mm diameter spun pile with an 80 mm wall thickness was employed. It was made of f’c 50 MPa concrete strength and reinforced with 10 strands of 7.1 mm prestressed wire. It was confined by a 4 mm diameter spiral with a pitch of 120 mm. SPPC06 is similar to SPPC07 without the presence of 6D19. The pile cap dimension was 1700 × 1200 × 700 mm, which was constructed with f’c 30 MPa concrete strength and reinforced with 1% of reinforced bar. The spun pile was embedded into the pile cap to a depth of 100 mm. The anchorage length of the prestressed concrete (PC) wire to the pile cap was determined according to ACI 318-14M, where the required length was 540 mm. To reduce the depth of the pile cap, the length was made 500 mm straight with an additional 200 mm bent at 30 degrees. Table 1 presents the steel reinforcement.

Figure 1.

(a) Connection detail. (b) Detail of the spun pile of SPPC07. (c) Detail of the spun pile of SPPC05.

Table 1.

The Steel Strength.

Referring to ASCE 7-16, a 450 mm diameter spun pile loaded with 0.1 f’cAg axial load needs 1.78% transverse reinforcement, and the ratio cannot be less than 0.601%. Meanwhile, the ratio of spiral with a 4 mm diameter and 120 mm spacing is 0.113%, which is only 19% of the minimum ratio. Considering the confinement provided by an 8 mm diameter of spiral reinforcement spaced at 75 mm, the confinement ratio of the core concrete within the infill concrete is 1.165%. Accordingly, the overall confinement ratio of specimen SPPC07 increases to 0.501%. This value was calculated by assuming that the concrete core within the infill concrete is confined at 1.165%, while the remaining portion of the concrete, excluding the spun pile cover, is confined at 0.113%. By multiplying each confinement ratio by the corresponding area, a combined confinement ratio of 0.501% is obtained.

As shown in figure, steel jacket of 7 mm thickness was attached to the spun pile. The grout, 25 mm thick and made of f’c 61 MPa concrete, was attached to the pile to transfer force from the pile to the jacket. The jacket provided confinement to a concrete cover, where the ratio is 0.622%. When the steel jacket is included, the confinement ratio of specimen SPPC07 increases from 0.501% to 0.537%, which remains slightly below the minimum requirement. The improvement in confinement ratio provided by the steel jacket is negligible and thus does not substantially enhance the confinement effect. Instead, its primary contribution is in preventing spalling of the concrete cover, which plays a more decisive role in maintaining structural performance. Therefore, a spun pile with a steel jacket should not be strictly bound to the minimum ρ requirement as long as the steel jacket is properly bonded with the spun pile to prevent the spalling of concrete cover during large deformation.

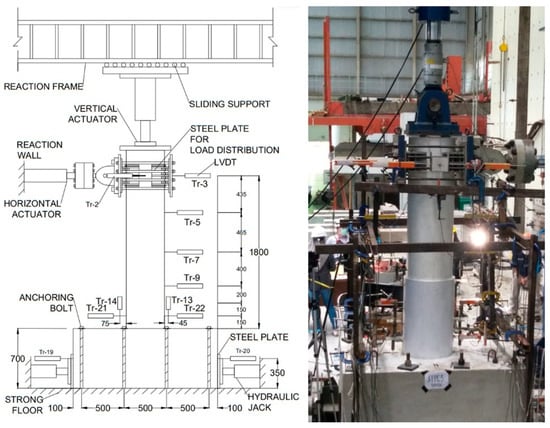

2.2. The Setup

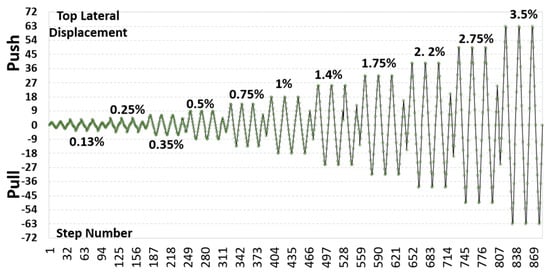

Figure 2 presents the test setup. The specimen was attached to a strong floor with 10 anchoring bolts. Seven transducers were installed to measure the horizontal displacement of the spun pile, and two transducers were aimed to measure the vertical displacement. The movement of the pile was captured by another pair of transducers (Tr-19 and Tr-20). The specimens were tested following the loading protocol specified by ACI 437-07 as shown in Figure 3. The targeted drift was 3.5%. A constant vertical load of 500 kN, which was equal to 0.1 f’cAg, was applied. The axial load level reflects practical conditions, as design typically limits the loads on piles to the range of 0.1–0.2 f’cAg. The use of this conservative value is consistent across most experimental studies on spun pile–pile cap connections [6,8,9]. The jack was attached to a sliding frame to ensure the verticality of the load. The test was terminated upon reaching the target drift or a strength degradation exceeding 50%, whichever condition occurred first.

Figure 2.

The Experimental Setup.

Figure 3.

The Horizontal Loading Protocol.

2.3. The Results

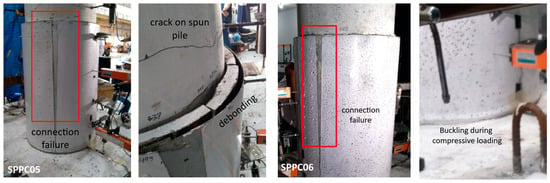

The failure mode of the three specimens is presented in Figure 4 and Figure 5. Specimens SPPC05 and SPPC06 failed earlier due to the detachment of the steel jacket connection at a drift of 1.75%. The placement of the steel jacket connection on the spun pile was not purposely arranged. For SPPC05 and SPPC06, the connections are located approximately 30 degrees from the horizontal load path. Once the connection of the steel jacket failed, debonding occurred between the jacket and the grout as well as between the grout and the spun pile, as shown in Figure 4. The debonding breaks forth from the farthest part of the pile cap surface and spreads downward. When the connection began to fail, the confinement from the steel jacket was revealed to be still effective on the lower side. Therefore, the failure of the steel jacket did not result in a sudden loss of strength in the connection, as can be seen on the hysteretic curves presented in Figure 6a,c. Another failure mode observed in SPPC06 was the buckling of the steel jacket next to the pile cap. The buckling indicated that the steel jacket lost the lateral support due to debonding from the grout. Interestingly, fracture of the PC wire was also detected during the testing, indicated by the sound of the bar breaking in all three specimens.

Figure 4.

The failure modes of SPPC05 and SPPC06.

Figure 5.

The failure mode of SPPC07.

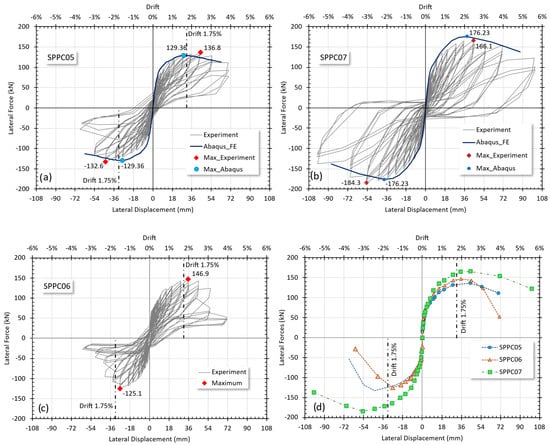

Figure 6.

The hysteretic curve of the experimental results: (a) SPPC05; (b) SPPC07; (c) SPPC06. (d) The skeleton comparison of three specimens.

SPPC07 was the only specimen where the steel jacket performed without the failure of its connection since it was located perpendicular to the horizontal loading path. Hence, the spun pile in the connection zone had sufficient confinement throughout the testing. The failure mode of SPPC07 is shown in Figure 5. Cracks occurred on the spun pile outside the steel jacket and on the surface of the pile cap. At the end of the test, fractures in the steel jacket occurred.

The results of the cyclic loading test are presented as the hysteretic curves shown in Figure 6. As shown, the spun pile with steel jackets exceeds the target drift 3.5%; meanwhile, SPPC07 even reaches a drift of 5%. SPPC06 exhibited an asymmetrical hysteretic curve during push and pull cycles. This was caused by the failure of the steel jacket connection and the different failure modes on each side. Buckling was observed only on one side of the steel jacket. This behavior is reflected in the hysteretic curve, and the maximum capacity on both sides is different by up to 15%.

The comparison of three specimens, SPPC05, SPPC06, and SPPC07, is displayed in the envelope curves shown in Figure 6d. SPPC07 shows better performance in terms of strength and energy absorption. SPPC07 has the greatest capacity because it has additional reinforcement bars (6D19), and also the jacket confines the concrete cover of the spun pile throughout the test.

Compared to the specimen without a steel jacket in the first series test, the jacket on SPPC07 increases the bending strength by 18% [17]. As the steel jacket was embedded into the pile cap, it resulted in the development of its tensile strength. Moreover, the adequate bonding between the steel jackets and the grout effectively increased the diameter of the spun pile from 450 mm to 500 mm. The additional moment arm provided by the steel jacket on the outer side of the spun pile also contributed to the increase in overall strength of the connection.

The experimental results show that SPPC07 was able to deform up to a 5% drift, leading to higher energy dissipation, which is 1.8 times compared to that without a steel jacket. However, in terms of the displacement ductility ratio, the steel jacket slightly affects the ductility of the connection. This is similar to the research found by Yang [11] when using CFRP as external confinement of the spun pile. However, the steel jacket not only provides additional confinement, thereby allowing the connection to deform further, but also contributes to an increase in strength.

3. The Numerical Study

A finite element study is used to further investigate the parameters affecting the behavior of connections reinforced with steel jackets. Two parameters are examined: the thickness and height of the steel jacket on connection behavior. Model validation is conducted to ensure that the model accurately represents the experiment.

3.1. The Geometric Model

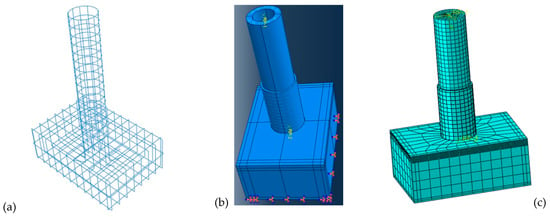

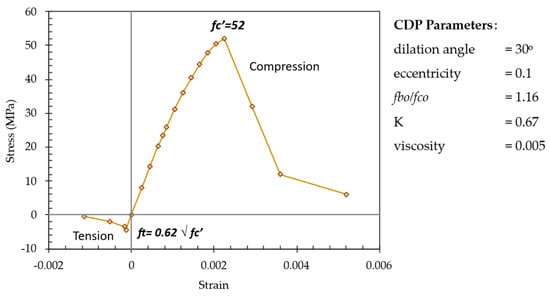

The FE model utilizes C3D8R solid elements for the spun pile and pile cap concrete. It is a three-dimensional (3D) continuum solid element consisting of eight nodes with reduced integration. The concrete infill and its connection to the pile cap use C3D6 elements, which are 3D solid elements consisting of six nodes. The shell element S4R, which consisted of four nodes with reduced integration, was used to model the steel jacket. All reinforcing bars used a T3D2 truss element with two nodes. The geometric model and meshing of spun pile to pile cap connections are shown in Figure 7 and Figure 8.

Figure 7.

The geometric model of (a) reinforcing bars, (b) pile cap, spun pile, and steel jacket. (c) The FE meshing of the spun pile–pile cap connection.

Figure 8.

The meshing of each component of the spun pile–pile cap connection.

The prestressing force in the PC wire was modeled using a predefined field by applying an initial stress of 0.75 fpu, which was 1080 MPa. Assuming a prestress loss of 20%, the remaining stress was 864 MPa. The prestressing force was assumed to increase linearly over a length equal to one pile diameter (1D) or 450 mm. A fixed support is applied at the bottom part of the pile cap to represent the experimental test where the pile cap was anchored with ten 32 mm diameter bolts embedded into a 500 mm thick strong floor.

During testing, a 25 mm thick steel plate was placed on top of the spun pile to distribute the vertical load. The plate was represented by a reference point (RP) at the center of the top surface of the spun pile, which connected all nodes in that area as a rigid body. This ensured that the applied vertical and horizontal loads acted on the top surface of the spun pile without causing stress concentration.

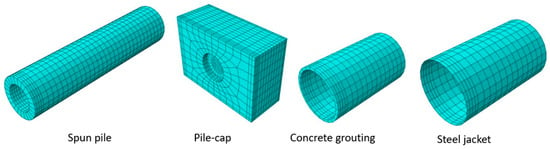

3.2. The Constitutive Laws of Material

Figure 9 shows the stress–strain curve of concrete in compression and tension used in the FE model. The compression behaviour refer to the Reddiar model, which was a modification of Mander’s concrete model with a post-peak softening phase. The tensile behavior follows the Wahalathantri et al. model [18], which is chosen for numerical simplicity and to avoid errors in Abaqus analysis. The tensile strength of concrete is taken as 0.62 √f’c. The Concrete Damage Plasticity (CDP) model is used to simulate the damage in concrete after reaching its maximum strength under both tension and compression. The plasticity parameters used in the FE model are as follows: dilation angle, eccentricity, fbo/fco, K, and viscosity, where their values are 30o, 0.1, 1.16, 0.67, and 0.005, respectively.

Figure 9.

Constitutive Law of Concrete and The Parameters of Concrete Damage Plasticity (CDP).

The constitutive law of all reinforcement steel bars, such as longitudinal and transverse rebar of concrete infill, transverse rebar of spun piles, and reinforcement of pile caps, is based on Park and Paulay’s law. The engineering stress–strain curve was converted into true stress–strain data to account for the reduction in cross-sectional area due to necking. The constitutive model used for prestressing bars is based on Thompson and Park. Additionally, the ductile damage failure model is applied to represent the fracture process of the reinforcement.

The interaction between components significantly influences the behavior of the connection. The bond between steel rebars and concrete was modeled as an embedded region, meaning a perfect bond without slip, ensuring that both elements share the same degrees of freedom. The interaction between the spun pile and pile cap, as well as between the spun pile and concrete infill, was defined as hard contact in the normal direction. In the tangential direction, the interaction between the two surfaces was represented using Coulomb friction. Based on the study conducted by [19], the friction coefficient (μ) between two dry concrete surfaces, from smooth to very rough, ranges from 0.5 to 0.9. A friction value of 0.5 was used at the interface between the spun pile and pile cap.

3.3. The Comparison of the FE Results and the Experiments

According to the testing scheme, the vertical load of 0.1 f’cAg and the weight of the steel plate were applied as a constant, uniformly distributed load acting on the top surface of the spun pile. The magnitude was 5.43 MPa for an empty spun pile, and it was 3.15 MPa for piles with infill concrete. After the vertical load was applied, a monotonic pushover analysis was conducted horizontally until a targeted drift of 3.5% or 63 mm.

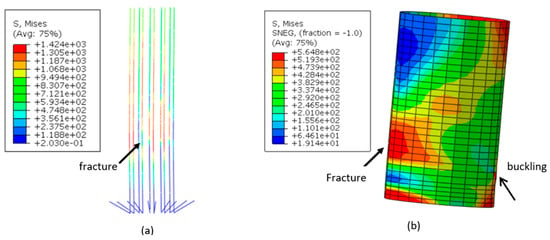

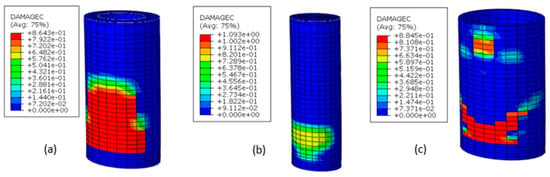

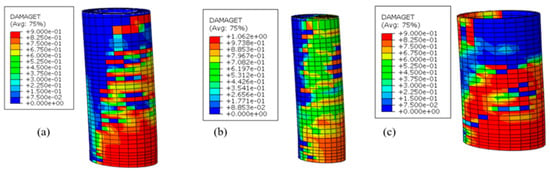

The results of the FE analysis, presented as lateral force versus lateral displacement at the top of the pile, are shown in Figure 6. It is compared to the hysteretic curve of the experimental results of specimens SPPC05 and SPPC07. As observed, the FE analysis closely matches the experiment. The FE model is able to accurately represent the linear phase and the post-peak behaviour. The difference in the maximum lateral forces between the experiments of SPPC05 and SPPC07 is only 5.5% and 6.1%, respectively. The failure modes from the FE results are similar to those observed in the experiment, as shown in Figure 10, Figure 11 and Figure 12. Fracture of the PC wires and buckling of the steel jacket occurred on the FE analysis. Crushing on compression zone and similar crack pattern was also found on the concrete surface of the spun pile as shown in Figure 11 and Figure 12. Therefore, the models were considered valid, and further parametric study could be carried out.

Figure 10.

Stress contour of (a) prestress wire and (b) steel jacket.

Figure 11.

Compression damage of (a) spun pile, (b) infill concrete, and (c) concrete grouting.

Figure 12.

Tension damage of (a) spun pile, (b) infill concrete, and (c) concrete grouting.

4. Parametric Study

The experimental results indicate that one of the weaknesses of the steel jacket lies in its connections. Hence, the position of the jacket connection relative to the loading direction affects the effectiveness of the steel jacket as confinement. To be promoted as an additional confinement, it must be ensured that no failure occurs at the connections. In the finite element (FE) study, the steel jacket is assumed to be perfectly connected, with the expectation that in the future it will be fabricated in factories, thereby eliminating connection issues. Consequently, the connections of the steel jacket are not included as one of the parameters investigated. Instead, the parametric FE study is focused on exploring other parameters that influence the behavior of spun pile–pile cap connections, such as the effect of confinement ratio, the bonding of several components, the penetration of the steel jacket to the pile cap, the thickness and the depth of the steel jacket, and the effect of axial load magnitude.

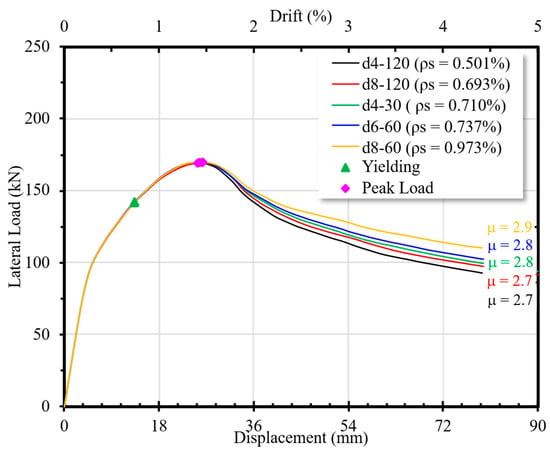

4.1. The Effect of Confinement Ratio

Figure 13 illustrates the influence of the confinement ratio on the ductility of five specimens of spun pile connection without a steel jacket. The confinement ratio is calculated by considering the contribution of spiral reinforcement to the concrete infill. All specimens have similar reinforcement, which is 8 mm in diameter with 75 mm spacing. The ratio is varied from 0.501% to 0.973%. As shown, the ratio affects the post-peak behavior of the connection. The force–displacement curve shows a more gradual decline in specimens with higher levels of confinement. Meanwhile, the piles with limited confinement experience a more drastic strength reduction. Adequate confinement helps the concrete reach its confined compressive strength (f’cc), preventing a sudden loss of strength at higher deformation levels. This influences the ductility of the connection, although its effect is not significant, as the ductility values remain relatively similar, ranging from 2.7 to 2.9.

Figure 13.

Load–displacement curves of different confinement ratios of the spun pile without a steel jacket.

The ductility present here is a displacement ductility, which is calculated as the ratio of ultimate displacement (du) to yield displacement (dy). For reinforced concrete structures, dy is not well defined due to the nonlinearity of the two materials, i.e., concrete and steel. In this study, dy is defined based on the secant stiffness of the load displacement curve, whereas du represents the deformation at which the structure experiences a 15% reduction in strength.

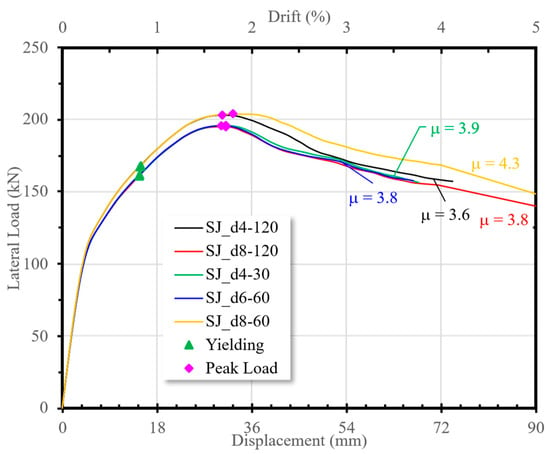

Figure 14 illustrates the behavior of the connection with an identical confinement configuration, supplemented by a steel jacket with 7 mm thickness. As described earlier, the presence of the steel jacket slightly enhances the confinement ratio of the connection. However, the crucial role of the steel jacket is to prevent spalling of the concrete cover. The steel jacket is assumed to be perfectly bonded. The jacket provides external confinement to the spun pile, allowing it to sustain post-peak deformation more effectively without a significant loss of strength. As observed, the strength degradation in the spun pile with a jacket is more gradual compared to the spun pile without a steel jacket, as shown in Figure 12. The ductility of the connection with a steel jacket increases to a range of 3.6–4.3 from 2.7–2.9 for those without a steel jacket. It implies that the steel jacket improves ductility significantly.

Figure 14.

Load–displacement curves of different confinement ratios of the spun pile with a steel jacket.

A clear discrepancy was found between the FE results and the experimental observations. In comparison, the test showed similar displacement ductility for specimens with and without a steel jacket (3.9–4.0) [17]. The FE parametric study predicted a significantly lower ductility ratio (2.7–2.9) for the specimen without a steel jacket. This inconsistency highlights the limitation of the FE model, which employed monotonic loading rather than cyclic loading. Monotonic loading accelerates spalling of the concrete cover on the tension side, leading to premature strength loss and reduced ultimate displacement. In contrast, cyclic loading alternates tension and compression, delaying cover spalling and resulting in more gradual post-peak degradation and higher displacement ductility. These findings suggest that the choice of loading scheme in numerical modeling has a decisive influence on the predicted ductility and should be carefully considered in future studies.

The study confirms that the steel jacket increases the connection strength, largely due to its 100 mm embedment into the pile cap, which enables it to act not only as a confinement element but also as additional longitudinal reinforcement. More importantly, the findings highlight that the primary effectiveness of the steel jacket lies in its role as external confinement, particularly in preventing spalling of the concrete cover. This mechanism is shown to be more effective than enhancing the confinement of the concrete core by increasing the amount of transverse reinforcement. These results suggest that, in practical design, steel jacketing should be considered primarily for its ability to maintain cover integrity and delay surface deterioration, rather than as a substitute for core confinement. The confinement degree of the steel jacket could be calculated by referring to B.Lai [20].

4.2. The Effect of Steel Jacket Bonding to the Spun Pile

The contact between the steel jacket, grout, and spun pile plays a crucial role in the behavior of the connection, ensuring effective force transfer among the three components and allowing the steel jacket to provide optimal confinement. Experimental studies have shown that when the steel jacket detaches from the spun pile, its role as confinement is lost, significantly reducing its effectiveness in enhancing the connection’s performance.

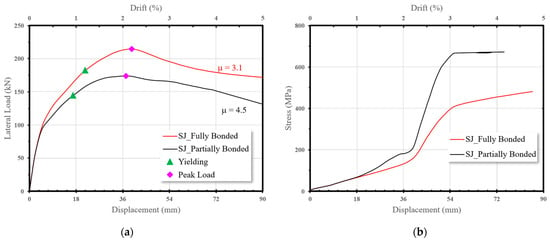

In the FE model, hard contact is used to represent the experimental conditions, where the friction coefficients are set as follows: 0.8 between the infill concrete and the inner surface of the spun pile, 0.5 between the outer surface of the spun pile and the grout, and 0.3 between the grout and the steel surface [19]. In the fully bonded specimen, it is assumed that the steel jacket is perfectly bonded to the grout, and the grout is perfectly bonded to the spun pile. As observed from the force–displacement curve in Figure 15, perfect bonding enhances the strength of the connection. However, in terms of ductility, partially bonded results in a gradual post-peak strength reduction, leading to better ductility.

Figure 15.

The effect of bonding on (a) the load–displacement curve and (b) the stress development of the bottom stirrup of the spun pile.

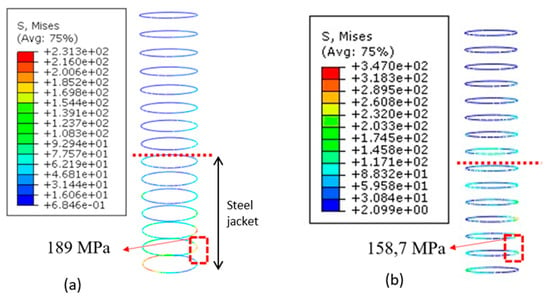

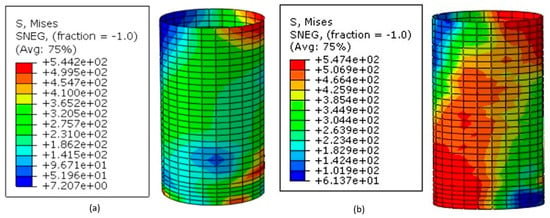

Figure 15, Figure 16 and Figure 17 illustrate the role of the steel jacket as transverse reinforcement. In the fully bonded condition, the steel jacket provides better confinement, thereby reducing the stress demand on the spirals located within the jacketed region. With perfect bonding, the stirrups remain below their yield stress as shown in Figure 15b and Figure 16. The fully bonded condition improves the strength of the connection, as the spun pile behaves as a composite section and the steel jacket contributes more effectively as longitudinal reinforcement. The steel jacket develops yielding and eventually fractures, as shown in Figure 17. However, due to the brittle nature of high-strength steel, this mechanism also leads to a pronounced post-peak strength reduction. Consequently, the ultimate displacement (du) decreases, resulting in a less ductile response compared with the partially bonded condition. These findings suggest a trade-off in design: while full bonding enhances strength, it may compromise ductility, and thus the choice between fully and partially bonded configurations should be made according to the desired balance between strength and deformability.

Figure 16.

Stress distribution on the transverse reinforcement of the specimen when the jacket is (a) partially and (b) fully bonded.

Figure 17.

Stress distribution on the steel jacket when it is (a) partially and (b) fully bonded.

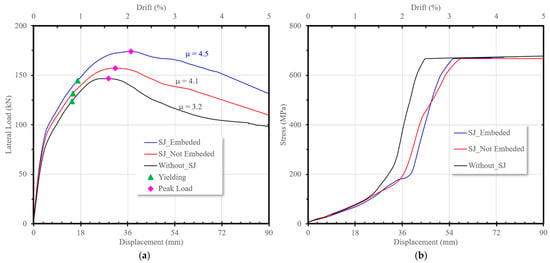

4.3. The Effect of the Steel Jacket Penetration on the Pile Cap

To ensure that the steel jacket provides confinement up to the end of the spun pile, the experimental study penetrated the steel jacket into the pile cap by 100 mm. The FE study compares the effect of the specimen where the jacket stops at the surface of the pile cap and that without a steel jacket. The results are presented in Figure 18. Although the embedment depth is only 100 mm, it significantly influences the connection behavior, as the steel jacket not only provides confinement but also contributes to enhancing the connection strength.

Figure 18.

The effect of steel jacket penetration on (a) the load–displacement curve and (b) the stress development of the bottom stirrup of the spun pile.

The connection with an embedded steel jacket has a ductility value of 4.5, whereas the non-embedded steel jacket has 4.1. Meanwhile, the connection without a steel jacket has a ductility value of only 3.2. Referring to the stress development of the stirrups located at the bottom shown in Figure 15b, it can be seen that all three FE models are able to reach the yield stress. However, the steel jacket delays the occurrence of yielding of the stirrups compared to the connection without a steel jacket. Therefore, the presence of a steel jacket increases the ductility since it is calculated as the ratio of the maximum displacement to the yield displacement.

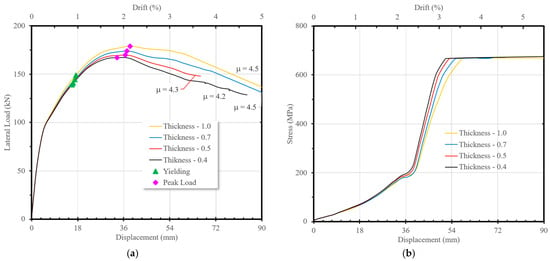

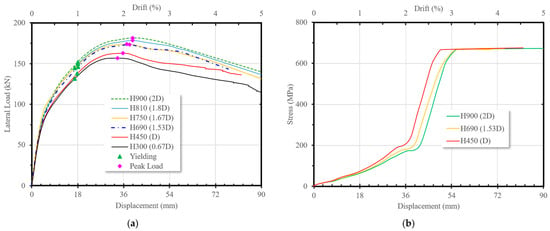

4.4. The Effect of Different Thickness and Height of Steel Jacket

The effect of variation in steel jacket thickness on the load–displacement curve is shown in Figure 19. The FE model is based on SPPC07, which has a steel jacket with a depth of 800 mm that penetrates 100 mm into the pile cap. The contact between the spun pile and concrete infill, as well as between the steel jacket and concrete grouting, is similar to that used in the model validation. Based on the force–displacement curve, the behavior appears to be almost identical. As predicted, a thicker steel jacket increases the structural strength, but the effect is not very significant. There are no significant differences observed in the ductility of the connection. However, a thicker steel jacket delays the yielding of the spun pile stirrups.

Figure 19.

The effect of variation in thickness of the steel jacket on (a) the load–displacement curve and (b) the stress development of the bottom stirrup of the spun pile.

Figure 20 illustrates the effect of steel jacket height, expressed as a ratio to the pile diameter (D), on the load–displacement response. In the analysis, the steel jacket was assumed to be embedded 100 mm into the pile cap, consistent with the experimental arrangement under fully bonded conditions. An increase in jacket height enhanced the connection capacity; however, the improvement became negligible once the height exceeded 1.53D. Figure 20b shows the stress development in the stirrups located at the bottom of the spun pile, indicating that a greater jacket height delayed the onset of yielding.

Figure 20.

The effect of variation in height of the steel jacket on (a) the load–displacement curve and (b) the stress development of the bottom stirrup of the spun pile.

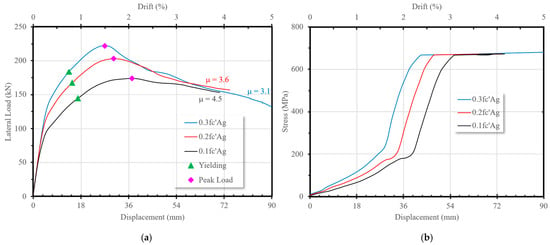

4.5. The Effect of Different Axial Loads

As previously mentioned, an axial load equivalent to 0.1 f’cAg was applied in the experiment to simulate the typical axial load sustained by spun piles under real conditions. According to ASCE provisions, the required confinement in column structures is affected by the magnitude of axial load. In this study, the effect of axial load on the behavior of spun piles was considered as one of the key parameters. Figure 21 presents the effectiveness of the steel jacket for axial load variations of 0.1 f’cAg, 0.2 f’cAg, and 0.3 f’cAg. From the figure, it can be observed that the axial load significantly affects the strength and the ductility of the connection. As the axial load increases, the ductility of the connection decreases. Earlier yielding of the stirrups is observed when the axial load applied to the spun pile is higher.

Figure 21.

The effect of variation in axial load magnitude on (a) the load–displacement curve and (b) the stress development of the bottom stirrup of the spun pile.

5. Conclusions

The steel jacket offers an alternative solution to address the lack of confinement of spun piles, particularly given the uncertainty of hard soil. The steel jacket provides external confinement and plays an important role in preventing spalling of the concrete cover and maintaining the ductile behaviour of the connection.

The experimental results indicate that the effectiveness of the steel jacket in providing additional confinement depends on the integrity of its connection. The penetration of the steel jacket together with the spun pile into the pile cap develops tensile strength in the jacket, which contributes to the moment capacity of the connection.

Parametric study based on finite element analysis found that the steel jacket effectively provides external confinement to the pile. It delays the yielding of the stirrup of the spun pile. The use of a steel jacket as an external confinement was found to enhance the connection performance more effectively, rather than increasing the amount of spiral reinforcement within the spun pile. An increase in the amount of spiral reinforcement had a negligible impact on the ductility of the connection. In contrast, the use of a steel jacket significantly improved the ductility, raising it from approximately 2.7 to 3.6.

The parametric study found that variations in jacket thickness did not significantly impact the connection’s performance. A jacket height equal to 1.53 times the pile diameter was found to be the maximum effective length. The height corresponds to the length of the concrete cracks observed in the spun pile without a steel jacket. Beyond this height, there is little influence on the connection behavior. The study also found that partial bonding between the steel jacket, grout, and pile was found to be acceptable within a certain range, and even exhibited more ductile behavior compared to fully bonded conditions. The amount of axial load significantly affects the behaviour of the connection. Higher axial loads led to a sudden drop in connection strength, resulting in reduced ductility.

6. Patents

The steel jacket and the associated construction methods have been registered with the Indonesian Patent [registration number: P00202109462] in 2023.

Author Contributions

Conceptualization, Y.L. and W.A.P.; Data curation, M.O.; Formal analysis, M.O., J.R. and S.L.J.H.; Funding acquisition, W.A.P.; Investigation, M.O., J.R. and S.L.J.H.; Methodology, Y.L. and W.A.P.; Project administration, Y.L. and W.A.P.; Resources, M.O.; Validation, Y.L., M.O. and W.A.P.; Visualization, M.O.; Writing—original draft, M.O., J.R. and S.L.J.H.; Writing—review and editing, Y.L., M.O. and W.A.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the Indonesia Ministry of Research and Universitas Indonesia through Puti Pascasarjana (contract number: NKB-287/UN2.RST/HKP.05.00/2023) and Applied Research Grant (contract number: NKB-254/UN2.RST/HKP.05.00/2021) as part of a research collaboration with PT Wijaya Karya Beton, Tbk.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors acknowledge the contribution of PT Wijaya Karya Beton, Tbk, which provided materials for the experimental program, and PT NS Bluescope Lysagh Indonesia for steel jacket materials.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- SNI 8460-2017; Geotechnical Design Requirements. Badan Standarnisasi National (BSN): Jakarta, Indonesia, 2017.

- ACI 318-19; Building Code Requirements for Structural Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2019. [CrossRef]

- Kaneko, O.; Kawamata, S.; Nakai, S.; Sekiguchi, T.; Mukai, T. Analytical study of the main causes of damage to pile foundations during the 2011 off the Pacific coast of Tohoku earthquake. Jpn. Archit. Rev. 2018, 1, 235–244. [Google Scholar] [CrossRef]

- ASCE 7-16; Minimum Design Loads and Associated Criteria for Buildings and Other Structures. American Society of Civil Engineers: Reston, VA, USA, 2017. [CrossRef]

- Irawan, C.; Djamaluddin, R.; Raka, I.G.P.; Suprobo, P.; Gambiro. Confinement behavior of spun pile using low amount of spiral reinforcement—An experimental study. Int. J. Adv. Sci. Eng. Inf. Technol. 2018, 8, 501–507. [Google Scholar] [CrossRef][Green Version]

- Mulia, O.; Adi, P.W.; Nadila, M. Numerical study of low confinement spun pile to pile cap connection. E3S Web Conf. 2022, 347, 01002. [Google Scholar] [CrossRef]

- Orientilize, M.; Prakoso, W.A.; Lase, Y.; Purnomo, S.; Sumartono, I.H.; Agustin, W. The Evaluation of Displacement Ductility of Low Confinement Spun Pile to Pile Cap Connections. Int. J. Technol. 2023, 14, 823–832. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, W. Experimental and numerical investigation on the behaviour of prestressed high strength concrete pile-to-pile cap connections. KSCE J. Civ. Eng. 2016, 20, 1903–1912. [Google Scholar] [CrossRef]

- Bang, J.W.; Oh, S.J.; Lee, S.S.; Kim, Y.Y. Pile-cap Connection Behavior Dependent on the Connecting Method between PHC pile and Footing. J. Korea Inst. Struct. Maint. Insp. 2016, 20, 25–32. [Google Scholar] [CrossRef]

- Guo, Z.; He, W.; Bai, X.; Chen, Y.F. Seismic performance of pile-cap connections of prestressed high-strength concrete pile with different details. Struct. Eng. Int. 2017, 27, 546–557. [Google Scholar] [CrossRef]

- Yang, Z.; Li, G.; Nan, B. Study on Seismic Performance of Improved High-Strength Concrete Pipe-Pile Cap Connection. Adv. Mater. Sci. Eng. 2020, 2020, 4326208. [Google Scholar] [CrossRef]

- Li, Y.F.; Hwang, J.S.; Chen, S.H.; Hsieh, Y.M. A study of reinforced concrete bridge columns retrofitted by steel jackets. J. Chin. Inst. Eng. Trans. Chin. Inst. Eng. Ser. A/Chung-Kuo K. Ch’eng Hsuch K’an 2005, 28, 319–328. [Google Scholar] [CrossRef]

- Liu, J.; Teng, Y.; Zhang, Y.; Wang, X.; Chen, Y.F. Axial stress-strain behavior of high-strength concrete confined by circular thin-walled steel tubes. Constr. Build. Mater. 2018, 177, 366–377. [Google Scholar] [CrossRef]

- He, A.; Cai, J.; Chen, Q.J.; Liu, X.; Huang, P.; Tang, X.L. Seismic behaviour of steel-jacket retrofitted reinforced concrete columns with recycled aggregate concrete. Constr. Build. Mater. 2018, 158, 624–639. [Google Scholar] [CrossRef]

- Zhang, R.; Zhao, R.; Liu, Z.; Chen, K.; Hu, P.; Liu, Z. Cyclic behavior of existing flexure-dominated RC bridge columns retrofitted by ECC jackets in the region of plastic hinge. Eng. Struct. 2022, 269, 114820. [Google Scholar] [CrossRef]

- Orientilize, M.; Prakoso, W.A.; Fadel, M.; Fernaldy, R.P. Fernaldy, Study of spun pile connection with steel jacket strengthening. IOP Conf. Ser. Earth Environ. Sci. 2021, 622, 1. [Google Scholar] [CrossRef]

- Lase, Y.; Orientilize, M.; Prakoso, W.A.; Purnomo, S.; Sumartono, I.H. Experimental Study of Spun Pile to Pile Cap Connection Confined by Steel Jacket. Int. J. GEOMATE 2024, 27, 95–103. [Google Scholar] [CrossRef]

- Wahalathantri, B.; Thambiratnam, D.; Chan, T.; Fawzia, S. A material model for flexural crack simulation in reinforced concrete elements using ABAQUS. In Proceedings of the First International Conference on Engineering, Design and Developing the Built Environment for Sustainable Wellbeing, Brisbane, QLD, Australia, 27–29 April 2011; pp. 260–264. [Google Scholar]

- Mohamad, M.E.; Ibrahim, I.S.; Abdullah, R.; Rahman, A.A.; Kueh, A.B.H.; Usman, J. Friction and cohesion coefficients of composite concrete-to-concrete bond. Cem. Concr. Compos. 2015, 56, 1–14. [Google Scholar] [CrossRef]

- Lai, B.L.; Zhou, X.; Zheng, X.F.; Li, S. Theoretical reevaluation and machine learning analysis on the concrete confinement effect of square reinforced concrete columns. Struct. Concr. 2024, 26, 4215–4239. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).