Abstract

Plastic waste signifies a global predicament, aggravated by deficient management practices. Unearthing methods to repurpose energy from this waste is pivotal. This study delves into the pyrolytic degradation of low-density plastics to convert plastic waste into valuable products on a modest scale. A small-scale, low-CO2 emitting distiller was employed in the process. A zeolite was harnessed as a catalyst to augment the temperature and hasten the pyrolysis process. A comprehensive life cycle analysis was executed to assess the environmental impact of the process. In this scenario, zeolite-facilitated pyrolysis was more proficient compared to traditional thermal pyrolysis, generating a yield of 22.5% with the catalyst, contrasting with 18% without. A kinetic model was formulated, observing reaction mechanisms and temperature escalation and culminating in the extraction of aromatic oils. These oils were further distilled to produce liquid hydrocarbons, beginning the distillation at 60 °C with the catalyst. Characterization of the secured hydrocarbons was conducted using infrared, Raman spectroscopy, and gas chromatography, discovering compounds akin to gasoline, such as benzene, toluene, and xylenes. Additionally, the procedure exhibited a minimal environmental detriment, as validated by the life cycle analysis. This study concludes by highlighting the potential of small-scale, low-CO2 emitting pyrolytic degradation of low-density plastics for energy recovery from plastic waste, demonstrating the practical and environmental benefits of this avant-garde method.

Keywords:

catalyst pyrolysis; small scale; distillation; kinetic reaction model; IR; Raman; gas chromatography 1. Introduction

Plastic waste management stands as a contentious issue with several options considered, including recycling and energy recovery. The focus on converting this waste into energy aims to minimize environmental pollution. While the global demand for liquid petroleum products is projected to rise, the pressing need to adopt renewable energy sources becomes increasingly evident as we move into the future. The potential depletion of oil and gas reserves underscores the necessity to explore and adopt alternative and sustainable energies. This exploration is crucial to ensure long-term energy supplies and reduce our dependence on non-renewable resources [1,2].

To address these challenges comprehensively, a long-term and reliable plastic waste management scheme is required. Such a scheme is essential not only to avoid environmental pollution but also to simultaneously overcome the issues of the energy crisis.

Nowadays, plastic materials are indispensable all over the world due to their efficiency, lightness, and durability. Due to their lower price, light weight, ease of use, corrosion resistance, and structural properties, plastic containers have become increasingly popular among packaging materials. Plastics are used in a wide range of industrial and domestic applications. Therefore, it has become an indispensable material and, at the same time, a very serious environmental problem due to its massive use in all types of products and its slow degradation. Some studies indicate that average estimates of how long plastic bags will degrade fall into one of two categories: 10–20 years or 500–1000 years, but other estimates exceed 100 years. Furthermore, scientific studies of plastic degradation times are evolving, and estimates may change dramatically. Typical wastes include high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyethylene terephthalate (PET), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC). These include bottles, tubes, packages, cups, trays, bags, lids, foils, containers, and more [3,4].

The truth is that plastic waste is a very serious problem all over the world because it is a waste that does not degrade easily, and its management is very complicated. It is found as waste in rivers, lakes, forests, beaches, parks, cities, countryside, rural areas, and so on. In 2015, approximately 400 million tons of plastic were produced worldwide. Global production of plastics is expected to increase steadily from 300 million metric tons in 2015 to 1800 million metric tons in 2050. However, plastic recycling and pyrolysis are considered alternatives that can not only solve the problem of plastic waste pollution in a satisfactory way but also provide a high percentage of the energy demand [4,5].

Plastic bags, commonly composed of low-density polyethylene (LDPE) and high-density polyethylene (HDPE), are crafted from plastic materials known for their flexibility, resilience, and durability, rendering them particularly suitable for applications such as shopping bags. The low-density polymer, LDPE, derived from polyethylene (PE), exhibits a versatile range of applications and is characterized by a basic chemical structure (-CH2-CH2-) n. Its chemical properties align with those of a high-molecular-weight alkane. Both HDPE and LDPE share ethylene as their repeating unit, highlighting a commonality, but the primary distinction lies in their respective structures. HDPE, less branched than LDPE, possesses a higher density, influencing the unique properties of these polymers [6,7].

Due to their composition, plastics can be transformed into hydrocarbons. The process used to convert plastics into aromatic oils is based on the pyrolysis of plastics. The methods used to convert waste plastics into oils depend on the types of plastics to be converted and the characteristics of other wastes that may be used. The degradation of plastics by pyrolysis has been developed since the last decade of the 20th century until now due to scarcity, high prices, and the search for alternative energy sources such as biofuels. Plastics suitable for conversion are placed in a reactor where they decompose at 450 °C to 550 °C to produce liquid fuel. The main product of the pyrolysis is an oil (mixture of liquid hydrocarbons), which is continuously obtained through the condenser. This occurs when the waste plastics decompose enough in the reactor to evaporate when the reaction temperature is reached [8,9,10,11].

The use of catalysts in pyrolysis is a method already known as catalytic pyrolysis and although some of the advantages of its use are known, the results depend on other factors, such as the type and design of the furnace, the type and quantity of the catalyst, etc. [12]. On the other hand, the catalysts used in the pyrolysis of plastics include metallic oxides and activated clays. Each catalyst has its own properties and advantages and is used depending on the specific needs of the pyrolysis process. This technique is used to distill and obtain fuels from petroleum or to obtain oils by pyrolysis of plastics by fractional distillation using the boiling points of the contained substances with carbon numbers from C5 to C27 at different temperatures [13].

Traditionally, gas chromatography has been used to detect aromatic hydrocarbons. Recently, alternative identification techniques have been proposed, including optical and spectroscopic methods, such as infrared radiation (IR) and Raman spectroscopy [14,15].

Optical techniques, especially Raman spectroscopy, have been used in several applications to characterize food nutrients. However, it has rarely been used in the petroleum field, although it has been proposed for quantitative analysis in industry. Recently, Raman spectroscopy has been used to analyze hydrocarbons, such as gasoline and petroleum products. IR reflects the transition of vibrational and rotational energy levels between atoms in a molecule and has become popular due to its advantages of non-destructive, rapid analysis, and minimal sample preparation and can be used as a potential method for the quantitative analysis of polycyclic aromatic. It is a rapid technique that provides information on the chemical composition of the sample, allowing the identification of functional groups and the acquisition of spectral fingerprints [16,17].

In this work, various techniques and methods have been combined to characterize the products of the pyrolysis of low-density plastics. The pyrolysis technique with a zeolite catalyst is used, and optical methods, such as infrared (IR) and Raman spectroscopy, as well as gas chromatography, are used for the characterization of the hydrocarbons obtained. The identification of the hydrocarbons obtained through pyrolysis is crucial to determine the type of fuel and its possible applications.

This study highlights the use of a small-scale pyrolyzer, with important positive implications for the environment. The use of smaller equipment not only reduces the carbon footprint associated with building and operating larger industrial machinery but also allows for more controlled and efficient operation, thereby minimizing emissions of greenhouse gases and other pollutants. The manageable dimensions of the pyrolyzer facilitate its implementation in small communities that could benefit from the transformation of plastic waste into useful fuels while contributing to sustainable waste management.

In this context, a life cycle assessment (LCA) of the pyrolysis process was carried out to thoroughly evaluate its environmental impact at all stages, from materials production to operation and eventual dismantling of the pyrolyzer. The LCA results support the environmental feasibility of this approach, demonstrating that small-scale zeolite-assisted pyrolysis of low-density plastics is a promising strategy for energy recovery from plastic waste with limited environmental impact.

2. Materials and Methods

This section details the crucial processes employed in this experimental study. The first step involved the utilization of the pyrolysis process to obtain oil, followed by the distillation process to extract liquid fuel from the same oil.

Subsequently, the characterization of the obtained liquid fuels was conducted using various optical methods, including gas chromatography and IR and Raman spectroscopy. These techniques allowed for a comprehensive analysis of the chemical composition and properties of the liquid fuels.

Finally, the life cycle assessment for the extraction of hydrocarbons from low-density plastics is presented, adhering to the ISO 14040 and ISO 14044 standards.

In addition to the characterization methods, a concise overview of the pyrolysis system employed in this study is presented. Notably, the system was constructed in an artisanal manner, underscoring the hands-on and craft-oriented approach taken in designing and implementing the pyrolysis process.

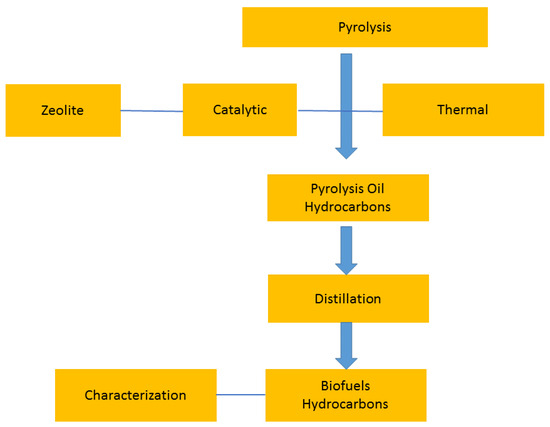

To enhance the understanding of the methodology employed during the experimental process, Figure 1 is presented, offering a schematic representation.

Figure 1.

Methodology diagram.

The experimental development focused on the pyrolysis of low-density plastic bags. The traditional method involves subjecting the plastic to a pyrolysis process, where the temperature is gradually increased until the plastic degrades. In an alternative approach, a catalyst, specifically a zeolite, is introduced, and the temperature is similarly increased to facilitate plastic degradation. Pyrolysis is a defined process wherein thermal cracking reactions, occurring in an oxygen-free environment, transform long, high-molecular-weight polymers into smaller molecules.

The experimental setup involved the construction of a homemade cast iron reactor designed specifically for pyrolysis. This reactor comprises a cylindrical container with a hermetic lid, ensuring a sealed environment. To enhance its efficiency, a shell was added around the cylinder, creating a space between the cylinder and the shell to act as an insulator and prevent heat loss. The lid of the reactor is equipped with a thermometer for temperature monitoring and a gas exhaust piston.

The overall system for pyrolysis includes the reactor, a condenser designed with copper pipes, and an ice-water feed to facilitate efficient heat transfer. Additionally, a vacuum pump, assisted by a compressor, was integrated into the system to create a controlled vacuum, aiding in the condensation of gases. This comprehensive system plays a crucial role in regulating internal pressure, thereby establishing a favorable environment for condensation.

The copper tubing of the condenser plays a pivotal role in this process, offering excellent thermal conductivity to promote the rapid condensation of gases. Simultaneously, the condenser removes air and reduces pressure in the reactor. This dual functionality allows for precise adjustment and maintenance of the desired pressure levels, ensuring optimal conditions for the pyrolysis process.

This comprehensive design ensures precise control of system conditions, optimizing process efficiency and facilitating the effective condensation of gaseous components. Figure 2 displays photos of the process taken during the experiments.

Figure 2.

Equipment and reactor for pyrolysis.

2.1. Thermal and Catalytic Pyrolysis Process

To conduct the pyrolysis experiments, one kilogram of low-density plastic bags served as the foundation. The pyrolysis reaction was executed in the pyrolysis reactor, fueled by liquefied petroleum gas, under the following points.

- The equipment was cleaned, assembled, and connected.

- The LDPE bag was weighed.

- The condenser was filled with water and ice.

- The LDPE bag was placed in the reactor.

- The valves were checked and the vacuum pump was started with the air compressor.

- The gas burner was ignited to start the pyrolysis process.

- The chronometer was switched on, and the time and temperature were recorded, along with any other observations made during the process.

- The time and temperature at which the LDPE pyrolysis oil started to come out were observed.

- The time at which the liquid product came out of the condenser was recorded in the log.

- It was observed when the liquid product stopped coming out, the L.P. gas burner was turned off, and the time and duration of the test completion were recorded.

- After the equipment had cooled down, the residue (coke) remaining in the reactor was cleaned, observed, weighed, and recorded.

In the catalytic pyrolysis process, the thermal pyrolysis process is redone, only now a catalyst is incorporated into the process. On this occasion, a zeolite was used at a concentration of 20% by weight.

Clinoptilolite is a hydrated aluminosilicate of sodium, potassium, and calcium with the molecular formula (Ca3(Si30Al6)O72·20H2O, K6(Si30Al6)O72·20H2O, Na6(Si30Al6)O72·20H2O). It is a zeolite that belongs to the heulandite family, along with laumontite and mordenite, among others [18,19,20,21].

2.2. Oil Distillation

Once the LDPE was subjected to the pyrolysis process, a product called oil was obtained, which is considered biocrude. This oil was refined using a fractional distillation method to improve the physicochemical characteristics and separate the different compounds it contains. The distillation equipment, made of stainless steel, consisted of a distillation vessel, a condenser with a capacity of 3 L, a submersible pump for moving water through the condenser pipe, and hoses for operating the equipment.

The following protocol was followed:

- The distillation equipment was cleaned. Care was taken to ensure that no residue or dust was left on the entire inside of the stainless steel pot.

- The distillation equipment was assembled.

- Two separate distillations were performed, one with 500 mL of the LDPE pyrolysis oil product and the other with LDPE + zeolite.

- The burner was ignited to start the distillation, the submersible pump that feeds the condenser and circulates the water was turned on, and the L.P. gas burner was also turned on to start the distillation process. At the same time the stopwatch was turned on and the temperatures began to be recorded in the log.

- The thermometer was observed to register and collect the distilled substances in the temperatures: 40–70 °C, 71–120 °C, 121–180 °C, 181–190 °C, 191–210 °C, 210–260 °C, and greater than 260 °C, which are the vapor-condensation cycles for the fractional distillation of gasoline, diesel, and other fuels.

- Fuel samples were collected and separated in glass containers or test tubes, and quantities were recorded and labeled.

- Once the temperature exceeded 260 °C, the power source was shut off in both processes.

- The process time was recorded in the log and the equipment was allowed to cool before cleaning. Figure 3 shows the by-products obtained from pyrolysis. After pyrolyzation, these are distilled to obtain liquid hydrocarbons that illustrate the distillation process.

Figure 3. Distillation process.

Figure 3. Distillation process.

2.3. Raman Spectroscopy

The equipment used for Raman spectroscopy consisted of a microscope and a spectrometer for absorption and Raman scattering; the equipment was a Thermo Scientific Nicolet Almega XR (Waltham, MA, USA, Thermo Scientific manufacturer). The microscope has a full interface with the spectrometer to provide high throughput.

The liquid sample was placed in a quartz cuvette. Once the equipment was turned on and stabilized, the software corresponding to the equipment was selected for the Raman analysis technique to measure the liquid sample. We readjusted analysis parameters such as wavelength, integration time, number of scans averaged, etc. Subsequently, a reading was taken to establish a baseline. Afterwards, we measured the sample and acquired the spectral data of the liquid sample. The equipment returns the transmittance spectra.

2.3.1. Infrared Spectroscopy

The IR spectra of the samples were acquired using a Nicolet; the model is a Nexus 670 FT-IR in the (5000–600 cm−1) range. The analysis was performed in the vapor phase. Basically, the vapor from the samples was injected into a cell that was analyzed. Previously, the equipment was purged with nitrogen to eliminate the peaks from water vapor and carbon dioxide. In addition, a non-sample reading is taken to subtract the background. The sample is then injected and read by subtracting the background signal.

2.3.2. Gas Chromatography

A SCION 456GC chromatograph was used to determine the components present in the distillate mixture obtained from the pyrolysis processes. The chromatograph was equipped with a liquid autosampler, an internal oven for temperature control, and a 30 m × 0.25 mm capillary column with 0.25 micrometer internal diameter.

2.4. Life Cycle Assessment for Obtaining Hydrocarbons from Low-Density Plastics

The life cycle assessment (LCA) for the extraction of hydrocarbons from low-density plastics encompasses a comprehensive evaluation of the environmental impacts attributable to the entire life cycle of these plastics. This study accounts for every phase from raw material acquisition to end-of-life management, enabling a holistic understanding of the environmental implications of hydrocarbon extraction from these materials.

Methodology:

- The LCA is conducted adhering to the ISO 14040 and ISO 14044 standards, ensuring methodological rigor and consistency. It is divided into four main stages [22]:

- Definitions:

- Goal.1: To evaluate the environmental impacts of hydrocarbon extraction from low-density plastics.

- Scope.1: Covers the entire life cycle from raw material extraction to hydrocarbon recovery and end-of-life processing.

- Functional Unit.1: Defined as the amount of hydrocarbons obtained from one kilogram of low-density plastic waste.

- Inventory Analysis.1: A comprehensive inventory of inputs (energy, resources) and outputs (emissions, waste) is compiled.

- Data are collected from reliable and pertinent sources, ensuring their relevance and accuracy for the assessment.

- Impact Assessment.1: The gathered data are analyzed to assess their impact on various environmental categories, such as global warming potential, eutrophication, and acidification. Characterization factors are applied to convert the inventory data into impact assessment results.

- Interpretation.1: Results are analyzed, and conclusions are drawn according the environmental impact of hydrocarbon extraction from low-density plastics.

- Recommendations are made for enhancing environmental performance and reducing adverse effects.

- Considerations.1: A critical review is conducted by a panel of external experts to ensure the validity and re-liability of the LCA study. Sensitivity analysis and uncertainty assessment are included to account for potential variability and assumptions in the study.

- Goal.2: To evaluate the environmental impacts of hydrocarbon extraction from low-density plastics.

- Scope.2: Covers the entire life cycle from raw material extraction to hydrocarbon recovery and end-of-life processing.

- Functional Unit.2: Defined as the amount of hydrocarbons obtained from one kilogram of low-density plastic waste.

- Inventory Analysis.2: A comprehensive inventory of inputs (energy, resources) and outputs (emissions, waste) is compiled. Data are collected from reliable and pertinent sources, ensuring its relevance and accuracy for the assessment.

- Impact Assessment.2: The gathered data are analyzed to assess their impact on various environmental categories, such as global warming potential, eutrophication, and acidification. Characterization factors are applied to convert the inventory data into impact assessment results.

- Interpretation.2: Results are analyzed, and conclusions are drawn regarding the environmental impact of hydrocarbon extraction from low-density plastics. Recommendations are made for enhancing environmental performance and reducing adverse effects.

- Considerations.2: A critical review is conducted by a panel of external experts to ensure the validity and re-liability of the LCA study. Sensitivity analysis and uncertainty assessment are included to account for potential variability and assumptions in the study [23].

3. Results

3.1. Pyrolysis

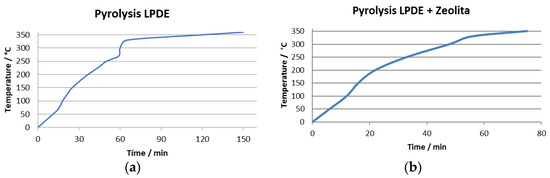

The pyrolization of LDPE was carried out in a homemade reactor. The reactor reached temperatures of 360 °C. The pyrolytic processes from LDPE to obtain oils and flammable gaseous products started at 65 min. The product obtained was as thick as beeswax and 90% of the product was obtained in about three hours. For LDPE + zeolite, the oil was obtained after 55 min at a temperature of 330 °C, and the process was completed only 20 min later at a temperature of 350 °C. A total of 75% of the product obtained was very thick oils. The graphs in Figure 4 show how the temperature increases with time. The differences between the two processes can be seen.

Figure 4.

Pyrolysis process without and with zeolite.

Based on the reaction mechanism, as well as the requirement in the temperature increase, the following kinetic reaction model is obtained:

where CLDPE is CHDPE polyethylene (% w/v); GLDPE is GHDPE gas production (% w/w), and LLDPE is LHDPE light oil (% w/w), and k1, …and k7 are rate constants.

It should also be noted that although the use of catalysts can potentially reduce the cost of producing pyrolysis products, other factors such as the initial cost of the catalysts and the energy required for the pyrolysis process should also be taken into account. Overall, the use of pyrolysis as a method for plastic waste management is still an area of active research and development, and further studies are needed to optimize the process and improve its economic feasibility.

3.2. Distillation of the Products Obtained from Pyrolysis

To perform the distillation process, 500 milliliters of each type of oil was used: oil obtained from the pyrolysis of LDPE and oil obtained from the pyrolysis of LDPE + zeolite.

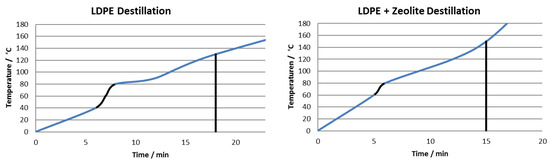

In the product distillation process of the oil obtained by traditional pyrolysis, 20% of the liquid fuel was obtained. The distillation started at 40 °C and ended at 130 °C. In the process of distilling the oil obtained from catalysis of the LDPE + zeolite, 30% of the liquid fuel was obtained. The distillation process started at 60 °C and ended at 150 °C.

The graphs of Figure 5 show the behavior of the oil temperature and phase change with respect to time.

Figure 5.

Temperatures and times reached during the distillation processes.

The process times were similar, 18 and 15 min, as can be seen from the graphs in Figure 5. But the quantities of liquid hydrocarbons obtained are significantly different.

The distillation process of the oil obtained with a catalyst was faster than the one that did not use a catalyst. In the same way, it happened with the change in phase from oil to liquid. Without a catalyst, the phase change was carried out from 40 to 60 °C and with a catalyst from 60 to 80 °C.

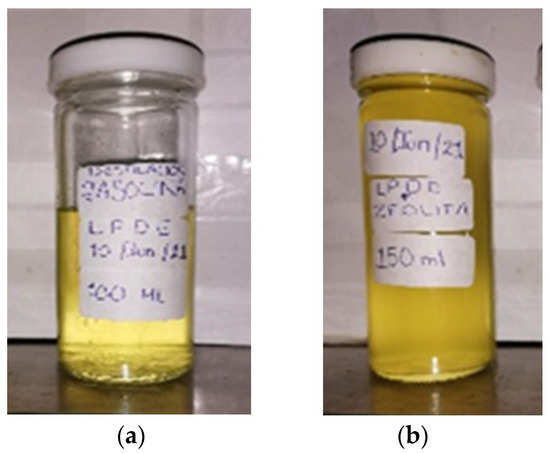

Figure 6 shows the volumes of hydrocarbon liquid produced during the distillation processes.

Figure 6.

Liquid hydrocarbons. (a) the product from the distillation of oil obtained from the traditional thermal pyrolysis; (b) the product from the distillation of the oil obtained with a catalyst.

The liquid of bottle Figure 6a corresponds to the product from the distillation of oil obtained from the traditional thermal pyrolysis and the liquid of bottle Figure 6b to the product from the distillation of the oil obtained with a catalyst. As can be seen in Figure 3, the largest amount of liquid hydrocarbon was obtained from pyrolization with the catalyst. A total of 30% more liquid product was obtained from the oil obtained from the catalytic pyrolization.

3.3. Characterization

3.3.1. Raman Characterization

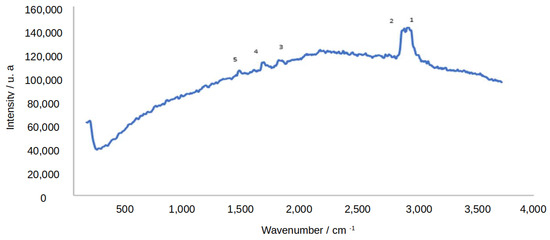

Raman spectroscopy was used to detect the bands of the hydrocarbons obtained from the distillation processes. In the case of putative hydrocarbons, Raman spectroscopy was used to determine the presence of carbon-carbon and carbon-hydrogen bonds. Furthermore, the stretching and deformation vibrations of these bonds can provide information about the structure and conformation of molecules. In aliphatic hydrocarbons, the Raman bands corresponding to the stretching vibrations of the C-C bond and in aromatic hydrocarbons, the Raman bands corresponding to the stretching vibrations of the aromatic rings usually appear in the region of 1400 to 1700 cm−1 [24,25].

Figure 7 shows the spectrum of hydrocarbons obtained after distillation. Where five peaks associated with known hydaTrocarbons are observed.

Figure 7.

Spectrum of hydrocarbons.

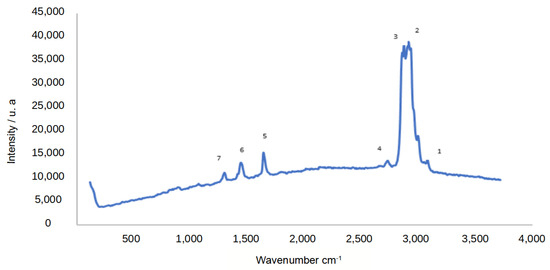

Figure 8 shows the spectrum of hydrocarbons from the catalyst and obtained after distillation. In this spectrum it is observed that more hydrocarbon peaks were detected unlike the previous figure.

Figure 8.

Spectrum of hydrocarbons LEPD + zeolite.

From the Raman spectrum of hydrocarbons obtained from traditional pyrolysis, five groups of Raman bands near ≈1300, ≈1500, ≈1600, and others at approximately the 3000 cm−1 regions were detected for the two hydrocarbons, and these bands varied significantly in intensity according to the type of pyrolysis. The purity of a substance can be evaluated in several ways, and the analysis of its spectral bands can be one of them. When a substance is pure, its absorption or emission spectrum will be consistent and reproducible. This means that the spectral bands of the substance will be strong, sharp, and easily identifiable. Therefore, the greater the intensity of the spectral bands of a substance, the greater the probability that it is pure. Therefore, the hydrocarbons obtained with the catalyst are purest.

The sample with catalyst yielded seven peaks representing the vibrational bands of the functional groups present. While the peaks obtained from simple pyrolysis only present five peaks. Table 1 shows the hydrocarbon bands obtained with the two processes.

Table 1.

Functional groups obtained by Raman spectroscopy from LDPE.

Gasoline is a complex mixture of hydrocarbons that can be classified into several groups based on their molecular structures. The four main groups are paraffins (also known as alkanes), olefins, cycloparaffins (also known as cycloalkanes), and aromatics. Aromatics are hydrocarbons that contain a ring of atoms with alternating double bonds, such as benzene. The aromatic fraction of gasoline consists mainly of benzene, toluene, ethylbenzene, and xylenes (collectively referred to as BTEX), which are important components in the petrochemical industry. Therefore, efforts are being made to limit the amount of benzene in gasoline and other products [26,27,28].

3.3.2. IR Characterization

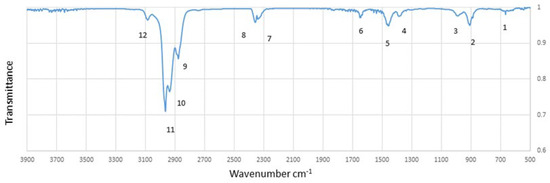

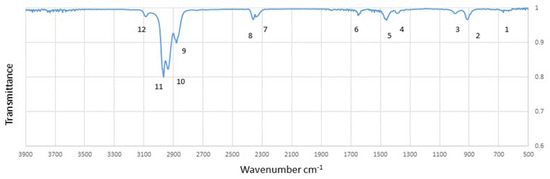

The analysis of infrared spectra by transmittance is a technique used to determine the molecular vibrations of a sample as a function of the absorption of infrared radiation. This technique is based on the Beer–Lambert law, which states that the amount of radiation absorbed by a sample is proportional to the concentration of the sample and the length of the optical path. The information presented in Figure 9 and Figure 10 show the transmittance infrared spectrum.

Figure 9.

Infrared spectrum hydrocarbon.

Figure 10.

Infrared spectrum hydrocarbon (+zeolite).

The plots provide information about the molecular vibrations of the sample, including the presence and location of functional groups. Generally, the graphs in the infrared spectrum are identified, on the Y axis is the transmittance index, on the X axis is the wavelength in cm−1.

In both graphs the IR shows the presence of 12 peaks, indicating the presence of unsaturated alkenes and some branched alkanes, i.e., peaks 1 to 6 are a mixture of n-alkanes and branched alkanes, peaks 7 and 8 are branched alkenes, peak 9 is xylenes, 10 and 11 are ethylbenzene and 12 is toluene. Thus, comparing figures, the same bands are observed, only with different intensities. The data for each band can be seen in Table 2.

Table 2.

Functional groups obtained by IR spectroscopy from LDPE.

3.3.3. Gas Chromatography

Gas chromatography is a widely used technique for the analysis and characterization of a wide variety of compounds, including hydrocarbons. The technique involves separating the components of a mixture based on their different volatilities and interactions with a stationary phase and a mobile phase. In this case, a capillary column was used, which is a type of gas chromatography column with a small diameter and a long length, typically several meters. This type of column allows for efficient separation of components due to the increased surface area of the stationary phase and the longer retention time of the sample components. Injection of 0.01 L, or 10 microliters, is a typical injection volume for gas chromatographic analysis. This volume is small enough to minimize band broadening and sample dispersion, but large enough to ensure adequate sample detection and resolution, with a retention time of 4 h.

For the determination of the components, 12 peaks were identified, which are described in Table 3, where the concentrations and the characteristics of the components present are provided.

Table 3.

Gas chromatography characterization.

On the other hand, when pyrolysis was performed using a catalyst, a higher concentration of some of the compounds was observed (see Table 4). Catalysts are substances that can increase the rate of a chemical reaction without being consumed in the process. In the context of pyrolysis, a catalyst can facilitate the decomposition of complex hydrocarbons into simpler compounds, resulting in a different composition of the final product. This can result In higher concentrations of certain compounds In the liquid product obtained with a catalyst compared to that obtained without a catalyst.

Table 4.

Gas chromatography characterization (+zeolite).

The use of a zeolite as a catalyst increases the transfer area due to the presence of active sites being effective at breaking the LDPE polymer chains at low temperatures compared to other similar processes or catalytic reactors using virgin material or residues of polymers [29]; the use of zeolites is a process of low energy consumption and high efficiency. Although competitive reactions occur, the reaction that controls the decomposition of the LDPE mixture in the process must be demonstrated by pyrolysis.

3.4. Life Cycle Assessment

The life cycle analysis of producing gasoline and other fuels from recycled low-density polyethylene (LDPE) plastic details the following impacts:

Natural Resources and Ecological Health Impact: Positive Impact: The process contributes 473.34 MJ of energy and recycles 8.8 Kg of LDPE.

Negative Impact: It utilizes 24.31 MJ of energy, emits greenhouse gases (GHGs) amounting to 1.67 kg of CO2, and releases 0.84 Kg of coke.

Energy Comparison: Comparing the input energy (24.31 MJ) and the output energy (473.34 MJ), the system yields substantially more energy than it consumes.

Recycling and Emissions: LDPE is recycled, but there are emissions of CO2 (GHG) and coke to the environment.

CO2-Energy Ratio: 9.8 L of fuels are produced, contributing 473.34 MJ of energy, with the production of 1.67 Kg of CO2.

4. Discussion

The quantities and characteristics of pyrolysis products are significantly influenced by various factors, including plastic type, pyrolysis method (slow pyrolysis, fast pyrolysis, and flash pyrolysis), reactor type, and particle size. Liquid oil emerges as the primary product in the process of pyrolyzing plastic waste [13].

The typical plastic waste pyrolysis process is conducted in a batch-type reactor under controlled pressure and temperature conditions, utilizing nitrogen gas as the fluidizing medium. Initially, the plastic is uniformly heated within a defined temperature range, with minimal fluctuations. Oxygen is then extracted from the pyrolysis chamber. Subsequently, the system is allowed to cool, and the byproduct, known as carbonaceous oil, is extracted. Finally, the carbonaceous oil undergoes a specific fractionation and condensation processes during heating, resulting in the production of a high-quality distillate.

In contrast to the reactor presented in this study, which was handmade, we attempted to manually control the conditions and the objective was for this system to be reproducible in small communities. Simultaneously, it aims to recycle plastic waste and obtain liquid fuel.

In previous studies, it was observed that low-temperature (<500 °C) pyrolysis of low-density plastics tends to favor the production of waxes, approximately comprising 20% to 90% by weight. Slow pyrolysis is distinguished by lower heating rates, longer solid and vapor residence periods (minutes to hours), and lower temperatures. Additionally, catalysts are employed in pyrolysis at higher temperatures, primarily for the production of gases or products with a high-octane number.

In Table 5, a comparison is presented, displaying the weights as a percentage of the products obtained from the slow pyrolysis of low-density plastics as found in the literature.

Table 5.

Summary pyrolysis slow of LDPE.

Comparing the findings of this study, the temperature at which the HLPE was pyrolyzed was lower than 360 °C, both with and without a catalyst. This categorizes it in the low-temperature range. The wax content was higher without a catalyst, but the process duration was 180 min. With the catalyst, the wax weight was 75% with a shorter time frame of 20 min. However, the liquid fuel obtained after distillation was 20% without a catalyst and 30% with a catalyst. Therefore, in this study, the catalyst was used to reduce times and obtain better performance of the liquid fuel, unlike the data obtained in the literature that used the catalyzer to obtain gas.

The use of other methods, such as packed bed reactors using a pyrolytic gasification process applied to virgin materials such as LDPE, HDPE and PP, provides yields between 66 and 68%, which are similar to a biomass polymer waste with the same characteristics but having the disadvantage of a temperature at 700 °C [29]. The present study yields 10% less than those obtained in a packed bed reactor but with maximum temperatures of 220 °C and using nonvirgin material or polymeric.

On the other hand, gasoline is made up of hundreds of compounds, which structurally can be divided into four main groups: paraffins, olefins, cycloparaffins, and aromatics. The aromatic fraction of gasoline is mainly represented by benzene, toluene, ethylbenzene, and xylenes, which are usually referred to with the acronym BTEX (meaning benzene, toluene, ethylbenzene, and xylenes) [27]. Regarding the composition of the liquid fuel, it exhibits diversity, influenced by the pressure and temperature conditions during the pyrolysis process. In comparison with other LDPE cracking or pyrolysis processes and in the presence of catalysts such as simple oxides or simple oxides with clays (zeolites), it is observed that the use of bimetallic catalysts, such as CoMo/Al2O3, in the presence of toluene and at temperatures between the intervals of 260 and 325 °C and a reaction time of 2 h, yields 25% of n-olefins, n-paraffins, and isoparaffins [34] compared to the method used in this work. The yield is between 45 and 55% of the same hydrocarbons using a zeolite based on aluminum oxide. Table 6 shows the composition of some studies referring to the pyrolysis of LEPE.

Table 6.

Chemical composition of LDPE.

The pyrolysis process of LDPE is designed with the goal of producing oil or wax. These resulting products can be recycled to generate raw materials, such as gasoline. The compounds marked in the table are typical substances in gasoline [27].

5. Conclusions

In this work, a functional reactor was developed for the pyrolysis of low-density plastics. The results indicate that the quantity of oil obtained from the pyrolysis of low-density polyethylene (LDPE) was higher compared to the pyrolysis of LDPE with a zeolite catalyst. However, during the distillation process, a greater amount of liquid was obtained when distilling the oil with zeolite.

To elaborate, with traditional pyrolysis, a yield of 90% oil was obtained, and from this oil, 20% were hydrocarbons from the distillation process. This means that from 1 kg of plastic, 180 mL of hydrocarbons were obtained. On the other hand, in the catalytic pyrolysis process, a yield of 75% oil with a zeolite was obtained. From this mixture, 30% were hydrocarbons from the distillation process. In total, from 800 g of plastic plus 200 g of zeolite, 225 mL of enhanced hydrocarbons were obtained.

These findings suggest that the zeolite catalyst was effective in facilitating the breakdown of complex hydrocarbons into simpler compounds compared to the traditional LDPE pyrolysis. This indicates that the addition of a zeolite catalyst may have contributed to a higher yield of fuel or distillate at a lower distillation temperature, suggesting a potentially more energy-efficient process.

The utilization of pyrolysis and fractional distillation to recover hydrocarbons or fuels from low-density plastics presents a promising approach for reducing plastic waste and obtaining valuable products. The presence of aromatic compounds, such as benzene, toluene, and xylenes—typical components of gasoline and diesel fuels—suggests that the products derived from this process could hold high commercial value as fuels or fuel additives.

This analysis provides a well-balanced assessment of the environmental impacts associated with gasoline and other fuels’ production from recycled LDPE. It underscores the positive energy contribution and recycling benefits while taking into account greenhouse gas (GHG) emissions and coke emissions. The detailed insights into the various impacts serve as valuable information for guiding further research and development efforts aimed at enhancing the environmental sustainability of this production process.

Nevertheless, it is crucial to consider the environmental impact and sustainability of this process concerning energy consumption, emissions, and waste generation.

The pyrolysis process proposed in the present work demonstrates sustainability from an energy perspective, especially when compared to the use of bi-metallic catalysts or packed bed gasification reactors. While the performances of the latter are comparable to those presented in this work, their energy consumption exceeds 200–300%. In contrast, the implementation of catalysts based on non-functionalized clays (natural zeolites) proves to be both feasible and viable from an energy sustainability standpoint.

Author Contributions

J.A.T.T. wrote the first draft of the manuscript which was then refined by H.S.-C., and the final article was written with comments and suggestions from M.G.-A., H.S. and F.J.S.-R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data can be requested from the corresponding author.

Acknowledgments

The authors express their gratitude to the Laboratorio Universitario de Caracterización Espectroscópica (LUCE-ICAT-UNAM), and to R. Sato-Berrú and J.O. Flores-Flores for the characterization of the samples using infrared spectroscopy and gas chromatography. Additionally, the authors thank the Universidad Intercultural Indígena de Michoacán (UIIM), Environment Engineering Faculty, Universidad Autonoma Popular del Estado de Puebla, and Consejo Nacional de Humanidades, Ciencias y Tecnologías (CONAHCYT).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Outlook Energy. International Energy Outlook; U.S. Energy Information Administration (EIA): Washington, DC, USA, 2016. [Google Scholar] [CrossRef]

- Tanveer, A.; Zhang, D. A critical review of comparative global historical energy consumption and future demand: The story told so far. Energy Rep. 2020, 6, 1973–1991. [Google Scholar] [CrossRef]

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef]

- Wong, S.L.; Ngadi, N.; Abdullah, T.A.T.; Inuwa, I.M. Current state and future prospects of plastic waste as source of fuel: A review. Renew. Sustain. Energy Rev. 2015, 50, 1167–1180. [Google Scholar] [CrossRef]

- Eze, W.U.; Umunakwe, R.; Obasi, H.C.; Ugbaja, M.I.; Uche, C.C.; Madufor, I.C. Plastics waste management: A review of pyrolysis technology. Clean Technol. Recycl. 2021, 1, 50–69. Available online: https://www.aimspress.com/article/doi/10.3934/ctr.2021003 (accessed on 31 July 2022). [CrossRef]

- Jang, Y.C.; Lee, G.; Kwon, Y.J.; Lim, H.; Jeong, J.H. Recycling and management practices of plastic packaging waste towards a circular economy in South Korea Resources. Conserv. Recycl. 2020, 158, 104798. [Google Scholar] [CrossRef]

- Raju, F. Recycling of Polymers: Methods, Characterization and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Khan, M.Z.H.; Sultana, M.; Al-Mamun, M.R.; Hasan, M.R. Pyrolytic Waste Plastic Oil and Its Diesel Blend: Fuel Characterizacion. Hiundwi Publ. Corp. J. Environ. 2016, 28, 7869080. [Google Scholar] [CrossRef] [PubMed]

- Anene, A.F.; Frderiksen, S.B.; Setre, K.A.; Tokheim, L.A. Experimental study of thermal and catalytic pyrolysis of plastic waste components. Sustainability 2018, 10, 3979. [Google Scholar] [CrossRef]

- Thokchom Subhaschandra, S.; Tikendra Nath, V.; Huirem Neeranjan, S. A lab scale waste to energy conversion study for pyrolysis of plastic with and without catalyst: Engine emissions testing study. Fuel 2020, 277, 118176. [Google Scholar] [CrossRef]

- Sekar, M.; Ponnusamy, V.K.; Pugazhendhi, A.; Nižetić, S.; Praveenkumar, T.R. Production and utilization of pyrolysis oil from solidplastic wastes: A review on pyrolysis process and influence of reactors design. J. Environ. Manag. 2022, 302 Pt B, 114046. [Google Scholar] [CrossRef]

- Al-Salem, S.M.A.; Antelava, C.A.; Manos, G.; Dutta, A. A review on thermal and catalytic pyrolysis of plastic solid waste (PSW). J. Environ. Manag. 2017, 197, 177–198. [Google Scholar] [CrossRef]

- Yehya, J.; Jaafara, Y.; Abdelouaheda, L.; El Hageb, R.; El Samranic, A.; Taouka, B. Pyrolysis of common plastics and their mixtures to produce valuable petroleum-like products. Polym. Degrad. Stab. 2022, 195, 109770. [Google Scholar] [CrossRef]

- Rahman, M.M.; Lui, R.; Cai, J. Catalytic fast pyrolysis of biomass over zeolites for high quality bio-oil—A review. Fuel Process. Technol. 2018, 180, 32–46. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Y.W.; Zhao, Y. Characterization of polycyclic aromatic hydrocarbons using Raman and surface-enhanced Raman spectroscopy. J. Raman Spectrosc. 2014, 46, 64–69. [Google Scholar] [CrossRef]

- Maddams, W.F.; Royaud, I.A.M. The characterization of polycyclic aromatic hydrocarbons by Raman spectroscopy. Spectrochim. Acta Part A Mol. Spectrosc. 1999, 46, 309–314. [Google Scholar] [CrossRef]

- Ardila, J.A.; Felipe Solares, F.L.; Santos Farias, M.A.D.; Lajarim Carneiro, R. Characterization of Gasoline by Raman Spectroscopy with Chemometric Analysis. Anal. Lett. 2016, 50, 1126–1138. [Google Scholar] [CrossRef]

- Jones, R.R.; Hooper, D.C.; Zhang, L.; Wolverson, D.; Valev, V.K. Raman techniques: Fundamentals and frontiers. Nanoscale Res. Lett. 2019, 14, 231. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Feng, Y.; Yu, Y.; Zhang, T.; Yan, C.; Tang, H.; Sheng, Q.; Li, H. Quantitative analysis of polycyclic aromatic hydrocarbons in soil by infrared spectroscopy combined with hybrid variable selection strategy and partial least squares. Spectrochim. Acta Part A: Mol. Biomol. Spectrosc. 2021, 2021, 119771. [Google Scholar] [CrossRef] [PubMed]

- Iliopoulou, E.F.; Triantafyllidis Kostas, S.; Lappas Angelos, A. Overview of catalytic upgrading of biomass pyrolysis vapors toward the production of fuels and high-value chemicals. Wiley Interdiscip. Rev. Energy Environ. 2019, 8, e322. [Google Scholar] [CrossRef]

- Tasić, Ž.Z.; Bogdanović, G.D.; Antonijević, M.M. Application of natural zeolite in wastewater treatment: A review. J. Min. Metall. A Min. 2019, 55, 167–179. Available online: https://scindeks.ceon.rs/article.aspx?artid=1450-59591901067T (accessed on 23 March 2022). [CrossRef]

- Bjørn, A.; Owsianiak, M.; Molin, C.; Hauschild, M.Z. LCA History. In Life Cycle Assessment: Theory and Practice; Springer: Cham, Switzerland, 2018; pp. 17–30. [Google Scholar] [CrossRef]

- Arabiourrutia, M.; Elordi, G.; Lopez, G.; Borsella, E.; Bilbao, J.; Olazar, M. Characterization of the waxes obtained by the pyrolysis of polyolefin plastics in a conical spouted bed reactor. J. Anal. Appl. Pyrolysis 2012, 94, 230–237. [Google Scholar] [CrossRef]

- Sheppard, N. Some characteristic frequencies in the Raman spectra of saturated aliphatic hydrocarbons. J. Chem. Phys. 1948, 16, 690–697. [Google Scholar] [CrossRef]

- Endo, M.; Nishimura, K.; Kim, Y.A.; Hakamada, K.; Matushita, T.; Dresselhaus, M.S.; Dresselhaus, G. Raman spectroscopic characterization of submicron vapor-grown carbon fibers and carbon nanofibers obtained by pyrolyzing hydrocarbons. J. Mater. Res. 1999, 14, 4474–4477. [Google Scholar] [CrossRef]

- Yousef, S.; Eimontas, J.; Zakarauskas, K.; Striugas, N. Microcrystalline paraffin wax, biogas, carbon particles and aluminum recovery from metallised food packaging plastics using pyrolysis, mechanical and chemical treatments. J. Clean. Prod. 2021, 290, 127858. [Google Scholar] [CrossRef]

- Boluda, C.J.; Macías, M.; González Marrero, J. The chemical complexity of automotive gasolines. Cienc. Ing. Apl. 2019, 2, 51–79. Available online: https://repositoriobiblioteca.intec.edu.do/handle/123456789/2536 (accessed on 19 April 2022).

- Weaver, L.W.; Exum, L.R.; Prieto, L.M. Gasoline Composition Regulations Affecting LUST Sites. US Environmental Protective Agency, Office of Research and Development, 2010, Gra and I, p. 39. Available online: https://hero.epa.gov/hero/index.cfm/reference/details/reference_id/1580235 (accessed on 31 July 2022).

- Kumar Ghodke, P.; Kumar Sharma, A.; Moorthy, K.; Chen, W.H.; Patel, A.; Matsakas, L. Experimental Investigation on Pyrolysis of Domestic Plastic Wastes for Fuel Grade Hydrocarbons. Processes 2022, 11, 71. [Google Scholar] [CrossRef]

- Maqsood, T.; Dai, J.; Zhang, Y.; Guang, M.; Li, B. Pyrolysis of plastic species: A review of resources and products. J. Anal. Appl. Pyrolysis 2021, 159, 105295. [Google Scholar] [CrossRef]

- Sharuddin, S.D.A.; Abnisa, F.; Daud, W.M.A.W.; Aroua, M.K. Pyrolysis of plastic waste for liquid fuel production as prospective energy resource. IOP Conf. Ser. Mater. Sci. Eng. 2018, 334, 012001. [Google Scholar] [CrossRef]

- Onwudili, J.A.; Insura, N.; Williams, P.T. Composition of products from the pyrolysis of polyethylene and polystyrene in a closed batch reactor: Effects of temperature and residence time. J. Anal. Appl. Pyrolysis. 2009, 86, 293–303. [Google Scholar] [CrossRef]

- Uddin, M.A.; Koizumi, K.; Murata, K.; Sakata, Y. Thermal and catalytic degradation of structurally different types of polyethylene into fuel oil. Polym. Degrad. Stab. 1996, 56, 37–44. [Google Scholar] [CrossRef]

- Abdulkareem, S.A.; Abu, T.O.; Eleburuike, N.A. Thermal and Catalytic Pyrolysis of Low-Density Polyethylene (LDPE) Wastes into Useful Fuel Oils: Comparative Studies. ABUAD J. Eng. Res. Dev. (AJERD) 2019, 2, 36–41. Available online: http://ajerd.abuad.edu.ng/wp-content/uploads/2019/04/AJERD0201_05.pdf (accessed on 3 March 2022).

- Williams, P.T.; Williams, E.A. Fluidised bed pyrolysis of low density polyethylene to produce petrochemical feedstock. J. Anal. Appl. Pyrolysis 1999, 51, 107–126. [Google Scholar] [CrossRef]

- Lin, X.; Lei, H.; Huo, E.; Qian, M.; Mateo, W.; Zhang, Q.; Zhao, Y.; Wang, C.; Villota, E. Enhancing jet fuel range hydrocarbons production from catalytic co-pyrolysis of Douglas fir and low-density polyethylene over bifunctional activated carbon catalysts. Energy Convers. Manag. 2020, 211, 112757. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).