Abstract

Despite technological developments, modern methods for the disposal of end-of-life tires most often involve either their incineration in cement kilns or the destruction of tires in special landfills, demonstrating a lack of sustainable recycling of this valuable material. The fundamental role of recycling is evident, and the development of high-efficiency processes represents a crucial priority for the European market. Therefore, the investigation of end-of-life rubber processing methods is of high importance for both manufacturers and recyclers of rubber materials. In this paper, we review existing methods for processing of end-of-life tires, in order to obtain rubber crumb, which can later be used in the production of new industrial rubber goods and composites. We consider processes for separating end-of-life tires into fractions (in terms of types of materials) using chemical, mechanochemical, and mechanical methods to process the materials of used tires, in order to obtain crumb rubber of various fractions and chemical reactivities.

1. Introduction

Processing end-of-life tires and rubber is a critical aspect of modern waste management. End-of-life tires (ELT) and elastomer products have been recognized by the European Union as a critical and valuable resource for the circular economy [1]. In this context, the use of the principles of sustainable development requires a smart approach to waste, using the environmentally friendly concept of secondary raw material manufacturing from end-of-life tires [2].

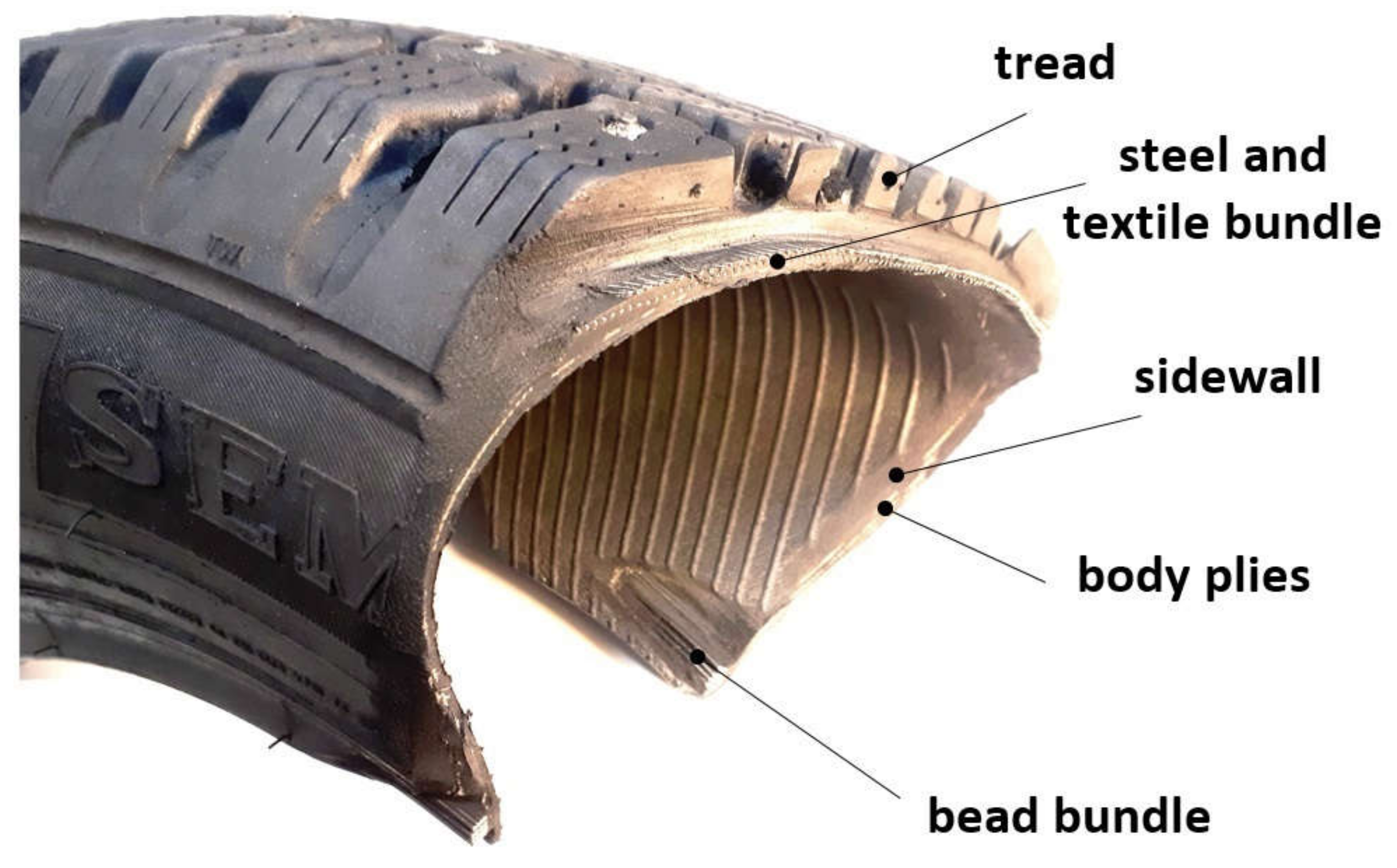

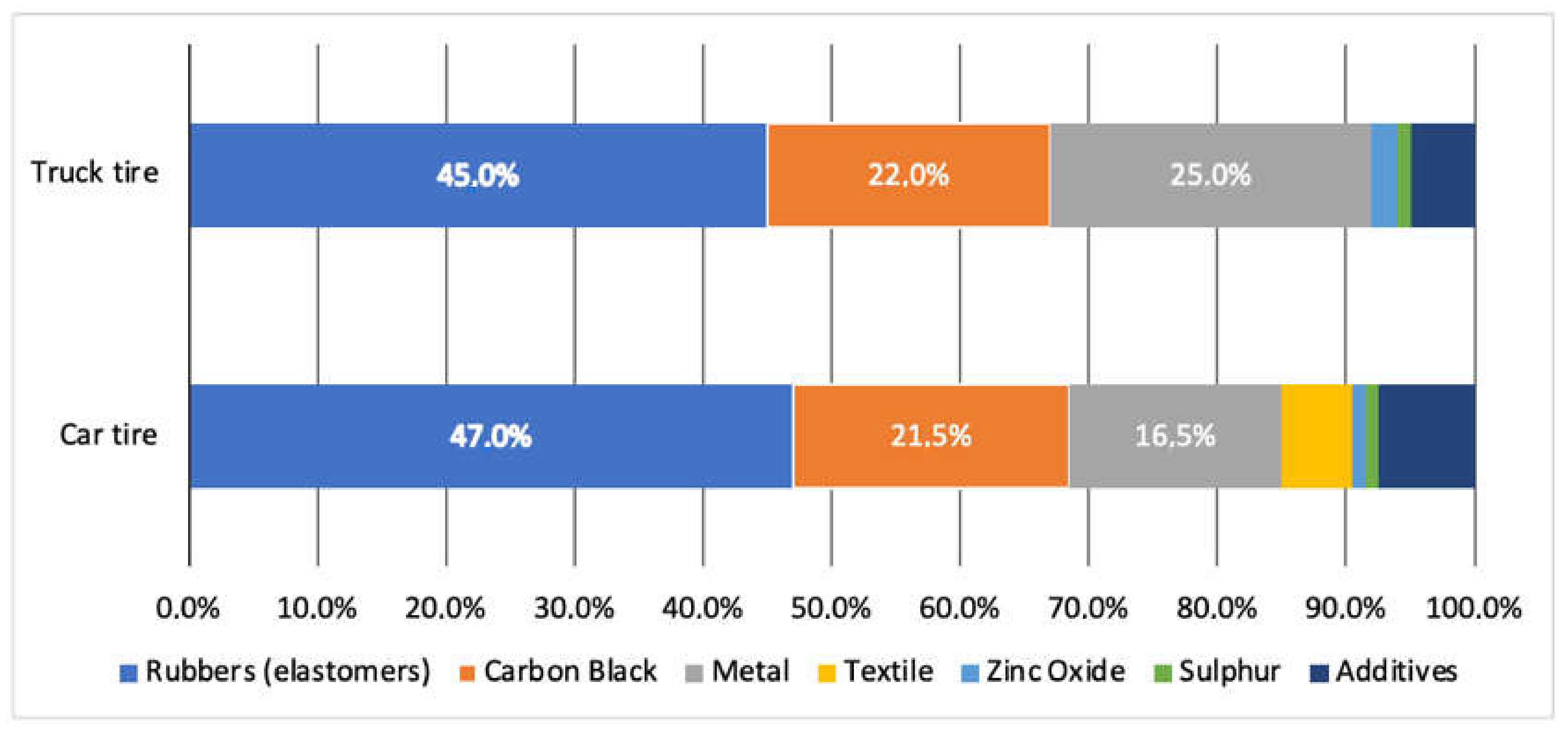

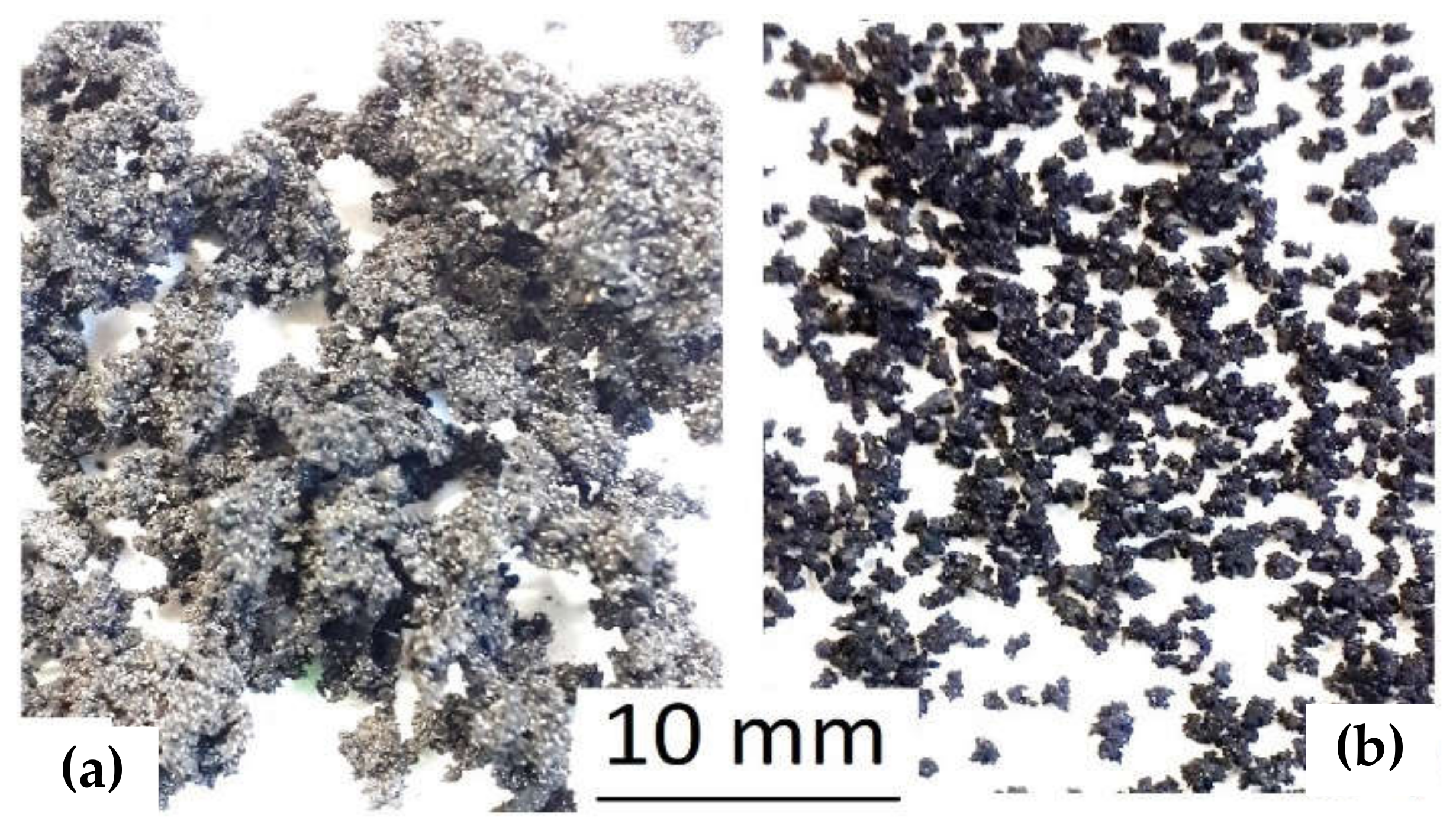

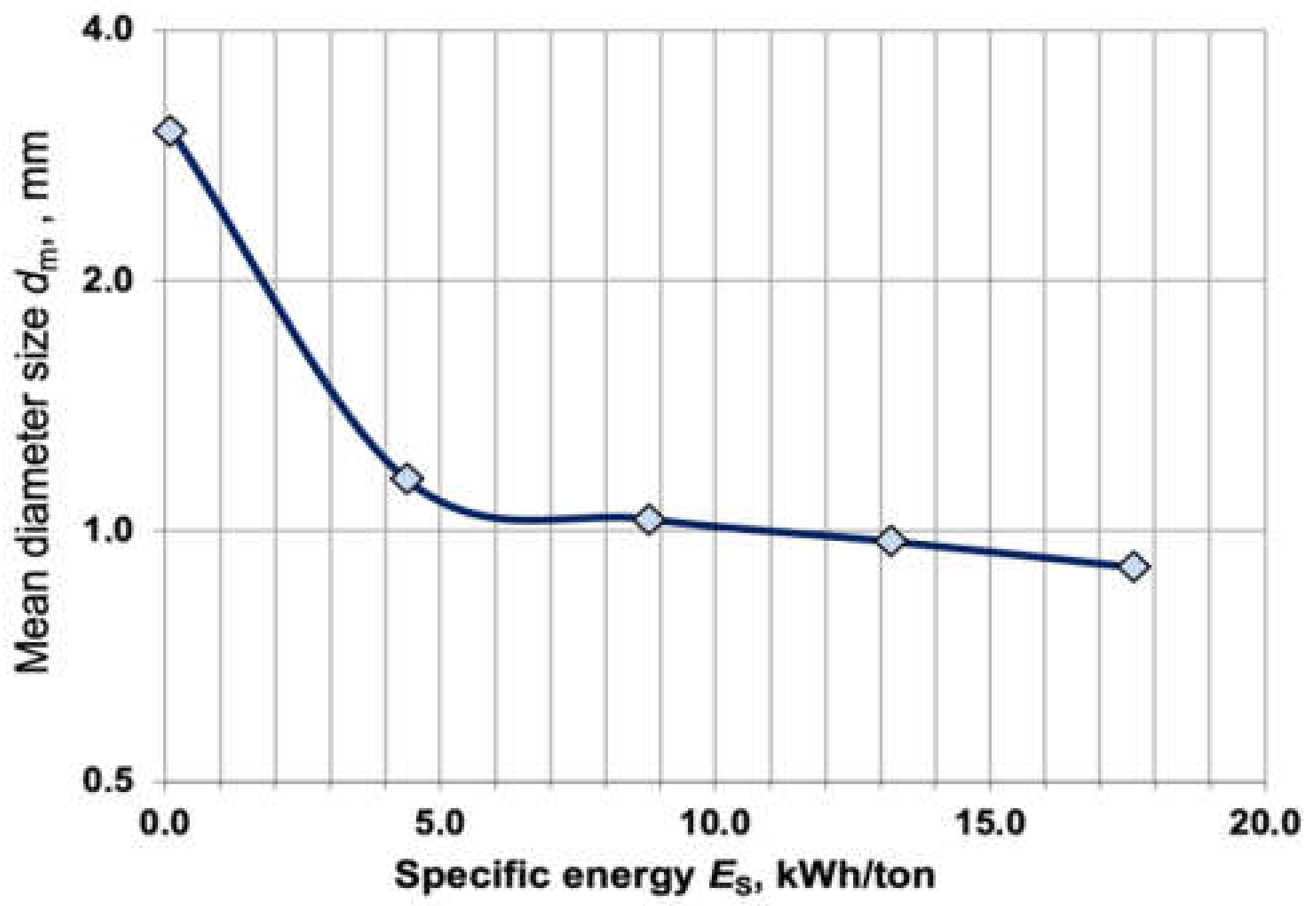

End-of-life tires have a complex composition, containing rubber, steel, textiles, and additives. According to the U.K. Waste and Resources Action Programme (WRAP) and the European Tire and Rubber Manufacturers’ Association (ETRMA) report, the compositions of passenger and light truck tires are given in Figure 1 and Figure 2 [3].

Figure 1.

Typical passenger car tire construction (author’s image).

Figure 2.

Typical composition of passenger and truck tires, wt%.

Waste rubber is very difficult to recycle for the following main reasons:

- the presence of a three-dimensional network formed during vulcanization;

- the variety of formulations of rubber compound;

- the complex structure of rubber products.

The polymer chains in rubber are cured during vulcanization. High energy chemical bonds are formed. The most common crosslinking agent is sulfur. Sulfur crosslinks are similar to bond energy in the polymer chain (Table 1) [4].

Table 1.

Energy of bonds in sulfur cured rubber.

The three-dimensional network makes the rubber capable of high reversible deformations. This makes rubber very difficult to grind. The three-dimensional network prevents the rubber from dissolving, and therefore rubber swells only to a limited extent in some solvents. The complexity of grinding and insolubility make it impossible to chemically destroy the crosslinks in the mass of rubber [5]

Rubbers are made from different polymers. The polymer base gives special properties to the product. These polymers often do not fit well with each other. Therefore, it is important to know rubber composition during its reusing. Rubber compounds may consist of many different polymers, which in turn may contain 10–20 other chemical compounds. Rubber products are often reinforced with metal or textiles [6]. For processing of tires, conveyor belts or lip seals, it is necessary to separate the reinforcing material from the rubber. It is difficult to implement technically, since, at the development stage, the goal is to ensure the strongest coupling between the rubber and the reinforcing material. Therefore, the collection and sorting of rubber waste is critical to the efficient processing of rubber waste.

Most end-of-life tires collected in the EU are subjected to recycling through processes of material recovery [7]. However, the manufacturing of materials and products with added value based on recycled ELTs can be considered to be a critical issue for the European circular economy. One of the known approaches for recycling ELTs is to process them through mechanical shearing and grinding. This approach produces crumb rubber, which can be used as a material to entirely or partially replace mineral aggregates, producing more environmentally friendly composite materials, such as rubberized asphalt pavement [8,9]. Binder modification with crumb rubber is a modern technology for asphalt production with lower ductility [10]. An environmentally friendly approach for tire recycling is devulcanization [11,12].

2. Processing Methods for Rubber Wastes

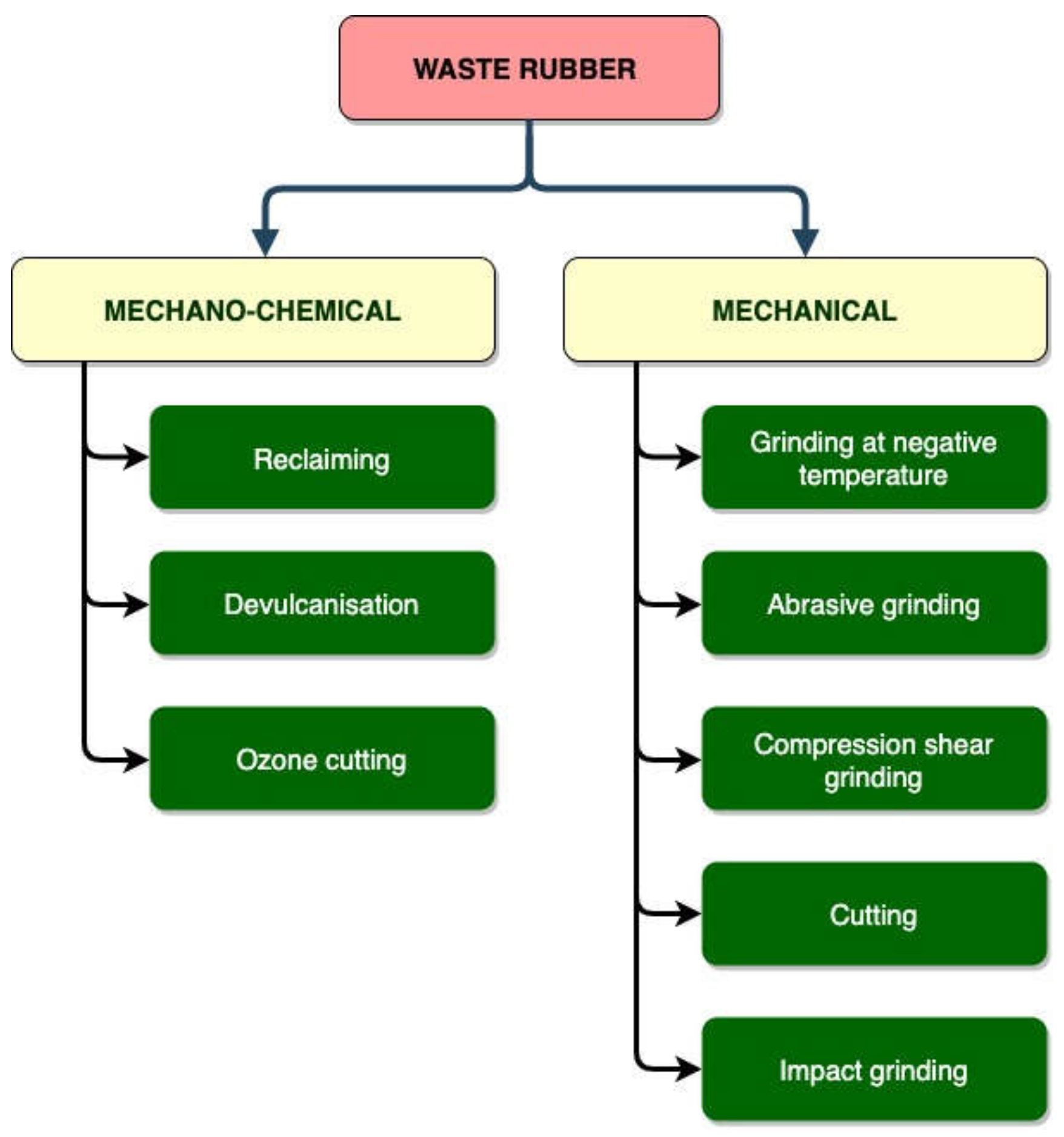

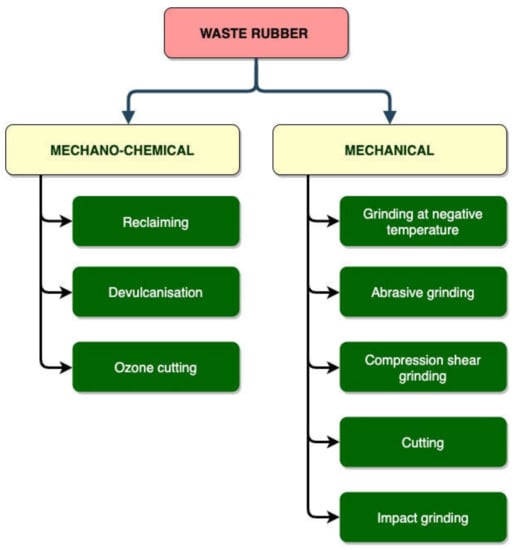

The current review is devoted to waste rubber processing methods, which can be classified according to the modifications that occur in the elastomeric matrix during processing (see Figure 3).

Figure 3.

Waste rubber processing methods (author’s concept).

Chemical processing methods lead to irreversible changes in the structure of the elastomeric matrix and other rubber components. In most cases, the chemical processing of rubber waste is carried out at high temperatures and consists of the thermal destruction of polymers, which occurs in a specific environment.

Mechanochemical methods make it possible to preserve the valuable properties of elastomers to a greater extent as compared with chemical methods, as there is no complete decomposition of the polymer. Due to their thermal, mechanical, and chemical actions, these methods allow for the partial destruction of the three-dimensional structure of rubbers, and thus obtain a product that has plastic properties, is capable of crosslinking during vulcanization, and can partially replace rubber in rubber compound formulations.

The original structures and properties of the elastomers that are part of the waste are most fully preserved when using mechanical processing methods. The primary method in this class is grinding.

New methods for improving rubber processing products are continually being developed, such as surface treatment, catalytic regeneration, ultrasonic and chemical devulcanization, and many others [12]. Studies have shown that process parameters (e.g., the temperature), the intensity of mechanical action, and the parameters of the reaction medium are essential [13].

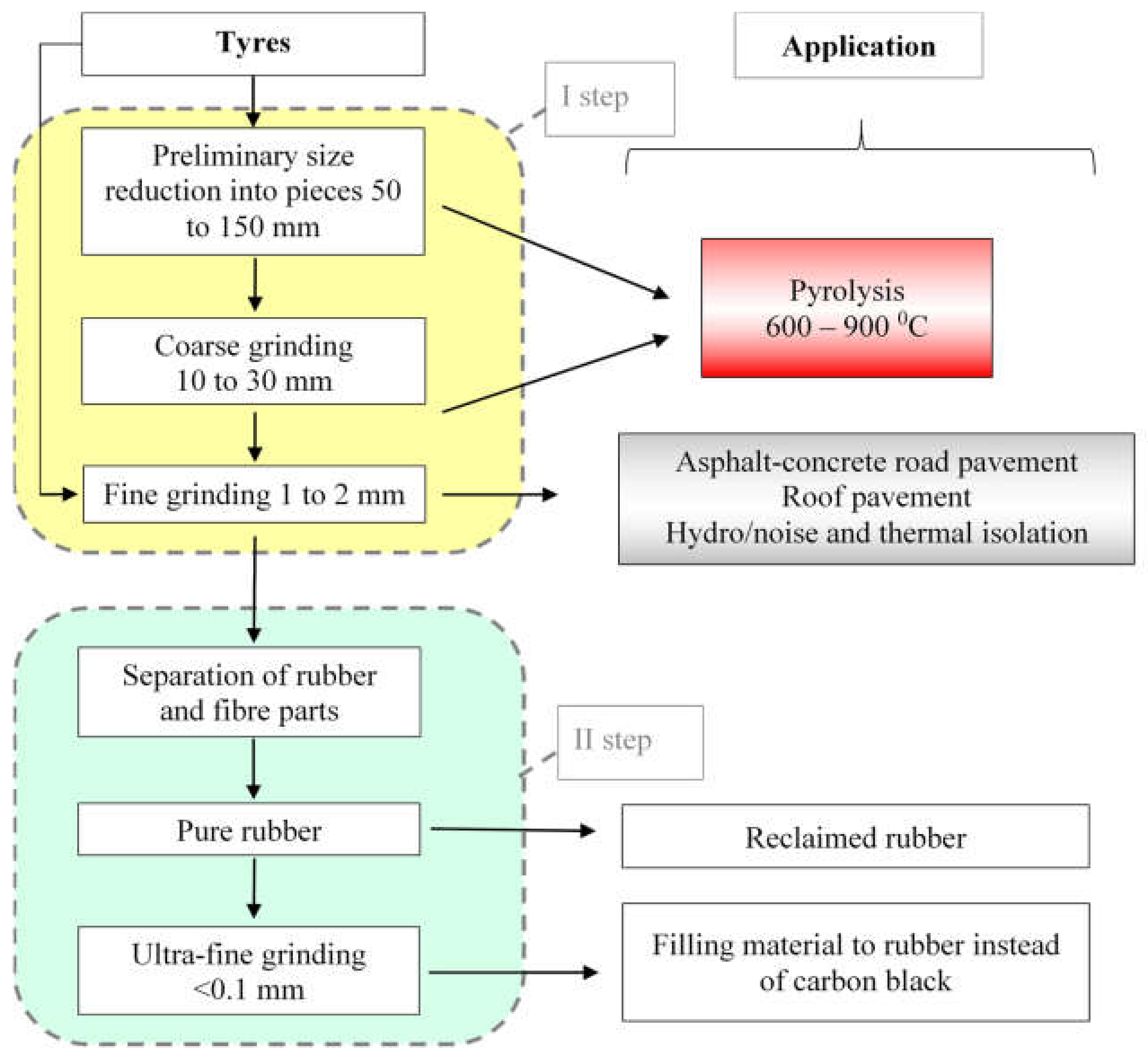

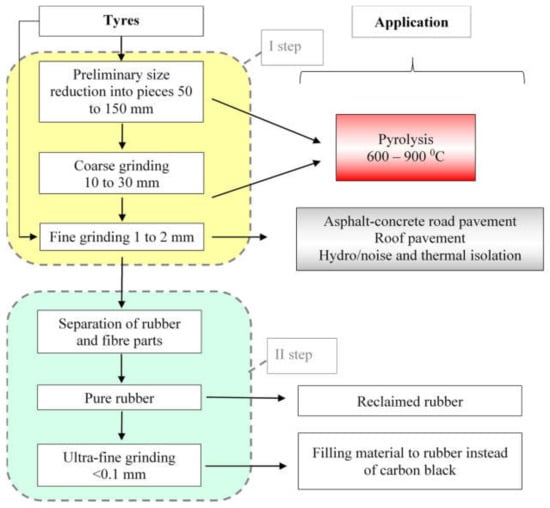

Shredding tires and separating components are essential processes to recover useful recycled materials. Moreover, preliminary grinding of the material is necessary to select the processing method. Figure 4 demonstrates a two-stage grinding concept for end-of-life tires, showing the possible uses of different particle sizes of rubber as secondary raw materials.

Figure 4.

Staged grinding of end-of-life tires indicating the options for use of individual fractions of rubber.

2.1. Mechanochemical Processing

2.1.1. Reclaiming

Rubber reclaiming is a technological process of converting mainly worn-out tires, as well as vulcanized rubber waste, into reclaimed rubber; a product with predominantly plastic properties, which is characterized by its ability to mix with rubber ingredients and undergo re-vulcanization. The use of reclaimed rubber in the production of elastomeric materials and products saves rubber, carbon black, and softeners.

When the regenerate is obtained by a water-neutral method, devulcanization of rubber occurs in an autoclave using an aqueous medium with an acidic reaction under continuous stirring. As a result, the conditions for the swelling of rubbers in the softener and heat transfer from the walls of the autoclave to the rubber are improved, the remnants of the tissue contained in the crumb are entirely destroyed, and the degree of contamination under devulcanization decreases [14].

The most widespread method is the continuous thermomechanical method. Due to the continuity, speed, complete mechanization, and significant automation of the devulcanization process, this method of obtaining reclaimed rubber is the most technologically advanced as compared with other applied methods of rubber reclamation.

2.1.2. Devulcanization

During the mechanical processing of crushed vulcanizate in the presence of a reducing agent (e.g., thiuram [15], amines [16], bisphenols [17], benzoyl peroxide [18], and so on), the process of devulcanization can occur. When using alkylphenol formaldehyde resins, surface devulcanization of various crushed vulcanizates with a particle size from 0.5 to 5 mm can be carried out on rollers. The introduction of styrene-butadiene rubber based elastomeric composites into the composition leads to an increase in resistance to ageing and abrasive wear as compared with untreated rubber powder [19].

In [20], the tensile, curing, viscoelastic, morphological, and thermal properties of natural fiber-reinforced rubber composites and reclaimed rubber were reviewed. The thermal-mechanical shearing devulcanization has been studied in [21], including the effects of different proportions on the vulcanization process parameters of reclaimed rubber and natural rubber, as well as the impact of the dosage of the reclaimed rubber and the curing rate and time of compounds.

Devulcanization of sulfur-crosslinked nitrile butadiene rubber can be carried out in a nitrobenzene medium at a temperature of 200 °C for 3 hours [22].

The use of benzoyl peroxide as a devulcanizing agent for rubbers based on natural rubber has been proposed. This process can be carried out at a temperature of 80 °C in a xylene medium with a 2 g dosage of benzoyl peroxide, as well as in a rubber mixer [23].

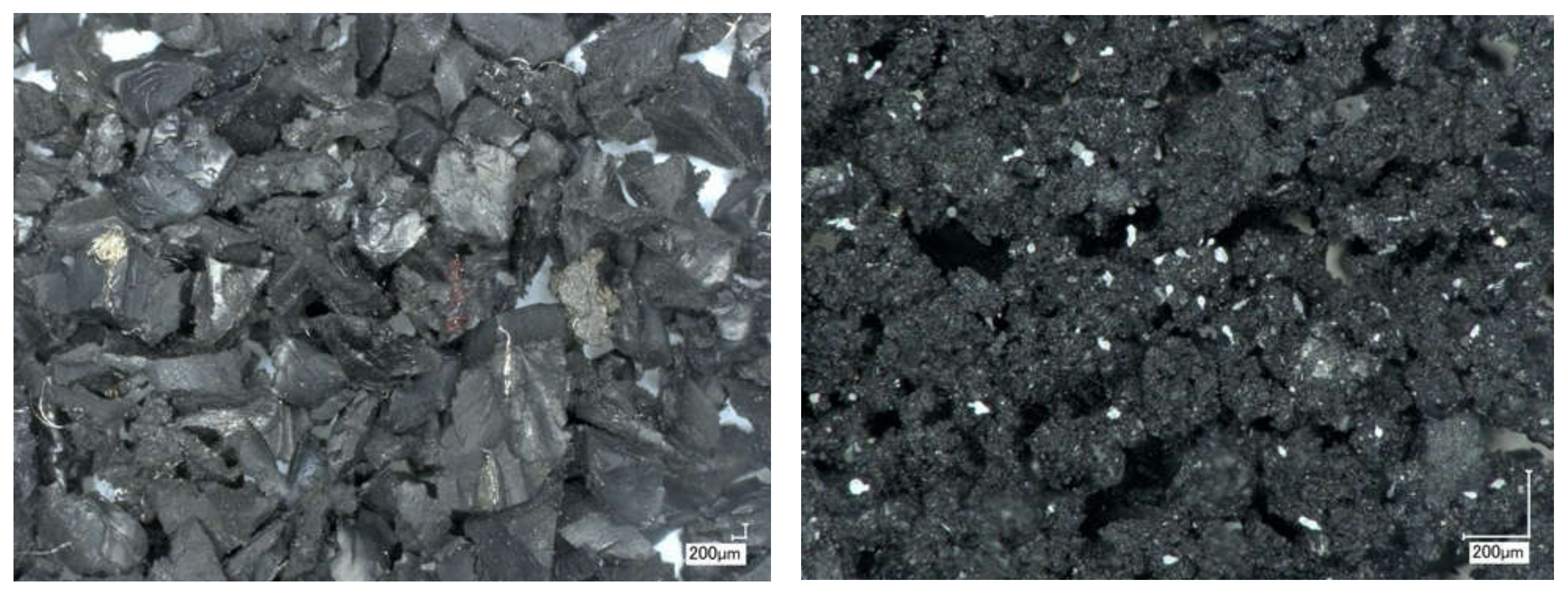

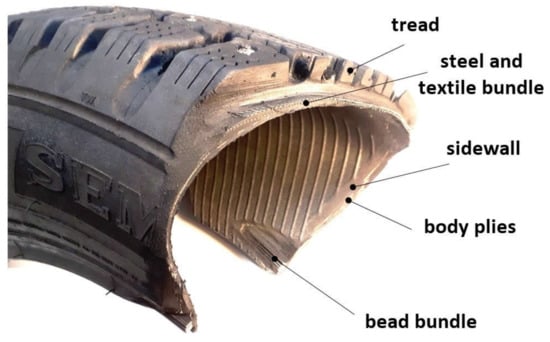

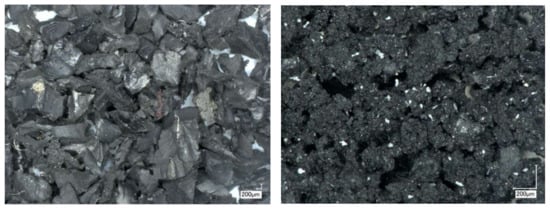

State-of-the-art rubber devulcanization has recently been reviewed in [24], demonstrating alternatives for end-of-life tire conversion into products with added value. The latest developments in the rubber and rubber parts devulcanization are reviewed in [25,26]. A mechanochemical devulcanization process in a two-roll mixing mill with the addition of a devulcanizing agent has been proposed in [25], while thiol acid has been suggested by Jana et al. [26]. The obtained devulcanized rubber materials represent powder- and sponge-type aggregates, as shown in Figure 5 [27].

Figure 5.

Crumb rubber (left) and devulcanized crumb rubber (right) after mechanochemical processing in a multi-roll system (author’s images).

2.1.3. Ozone Cutting

Rubber products can be subjected to the simultaneous action of mechanical stress and ozone, which leads to cracking of the rubber and separation of reinforcing elements from it without mechanical cutting or crushing.

The main technological line is an ozone disintegration unit. Ozone acts as a “chemical knife”, where the rubber is separated from the metal and textile frames. Cracking of rubber in the presence of ozone occurs primarily in places of stress concentration (i.e., along growing cracks). Therefore, the ozonation process occurs along the cavities of the “cut” while the rubber practically retains its properties [28,29].

The benefits of ozone technology include the following:

- low energy consumption (5–10 times less than mechanical crushing);

- environmental friendliness (low gas emissions);

- the process takes place at room temperature.

The ozone method of rubber destruction can be considered to be a promising technique, in which the energy consumption per 1 kg of obtained crumb rubber does not exceed 0.02 kW per hour. This method does not destroy the metal and synthetic cords of the tire, and there are no associated costs for cutting the tire into pieces.

Ozone is used as an active agent for surface oxidation and modification of the rubber (tire) crumb. The crumb rubber reacts with ozone to produce CO2 in the initial stages, resulting in a surface oxidized product. The reaction rate constant between ozone and crumb rubber can be determined by Fourier transform infrared spectroscopy, which monitors the absorption of ozone in the gas phase in the presence of crumb. The oxidation state is determined by using the intensity of the ketone band at 1710 cm−1 as a reference. The ratio between the amount of ozone (in milligrams) reacting with crumb rubber (in grams) is used as a parameter for the surface oxidation state. Thermogravimetric, differential thermal, and pyrolysis gas chromatography analyses have shown that ozonation of the crumb rubber exclusively occurs on the surface and does not affect the properties in the mass. The surface of the oxidized crumb is characterized by surface acidity and hydrophilicity [30].

2.2. Mechanical Processing

When recycling waste, it is essential to preserve the original structure and properties of the contained polymers. From this point of view, the best way to process rubber waste is mechanical shredding.

2.2.1. Grinding at Negative Temperature

It has been established that the grinding of polymers occurs best under conditions when they have the least deformability (i.e., at low temperatures or high speeds). At low temperatures, a minimum of specific work can be observed, which is spent from the onset of deformation to fracture.

Cryogenic grinding consists of cooling the rubber below the glass transition temperature, followed by mechanical action. For cooling, liquid nitrogen [31] or supercritical CO2 [32] are typically used. Liquid nitrogen is preferred, which allows for sufficient physical contact and maintains an inert medium during grinding, preventing oxidative processes. Mechanical action during cryogenic grinding can be carried out by impact, abrasion, or compression, as well as due to the work of an electromagnetic pulse.

The ground vulcanizate obtained by cryogenic grinding has, as a rule, a smooth process surface [33], which reduces the level of interaction with the elastomeric matrix but, at the same time, contributes to good flowability and miscibility when it is introduced into rubber compounds.

The advantages of the cryogenic grinding method include the absence of thermal or oxidative destruction of the powder, fire and explosion safety, and efficiency of separation of metal and textiles from crumb rubber after grinding.

The disadvantage of the cryogenic method is the high consumption of refrigerant, especially when obtaining rubber powders with particles less than 0.25 mm in size.

Other methods of grinding waste rubber use positive temperatures. One of the necessary conditions determining the possibility of polymer grinding at positive temperatures is the creation of a temperature regime, the lower limit of which would be equal to 80–100 °C.

Mechanical grinding at positive temperatures can be carried out by abrasion, shearing, compression, cutting, and impact [34,35].

2.2.2. Abrasive Grinding

This process is carried out by supplying the material to an abrasive tool [35], which is usually constructed in the form of a tape or a circle, at either negative or positive temperatures. To prevent the sticking of crushed material to the tool and to ensure intensive cooling of the treatment zone, water is supplied to the product in order to reduce the temperature at the contact zone of the instrument.

The fineness of the resulting product and the performance of the equipment is mainly influenced by the tool rotation frequency and the rubber feed rate. The quality of the material obtained affects the subsequent possibility of its use in the production of industrial rubber goods [36].

This method makes it possible to grind tires without preliminary crushing of the tire, which is a distinct advantage. However, the need to dry the resulting product and the significant heterogeneity of particle size limits the industrial use of grinding by attrition.

2.2.3. Compression Shear Grinding

Compression shear grinding is usually carried out using crushing and grinding rollers operating in a closed cycle with a classifier [37]. The disadvantages of this method are due to the low efficiency of using the surface of the working bodies, which makes it necessary to repeatedly pass the crushed material through the gap, as well as the associated low productivity and high energy consumption.

An increase in the efficiency of grinding rubbers on roller machines can be achieved by changing the ratio of roll rotation frequency. Because the simple act of destruction on the rollers is due to the creation of ultimate stresses in the particles of the crushed material, which arise due to the difference in the speeds of rotation of the rollers, it has been found that an increase in roll friction leads to an increase in productivity. To increase the yield of grinding crumbs to 1.0 mm and increase the productivity of the equipment, the grinding of vulcanized waste can be carried out on a roller mill in the presence of an aqueous solution of a copolymer of (meth)acrylic acid and acrylonitrile. In this case, the friction is 1:100–1:400. The copolymer dosage per 100 wt including secondary rubber should be equal to 0.2–0.6 mass. hours (on the dry matter). With an increase in friction to a value of 1:100 or more, the mechanism of rubber destruction changes. In this case, the destruction of the material occurs in the surface layer of the rubber, which is crushed when in contact with the surface of the high-speed roller, leading to the formation of small-sized individual rubber particles.

It is possible to carry out grinding in a complexly deformed (i.e., a combination of compression and shear in different directions) state using extruders equipped with various types of grinding heads. In such grinding units, screws with a small clearance to the cylinder can be used as working elements [38].

Research has been carried out to determine the effect of a crushed vulcanizate, which was obtained by the method of high-temperature shear deformation. This method is based on the phenomenon of multiple cracking of a solid and its destruction into separate particles under conditions of intense compression and simultaneous shear deformation carried out at high temperatures. This grinding method makes it possible to obtain a ground vulcanizate with a bimodal particle size distribution. The first maximum is observed in the range of 350–370 µm, while the second is in the range of 1400–1500 µm. In this case, in dosages of 5–10 mass., including IV obtained by this method, can be used in mixtures based on styrene-butadiene, natural, isoprene, and nitrile butadiene rubbers without a significant reduction in the conventional tensile strength and elongation at break. This method is also applicable for grinding vulcanizates of ethylene propylene diene and silicone rubber.

For high-speed grinding of complexly deformed rubber composites, the SD-25 grinder has been designed to model the grinding process of intact tires and for producing rubber crumbs of size 1–3 mm. This result was achieved using a special compound tool. The preliminary results enabled the design of a compound grinder that can directly process tires to 1–3 mm rubber powder. Tires can be worked up by saving tire beads and extracting spikes.

The processing of rubber composites is particularly effective, in which textiles and metal cords become stress concentrators and facilitate fracture [39].

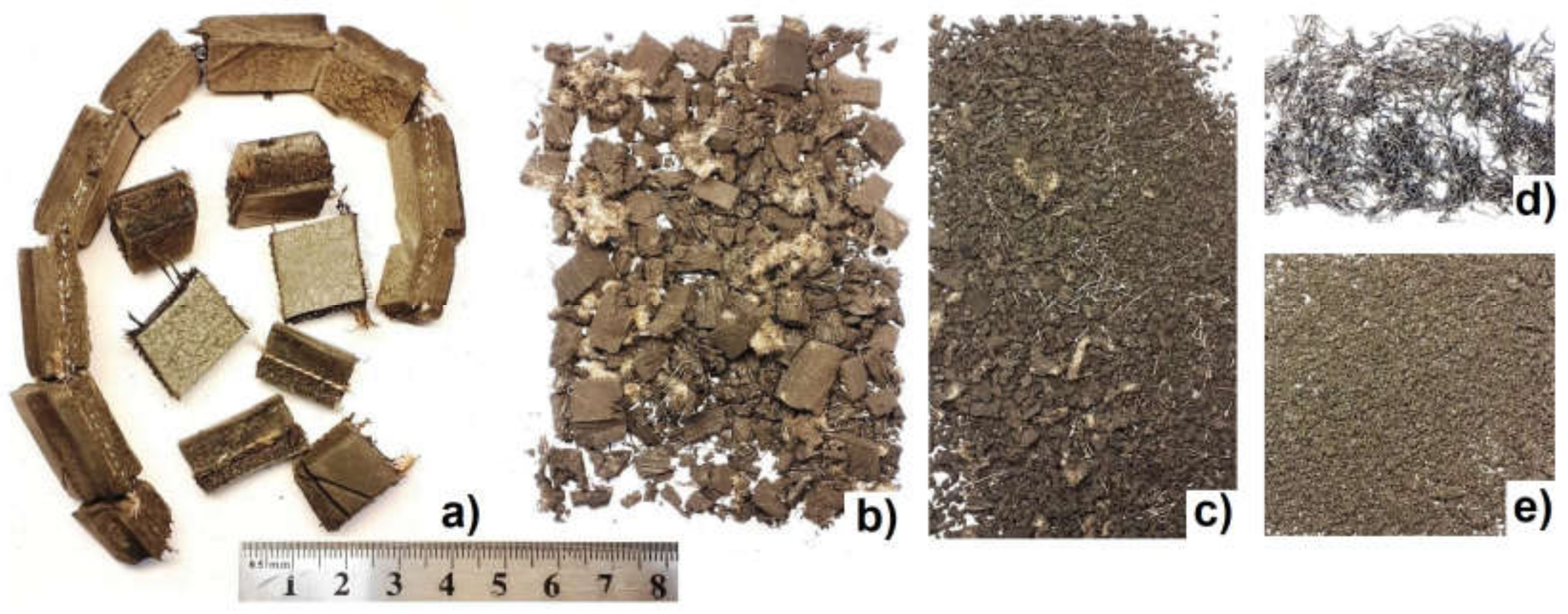

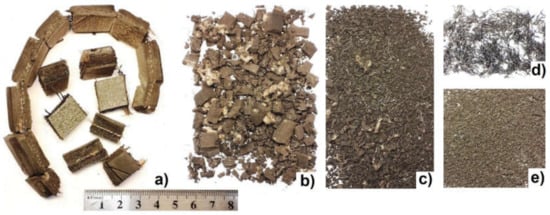

The results of changing the size of a rubber composite and separating its constituent components using the example of processing the tread of a car tire using the SD-25 setup are shown in Figure 6.

Figure 6.

Grinding at ambient temperature using the SD-25 grinder. (a) Initial pieces; (b) Pre-crushed; (c) Milled tire; (d) Separated wire; and (e) Rubber.

2.2.4. Cutting

Cutting is the process of dividing the body into parts using stress concentrators (knives).

The production and use of highly dispersed active rubber powders has significant advantages as compared with reclaimed rubber; therefore, rubber reclaim plants are being closed in many countries and a transition to processing rubber waste into crushed vulcanizates is taking place [40].

In [41], the possibility of producing composites by joint crushing of rubber crumb and textile cord in a disk grinder has been demonstrated. The resulting material contained 5–20% cord. In this case, the effect of joint grinding made it possible to increase the strength of the composite by approximately 1.5–2.0 times as compared with a vulcanized mixture of rubber crumb and cord, which had not been jointly processed.

The above paper described a method for crushing rubber waste using an ultra-high-pressure water flow (180–300 MPa). This method can be used to obtain ground vulcanizate with a particle size of 100–800 µm. This facilitates the separation of metal reinforcing materials from rubber waste and also reduces the degree of degradation of the elastomeric matrix, as the water also serves as a cooling agent [42].

2.2.5. Impact Milling

The material can be destroyed under the action of a mechanical shock [39] (constrained or free), due to the conversion of the kinetic energy of the working body of the equipment into the energy of deformation of destruction [43].

With a constrained impact, the destruction of the material occurs between two colliding surfaces; in this case, the destructive effect depends on the impulse of the working fluid.

With a free impact, destruction occurs due to the collision between the material particles and the working parts of the equipment. Therefore, the destructive effect depends on the inertial forces of the crushed material.

In impact grinders, the processing of rubber waste can be carried out at negative and positive temperatures. These are used to obtain lumps from the bulky waste, and then further process them into fine powders.

A well-known method allows for the reduction of energy consumption during crushing by impact. In this case, the crushing of rubber-based material (e.g. car tires) is performed with simultaneous or preliminary deformation of the rubber base in a plane perpendicular to the direction of impact. When the impact speed is exceeded by 20% or more over sound in rods and plates, the energy consumption can be reduced by about 2.5 times.

2.2.6. Processing in Disintegrators

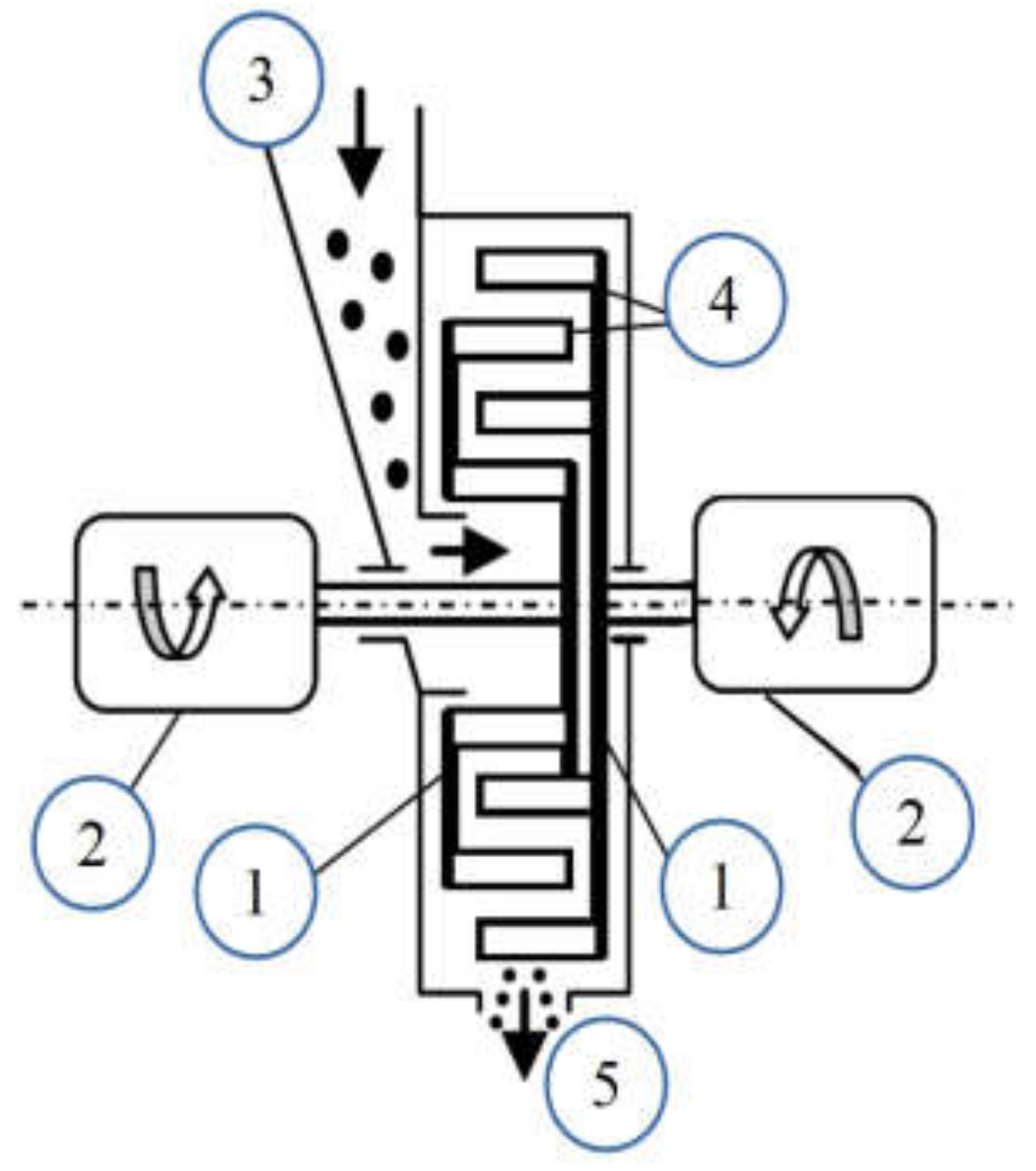

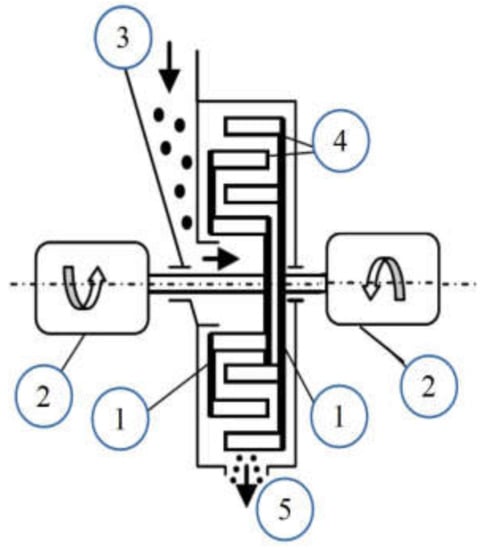

A disintegrator is an impact grinder that refines material by collisions [39] (see Figure 7), where the elementary colliding contact of the material piece with the tool is 10−3–10−5 s and the processing time in the machine for each element does not exceed 0.1 s. This avoids any heating of the treated material.

Figure 7.

Impact disintegrator DSL-175 (Tallinn University of Technology (TalTech)). 1, rotors; 2, electric drivers; 3, inlet for raw material; 4, grinding elements (pins, blades); 5, outlet for processed (milled) material.

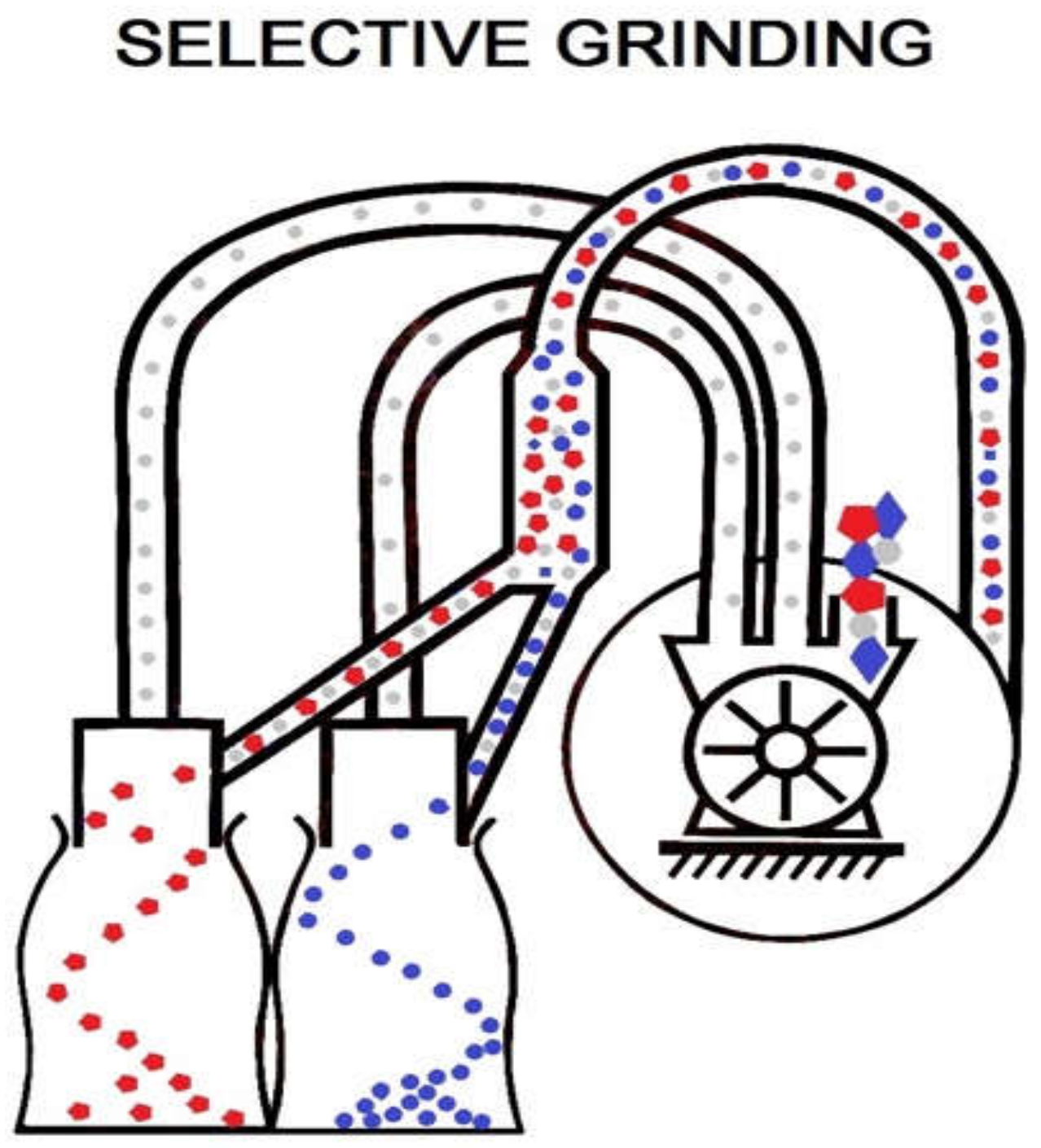

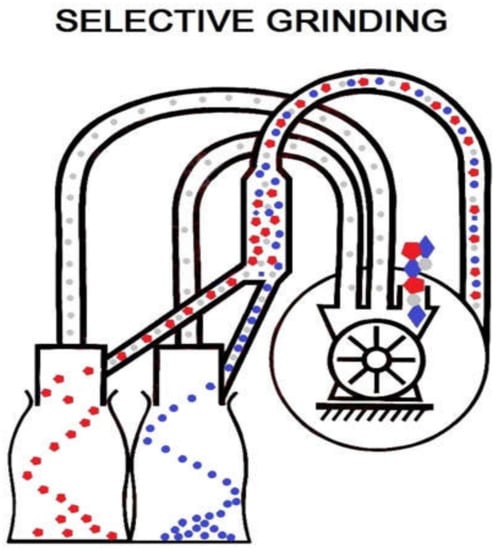

Unlike traditional grinding methods, disintegration breaks up the material through a series of high-speed impacts, which generate stress within the material particle tens of times greater than its ultimate strength. The use of a built-in inertial separation system makes it possible to produce material powders that are generally considered impossible to obtain using such types of mills [44]. One variant of such a built-in inertial separation system (selective grinding mode in Figure 8) also makes it possible to separate the components of complex composites released by impact from each other [45].

Figure 8.

Schematic of selective grinding mode (material fractionation, author’s image).

The processes accompanying disintegration also significantly alter the mechanical and chemical properties of the material [45]. When the particles are rapidly destroyed, surface oxide films are torn off and a large amount of new non-oxidized surface is formed, which has exceptionally high chemical reactivity. The spatial pattern of the grains of the material is distorted and numerous defects may emerge. Thus, mechanochemical processes are taking place not only on the freshly formed surfaces but also in the volume of ground grains.

Disintegration is especially useful for grinding elastic materials (e.g., rubber and its composites) at low temperatures, when the rubber becomes brittle and rapidly degrades. The shortness of the process avoids heating of the processed material. Low temperature milling of different materials by disintegrator systems requires feed materials with sizes from 2.5 to 150 mm (depending on the disintegrator type and design). The use of disintegrators has shown good efficiency in deagglomeration of devulcanized rubber after mechanical-chemical treatment [46].

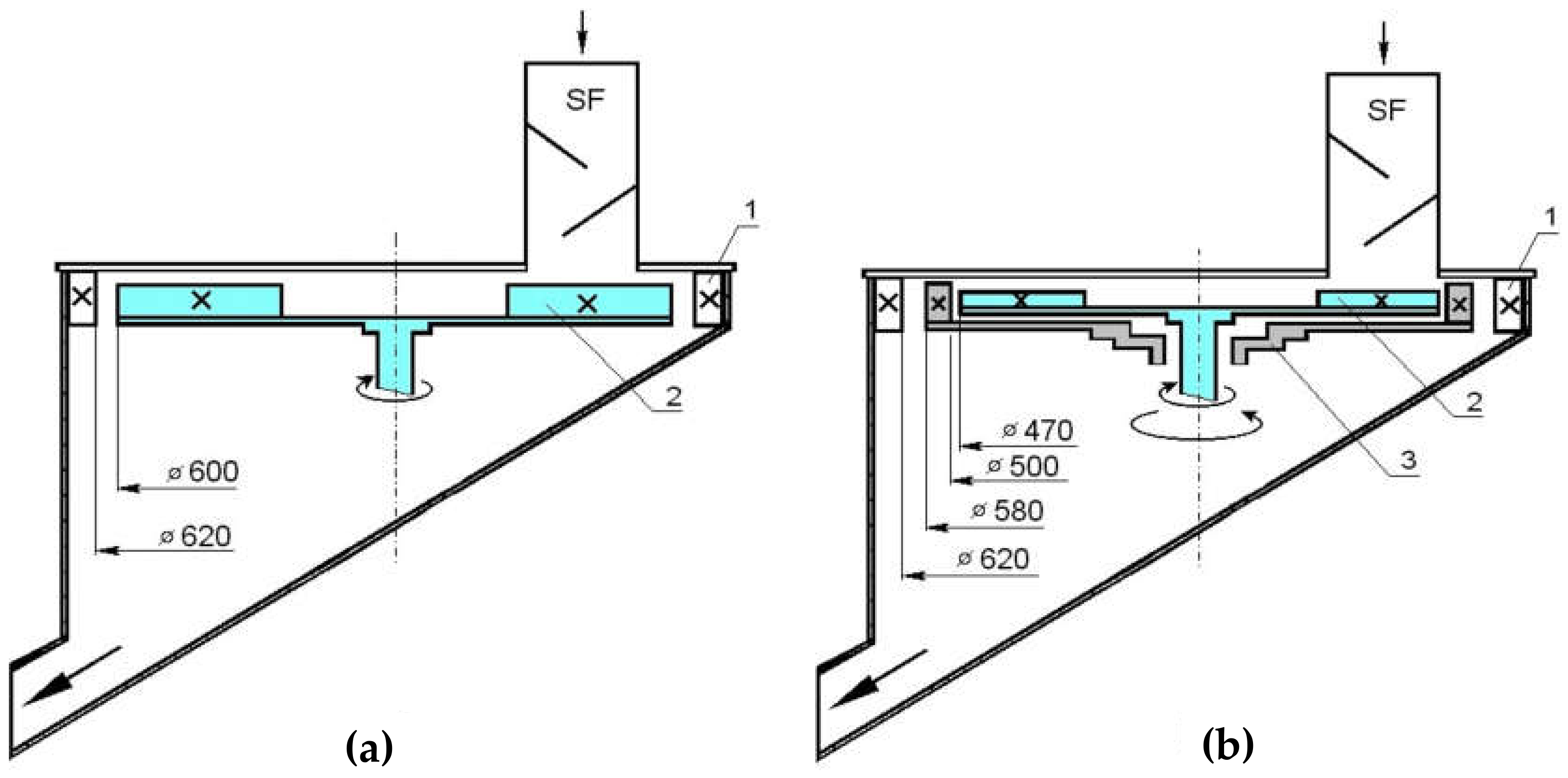

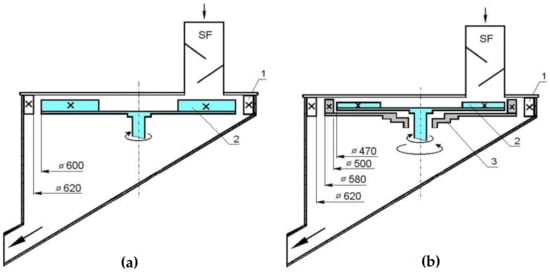

For these purposes, a special machine, a centrifugal accelerator for preliminary size reduction of material parts by impact, has been designed. The centrifugal type pre-crusher DS-178 is presented in Figure 9 and the main kinetic parameters of the device are given in Table 2.

Figure 9.

Schematic representation of centrifugal accelerator (disintegrator DSL-178). (a) Mono-rotor (MR) system; (b) Duplex-rotor (DR) system, SF-side feed, 1–3 treatment rings with grinding elements.

Table 2.

Maximum velocity of impact and specific energy of treatment ES of treated material in DSL-178.

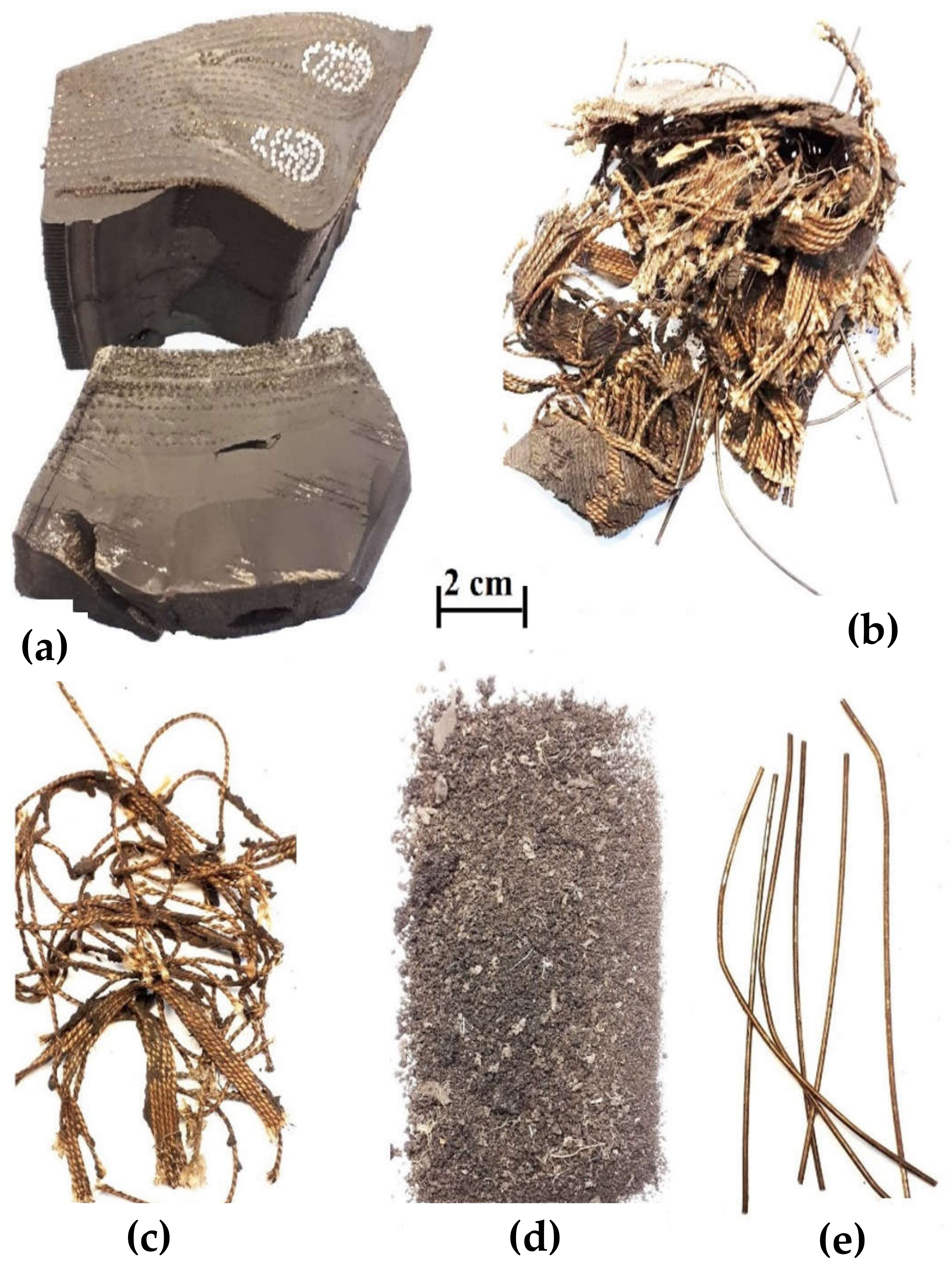

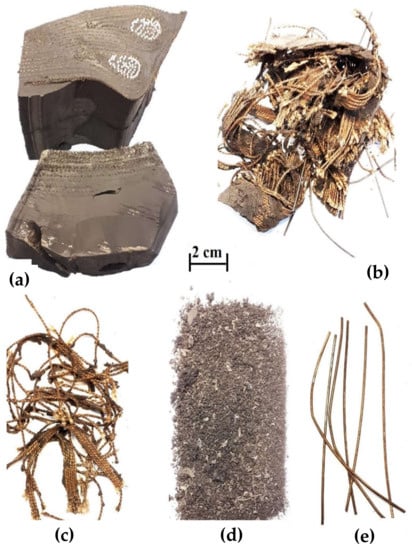

The shredded end-of-life tires are subjected to cooling in liquid nitrogen, and then are fed piece-by-piece with dimensions of 50 × 60 × 100 mm (see Figure 10) into the DS-178 disintegrator using a mono-rotor (MR) system for pre-crushing and a duplex-rotor (DR) system for separative milling. As a result of processing, completely separated tire components are obtained.

Figure 10.

Cryogenic grinding using a disintegrator. (a) Raw material, pieces of cut tires; (b) Treated material, pre-crushed tire (specific grinding energy ES = 0.32 kWh/t), or ground and separated components of tire (ES = 2.26 kWh/t); (c) Textile; (d) Rubber; and (e) Cord (wire).

The cryogenic grinding of rubber has a significant effect on the energy consumption required for rubber destruction and contributes to the production of fine rubber fractions from end-of-life tires.

Considering that the consumption of cryogenic grinding of 1 kg of rubber is about 1 kg of liquid nitrogen and that the specific energy of grinding is very low, it seems that the process can be carried out with some economic benefit.

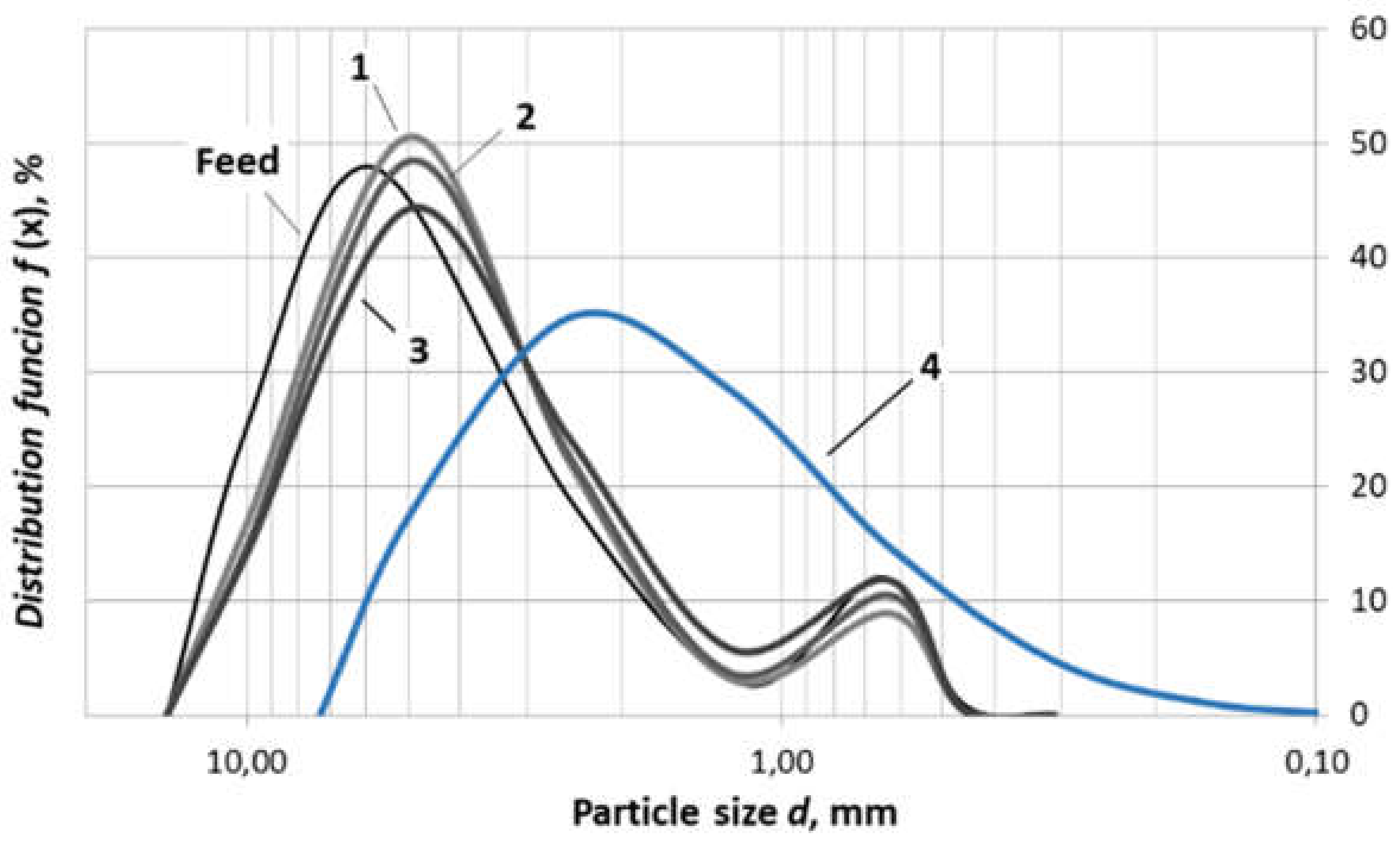

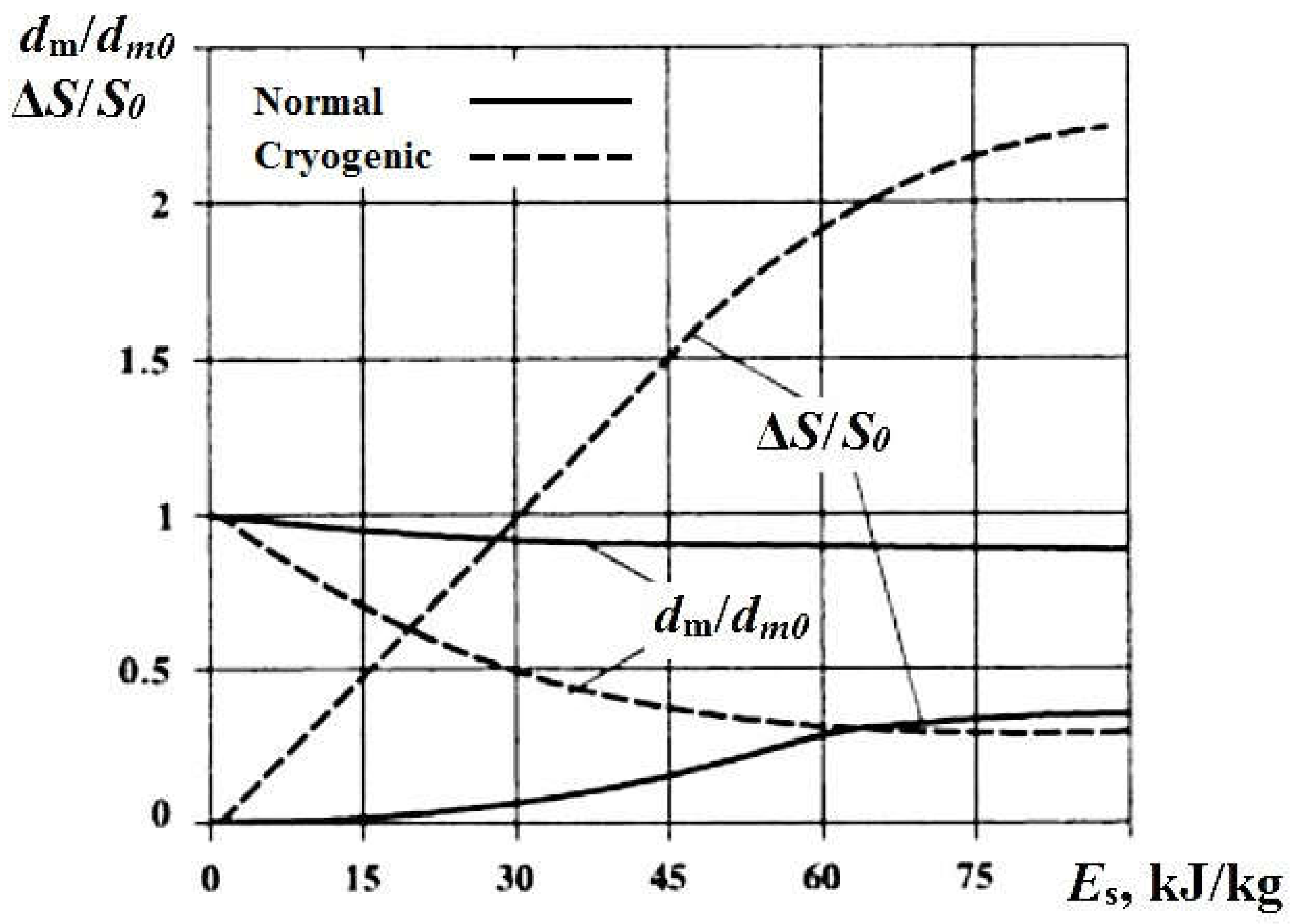

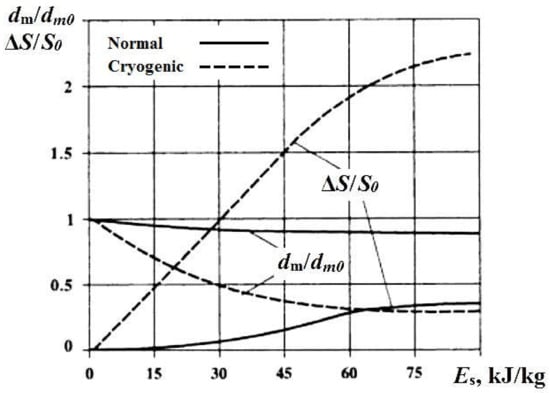

Grinding of pure rubber and composites using classical impact disintegrator mills at normal temperatures is much (by orders of magnitude) less effective than grinding in liquid nitrogen (Figure 11 and Figure 12). This is due to its high elastic properties. Under impact, kinetic energy leads to strong elastic deformations of rubber pieces, which preferentially heat the material but do not destroy it.

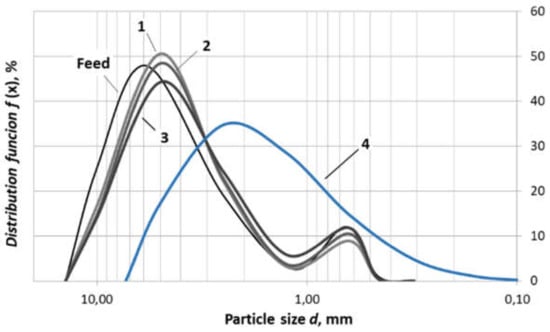

Figure 11.

Dependence of the granularity of ground rubber particles on the specific energy of treatment. Grinding at normal temperature with energy. (1) 30 kJ kg−1; (2) 60 kJ kg−1; (3) 90 kJ kg−1; (4) Cryogenic grinding with energy 32 kJ kg−1.

Figure 12.

Dependence of ratio of median size to initial value dm/dm0 on specific energy of treatment (ES) at normal and cryogenic temperatures.

Therefore, it is rational to use such a grinding method for the following:

- ▪

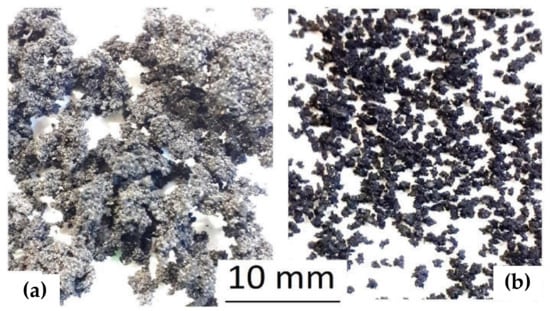

- Pre-crushing of rubber agglomerates (Figure 13a);

Figure 13. Pure rubber particles before (a) and after (b) grinding by disintegrator mills.

Figure 13. Pure rubber particles before (a) and after (b) grinding by disintegrator mills. - ▪

- changing material properties, such as:

- (a)

- creation of interstitial composites (e.g., rubber iron powder);

- (b)

- spheroidizing to reduce the surface and improve the free-flow properties of the powders (Figure 13b);

- (c)

- changing chemical properties under the influence of strong shear shock loads (devulcanization).

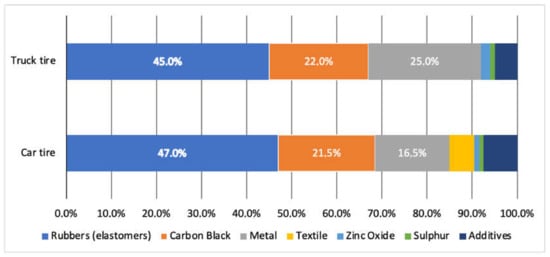

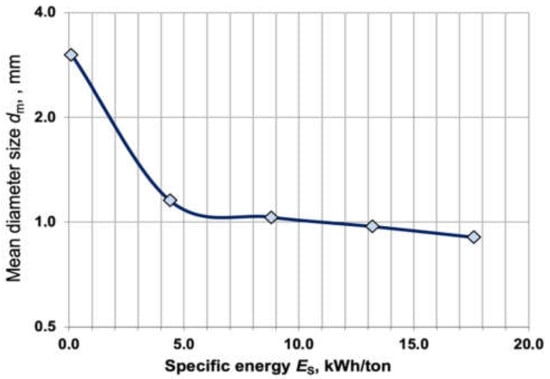

The degree of grinding is directly related to the energy consumption of the process. Thus, the feasibility of energy costs for the rubber grinding process is associated with the minimum particle size obtained during grinding. Figure 14 shows the dependence of the average diameter of rubber particles on the specific grinding energy.

Figure 14.

Dependence of the mean diameter size (dm) of treated pure rubber on the specific energy of disintegrator milling (ES).

3. Applications of Crumb Rubber as a Secondary Raw Material for New Products Manufacturing

Crumb rubber is used as a component of complex mixtures to produce various materials for non-tire technical applications. Some popular applications are listed in Table 3 [47,48].

Table 3.

Crumb rubber uses in technical applications.

Rubber crumb with particle size ranging from 0.1 to 0.45 mm can be used as an additive (5–20%) in rubber mixtures for the manufacture of new car tires, massive tires, and other rubber products. The use of rubber powder with a highly developed particulate specific surface area (2500–3500 cm2/g), as can be obtained by mechanical grinding, increases the resistance of tires to bending and impact, thus, increasing their service life. Furthermore, the obtained crumb can be used for the production of reclaimed rubber. The reclaimed rubber is widely used in rubber compounds and for the manufacturing of new tires as a rubber substitute; at the same time, rubber reclaimed from tire crumb is four times cheaper than rubber. Consequently, there is a reliable and permanent economic factor for the use of reclaimed rubber in the domestic rubber and tire industry.

Rubber crumb with particle size up to 0.6 mm can be used as an additive (up to 50–70%) for manufacturing rubber footwear and other rubber products. Moreover, the properties of such rubbers (e.g., strength and deformability) do not practically differ from the properties of ordinary rubber made from raw rubbers. Furthermore, crushed vulcanizate with a particle size of up to 0.6 mm can be used in a dosage of up to 50 mass. h in composition for the production of automotive glass seals [49].

Crumb with a particle size of up to 1.0 mm can be used for the manufacture of composite roofing materials (i.e., roll roofing and rubber slate), rubber-bitumen mastics [50], and vulcanized and non-vulcanized roll waterproofing materials [51]. Powdered rubber can be used in the manufacture of rubber mats and rubber tiles for roofing [52].

Crumbs with particle sizes ranging from 0.5 to 1.0 mm can be used to increase the strength of road surfaces, additionally increasing their impact resistance, frost resistance, and resistance to cracking at temperature extremes [53]. The volume of crushed rubber in such improved coatings should be about 2% by weight of the mineral material (i.e., 60–70 tons per 1 km of roadbed). In this case, the service life of the roadway can be increased by 1.5–2 times. In Western Europe, more than 900,000 kilometers of roads require periodic repairs, more than 700,000 km in the USA, 100,000 km in Canada, and 130,000 km in Japan. To replace the old road surfaces with new ones using rubber powder, about 25 million tons of crumb rubber of fine fractions will be required in the countries mentioned above.

The use of rubber chips in building mixtures has been investigated for construction elements, [54] as well as materials with increased resistance to low temperatures [55]. The addition of crumb rubber to the cement compositions leads to compressive strength decrease. In the work by [56], the polymer reinforcement was used as a substitute for some of the mineral components used in traditional concrete. The development of three-dimensional (3D) printing for the production of building structures and entire buildings has led to the creation of building 3D printable cement-based mix with the addition of crumb rubber, suitable for construction [57]. Extensive research work of cementitious aggregates containing a crumb rubber produced by means of 3D printing technique is outlined in [58].

Such powders can also be used as a sorbent for collecting crude oil and liquid petroleum products from the surface of water and soil, for plugging oil wells, for green waterproofing layers, and so on. Composite materials can be designed based on finely dispersed rubber powders with a highly developed specific surface (2500–3500 cm2 g−1) and other free-flowing organic additives. Such powders have a high ability to absorb crude oil and liquid oil products, with many known sorbents of oil and oil products being based on rubber powders. The mass ratio of absorbed oil or oil products by such sorbents is 6.5–7.0:1. They do not sink in water, although the raw material for the production of its main component, i.e., finely dispersed rubber powder derived from worn out pneumatic tires and technological waste rubber, has a mass density of more than 1.3. As a result of the sorption of oil or liquid petroleum products, the sorbents are collected on the water into large agglomerates weighing up to several kilograms, which can remain on the surface in any condition for several months and are relatively easily collected mechanically without leaving any traces, even in the form of thin oil films. These sorbents are non-toxic and environmentally friendly [59].

Research has been carried out to determine the effect of crumb rubber with an average particle size of 0.6 mm on the properties of wood-based composite materials obtained by hot pressing [60].

Rubber crumb with particle sizes from 2 to 10 mm can be used in the manufacture of massive rubber plates for completing tram and railway crossings, which have been characterized by long-term operations, excellent weather resistance, low noise level, and modern design; these can be further used in the design of sports grounds with a comfortable and safe surface, livestock buildings, and so on.

Porous boards can be obtained by hot pressing rubber powder mixed either with the addition of vulcanizing agents or with powder of polyethylene (PET), and so on. Such slabs can be used in residential construction, as thermal and sound insulation layers in wall panels, as well as for flooring and insulation coatings [61]. A promising application of powdered rubber lies in its use as a filler for various synthetic thermoplastics [62]. These composites undergo dynamic vulcanization, have rubber-like properties at room temperature, and are processed at elevated temperatures. Studies have been carried out to assess the possibility of using tire crumb rubber in composites based on a combination of butyl rubber and chlorosulphonated polyethylene. The resulting composites were demonstrated to have increased thermal stability [63]. Studies of the properties of composites based on natural rubber and devulcanized BNK showed a decrease in the degree of swelling in an aggressive environment [64].

Research has also been carried out on thermoplastic composites, with polyethylene [65], polypropylene [66,67], polyamide [68], or maleated polyethylene [69] being used as binders. It should be noted that the strength properties of these composites deteriorate with an increase in the content of crushed vulcanizate. A mixture of polyethylene and crumb rubber in a 50:50 ratio has been shown to possess properties similar to composites based on a mixture of natural rubber and polyethylene [70].

A material based on thermoplastic polymers (e.g., polystyrene) containing rubber crumb in a dosage of 15–20 phr has been investigated [71]. The strength of this composite was 6–8 MPa. This thermoplastic elastomeric material can be used for the preparation of conveyor belts, drive belts, flooring and walkways, floor tiles, rugs, mounting flanges, shock absorber covers, sound barriers, safety guards, carpet backing, car bumpers, wheel arch gaskets, car door and window seals, sealing rings, gaskets, irrigation systems, pipe or hose materials, flowerpots, building blocks, roofing materials, geomembranes, and so on. The development of composites with a polymer matrix and crumb rubber is well described in a recent review [72]. Uses of ground tire rubber in insulation materials containing polymeric matrix are reviewed in [73]. The recycling of such composite materials leads to the production of new composites with sacrificing the product quality due to low interface quality between rubber and polymeric matrix [74].

It is possible to make massive rubber products based on partially vulcanized waste rubber mixtures [75]. When the dosage of vulcanized waste is 20–35% of the mass, the vulcanizates have a strength of 7.0–8.0 MPa and a relative elongation of 250–300%.

Rubber crumb of 2–3 mm in size can be used as an adsorbent for fuel components [76]. Intensive processing in rubber crumb disintegrators and devulcanized rubber crumb with additional components leads to the formation of composite mixture materials for environmental applications [75].

The use of crumb rubber in flexible polyurethane foams has a significant effect on the structure of the material, in which the density of cross-inking increases significantly. This increases the thermal stability of the material, where the decomposition temperature increased by 14 °C as compared with the sample without crumb rubber [77].

In work [78], the possibility of manufacturing a water-repellent material based on crushed rubber has been reported. The water-repellent properties of the resulting material were due to the air that accumulated in the pores of the ground rubber surface.

Table 4 summarizes the data on the methods of material grinding along with the properties of the obtained crumb rubber and possible risks to the environment.

Table 4.

Overview of waste rubber recycling approaches, crumb rubber properties, and associated environmental risks.

4. Conclusions

The methods reviewed in this article demonstrate that it is possible to obtain crushed rubber from waste tires in various fractions, which can later be used in the production of industrial rubber goods and composite materials.

Unfortunately, it is not possible to distinguish from the described rubber processing methods, one universal or optimal method that can be considered to be the best for all situations. It would be useful if the best methods were known in the search for an optimal solution to a particular technological problem and if some methods could be excluded, in order to avoid confusion. It would also be useful to know the alternatives, from which the appropriate method could be chosen, based on cost–benefit, environmental impact, and feasibility analyses.

With the rapid development of production technologies, the ever-increasing requirements for the technological properties of products, as well as the tightening of requirements for their processing and reuse, have led to the rejection of certain technological processes in favor of combining them into two or more processing methods.

Author Contributions

Conceptualization, V.L.; methodology, V.L. and V.M. (Viktors Mironovs); investigation, V.L., A.K., V.M. (Vadim Myadelets), and D.G.; resources and data curation, V.L., A.K., V.M. (Vadim Myadelets), and D.G.; writing—original draft preparation, V.L.; writing—review and editing, V.L., V.M. (Viktors Mironovs), A.K., V.M. (Vadim Myadelets), and D.G.; visualization, V.L. and V.M. (Viktors Mironovs); supervision, V.L., V.M. (Viktors Mironovs); project administration, V.L.; funding acquisition, V.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been supported by the European Regional Development Fund within the Activity 1.1.1.2 “Post-doctoral Research Aid” of the Specific Aid Objective 1.1.1 “To increase the research and innovative capacity of scientific institutions of Latvia and the ability to attract external financing, investing in human resources and infrastructure” of the Operational Programme “Growth and Employment” (No. 1.1.1.2/VIAA/1/16/175). This work was supported by the Estonian Research Council, grants PRG643 and PRG665, and by the Environmental Investment Centre Foundation, grant KIK19019.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Tyre & Rubber Manufacturers’ Association. Annual Report 2017: Moving Innovation That Cares; European Tyre & Rubber Manufacturers’ Association: Brussels, Belgium, 2017; p. 32. [Google Scholar]

- Bulei, C.; Todor, M.P.; Heput, T.; Kiss, I. Directions for material recovery of used tires and their use in the production of new products intended for the industry of civil construction and pavements. IOP Conf. Ser. Mater. Sci. Eng. 2018, 294, 012064. [Google Scholar] [CrossRef]

- European Tyre & Rubber Manufacturers’ Association. End-Of-Life Tyre Report 2015; European Tyre & Rubber Manufacturers’ Association: Brussels, Belgium, 2015; p. 36. [Google Scholar]

- Mark, J.; Erman, B.; Roland, M. The Science and Technology of Rubber, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 978-0-12-394584-6. [Google Scholar]

- De, S.K.; Isayev, A.I.; Khait, K. (Eds.) Rubber Recycling; Taylor & Francis/CRC Press: Boca Raton, FL, USA, 2005; ISBN 978-0-8493-1527-5. [Google Scholar]

- Gent, A.N. Engineering with Rubber: How to Design Rubber Components, 3rd ed.; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2012; ISBN 978-3-446-42764-8. [Google Scholar]

- Torretta, V.; Rada, E.C.; Ragazzi, M.; Trulli, E.; Istrate, I.A.; Cioca, L.I. Treatment and disposal of tyres: Two EU approaches. A review. Waste Manag. 2015, 45, 152–160. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Xiao, F.; Amirkhanian, S.; Huang, W.; Zheng, M. A review on low temperature performances of rubberized asphalt materials. Constr. Build. Mater. 2017, 145, 483–505. [Google Scholar] [CrossRef]

- Bressi, S.; Fiorentini, N.; Huang, J.; Losa, M. Crumb Rubber Modifier in Road Asphalt Pavements: State of the Art and Statistics. Coatings 2019, 9, 384. [Google Scholar] [CrossRef]

- Asaro, L.; Gratton, M.; Seghar, S.; Aït Hocine, N. Recycling of rubber wastes by devulcanization. Resour. Conserv. Recycl. 2018, 133, 250–262. [Google Scholar] [CrossRef]

- Gheni, A.A.; Lusher, S.M.; ElGawady, M.A. Retention behavior of crumb rubber as an aggregate in innovative chip seal surfacing. J. Clean. Prod. 2018, 197, 1124–1136. [Google Scholar] [CrossRef]

- Dick, J.S.; Annicelli, R.A. Rubber Technology: Compounding and Testing for Performance; Hanser Publishers: Munich, Germany, 2001; ISBN 978-1-56990-278-3. [Google Scholar]

- Shi, J.; Jiang, K.; Ren, D.; Zou, H.; Wang, Y.; Lv, X.; Zhang, L. Structure and performance of reclaimed rubber obtained by different methods. J. Appl. Polym. Sci. 2013, 129. [Google Scholar] [CrossRef]

- Rajan, V.V.; Dierkes, W.K.; Joseph, R.; Noordermeer, J.W.M. Science and technology of rubber reclamation with special attention to NR-based waste latex products. Prog. Polym. Sci. 2006, 31, 811–834. [Google Scholar] [CrossRef]

- Ghorai, S.; Bhunia, S.; Roy, M.; De, D. Mechanochemical devulcanization of natural rubber vulcanizate by dual function disulfide chemicals. Polym. Degrad. Stab. 2016, 129, 34–46. [Google Scholar] [CrossRef]

- Lewandowski, W.M.; Januszewicz, K.; Kosakowski, W. Efficiency and proportions of waste tyre pyrolysis products depending on the reactor type—A review. J. Anal. Appl. Pyrolysis 2019, 140, 25–53. [Google Scholar] [CrossRef]

- Zhang, X.; Saha, P.; Cao, L.; Li, H.; Kim, J. Devulcanization of waste rubber powder using thiobisphenols as novel reclaiming agent. Waste Manag. 2018, 78, 980–991. [Google Scholar] [CrossRef] [PubMed]

- Sabzekar, M.; Chenar, M.P.; Mortazavi, S.M.; Kariminejad, M.; Asadi, S.; Zohuri, G. Influence of process variables on chemical devulcanization of sulfur-cured natural rubber. Polym. Degrad. Stab. 2015, 118, 88–95. [Google Scholar] [CrossRef]

- Carli, L.N.; Bianchi, O.; Mauler, R.S.; Crespo, J.S. Accelerated aging of elastomeric composites with vulcanized ground scraps. J. Appl. Polym. Sci. 2012, 123, 280–285. [Google Scholar] [CrossRef]

- Mente, P.; Tshwafo, M. Natural Rubber and Reclaimed Rubber Composites—A Systematic Review. Polym. Sci. 2016, 2. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, H.; Zhang, D.; Zhang, Z.; Peng, S.; Sun, Y. Curing behaviors, mechanical properties, dynamic mechanical analysis and morphologies of natural rubber vulcanizates containing reclaimed rubber. E-Polymer 2019, 19, 482–488. [Google Scholar] [CrossRef]

- Masaki, K.; Ohkawara, S.-I.; Hirano, T.; Seno, M.; Sato, T. Devulcanization of nitrile butadiene rubber in nitrobenzene. J. Appl. Polym. Sci. 2004, 91, 3342–3353. [Google Scholar] [CrossRef]

- Rooj, S.; Basak, G.; Maji, P.; Bhowmick, A. New Route for Devulcanization of Natural Rubber and the Properties of Devulcanized Rubber. J. Polym. Environ. 2012, 19, 382–390. [Google Scholar] [CrossRef]

- Markl, E.; Lackner, M. Devulcanization Technologies for Recycling of Tire-Derived Rubber: A Review. Materials 2020, 13, 1246. [Google Scholar] [CrossRef]

- Ozernovs, O.; Jevmenovs, I. Method for devulcanization of rubber and devulcanization catalyst for such purpose. Patent Application PCT/IB2014/066580, 11 June 2015. [Google Scholar]

- Jana, G.K.; Mahaling, R.N.; Das, C.K. A novel devulcanization technology for vulcanized natural rubber. J. Appl. Polym. Sci. 2006, 99, 2831–2840. [Google Scholar] [CrossRef]

- Lapkovskis, V.; Mironovs, V.; Goljandin, D. Suitability of devulcanized crumb rubber for oil spills remediation. Energy Procedia 2018, 147, 351–357. [Google Scholar] [CrossRef]

- Khodos, D.; Mirmov, N.; Vassiliev, A.; Vernyi, A. Plant for Reprocessing Waste Tires and for Modifying Rubber Crumb. Patent Application EP2106893A1, 7 October 2009. [Google Scholar]

- Chuiko, S.V.; Danschikov, E.V.; Luchnik, I.N.; Ryazanov, A.V. Method of Reprocessing Industrial Rubber Articles. Patent Application EP0816035A1, 7 January 1998. [Google Scholar]

- Cataldo, F.; Ursini, O.; Angelini, G. Surface oxidation of rubber crumb with ozone. Polym. Degrad. Stab. 2010, 95, 803–810. [Google Scholar] [CrossRef]

- Rowhani, A.; Rainey, T. Scrap Tyre Management Pathways and Their Use as a Fuel—A Review. Energies 2016, 9, 888. [Google Scholar] [CrossRef]

- Li, X.; Xu, X.; Liu, Z. Cryogenic grinding performance of scrap tire rubber by devulcanization treatment with ScCO2. Powder Technol. 2020, 374, 609–617. [Google Scholar] [CrossRef]

- Adhikari, J.; Das, A.; Sinha, T.; Saha, P.; Kim, J.K. Chapter 1: Grinding of Waste Rubber. In Rubber Recycling: Challenges and Developments; Royal Society of Chemistry: London, UK, 2018; pp. 1–23. [Google Scholar] [CrossRef]

- Ramos, G.; Alguacil, F.J.; López, F.A. The recycling of end-of-life tyres. Technological review. Rev. Metal. 2011, 47, 273–284. [Google Scholar] [CrossRef]

- Muhr, A.H.; Roberts, A.D. Rubber abrasion and wear. Wear 1992, 158, 213–228. [Google Scholar] [CrossRef]

- Wellappili, C.J.; De Silva, K.; Dharmatilake, M.; Denawaka, I. Effect of Chemically Treated Buffing Dust on Technological Properties of Tyre Tread Compounds. Prog. Rubber Plast. Recycl. Technol. 2007, 23, 1–19. [Google Scholar] [CrossRef]

- Recycling of Outworn Tyres by Grinding at Normal Temperature. IFAC Proc. Vol. 1998, 31, 123–128. [CrossRef]

- Chaubey, T.; Arastoopour, H. Studying the pulverization mechanism of rubber with a modified design of the solid-state shear extrusion process. J. Appl. Polym. Sci. 2011, 119, 1075–1083. [Google Scholar] [CrossRef]

- Goljandin, D.; Kulu, P. Disintegrators and Disintegrator Treatment of Materials; LAP LAMBERT Academic Publishing: Riga, Latvia, 2015; p. 168. [Google Scholar]

- Fang, Y.; Zhan, M.; Wang, Y. The status of recycling of waste rubber. Mater. Des. 2001, 22, 123–128. [Google Scholar] [CrossRef]

- Zhang, X.-X.; Lu, C.-H.; Liang, M. Preparation of rubber composites from ground tire rubber reinforced with waste-tire fiber through mechanical milling. J. Appl. Polym. Sci. 2007, 103, 4087–4094. [Google Scholar] [CrossRef]

- Hu, Y.; Kang, Y.; Wang, X.-C.; Li, X.-H.; Long, X.-P.; Zhai, G.-Y.; Huang, M. Mechanism and experimental investigation of ultra high pressure water jet on rubber cutting. Int. J. Precis. Eng. Manuf. 2014, 15, 1973–1978. [Google Scholar] [CrossRef]

- Peetsalu, P.; Goljandin, D.; Kulu, P.; Mikli, V.; Käerdi, H. Micropowders producted by disintegrator milling. Powder Metall. Prog. 2003, 12, 99–110. [Google Scholar]

- Congress, W.; Ii, D.T. Mechanical Disintegration of Al-W-B Waste Material. In Proceedings of the PM2010 World Congress, Washington DC, USA, 10 June 2010; Volume 4, pp. 597–601. [Google Scholar]

- Shishkin, A.; Mironov, V.; Goljandin, D.; Lapkovsky, V. Mechanical disintegration of Al-W-B waste material. In Proceedings of the World Powder Metallurgy Congress PM 2010, Florence, Italy, 10–14 October 2010; pp. 597–601. [Google Scholar]

- Lapkovskis, V.; Mironovs, V.; Irtiseva, K.; Goljandin, D.; Shishkin, A. Investigation of Devulcanised Crumb Rubber Milling and Deagglomeration in Disintegrator System. Key Eng. Mater. 2019, 800, 216–220. [Google Scholar] [CrossRef]

- Brown, C. Best Practices in Scrap Tire and Rubber Recycling. Resour. Recycl. 1997, 21–26. [Google Scholar]

- Perez, G.; Vila, A.; Rincón, L.; Solé, C.; Cabeza, L.F. Use of rubber crumbs as drainage layer in green roofs as potential energy improvement material. Appl. Energy 2012, 97, 347–354. [Google Scholar] [CrossRef]

- Carli, L.; Boniatti, R.; Teixeira, C.; Nunes, R.C.; Crespo, J. Development and characterization of composites with ground elastomeric vulcanized scraps as filler. Mater. Sci. Eng. C 2009, 29, 383–386. [Google Scholar] [CrossRef]

- Thodesen, C.; Xiao, F.; Amirkhanian, S. Modeling viscosity behavior of crumb rubber modified binders. Constr. Build. Mater. 2009, 23, 3053–3062. [Google Scholar] [CrossRef]

- Wang, R.; Gao, P.; Tian, M.; Dai, Y. Experimental study on mechanical and waterproof performance of lightweight foamed concrete mixed with crumb rubber. Constr. Build. Mater. 2019, 209, 655–664. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martínez-Boza, F.J.; Gallegos, C. Novel recycled polyethylene/ground tire rubber/bitumen blends for use in roofing applications: Thermo-mechanical properties. Polym. Test. 2010, 29, 588–595. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.N.; Shen, J.; Putman, B. Influences of crumb rubber size and type on reclaimed asphalt pavement (RAP) mixtures. Constr. Build. Mater. 2009, 23, 1028–1034. [Google Scholar] [CrossRef]

- Chaikaew, C.; Sukontasukkul, P.; Chaisakulkiet, U.; Sata, V.; Chindaprasirt, P. Properties of Concrete Pedestrian Blocks Containing Crumb Rubber from Recycle Waste Tyres Reinforced with Steel Fibres. Case Stud. Constr. Mater. 2019, 11, e00304. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.; Edmondson, V.; Dias, E. Crumb rubber used in concrete to provide freeze–thaw protection (optimal particle size). J. Clean. Prod. 2016, 112, 599–606. [Google Scholar] [CrossRef]

- Valente, M.; Sibai, A. Rubber/crete: Mechanical properties of scrap to reuse tire-derived rubber in concrete: A review. J. Appl. Biomater. Funct. Mater. 2019. [Google Scholar] [CrossRef] [PubMed]

- Sambucci, M.; Valente, M.; Sibai, A.; Marini, D.; Quitadamo, A.; Musacchi, E. Rubber-Cement Composites for Additive Manufacturing: Physical, Mechanical and Thermo-Acoustic Characterization. In Second RILEM International Conference on Concrete and Digital Fabrication; Bos, F.P., Lucas, S.S., Wolfs, R.J.M., Salet, T.A.M., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 113–124. [Google Scholar]

- Sambucci, M.; Marini, D.; Valente, M. Tire Recycled Rubber for More Eco-Sustainable Advanced Cementitious Aggregate. Recycling 2020, 5, 11. [Google Scholar] [CrossRef]

- Lin, C.; Huang, C.-L.; Shern, C.-C. Recycling waste tire powder for the recovery of oil spills. Resour. Conserv. Recycl. 2008, 52, 1162–1166. [Google Scholar] [CrossRef]

- Xu, M.; Li, J. Effect of adding rubber powder to poplar particles on composite properties. Bioresour. Technol. 2012, 118, 56–60. [Google Scholar] [CrossRef]

- Cristina, C.; Duta, A. Rubber/Thermoplastic Blends: Micro and Nano Structured. In Advances in Elastomers; Springer: Berlin/Heidelberg, Germany, 2013; pp. 183–228. [Google Scholar]

- Karger-Kocsis, J.; Mészáros, L.; Bárány, T. Ground tyre rubber (GTR) in thermoplastics, thermosets, and rubbers. J. Mater. Sci. 2013, 48, 1–38. [Google Scholar] [CrossRef]

- Marković, G.; Veljković, O.; Marinović-Cincović, M.; Jovanović, V.; Samaržija-Jovanović, S.; Budinski-Simendić, J. Composites based on waste rubber powder and rubber blends: BR/CSM. Compos. Part B Eng. 2013, 45, 178–184. [Google Scholar] [CrossRef]

- Ahmad, H.; Ismail, H.; Azura, A. Comparison properties of natural rubber/virgin acrylonitrile–butadiene rubber and natural rubber/recycled acrylonitrile–butadiene rubber blends. Iran. Polym. J. 2015, 24, 185–195. [Google Scholar] [CrossRef]

- Sonnier, R.; Leroy, E.; Clerc, L.; Bergeret, A.; Lopez-Cuesta, J.-M.; Bretelle, A.-S.; Ienny, P. Compatibilizing thermoplastic/ground tyre rubber powder blends: Efficiency and limits. Polym. Test. 2008, 27, 901–907. [Google Scholar] [CrossRef]

- Zhang, S.L.; Zhang, Z.X.; Pal, K.; Xin, Z.X.; Suh, J.; Kim, J.K. Prediction of mechanical properties of waste polypropylene/waste ground rubber tire powder blends using artificial neural networks. Mater. Des. 2010, 31, 3624–3629. [Google Scholar] [CrossRef]

- Xin, Z.X.; Zhang, Z.X.; Pal, K.; Byeon, J.U.; Lee, S.H.; Kim, J.K. Study of microcellular injection-molded polypropylene/waste ground rubber tire powder blend. Mater. Des. 2010, 31, 589–593. [Google Scholar] [CrossRef]

- Hassan, M.M.; Badway, N.A.; Gamal, A.M.; Elnaggar, M.Y.; Hegazy, E.-S.A. Studies on mechanical, thermal and morphological properties of irradiated recycled polyamide and waste rubber powder blends. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2010, 268, 1427–1434. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Rodrigue, D. Impact modification of polypropylene-based composites using surface-coated waste rubber crumbs. Polym. Compos. 2014, 35, 2280–2289. [Google Scholar] [CrossRef]

- Nevatia, P.; Banerjee, T.; Dutta, B.; Jha, A.; Naskar, A.; Bhowmick, A. Thermoplastic elastomers from reclaimed rubber and waste plastics. J. Appl. Polym. Sci. 2002, 83, 2035–2042. [Google Scholar] [CrossRef]

- Resmini, E.; Tirelli, D.; Galbusera, M. Thermoplastic Elastomeric Material Comprising a Vulcanized Rubber in a Subdivided Form. Patent Application WO2005097887A1, 20 October 2005. [Google Scholar]

- Fazli, A.; Rodrigue, D. Recycling Waste Tires into Ground Tire Rubber (GTR)/Rubber Compounds: A Review. J. Compos. Sci. 2020, 4, 103. [Google Scholar] [CrossRef]

- Marín-Genescà, M.; García-Amorós, J.; Mujal-Rosas, R.; Vidal, L.M.; Arroyo, J.B.; Fajula, X.C. Ground Tire Rubber Recycling in Applications as Insulators in Polymeric Compounds, According to Spanish UNE Standards. Recycling 2020, 5, 16. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Waste Rubber Recycling: A Review on the Evolution and Properties of Thermoplastic Elastomers. Materials 2020, 13, 782. [Google Scholar] [CrossRef]

- Bartsevich, V.A.E.; Kazak, I.M.; Konojko, V.V.; Krotova, T.J.V.; Lejzeronok, M.E.E.; Marusova, S.J.N.; Rusetskaja, I.G.E.; Rusetskij, D.V.E.; Rusetskij, V.V.; Tolstik, S.M. Composite Material for Making Large Industrial Rubber Articles. Patent Number RU2492194C2, 10 September 2013. [Google Scholar]

- Alamo-Nole, L.A.; Perales-Perez, O.; Roman-Velazquez, F.R. Sorption study of toluene and xylene in aqueous solutions by recycled tires crumb rubber. J. Hazard. Mater. 2011, 185, 107–111. [Google Scholar] [CrossRef]

- Piszczyk, Ł.; Hejna, A.; Formela, K.; Danowska, M.; Strankowski, M. Effect of ground tire rubber on structure, mechanical and thermal properties of flexible polyurethane foams. Iran. Polym. J. 2015, 24, 75–84. [Google Scholar] [CrossRef]

- Bormashenko, E.; Goldshtein, V.; Barayev, R.; Stein, T.; Whyman, G.; Pogreb, R.; Barkay, Z.; Aurbach, D. Robust method of manufacturing rubber waste-based water repellent surfaces. Polym. Adv. Technol. 2009, 20, 650–653. [Google Scholar] [CrossRef]

- Adhikari, B.; De, D.; Maiti, S. Reclamation and recycling of waste rubber. Prog. Polym. Sci. 2000, 7, 909–948. [Google Scholar] [CrossRef]

- Cavalieri, F.; Padella, F.; Cataldo, F. Mechanochemical surface activation of ground tire rubber by solid-state devulcanization and grafting. J. Appl. Polym. Sci. 2003, 90, 1631–1638. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).