Diversity of Iron Oxides: Mechanisms of Formation, Physical Properties and Applications

Abstract

1. Introduction

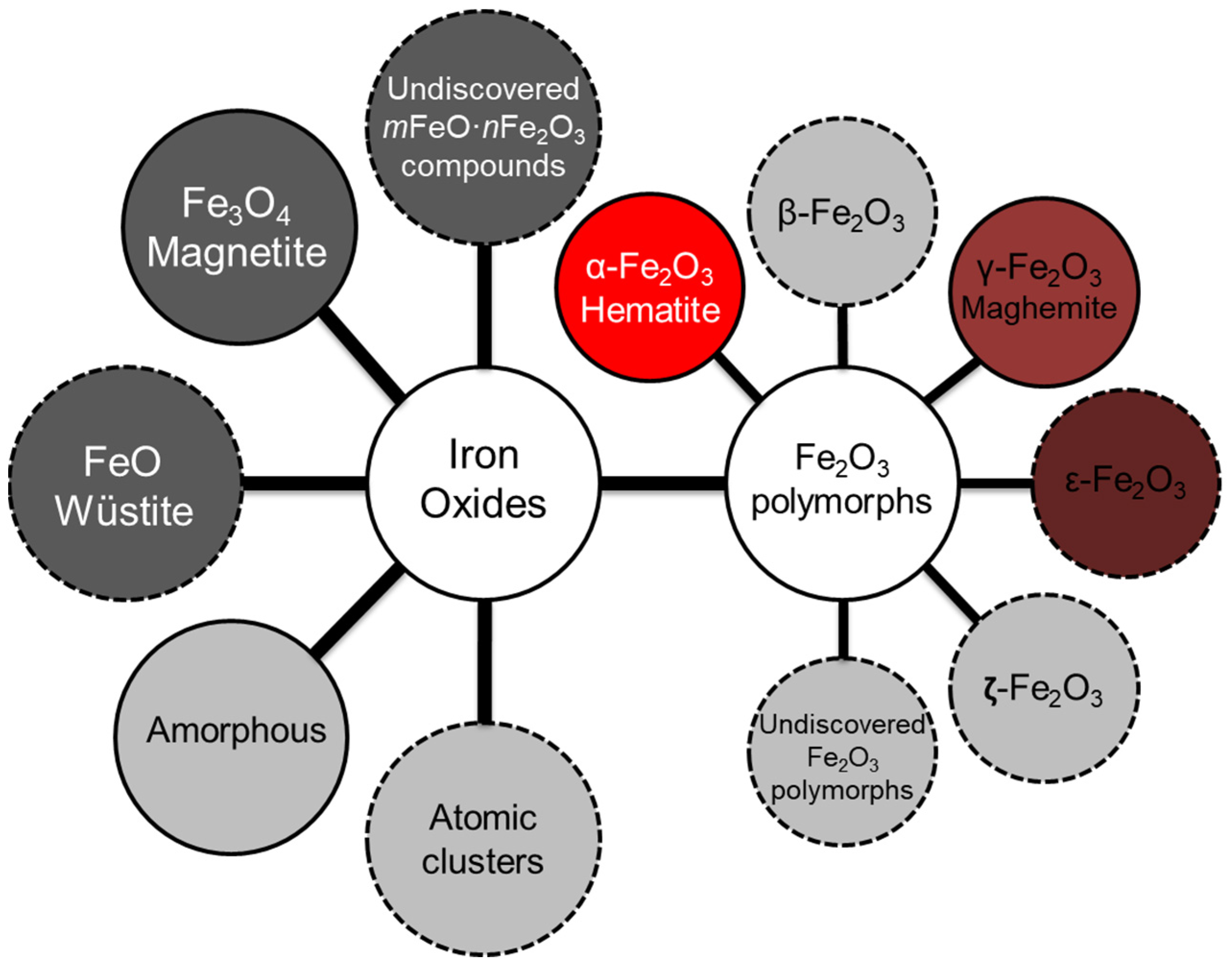

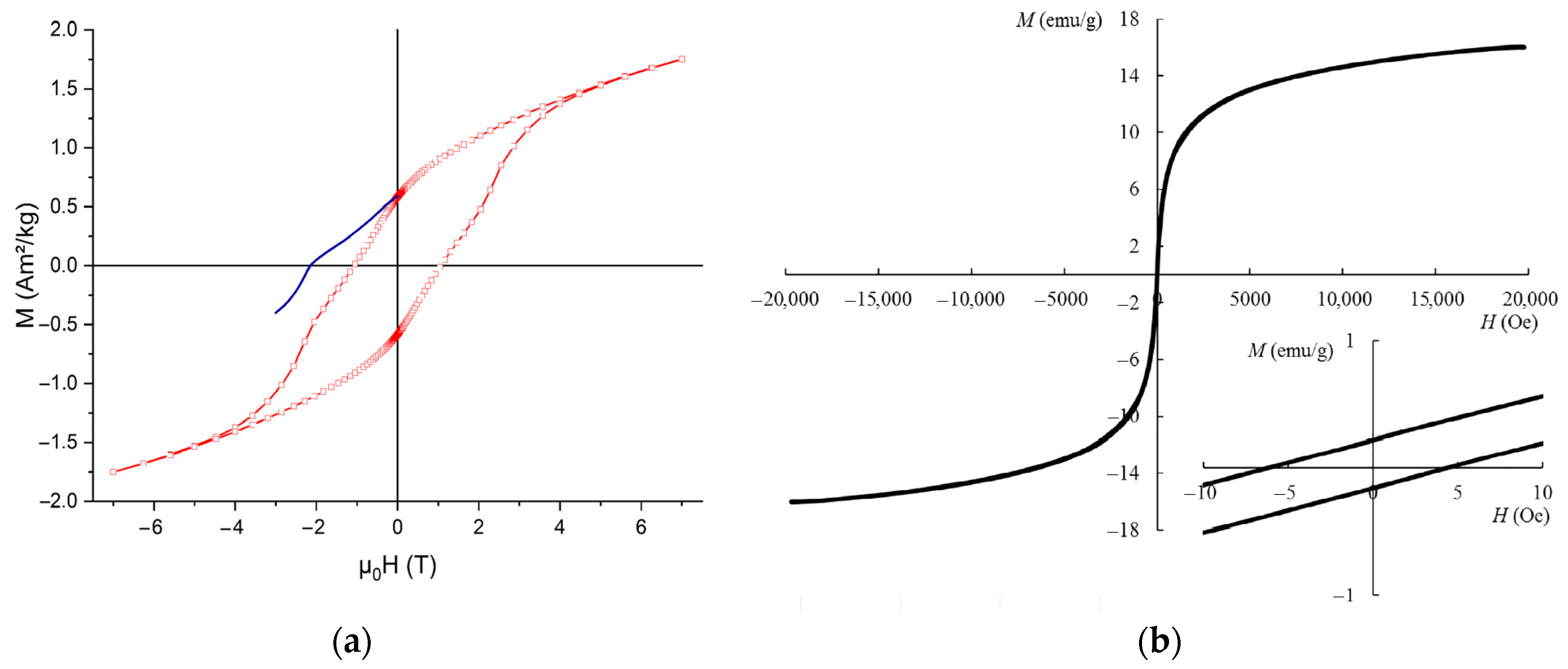

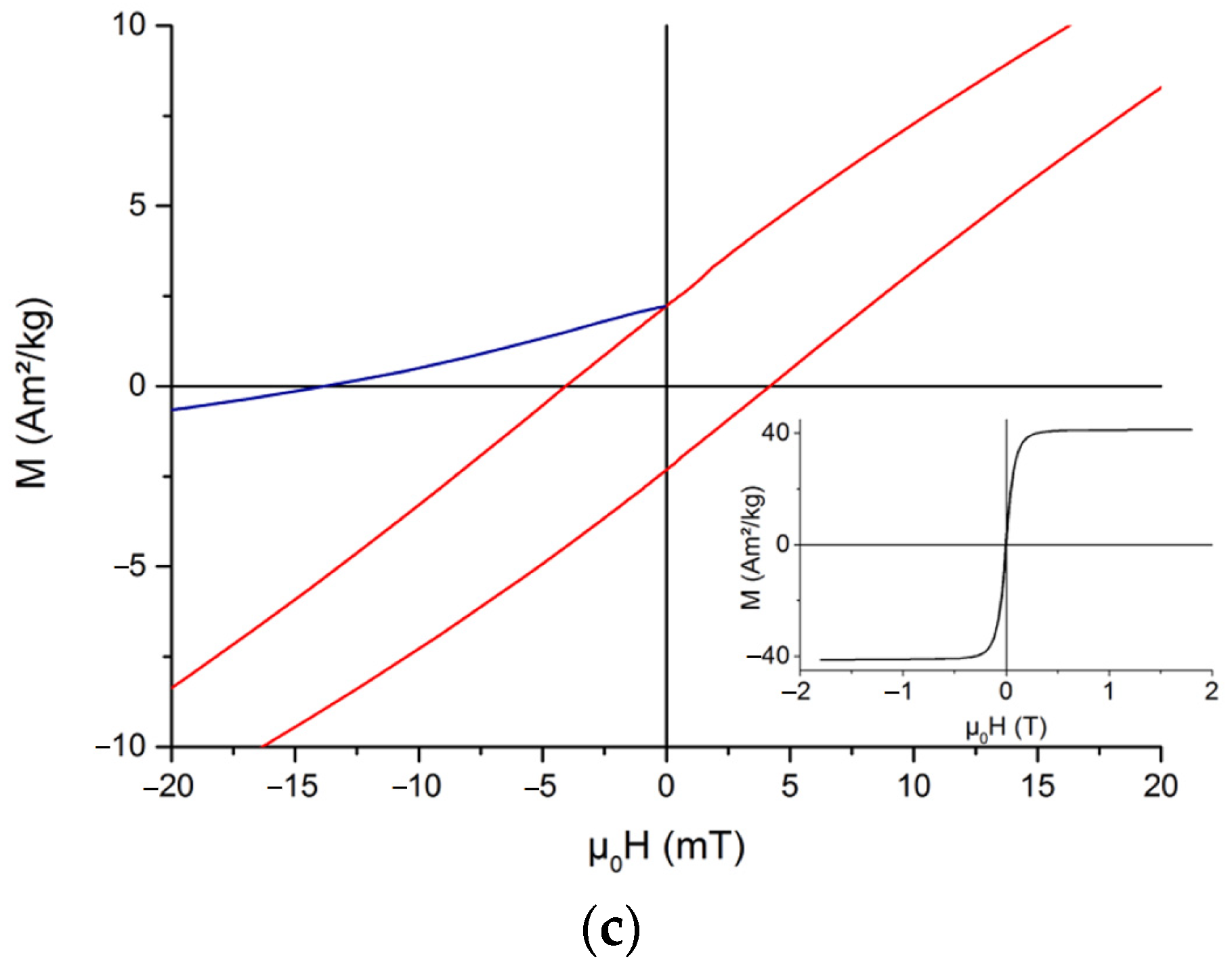

2. Physical Properties of Various Iron Oxide Compounds

3. Mechanisms of Iron Oxide Formation

3.1. The Structures Containing Pure Phases of FeO, Fe4O5, Fe3O4, and α-, β-, γ-, δ-, ε- and ζ-Polymorphs of Fe2O3

| Composition | Main Mechanisms of Iron Oxide Formation | Declared Applications | Phase Verification Techniques | Refs. |

|---|---|---|---|---|

| FeO NPs | Thermal decomposition of the iron(II) precursor, mechanochemical reduction of magnetite, flame synthesis, laser target interaction in liquid carrier media | Biomedicine, electronics, spintronics, magnetic force microscopy, metastability studies | XRD 1, UV–Vis 2, MALDI-TOF MS 3, EELS 4, F-AAS 5 HAADF-STEM 6, | [41,74,75,76,77,78,79,80] |

| Ultra-thin FeO film | Oxidation of iron monocrystal surface | Iron oxidation kinetics study | RMDS 7 | [141] |

| Electron-beam deposition on Au(111) surface | Iron catalysis, electronics, biomedicine | STM 8 | [142] | |

| Millimeter-sized iron oxide particles | Magnetite reduction with iron as reducing agent | Catalysts for ammonia synthesis | TG-DSC 9 | [40] |

| FeO layer on the metal alloy surface | Invar oxidation in a static carbon dioxide atmosphere | Iron oxidation kinetics study | XRD, TG-DSC, TEM 10 | [143] |

| Wüstite inclusions in titanomagnetite particles | Titanomagnetite ironsand-fluidized bed reduction by hydrogen | Commercial iron making | XRD | [144] |

| FeO powder | Reduction of hematite in a gas-controlled electric furnace | Earth’s mantle sound velocity studies | XRD, IXS 11 | [145] |

| FeO inclusions in the mold flux | Iron oxide formation in molten mold flux | Study of the oxidation mechanism of mold flux-covered molten iron | XRF 12 | [146] |

| FeO inclusions within the dense iron shell | Porous hematite gas reduction under isothermal conditions | Industrial exploitation of low-grade iron ores | TG-DSC, XRD | [147] |

| FeO clusters within the stable iron oxide matrix | The reduction of magnetite/hematite at temperatures of 400~500 °C | Iron catalysis | Quantitative theoretical analysis | [148] |

| Composition | Main Mechanisms of Iron Oxide Formation | Declared Applications | Phase Verification Techniques | Refs. |

|---|---|---|---|---|

| Fe3O4 NPs | Co-precipitation from iron salt solution, co-precipitation from iron oxyhydroxide solution, solvothermal synthesis, electrochemical formation from a pure iron, thermal decomposition of the iron oleate complex, biomimetic process with use of a leaf extract, nucleation mediated by iron-binding protein Mms6, biogeneration with a use of amyloid peptide Aβ42 | Biomedicine, magnetic separation, antimicrobial and antioxidant applications, contaminant removal, black pigment production, ferrofluids | TEM, XRD, SAXS 1, RS 2, FTIR 3, XPS 4, HAADF-STEM, EELS, TG-DSC, UV–Vis, PL 5, MSP 6, SAED 7 | [81,82,83,84,85,86,87,88,89,90,91,149,150,151,152,153,154,155,156,157,158,159,160,161,162] |

| Bacterial magnetosomes | Bacterial biomineralization, transient phosphate-rich ferric hydroxide reduction to magnetite, formation by dissimilatory iron-reducing bacteria | Biomedicine, paleomagnetism, microbial iron cycle studies, bioremediation of toxic compounds | HAADF-STEM, TEM, XAS 8, SAED, XMCD 9 | [93,94,95,96,97,98,163] |

| Inclusions of Fe3O4 within ore samples | Abiotic hydrothermal mineralization, iron oxide formation derived from continental weathering, extrusive magmatic formation from iron oxide-melt liquid | Geochemistry, environmental magnetism studies, early Earth iron cycle studies, origin and evolution of iron oxides studies | XRD, RS, XPS, EDS 10, ICP-AES 11 | [99,100,101,102] |

| External magnetite layer on a metal surface | Oxidation of a steel surface, slow oxidation of green rusts at room temperature, high-temperature corrosion | Corrosion studies | XRD, EDS, XRF, RS, XPS, AES 12 | [105,106,107,108,109,110] |

| Fe3O4 microparticles | Microbial-induced precipitation with the use of Sporosarcina pasteurii | Green synthesis of magnetite | EDS | [28] |

| Aging of ferrous hydroxide gels at elevated temperatures | Colloidal crud formation studies | XRD, TEM | [162] | |

| Self-assembled Fe3O4 mesocrystalline films | Heat-up method with the use of iron(III) chloride and sodium oleate | Biomedicine and industrial applications | TEM, SAED, XAS, SAXS | [163] |

| Fe0/Fe3O4 composite | Controlled reduction of the starting Fe3O4 with H2 | Treatment of wastewater | MSP, XRD | [164] |

| Magnetite nanowires | Supercritical fluid inclusion within a mesoporous silica matrix | Soft magnetic materials | TEM, SAED, XRD, FTIR | [165] |

| Inclusions of Fe3O4 NPs | Bacterial reduction of amorphous hydrous ferric oxide | Biogeochemistry | TEM, SAED, XRD, EDS | [166] |

| Fe3O4 layer on the zerovalent iron surface | Surface oxidation of iron by oxygen in an aqueous medium | Organic pollutant removal | EDS, XRD | [167] |

| Epoxy/magnetite nanocomposites | Reduction of anhydrous ferric chloride by ammonium hydroxide | Marine coatings of steel | FTIR, XRD, TEM | [168] |

| Iron oxide nanocomposite hydrogel | Co-precipitation process by ammonium hydroxide | Biomedicine | XRD, TEM, TG-DSC, EDS | [169] |

| Surface film containing Fe3O4 NPs | Bacterial mineralization in the air–water interface in Arctic tundra waters | Anaerobic microbial carbon cycle | TEM, EDS, STEM, EELS, FTIR, RS | [170] |

| Nanocomposite hydrogel with Fe3O4 NPs | Reduction with ammonia from a remixed solution of FeCl3 and FeCl2 | Biomedicine | TEM, XRF, EDS, TG-DSC, FTIR | [171] |

| Biochar composite with Fe3O4 NPs | One-pot solvothermal method using phoenix tree leaf-derived biochar | Treatment of wastewater | TEM, XRD, FTIR, XPS, ICP-AES | [172] |

| Fe3O4 NP inclusions in the surface layer | Formation of NPs along with cracks and pores during pre-oxidation | Plasma nitriding of steel | XRD | [173] |

| Chitosan/graphene oxide composite with Fe3O4 | Co-precipitation of Fe3O4 and chitosan/graphene oxide | Organic pollutant removal | XRD, XPS, RS, FTIR | [174] |

| Fe3O4 layer on carbon fibers of a carbon paper | Deposition on the carbon paper gas diffusion layer at the cathode | Corrosion studies | XRD, EDS | [175] |

| Mesocrystals assembled from Fe3O4 nanocubes | Heat-up method with the use of iron(III) chloride and sodium oleate | Mesocrystal applications | TEM | [176] |

| Fe3O4 nanorods | Formation in electron-beam-induced deposition from iron pentacarbonyl | Electronics | TEM, EELS | [177] |

| Lipase immobilized on coated Fe3O4 NPs | Solvothermal method with the use of FeCl3·6H2O and ethylene glycol | Biodiesel production | TEM, XRD, FTIR | [178] |

| Spherical mesoporous magnetite aggregates | Precipitation from iron(III) ethoxide with ethanol in the surfactant solution | Catalysis, sustainability | FTIR, XPS, EDS, TEM, MSP | [179] |

| Perfluorocarbon-loaded hydrogel microcapsules | Coaxial interface shearing double emulsion method | Biomedicine | – | [180] |

| Mesoporous magnetite | Ball milling of Fe3O4 and SiO2 followed by partial reduction | Recyclable absorbent for toxic Cr(VI) ions | TEM, XRD, XPS, ICP-AES | [181] |

| Magnetite crystal model | Local spin-density approximation density-functional calculation | Magnetite electron structure studies | Density-functional calculations | [43] |

| Spherulite nanostructure with inclusions of Fe3O4 | Electron-beam irradiation of the precursor solution with iron nitrate | Crystal growth dynamics studies | TEM, STEM, EDS | [182] |

| Composition | Main Mechanisms of Iron Oxide Formation | Declared Applications | Phase Verification Techniques | Refs. |

|---|---|---|---|---|

| α-Fe2O3 NPs | Hydrothermal synthesis, precipitation from a ferric salt solution using a natural leaf extract, precipitation and aging of ferrihydrite in an oxidized system, direct transformation of α-FeOOH via high-energy ball milling | Biomedicine, bioremediation of toxic compounds, photocatalysis, geochemistry, electronics, antibacterial activity studies, geochemistry | XRD, FTIR, UV–Vis, EDS, TEM, RS, XPS, XAS, ICP-AES, EPR 1, HAADF-STEM, WAXS 2 | [105,106,107,108,109,110,111,180,181,182,183,184,185,186,187,188,189,190,191,192] |

| Inclusions of α-Fe2O3 in ore samples | Precipitation from oxygenated iron-rich water or biomineralization, dissolution of Fe(III) hydroxides by Fe(III)-reducing bacteria, terrestrial subglacial oxidation of glacial iron fluvial deposition | Terrestrial iron oxide concretion studies, Precambrian iron formation studies, Antarctic glacier studies, biogeochemistry | EDS, RS, TEM, HAADF-STEM, XRD, SAED, FTIR, UV–Vis | [112,113,114,115,116,117,118,119] |

| α-Fe2O3 layer on a metal surface | Anodic potentiostatic oxidation of stainless steel sheet | Anodic passivation of stainless steel | AES | [193] |

| Oxidation of steel in an O2-N2 atmosphere at high temperature | Improvement of steel coating quality | TEM, EDS, GD-OES 3 | [194] | |

| Corrosion of chromia-forming alloys in simplified combustion atmosphere | Fireside corrosion studies | EDS, XRD | [195] | |

| Porous α-Fe2O3 nanostructures | Hydrothermal synthesis from FeCl3·6H2O in a microwave reactor | Lithium-ion batteries | XRD, TEM, SAED, XPS, TG-DTG | [196] |

| Sol–gel transformations of precursors in self-organized nanocellulose | Energy conversion and storage | XRD, TEM, SAED, XPS, TG-DSC | [197] | |

| Martian hematite deposits | Precipitation from oxygenated iron-rich water or biomineralization | Search for evidence of life on Mars | EDS, TEM | [198] |

| Hematite layers on sandstone grains | Precipitation from oxidizing iron-saturated fluid | Geochemistry | XRD, ICP-MS 4 | [199] |

| Double-walled hematite nanotubes | Growth of Fe nanowires inside porous templates and oxidation | Photocatalysis, biomedicine | XRD, EELS, HAADF-STEM, RS | [200] |

| Coral-like and nanowire α-Fe2O3 | Thermal oxidation of iron foils in air- and water vapor-assisted conditions | Removal of Cr ions from aqueous systems | XRD, RS, TEM, XPS | [201] |

| α-Fe2O3 NPs on mineral surfaces | Weathering of Fe-bearing silicate minerals or partial oxidation of Fe3O4 | Paleoclimate studies | XRD, TEM, SAED | [202] |

| α-Fe2O3 nanorods | Controlled aqueous growth from FeCl3·6H2O and NaNO3 | Photoelectrochemical water splitting | XRD | [203] |

| Inclusions of α-Fe2O3 in regolith simulant | Ball milling of commercial α-Fe2O3 samples in isopropyl alcohol | Combustion studies | XRD, TG-DSC | [204] |

| Inclusions of α-Fe2O3 in stone matrix | Bacterial mineralization | Heritage sciences | XRD, EDS, RS | [205] |

| Inclusions of α-Fe2O3 in auriferous quartz | Terrigenous abiotic mineralization | Geochemistry | EDS | [206] |

| Hematite layers on sandstone grains | Terrigenous co-precipitation with sandstone and uranium | Geochemistry of radionuclides | Gamma-ray spectrometry, ICP-MS | [207] |

| Hematite inclusions encapsulated in chert | Dehydration of the interstitial goethite to hematite microplates | Geochemistry | TEM, XRD, EDS | [208] |

| Hollow α-Fe2O3 nanofibers | Electrospinning with a use of iron chloride and poly(vinylpyrrolidone) | Photoelectrochemical water splitting | EDS, TEM, SAED, TG-DSC, UV–Vis | [209] |

| Fossilized bacteria with α-Fe2O3 | Biomineralization by anoxygenic photoferrotrophy | Biogeochemistry | RS | [210] |

| Porous α-Fe2O3 xerogel and aerogel | Sol–gel synthesis from Fe(III) salts with addition of propylene oxide | Catalysis, sensors, biology | TEM | [211] |

| Iron oxide nanostructures | Microbial Fe(II) oxidation of carbonate green rust by Fe(II)-oxidizing bacteria | Precambrian iron formation studies | MSP | [212] |

| Iron oxide biogenic precipitates | Bacterial mineralization | Biogenic iron oxide formation studies | XAS | [213] |

| Steel-wearing ejected debris with α-Fe2O3 | Steel fretting wear controlled by oxygen ingress to the contact | Steel fretting wear studies | XRD | [214] |

| α-Fe2O3 NPs on a steel surface | Oxidation of iron-bonded diamond precision-polishing wheel | Grinding of hard and brittle materials | XRD, XPS, TEM | [215] |

| Nanostructured α-Fe2O3 films | Electrochemical anodization of steel in an alkaline solution | Photocatalysis, anti-bioadhesion | RS, UV–Vis | [216] |

| Monodispersed micaceous α-Fe2O3 | Hydrothermal synthesis from iron chromium hydroxide precursors | Iron chromium grinding waste recycling | ICP-AES, XRD, XPS | [217] |

| Nanoporous α-Fe2O3 layer on an iron foil | Anodization of iron is an ethylene glycol and NH4F aqueous solution | Photocatalysis | TEM, RS, XRD, UV–Vis, EDS, EELS | [218] |

| Natural α-Fe2O3 from the iron deposits | Terrigenous abiotic mineralization | Photocatalytic recycling of toxic wastewater | RS, EDS, UV–Vis | [219] |

| Nanocomposite containing α-Fe2O3 | Wet impregnation of Co3O4 powder with an Fe(NO3)⋅9H2O solution | Catalysis | XPS, XRD, TG-DSC, EDS, TEM | [220] |

| Stepped α-Fe2O3 (0001) surfaces | First principles spin-polarized density-functional theory simulation | Chloride-induced iron depassivation studies | Density-functional theory calculations | [221] |

| α-Fe2O3 powder | In situ generation of iron oxide via decomposition of Fe(NO3)3·9H2O | Catalysis | XRD | [222] |

| α-Fe2O3 nanorods | Hydrothermal precipitation and air calcination of goethite nanorods | Catalysis, lithium-ion batteries, sensors | XRD, MSP, UV–Vis, EDS, TG-DSC | [223] |

| α-Fe2O3 nano- and microparticles | Chemically synthesized commercial α-Fe2O3 samples | Mechanisms of oxide toxicity toward bacteria | FTIR, XAS | [224] |

| α-Fe2O3 nanowires | Heating of iron wires suspended between two electric contacts | Vacuum electronic devices | TEM, EDS, XPS, RS | [225] |

| α-Fe2O3 layer on zerovalent iron NPs | Iron oxide film formation under aerobic conditions | Remediation of water pollutants | TEM, FTIR, XPS, XRD | [226] |

| Inclusions of α-Fe2O3 in rock varnish | Terrigenous abiotic mineralization or biotic processes | Geomicrobiology | XRD, RS, EDS | [227] |

| Nanolayers of α-Fe2O3 in polymer composite | Iron pentacarbonyl transformation with diamond anvil cells in Ar gas | High-energy density solid studies | RS, TEM, XRD | [228] |

| Jian ware blue-colored glaze with α-Fe2O3 | Calcination of a milled mix at a high temperature in oxidizing atmosphere | Ancient ceramics studies | XRD, UV–Vis, TEM, XPS | [229] |

| Inclusions of α-Fe2O3 in sediment samples | Microbial reduction of surface Fe(III) by iron-reducing bacteria | Microbial iron reduction studies | XRD | [230] |

| Core-shell iron/iron oxide NPs | Zerovalent Fe core-controlled oxidation during deposition | Oxide formation under e-beam radiation studies | TEM, EELS | [231] |

| α-Fe2O3 film on a dielectric substrate | Liquid-phase atomic layer deposition of crystalline hematite | Catalysis, sensors, lithium-ion batteries | XRD, UV–Vis | [232] |

| Cube-shaped α-Fe2O3 microstructures | Facile hydrothermal method using hydrated ferric nitrate and NaOH | Ethanol gas sensing | XRD, FTIR, EDS, RS | [233] |

| Iron oxide/Ti composites | Plasma electrolytic oxidation, impregnation and annealing | Phenol photodegradation | XRD, EDS, FTIR, XPS | [234] |

| Microporous α-Fe2O3 NPs | Precipitation from iron(II) sulfate using a natural leaf extract | Sustainability | XRD, UV–Vis, XPS, FTIR | [235] |

| Inclusions of α-Fe2O3 in artificial clay | Fe(OH)3 colloid mixing into chemically pure kaolin | Laterite engineering | XRD | [236] |

| Iron oxide nanotubes | Potentiostatic anodization of iron foil in electrolytes containing NH4F | Catalysis, sensors, supercapacitors | XRD, TEM, SAED | [237] |

| α-Fe2O3 thin film | Spray pyrolysis from FeCl3 and methanol solution | Electrochemical supercapacitors | XRD, UV–Vis | [44] |

| Corroded steel tube samples with α-Fe2O3 | Steel corrosion in an aqueous medium with oxygen and chlorine | Pipeline corrosion assessment | XRD, EDS, TEM, SAED | [238] |

| Inclusions of α-Fe2O3 in stone samples | Formation by washing and leaching of a stone object by rainwater | Limestone artifact studies | RS, FTIR, EDS, XRF | [239] |

| Iron oxide-loaded slag | Precipitation from FeCl3 solution with NaOH into melted slag | Arsenic removal from water | ICP-AES, XRD | [240] |

| 3D-ordered macroporous α-Fe2O3 | Impregnation of polymer matrices and high-temperature calcination | Catalysis | XRD, TG-DSC, FTIR, SAED, UV–Vis, XPS | [241] |

| α-Fe2O3/mesoporous silica core-shell NPs | Solvothermal synthesis from ferric nitrate with sol–gel silica coating | Catalysis, biomedicine | XRD, TEM, FTIR, UV–Vis | [242] |

| Spindle-shaped α-Fe2O3 mesocrystal | Interface-driven nucleation by ferrihydrate oxidation and attachment | Thermoelectronics, photonics, catalysis, photovoltaics | TEM, SAED, FTIR, EDS | [243] |

| Hematite nanopillars | Electron-beam evaporation using anodized aluminum oxide templates with well-defined pore diameters | Photoelectrochemical water splitting | XRD, XPS, UV–Vis | [244] |

| Composition | Main Mechanisms of Iron Oxide Formation | Declared Applications | Phase Verification Techniques | Refs. |

|---|---|---|---|---|

| γ-Fe2O3 NPs | Solvothermal synthesis from iron salts, bacterial mineralization, lepidocrocite calcination in an air atmosphere, hydrothermal and solvothermal synthesis from salt solutions | Catalysis, biomedicine, nucleation and formation of biogenic iron oxide studies, electronics, maghemite to hematite transition studies, sensors | TEM, EDS, SAED, XRD, XPS, EPR, FTIR, UV–Vis, ICP-AES, HAADF-STEM, MSP, in situ total scattering, XAS, SAXS, RS | [93,125,126,127,128,129] |

| γ-Fe2O3 NPs in silica matrix | Gas-phase synthesis in a furnace aerosol reactor from iron pentacarbonyl | Biomedicine | XRD, TEM, EDS, FTIR, UV–Vis | [245] |

| Dehydration of iron(III) hydroxide to magnetite followed by oxidation | Catalysis | XRD, FTIR | [246] | |

| γ-Fe2O3 powder | Chemically synthesized commercial γ-Fe2O3 samples | Catalytic oxidation of S(IV) | ICP-MS, FTIR | [247] |

| 26-faceted maghemite polyhedrons | Direct burning of ferrocene in different solvents in an alcohol lamp | Lithium-ion batteries | XRD, TEM | [248] |

| Magnetic polymeric NPs with γ-Fe2O3 | Co-precipitation of FeCl3/FeCl2·4H2O with NH4OH solution | Biomedicine | TEM, TG-DSC, FTIR | [249] |

| γ-Fe2O3 NP superlattice thin films | Chemically synthesized commercial γ-Fe2O3 samples | Electronics, optical coatings | Grazing incidence small angle X-ray scattering | [250] |

| Maghemite-decorated graphene nanoscrolls | Hydrolysis of FeCl3·6H2O and W(CO)6, promoted with hydrazine | Energy storage | TEM, XPS, TG-DSC, RS | [251] |

| Hollow iron oxide NPs | Gas-phase vaporization synthesis of Fe NPs and oxidation to γ-Fe2O3 | Optics, nanoelectronics | TEM, HAADF-STEM, EDS | [252] |

| Mesoporous iron oxide | Inverse micelle synthesis from Fe(NO3)3·9H2O butanol solution | Arsenic removal from water | XRD, FTIR, RS, XPS | [253] |

| Composition | Main Mechanisms of Iron Oxide Formation | Declared Applications | Phase Verification Techniques | Refs. |

|---|---|---|---|---|

| Pristine and co-substituted ε-Fe2O3 | Simulated crystal structure with a use of density-functional calculations | Magnetoelectric material development | Density-functional theory calculations | [254] |

| ε-Fe2O3 embedded in biomimetic graphene | Precipitation from ferric and ferrous chloride with a biocompatible polymer | Biomedicine | XRD, TEM, SAED, RS, XPS, TG-DSC, FTIR | [130] |

| Epitaxially stabilized thin-film ε-Fe2O3 | Epitaxy on (100)-oriented yttrium-stabilized zirconia substrates | Electronics, permanent magnets, biomedicine | XRD, HAADF-STEM | [136] |

| ε-Fe2O3 in ancient black glazed wares | Surface iron enrichment and a firing of wares under reducing conditions | Electronics, spintronics | XRF, XAS, XRD, RS, TEM, EDS | [132] |

| ε-Fe2O3 NPs | Hydrolysis of tetraethoxysilane in a solution of ferric nitrate and annealing | Wireless technologies, electronics | XRD, TEM, THz-TDS 1 | [255] |

| ε-Fe2O3 inclusions in fired clay samples | Stabilization of ε-Fe2O3 NPs in a matrix of silicates during firing of clays | Paleomagnetism | XRD, EDS | [134] |

| Y3Fe5O12 matrix including ε-Fe2O3 | Formation of ε-Fe2O3 in the Y3Fe5O12 matrix using the sol–gel method | Magnetoelectric material development | XRD, XPS, TG-DSC, FTIR | [256] |

| δ-Fe2O3 in layered double hydroxyl | Dry impregnation of layered double hydroxyl structure with ferric nitrate | Photocatalysis | XRD, FTIR, XRF, TG-DSC, UV–Vis | [22] |

| ε-Fe2O3-SiO2 | Reverse micelle method with the use of ferric nitrate | Oxidative dehydrogenation of n-butene | XRD | [136] |

| β-Fe2O3 | Milling of Fe2(SO4)3 and NaCl and calcination at 550 °C in air | |||

| Ga-substituted ε-Fe2O3 NPs | Calcination of a mesoporous silica impregnated with metal nitrates | Biomedicine | XRD, XRF, TEM, ICP-MS | [131] |

| ε-Fe2O3 in archeological brick and baked clay | High-temperature firing of bricks and clays in air | Archaeomagnetism, paleomagnetism | RS | [138] |

| ε-Fe2O3 in archeological samples, ε-Fe2O3 NPs | Sol–gel synthesis from ferric and barium nitrate with tetraethyl orthosilicate | XRD, RS | [135] | |

| ε-Fe2O3 coatings on Si(100) substrates | One-pot sol–gel recipe assisted by glycerol in an acid medium | Paleomagnetism, biomedicine, electronics | RS, XAS, EELS, HAADF-STEM | [257] |

| ε-Fe2O3/SiO2 composite powder | Sol–gel synthesis from ferric and barium nitrate with tetraethyl orthosilicate | Electronics | XRD, TEM | [133] |

| ε-Fe2O3 nanorods | Chemical vapor deposition from the Fe organic liquid source | Photocatalysis, electronics | XPS | [258] |

| ε-Fe2O3/SiO2 composite | Sol–gel synthesis from nitrate with tetraethyl orthosilicate and nitric acid | Electronics, spintronics, magnetizable printing | TG-DSC, XRD, TEM | [259] |

| ε-Fe2O3 NPs | Immersion of mesoporous silica with an FeSO4 or Fe(C10H9CHO) solution and high-temperature calcination | High-coercivity material development | TEM, XRD, MSP, TEM, SAED | [20,41] |

| β-Fe2O3 NPs | Sensors, lithium-ion batteries | |||

| Epitaxial ε-Fe2O3 films on GaN substrate | Pulsed laser deposition on the Ga-terminated surface of the GaN (0001) | Electronics | XRD, RHEED 2, TEM, XAS, XMCD | [260] |

| Silica-coated ε-Fe2O3 NPs | Sol–gel treatment of β-FeOOH nanorods with tetraethoxysilane and calcination | Electronics | XRD, TEM, EDS, MSP | [261] |

| ε-Fe2O3 in a Hare’s Fur Jian ware | High-temperature firing of local iron-rich area on the ceramic glaze | Magnetoresistance materials | XRF, XAS, EDS, XRD, RS | [140] |

| Metal-substituted ε-Fe2O3 | Impregnation of mesoporous silica NPs with rhodium-substituted ε-Fe2O3 | Electronics, magnetic force microscopy, biomedicine | XRD | [262] |

| β-Fe2O3 NPs | Thermally-induced solid-state reaction of NaCl with Fe2(SO4)3 in air | Sensors, lithium-ion batteries | XRD, MSP, TEM, SAED | [20] |

| ζ-Fe2O3 | Pressure treatment of β-Fe2O3 NPs at pressures above 30 GPa | n/a | ||

| ε-Fe2O3 in a thin MgO(111) layer | Pulsed laser deposition from MgO and Fe2O3 targets ablated using a KrF laser | Electronics | RHEED, XRD, neutron reflectometry | [263] |

| Single crystal of Fe4O5 | Synthesis in the diamond anvil cell at high pressure after laser heating | Solid Earth studies | Density-functional theory calculations | [23] |

| Nanometer-scale lamellae of Fe4O5 | High-pressure and high-temperature multi-anvil synthesis | Deep Earth studies | XRD, TEM, SAED, EDS, STEM | [264] |

| Powder of Fe4O5 | High-pressure and high-temperature direct synthesis from a mixture of Fe3O4 and Fe | Electronics | XRD, neutron diffraction | [265] |

| β-Fe2O3 NPs | Thermally-induced solid-state reaction of NaCl with Fe2(SO4)3 in air | Optoelectronics, sensors, lithium-ion batteries | XRD, MSP, TEM | [64] |

| Hydrolysis of 2M FeCl3 in boiling water and cooling down slowly at room temperature | Biomedicine | UV–Vis, TEM, XRD, FTIR, EDS, SAED | [63] |

3.2. The Structures Containing Iron Oxide Atomic Clusters and an Amorphous Iron Oxide Phase

3.3. The Structures Containing Two Co-Existing Iron Oxide Crystal Phases

| Composition | Main Mechanisms of Iron Oxide Formation | Declared Applications | Phase Verification Techniques | Refs. |

|---|---|---|---|---|

| Iron oxide atomic clusters | Combustion synthesis from Fe(CO)5 mixed with hydrogen and oxygen, high irradiance laser ionization from pressed Fe2O3 and Fe3O4 tablets, biomineralization inside the ferritin shell, reaction of laser ablated iron foil with 5% O2 seeded in a helium carrier gas | Catalysis, biomedicine, electronics, sensors, prediction of the magnetic properties of FeOx NPs, natural iron storage process studies, photovoltaics | MBMS 1, PMS 2, RMDS 3, TEM, LI-TOFMS 4, density-functional theory calculations, European Synchrotron Radiation Facility | [271,272,273,274,275,276,277,281] |

| Surface iron oxide layer on metal | Multicycling of an iron foil electrode between the switching potentials, formation of iron oxide species after reaction with Cr(VI) and Cu(II) | Chemical water treatment, production of molecular hydrogen, removal of contaminants | RMDS, XRD, XPS, FTIR, EDS | [278,279,282] |

| Amorphous ferric oxides | Adding Fe(II) or Fe(III) to seawater | Bioavailable iron studies | XAS, XRD | [266] |

| Addition of Fe(III) to synthetic buffered solution or soluble microbial systems | Chemical water treatment | UV–Vis | [267] | |

| Amorphous Fe2O3 in a silica matrix | Impregnation of mesoporous silica with ferric nitrate and calcination | Antibiotic adsorption | TEM, XRD, FTIR, UV–Vis | [268] |

| Poorly crystalline iron oxides | Iron oxide biomineralization by iron-reducing bacteria | Geochemistry | ICP-MS | [270] |

| Amorphous iron oxide nanostructures | Photothermal reaction inside a droplet of iron(III) acetylacetonate solution | Electronics, sensors | TEM, SAED, EDS, RS | [269] |

| Two-dimensional iron oxide on Au(111) | Evaporating iron atoms, annealing and cooling down to 300 K in O2 | Catalysis | STM, density-functional theory calculations | [142] |

| Iron oxide layer on zerovalent iron NPs | Zerovalent iron corrosion in an electrolyte solution | Treatment of contaminated aquifers | UV–Vis, XAS | [283] |

| Ferric oxide NPs | Protein-promoted conversion of Fe(II) into insoluble ferric iron oxides | Mitochondrial iron mishandling studies | UV–Vis | [284] |

| Ultra-thin iron oxide nanowhiskers | Iron oleate complex followed by selective decomposition at 150 °C | Biomedicine | TG-DSC, TEM, SAED, RS, XPS, FTIR | [285] |

| High valent iron oxo complexes | Fluorine-substituted Fe−tetra-amidomacrocyclic ligand oxidation | Photocatalysis | UV–Vis, EPR, high-resolution mass spectrometry | [286] |

| FeO(111)-like film on Fe(110) surface | Initial oxidation of Fe(110) in oxygen via Frank–Van der Merwe mechanism | Catalysis, pigments, electronics | XPS, XAS, STM, AES, LEED 5, STS 6 | [280] |

| Colloidal Fe-FexOy composite NPs | Oxidation of metal NPs via a nanoscale Kirkendall process | Clean fuels, catalysis, electrochemical energy | TEM, SAXS, WAXS, RMDS | [287] |

| Biogenic microtubular iron oxides | Biotic formation of organic sheaths and subsequent abiotic deposition of Fe | Catalysis, pigments | EDS, RS, TEM, XRD, STEM | [288] |

| Iron oxide model thin-film electrodes | Thermal oxidation of pure metal iron substrates at 300 ± 5 °C in air | Lithium-ion batteries | RS, XPS, SIMS 7 | [289] |

| Iron(III) oxide/ hydroxide nanonetworks | Synthesis of iron(III) oxide/hydroxide xerogels from a hydrated ferric nitrate | Electronics, catalysis, sensors | XPS, FTIR, XRD, TEM | [290] |

| Fe0-iron oxide core-shell NPs | Precipitation from ferrous sulfate with leaf extracts | Removal of nitrate in aqueous solution | EDS, XRD, FTIR | [291] |

| Soil samples with amorphous iron oxides | Abiotic mineralization in soil pore structures | Soil weathering studies | XRD, ICP-AES | [292] |

| Reticular pipeline cracks filled with iron oxide | Decarburization and diffusive oxidation of steel matrix | Corrosion resistance studies | EDS | [293] |

| Composition | Main Mechanisms of Iron Oxide Formation | Declared Applications | Phase Verification Techniques | Refs. |

|---|---|---|---|---|

| Saprolitic soil samples | Aerobic weathering of Fe-bearing minerals | Pedogenic process studies | XRF, UV–Vis, XRD | [298] |

| Loess and paleosol samples with iron oxides | Aerobic weathering of Fe-bearing silicate minerals | XRD, UV–Vis | [297] | |

| Oxidized iron items | Soil iron corrosion limited by the diffusion of dissolved oxygen | Heritage science | EDS, XRD, RS | [295] |

| Surface iron oxide layer on metal | Anodic film formation on steel immersed in sour acid media | Corrosion resistance studies | XRD, EDS | [302] |

| Graphene-iron oxide nanotube composite | An adept template-free hydrothermal route from ferrous sulfate | Removal of the toxic heavy metal Cr(VI) | EDS, XRD, FTIR, UV–Vis, TEM | [299] |

| Polyacrylonitrile/iron oxide composite | Hydrothermal method for in situ growth of iron oxide; iron alkoxide hydrolysis | Removal of Congo red dye from water | FTIR, XRD, EDS, ICP-AES | [300] |

| Carbon/FexOy magnetic composites | Mechanical mixing and thermal treatment under N2 atmosphere | Wastewater treatment | XRD, TG-DSC, EDS, FTIR | [301] |

| Isoelement synthetic heterostructures | Hydrothermal method combined with controlled partial annealing process | Visible-light photocatalysis | XRD, TEM, XPS, UV–Vis, EPR | [296] |

| Composition | Main Mechanisms of Iron Oxide Formation | Declared Applications | Phase Verification Techniques | Refs. |

|---|---|---|---|---|

| Inclusions of iron oxides in ore samples | Precipitation during protracted hydrothermal fluid/rock interaction, biological oxidation of Fe(II) by photoautotrophs, microbial sedimentary ferric iron flux, infiltration by hypogene and supergene fluids during or after deformation | Banded iron formation studies, geochemistry, late Archean and early Paleoproterozoic studies, iron oxide copper gold system studies | ICP-MS, EDS, XRF, SAED, TEM, XRD, ICP-AES, TG-DSC | [303,304,305,306,307,308,309,310,311] |

| Surface iron oxide layer on metal | Tribo-oxidation wear of the cast iron disc | Brake system wear studies | EDS, XRD, TEM, SAED | [315] |

| Iron oxide NPs | Anodization of Fe sheet in ethylene glycol electrolyte and calcination | Biomedicine, catalysis, photovoltaics, electronics | XRD, EDS, XPS, RS, FTIR | [312] |

| Iron oxide inclusions in concrete samples | Corrosion of a steel-reinforcing bar in air-entrained concrete with chlorides | Corrosion resistance studies | EDS | [318] |

| Iron oxide nanosheets and nanowires | Thermal oxidation of iron foils in the presence of water vapor | Cr(VI) removal | XRD, TEM, RS, UV–Vis | [319] |

| Iron oxide hollow spheres | Microwave–hydrothermal ionic liquid method, calcination and autocatalysis | Photocatalysis | XRD, TEM, UV–Vis | [314] |

| Inclusions of iron oxides in mineralized rocks | Abiotic formation of a mineral deposit | Geochemistry | XRF | [320] |

| Theoretically calculated iron oxide phases | Radiation-chemical oxidation of Fe depending on pH and oxygen content | Precambrian studies | Kinetics of iron oxidation calculations | [321] |

| Iron oxide NPs supported on biogenic silica | Iron oxide NP impregnation under hydrothermal conditions and calcination | Rhodamine B photocatalytic degradation | EDS, XRD, UV–Vis, TEM | [316] |

| Sediment samples with inclusions of iron oxides | Mineralization by variable diagenetic processes | Rock magnetism studies | XRD, EDS | [322] |

| Iron oxide nanorods | Sols of ferric hydroxide radiolysis in water under gamma irradiation | Electronics, biomedicine | XRD, TEM | [314] |

| Spinel-bearing peridotite | Oxidation of ferrous iron in olivine and pyroxene into ferric iron | Serpentinization studies | FTIR, EDS | [323] |

| Iron oxide inclusions in kaolin clay samples | Abiotic chemical precipitation | Clay chemistry and morphology studies | ICP-AES, XRD, XRF, TG-DSC | [324] |

| Precipitates containing iron oxide inclusions | Biomineralization by photosynthetic Fe(II)-oxidizing bacteria | Banded iron formation studies | XRD, EDS | [325] |

| Iron-mineralized biofilms | Dissolution and re-precipitation of iron oxide minerals | Bioremediation of iron ore mines | – | [326] |

| Iron oxide nanotubes | Template-based electrodeposition and calcination under oxidizing atmospheres | Biomedicine, electronics, gas sensors, catalysis | TEM, XRD, SAED | [317] |

| Iron oxide powder | Hydrothermal process with a use of pyrite cinder lixivium | Pyrite cinder reutilization | FTIR, XRD, TEM, SAED | [327] |

| Growth model for submarine deposits | Transformation of primary (hydr)oxides via reduction by organic matter | Banded iron formation studies | – | [328] |

| Composition | Main Mechanisms of Iron Oxide Formation | Declared Applications | Phase Verification Techniques | Refs. |

|---|---|---|---|---|

| Fe-rich carbonates with inclusions of iron oxides | Laser heating of natural goethite in a diamond anvil cell in CO2 | Earth’s mantle studies | XRD, XAS, TEM, EELS, HAADF-STEM, SAED | [329] |

| Samples with partially reduced FeO and Fe3O4 | Porous iron growth from wüstite in CO/CO2 and H2/H2O systems | Porous iron growth mechanism studies | – | [330] |

| Fe/oxide core-shell NPs | Formation of Fe3O4 during the oxidation of Fe NPs; high-temperature reduction of Fe3O4 to FeO by an electron-beam | Environmental remediation, electronics, catalysis, biomedicine, energy storage | TEM, SAED, EELS, HAADF-STEM, EDS | [331] |

| Composition | Main Mechanisms of Iron Oxide Formation | Declared Applications | Phase Verification Techniques | Refs. |

|---|---|---|---|---|

| Iron oxide NPs | Thermal decomposition of iron oleate, continuous flow synthesis, co-precipitation of Fe3+/Fe2+ ions, aerosol spray pyrolysis with the use of ferric nitrate and ferric chloride, precipitation from iron salts with natural leaf extract | Biomedicine, soil remediation, metal removal, wastewater treatment, electronics, catalysis, energy storage, groundwater remediation | TEM, XRD, FTIR, SAED, TG-DSC, UV–Vis, SAXS, neutron diffraction, EDS, MSP, EELS, EPR, ICP-MS, XAS, RS | [45,332,333,334,335,336,337,338,339,340,352,353,354,355,358,359,360,361,362] |

| Surface iron oxide layer on metal | Oxidation of a pure iron surface in oxygen, electrochemical reduction of lepidocrocite and ferrihydrite, in situ formation on an iron surface depending on the applied potential | Iron oxidation studies, atmospheric steel corrosion studies, groundwater remediation, corrosion protection studies | XPS, XRD, XAS, RS, AES, ellipsometry | [345,346,347,348,349] |

| Oxidation layer on archaeological steel | Combined iron oxidation/iron(III) oxyhydroxide reduction without O2 | Corrosion studies on ancient metallic objects | EDS, RS | [343] |

| Iron oxide-TiO2 nanorod heterostructures | Precipitation by injection of Fe(CO)5 into stirred TiO2 containing mixture | Optoelectronics, biomedicine, catalysis | XRD, XAS, ICP-AES, TEM, UV–Vis | [363] |

| Iron oxide in nanoscrolls and nanoribbons | Precipitation from ferric and ferrous chloride with ammonia solution | Lithium-ion storage, photocatalysis, biosensors | TEM, FTIR | [364] |

| Iron oxide hollow core/Shell NPs | Solvothermal synthesis from FeCl3 and urea in ethylene glycol and calcination | Biomedicine | XRD, TEM, TG-DSC, UV–Vis | [365] |

| Thin-film nanocomposite membrane with iron oxide | In situ synthesis from aqueous solutions containing ferric chloride | Biofouling protection | EDS, TEM, XPS, UV–Vis, XRD, TG-DSC | [366] |

| Magnetoferritin iron oxide NPs | Controlled mineralization from recombinant human H-chain ferritin | Biomedicine | TEM | [367] |

| Iron oxide-based hollow magnetic nanoparticles | Synthesis from iron pentacarbonyl in 1-octadecene and oleylamine | Exchange bias studies | XRD, TEM, FTIR, MSP, F-AAS | [368] |

| Albumin protein-based magnetic NPs | Co-precipitation of FeCl2 and FeCl3 by ammonia in the presence of protein | Biomedicine | TEM, TG-DSC | [369] |

| Composite of organic matrix and iron oxide NPs | Thermal decomposition of iron(III) oleate complex | Biomedicine | TEM | [370] |

| Iron oxide powder | Photochemical oxidation of siderite (FeCO3) by ultraviolet radiation | Banded iron formation studies | XRD | [371] |

| Interfacial iron oxide layer on iron artifacts | Iron corrosion in an anoxic environment after a pH increase at the interface | Anoxic corrosion of archaeological steel studies | HAADF-STEM, RS, EDS, SAED, SIMS | [344] |

| Iron oxide hydroxyapatite core/shell nanocomposites | Precipitation from ferric and ferrous chloride with ammonia under N2 | Biomedicine | TEM, FTIR, XRD, AAS, EDS | [372] |

| Chitosan-based beads with iron oxide NPs | Co-precipitation from ferric and ferrous chloride with NaOH solution | Remediation of water sources | XRD, FTIR, TG-DSC, EDS | [356] |

| Silica–iron oxide nanocomposite | Co-precipitation from ferric and ferrous chloride with ammonia solution | Toxic species removal | XRD, TEM, FTIR, UV–Vis, SAED | [357] |

| Vertical tube-shaped iron-oxide accumulations | Deep water corrosion of carbon steel | Marine corrosion studies | EDS | [351] |

| Hydrogels with embedded iron oxide NPs | In situ mineralization of iron ions in a hydrogel matrix | Dye removal | XRD, FTIR, TG-DSC, TEM | [373] |

| Corroded reinforced concrete | Iron corrosion in a laboratory corrosion chamber | Steel rebar corrosion studies | XRD, EDS | [350] |

| Porous hollow iron oxide NPs on carbon nanotubes | Etching of Fe-FexOy intermediate with nitric acid aqueous solution and drying | Biomedicine, catalysis, separation | TEM, XRD | [374] |

| Iron oxide embedding of bacterial cells | Biomineralization by thermophilic iron-reducing bacteria | Biogenic iron mineral formation studies | XRD | [375] |

| Activated carbon aerogel with iron oxide inclusions | Hydrothermal synthesis from ferrous sulfate with ammonia | Catalytic oxidation of pesticides | XRD, FTIR, XPS, TEM | [376] |

| Polyglycerol-grafted iron oxide NPs | Thermal decomposition of iron(III) acetylacetonate in triethylene glycol | Biomedicine | TEM, TG-DSC, FTIR, ICP-AES | [377] |

3.4. The Structures Containing Three or More Co-Existing Iron Oxide Phases

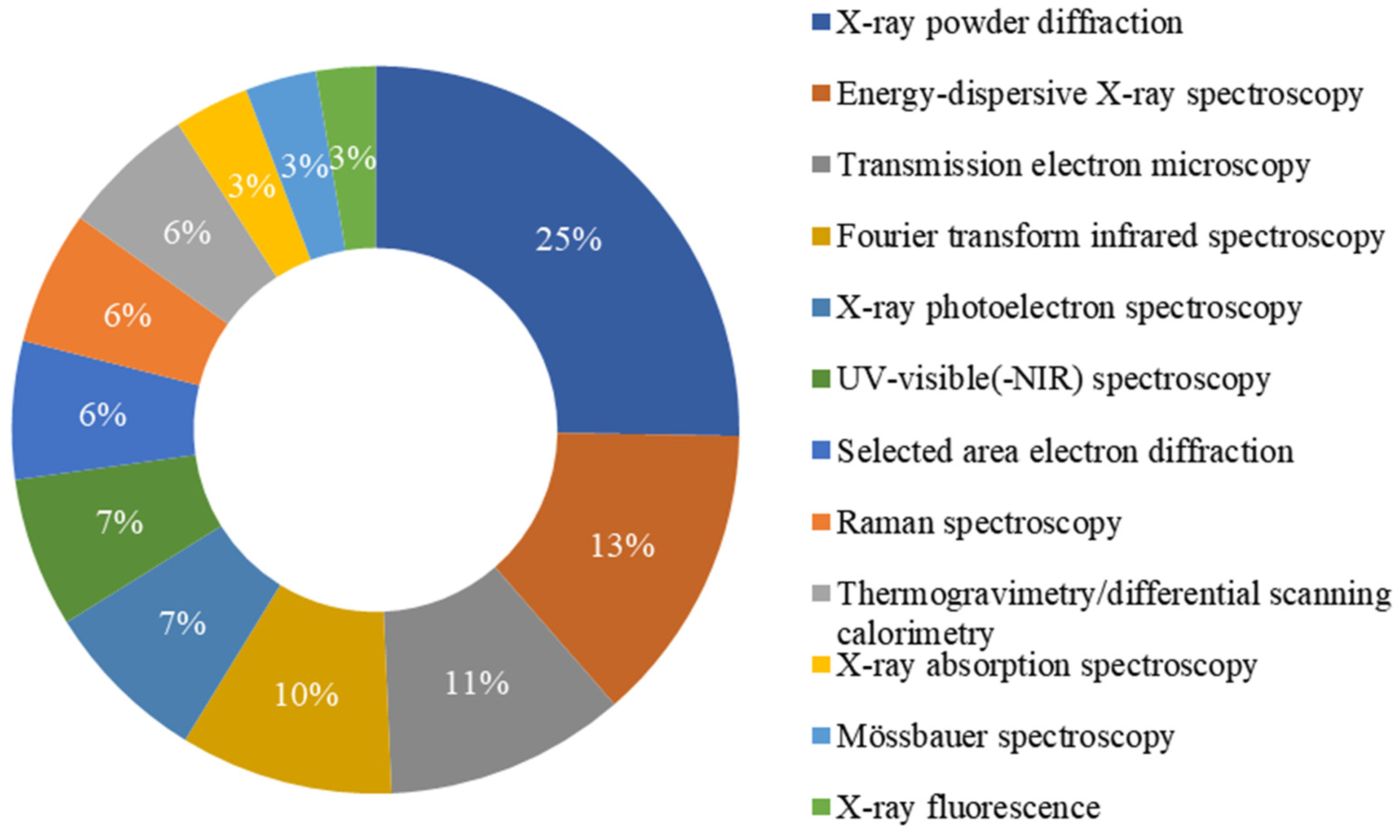

3.5. The Main Characterization Techniques Used to Verify Phase Composition

3.6. The Analysis of the Distribution of Iron Oxide Compounds by their Frequency of Mention

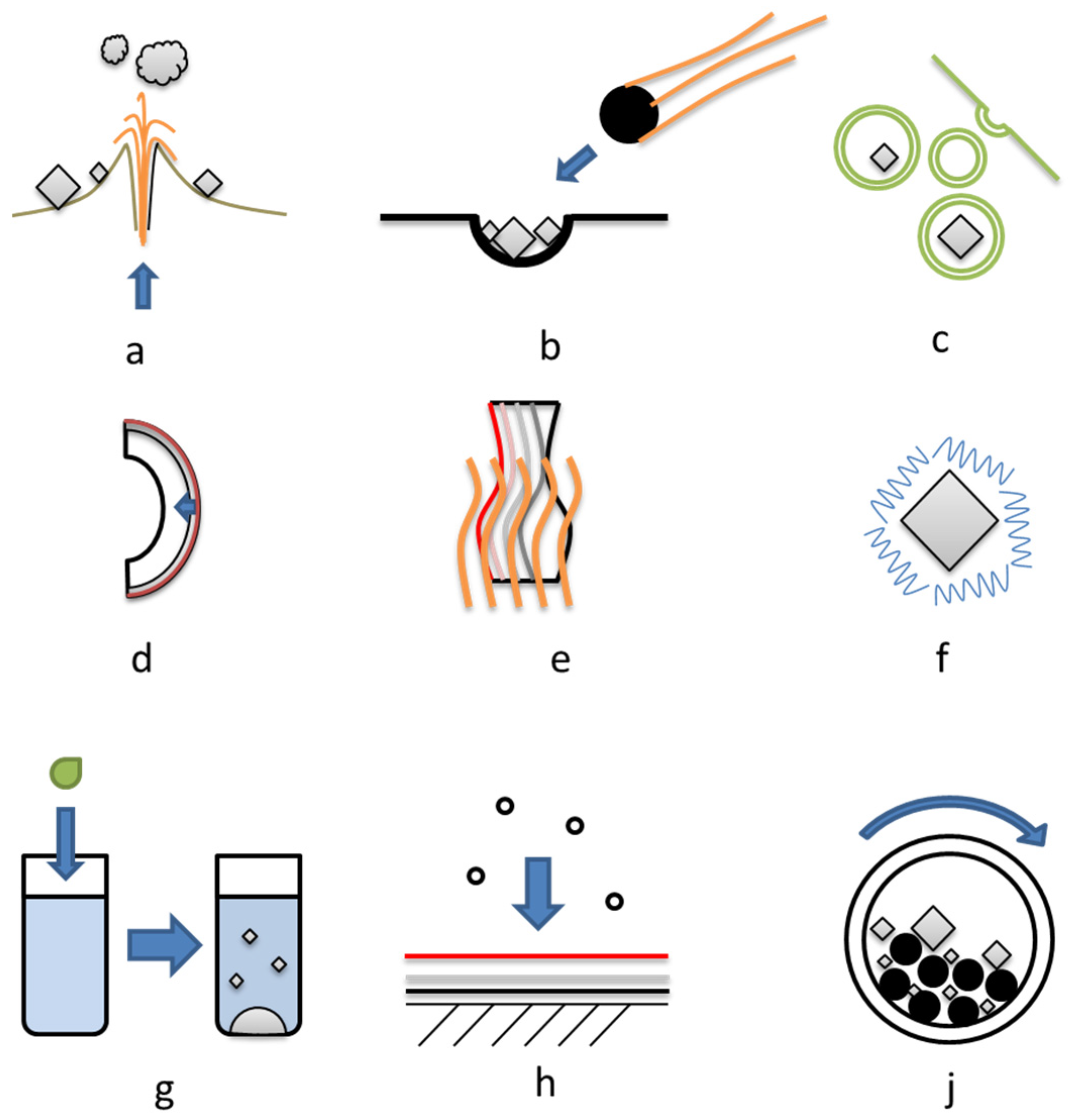

3.7. The Main Mechanisms of Iron Oxide Formation

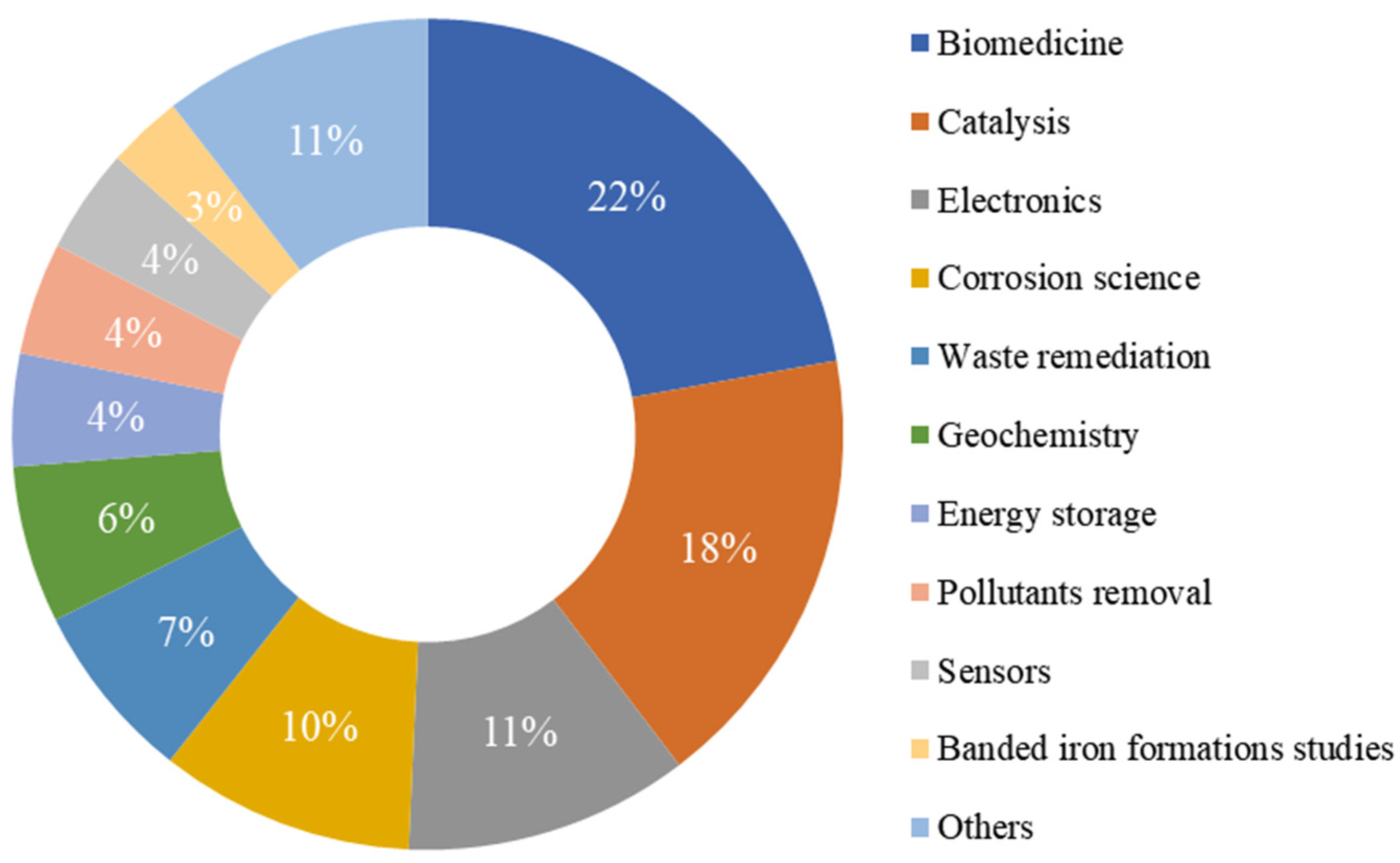

4. The Main Applications of the Structures Containing Iron Oxides

5. Summary and Perspectives

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jolivet, J.P.; Chanéac, C.; Tronc, E. Iron oxide chemistry. From molecular clusters to extended solid networks. Chem. Commun. 2004, 5, 477–483. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Barnard, A.S. Naturally occurring iron oxide nanoparticles: Morphology, surface chemistry and environmental stability. J. Mater. Chem. A 2013, 1, 27–42. [Google Scholar] [CrossRef]

- Parkinson, G.S. Iron oxide surfaces. Surf. Sci. Rep. 2016, 71, 272–365. [Google Scholar] [CrossRef]

- Simonson, B.M. Origin and evolution of large Precambrian iron formations. Spec. Pap. Geol. Soc. Am. 2003, 370, 231–244. [Google Scholar] [CrossRef]

- Skirrow, R.G. Iron oxide copper-gold (IOCG) deposits—A review (part 1): Settings, mineralogy, ore geochemistry and classification. Ore Geol. Rev. 2022, 140, 104569. [Google Scholar] [CrossRef]

- Kharitonskii, P.; Bobrov, N.; Gareev, K.; Kosterov, A.; Nikitin, A.; Ralin, A.; Sergienko, E.; Testov, O.; Ustinov, A.; Zolotov, N. Magnetic granulometry, frequency-dependent susceptibility and magnetic states of particles of magnetite ore from the Kovdor deposit. J. Magn. Magn. Mater. 2022, 553, 169279. [Google Scholar] [CrossRef]

- Navrotsky, A.; Mazeina, L.; Majzlan, J. Size-driven structural and thermodynamic complexity in iron oxides. Science 2008, 319, 1635–1638. [Google Scholar] [CrossRef] [PubMed]

- Strbak, O.; Dobrota, D. Archean Iron-Based Metabolism Analysis and the Photoferrotrophy-Driven Hypothesis of Microbial Magnetotaxis Origin. Geomicrobiol. J. 2019, 36, 278–290. [Google Scholar] [CrossRef]

- Narayanan, S.; Shahbazian-Yassar, R.; Shokuhfar, T. Transmission electron microscopy of the iron oxide core in ferritin proteins: Current status and future directions. J. Phys. D. Appl. Phys. 2019, 52, 453001. [Google Scholar] [CrossRef]

- Svobodova, H.; Kosnáč, D.; Tanila, H.; Wagner, A.; Trnka, M.; Vitovič, P.; Hlinkova, J.; Vavrinsky, E.; Ehrlich, H.; Polák, Š.; et al. Iron-oxide minerals in the human tissues. Biometals 2020, 33, 1–13. [Google Scholar] [CrossRef]

- Grüttner, C.; Müller, K.; Teller, J.; Westphal, F. Synthesis and functionalisation of magnetic nanoparticles for hyperthermia applications. Int. J. Hyperth. 2013, 29, 777–789. [Google Scholar] [CrossRef] [PubMed]

- Kment, Š.; Sivula, K.; Naldoni, A.; Sarmah, S.P.; Kmentová, H.; Kulkarni, M.; Rambabu, Y.; Schmuki, P.; Zbořil, R. FeO-based nanostructures and nanohybrids for photoelectrochemical water splitting. Prog. Mater. Sci. 2020, 110, 100632. [Google Scholar] [CrossRef]

- Kralj, S.; Marchesan, S. Bioinspired Magnetic Nanochains for Medicine. Pharmaceutics 2021, 13, 1262. [Google Scholar] [CrossRef]

- Tran, H.V.; Ngo, N.M.; Medhi, R.; Srinoi, P.; Liu, T.; Rittikulsittichai, S.; Lee, T.R. Multifunctional Iron Oxide Magnetic Nanoparticles for Biomedical Applications: A Review. Materials 2022, 15, 503. [Google Scholar] [CrossRef]

- Lam, A.; Hyler, F.; Stagg, O.; Morris, K.; Shaw, S.; Velázquez, J.M.; Navrotsky, A. Synthesis and thermodynamics of uranium-incorporated α-Fe2O3 nanoparticles. J. Nucl. Mater. 2021, 556, 153172. [Google Scholar] [CrossRef]

- Huber, S.E.; Mauracher, A.; Sukuba, I.; Urban, J.; Maihom, T.; Probst, M. Electron impact ionisation cross sections of iron oxides. Eur. Phys. J. D 2017, 71, 335. [Google Scholar] [CrossRef]

- Fabrichnaya, O.; Saxena, S.K.; Richet, P.; Westrum, E.F. Thermodynamic Data, Models, and Phase Diagrams in Multicomponent Oxide Systems: An Assessment for Materials and Planetary Scientists Based on Calorimetric, Volumetric and Phase Equilibrium Data; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2004; ISBN 978-3-642-08445-4. [Google Scholar]

- Carter, C.B.; Norton, M.G. Equilibrium Phase Diagrams. In Ceramic Materials; Springer: New York, NY, USA, 2013; pp. 123–139. [Google Scholar] [CrossRef]

- Machala, L.; Tuček, J.; Zbořil, R. Polymorphous transformations of nanometric iron(III) oxide: A review. Chem. Mater. 2011, 23, 3255–3272. [Google Scholar] [CrossRef]

- Tuček, J.; Machala, L.; Ono, S.; Namai, A.; Yoshikiyo, M.; Imoto, K.; Tokoro, H.; Ohkoshi, S.I.; Zbořil, R. Zeta-Fe2O3—A new stable polymorph in iron(III) oxide family. Sci. Rep. 2015, 5, 15091. [Google Scholar] [CrossRef]

- Kim, H.J. Short review on Fe2O3 polymorphs and ε-Fe2O3 thin films. New Phys. Sae Mulli 2018, 68, 819–828. [Google Scholar] [CrossRef]

- Kerchich, S.; Boudjemaa, A.; Chebout, R.; Bachari, K.; Mameri, N. High performance of δ-Fe2O3 novel photo-catalyst supported on LDH structure. J. Photochem. Photobiol. A Chem. 2021, 406, 113001. [Google Scholar] [CrossRef]

- Lavina, B.; Dera, P.; Kim, E.; Meng, Y.; Downs, R.T.; Weck, P.F.; Sutton, S.R.; Zhao, Y. Discovery of the recoverable high-pressure iron oxide Fe4O5. Proc. Natl. Acad. Sci. USA 2011, 108, 17281–17285. [Google Scholar] [CrossRef]

- Huang, S.; Hu, Q. Medium-range structure motifs of complex iron oxides. J. Appl. Phys. 2022, 131, 070902. [Google Scholar] [CrossRef]

- Pereira, M.C.; Oliveira, L.C.A.; Murad, E. Iron oxide catalysts: Fenton and Fentonlike reactions—A review. Clay Miner. 2012, 47, 285–302. [Google Scholar] [CrossRef]

- Pouran, S.R.R.; Raman, A.A.A.; Daud, W.M.A.W. Review on the application of modified iron oxides as heterogeneous catalysts in Fenton reactions. J. Clean. Prod. 2014, 64, 24–35. [Google Scholar] [CrossRef]

- Mu, Y.; Jia, F.; Ai, Z.; Zhang, L. Iron oxide shell mediated environmental remediation properties of nano zero-valent iron. Environ. Sci. Nano 2017, 4, 27–45. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, G.; Qi, H. Precipitation of magnetic iron oxide induced by sporosarcina pasteurii cells. Microorganisms 2021, 9, 331. [Google Scholar] [CrossRef]

- Antone, A.J.; Sun, Z.; Bao, Y. Preparation and application of iron oxide nanoclusters. Magnetochemistry 2019, 5, 45. [Google Scholar] [CrossRef]

- De Yoreo, J.J. In-situ liquid phase TEM observations of nucleation and growth processes. Prog. Cryst. Growth Charact. Mater. 2016, 62, 69–88. [Google Scholar] [CrossRef]

- Faivre, D.; Godec, T.U. From bacteria to mollusks: The principles underlying the biomineralization of iron oxide materials. Angew. Chem.-Int. Ed. 2015, 54, 4728–4747. [Google Scholar] [CrossRef] [PubMed]

- Fortin, D.; Langley, S. Formation and occurrence of biogenic iron-rich minerals. Earth-Sci. Rev. 2005, 72, 1–19. [Google Scholar] [CrossRef]

- Obara, N.; Murao, R.; ShinOda, K.; Suzuki, S. Structural Changes of Minerals in Iron Ores via Aqueous Solution. Tetsu-Hagane J. Iron Steel Inst. Jpn. 2021, 107, 534–541. [Google Scholar] [CrossRef]

- Fatimah, I.; Fadillah, G.; Yudha, S.P. Synthesis of iron-based magnetic nanocomposites: A review. Arab. J. Chem. 2021, 14, 103301. [Google Scholar] [CrossRef]

- Ohkoshi, S.I.; Sakurai, S.; Jin, J.; Hashimoto, K. The addition effects of alkaline earth ions in the chemical synthesis of ε-Fe2O3 nanocrystals that exhibit a huge coercive field. J. Appl. Phys. 2005, 97, 10K312. [Google Scholar] [CrossRef]

- Ohkoshi, S.I.; Tokoro, H. Hard magnetic ferrite: ε-Fe2O3. Bull. Chem. Soc. Jpn. 2013, 86, 897–907. [Google Scholar] [CrossRef]

- Testov, D.O.; Gareev, K.G.; Khmelnitskiy, I.K.; Kosterov, A.; Surovitskii, L.; Luchinin, V.V. Influence of the Preparation Technique on the Magnetic Characteristics of ε-Fe2O3-Based Composites. Magnetochemistry 2023, 9, 10. [Google Scholar] [CrossRef]

- Kharitonskii, P.; Kamzin, A.; Gareev, K.; Valiullin, A.; Vezo, O.; Sergienko, E.; Korolev, D.; Kosterov, A.; Lebedev, S.; Gurylev, A.; et al. Magnetic granulometry and Mössbauer spectroscopy of FemOn-SiO2 colloidal nanoparticles. J. Magn. Magn. Mater. 2018, 461, 30–36. [Google Scholar] [CrossRef]

- Machala, L.; Zboril, R.; Gedanken, A. Amorphous iron(III) oxide—A review. J. Phys. Chem. B 2007, 111, 4003–4018. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Han, W.; Huo, C.; Cen, Y. Development and application of wüstite-based ammonia synthesis catalysts. Catal. Today 2020, 355, 110–127. [Google Scholar] [CrossRef]

- Sakurai, S.; Namai, A.; Hashimoto, K.; Ohkoshi, S. First Observation of Phase Transformation of All Four Fe2O3 Phases (γ → ε → β → α-Phase). J. Am. Chem. Soc. 2009, 131, 18299–18303. [Google Scholar] [CrossRef] [PubMed]

- Yin, M.; Chen, Z.; Deegan, B.; O’Brien, S. Wüstite nanocrystals: Synthesis, structure and superlattice formation. J. Mater. Res. 2007, 22, 1987–1995. [Google Scholar] [CrossRef]

- Zhang, Z.; Satpathy, S. Electron states, magnetism, and the Verwey transition in magnetite. Phys. Rev. B 1991, 44, 13319–13331. [Google Scholar] [CrossRef]

- Yadav, A.A.; Deshmukh, T.B.; Deshmukh, R.V.; Patil, D.D.; Chavan, U.J. Electrochemical supercapacitive performance of Hematite α-Fe2O3 thin films prepared by spray pyrolysis from non-aqueous medium. Thin Solid Films 2016, 616, 351–358. [Google Scholar] [CrossRef]

- Roca, A.G.; Marco, J.F.; Del Puerto Morales, M.; Serna, C.J. Effect of nature and particle size on properties of uniform magnetite and maghemite nanoparticles. J. Phys. Chem. C 2007, 111, 18577–18584. [Google Scholar] [CrossRef]

- Jin, J.; Ohkoshi, S.I.; Hashimoto, K. Giant Coercive Field of Nanometer-Sized Iron Oxide. Adv. Mater. 2004, 16, 48–51. [Google Scholar] [CrossRef]

- Schrettle, F.; Kant, C.; Lunkenheimer, P.; Mayr, F.; Deisenhofer, J.; Loidl, A. Wüstite: Electric, thermodynamic and optical properties of FeO. Eur. Phys. J. B 2012, 85, 164. [Google Scholar] [CrossRef]

- Faure, B.; Salazar-Alvarez, G.; Bergström, L. Hamaker constants of iron oxide nanoparticles. Langmuir 2011, 27, 8659–8664. [Google Scholar] [CrossRef] [PubMed]

- Gomaa, M.M. Forward and inverse modelling of the electrical properties of magnetite intruded by magma, Egypt. Geophys. J. Int. 2013, 194, 1527–1540. [Google Scholar] [CrossRef]

- Lunt, R.A.; Jackson, A.J.; Walsh, A. Dielectric response of Fe2O3 crystals and thin films. Chem. Phys. Lett. 2013, 586, 67–69. [Google Scholar] [CrossRef]

- Ghigna, T.; Zannoni, M.; Jones, M.E.; Simonetto, A. Permittivity and permeability of epoxy-magnetite powder composites at microwave frequencies. J. Appl. Phys. 2020, 127, 045102. [Google Scholar] [CrossRef]

- Bhavani, P.; Reddy, N.R.; Reddy, I.V.S. Synthesis and physical characterization of γ-Fe2O3 and (α + γ)-Fe2O3 nanoparticles. J. Korean Phys. Soc. 2017, 70, 150–154. [Google Scholar] [CrossRef]

- Gich, M.; Frontera, C.; Roig, A.; Fontcuberta, J.; Molins, E.; Bellido, N.; Simon, C.; Fleta, C. Magnetoelectric coupling in ε-Fe2O3 nanoparticles. Nanotechnology 2006, 17, 687. [Google Scholar] [CrossRef]

- Dubrovskiy, A.A.; Balaev, D.A.; Krasikov, A.A.; Yakushhkin, S.S.; Kirillov, V.L.; Martyanov, O.N. Magnetodielectric effect in a metamaterial consisting of xerogel with embedded ε-Fe2O3 iron oxide nanoparticles. Solid State Commun. 2019, 289, 27–29. [Google Scholar] [CrossRef]

- Gheisari, M.; Mozaffari, M.; Acet, M.; Amighian, J. Preparation and investigation of magnetic properties of wüstite nanoparticles. J. Magn. Magn. Mater. 2008, 320, 2618–2621. [Google Scholar] [CrossRef]

- Chen, C.J.; Chiang, R.K.; Lai, H.Y.; Lin, C.R. Characterization of monodisperse wüstite nanoparticles following partial oxidation. J. Phys. Chem. C 2010, 114, 4258–4263. [Google Scholar] [CrossRef]

- Özdemir, Ö. Coercive force of single crystals of magnetite at low temperatures. Geophys. J. Int. 2000, 141, 351–356. [Google Scholar] [CrossRef]

- Tadic, M.; Panjan, M.; Tadic, B.V.; Lazovic, J.; Damnjanovic, V.; Kopani, M.; Kopanja, L. Magnetic properties of hematite (α-Fe2O3) nanoparticles synthesized by sol-gel synthesis method: The influence of particle size and particle size distribution. J. Electr. Eng. 2019, 70, 71–76. [Google Scholar] [CrossRef]

- Araujo, R.N.; Nascimento, E.P.; Raimundo, R.A.; Macedo, D.A.; Mastelaro, V.R.; Neves, G.A.; Morales, M.A.; Menezes, R.R. Hybrid hematite/calcium ferrite fibers by solution blow spinning: Microstructural, optical and magnetic characterization. Ceram. Int. 2021, 47, 33363–33372. [Google Scholar] [CrossRef]

- Mirza, I.M.; Ali, K.; Sarfraz, A.K.; Ali, A.; Haq, A.U. A study of dielectric, optical and magnetic characteristics of maghemite nanocrystallites. Mater. Chem. Phys. 2015, 164, 183–187. [Google Scholar] [CrossRef]

- Shokrollahi, H. A review of the magnetic properties, synthesis methods and applications of maghemite. J. Magn. Magn. Mater. 2017, 426, 74–81. [Google Scholar] [CrossRef]

- Danno, T.; Nakatsuka, D.; Kusano, Y.; Asaoka, H.; Nakanishi, M.; Fujii, T.; Ikeda, Y.; Takada, J. Crystal structure of β-Fe2O3 and topotactic phase transformation to α-Fe2O3. Cryst. Growth Des. 2013, 13, 770–774. [Google Scholar] [CrossRef]

- Kumar, A.; Singhal, A. Synthesis of colloidal β-Fe2O3 nanostructures—Influence of addition of Co2+ on their morphology and magnetic behavior. Nanotechnology 2007, 18, 475703. [Google Scholar] [CrossRef]

- Malina, O.; Tuček, J.; Jakubec, P.; Kašlík, J.; Medřík, I.; Tokoro, H.; Yoshikiyo, M.; Namai, A.; Ohkoshi, S.I.; Zbořil, R. Magnetic ground state of nanosized β-Fe2O3 and its remarkable electronic features. RSC Adv. 2015, 5, 49719–49727. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, X.; Feng, J.; Huang, H.; Guo, Y.; Li, Z.; Zou, Z. Paving the road toward the use of β-Fe2O3 in solar water splitting: Raman identification, phase transformation and strategies for phase stabilization. Natl. Sci. Rev. 2020, 7, 1059–1067. [Google Scholar] [CrossRef]

- Levy, D.; Giustetto, R.; Hoser, A. Structure of magnetite (Fe3O4) above the Curie temperature: A cation ordering study. Phys. Chem. Miner. 2012, 39, 169–176. [Google Scholar] [CrossRef]

- Özdemir, Ö.; Banerjee, S.K. High temperature stability of maghemite (γ-Fe2O3). Geophys. Res. Lett. 1984, 11, 161–164. [Google Scholar] [CrossRef]

- Jordan, K.; Cazacu, A.; Manai, G.; Ceballos, S.F.; Murphy, S.; Shvets, I.V. Scanning tunneling spectroscopy study of the electronic structure of Fe3O4 surfaces. Phys. Rev. B—Condens. Matter Mater. Phys. 2006, 74, 085416. [Google Scholar] [CrossRef]

- Liu, H.; Di Valentin, C. Band Gap in Magnetite above Verwey Temperature Induced by Symmetry Breaking. J. Phys. Chem. C 2017, 121, 25736–25742. [Google Scholar] [CrossRef]

- Bowker, M.; Hutchings, G.; Davies, P.R.; Edwards, D.; Davies, R.; Shaikhutdinov, S.; Freund, H.J. Surface structure of γ-Fe2O3(111). Surf. Sci. 2012, 606, 1594–1599. [Google Scholar] [CrossRef]

- Silva, M.F.; De Oliveira, L.A.S.; Ciciliati, M.A.; Silva, L.T.; Pereira, B.S.; Hechenleitner, A.A.W.; Oliveira, D.M.F.; Pirota, K.R.; Ivashita, F.F.; Paesano, A.; et al. Nanometric particle size and phase controlled synthesis and characterization of γ-Fe2O3 or (α + γ)-Fe2O3 by a modified sol-gel method. J. Appl. Phys. 2013, 114, 104311. [Google Scholar] [CrossRef]

- Elouafi, A.; Moubah, R.; Tizliouine, A.; Derkaoui, S.; Omari, L.H.; Lassri, H. Effects of Ru doping and of oxygen vacancies on the optical properties in α-Fe2O3 powders. Appl. Phys. A Mater. Sci. Process. 2020, 126, 228. [Google Scholar] [CrossRef]

- Nasu, T.; Yoshikiyo, M.; Tokoro, H.; Namai, A.; Ohkoshi, S.I. First-Principles Calculations and Optical Absorption Spectrum of a Light-Colored Aluminum-Substituted ε-Iron Oxide Magnet. Eur. J. Inorg. Chem. 2017, 2017, 531–534. [Google Scholar] [CrossRef]

- Dadashi, S.; Poursalehi, R.; Delavari, H. Structural and Optical Properties of Pure Iron and Iron Oxide Nanoparticles Prepared via Pulsed Nd:YAG Laser Ablation in Liquid. Procedia Mater. Sci. 2015, 11, 722–726. [Google Scholar] [CrossRef]

- Feld, A.; Weimer, A.; Kornowski, A.; Winckelmans, N.; Merkl, J.P.; Kloust, H.; Zierold, R.; Schmidtke, C.; Schotten, T.; Riedner, M.; et al. Chemistry of Shape-Controlled Iron Oxide Nanocrystal Formation. ACS Nano 2019, 13, 152–162. [Google Scholar] [CrossRef] [PubMed]

- Kampferbeck, M.; Klauke, L.R.; Weller, H.; Vossmeyer, T. Little Adjustments Significantly Simplify the Gram-Scale Synthesis of High-Quality Iron Oxide Nanocubes. Langmuir 2021, 37, 9851–9857. [Google Scholar] [CrossRef] [PubMed]

- Marinca, T.F.; Chicinaş, H.F.; Neamţu, B.V.; Isnard, O.; Pascuta, P.; Lupu, N.; Stoian, G.; Chicinaş, I. Mechanosynthesis, structural, thermal and magnetic characteristics of oleic acid coated Fe3O4 nanoparticles. Mater. Chem. Phys. 2016, 171, 336–345. [Google Scholar] [CrossRef]

- Leszczyński, B.; Hadjipanayis, G.C.; El-Gendy, A.A.; Załȩski, K.; Śniadecki, Z.; Musiał, A.; Jarek, M.; Jurga, S.; Skumiel, A. The influence of oxidation process on exchange bias in egg-shaped FeO/Fe3O4 core/shell nanoparticles. J. Magn. Magn. Mater. 2016, 416, 269–274. [Google Scholar] [CrossRef]

- Narnaware, P.K.; Ravikumar, C. Mechanistic Insights into the Formation and Growth of Anisotropic-Shaped Wüstite-Spinel Core-Shell Iron Oxide Nanoparticles in a Coordinating Solvent. J. Phys. Chem. C 2020, 124, 25010–25027. [Google Scholar] [CrossRef]

- Kluge, S.; Deng, L.; Feroughi, O.; Schneider, F.; Poliak, M.; Fomin, A.; Tsionsky, V.; Cheskis, S.; Wlokas, I.; Rahinov, I.; et al. Initial reaction steps during flame synthesis of iron-oxide nanoparticles. CrystEngComm 2015, 17, 6930–6939. [Google Scholar] [CrossRef]

- Ahn, T.; Kim, J.H.; Yang, H.M.; Lee, J.W.; Kim, J.D. Formation pathways of magnetite nanoparticles by coprecipitation method. J. Phys. Chem. C 2012, 116, 6069–6076. [Google Scholar] [CrossRef]

- Besenhard, M.O.; LaGrow, A.P.; Hodzic, A.; Kriechbaum, M.; Panariello, L.; Bais, G.; Loizou, K.; Damilos, S.; Cruz, M.M.; Thanh, N.T.K.; et al. Co-precipitation synthesis of stable iron oxide nanoparticles with NaOH: New insights and continuous production via flow chemistry. Chem. Eng. J. 2020, 399, 125740. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, J.; Wang, Z.; Zhou, Z. Solvothermal synthesis of size-controlled monodispersed superparamagnetic iron oxide nanoparticles. Appl. Sci. 2019, 9, 5157. [Google Scholar] [CrossRef]

- Grabs, I.M.; Bradtmöller, C.; Menzel, D.; Garnweitner, G. Formation mechanisms of iron oxide nanoparticles in different nonaqueous media. Cryst. Growth Des. 2012, 12, 1469–1475. [Google Scholar] [CrossRef]

- Kozakova, Z.; Kuritka, I.; Kazantseva, N.E.; Babayan, V.; Pastorek, M.; Machovsky, M.; Bazant, P.; Saha, P. The formation mechanism of iron oxide nanoparticles within the microwave-assisted solvothermal synthesis and its correlation with the structural and magnetic properties. Dalton Trans. 2015, 44, 21099–21108. [Google Scholar] [CrossRef]

- Lozano, I.; Casillas, N.; de León, C.P.; Walsh, F.C.; Herrasti, P. New Insights into the Electrochemical Formation of Magnetite Nanoparticles. J. Electrochem. Soc. 2017, 164, D184–D191. [Google Scholar] [CrossRef]

- Kertmen, A.; Torruella, P.; Coy, E.; Yate, L.; Nowaczyk, G.; Gapiński, J.; Vogt, C.; Toprak, M.; Estradé, S.; Peiró, F.; et al. Acetate-Induced Disassembly of Spherical Iron Oxide Nanoparticle Clusters into Monodispersed Core-Shell Structures upon Nanoemulsion Fusion. Langmuir 2017, 33, 10351–10365. [Google Scholar] [CrossRef]

- Nene, A.; Takahashi, M.; Somani, P.R. Fe3O4 and Fe Nanoparticles by Chemical Reduction of Fe(acac)3 by Ascorbic Acid: Role of Water. World J. Nano Sci. Eng. 2016, 6, 20–28. [Google Scholar] [CrossRef]

- Perecin, C.J.; Tirich, B.M.; Nagamine, L.C.C.M.; Porto, G.; Rocha, F.V.; Cerize, N.N.P.; Varanda, L.C. Aqueous synthesis of magnetite nanoparticles for magnetic hyperthermia: Formation mechanism approach, high water-dispersity and stability. Colloids Surf. A Physicochem. Eng. Asp. 2021, 627, 127169. [Google Scholar] [CrossRef]

- Tahir, A.; Saeed, A.; Ramzan, I.; Hayat, S.S.; Ahmad, W.; Naeem, S.; Afzal, M.; Mukhtar, A.; Mehmood, T.; Khan, B.S. Mechanism for the formation of magnetite iron oxide nanostructures by Ficus carica dried fruit extract using green synthesis method. Appl. Nanosci. 2021, 11, 1857–1865. [Google Scholar] [CrossRef]

- Gan, L.; Lu, Z.; Cao, D.; Chen, Z. Effects of cetyltrimethylammonium bromide on the morphology of green synthesized Fe3O4 nanoparticles used to remove phosphate. Mater. Sci. Eng. C 2018, 82, 41–45. [Google Scholar] [CrossRef]

- Kashyap, S.; Woehl, T.J.; Liu, X.; Mallapragada, S.K.; Prozorov, T. Nucleation of iron oxide nanoparticles mediated by mms6 protein in situ. ACS Nano 2014, 8, 9097–9106. [Google Scholar] [CrossRef]

- Baaziz, W.; Ghica, C.; Cypriano, J.; Abreu, F.; Anselme, K.; Ersen, O.; Farina, M.; Werckmann, J. New phenotype and mineralization of biogenic iron oxide in magnetotactic bacteria. Nanomaterials 2021, 11, 3189. [Google Scholar] [CrossRef] [PubMed]

- Ben-Shimon, S.; Stein, D.; Zarivach, R. Current view of iron biomineralization in magnetotactic bacteria. J. Struct. Biol. X 2021, 5, 100052. [Google Scholar] [CrossRef]

- Lovley, D.R.; Stolz, J.F.; Nord, G.L.; Phillips, E.J.P. Anaerobic production of magnetite by a dissimilatory iron-reducing microorganism. Nature 1987, 330, 252–254. [Google Scholar] [CrossRef]

- Garber, A.I.; Cohen, A.B.; Nealson, K.H.; Ramírez, G.A.; Barco, R.A.; Enzingmüller-Bleyl, T.C.; Gehringer, M.M.; Merino, N. Metagenomic Insights into the Microbial Iron Cycle of Subseafloor Habitats. Front. Microbiol. 2021, 12, 667944. [Google Scholar] [CrossRef] [PubMed]

- Staniland, S.; Ward, B.; Harrison, A.; Van Der Laan, G.; Telling, N. Rapid magnetosome formation shown by real-time X-ray magnetic circular dichroism. Proc. Natl. Acad. Sci. USA 2007, 104, 19524–19528. [Google Scholar] [CrossRef] [PubMed]

- Rahn-Lee, L.; Komeili, A. The magnetosome model: Insights into the mechanisms of bacterial biomineralization. Front. Microbiol. 2013, 4, 352. [Google Scholar] [CrossRef]

- Hu, X.; Chen, H.; Beaudoin, G.; Zhang, Y. Textural and compositional evolution of iron oxides at Mina Justa (Peru): Implications for mushketovite and formation of IOCG deposits. Am. Mineral. 2020, 105, 397–408. [Google Scholar] [CrossRef]

- Hua, X.; Zheng, Y.; Xu, Q.; Lu, X.; Cheng, H.; Zou, X.; Song, Q.; Ning, Z. Interfacial reactions of chalcopyrite in ammonia–ammonium chloride solution. Trans. Nonferrous Met. Soc. China Engl. Ed. 2018, 28, 556–566. [Google Scholar] [CrossRef]

- Velasco, F.; Tornos, F.; Hanchar, J.M. Immiscible iron- and silica-rich melts and magnetite geochemistry at the El Laco volcano (northern Chile): Evidence for a magmatic origin for the magnetite deposits. Ore Geol. Rev. 2016, 79, 346–366. [Google Scholar] [CrossRef]

- Warrier, A.K.; Sebastian, J.G.; Amrutha, K.; Sali, A.S.Y.; Mahesh, B.S.; Mohan, R. Magnetic properties of surface sediments in Schirmacher Oasis, East Antarctica: Spatial distribution and controlling factors. J. Soils Sediments 2021, 21, 1206–1221. [Google Scholar] [CrossRef]

- Dodd, M.S.; Wang, H.; Li, C.; Towner, M.; Thomson, A.R.; Slack, J.F.; Wan, Y.S.; Pirajno, F.; Manikyamba, C.; Wang, Q.; et al. Abiotic anoxic iron oxidation, formation of Archean banded iron formations, and the oxidation of early Earth. Earth Planet. Sci. Lett. 2022, 584, 117469. [Google Scholar] [CrossRef]

- Yang, X.; Guo, Q.; Boyko, V.; Avetisyan, K.; Findlay, A.J.; Huang, F.; Wang, Z.; Chen, Z. Isotopic reconstruction of iron oxidation-reduction process based on an Archean Ocean analogue. Sci. Total Environ. 2022, 817, 152609. [Google Scholar] [CrossRef]

- Xiong, X.; Liu, X.; Tan, H.; Deng, S. Investigation on high temperature corrosion of water-cooled wall tubes at a 300 MW boiler. J. Energy Inst. 2020, 93, 377–386. [Google Scholar] [CrossRef]

- Martinelli, L.; Balbaud-Célérier, F.; Terlain, A.; Bosonnet, S.; Picard, G.; Santarini, G. Oxidation mechanism of an Fe-9Cr-1Mo steel by liquid Pb-Bi eutectic alloy at 470 °C (Part II). Corros. Sci. 2008, 50, 2537–2548. [Google Scholar] [CrossRef]

- Misawa, T.; Hashimoto, K.; Shimodaira, S. The mechanism of formation of iron oxide and oxyhydroxides in aqueous solutions at room temperature. Corros. Sci. 1974, 14, 131–149. [Google Scholar] [CrossRef]

- Odziemkowski, M.S.; Schuhmacher, T.T.; Gillham, R.W.; Reardon, E.J. Mechanism of oxide film formation on iron in simulating groundwater solutions: Raman spectroscopic studies. Corros. Sci. 1998, 40, 371–389. [Google Scholar] [CrossRef]

- Liu, M.; Cheng, X.; Li, X.; Pan, Y.; Li, J. Effect of Cr on the passive film formation mechanism of steel rebar in saturated calcium hydroxide solution. Appl. Surf. Sci. 2016, 389, 1182–1191. [Google Scholar] [CrossRef]

- Castro-Ocampo, O.; Celaya, C.A.; González-Reyes, L.; Hernández-Pérez, I.; Garibay-Febles, V.; Jaramillo-Quintero, O.A.; Lara-García, H.A.; Muñiz, J.; Suárez-Parra, R. Understanding hydroxyl radicals addition to CO2 on α-Fe2O3(1 1 0) surface photocatalyst for organic compounds production. Fuel 2022, 310, 122465. [Google Scholar] [CrossRef]

- Kusior, A.; Michalec, K.; Jelen, P.; Radecka, M. Shaped Fe2O3 nanoparticles-synthesis and enhanced photocatalytic degradation towards RhB. Appl. Surf. Sci. 2019, 476, 342–352. [Google Scholar] [CrossRef]

- Sivaranjani, R.; Thayumanavan, A.; Sriram, S. Photocatalytic activity of Zn-doped Fe2O3 nanoparticles: A combined experimental and theoretical study. Bull. Mater. Sci. 2019, 42, 185. [Google Scholar] [CrossRef]

- Shkrob, I.A.; Chemerisov, S.D.; Marin, T.W. Photocatalytic decomposition of carboxylated molecules on light-exposed martian regolith and its relation to methane production on mars. Astrobiology 2010, 10, 425–436. [Google Scholar] [CrossRef] [PubMed]

- Bolanz, R.M.; Bläss, U.; Ackermann, S.; Ciobotǎ, V.; Rösch, P.; Tarcea, N.; Popp, J.; Majzlan, J. The effect of antimonate, arsenate, and phosphate on the transformation of ferrihydrite to goethite, hematite, feroxyhyte, and tripuhyite. Clays Clay Miner. 2013, 61, 11–25. [Google Scholar] [CrossRef]

- Börsig, N.; Scheinost, A.C.; Shaw, S.; Schild, D.; Neumann, T. Uptake mechanisms of selenium oxyanions during the ferrihydrite-hematite recrystallization. Geochim. Cosmochim. Acta 2017, 206, 236–253. [Google Scholar] [CrossRef]

- Brandt, F.; Schäfer, T.; Claret, F.; Bosbach, D. Heterogeneous formation of ferric oxide nanoparticles on chlorite surfaces studied by X-ray absorption spectromicroscopy (STXM). Chem. Geol. 2012, 329, 42–52. [Google Scholar] [CrossRef]

- Chan, M.A.; Johnson, C.M.; Beard, B.L.; Bowman, J.R.; Parry, W.T. Iron isotopes constrain the pathways and formation mechanisms of terrestrial oxide concretions: A tool for tracing iron cycling on Mars? Geosphere 2006, 2, 324–332. [Google Scholar] [CrossRef]

- Chan, M.A.; Ormö, J.; Park, A.J.; Stich, M.; Souza-Egipsy, V.; Komatsu, G. Models of iron oxide concretion formation: Field, numerical, and laboratory comparisons. Geofluids 2007, 7, 356–368. [Google Scholar] [CrossRef]

- Gao, B.F.; Wu, C.Z.; Yang, T.; Santosh, M.; Dong, L.H.; Zhao, T.Y.; Ye, H.; Lei, R.X.; Li, W. The Neoproterozoic “Blood Falls” in Tarim Craton and Their Possible Connection With Snowball Earth. J. Geophys. Res. Earth Surf. 2019, 124, 229–244. [Google Scholar] [CrossRef]

- Magnol, R.V.; Macedo, M.Q.; de Macêdo, M.C.S.; Scandian, C. Tribological characterization of jaspilite by linear scratch test. Wear 2019, 426–427, 142–150. [Google Scholar] [CrossRef]

- Rasmussen, B.; Muhling, J.R. Development of a greenalite-silica shuttle during incursions of hydrothermal vent plumes onto Neoarchean shelf, Hamersley region, Australia. Precambrian Res. 2021, 353, 106003. [Google Scholar] [CrossRef]

- Parker, C.W.; Wolf, J.A.; Auler, A.S.; Barton, H.A.; Senko, J.M. Microbial reducibility of Fe(III) phases associated with the genesis of iron ore caves in the Iron Quadrangle, Minas Gerais, Brazil. Minerals 2013, 3, 395–411. [Google Scholar] [CrossRef]

- Wu, Z.; Yuan, L.; Jia, N.; Wang, Y.; Sun, L. Microbial biomineralization of iron seepage water: Implication for the iron ores formation in intertidal zone of Zhoushan Archipelago, East China Sea. Geochem. J. 2009, 43, 167–177. [Google Scholar] [CrossRef]

- Singh, M.; Singhal, J.; Prasad, K.A.; Rajesh, V.J.; Ray, D.; Sahoo, P. Spectral characteristics of banded iron formations in Singhbhum craton, eastern India: Implications for hematite deposits on Mars. Geosci. Front. 2016, 7, 927–936. [Google Scholar] [CrossRef]

- Bandi, S.; Srivastav, A.K. Understanding the Growth Mechanism of Hematite Nanoparticles: The Role of Maghemite as an Intermediate Phase. Cryst. Growth Des. 2021, 21, 16–22. [Google Scholar] [CrossRef]

- Gallo-Cordova, A.; Ovejero, J.G.; Pablo-Sainz-Ezquerra, A.M.; Cuya, J.; Jeyadevan, B.; Veintemillas-Verdaguer, S.; Tartaj, P.; Morales, M.D.P. Unravelling an amine-regulated crystallization crossover to prove single/multicore effects on the biomedical and environmental catalytic activity of magnetic iron oxide colloids. J. Colloid Interface Sci. 2022, 608, 1585–1597. [Google Scholar] [CrossRef] [PubMed]

- Gavilán, H.; Sánchez, E.H.; Brollo, M.E.F.; Asín, L.; Moerner, K.K.; Frandsen, C.; Lázaro, F.J.; Serna, C.J.; Veintemillas-Verdaguer, S.; Morales, M.P.; et al. Formation Mechanism of Maghemite Nanoflowers Synthesized by a Polyol-Mediated Process. ACS Omega 2017, 2, 7172–7184. [Google Scholar] [CrossRef]

- Jensen, K.M.Ø.; Andersen, H.L.; Tyrsted, C.; Bøjesen, E.D.; Dippel, A.C.; Lock, N.; Billinge, S.J.L.; Iversen, B.B.; Christensen, M. Mechanisms for iron oxide formation under hydrothermal conditions: An in situ total scattering study. ACS Nano 2014, 8, 10704–10714. [Google Scholar] [CrossRef]

- Kabelitz, A.; Guilherme, A.; Joester, M.; Reinholz, U.; Radtke, M.; Bienert, R.; Schulz, K.; Schmack, R.; Kraehnert, R.; Emmerling, F. Time-resolved in situ studies on the formation mechanism of iron oxide nanoparticles using combined fast-XANES and SAXS. CrystEngComm 2015, 17, 8463–8470. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Roychowdhury, A.; Das, D.; Nayar, S. Multi-functional biomimetic graphene induced transformation of Fe3O4 to ε-Fe2O3 at room temperature. RSC Adv. 2015, 5, 89488–89497. [Google Scholar] [CrossRef]

- Královec, K.; Havelek, R.; Koutová, D.; Veverka, P.; Kubíčková, L.; Brázda, P.; Kohout, J.; Herynek, V.; Vosmanská, M.; Kaman, O. Magnetic nanoparticles of Ga-substituted ε-Fe2O3 for biomedical applications: Magnetic properties, transverse relaxivity, and effects of silica-coated particles on cytoskeletal networks. J. Biomed. Mater. Res.—Part A 2020, 108, 1563–1578. [Google Scholar] [CrossRef] [PubMed]

- Dejoie, C.; Sciau, P.; Li, W.; Noé, L.; Mehta, A.; Chen, K.; Luo, H.; Kunz, M.; Tamura, N.; Liu, Z. Learning from the past: Rare e-Fe2O3 in the ancient black-glazed Jian (Tenmoku) wares. Sci. Rep. 2014, 4, 4941. [Google Scholar] [CrossRef]

- Ma, J.; Wang, Y.; Chen, K. Refining single-crystalline epsilon iron oxide nanorods via low-temperature aging. Adv. Powder Technol. 2019, 30, 3021–3027. [Google Scholar] [CrossRef]

- Gurylev, A.; Kharitonskii, P.; Kosterov, A.; Berestnev, I.; Sergienko, E. Magnetic properties of fired clay (bricks) possibly containing epsilon iron (III) oxide. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2019; Volume 1347. [Google Scholar] [CrossRef]

- López-Sánchez, J.; Palencia-Ortas, A.; del Campo, A.; McIntosh, G.; Kovacheva, M.; Martín-Hernández, F.; Carmona, N.; de la Fuente, O.R.; Marín, P.; Molina-Cardín, A.; et al. Further progress in the study of epsilon iron oxide in archaeological baked clays. Phys. Earth Planet. Inter. 2020, 307, 106554. [Google Scholar] [CrossRef]

- Corbellini, L.; Lacroix, C.; Harnagea, C.; Korinek, A.; Botton, G.A.; Ménard, D.; Pignolet, A. Epitaxially stabilized thin films of ϵ-Fe2O3 (001) grown on YSZ (100). Sci. Rep. 2017, 7, 3712. [Google Scholar] [CrossRef] [PubMed]

- Kiyokawa, T.; Ikenaga, N. Oxidative dehydrogenation of n-butene to buta-1,3-diene with novel iron oxide-based catalyst: Effect of iron oxide crystalline structure. Mol. Catal. 2021, 507, 111560. [Google Scholar] [CrossRef]

- López-Sánchez, J.; McIntosh, G.; Osete, M.L.; del Campo, A.; Villalaín, J.J.; Pérez, L.; Kovacheva, M.; de la Fuente, O.R. Epsilon iron oxide: Origin of the high coercivity stable low Curie temperature magnetic phase found in heated archeological materials. Geochem. Geophys. Geosystems 2017, 18, 2646–2656. [Google Scholar] [CrossRef]

- Kosterov, A.; Kovacheva, M.; Kostadinova-Avramova, M.; Minaev, P.; Salnaia, N.; Surovitskii, L.; Yanson, S.; Sergienko, E.; Kharitonskii, P. High-coercivity magnetic minerals in archaeological baked clay and bricks. Geophys. J. Int. 2021, 224, 1256–1271. [Google Scholar] [CrossRef]

- Tao, S.; Liu, S.; Yuan, Y.; Dong, J.; Li, Q. A Microstructural and Compositional Study of ε-Fe2O3 Crystals in the Hare’s Fur Jian Ware. Crystals 2022, 12, 367. [Google Scholar] [CrossRef]

- Jeon, B.; Van Overmeere, Q.; Van Duin, A.C.T.; Ramanathan, S. Nanoscale oxidation and complex oxide growth on single crystal iron surfaces and external electric field effects. Phys. Chem. Chem. Phys. 2013, 15, 1821–1830. [Google Scholar] [CrossRef]

- Jiang, Y.; Bu, S.; Zhou, D.; Shi, X.; Pan, F.; Ji, Q.; Niu, T. Two-Dimensional Iron Oxide on Au(111): Growth Mechanism and Interfacial Properties. J. Phys. Chem. C 2021, 125, 24755–24763. [Google Scholar] [CrossRef]

- Menecier, S.; Valette, S.; Denoirjean, P.; Lefort, P. Invar oxidation in CO2:Kinetics and mechanism of formation of a wustite layer. J. Therm. Anal. Calorim. 2012, 107, 607–616. [Google Scholar] [CrossRef]

- Prabowo, S.W.; Longbottom, R.J.; Monaghan, B.J.; del Puerto, D.; Ryan, M.J.; Bumby, C.W. Phase transformations during fluidized bed reduction of New Zealand titanomagnetite ironsand in hydrogen gas. Powder Technol. 2022, 398, 117032. [Google Scholar] [CrossRef]

- Tanaka, R.; Sakamaki, T.; Ohtani, E.; Fukui, H.; Kamada, S.; Suzuki, A.; Tsutsui, S.; Uchiyama, H.; Baron, A.Q.R. The sound velocity of wüstite at high pressures: Implications for low-velocity anomalies at the base of the lower mantle. Prog. Earth Planet. Sci. 2020, 7, 23. [Google Scholar] [CrossRef]

- Wang, M.; Kobayashi, Y.; Endo, R.; Susa, M. Formation kinetics of iron oxide in mould flux during continuous casting. ISIJ Int. 2013, 53, 56–61. [Google Scholar] [CrossRef]

- Wei, Z.; Zhang, J.; Qin, B.; Dong, Y.; Lu, Y.; Li, Y.; Hao, W.; Zhang, Y. Reduction kinetics of hematite ore fines with H2 in a rotary drum reactor. Powder Technol. 2018, 332, 18–26. [Google Scholar] [CrossRef]

- Chen, Z.; Chou, K.C.; Morita, K. Mechanism of metastable Wüstite formation in the reduction process of iron oxide below 570 °C. Mater. Trans. 2016, 57, 1660–1663. [Google Scholar] [CrossRef]

- Vasylkiv, O.; Bezdorozhev, O.; Sakka, Y. Synthesis of iron oxide nanoparticles with different morphologies by precipitation method with and without chitosan addition. J. Ceram. Soc. Jpn. 2016, 124, 489–494. [Google Scholar] [CrossRef]

- Manikandan, A.; Vijaya, J.J.; Mary, J.A.; Kennedy, L.J.; Dinesh, A. Structural, optical and magnetic properties of Fe3O4 nanoparticles prepared by a facile microwave combustion method. J. Ind. Eng. Chem. 2014, 20, 2077–2085. [Google Scholar] [CrossRef]

- Cabrera, L.; Gutierrez, S.; Menendez, N.; Morales, M.P.; Herrasti, P. Magnetite nanoparticles: Electrochemical synthesis and characterization. Electrochim. Acta 2008, 53, 3436–3441. [Google Scholar] [CrossRef]

- Kim, D.W.; Kim, T.H.; Choi, S.; Kim, K.S.; Park, D.W. Preparation of silica coated iron oxide nanoparticles using non-transferred arc plasma. Adv. Powder Technol. 2012, 23, 701–707. [Google Scholar] [CrossRef]

- Kamura, A.; Idota, N.; Sugahara, Y. Nonaqueous synthesis of magnetite nanoparticles via oxidation of tetrachloroferrate anions by pyridine-N-oxide. Solid State Sci. 2019, 92, 81–88. [Google Scholar] [CrossRef]

- Pedrosa, J.; Costa, B.F.O.; Portugal, A.; Durães, L. Controlled phase formation of nanocrystalline iron oxides/hydroxides in solution—An insight on the phase transformation mechanisms. Mater. Chem. Phys. 2015, 163, 88–98. [Google Scholar] [CrossRef]

- Samulewski, R.B.; Gonçalves, J.M.; Urbano, A.; Da Costa, A.C.S.; Ivashita, F.F.; Paesano, A.; Zaia, D.A.M. Magnetite synthesis in the presence of cyanide or thiocyanate under prebiotic chemistry conditions. Life 2020, 10, 34. [Google Scholar] [CrossRef]

- Shen, L.; Qiao, Y.; Guo, Y.; Tan, J. Preparation and formation mechanism of nano-iron oxide black pigment from blast furnace flue dust. Ceram. Int. 2013, 39, 737–744. [Google Scholar] [CrossRef]

- Sun, S.; Gebauer, D.; Cölfen, H. Alignment of Amorphous Iron Oxide Clusters: A Non-Classical Mechanism for Magnetite Formation. Angew. Chem.-Int. Ed. 2017, 56, 4042–4046. [Google Scholar] [CrossRef] [PubMed]

- Suppiah, D.D.; Abd Hamid, S.B. One step facile synthesis of ferromagnetic magnetite nanoparticles. J. Magn. Magn. Mater. 2016, 414, 204–208. [Google Scholar] [CrossRef]

- Demirbas, A.; Kislakci, E.; Karaagac, Z.; Onal, I.; Ildiz, N.; Ocsoy, I. Preparation of biocompatible and stable iron oxide nanoparticles using anthocyanin integrated hydrothermal method and their antimicrobial and antioxidant properties. Mater. Res. Express 2019, 6, 125011. [Google Scholar] [CrossRef]

- Tahirbegi, I.B.; Pardo, W.A.; Alvira, M.; Mir, M.; Samitier, J. Amyloid Aβ42, a promoter of magnetite nanoparticle formation in Alzheimer’s disease. Nanotechnology 2016, 27, 465102. [Google Scholar] [CrossRef]

- Baumgartner, J.; Morin, G.; Menguy, N.; Gonzalez, T.P.; Widdrat, M.; Cosmidis, J.; Faivre, D. Magnetotactic bacteria form magnetite from a phosphate-rich ferric hydroxide via nanometric ferric (oxyhydr)oxide intermediates. Proc. Natl. Acad. Sci. USA 2013, 110, 14883–14888. [Google Scholar] [CrossRef] [PubMed]

- Sugimoto, T.; Matijević, E. Formation of uniform spherical magnetite particles by crystallization from ferrous hydroxide gels. J. Colloid Interface Sci. 1980, 74, 227–243. [Google Scholar] [CrossRef]

- Brunner, J.; Baburin, I.A.; Sturm, S.; Kvashnina, K.; Rossberg, A.; Pietsch, T.; Andreev, S.; Sturm, E.; Cölfen, H. Self-Assembled Magnetite Mesocrystalline Films: Toward Structural Evolution from 2D to 3D Superlattices. Adv. Mater. Interfaces 2017, 4, 1600431. [Google Scholar] [CrossRef]

- Costa, R.C.C.; Moura, F.C.C.; Ardisson, J.D.; Fabris, J.D.; Lago, R.M. Highly active heterogeneous Fenton-like systems based on Fe0/Fe3O4 composites prepared by controlled reduction of iron oxides. Appl. Catal. B Environ. 2008, 83, 131–139. [Google Scholar] [CrossRef]

- Crowley, T.A.; Ziegler, K.J.; Lyons, D.M.; Erts, D.; Olin, H.; Morris, M.A.; Holmes, J.D. Synthesis of metal and metal oxide nanowire and nanotube arrays within a mesoporous silica template. Chem. Mater. 2003, 15, 3518–3522. [Google Scholar] [CrossRef]

- Fredrickson, J.K.; Zachara, J.M.; Kennedy, D.W.; Dong, H.; Onstott, T.C.; Hinman, N.W.; Li, S.M. Biogenic iron mineralization accompanying the dissimilatory reduction of hydrous ferric oxide by a groundwater bacterium. Geochim. Cosmochim. Acta 1998, 62, 3239–3257. [Google Scholar] [CrossRef]

- Fujioka, N.; Suzuki, M.; Kurosu, S.; Kawase, Y. Linkage of iron elution and dissolved oxygen consumption with removal of organic pollutants by nanoscale zero-valent iron: Effects of pH on iron dissolution and formation of iron oxide/hydroxide layer. Chemosphere 2016, 144, 1738–1746. [Google Scholar] [CrossRef] [PubMed]

- Atta, A.M.; El-Saeed, A.M.; El-Mahdy, G.M.; Al-Lohedan, H.A. Application of magnetite nano-hybrid epoxy as protective marine coatings for steel. RSC Adv. 2015, 5, 101923–101931. [Google Scholar] [CrossRef]