Abstract

Agricultural systems must identify fertilization strategies in line with the principles of sustainable development and the circular economy to achieve environmentally friendly food production and to meet the fertilizer-reduction targets set by some territories, such as the European Union (EU). The objective of this work was to identify the multifunctionality and cost-effectiveness in the use of the biodisinfection technique in greenhouse horticultural crops. For this purpose, a cost comparison of the different cultivation strategies was conducted, based on a systematic review of the existing literature. The results of this work suggest that the biodisinfection of soil containing agricultural biomass serves as a fertilization strategy that allows a reduction in a large part of inorganic fertilizers in protected horticultural crops of intensive nature, in addition to mitigating the expression of soil pathogens. Reducing the use of fertilizers and phytosanitary products, management fees, and important means of production, such as water, allows a reduction of up 6.1% in production costs. The biodisinfection technique is a methodology that can promote circularity in farms while favoring the use of waste, such as agricultural biomass, which can damage the environment when not properly treated.

1. Introduction

Agriculture has generated serious environmental impacts on ecosystems, mainly since the middle of the 20th century with the advent of the Green Revolution [1]. The primary negative impacts include erosion, loss of genetic diversity, loss of quality of water bodies (above and below ground), emission of greenhouse gases, and ozone layer degradation, among others [2,3,4,5,6,7].

Environmental damage has been caused by the intensification of production processes, which have expanded dependence on inputs such as fertilizers, phytosanitary products, and energy. This has led to increased consumption of natural resources and polluted ecosystems. The objective of this intensification was to expand the carrying capacity of the planet to supply food and fiber to a steadily increasing population. We are currently in a similar situation where productivity needs to be increased again as the world population is expected to reach 9.7 billion in 2050 [1,8].

However, despite the similarity of the situations discussed above, the production principle has changed. Today, there is a desire to produce food in a way that increases field productivity while reducing dependence on agri-food inputs and respecting ecosystem and socioeconomic balances [9]. This approach derives from the international agreements reached by the United Nations (UN) member states through the 2030 Agenda signed in 2015. This document brings together the main economic, social, and environmental issues on a global scale through the 17 Sustainable Development Goals (SDGs) and their 169 targets. The sustainability of agricultural production is reflected in several SDGs, but mainly in the second and twelfth [10].

Faced with this situation, several countries have reformulated their structural policies. The EU has positioned itself as a vanguard territory and has published several ambitious strategies and action plans [11]. These include the European Green Pact, which seeks environmental neutrality by 2050 while aiming to make its net carbon emissions disappear [12], and the implementation of an economic system based on the circular economy that seeks to reduce the consumption of inputs, reuse by-products generated in production processes, and recycle the waste that is generated [13,14]. Spain is one of the most advanced territories regarding the implementation of the circular economy [15].

Despite this radical change, the EU has divided it into phases. The first phase ends in 2030. In this period, agriculture is and will be affected by the Farm-to-Table and Biodiversity Strategies, with a 20% reduction in fertilizer usage and a 50% reduction in pesticides projected, as well as an expansion of organic farming to 25% of agricultural fields, and the maintenance of biodiversity [16,17]. These objectives imply that farmers must get rid of inputs that have been in place for more than six decades. Farmers must, therefore, be offered tools to cope with the proposed paradigm shift, particularly regarding the reduction in soil fumigants and fertilizers, in order not to reduce the profitability and productivity of agricultural systems and not to compromise the sovereignty and food security of the European territory [18,19]. The European Parliament has recently approved the Nature Restoration Law, which aims to restore 20% of degraded ecosystems by 2030 and practically 100% by 2050. This law will establish binding, mandatory, and common objectives among EU Member States, which may affect the use of agrochemicals. The main professional agricultural organizations at the European level (Copa-Cogeca and Europêche) have indicated that it is necessary to identify effective and feasible alternatives to avoid decreased productivity of agricultural fields before establishing such drastic measures. One of the measures proposed in the new law is the obligation to leave 10% of agricultural land as biodiversity reservoirs. For this reason, it is of great interest to identify and communicate the benefits of production techniques that help achieve this objective without reducing crop yields [20,21,22].

Greenhouse production models are one of the agricultural systems that may be affected by this change [18], although these systems are one of the alternatives that will safeguard food sovereignty and security in the Eurozone and other parts of the world. About 210,000 hectares of greenhouses have been identified in the EU, with a concentration of 76,000 hectares in Spain. In the Spanish territory, the main production area is the southeastern portion of the peninsula, where the province of Almeria concentrates 32,827 hectares [23,24,25]. Almeria’s protected production system specializes in the horticultural production of eight products (tomato, sweet pepper, watermelon, cucumber, eggplant, melon, zucchini, and bean) and accounts for 6.5% of the EU’s horticultural production. The Almeria horticultural system is the sixth-largest vegetable producer in Europe, generating more merchandise than 22 EU Member States [18,26,27,28]. The productive importance of the Almeria Model leads it to generate an estimated income of EUR 2200 million per year, making protected agriculture and its auxiliary industry Almeria’s socioeconomic engine [29,30].

In addition, the production techniques used in protected agriculture in Almeria make it an agri-food system with a smaller energy footprint than other greenhouse systems in the EU, which is possible thanks to the benevolent climate and the use of greenhouses without climate control [30,31]. Agriculture in Almeria is based in the framework of integrated production and agro-ecological techniques, such as biological control [32].

However, the Almeria Model has some negative externalities. For example, the management and subsequent treatment of agricultural biomass were some of the main problems that afflicted the protected Almeria model at the end of the 20th century because of the indiscriminate dumping of this material in natural areas. Nowadays, although the situation has improved significantly, some significant problems regarding the management of the residual agricultural biomass have been identified [33]. To begin with, there is high production volume (i.e., 1.8 million tons per year), which is seasonal given that about 80% of the organic material is generated in only three months (February, May, and June). This issue prevents adequate sizing of the management plants. In addition, farms are located far from the production centers, which generates increased costs for the transport of the material. Finally, vegetal debris is usually mixed with other products, mainly plastic waste (i.e., raffia and rings for grooving) [34], complicating its management even further. Thus, some of the alternatives studied to solve the problem do not offer an adequate solution to this issue (i.e., bioenergy or animal feed) [35,36]. The EU has defined agricultural biomass as wasted material [37], that being the main agricultural waste generated in protected agri-food systems and surpassing plastics [38].

Because of the need for sustainable production with low dependence on fertilizers to promote circularity, several previous studies have tried to develop a fertilization strategy adapted to horticultural crops in the southeast of the Iberian Peninsula through the use of agricultural biomass on the farm, which can be extrapolated to other agri-food systems. This fertilization plan consists of nourishing crops with nutrients obtained from the agricultural biomass generated in the same shed using the biodisinfection technique. The communication of the technical and economic benefits of these techniques has focused mainly on the long-cycle tomato crop, and they have not been identified in other horticultural crops [18,39].

In this context, the objective of this research was to identify the fertilization capacity of the biodisinfection technique in soils both affected and unaffected by telluric diseases to be used as an alternative in the southeastern portion of the Iberian Peninsula to the reduction in fertilizers proposed by the EU. This study also aimed to verify the effects of the biodisinfection technique on the decrease in production costs in the cultivation of tomato, sweet pepper, and watermelons.

To this end, this article is subdivided into the following sections. First, the methodology is described. Next, the theoretical framework is indicated, characterizing the productive benefits of soil biodisinfection in horticultural crops. Then, a cost analysis of the use of the biodesinfection technique utilizing the agricultural biomass generated in the same greenhouse is presented. Finally, the conclusions are presented.

2. Materials and Methods

2.1. General Technical Characteristics of Greenhouse Agriculture in Almeria

This study identified the fertilization capacity of the biodesinfection technique in protected agriculture in Almeria. This production system is characterized by intensive agriculture under a greenhouse that combines the execution of crops per season in a long cycle (i.e., a 320-day-after-transplanting (DAT) crop) or in two short cycles (i.e., two crops of 160 DAT each) [18,40]. This protected cultivation system specializes in producing eight vegetable species: tomato, sweet pepper, watermelon, zucchini, cucumber, eggplant, melon, and beans. Several sustainable techniques, such as integrated pest and disease control, biological control, and grafting, are implemented in the production process [30]. In addition, solarization is used by 95.2% of farmers, either as the principal method or in combination with chemical fumigants [41].

Before describing the biodisinfection techniques and their effect on crop productivity, it is necessary to define the concept of “solarization” because of its close relationship with the aforementioned techniques [18]. This method is widely used for soil disinfection. For example, in greenhouse agriculture in Almeria, it is used [41,42].

The production follows international standards such as GLOBALGAP [29,32,43], although organic production represents almost 10% of the greenhouse area [44].

In addition, due to its benevolent climatic conditions, production is carried out in greenhouses that do not require climatic correction, as opposed to other European greenhouse systems, which require more energy [31]. Crops are grown in “raspa y amagado”-type modules. The predominant productive structures in the long cycles have heights of 6.0, 5.0, and 4.7 m at the ridge, under the canal, and in the trellis, respectively, while the short cycles have heights of 4.5, 3.5, and 3.0 at the ridge, under the canal, and in the trellis, respectively. These structures have lateral windows around the perimeter and zenithal windows on the ridge. The irrigation system consists of high-frequency irrigation equipment with emitters having a nominal flow rate of 3 L·h−1 and an irrigation controller consisting of five tanks where the inorganic or ecological fertilizers added through the fertigation equipment are deposited. Pest and disease control follows the Integrated Production regulations, except in farms that produce under the Organic Production regulations. The climate control in the sheds has a passive character thanks to the benevolent climate of Almeria, so it requires less energy than other European greenhouse production systems [30,32,40,45].

2.2. Systematic Literature Review

First, a systematic review of the scientific literature was performed. This procedure allows for synthesizing information on a specific topic [46,47]. This step aimed to describe biodisinfection techniques and their benefits on crop yield, both in disease and disease-free soils, and in crops with and without the addition of inorganic fertilizers. The literature review was performed using the “snowball” or ”chain of references method” [48].

In this process, we used scientific literature published in English and submitted to a peer-review process before publication. The database used was Scopus [49], The terms introduced were biodisinfection, biosolarization, biofumigation, solarization, or their synonyms. The bibliographic review focused on publications that analyzed their effect on horticultural crops. In addition, publications derived from field trials performed at the “Catedrático Eduardo Fernández” Experimental Farm of the UAL-ANECOOP Foundation were reviewed. These works addressed the evaluation of a fertilization strategy based exclusively on the use of agricultural biomass with the application of the biodisinfection technique [18,39,50,51]. The literature review was carried out from January to March 2023.

2.3. Cost Analysis

Furthermore, an economic impact analysis was performed to identify the influence and economic benefits of using agricultural biomass with biodisinfection in the horticultural system of Almeria, the most important agricultural production area in the southeast of the peninsula. For this purpose, an analysis of total and partial costs was used. The study parameters selected were partial and total fixed and variable costs, as recommended in previous research [18,52,53,54,55,56,57,58,59,60,61,62,63].

The crops chosen were tomato in a long cycle, serving as a reference value [18]; the alternative of tomato and watermelon crops, both in a short cycle; and the alternative of sweet pepper and watermelon crops, also in a short cycle (Table 1). These three crop alternatives were evaluated via two production methods, conventional production (C), described by Camacho-Ferre [40], and via the production method using soil biodisinfection with the use of agricultural biomass (A) (100% reduction in fertilizer, 100% reductions in the use of chemical soil fumigants, 37.2% decrease in water consumption, elimination of external management costs of agricultural biomass). These criteria were used because they were recommended in previous research [18]. Table S1 shows the specific production criteria for each plant species.

Table 1.

Species and crops evaluated.

Cost Structure

We used the same cost structure as the Experimental Farm “Catedrático Eduardo Fernández” of the UAL-ANECOOP Foundation. The production costs for the cultivation of the plant species evaluated in this work were obtained from those reported by Camacho-Ferre and Toresano [64] for the economic valuation carried out for Agroseguros, S.A. This entity specializes in managing insurance on behalf of the insurance companies that are part of the coinsurance pool [65]. The procedure for determining production costs has been described in previous research. To calculate the costs, the means of production and demand for specific inputs for the production model are used [18], as indicated in Section 2.1. All production costs used in this research were obtained under the same production criteria. Therefore, they are comparable to each other. The values were updated to current prices through the ECOICOP Index [66]. The value of the total cost of cultivation was calculated by the sum of fixed and variable costs using the following mathematical expression:

TC = VC + FC,

- -

- TC: total costs (EUR/ha·year);

- -

- VC: variable costs (EUR/ha·year);

- -

- FC: fixed costs (EUR/ha·year).

In addition, the rate of variation was calculated:

- -

- RC: variation rate (%);

- -

- IV: initial value (EUR/ha·year);

- -

- FV: final value (EUR/ha·year).

3. Theoretical Framework

3.1. Biodesinfection Techniques

3.1.1. Soil Solarization

The solarization technique was originally used by Israeli farmers during the second-half of the 20th century and was described by Katan et al. [67]. The authors used a transparent plastic sheet with a thickness of 0.03 mm to reduce the expression of two pathogenic organisms that they had introduced into the soil before spraying in a greenhouse in Israel. The inoculum consisted of Fusarium oxysporum f. sp. lycopersici and Verticillum dahliae. After completing the soil disinfection and carrying out their respective analyses, they obtained a reduction in microbial populations in the first few centimeters of the soil and also a decrease in the severity index of the disease and increased plant growth. This research triggered a series of trials in different parts of the world to test the effect of this technique on crop productivity under different conditions [68]. The technique can be applied both in open-air and greenhouses. In the latter, it can be used directly on natural soil or organic and inorganic substrates [18,39,69,70,71].

Solarization is a physical soil-disinfection protocol that consists of hydrothermally fumigating the soil through solar energy captured in the surface layer of the soil (0–30 cm) and its humidity. For its execution, the soil to be treated must be conditioned before applying the fumigant treatment. To do so, the land has to be labeled beforehand as it is necessary to uninstall the irrigation system if it exists. After preparing the soil and reinstalling the irrigation system, it is necessary to check the correct emission of water due to the importance of wetting the soil profile for the process. Afterward, the soil is covered with a thin and transparent plastic sheet (about 100 gauges). Once the sheet has been sealed between its perimeter and it is confirmed that there are no air pockets that may reduce the thermal conductivity, irrigation is applied at field capacity. The process should be maintained for 4 to 6 weeks and it is recommended that it be carried out during the summer due to the higher radiation present during this period [18,39,50,67,68,72]. After irrigation, the temperature of the upper-soil profile rises and can exceed 60 °C in greenhouse conditions, provided that there is adequate humidity and heat transfer so that the nocturnal temperature drop is not high [73]. This technique limits the development and expression of pathogens that limit crop productivity. In addition, this control technique is non-hazardous, non-toxic, simple, and economical. Further, it can be combined with chemical fumigants or organic amendments. Ultimately, it enables a reduction in chemical disinfectants, facilitates the expansion of the circular economy within farms, and increases the sustainability of food production [18,30,67,71].

3.1.2. Soil Biodisinfection

This protocol can be subdivided into:

- Biofumigation

Biofumigation is soil disinfection caused by volatile substances generated during the bio-decomposition of organic amendments that have been previously mixed and moistened in the upper-soil profile (0–30 cm). It was initially called biological fumigation and was described by Kirkegaard et al. [74] and renamed biofumigation by the same authors in later works [75]. The researchers observed an increase in the productivity of the evaluated crop after biofumigating the soil due to the mitigation of the disease that limited the crop productivity. Thus, the authors used green manure composed of Brassicas plants as an organic amendment and attributed the suppressive effect to the liberation of isothiocyanates produced during the hydrolysis of glucosinolates generated by the enzyme myrosinase. This process has a fumigant effect similar to metam-sodium, a broad-spectrum chemical disinfectant that generates methyl-isothiocyanate [7,76,77]. Another noteworthy feature is that isothiocyanates have variable effectiveness during fumigation since the maximum concentration is produced in the first hours of bio-decomposition [78], specifically in a period ranging from 5 to 8 days after application [79]. A rapid decrease in concentration is observed as a result of isothiocyanates not being able to retain the volatile substances in the soil. In addition, the effectiveness of the technique in arid climates can be reduced by the higher evapotranspiration of the soil, which limits the bio-decomposition of organic nutrients and leads to an increase in the water supply needed to maintain adequate humectation [80]. Soil texture can also harm its efficacy: clay soils are more effective in the hydrolysis of glucosinolates than sandy soils [7].

- Biosolarization

The fact that the biofumigation technique is not suitable for all agricultural fields led to the combination of solarization and biofumigation techniques. The main problem of biofumigation was the retention of gases released during the bio-decomposition of organic amendments and the maintenance of adequate humidity conditions, which was solved with the plastic cover. This led to biosolarization, which allows for the retention of mobile nutrients in the soil, such as nitrates, due to the lower water supply, thus protecting the environment and improving the sustainability of agricultural systems [72,80].

The biosolarization technique can be defined as the hyperthermic fumigant action obtained from the solar energy captured by a plastic film, previously installed on the soil surface and sealed around its entire perimeter, and from the energy released by the metabolism of the microorganisms that participate in the bio-decomposition process of the organic amendments, in combination with the disinfectant action harvested by the volatile substances generated during this bio-decomposition and retained by the plastic film [18,19,72,81,82,83]. Table 2 shows a comparison of the soil temperature after solarization and biosolarization in a net greenhouse in the Canary Islands. The combination of organic amendments and solarization increases the soil temperature in each parameter evaluated and the number of hours where the soil temperature at 10 cm depth is higher than 40 °C. Another example has been recorded in the protected horticultural system of Almeria, where the biosolarization technique can cause a temperature increase of up to 5 °C compared to solarization [84]. The biosolarization technique has been described as a suitable methodology to reduce the expression of diseases of edaphic origin. A list of diseases controlled via the biosolarization technique is shown in Table 3.

Table 2.

Soil temperature reached via solarization and biosolarization vs. control treatment.

Table 3.

Soil diseases controlled via soil biosolarization.

The action time of the biosolarization technique is around four weeks in Mediterranean conditions, although it can be up to 12 weeks [18,19,39,72]. During this period, two differentiated phases occur based on the oxygen concentration in the atmosphere generated under plastic. First, an anaerobic phase takes place. During this phase the microorganisms consume the carbon in the organic compounds and the oxygen in the soil while triggering a significant rise in temperature and a large release of carbon dioxide and water. After this release, the expansion of aerobic microorganisms stops and the metabolism of those that develop under anaerobic conditions begins to increase. During the anaerobic phase, compounds such as organic acids (e.g., acetic acid and butyric acid), ammonium, or nitrous acid are generated [81,97,98,99]. The anaerobic phase of biosolarization has also been named Biological Soil Disinfection, Aerobic Soil Disinfection, and Reductive Soil Disinfection [90,100,101].

- Useful organic amendments in the process

The organic amendment originally used in the biodisinfection process was agricultural biomass obtained from plants of the Brassicas genus, as indicated above. The variable presence of glucosinolates in plants of the Brassicaceae genus led to the evaluation of different plant species to identify the one that released the greatest amount of the compound. For this purpose, Brassica campestris, Brassica carinata, Brassica juncea, Brassica napus [78], Brassica nigra, Brassica oleracea, Raphanus sativus, and Sinapsis alba, among others, were studied [74,75,78,102,103,104]. The conclusion was that Brassica carinata releases the highest amount of the fumigant molecule, which has led to the formulation of commercial products composed of this plant species.

Different authors have evaluated the disinfection capacity of different organic amendments (manure, agro-industrial waste, plant residue, green manure, etc.) versus the efficacy of Brassica carinata pellets and chemical disinfectants. Research results show that manure, agro-industrial residue, plant remains, and green manure achieve similar effects to Brassica carinata pellets and chemical disinfectants [71,86,87]. Guerrero et al. [86] obtained this result in a sweet-pepper crop affected by Phytophthora capsici and phytopathogenic nematodes of the genus Meloidogyne. In this case, their biosolarized treatment with 2.5 kg·m−2 of fresh sheep manure showed total commercial productivity similar to biosolarization with Brassica carinata pellets and higher than the control group disinfected with methyl bromide for two consecutive crops. This was also shown by García-Ruiz et al. [70] in a carnation crop affected by Fusarium oxysporum f. sp. dianthi, where biosolarization with 5 kg·m−2 of compost consisting of carnation and chrysanthemum residues and 5 kg·m−2 of chicken manure resulted in a significantly lower mortality rate compared to the control treatment disinfected with methyl bromide during 672 days of cultivation. These results are due to the reduction in NO3−, Mn4+, Fe3+, and SO42− during the bio-decomposition of organic amendments, mainly in the anaerobic phase. This process generates various gases (ammonia, hydrogen sulfide, and nitrous oxide) and organic acids (butyric, maleic, lactic, acetic, citric, and propionic), thus resulting in the control of weeds, pathogens, and pests [105,106,107]. Table 4 identifies a list of organic amendments that have been used in biodesinfection with favorable results. Agricultural residues are suitable for use as an organic amendment, favoring the reuse of by-products within the framework of the circular economy and improving the management of agricultural residues, which has been a major problem in many agricultural systems [18,19,35,51,108].

Table 4.

Organic amendments and doses used in biodisinfection.

The capacity to control pathogens limiting the productivity of different crops has resulted in biodisinfection techniques, mainly biosolarization (Table 3), to trigger strong increases in crop productivity and plant vigor compared to the non-disinfected plot. However, in some experiments, the increase in productivity has been greater than that achieved in the control disinfected with a chemical fumigant [116]. In this regard, Guerrero-Díaz et al. [94] obtained an increase in the commercial production of a sweet-pepper crop affected by the phyto-parasitic Meloidogyne incógnita after biosolarizing with 0.3 kg·m−2 of Brassica carinata pellets versus plots fumigated with methyl bromide. Guerrero et al. [86] achieved the same increase in productivity during two consecutive years in a sweet-pepper crop affected by Meloidogyne incognita and Phytophthora capsici via a biosolarization treatment with 0.3 kg·m−2 of Brassica carinata pellets and via another biosolarization treatment with 2.5 kg·m−2 of fresh sheep manure. Table 5 shows a list of crops where biodisinfection has increased productivity compared to the control treatment without disinfection and has equaled or surpassed the control treatment disinfected with a chemical fumigant.

Table 5.

List of crops where biodisinfection has increased crop productivity in soils affected by soil-borne pathogens vs. undisinfected treatment.

The benefits of soil biodisinfection on crop productivity also extend to crops with good soil health and not affected by any soil pathology. These results were reported by Mauromicale et al. [127,128] and Marin-Guirao et al. [72]. In this sense, Mauromicale et al. [127,128] recorded an increase in the commercial production of various tomato crops grown in a greenhouse after biosolarizing their experimental plots compared to plots that were only solarized. Furthermore, Marín-Guirao et al. [72] observed an increase in the total and commercial production of a tomato crop grown under greenhouse conditions after applying biosolarization versus biofumigation. The production benefit disappeared in the watermelon crop grown in the same season after the autumn tomato-crop cycle. The authors did not repeat the soil biodisinfection in the following season and obtained the productivity increase in either the autumn tomato or the spring watermelon cycles. Therefore, this benefit could be due to a possible improvement in soil fertility, which benefits the crop grown immediately after the application of biosolarization [39].

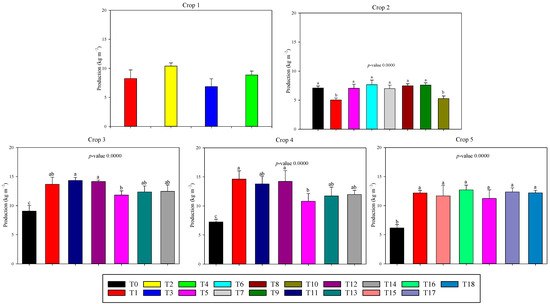

The fertilizing power of soil biodisinfection could have been masked in such investigations by the fertigation applied during their production cycles [72,127,128]. In this regard, Castillo-Diaz et al. [18,129] showed the results of a trial in an experimental greenhouse located in the protected agriculture of southeastern Spain (Almería, Spain) where biodesinfection was applied during five consecutive agricultural seasons, the use of tomato agricultural biomass predominated, and soil solarization (combined or not with fertigation) was performed. During the first two years, cycles of up to 170 days after transplanting (DAT) were carried out, which was equivalent to a short production cycle. During the remaining three years, the production cycles were extended up to 217 DAT, which is equivalent to a long production cycle. Their results show that biosolarization without fertigation yielded similar productivity during the five years of cultivation in cycles of up to 170 DAT compared to conventional cultivation composed of solarization and fertigation. Regarding the cycles of up to 217 DAT, they obtained similar productivity in two of the three cycles. However, these authors point out that the production difference between the exclusive fertilization with biosolarization and the combination of solarization and fertigation, in favor of the latter, in one of the campaigns, was due to an uncontrollable epidemic of Botrytis cinerea that emerged from 160 DAT and caused the death of up to 80% of the plants in each experimental plot. Figure 1 summarizes the results of the experiments carried out by these authors [18,129].

Figure 1.

Final production of various tomato crops where biosolarization and solarization were applied with or without fertigation. Note: all treatments were solarized. T0: Without fertilization; T1: Fertigation; T2: 2 kg·m−2 of chicken manure; T3: 2 kg·m−2 of chicken manure + 5 kg·m−2 of vegetable waste; T4: 5 kg·m−2 of tomato plant remains; T5: 3.5 kg·m− 2 of tomato plant remains; T6: 1.6 kg·m−2 of radish plant remains; T7: 2 kg·m−2 of mustard plant remains; T8: 0.3 kg·m−2 of Brassica carinata pellets, T9: 0.8 kg·m−2 of broccoli; T10: Fertigation + 0.3 kg·m−2 of Brassica carinata pellets; T11: fertigation + 0.5 kg·m−2 of Brassica carinata pellets; T12: fertigation + 1.0 kg·m−2 of Brassica carinata pellets; T12: 3.5 kg·m−2 of fresh-tomato plant remains; T13: 3.5 kg·m−2 of fresh-tomato plant remains + 0.5 kg/m−2 of Brassica carinata pellets; T14: 3.5 kg·m−2 of fresh-tomato plant remains + 1.0 kg/m−2 of Brassica carinata pellets; T15: fertigation + 3.5 kg·m−2 of fresh-tomato plant remains; T16: fertigation + 5.0 kg·m−2 of fresh-tomato plant remains; T17: 5.0 kg·m−2 of fresh-tomato plant remains; T18: 6.5 kg·m−2 of fresh-tomato plant remains. Different letters indicate significant differences (p ≤ 0.05; Tukey HDS Test). Source: own elaboration based on other authors [18,129].

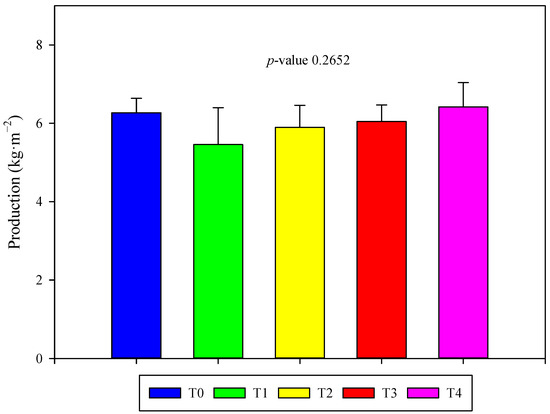

Other authors observed similar results in a sweet-pepper crop under greenhouse in southeastern Spanish agriculture (Almeria, Spain) [100]. These authors used papaya residues, combined with coconut fiber, to which they applied the biodisinfection technique, without using any inorganic fertilizer. The results were compared with the final production obtained by the sector in the last six years (2016–2021) in short cycles of 199 DAT (Figure 2). In any case, no statistically significant differences were observed.

Figure 2.

Final production of a sweet-pepper crop fertilized with papaya plant debris versus treatment without fertilization and average productivity of the protected-agriculture sweet pepper in the province of Almeria in production cycles of 199 DAT. T0: average productivity of protected-agriculture sweet pepper of Almeria modulated at 199 DAT from 2016 to 2021. T1: 5 kg·m−2 of papaya plant debris; T2: 5 kg·m−2 of papaya and 7 kg·m−2 of coconut fiber; T3: 10 kg·m−2 of papaya and 7 kg·m−2 of coconut fiber; T4: 15 kg·m−2 of papaya and 7 kg·m−2 of coconut fiber. Different letters indicate significant differences (p ≤ 0.05; Tukey HDS test). Note: The crop was grown in a multitunnel greenhouse and a 59-day biodisinfection procedure was applied between May and June. Source: Own elaboration based on other authors [28,51,130].

The results show the multifunctionality of the soil-biodisinfection technique, which, besides being a useful method to mitigate telluric diseases, affects the fertilization of horticultural crops and allows for a reduction of up to 100% of the synthetic fertilizers normally used in production cycles of up to 217 DAT in intensive-production models, such as protected agriculture of a horticultural nature in southeastern Spain. Moreover, due to the diversity of organic amendments that can be used in the process (Table 4), it facilitates the management of the agricultural biomass recurrently generated at the end of crop cycles. Thus, this technique is a high-value resource for farms because it reduces dependence on fertilizers by applying the principles of the circular economy. This is in line with the EU Farm-to-Table Strategy. In addition, the biodisinfection technique is necessary when reusing agricultural biomass. This organic material is affected by pests and diseases that normally affect plant species during the crop cycle, so these must be inactivated to ensure the plant’s health during the next crop, which is achieved with this procedure. Repeated application of the biodisinfection technique does not reduce the density or the biodiversity of agricultural soils. This is because the microorganisms can re-establish themselves at the end of each crop cycle at a similar level to that shown before applying the fumigant treatment, thus respecting the principles indicated in the EU Biodiversity Strategy [16,39].

4. Results and Discussion

Cost Analysis

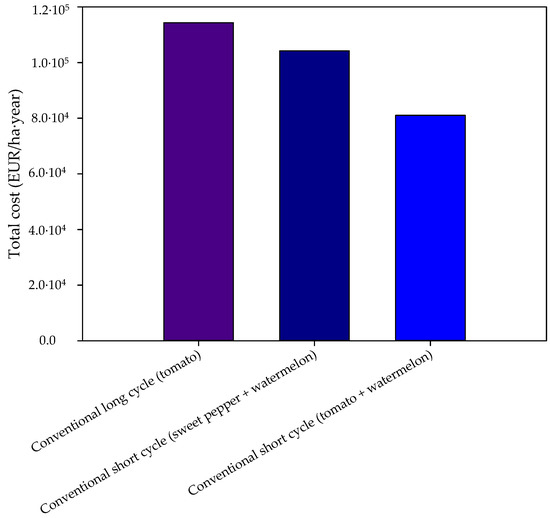

Table 6 shows the production costs of long-cycle tomato crops, tomato-plus-watermelon short-cycle crops, and sweet-pepper-plus-watermelon crops in the conventional production system. The alternative of self-management of agricultural biomass by means of the biodisinfection technique under the criteria described in the methodology is also presented.

Table 6.

Production costs of different vegetable-crop alternatives with and without applying the biodisinfection technique.

Results suggest that the highest production costs are registered in conventional crops and in the long-cycle tomato crop. Production costs reach up to 114,324 EUR/ha·year, although in the alternatives that combine short cycles, the total cost of cultivation reaches 81,031.0 EUR/ha·year (tomato + watermelon) and 104,224.0 EUR/ha·year (sweet pepper + watermelon) (Figure 3). In recent years, there has been an increase in the cost of inputs and means of production in the protected horticultural system of Almeria, which has accelerated recently due to inflation in the Eurozone. Farmers in this system can see how their economic margins are reduced yearly due to the continued stability of the price at origin of fruit and vegetable products [42,131].

Figure 3.

Total cultivation costs of the different production cycles evaluated within the framework of conventional production in Almeria. Source: own elaboration based on other authors [18,64].

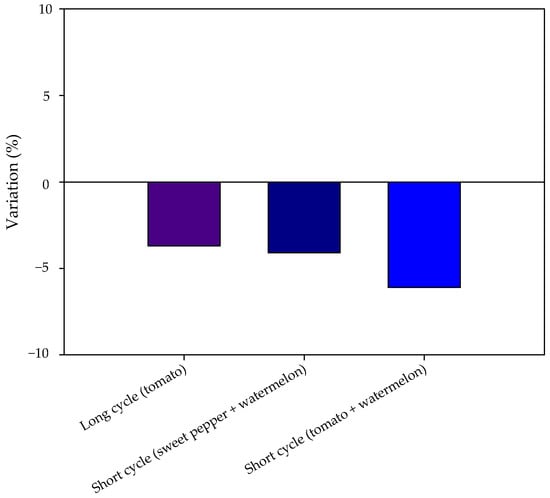

The production system that performs self-management of agricultural biomass through the biodisinfection technique shows a decrease in total production costs ranging from 3.7% to 6.1% (Figure 4). Essentially, this decrease takes place in variable costs because fixed operating costs remain at similar levels in the two alternatives: conventional and with biodisinfection technique (Table 6). The reduction in production costs reported by other authors for the main cultivation alternatives in a similar system in the Almeria model is 4.8% in periods of 48 months. This value is very similar to those shown in our work [18]. The long-cycle crop has a lower production-cost-reduction rate than the other two alternatives evaluated, mainly due to the expansion in demand for tomatoes in the long cycle as a result of being the main economic expense (average value of +35.2%). Other research has shown how implementing eco-innovations can expand the economic benefit perceived by agricultural producers either through reduced production costs, expanded crop yields, or increased exports from their marketing channel [131,132,133].

Figure 4.

Variation in the total cost of cultivation for the different production cycles evaluated in long and short cycles. Source: own elaboration based on other authors [18,64].

Production costs are reduced because of lower demand for certain inputs, which are cataloged in international literature as environmentally harmful materials. In the first place, there are 100% reductions in the number of chemical soil fumigants because the biodisinfection technique has proved to be a useful procedure to control telluric diseases (Table 3). Also, there has been a decrease in the consumption of synthetic chemical fertilizers. Fertilizer consumption is reduced because added organic amendment provides readily available nutrients for plants. The repeated addition of tomato agricultural biomass can increase the concentration of edaphic organic matter and essential nutrients, such as total nitrogen or readily available potassium. Finally, water consumption is reduced due to the self-management of agricultural biomass as a result of improving soil fertility and hydraulic conductivity [18]. Therefore, this research contributes to showing the existence of real and effective alternatives to reduce agrochemical products, as proposed by the EU, without diminishing the agricultural and economic performance of horticultural producers [17,21].

In addition, if an extra supply of nutrients is needed, this fertilization strategy (agricultural biomass with the biodisinfection technique) could be combined with the application of other types of new-generation fertilizers, such as nano-fertilizers, which offer significant benefits compared to conventional fertilizers when it comes to plant nutrition [18,134].

In this context, the fertilization strategy framed in the principles of the circular economy facilitates both the reduction in inputs and the use of materials that can damage the environment if not properly treated. This material causes serious problems in autumn, and farms far from the productive nucleus continue experiencing difficulties managing it [35].

The results of this research suggest that implementing agricultural policies that promote a fertilization strategy consisting of self-management of agricultural biomass from the previous season and biodisinfection, while reducing synthetic fertilizers, can lower the production costs of greenhouse horticultural crops and sustain crop productivity. However, in the protected agriculture of Almeria, the most important producing area of protected agriculture in southeastern Spain, only 15.3% of the farmers self-manage their crop residues on their farms. Of these farmers, only a few do not use chemical fertilizers on their crops [34,44,135].

Consequently, it is necessary to establish a system of incentives to promote the implementation of this sustainable technique among the operators of horticultural agriculture in Almeria. This incentive system can focus on satisfying the formation needs of agricultural producers and offer economic support as an attractive measure, with each amount segmented for each concept (i.e., formation or economic support) as opposed to the current support that offers a single amount for the incorporation of the crop residues into the soil.

5. Conclusions

This work aimed to identify the availability of alternatives to reduce the dependence on inorganic fertilizers in greenhouse horticultural farms. Thus, the multi-functionality of the biodesinfection technique in its biosolarization modality was identified. This technique was attributed to benefits in the mitigation of diseases of edaphic origin and increasing productivity due to the decrease in the severity index of the disease. However, the utilization of inorganic fertilization in combination with the organic amendments used in the fumigant technique masked its fertilizing power. This fact was demonstrated via research using treatments that do not add this type of synthetic fertilizers compared to conventional cultivation in disease-free soils.

Additionally, given the diversity of organic amendments that can be used in the biodisinfection technique, it is possible to improve the management and treatment of agricultural residues that have generated serious sanitary crises in important horticultural production models (i.e., the Almeria Model). This is achieved thanks to using agricultural biomass, the main organic waste generated in this type of production system, as fumigant material in the biodisinfection technique. It is necessary to apply the fumigant treatment to the agricultural biomass to thermally inactivate the pathogens that may have affected the plant material during the production cycle to ensure the health of the following crop.

Therefore, the biodisinfection technique is a fertilization strategy that makes it possible to significantly reduce the use of inorganic fertilizers in long-term intensive horticultural cycles. This is a result of paramount importance for farmers of this type of production model that require alternatives to frame their production systems within the principles of sustainable development and, in the case of the EU, of the circular economy, where European strategies also call for significant reductions in fertilizers and phytosanitary products. There is a reduction in total costs of up to −6.1% in long-term production cycles in intensive greenhouse agriculture. This strategy also positively affects producer expense accounts because of the reduction in the disbursement of the previously mentioned inputs, the lower consumption of water, and the elimination of the cost of managing the material externally. All of this helps to maintain and promote the socioeconomic development of the territories where economic activity depends on this type of agriculture and also helps to sustain food sovereignty and security. The administration should promote this fertilization technique through an incentive system that includes formation and extra economic support to make its use more attractive.

Although the results of this research expand the knowledge in this field, they are not without limitations. The main limitation derives from using average production costs, since the results do not apply to a particular farmer but to the sector as a whole. However, our study provides a clear overview of the situation and can be the basis for policymakers to make the right decisions. These decisions should lead toward safeguarding the European Union’s food sovereignty without reducing the economic benefit of producers by expanding the environmental subcomponent of sustainability.

Future research should identify the adequacy of the fertilization strategy in outdoor horticultural crops and test the fertilization power of agricultural biomass of other horticultural crops, both under greenhouse and outdoor conditions (e.g., watermelon, melon, eggplant, etc.).

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/horticulturae9080859/s1.

Author Contributions

Conceptualization, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; methodology, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; software, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; validation, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; formal analysis, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; investigation, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; resources, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; data curation, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; writing—original draft preparation, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; writing—review and editing, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; visualization, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; supervision, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; project administration, F.J.C.-D., L.J.B.-U., A.B.-d. and F.C.-F.; funding acquisition, F.C.-F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data used are referenced in the article itself.

Conflicts of Interest

The authors declare no conflict of interest.

References

- FAO. Background Notes on Sustainable, Productive and Resilient Agro-Food Systems: Value Chains, Human Capital, and the 2030 Agenda; FAO: Rome, Italy, 2019; ISBN 9789251316474. [Google Scholar]

- Gómez-Tenorio, M.Á.; Magdaleno-González, J.; Tello-Marquina, J.C. Evaluación e Implementación de Técnicas Regenerativas Para la Mejora de la Fertilidad en el Cultivo del Almendro en las Provincias de Almería y Granada; Editorial Tecnoagrícola de Spain: Madrid, Spain, 2021; ISBN 978-84-17596-98-9. [Google Scholar]

- Jacobs, A.A.; Evans, R.S.; Allison, J.K.; Garner, E.R.; Kingery, W.L.; Mcculley, R.L.; Major, G.; Resource, L.; Soil, A.; Office, S.; et al. Soil & Tillage Research Cover crops and no-tillage reduce crop production costs and soil loss, compensating for lack of short-term soil quality improvement in a maize and soybean production system. Soil Tillage Res. 2022, 218, 105310. [Google Scholar] [CrossRef]

- Martínez-Francés, M.A.; Lacasa-Plasencia, A.; Tello-Marquina, J.C. Ecología de la Microbiota Fúngica de los Suelos de los Invernaderos de Pimiento y su Interés Agronómico; Ministerio de Agricultura Pesca y Alimentacion: Madrid, Spain, 2009; ISBN 9788449109874.

- European Union of Audit. European Union Audit Preview. Biodiversity in Farming; European Union of Audit: Luxembourg, 2019. [Google Scholar]

- Región de Murcia, C.D.G. Decreto-Ley 2/2019 de 26 de Diciembre, de Protección Integral del Mar Menor; Boletín Oficial de la Región de Murcia: Murcia, Spain, 2019; pp. 36008–36089. [Google Scholar]

- Díez-Rojo, M.A.; López-Pérez, J.A.; Urbano-Terrón, P.; Bello-Pérez, A. Biodesinfección de Suelos y Manejo Agronómico Biodesinfección de Suelos y Manejo Agronómico; Ministerio de Medio Ambiente y Medio Rural y Marino: Madrid, Spain, 2010.

- UN. World Population Prospects 2022; United Nations, Ed.; UN: New York, NY, USA, 2022; ISBN 9789211483734. [Google Scholar]

- MAPA; Cajamar. Diagnóstico Inicial del Estado de la Transformación Digital del Sector Agroalimentario Español; Ministerio de Agricultura Pesca y Alimentacion y Cajamar: Madrid, Spain, 2022.

- UN. Draft Outcome Document of the United Nations Summit for the Adoption of the Post-2015 Development Agenda; UN: New York, NY, USA, 2015; Volume 13689. [Google Scholar]

- Cifuentes-Faura, J. European Union policies and their role in combating climate change over the years. Air Qual. Atmos. Health 2022, 15, 1333–1340. [Google Scholar] [CrossRef] [PubMed]

- European Comission. The European Green Deal; Office of the European Union: Brussels, Belgium, 2019; pp. 1–28. [Google Scholar]

- European Comission. A New Circular Economy Action Plan. In For a Cleaner and More Competitive Europe; Office of the European Union: Brussels, Belgium, 2020; p. 23. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Resources, Conservation & Recycling Conceptualizing the circular economy: An analysis of 114 de fi nitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Mazur-Wierzbicka, E. Circular economy: Advancement of European Union countries. Environ. Sci. Eur. 2021, 33, 111. [Google Scholar] [CrossRef]

- European Comission. EU Biodiversity Strategy for 2030. Bringing Nature Back into Our Lives; Office of the European Union: Brussels, Belgium, 2020; pp. 1–27. [Google Scholar]

- European Comission. A Farm to Fork Strategy for a Fair, Healthy and Environmentally-Friendly Food System; Office of the European Union: Brussels, Belgium, 2020; pp. 1–23. [Google Scholar]

- Castillo-Díaz, F.J.; Belmonte-Ureña, L.J.; Camacho-Ferre, F.; Tello-Marquina, J.C. Biodisinfection as a Profitable Fertilization Method for Horticultural Crops in the Framework of the Circular Economy. Agronomy 2022, 12, 521. [Google Scholar] [CrossRef]

- Gómez-Tenorio, M.A.; Lupión-Rodríguez, B.; Boix-Ruiz, A.; Ruiz-Olmos, C.; Marín-Guirao, J.I.; Tello-Marquina, J.C.; Camacho-Ferre, F.; De Cara-García, M. Meloidogyne-infested tomato crop residues are a suitable material for biodisinfestation to manage Meloidogyne sp. in greenhouses in Almería (south-east Spain). Acta Hortic. 2018, 1207, 217–221. [Google Scholar] [CrossRef]

- European Commision. Inception Impact Assessment. EU Nature Restoration Targets; Office of the European Union: Brussels, Belgium, 2021; p. 4. [Google Scholar]

- European Commission. Proposal for a Regulation of the European Parliament and of the Council on Nature Restoration; 22.6.2022 COM(2022) 304 Final; European Commission: Brussels, Belgium, 2022; Volume 0195, p. 91. [Google Scholar]

- Copa-Cogeca/Europêche. United Call for Rejection of Unrealistic Nature Legislation That Endangers Farmers and Fishers’ Livelihoods and Food Production in the EU; Copa-Cogeca/Europêche: Bruxelles, Belgium, 2023; p. 2. [Google Scholar]

- Rabobank. World Vegetable Map; Rabobank Gr.: Utrecht, The Netherlands, 2017; Volume 2017. [Google Scholar]

- MAPA. Encuesta Sobre Superficies y Rendimientos de Cultivos; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2023; p. 45.

- Junta de Andalucía. Cartografía de Invernaderos en Almería, Granada y Málaga; Año 2021. Cons. Agric. Ganad. Pesca y Desarro. Sosten.; la Junta Andalucía. 2022, pp. 1–27. Available online: https://www.juntadeandalucia.es/sites/default/files/2021-11/Cartografia%20_inv_AL_GR_MA_v210928%20_1.pdf (accessed on 3 December 2022).

- EUROSTAT. Crop Production in EU Standard Humidity (from 2000 Onwards). [V0000_S0000] Fresh Vegetables (Including Melons) and Strawberries. Available online: https://ec.europa.eu/eurostat/databrowser/view/APRO_CPSH1__custom_4031262/default/table?lang=en (accessed on 3 December 2022).

- Gutiérrez-Gutiérrez, C. Anuario Agrícola. 2021. Fhmurcia; Fhmurcia: Murcia, Spain, 2022. [Google Scholar]

- Junta de Andalucía. Anuario. Available online: https://www.juntadeandalucia.es/organismos/agriculturaganaderiapescaydesarrollosostenible/servicios/estadistica-cartografia/anuarios.html (accessed on 15 June 2022).

- Cajamar. Análisis de la Campaña Hortofrutícola. Campaña 2021/2022; Cajamar Caja Rural: Barcelona, Spain, 2022. [Google Scholar]

- Valera-Martínez, D.L.; Belmonte-Ureña, L.J.; Molina Aiz, F.D.; López MArtínez, A. Los Invernaderos de Almería. Análisis de su Tecnología y Rentabilidad; Cajamar Caja Rural: Almeria, Spain, 2014; p. 504. [Google Scholar]

- Vanthoor, B.H.E.; Stigter, J.D.; van Henten, E.J.; Stanghellini, C.; de Visser, P.H.B.; Hemming, S. A methodology for model-based greenhouse design: Part 5, greenhouse design optimisation for southern-Spanish and Dutch conditions. Biosyst. Eng. 2012, 111, 350–368. [Google Scholar] [CrossRef]

- Junta de Andalucía. Caracterización de los Invernaderos de Andalucía; Junta de Andalucía: Sevilla, Spain, 2015. [Google Scholar]

- Duque-Acevedo, M.; Lancellotti, I.; Andreola, F.; Barbieri, L.; Belmonte-ureña, L.J.; Camacho-ferre, F. Management of Agricultural Waste Biomass as raw material for the construction sector. An analysis of sustainable and circular alternatives. Environ. Sci. Eur. 2022, 34, 70. [Google Scholar] [CrossRef]

- Junta de Andalucía. Líneas de Actuación en Materia de Gestión de Restos Vegetales en la Horticultura de Andalucía; Cons. Agric. Ganad. Pesca y Desarro. Sosten.; la Junta Andalucía. 2016, pp. 1–45. Available online: https://www.juntadeandalucia.es/export/drupaljda/Lineas_actuacion_materia_gestion_restos_vegetales_horticultura_Andalucia.pdf (accessed on 3 December 2022).

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Plaza-Úbeda, J.A.; Camacho-Ferre, F. The management of agricultural waste biomass in the framework of circular economy and bioeconomy: An opportunity for greenhouse agriculture in Southeast Spain. Agronomy 2020, 10, 489. [Google Scholar] [CrossRef]

- Camacho-Ferre, F. Diferentes alternativas para la gestión del residuo biomasa procedente de cultivos de invernadero. In Innovaciones Tecnológicas en Cultivos de Invernadero; Rodríguez, E.J.F., Ed.; Universidad de Almería—Junta de Andalucía: Almería, Spain, 2003; pp. 211–237. ISBN 84-8748-052-7. [Google Scholar]

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment. Updated Bioeconomy Strategy; European Commission: Brussels, Belgium, 2018; ISBN 978-92-79-94144-3. [Google Scholar]

- Sayadi-Gmada, S.; Roc, C.; Rojas-Serrano, F.; Garc, R.; Lorbach-Kelle, M.B.; Manrique-Gordillo, T. Inorganic Waste Management in Greenhouse Agriculture in Almeria (SE Spain): Towards a Circular System in Intensive Horticultural Production. Sustainability 2019, 11, 3782. [Google Scholar] [CrossRef]

- Castillo Díaz, F.J.; Marín-Guirao, J.I.; Belmonte-Ureña, L.J.; Tello-marquina, J.C. Effect of Repeated Plant Debris Reutilization as Organic Amendment on Greenhouse Soil Fertility. Int. J. Environ. Res. Public Health 2021, 18, 11544. [Google Scholar] [CrossRef] [PubMed]

- Camacho-Ferre, F. Técnicas de Producción en Cultivos Protegidos; Instituto de Publicaciones de Cajamar: Almería, Spain, 2004; ISBN 84-95531-17-8. [Google Scholar]

- García-García, M.C.; Céspedes-López, A.J.; Cano-Banderas, M.; Martín-Expósito, E.; Cánovas-Fernández, G.; Párra-Gómez, S. Trends in soil disinfection in greenhouses in south-eastern Spain. In Proceedings of the X International Symposium on SOIL and Substrate Disinfestation, Almeria, Spain, 6–8 June 2023. [Google Scholar]

- Honoré, M.N.; Belmonte-Ureña, L.J.; Navarro-Velasco, A.; Camacho-Ferre, F. Profit analysis of papaya crops under greenhouses as an alternative to traditional intensive horticulture in Southeast Spain. Int. J. Environ. Res. Public Health 2019, 16, 2908. [Google Scholar] [CrossRef] [PubMed]

- Acebedo, M.M.; Diánez, F.; Santos, M. Almeria’s Green Pest Management Revolution: An Opportunity That Arose from a Food Safety Alert. Agronomy 2022, 12, 619. [Google Scholar] [CrossRef]

- COEXPHAL. Memoria Coexphal 2020/2021; Coexphal: Almeria, Spain, 2022. [Google Scholar]

- Valera-Martínez, D.L.; Belmonte-Ureña, L.J.; Molina Aiz, F.D.; Camacho-Ferre, F. The greenhouses of Almería, Spain: Technological analysis and profitability. Acta Hortic. 2017, 1170, 2019–2226. [Google Scholar] [CrossRef]

- Kitchenham, B. Procedures for Performing Systematic Reviews; Keele University Technical Report TR/SE-0401; Keele University: Newcastle, UK, 2004; pp. 1–34. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Batlles-delaFuente, A.; Abad-segura, E.; González, M.; Cortés-García, F.J. An Evolutionary Approach on the Framework of Circular Economy Applied to Agriculture. Agronomy 2022, 12, 620. [Google Scholar] [CrossRef]

- Elsevier Scopus. Available online: https://www.elsevier.com/es-es/solutions/scopus (accessed on 14 August 2022).

- García-Raya, P.; Ruiz-Olmos, C.; Marín-Guirao, J.I.; Asensio-Grima, C.; Tello-Marquina, J.C.; de Cara-García, M. Greenhouse Soil Biosolarization with Tomato Plant Debris as a Unique Fertilizer for Tomato Crops Greenhouse Soil Biosolarization with Tomato Plant Debris as a Unique Fertilizer for Tomato Crops. Int. J. Environ. Res. Public Health 2019, 16, 279. [Google Scholar] [CrossRef]

- Ruiz-Olmos, C.A.; Gómez-Tenorio, M.Á.; Camacho-ferre, F.; Belmonte-Ureña, L.J.; Tello-Marquina, J.C. Control de nematodos del género Meloidogyne en un suelo de invernadero cultivado con papaya utilizando la técnica de biosolarización de suelos. Terralia 2018, 116, 53–62. [Google Scholar]

- Batlles-delaFuente, A.; Belmonte-Ureña, L.J.; Duque-Acevedo, M.; Camacho-Ferre, F. A Profitable Alternative for the Spanish Southeast: The Case of Production of Figs in Greenhouses. Agronomy 2022, 12, 2577. [Google Scholar] [CrossRef]

- Subhashree, S.N.; Igathinathane, C.; Hendrickson, J.; Archer, D.; Liebig, M. Forage economics calculator web tool: A decision support system for forage management. Comput. Electron. Agric. 2023, 208, 107775. [Google Scholar] [CrossRef]

- Xu, Z.; Sarmento, L.; Ito, L.; Tokai, A. Cost and health benefit analysis of remediation alternatives for the heavy-metal-contaminated agricultural land in a Pb—Zn mining town in China. J. Clean. Prod. 2023, 397, 136503. [Google Scholar] [CrossRef]

- Zhuo, C.; Xueqin, L.; Zhiwei, W.; Yantao, Y.; Tanglei, S.; Taoli, H. Industrial Crops & Products Techno-economic and whole life cycle assessment of ester fuels production from agricultural waste via hydrothermal liquefaction. Ind. Crop. Prod. 2023, 192, 116096. [Google Scholar] [CrossRef]

- Castillo-Díaz, F.J.; Belmonte-Ureña, L.J.; Batlles-delaFuente, A.; Camacho-Ferre, F. Impact of the new measures related to the circular economy on the management of agrochemical packaging in Spanish agriculture and the use of biodegradable plastics. Environ. Sci. Eur. 2022, 34, 94. [Google Scholar] [CrossRef]

- Celiktopuz, E.; Kapur, B.; Saridas, M.A.; Güney, O.; Aksoy, F. Plant Physiology and Biochemistry Yield, quality and physiological variation of strawberry in response to irrigation regimes and exogenous proline with a cost benefit analysis. Plant Physiol. Biochem. 2023, 195, 238–246. [Google Scholar] [CrossRef] [PubMed]

- Colla, G. Foliar Applications of Protein Hydrolysate, Plant and Seaweed Extracts Increase Yield but Differentially Modulate Fruit Quality of Greenhouse Tomato. HortScience 2017, 52, 1214–1220. [Google Scholar] [CrossRef]

- Heinrich, T.; Park, H.; Orozco, R.; Ding, Z.; Álvarez-López, V.; Mosquera-losada, M.R.; Steinbeis, L.; Hoffmann, T. Biochar production from late-harvest grass—Challenges and potential for farm-scale implementation. Sustain. Prod. Consum. 2023, 37, 256–267. [Google Scholar] [CrossRef]

- López-Serrano, M.A.; Velasco-Muñoz, J.F.; Aznar-Sánchez, J.A.; Román-Sánchez, I.M. Financial Evaluation of the Use of Reclaimed Water in Agriculture in Southeastern Spain, A Mediterranean Region. Agronomy 2021, 11, 2218. [Google Scholar] [CrossRef]

- Morselli, N.; Boccaletti, S.; Meglioraldi, S.; Puglia, M.; Pedrazzi, S.; Allesina, G. Biomass-powered thermal weeding in wine farms: An environmental and economic assessment. J. Clean. Prod. 2023, 385, 135684. [Google Scholar] [CrossRef]

- Roberts, M.; Hawes, C.; Young, M. Environmental management on agricultural land: Cost benefit analysis of an integrated cropping system for provision of environmental public goods. J. Environ. Manag. 2023, 331, 117306. [Google Scholar] [CrossRef]

- Streimikis, J.; Baležentis, T. Agricultural sustainability assessment framework integrating sustainable development goals and interlinked priorities of environmental, climate and agriculture policies. Sustain. Dev. 2020, 28, 1702–1712. [Google Scholar] [CrossRef]

- Torresano, F.; Camacho-Ferre, F. Valoración de las Diferentes Labores Culturales en los Cultivos de Tomate, Pimiento, Calabacín, Pepino, Sandía, Melón, Judía y Berenjena; Agrupación Española de Entidades Aseguradoras de los Seguros Agrarios Combinados (Agroseguro); Universidad de Almería: Almería, Spain, 2012. [Google Scholar]

- Agroseguro. Agroseguro. Available online: https://agroseguro.es/conocenos/quienes-somos/ (accessed on 14 April 2023).

- INE. Índices Nacionales: General y de Grupos ECOICOP. Available online: https://www.ine.es/jaxiT3/Tabla.htm?t=22344 (accessed on 6 April 2023).

- Katan, J.; Greenberger, A.; Alon, H.; Grinstein, A. Solar Heating by Polyethylene Mulching for the Control of Diseases caused by Soil-Borne Pathogens. Phytopathology 1976, 66, 683–688. [Google Scholar] [CrossRef]

- Katan, J. Soil solarization: The idea, the research and its development. Phytoparasitica 2015, 43, 1–4. [Google Scholar] [CrossRef]

- Guerrero, M.M.; Lacasa, C.M.; Martínez, V.; Martínez-Lluch, M.C.; Larregla, S.; Lacasa, A. Soil biosolarization for Verticillium dahliae and Rhizoctonia solani control in artichoke crops in southeastern Spain. Span. J. Agric. Res. 2019, 17, e1002. [Google Scholar] [CrossRef]

- García-Ruiz, A.; Tello-Marquina, J.C.; Avilés-Guerrero, M.; Ordovás-Ascaso, J. Fusariosis del Clavel (Fusarium oxysporum f. sp. dianthi) Últimos Avances en su Control; Ediciones Agrotécnicas: Madrid, Spain, 2009. [Google Scholar]

- Palmero, D.; de Cara-García, M.; Santos, M.; Tello-Marquina, J.C. Control of diseases from forma especiales of Fusarium oxysporum causing wilt in intensive horticultural crops. Res. Signpost 2011, 661, 209–228. [Google Scholar]

- Marín-Guirao, J.I.; Tello-Marquina, J.C.; Díaz, M.; Boix, A.; Ruiz-Olmos, C.A.; Camacho-Ferre, F. Effect of greenhouse soil bio-disinfection on soil nitrate content and tomato fruit yield and quality. Soil Res. 2016, 54, 200–206. [Google Scholar] [CrossRef]

- Marín-Guirao, J.I.; de Cara-García, M.; Tello-Marquina, J.C. Effect of soil biodisinfection on soil fungal communities associated to horticultural crops. Ecosistemas 2019, 28, 63–72. [Google Scholar] [CrossRef]

- Kirkegaard, J.A.; Gardner, P.A.; Desmarchelier, J.M.; Angus, J.F. Benefits of brassica break crops in the Southeast wheatbelt. In Proceedings of the 7th Australian Agronomy Conference, Wagga Wagga, Australia, 19–24 September 1993; pp. 282–285. [Google Scholar]

- Kirkegaard, J.A.; Gardner, J.; Desmarcherlier, J.M.; Angus, J.F. Biofumigation Using Brassica species to Control Pest and Diseases in Horticulture and Agriculture. In Proceedings of the 9th Australian Research Assembly on Brassicas, Waga Wagga, Australia, 5–7 October 1993; Wrather, N., Mailes, R.J., Eds.; pp. 77–82. [Google Scholar]

- Lazzeri, L.; Leoni, O.; Manici, L.M. Biocidal plant dried pellets for biofumigation. Ind. Crop. Prod. 2004, 20, 59–65. [Google Scholar] [CrossRef]

- Lazzeri, L.; Manici, M. The glucosinolate-myrosinase system: A natural and practical tool for biofumigation. Acta Hortic. 2000, 532, 89–95. [Google Scholar] [CrossRef]

- Gardiner, J.B.; Morra, M.J.; Eberlein, C.V.; Brown, P.D.; Borek, V. Allelochemicals released in soil following incorporation of rapeseed (Brassica napus) green manures. J. Agric. Food Chem. 1999, 47, 3837–3842. [Google Scholar] [CrossRef] [PubMed]

- Gimsing, A.L.; Kirkegaard, J.A. Glucosinolate and isothiocyanate concentration in soil following incorporation of Brassica biofumigants. Soil Biol. Biochem. 2006, 38, 2255–2264. [Google Scholar] [CrossRef]

- Marín-guirao, J.I. Evaluación del Efecto de Distintas Materias Orgánicas Sobre la Microbiota Edáfica, Contenido de Nitratos en Suelo, y Producción y Calidad de Cultivos de Tomate y Sandía en Suelo Arenado Bajo Plástico; Universidad de Almería: Almería, Spain, 2016. [Google Scholar]

- Achmon, Y.; Harrold, D.R.; Claypool, J.T.; Stapleton, J.J.; Vandergheynst, J.S.; Simmons, C.W. Assessment of tomato and wine processing solid wastes as soil amendments for biosolarization. Waste Manag. 2016, 48, 156–164. [Google Scholar] [CrossRef]

- Seo, M.W.; Lee, S.W.; Lee, S.H.; Jang, I.B.; Heo, H.J. Effect of Green Manure Incorporation and Solarization on Root Rot Disease of 3-year-old Ginseng in Soil of Continuous Cropping Ginseng. Korean J. Med. Crop Sci. 2019, 27, 284–291. [Google Scholar] [CrossRef]

- Díaz-Hernández, S.; Gallo-Llobet, L.; Domínguez-Correa, P.; Rodríguez, A. Effect of repeated cycles of soil solarization and biosolarization on corky root, weeds and fruit yield in screen-house tomatoes under subtropical climate conditions in the Canary Islands. Crop Prot. 2017, 94, 20–27. [Google Scholar] [CrossRef]

- García-Raya, P. Efecto de la Adición de Restos de Cosecha de Tomate Mediante Biosolarización en la Producción, Calidad del Tomate y Morfología de la Planta; Universidad de Almería: Almeria, Spain, 2018. [Google Scholar]

- Gamliel, A.; Stapleton, J.J. Effect of Chicken Compost or Ammonium Phosphate and Solarization on Pathogen Control, Rhizosphere Microorganisms, and Lettuce Growth. Plant Dis. 1993, 77, 886. [Google Scholar] [CrossRef]

- Guerrero, M.M.; Ros, C.; Lacasa, C.M.; Martínez, V.; Lacasab, A.; Fernández, P.; Núñez-Zofío, M.; Larreglac, S.; Martíneza, M.A.; Díez-Rojo, M.A.; et al. Effect of biosolarization using pellets of brassica carinata on soil-borne pathogens in protected pepper crops. Acta Hortic. 2010, 883, 337–344. [Google Scholar] [CrossRef]

- Núñez-Zofio, M.; Larregla, S.; Garbisu, C. Repeated biodisinfection controls the incidence of Phytophthora root and crown rot of pepper while improving soil quality. Span. J. Agric. Res. 2012, 10, 794–805. [Google Scholar] [CrossRef]

- Klein, E.; Katan, J.; Austerweil, M.; Gamliel, A. Laboratory System to Study Soil Solarization and Organic Amendment Effects on Plant Pathogens. Phytopathology 2007, 97, 1476–1983. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Basallote-Ureba, M.J.; Vela-Delgado, M.D.; Capote, N.; Melero-Vara, J.M.; López-Herrera, C.J.; Prados-Ligero, A.M.; Talavera-Rubia, M.F. Control of Fusarium wilt of carnation using organic amendments combined with soil solarization, and report of associated Fusarium species in southern Spain. Crop Prot. 2016, 89, 184–192. [Google Scholar] [CrossRef]

- Blok, W.J.; Lamers, J.G.; Termorshuizen, A.J.; Bollen, G.J. Control of soilborne plant pathogens by incorporating fresh organic amendments followed by tarping. Phytopathology 2000, 90, 253–259. [Google Scholar] [CrossRef] [PubMed]

- Gilardi, G.; Pugliese, M.; Gullino, M.L.; Garibaldi, A. Effect of different organic amendments on lettuce fusarium wilt and on selected soilborne microorganisms. Plant Pathol. 2016, 65, 704–712. [Google Scholar] [CrossRef]

- Huang, X.Q.; Wen, T.; Zhang, J.B.; Meng, L.; Zhu, T.B.; Liu, L.L.; Cai, Z.C. Control of soil-borne pathogen Fusarium oxysporum by biological soil disinfestation with incorporation of various organic matters. Eur. J. Plant Pathol. 2015, 143, 223–235. [Google Scholar] [CrossRef]

- Marín-Guirao, J.I.; Tello-Marquina, J.C. Microbiota edáfica y fatiga de suelo en invernaderos de la provincia de Gran. In I Jornadas de Transferencia Hortofrutícola de Ciambital; Camacho-Ferre, F., Valera-Martínez, D.L., Belmonte-Ureña, L., Herrero-Sánchez, C., Reca-Cardeña, J., Marín-Membrive, P., del Pino-Gracia, A., Casa-Fernández, M., Eds.; Universidad de Almería: Almería, Spain, 2017; pp. 17–36. ISBN 978-84-16389-98-8. [Google Scholar]

- Guerrero-Díaz, M.M.; Lacasa-Martínez, M.; Hernández-Piñera, A.; Martínez-Alarcon, V.; Lacasa-Plasencia, A. Evaluation of repeated biodisinfestation using Brassica carinata pellets to control Meloidogyne incognita in protected pepper crops. Span. J. Agric. Res. 2013, 11, 485–493. [Google Scholar] [CrossRef]

- Valdes, Y.; Viaene, N.; Moens, M. Effects of yellow mustard amendments on the soil nematode community in a potato field with focus on Globodera rostochiensis. Appl. Soil Ecol. 2012, 59, 39–47. [Google Scholar] [CrossRef]

- Chamorro, M.; Miranda, L.; Domínguez, P.; Medina, J.J.; Soria, C.; Romero, F.; Santos, B.D.L. Evaluation of biosolarization for the control of charcoal rot disease (Macrophomina phaseolina) in strawberry. Crop Prot. 2015, 67, 279–286. [Google Scholar] [CrossRef]

- Epstein, E. The Science of Composting; CRC Press: New York, NY, USA, 1997. [Google Scholar]

- Simmons, C.W.; Guo, H.; Claypool, J.T.; Marshall, M.N.; Perano, K.M.; Stapleton, J.J.; VanderGheynst, J.S. Managing compost stability and amendment to soil to enhance soil heating during soil solarization. Waste Manag. 2013, 33, 1090–1096. [Google Scholar] [CrossRef][Green Version]

- Lazarovits, G. Management of soil-borne plant pathogens with organic soil amendments: A disease control strategy salvaged from the past. Can. J. Plant Pathol. 2001, 23, 1–7. [Google Scholar] [CrossRef]

- Momma, N.; Kobara, Y.; Uematsu, S.; Kita, N.; Shinmura, A. Development of biological soil disinfestations in Japan. Appl. Microbiol. Biotechnol. 2013, 97, 3801–3809. [Google Scholar] [CrossRef] [PubMed]

- Katase, M.; Kubo, C.; Ushio, S.; Ootsuka, E.; Takeuchi, T.; Mizukubo, T. Nematicidal activity of volatile fatty acids generated from wheat bran in reductive soil disinfestation. Jpn. J. Nematol. 2009, 39, 53–62. [Google Scholar] [CrossRef]

- Kirkegaard, J.A.; Sarwar, M. Biofumigation potential of brassicas: I. Variation in glucosinolate profiles of diverse field-grown brassicas. Plant Soil 1998, 201, 71–89. [Google Scholar] [CrossRef]

- Hansen, Z.R.; Keinath, A.P. Increased pepper yields following incorporation of biofumigation cover crops and the effects on soilborne pathogen populations and pepper diseases. Appl. Soil Ecol. 2013, 63, 67–77. [Google Scholar] [CrossRef]

- Ros, C.; Sánchez, F.; Martínez, V.; Lacasa, C.M.; Hernández, A.; Torres, J.; Guerrero, M.M.; Lacasa, A. El cultivo de brásicas para biosolarización reduce las poblaciones de Meloidogyne incognita en los invernaderos de pimiento del sudeste de Spain. ITEA Inf. Técnica Económica Agrar. 2016, 112, 109–126. [Google Scholar] [CrossRef]

- Lamers, J.G.; Runia, W.T.; Molendijk, L.P.G.; Bleeker, P.O. Perspectives of anaerobic soil disinfestation. Acta Hortic. 2010, 883, 277–284. [Google Scholar] [CrossRef]

- Rosskopf, E.N.; Kokalis-Burelle, N.; Hong, J. Status of ADS Development in Florida. In Proceedings of the Annual International Research Conference on Methyl Bromide. Alternatives and Emissions Reductions, Orlando, FL, USA, 30 October–2 November 2011; Volume 42, pp. 103–112. [Google Scholar]

- Fernandez-Bayo, J.D.; Shea, E.A.; Parr, A.E.; Achmon, Y.; Stapleton, J.J.; VanderGheynst, J.S.; Hodson, A.K.; Simmons, C.W. Almond processing residues as a source of organic acid biopesticides during biosolarization. Waste Manag. 2020, 101, 74–82. [Google Scholar] [CrossRef]

- MAGRAMA. Plan Estatal Marco de Gestión de Residuos PEMAR (2016–2022); Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2015; pp. 1–182.

- Guerrero, M.M.; Guirao, P.; Martinez-lluch, M.C.; Tello, J.C.; Lacasa, A. Soil fatigue and its specificity towards pepper plants in greenhouses. Span. J. Agric. Res. 2014, 12, 644–652. [Google Scholar] [CrossRef]

- Fernández, P.; Lacasa, A.; Guirao, P.; Larregla, S. Effects of Biosolarization with fresh sheep manure on soil physical properties of pepper greenhouses in Campo de Cartagena. In Proceedings of the 6th Workshop on Agri-Food Research, Cartagena, Spain, 8–9 May 2018; Artés-Hernández, F., Cos, J.E., Fernández-Hernández, J.A., Calatrava, J.A., Aguayo, E., Alarcón, J.J., Guitiérrez-Cortines, M.E., Eds.; pp. 97–100, ISBN 9788416325641. [Google Scholar]

- Ros, C.; Martínez, V.; Sánchez-Solana, F.; López-Marín, J.; Lacasa, C.M.; Guerrero, M.d.M.; Lacasa, A. Combination of biosolarization and grafting to control Meloidogyne incognita in greenhouse pepper crops. Crop Prot. 2018, 113, 33–39. [Google Scholar] [CrossRef]

- Medina, J.J.; Miranda, L.; Soria, C.; Palencia, P. Non-Chemical Alternatives to Methyl Bromide for Strawberry: Biosolarization as Case-Study in Huelva (Spain). Acta Hortic. 2009, 842, 961–964. [Google Scholar] [CrossRef]

- Miranda, L.; Domínguez, P.; Soria, C.; Zea, T.; Talavera, M.; Velasco, L.; Romero, F.; Santos, B.D.L.; Newton, A.I. Soil Biosolarization for Strawberry Cultivation. Acta Hortic. 2012, 926, 407–414. [Google Scholar]

- Marín-guirao, J.I.; Gómez-Tenorio, M.Á.; Castillo-Díaz, F.J.; Magdaleno-González, J.; Tello-Marquina, J.C. Incidencia de la biodesinfección de suelos de invernadero usando restos vegetales del cultivo de pimiento sobre la microbiota edáfica (Hongos y bacterias). In Proceedings of the I Congreso Internacional de Sistemas Agrarios Tradicionales, V Encuentro InterVegas, Tenerife, Spain, 24–26 October 2019. [Google Scholar]

- Serrano-Pérez, P.; De Santiago, A.; Rodríguez-Molina, M.d.C. Biofumigation with Pellets of Defatted Seed Meal of Brassica carinata: Factors Affecting Performance against Phytophthora nicotianae in Pepper Crops. Front. Sustain. Food Syst. 2021, 5, 664531. [Google Scholar] [CrossRef]

- Ros, M.; Garcia, C.; Hernandez, M.T.; Lacasa, A.; Fernandez, P.; Pascual, J.A. Effects of biosolarization as methyl bromide alternative for Meloidogyne incognita control on quality of soil under pepper. Biol. Fertil. Soils 2008, 45, 37–44. [Google Scholar] [CrossRef]

- Guerrero, M.; Martínez, M.; Ros, C.; Martínez, M.; Bello, A.; Lacasa, A. Biosolarización y biofumigación para la producción de pimiento ecológico en invernadero. In Proceedings of the VII Congreso SEAE, Zaragoza, Spain, 18–23 September 2006; p. 103. [Google Scholar]

- Martínez, M.A.; Guerrero, M.M.; Martínez, M.C.; Ros, C.; Lacasa, A.; Tello-Marquina, J.C. Efecto de la biosolarización reiterada sobre la microbiota fúngica en cultivos de pimiento. In Proceedings of the VII Congreso SEAE, Zaragoza, Spain, 18–23 September 2006; p. 212. [Google Scholar]

- Guerrero-Díaz, M.M.; Lacasa-Martinez, C.M.; Hernández, A.; Martínez, V.; Martínez, M.C.; Fernández-Molina, P.; Lacasa, A. Biosolarization with agroindustrial byproduct for the control of soilborne pathogens in protected pepper crops in southeast Spain. Acta Hortic. 2014, 1044, 157–161. [Google Scholar] [CrossRef]

- Mitidieri, M.S.; Brambilla, V.; Barbieri, M.; Piris, E.; Celié, R. Tomato Crop Health, Yield, and Greenhouse Soil Conditions after 17 Years of Repeated Treatments of Biofumigation and Solarization. Glob. J. Agric. Innov. Res. Dev. 2021, 8, 123–139. [Google Scholar] [CrossRef]

- Domínguez, P.; Miranda, L.; Soria, C.; de los Santos, B.; Chamorro, M.; Romero, F.; Daugovish, O.; López-Aranda, J.M.; Medina, J.J. Soil biosolarization for sustainable strawberry production. Agron. Sustain. Dev. 2014, 34, 821–829. [Google Scholar] [CrossRef]

- Domínguez, P.; Miranda, L.; Medina, J.J.; Santos, B.D.L.; Daugovish, O.; Soria, C.; Chamorro, M.; López-, J.M.; Domínguez, P.; Miranda, L.; et al. Evaluation of Non-Fumigant Alternative Soil Treatments for Strawberry Production in Huelva Evaluation of Non-Fumigant Alternative Soil Treatments for Strawberry Production in Huelva (Spain). Int. J. Fruit Sci. 2016, 16, 28–36. [Google Scholar] [CrossRef]

- Sánchez-Navarro, A.; Jiménez-Ballesta, R.; Girona-Ruiz, A.; Alarcón-Vera, I.; Delgado-Iniesta, M.J. Rapid Response Indicators for Predicting Changes in Soil Properties Due to Solarization or Biosolarization on an Intensive Horticultural Crop in Semiarid Regions. Land 2022, 11, 64. [Google Scholar] [CrossRef]

- López-Elías, J.; Jiménez, L.J.; Huez, L.M.A.; Garza, O.S.; Cruz, B.F.; Bautista, O.A.L. Medidas de control biológico en la producción de pepino, bajo condiciones de invernadero. Idesia (Arica) 2017, 35, 7–12. [Google Scholar] [CrossRef][Green Version]

- De la Lastra, E.; Marín-Guirao, J.I.; López-Moreno, F.J.; Soriano, T.; de Cara-García, M.; Capote, N. Potential inoculum sources of Fusarium species involved in asparagus decline syndrome and evaluation of soil disinfestation methods by qPCR protocols. Pest Manag. Sci. 2021, 77, 4749–4757. [Google Scholar] [CrossRef]

- Khadka, R.B.; Marasini, M.; Rawal, R.; Testen, A.L.; Miller, S.A. Effects of anaerobic soil disinfestation carbon sources on soilborne diseases and weeds of okra and eggplant in Nepal. Crop Prot. 2020, 135, 104846. [Google Scholar] [CrossRef]

- Mauromicale, G.; Lo Monaco, A.; Longo, A.M.G. Improved efficiency of soil solarization for growth and yield of greenhouse tomatoes. Agron. Sustain. Dev. 2010, 30, 753–761. [Google Scholar] [CrossRef]

- Mauromicale, G.; Longo, A.M.G.; Lo Monaco, A. The effect of organic supplementation of solarized soil on the quality of tomato fruit. Sci. Hortic. (Amsterdam) 2011, 129, 189–196. [Google Scholar] [CrossRef]

- Castillo-Díaz, F.J.; Ruiz-Olmos, C.A.; Gómez-Tenorio, M.Á.; Tello-Marquina, J.C. Efecto de la biosolarización sobre la producción de tomate cultivado bajo invernadero en Almería. Parte I: Evaluación de diferentes restos vegetales. Agrícola Vergel 2021, 432, 103–112. [Google Scholar]

- Junta de Andalucía. Observatorio de Precios y Mercados. Costes. Available online: https://www.juntadeandalucia.es/agriculturaypesca/observatorio/servlet/FrontController?action=List&table=11200&subsector=&page=1&ec=default (accessed on 12 April 2023).

- Castillo-Díaz, F.J.; Batlles-delafuente, A.; Belmonte-Ureña, L.J.; Camacho-ferre, F. Impact of environmental policies on the profitability of greenhouse agriculture in southeastern Spain. Sustain. Dev. 2023, 1–18. [Google Scholar] [CrossRef]