Effect of Sewage Sludge Compost and Urban Pruning Waste on Agronomic Parameters and Wine Composition in Arid Zones Under Climate Change

Abstract

1. Introduction

2. Materials and Methods

2.1. Composting and Compost

| Agronomic Parameters | Biologic and Microbiologic Parameters | Metal Content ** | |||

|---|---|---|---|---|---|

| pH | 7.98 ± 0.08 | GI (%) | 96.4 | Cd (mg·kg−1) | 0.8 |

| EC (μS·cm−1) | 2662 ± 10 | Escherichia coli (NMP/g) | <1 (1000) * | Cu (mg·kg−1) | 164 |

| OM (%) | 36.9 ± 1.4 (≥35%) * | Salmonella spp. (A/P/25 g) | A (Absent) * | Cr (mg·kg−1) | 63 |

| C/N | 11.3 (<20) * | Ni (mg·kg−1) | 19 | ||

| TKN (%) | 2.03 ± 0.15 | Pb (mg·kg−1) | 61 | ||

| P2O5 (%) | 4.26 ± 0.08 | Zn (mg·kg−1) | 525 | ||

| K2O (%) | 1.06 ± 0.03 | Hg (mg·kg−1) | 0.5 | ||

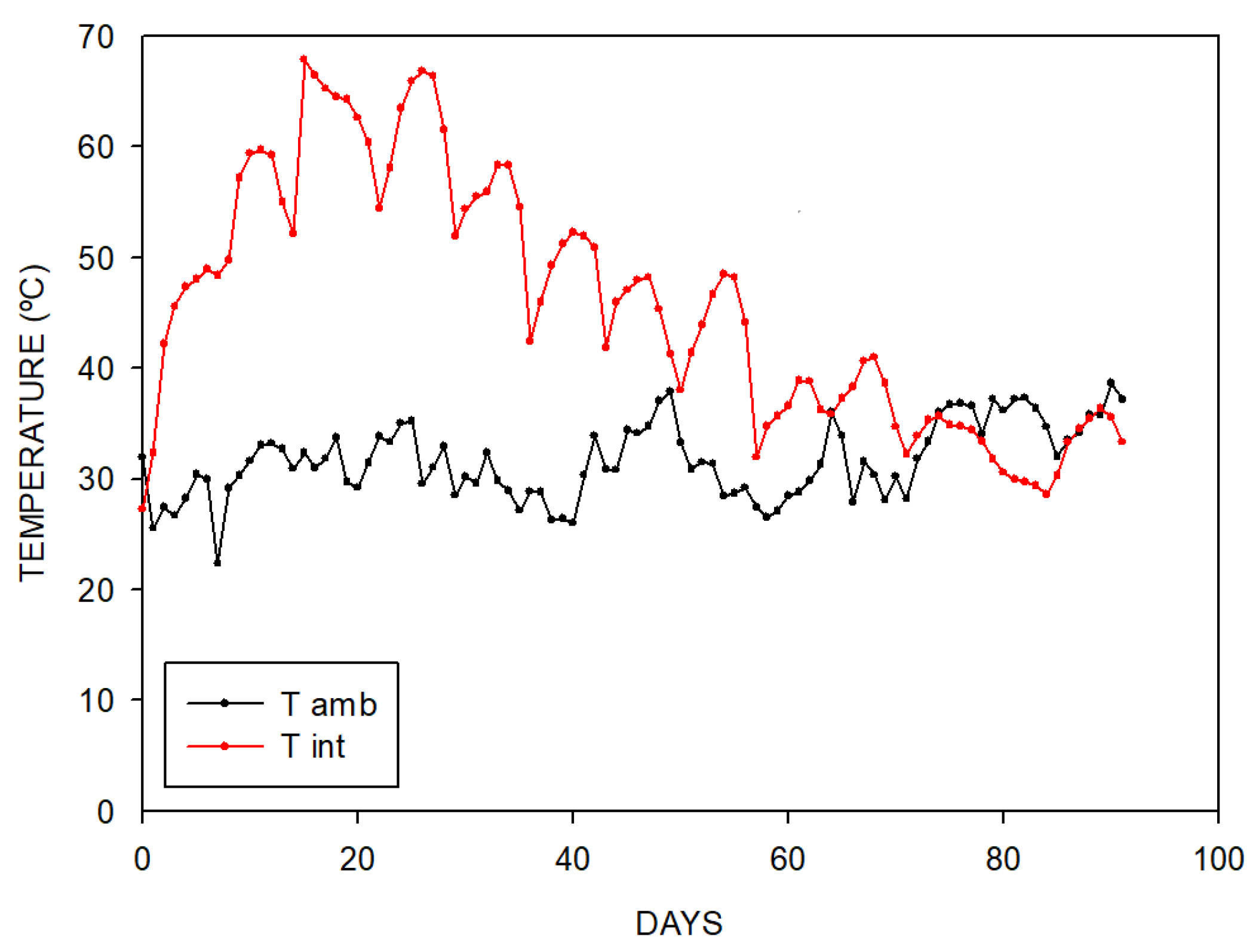

2.2. Study Area and Test Conditions

2.3. Analysis of Agronomic Parameters and Must Composition

2.4. Vinification and Wine Analysis

2.5. Analysis of Volatile Compounds

2.5.1. Major Volatile Compounds

2.5.2. Minor Volatile Compounds

2.5.3. Calculation of Aromatic Series

2.6. Organoleptic Characterization

2.7. Statistical Analysis

3. Results and Discussion

3.1. Agronomic Parameters and Must Composition

3.2. Vinifications

3.3. Volatile Composition

3.3.1. Chemical Families

3.3.2. Aromatic Series

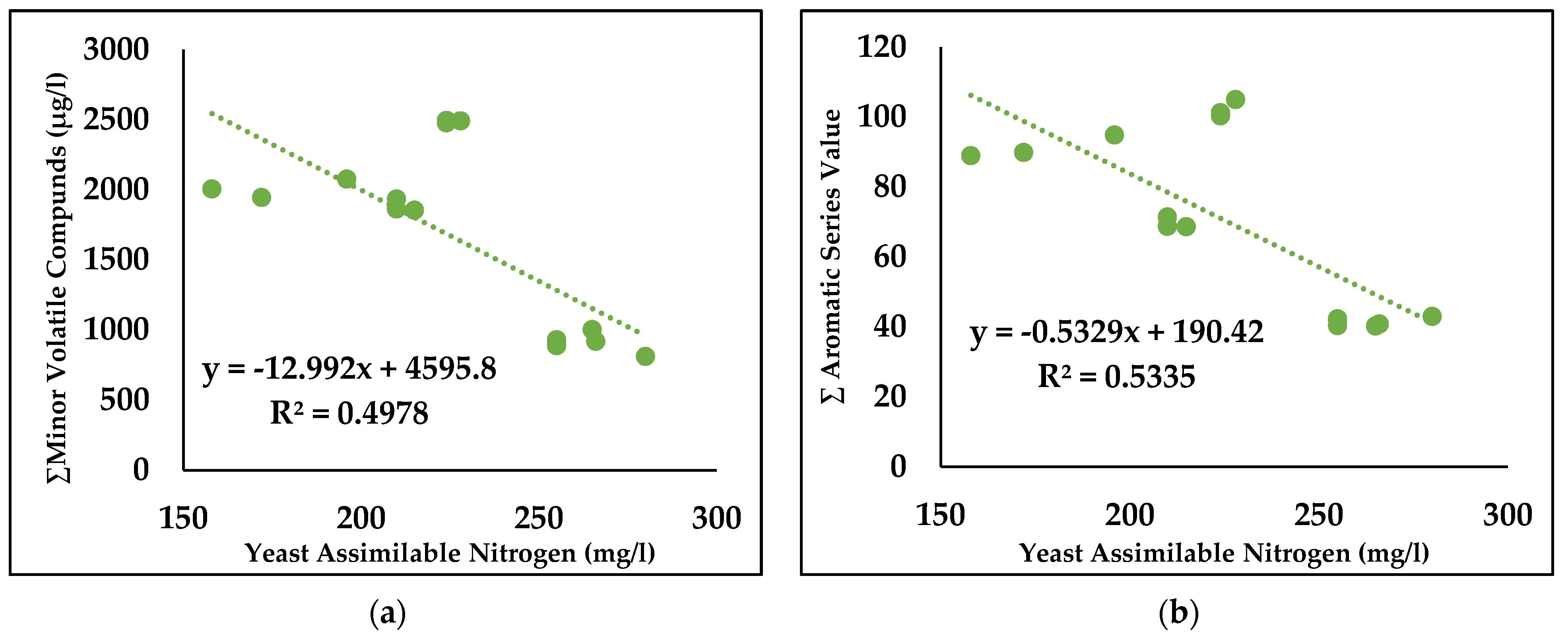

3.4. Relationship Between ∑VAO and Fertilisation

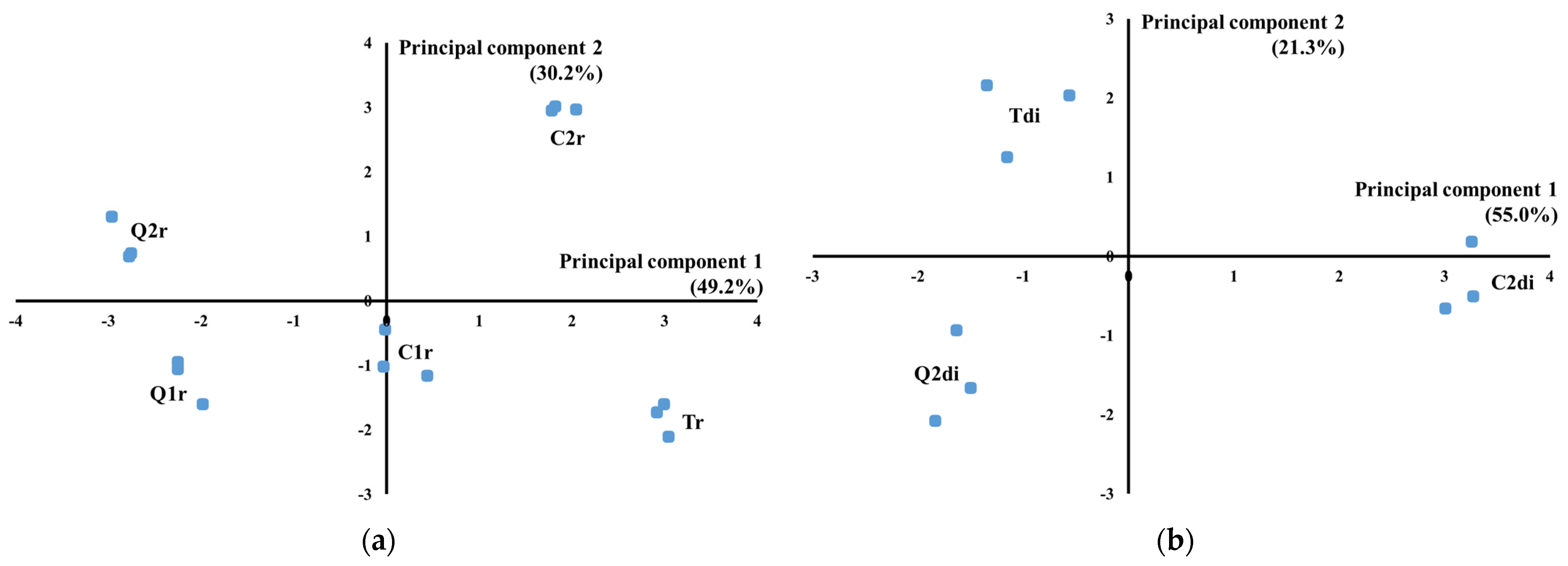

3.5. Principal Component Analysis

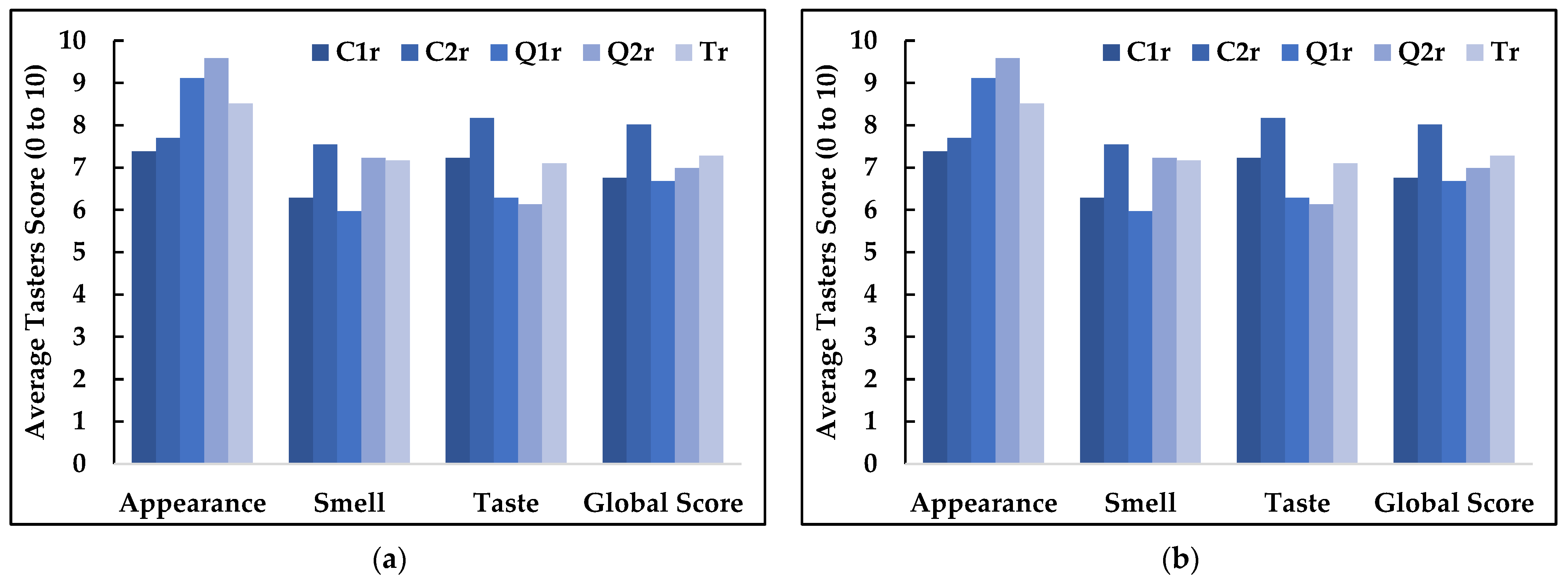

3.6. Organoleptic Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| A/P | Absence/Presence |

| AENOR | Spanish Association for Standardization and Certification |

| C/N | Carbon/Nitrogen Relation |

| C1r | Compost At 2800 Kg/Ha Rainfed |

| C2di | Compost At 5600 Kg/Ha Deficit Irrigated |

| C2r | Compost At 5600 Kg/Ha Rainfed |

| EC | Electrical Conductivity |

| FID | Flame Ionization Detector |

| GC-MS | Gas Chromatography Coupled to Mass Spectrometry |

| GI | Germination Index |

| ICP-MS | Inductively Coupled Plasma Mass Spectrometry |

| LRI | Linear Retention Index |

| MSW | Municipal Solid Waste |

| NTK | Total Kjeldahl Nitrogen |

| OF-MSW | Organic Fraction of Municipal Solid Waste |

| OIV | International Organization of Vine and Wine |

| OM | Organic Matter |

| Q1r | Mineral Fertilizer At 230 Kg/Ha Rainfed |

| Q2r | Mineral Fertilizer At 460 Kg/Ha Rainfed |

| Q2r | Mineral Fertilizer At 460 Kg/Ha Deficit Irrigated |

| Tdi | Control Deficit Irrigated |

| Tr | Control Rainfed |

| UFN | Nitrogen Fertilization Units (Kg) |

| WWTPs | Sludge From Urban Wastewater Treatment Plants |

| YAN | Yeast Assimilable Nitrogen |

References

- Fraga, H. Viticulture and Winemaking under Climate Change. Agronomy 2019, 9, 783. [Google Scholar] [CrossRef]

- Badalíková, B.; Burg, P.; Mašán, V.; Prudil, J.; Jobbágy, J.; Čížková, A.; Krištof, K.; Vašinka, M. Deep Placement of Compost into Vineyard Soil Affecting Physical Properties of Soils, Yield and Quality of Grapes. Sustainability 2022, 14, 7823. [Google Scholar] [CrossRef]

- Ferreira, C.S.S.; Seifollahi-Aghmiuni, S.; Destouni, G.; Ghajarnia, N.; Kalantari, Z. Soil Degradation in the European Mediterranean Region: Processes, Status and Consequences. Sci. Total Environ. 2022, 805, 150106. [Google Scholar] [CrossRef] [PubMed]

- Mugnai, S.; Masi, E.; Azzarello, E.; Mancuso, S. Influence of Long-Term Application of Green Waste Compost on Soil Characteristics and Growth, Yield and Quality of Grape (Vitis vinifera L.). Compost. Sci. Util. 2012, 20, 29–33. [Google Scholar] [CrossRef]

- Omar, L.; Ahmed, O.H.; Jalloh, M.B.; Nik Muhamad, A.M. Soil Nitrogen Fractions, Nitrogen Use Efficiency and Yield of Zea mays L. Grown on a Tropical Acid Soil Treated with Composts and Clinoptilolite Zeolite. Appl. Sci. 2020, 10, 4139. [Google Scholar] [CrossRef]

- Masullo, A. Organic Wastes Management in a Circular Economy Approach: Rebuilding the Link between Urban and Rural Areas. Ecol. Eng. 2017, 101, 84–90. [Google Scholar] [CrossRef]

- Arrobas, M.; Thais Nepomuceno Carvalho, J.; Raimundo, S.; Poggere, G.; Rodrigues, M.Â. The Safe Use of Compost Derived from Municipal Solid Waste Depends on Its Composition and Conditions of Application. Soil. Use Manag. 2022, 38, 917–928. [Google Scholar] [CrossRef]

- Aguilera, E.; Díaz-Gaona, C.; García-Laureano, R.; Reyes-Palomo, C.; Guzmán, G.I.; Ortolani, L.; Sánchez-Rodríguez, M.; Rodríguez-Estévez, V. Agroecology for Adaptation to Climate Change and Resource Depletion in the Mediterranean Region. A Review. Agric. Syst. 2020, 181, 102809. [Google Scholar] [CrossRef]

- Chen, J.; Lü, S.; Zhang, Z.; Zhao, X.; Li, X.; Ning, P.; Liu, M. Environmentally Friendly Fertilizers: A Review of Materials Used and Their Effects on the Environment. Sci. Total Environ. 2018, 613–614, 829–839. [Google Scholar] [CrossRef]

- Regus, F.; Laffont-Schwob, I.; Prudent, P.; Foli, L.; Capowiez, Y.; Capelle, J.; Hamrouni, R.; Dupuy, N.; Folzer, H.; Farnet Da Silva, A.M. Challenges in Viticulture Practices in a Changing Environment: Can Green Waste Amendment Benefit Soil Properties of Vineyards in the Mediterranean? Geoderma Reg. 2024, 38, e00844. [Google Scholar] [CrossRef]

- Calleja-Cervantes, M.E.; Fernández-González, A.J.; Irigoyen, I.; Fernández-López, M.; Aparicio-Tejo, P.M.; Menéndez, S. Thirteen Years of Continued Application of Composted Organic Wastes in a Vineyard Modify Soil Quality Characteristics. Soil Biol Biochem. 2015, 90, 241–254. [Google Scholar] [CrossRef]

- Burg, P.; Badalíková, B.; Mašán, V.; Csáki, Š.; Burgová, J.; Turan, J.; Matwijczuk, A. Evaluation of the Effect of Deep Compost Application in the Areas around Vineyard Tree Trunks on Selected Soil Chemical Properties and the Vegetative Growth of the Vine. Processes 2023, 11, 632. [Google Scholar] [CrossRef]

- Doni, S.; Masciandaro, G.; Macci, C.; Manzi, D.; Mattii, G.B.; Cataldo, E.; Gispert, M.; Vannucchi, F.; Peruzzi, E. Zeolite and Winery Waste as Innovative By-Product for Vineyard Soil Management. Environments 2024, 11, 29. [Google Scholar] [CrossRef]

- Gaiotti, F.; Marcuzzo, P.; Belfiore, N.; Lovat, L.; Fornasier, F.; Tomasi, D. Influence of Compost Addition on Soil Properties, Root Growth and Vine Performances of Vitis vinifera Cv Cabernet Sauvignon. Sci. Hortic. 2017, 225, 88–95. [Google Scholar] [CrossRef]

- Botelho, M.; Ribeiro, H.; Cruz, A.; Duarte, D.F.; Faria, D.L.; De Castro, R.; Ricardo-da-Silva, J. Mechanical Pruning and Soil Organic Amendments in Vineyards of Syrah: Effects on Grape Composition. OENO One 2021, 55, 267–277. [Google Scholar] [CrossRef]

- Baldi, E.; Polidori, G.; Germani, M.; Larocca, G.N.; Mazzon, M.; Allegro, G.; Pastore, C.; Quartieri, M.; Marzadori, C.; Filippetti, I.; et al. Fertilizer Potential of Organic-Based Soil Amendments on Cv. Sangiovese (V. vinifera L.) Vines: Preliminary Results. Agronomy 2022, 12, 1604. [Google Scholar] [CrossRef]

- You, R.; Margenat, A.; Cañameras, N.; Carazo, N.; Matamoros, V.; Bayona, J.M.; Díez, S. Impact of Repeated Organic Amendments on Trace Element Exposure and Health Risks via the Soil-Vegetable-Human Pathway. Environ. Res. 2025, 275, 121326. [Google Scholar] [CrossRef]

- Palenzuela, M.d.V.; López de Lerma, N.; Sánchez-Suárez, F.; Martínez-García, R.; Peinado, R.A.; Rosal, A. Aroma Composition of Wines Produced from Grapes Treated with Organic Amendments. Appl. Sci. 2023, 13, 8001. [Google Scholar] [CrossRef]

- González-Viñas, M.A.; Ferrer, M.; Sánchez-Palomo, E.; Delgado, J.A. Study of the Effect of Grape Pomace Compost as Fertilizer on the Aroma of White Wine. CHELVA. In Proceedings of the the 9° Congreso Internacional de Química de la ANQUE. Alimentos y Bebidas, Murcia, Spain, 17–20 June 2018; Volume 1. [Google Scholar]

- Alises, M.O.; Palomo, E.S.; González-Viñas, M.Á. Wine Waste Compost Addition to a Vineyard of Chelva Grape of Central Spain: Effect on Wine Volatile Compounds. Horticulturae 2025, 11, 219. [Google Scholar] [CrossRef]

- European Union. Reglamento UE1009/2019 REGLAMENTO (UE) 2019/1009 del Parlamento Europeo y del Consejo de 5 de Junio de 2019 Por El Que Se Establecen Disposiciones Relativas a La Puesta a Disposición En El Mercado de Los Productos Fertilizantes UE; European Union: Brussels, Belgium, 2019. [Google Scholar]

- ISO 7251:2005; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Detection and Enumeration of Presumptive Escherichia Coli—Most Probable Number Technique. ISO: Geneva, Switzerland, 2005.

- ISO 6579 (UNE-EN ISO 6579-1:2017/A1:2021); Horizontal Method for the Detection, Enumeration and Serotyping of Salmonella. ISO: Geneva, Switzerland, 2021.

- Rosal, A. Caracterización y Mejora de la Calidad en el Compostaje de Residuos Municipales. Doctoral Thesis, Universidad de Córdoba, Cordoba, Spain, 2007. [Google Scholar]

- RD 506/2013; Productos Fertilizantes. Boletín Oficial del Estado. Ministerio de la Presidencia: Madrid, Spain, 2013.

- Zucconi, F.; Pera, A.; Forte, M.; DeBertolli, M. Evaluating Toxicity of Immature Compost. Biocycle 1981, 22, 54–57. [Google Scholar]

- Hidalgo Fernández-Cano, L.; Hidalgo Togores, J. Tratado de Viticultura. Volumen I y II; Mundi Prensa: Madrid, Spain, 2019. [Google Scholar]

- Sánchez-de-Miguel, P.; Baeza, P.; Junquera, P.; Lissarrague, J.R. Vegetative Development: Total Leaf Area and Surface Area Indexes. In Methodologies and Results in Grapevine Research; Springer: Dordrecht, The Netherlands, 2010; pp. 31–44. [Google Scholar]

- OIV. Compendium of International Methods of Wine and Must Analysis; International Organisation of Vine and Wine: Dijon, France, 2023; ISBN 9782850380686. [Google Scholar]

- Peinado, R.A.; Moreno, J.A.; Muñoz, D.; Medina, M.; Moreno, J. Gas Chromatographic Quantification of Major Volatile Compounds and Polyols in Wine by Direct Injection. J. Agric. Food Chem. 2004, 52, 6389–6393. [Google Scholar] [CrossRef]

- Martín-García, F.J.; Palacios-Fernández, S.; López de Lerma, N.; García-Martínez, T.; Mauricio, J.C.; Peinado, R.A. The Effect of Yeast, Sugar and Sulfur Dioxide on the Volatile Compounds in Wine. Fermentation 2023, 9, 541. [Google Scholar] [CrossRef]

- AENOR. Análisis Sensorial. Tomo I. Alimentación; AENOR: Madrid, Spain, 1997. [Google Scholar]

- Consejería de Medio Ambiente y Rural; Políticas Agrarias y Territorio. Red de Asesoramiento al Regante de Extremadura (REDAREX). Available online: http://redarexplus.juntaex.es/REDAREX_plus/index.php?modulo=portada (accessed on 12 February 2025).

- Arris Pty Ltd.; SA Central Wine Australia. Grape and Wine Research and Development Corporation; Arris Pty Ltd. and SA Central Wine Australia: Urrbrae, Australia, 2011. [Google Scholar]

- Villette, J.; Cuéllar, T.; Verdeil, J.-L.; Delrot, S.; Gaillard, I. Grapevine Potassium Nutrition and Fruit Quality in the Context of Climate Change. Front. Plant Sci. 2020, 11, 123. [Google Scholar] [CrossRef] [PubMed]

- Moreno, J.J.; Peinado, R.A. Enological Chemistry; Academic Press: Newton, MA, USA, 2012. [Google Scholar]

- Wang, J.; Lu, Y.; Zhang, X.; Hu, W.; Lin, L.; Deng, Q.; Xia, H.; Liang, D.; Lv, X. Effects of Potassium-Containing Fertilizers on Sugar and Organic Acid Metabolism in Grape Fruits. Int. J. Mol. Sci. 2024, 25, 2828. [Google Scholar] [CrossRef]

- Martínez-Lüscher, J.; Kurtural, S.K. Same Season and Carry-Over Effects of Source-Sink Adjustments on Grapevine Yields and Non-Structural Carbohydrates. Front. Plant Sci. 2021, 12, 695319. [Google Scholar] [CrossRef]

- Reynolds, A.G. Managing Wine Quality: Volume 2: Oenology and Wine Quality; Woodhead Publishing: New Delhi, India, 2021. [Google Scholar]

- Marcuzzo, P.; Gaiotti, F.; Lucchetta, M.; Lovat, L.; Tomasi, D. Tuning Potassium Fertilization to Improve PH and Acidity in Glera Grapevine (Vitis vinifera L.) under a Warming Climate. Appl. Sci. 2021, 11, 11869. [Google Scholar] [CrossRef]

- Cordente, A.G.; Espinase Nandorfy, D.; Solomon, M.; Schulkin, A.; Kolouchova, R.; Francis, I.L.; Schmidt, S.A. Aromatic Higher Alcohols in Wine: Implication on Aroma and Palate Attributes during Chardonnay Aging. Molecules 2021, 26, 4979. [Google Scholar] [CrossRef]

- Waterhouse, A.L.; Sacks, G.L.; Jeffery, D.W. Understanding Wine Chemistry; Wiley: Hoboken, NJ, USA, 2016; ISBN 9781118627808. [Google Scholar]

- Su, Y.; Heras, J.M.; Gamero, A.; Querol, A.; Guillamón, J.M. Impact of Nitrogen Addition on Wine Fermentation by S. Cerevisiae Strains with Different Nitrogen Requirements. J. Agric Food Chem. 2021, 69, 6022–6031. [Google Scholar] [CrossRef]

- Sánchez-Palomo, E.; Trujillo, M.; García Ruiz, A.; González Viñas, M.A. Aroma Profile of Malbec Red Wines from La Mancha Region: Chemical and Sensory Characterization. Food Res. Int. 2017, 100, 201–208. [Google Scholar] [CrossRef]

- Allamy, L.; Van Leeuwen, C.; Pons, A. Impact of Harvest Date on Aroma Compound Composition of Merlot and Cabernet-Sauvignon Must and Wine in a Context of Climate Change: A Focus on Cooked Fruit Molecular Markers. OENO One 2023, 57, 99–112. [Google Scholar] [CrossRef]

- Gil, M.; Pontin, M.; Berli, F.; Bottini, R.; Piccoli, P. Metabolism of Terpenes in the Response of Grape (Vitis vinifera L.) Leaf Tissues to UV-B Radiation. Phytochemistry 2012, 77, 89–98. [Google Scholar] [CrossRef] [PubMed]

- Camesasca, L.; Minteguiaga, M.; Fariña, L.; Salzman, V.; Aguilar, P.S.; Gaggero, C.; Carrau, F. Overproduction of Isoprenoids by Saccharomyces Cerevisiae in a Synthetic Grape Juice Medium in the Absence of Plant Genes. Int. J. Food Microbiol. 2018, 282, 42–48. [Google Scholar] [CrossRef] [PubMed]

- García-Martínez, T.; Moreno, J.; Mauricio, J.C.; Peinado, R. Natural Sweet Wine Production by Repeated Use of Yeast Cells Immobilized on Penicillium Chrysogenum. LWT—Food Sci. Technol. 2015, 61, 503–509. [Google Scholar] [CrossRef]

- Hernandez-Orte, P.; Bely, M.; Cacho, J.; Ferreira, V. Impact of Ammonium Additions on Volatile Acidity, Ethanol, and Aromatic Compound Production by Different Saccharomyces Cerevisiae Strains during Fermentation in Controlled Synthetic Media. Aust. J. Grape Wine Res. 2006, 12, 150–160. [Google Scholar] [CrossRef]

- López de Lerma, N.; Peinado, R.A.; Puig-Pujol, A.; Mauricio, J.C.; Moreno, J.; García-Martínez, T. Influence of Two Yeast Strains in Free, Bioimmobilized or Immobilized with Alginate Forms on the Aromatic Profile of Long Aged Sparkling Wines. Food Chem. 2018, 250, 22–29. [Google Scholar] [CrossRef]

- Pérez, D.; Denat, M.; Heras, J.M.; Guillamón, J.M.; Ferreira, V.; Querol, A. Effect of Non-Wine Saccharomyces Yeasts and Bottle Aging on the Release and Generation of Aromas in Semi-Synthetic Tempranillo Wines. Int. J. Food Microbiol. 2022, 365, 109554. [Google Scholar] [CrossRef]

- Seguinot, P.; Rollero, S.; Sanchez, I.; Sablayrolles, J.-M.; Ortiz-Julien, A.; Camarasa, C.; Mouret, J.-R. Impact of the Timing and the Nature of Nitrogen Additions on the Production Kinetics of Fermentative Aromas by Saccharomyces Cerevisiae during Winemaking Fermentation in Synthetic Media. Food Microbiol. 2018, 76, 29–39. [Google Scholar] [CrossRef]

- Dumitriu, G.-D.; Peinado, R.A.; Cotea, V.V.; López de Lerma, N. Volatilome Fingerprint of Red Wines Aged with Chips or Staves: Influence of the Aging Time and Toasting Degree. Food Chem. 2020, 310, 125801. [Google Scholar] [CrossRef]

- Petronilho, S.; Lopez, R.; Ferreira, V.; Coimbra, M.A.; Rocha, S.M. Revealing the Usefulness of Aroma Networks to Explain Wine Aroma Properties: A Case Study of Portuguese Wines. Molecules 2020, 25, 272. [Google Scholar] [CrossRef]

- Gobert, A.; Tourdot-Maréchal, R.; Sparrow, C.; Morge, C.; Alexandre, H. Influence of Nitrogen Status in Wine Alcoholic Fermentation. Food Microbiol. 2019, 83, 71–85. [Google Scholar] [CrossRef]

- Martínez-García, R.; Roldán-Romero, Y.; Moreno, J.; Puig-Pujol, A.; Mauricio, J.C.; García-Martínez, T. Use of a flor yeast strain for the second fermentation of sparkling wines: Effect of endogenous CO2 over-pressure on the volatilome. Food Chem. 2019, 308, 125555. [Google Scholar] [CrossRef] [PubMed]

- Moreno, J. Influencia del Tipo de Envejecimiento Sobre el Perfil Aromático de Vinos Generosos Andaluces. Ph.D. Thesis, University of Córdoba, Córdoba, Spain, 2005. [Google Scholar]

- Buttery, B.G.; Turnbaugh, J.G.; Ling, L.C. Contribution of volatiles to rice aroma. J. Agric. Food Chem. 1988, 36, 1006–1009. [Google Scholar] [CrossRef]

- Available online: http://www.leffingwell.com/esters.htm (accessed on 12 February 2025).

- Guth, H. Identification of character impact odorants of different white wine varieties. J. Agric. Food Chem. 1997, 45, 3027–3032. [Google Scholar] [CrossRef]

- Gómez, M.J.; Cacho, J.F.; Ferreira, V.; Vicario, I.M.; Heredia, F.J. Volatile components of Zalema white wines. Food Chem. 2007, 100, 1464–1473. [Google Scholar] [CrossRef]

- Ferreira, V.; Lopez, R.; Cacho, J. Quantitative determination of the odorants of Young red wine from different grape varieties. J. Sci. Food Agric. 2000, 80, 1659–1667. [Google Scholar] [CrossRef]

- Peinado, R.; Moreno, J.; Medina, M.; Mauricio, J.C. Changes in volatile compounds and aromatic series in sherry wine with high gluconic acid levels subjected to aging by submerged flor yeast cultures. Biotechnol. Lett. 2004, 26, 757–762. [Google Scholar] [CrossRef]

- Etiévant, P.X. Wine. In Volatile Compounds of Food and Beverages; Maarse, H., Ed.; Marcel Dekker: New York, NY, USA, 1991; pp. 483–546. [Google Scholar]

- Ogawa, M.; Vararu, F.; Moreno-Garcia, J.; Mauricio, J.C.; Moreno, J.; Garcia-Martinez, T. Analyzing the Minor Volatilome of Torulaspora delbrueckii in an Alcoholic Fermentation. Eur. Food Res. Technol. 2022, 248, 613–624. [Google Scholar] [CrossRef]

- Zhang, S.; Petersen, M.A.; Liu, J.; Toldam-Andersen, T.B.; Ebeler, S.E.; Hopfer, H. Influence of Pre-Fermentation Treatments on Wine Volatile and Sensory Profile of the New Disease Tolerant Cultivar Solaris. Molecules 2015, 20, 21609–21625. [Google Scholar] [CrossRef]

- Song, X.; Dai, F.; Yao, J.; Li, Z.; Huang, Z.; Liu, H.; Zhu, Z. Characterization of the Volatile Profile of Feijoa (Acca sellowiana) Fruit at Different Ripening Stages by HS-SPME-GC/MS. LWT 2023, 184, 115011. [Google Scholar] [CrossRef]

- Zhu, L.X.; Zhang, M.M.; Shi, Y.; Duan, C.Q. Evolution of the Aromatic Profile of Traditional Msalais Wine during Industrial Production. Int. J. Food Prop. 2019, 22, 911–924. [Google Scholar] [CrossRef]

| Yield (kg/Plant) | SA 1 (m2/ha) | |

|---|---|---|

| Tr | 2.3 ± 0.8 a | 5500 ± 916 ab |

| C1r | 2.3 ± 0.8 a | 6148 ± 809 a |

| C2r | 1.6 ± 0.7 b | 5741 ± 819 ab |

| Q1r | 1.3 ± 0.5 b | 5148 ± 417 b |

| Q2r | 1.4 ± 0.7 b | 4870 ± 592 b |

| Tdi | 8.4 ± 0.6 | 7731 ± 440 a |

| Cdi | 8 ± 1 | 6690 ± 730 b |

| Qdi | 8 ± 1 | 7130 ± 454 ab |

| pH | Titratable Acidity (g/L TH2) | YAN (mg/L) | NH4 (mg/L) | |

|---|---|---|---|---|

| Tr | 3.96 ± 0.02 c | 3.7 ± 0.1 a | 175 ± 19 c | 110 ± 3 b |

| C1r | 3.98 ± 0.02 c | 3.54 ± 0.03 a | 212 ± 3 b | 110 ± 3 b |

| C2r | 4.09 ± 0.01 b | 3.15 ± 0.09 b | 225 ± 2 b | 124 ± 3 a |

| Q1r | 4.23 ± 0.03 a | 2.98 ± 0.06 b | 263 ± 14 a | 112 ± 3 b |

| Q2r | 4.18 ± 0.02 a | 3.2 ± 0.2 b | 262 ± 6 a | 122 ± 3 a |

| Tdi | 4.01 ± 0.02 a | 2.9 ± 0.02 | 175 ± 7 | 69 ± 3 |

| Cdi | 4.01 ± 0.02 a | 2.83 ± 0.09 | 166 ± 11 | 71 ± 3 |

| Qdi | 3.94 ± 0.03 b | 2.96 ± 0.04 | 156 ± 10 | 65 ± 3 |

| pH | Titratable Acidity (g/L TH2) | Ethanol (% v/v) | Volatile Acidity (g/L AcH) | Malic Acid (g/L) | Color Index | |

|---|---|---|---|---|---|---|

| Tr | 3.41 ± 0.05 b | 5.7 ± 0.09 a | 12.16 ± 0.05 c | 0.43 ± 0.02 a | 1.64 ± 0.02 a | 0.08 ± 0.01 |

| C1r | 3.31 ± 0.02 c | 5.4 ± 0.05 b | 12.6 ± 0.2 b | 0.33 ± 0.03 b | 1.4 ± 0.2 ab | 0.08 ± 0.01 |

| C2r | 3.54 ± 0.02 a | 4.81 ± 0.06 c | 12.9 ± 0.1 ab | 0.25 ± 0.02 c | 1.27 ± 0.05 b | 0.3 ± 0.4 |

| Q1r | 3.47 ± 0.05 ab | 5.2 ± 0.04 b | 12.9 ± 0.2 ab | 0.4 ± 0.02 a | 1.48 ± 0.09 ab | 0.1 ± 0.01 |

| Q2r | 3.49 ± 0.01 a | 4.8 ± 0.1 c | 13.1 ± 0.2 a | 0.44 ± 0.03 a | 1.37 ± 0.04 b | 0.12 ± 0.01 |

| Tdi | 3.31 ± 0.01 a | 5.16 ± 0.02 a | 11.73 ± 0.06 b | 0.31 ± 0.02 a | 1.29 ± 0.1 ab | 0.06 ± 0.01 a |

| Cdi | 3.33 ± 0.02 a | 5.1 ± 0.3 a | 11.9 ± 0.1 ab | 0.28 ± 0.02 a | 1.15 ± 0.07 b | 0.06 ± 0.01 a |

| Qdi | 3.32 ± 0.01 a | 5.5 ± 0.1 a | 12.1 ± 0.2 a | 0.4 ± 0.1 a | 1.43 ± 0.02 a | 0.06 ± 0.02 a |

| Tr | C1r | C2r | Q1r | Q2r | |

|---|---|---|---|---|---|

| Alcohols | |||||

| Mayor Alcohols (mg/L) | 436 ± 1 b | 470 ± 7 a | 291.7 ± 0.4 d | 372 ± 2 c | 389 ± 3 c |

| Methanol | 91 ± 4 ab | 101 ± 17 a | 25 ± 1 c | 26 ± 4 c | 71 ± 8 b |

| Propanol | 37 ± 1 b | 49 ± 7 a | 46.1 ± 0.8 a | 34 ± 1 b | 42 ± 1 ab |

| Iso-butanol | 25.3 ± 0.5 bc | 28 ± 2 b | 14 ± 0.2 d | 24.1 ± 0.5 c | 34.1 ± 0.3 a |

| 2-methylbutanol | 33 ± 1 bc | 35 ± 2 ab | 30.9 ± 0.1 c | 38 ± 1 a | 34.4 ± 0.6 ab |

| 3-methylbutanol | 233 ± 4 a | 241 ± 17 a | 152 ± 1 c | 221 ± 5 a | 190 ± 4 b |

| 2-phenylethanol | 17 ± 1 c | 17 ± 1 c | 23.4 ± 0.3 b | 29 ± 1 a | 17.9 ± 0.9 c |

| Minor Alcohols (µg/L) | 906 ± 96 a | 794 ± 26 ab | 578 ± 16 bc | 482 ± 43 c | 567 ± 41 bc |

| Hexanol | 856 ± 83 a | 758 ± 26 ab | 546 ± 15 bc | 436 ± 40 c | 538 ± 39 bc |

| 2-ethyl-1-hexanol | 49 ± 13 a | 36 ± 4 ab | 32 ± 2 ab | 45 ± 4 ab | 29 ± 3 b |

| Dodecanol | 0.41 ± 0.01 a | 0.37 ± 0.01 a | 0.38 ± 0.06 a | 0.37 ± 0.01 a | 0.39 ± 0.02 a |

| Esters | |||||

| Mayor Esters (mg/L) | 127 ± 1 b | 132 ± 4 a | 79 ± 1 c | 57 ± 1 d | 72 ± 1 c |

| Ethyl acetate | 50 ± 4 a | 37 ± 0.8 b | 55 ± 3 a | 23 ± 4 c | 42 ± 3 b |

| Ethyl lactate | 63 ± 3 b | 86 ± 9 a | 15.4 ± 0.5 c | 16 ± 0.2 c | 12.3 ± 0.5 c |

| Diethyl succinate | 14 ± 1 b | 9 ± 0.7 c | 8.57 ± 0.06 c | 18 ± 2 a | 17.6 ± 0.9 a |

| Minor Esters (µg/L) | 5755 ± 122 b | 5492 ± 134 b | 8834 ± 561 a | 3045 ± 123 c | 2604 ± 178 c |

| Ethyl iso-butanoate | 24 ± 2 c | 27 ± 2 c | 27 ± 3 c | 82.1 ± 0.9 a | 75 ± 0.7 b |

| Ethyl butanoate | 140 ± 4 b | 149 ± 5 b | 216 ± 5 a | 140 ± 7 b | 114 ± 4 c |

| Butyl acetate | 1.1 ± 0.2 a | 0.9 ± 0.1 a | 1.17 ± 0.05 a | 1.1 ± 0.2 a | 1.1 ± 0.1 a |

| Ethyl 2-methylbutanoate | 2 ± 0.2 a | 1.07 ± 0.07 b | 0.44 ± 0.06 c | 1.9 ± 0.2 a | 1.3 ± 0.1 b |

| Ethyl 3-methylbutanoate | 4.8 ± 0.4 a | 3.4 ± 0.1 b | 2.3 ± 0.1 cd | 2.6 ± 0.2 c | 1.8 ± 0.1 d |

| Isoamyl acetate | 3515 ± 57 b | 3395 ± 90 b | 5200 ± 517 a | 2386 ± 96 c | 2006 ± 191 c |

| Ethyl hexanoate | 714 ± 13 b | 605 ± 17 c | 884 ± 10 a | 142 ± 11 d | 97 ± 5 e |

| Hexyl acetate | 67 ± 2 a | 64 ± 1 a | 54.9 ± 0.5 b | 2.1 ± 0.2 c | 2.3 ± 0.2 c |

| Ethyl heptanoate | 1.47 ± 0.04 a | 0.29 ± 0.01 b | 0.12 ± 0.01 c | 0.04 ± 0 d | 0.05 ± 0 d |

| Z-3-hexenylbutyrate | 86 ± 3 b | 66 ± 2 c | 129 ± 5 a | 4.2 ± 0.5 d | 4.8 ± 0.5 d |

| Ethyl octanoate | 612 ± 43 b | 471 ± 11 c | 946 ± 39 a | 89 ± 1 d | 93 ± 2 d |

| 2-phenylethyl acetate | 483 ± 91 a | 577 ± 18 a | 567 ± 15 a | 161 ± 17 b | 120 ± 8 b |

| Ethyl do-decanaote | 139 ± 21 b | 116 ± 4 b | 778 ± 14 a | 23.2 ± 0.6 d | 76 ± 1 c |

| Phenethyl hexanoate | 0.22 ± 0.02 ab | N.D. | 0.23 ± 0.01 a | 0.2 ± 0.01 b | N.D. |

| Ethyl tetra-decanoate | 5 ± 2 b | 5.6 ± 0.4 b | 12.3 ± 0.8 a | 3.9 ± 0.2 b | 3.8 ± 0.5 b |

| Phenethyl benzoate | 0.56 ± 0.05 b | 0.75 ± 0.02 a | 0.74 ± 0.03 a | 0.72 ± 0.01 a | 0.73 ± 0.04 a |

| Ethyl hexa-decanoate | 6 ± 4 c | 11 ± 1 b | 15.7 ± 0.3 a | 5.2 ± 0.5 c | 5.4 ± 0.6 c |

| Aldehydes | |||||

| Mayor aldehydes (mg/L) | 108 ± 5 a | 64 ± 4 c | 79 ± 4 b | 93 ± 7 b | 122 ± 6 a |

| Acetaldehyde | 108 ± 5 a | 64 ± 4 c | 79 ± 4 b | 93 ± 7 b | 122 ± 6 a |

| Minor aldehydes (µg/L) | 34 ± 3 a | 16 ± 2 c | 23.7 ± 0.9 b | 20.1 ± 0.4 bc | 18 ± 1 c |

| Benzaldehyde | 4.3 ± 0.1 a | 1.7 ± 0.2 d | 4.1 ± 0.3 a | 2.2 ± 0.2 c | 3.4 ± 0.2 b |

| Hexanal | 4.6 ± 0.3 b | 6.8 ± 0.8 a | 7.3 ± 0.8 a | 6.8 ± 0.3 a | 6.6 ± 0.4 a |

| Nonanal | 0.1 ± 0.02 c | 0.6 ± 0.1 b | 1.3 ± 0.2 a | 0.14 ± 0.02 c | 1.1 ± 0.1 a |

| Phenylacetaldehyde | 25 ± 3 a | 7 ± 0.9 c | 9.9 ± 0.7 bc | 10.8 ± 0.3 b | 6.5 ± 0.5 c |

| (E,E)-2,4-Decadienal | 0.21 ± 0.03 a | 0.17 ± 0.02 ab | 0.18 ± 0.02 ab | 0.16 ± 0.02 b | 0.15 ± 0.01 b |

| Ketones | |||||

| Mayor ketones (mg/L) | 48 ± 6 a | 42 ± 4 ab | 32.8 ± 0.4 b | 43 ± 6 ab | 46 ± 4 a |

| Acetoin | 48 ± 6 a | 42 ± 4 ab | 32.8 ± 0.4 b | 43 ± 6 ab | 46 ± 4 a |

| Minor ketones (µg/L) | 0.09 ± 0.02 cd | 0.2 ± 0.03 b | 0.15 ± 0.03 bc | 0.51 ± 0.06 a | 0.06 ± 0.01 d |

| 3-Heptanone | 0.09 ± 0.02 cd | 0.2 ± 0.03 b | 0.15 ± 0.03 bc | 0.51 ± 0.06 a | 0.06 ± 0.01 d |

| Lactones (µg/L) | 3.02 ± 0.05 c | 7.7 ± 0.9 b | 6 ± 0.6 b | 18 ± 2 a | 7.4 ± 0.5 b |

| γ-Nonalactone | 3.02 ± 0.05 c | 7.7 ± 0.9 b | 6 ± 0.6 b | 18 ± 2 a | 7.4 ± 0.5 b |

| Terpenoids (µg/L) | 22 ± 4 b | 37 ± 2 a | 35 ± 2 a | 6 ± 0.2 c | 7.5 ± 0.5 c |

| E-Nerolidol | 18 ± 4 b | 35 ± 2 a | 31 ± 2 a | 3.7 ± 0.2 c | 5.3 ± 0.5 c |

| Z-Geranyl acetone | 1.5 ± 0.1 a | 1.53 ± 0.09 a | 1.39 ± 0.03 a | 1.5 ± 0.1 a | 1.44 ± 0.08 a |

| E-Methyl-dihydro-jasmonate | 1.87 ± 0.08 a | 0.97 ± 0.04 b | 2 ± 0.5 a | 0.76 ± 0.05 b | 0.7 ± 0.1 b |

| Tdi | C2di | Q2di | |

|---|---|---|---|

| Alcohols | |||

| Mayor Alcohols (mg/L) | 480 ± 6 a | 455 ± 4 b | 443 ± 2 c |

| Methanol | 79 ± 14 a | 83 ± 2 a | 73 ± 4 a |

| Propanol | 42 ± 3 a | 40 ± 1 a | 37 ± 2 a |

| Iso-butanol | 28 ± 1 a | 24 ± 2 b | 25.92 ± 0.02 ab |

| 2-methylbutanol | 42.3 ± 0.9 a | 36 ± 2 b | 44 ± 2 a |

| 3-methylbutanol | 265 ± 14 a | 253 ± 12 a | 241 ± 7 a |

| 2-phenylethanol | 23 ± 2 a | 19 ± 1 b | 22 ± 2 ab |

| Minor Alcohols | 482 ± 36 | 441 ± 34 | 432 ± 22 |

| Hexanol | 441 ± 39 | 397 ± 31 | 393 ± 19 |

| 2-ethyl-1-hexanol | 40 ± 4 a | 37 ± 4 a | 37 ± 3 a |

| Octanol | n.d. | 6.1 ± 0.2 a | n.d. |

| Farnesol | 0.62 ± 0.04 c | 1.15 ± 0.04 a | 1.07 ± 0.01 c |

| Esters | |||

| Mayor Esters (mg/L) | 128 ± 2 a | 134 ± 2 a | 107 ± 1 b |

| Ethyl acetate | 46 ± 6 a | 37.7 ± 0.7 a | 39 ± 3 a |

| Ethyl lactate | 69 ± 4 b | 90 ± 4 a | 61 ± 4 b |

| Diethyl succinate | 14 ± 1 a | 6.8 ± 0.3 b | 6.8 ± 0.4 b |

| Minor Esters (µg/L) | 4289 ± 232 b | 5701 ± 215 a | 4143 ± 242 b |

| Ethyl iso-butanoate | 28 ± 2 a | 23.4 ± 0.9 b | 27 ± 2 ab |

| Ethyl butanoate | 153 ± 9 a | 157 ± 14 a | 122 ± 8 b |

| Butyl acetate | 0.9 ± 0.1 b | 1.3 ± 0.2 a | 1 ± 0.1 ab |

| Ethyl 2-methylbutanoate | 1.3 ± 0.1 a | 1.1 ± 0.2 a | 1.3 ± 0.1 a |

| Ethyl 3-methylbutanoate | 3.5 ± 0.4 a | 2.8 ± 0.2 b | 3.4 ± 0.1 ab |

| Isoamyl acetate | 2176 ± 151 b | 2957 ± 170 a | 2152 ± 233 b |

| Ethyl hexanoate | 603 ± 46 b | 792 ± 5 a | 482 ± 20 c |

| Hexyl acetate | 22.2 ± 0.5 b | 44 ± 2 a | 20.6 ± 0.3 b |

| Ethyl heptanoate | 0.23 ± 0.01 b | 0.2 ± 0.01 b | 0.35 ± 0.02 a |

| Z-3-hexenylbutyrate | 75 ± 2 b | 84 ± 1 a | 72 ± 2 b |

| Ethyl octanoate | 543 ± 25 b | 617 ± 11 a | 521 ± 11 b |

| 2-phenylethyl acetate | 437 ± 7 b | 682 ± 33 a | 489 ± 27 b |

| Ethyl do-decanaote | 234 ± 7 b | 329 ± 8 a | 243 ± 4 b |

| Phenethyl hexanoate | 0.24 ± 0.01 b | 0.26 ± 0.01 a | 0.23 ± 0.01 b |

| Ethyl tetra-decanoate | 4.4 ± 0.1 a | 4.7 ± 0.2 a | 4.3 ± 0.1 a |

| Phenethyl benzoate | 0.71 ± 0.01 a | 0.74 ± 0.03 a | 0.71 ± 0.02 a |

| Ethyl hexa-decanoate | 5.3 ± 0.4 a | 5.1 ± 0.4 a | 4.7 ± 0.2 a |

| Aldehydes | |||

| Mayor aldehydes (mg/L) | 104 ± 8 a | 35 ± 1 b | 48 ± 4 b |

| Acetaldehyde | 104 ± 8 a | 35 ± 1 b | 48 ± 4 b |

| Minor aldehydes (µg/L) | 20 ± 2 a | 16.8 ± 0.6 b | 20 ± 0.5 a |

| Benzaldehyde | 1.19 ± 0.08 c | 1.8 ± 0.3 b | 2.6 ± 0.2 a |

| Hexanal | 6.8 ± 0.4 a | 5.4 ± 0.4 b | 6.3 ± 0.4 ab |

| Heptanal | n.d. | 0.37 ± 0.03 b | 0.76 ± 0.08 a |

| Nonanal | 1.3 ± 0.2 a | 1.36 ± 0.09 a | 0.74 ± 0.07 b |

| Phenylacetaldehyde | 10 ± 2 a | 7.3 ± 0.4 a | 9 ± 0.5 a |

| 4-methylbenzaldehyde | 0.5 ± 0.07 b | 0.52 ± 0.08 b | 0.7 ± 0.1 a |

| Ketones | |||

| Mayor ketones (mg/L) | 61 ± 5 a | 23 ± 2 b | 23 ± 2 b |

| Acetoin | 61 ± 5 a | 23 ± 2 b | 23 ± 2 b |

| Minor ketones (µg/L) | 2.9 ± 0.4 b | 5.3 ± 0.4 a | 2.6 ± 0.3 b |

| Benzophenone | 0.32 ± 0.03 | 0.37 ± 0.02 | 0.36 ± 0.03 |

| 3-Heptanone | 0.31 ± 0.03 b | 2.6 ± 0.1 a | 0.2 ± 0.1 b |

| Acetophenone | 2.3 ± 0.4 a | 2.3 ± 0.3 a | 2.1 ± 0.2 a |

| Lactones (µg/L) | 8.8 ± 0.2 b | 13 ± 1 a | 8 ± 1 b |

| γ-Nona-lactone | 7.7 ± 0.4 ab | 8.5 ± 0.9 a | 6.2 ± 0.7 b |

| γ-Deca-lactone | 1.1 ± 0.2 b | 4.3 ± 0.4 a | 1.4 ± 0.3 b |

| Terpenoids (µg/L) | 46 ± 2 a | 22 ± 1 b | 25.8 ± 0.8 b |

| Limonene | 17 ± 2 a | 2.4 ± 0.4 b | 14 ± 1 a |

| E-Nerolidol | 27.2 ± 0.7 a | 17 ± 1 b | 9.9 ± 0.2 c |

| Z-Geranyl acetone | 1.34 ± 0.03 a | 1.35 ± 0.02 a | 1.34 ± 0.02 a |

| E-Methyl-dihydro-jasmonate | 0.71 ± 0.06 a | 0.7 ± 0.1 a | 0.11 ± 0.01 b |

| Tr | C1r | C2r | Q1r | Q2r | |

|---|---|---|---|---|---|

| Fruity | 25.3 ± 0.6 b | 20.3 ± 0.3 c | 36 ± 1 a | 12.5 ± 0.4 d | 11.4 ± 0.1 d |

| Green fruit | 11.9 ± 0.1 b | 9.1 ± 0.1 c | 13.7 ± 0.3 a | 2.2 ± 0.2 d | 1.62 ± 0.03 e |

| Green | 7.3 ± 0.7 a | 3.3 ± 0.4 c | 4.4 ± 0.2 b | 4.2 ± 0.1 bc | 3.2 ± 0.2 c |

| Creamy | 0.84 ± 0.03 b | 1.11 ± 0.08 a | 0.52 ± 0.02 a | 1 ± 0.05 c | 0.64 ± 0.05 c |

| Citrus | 0.05 ± 0.01 c | 0.24 ± 0.06 b | 0.5 ± 0.1 a | 0.06 ± 0.01 c | 0.45 ± 0.04 a |

| Chemistry | 19.1 ± 0.8 a | 17 ± 1 ab | 15.1 ± 0.5 cd | 13.7 ± 0.7 d | 16.5 ± 0.4 bc |

| Honey | 8.2 ± 0.3 a | 4 ± 0.2 c | 4.8 ± 0.1 b | 3.3 ± 0.1 d | 2.1 ± 0.1 e |

| Waxy | 13 ± 1 b | 10 ± 0.2 c | 22.8 ± 0.8 a | 1.9 ± 0.02 d | 2.24 ± 0.04 d |

| Floral | 3.7 ± 0.3 bc | 4.1 ± 0.1 b | 4.7 ± 0.1 a | 3.54 ± 0.05 c | 2.3 ± 0.1 d |

| Tdi | C2di | Q2di | |

|---|---|---|---|

| Fruity | 22 ± 1 b | 24.9 ± 0.3 a | 20.4 ± 0.6 b |

| Green fruit | 9.4 ± 0.5 a | 11 ± 0.1 b | 8.4 ± 0.3 c |

| Green | 4 ± 0.5 a | 3.4 ± 0.1 a | 3.8 ± 0.1 a |

| Creamy | 1.15 ± 0.04 a | 1.14 ± 0.05 a | 0.8 ± 0.04 b |

| Citrus | 2.2 ± 0.2 a | 0.8 ± 0.1 c | 1.7 ± 0.1 b |

| Chemistry | 21.3 ± 0.6 a | 17.6 ± 0.4 b | 18.7 ± 0.7 b |

| Honey | 4.2 ± 0.4 a | 4.5 ± 0.1 a | 4.2 ± 0.2 a |

| Waxy | 12 ± 0.5 b | 14 ± 0.2 a | 11.6 ± 0.2 b |

| Floral | 4.2 ± 0.1 b | 4.8 ± 0.1 a | 4.3 ± 0.2 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez-Suárez, F.; Palenzuela, M.d.V.; Rosal, A.; Peinado, R.A. Effect of Sewage Sludge Compost and Urban Pruning Waste on Agronomic Parameters and Wine Composition in Arid Zones Under Climate Change. Fermentation 2025, 11, 292. https://doi.org/10.3390/fermentation11050292

Sánchez-Suárez F, Palenzuela MdV, Rosal A, Peinado RA. Effect of Sewage Sludge Compost and Urban Pruning Waste on Agronomic Parameters and Wine Composition in Arid Zones Under Climate Change. Fermentation. 2025; 11(5):292. https://doi.org/10.3390/fermentation11050292

Chicago/Turabian StyleSánchez-Suárez, Fernando, María del Valle Palenzuela, Antonio Rosal, and Rafael Andrés Peinado. 2025. "Effect of Sewage Sludge Compost and Urban Pruning Waste on Agronomic Parameters and Wine Composition in Arid Zones Under Climate Change" Fermentation 11, no. 5: 292. https://doi.org/10.3390/fermentation11050292

APA StyleSánchez-Suárez, F., Palenzuela, M. d. V., Rosal, A., & Peinado, R. A. (2025). Effect of Sewage Sludge Compost and Urban Pruning Waste on Agronomic Parameters and Wine Composition in Arid Zones Under Climate Change. Fermentation, 11(5), 292. https://doi.org/10.3390/fermentation11050292