Abstract

The purpose of this work is to explore the addition of cabbage (Brassica oleracea) waste interspersed with cattle dung into a continuous anaerobic digester that normally uses cattle dung as a substrate. In this work, a 200-L continuous anaerobic digester was operated to conduct the research. The digester was filled fully with a mixture of cattle dung and water (50%:50%). The digester was then operated by continuously adding a 5-L mixture of cattle dung and water (50%:50%) every day for 1 month. Subsequently, the digester was operated for 1 month with an additional 5-L mixture of cabbage waste and water (50%:50%) for odd-numbered days and a mixture of cattle dung and water (50%:50%) for even-numbered days. The methane composition was higher (in the range of 41–78%) with only the cattle dung in the system. With the addition of cabbage waste, the methane composition became lower (in the range of 20–60%).

1. Introduction

The biogas plant was considered an optimal tool for the prevention of water pollution and odor annoyance caused by an uncontrolled discharge of livestock wastewater to open water sources that integrated into the rural clean water supply. Biogas plants are also a tool for environmental sanitation as well [1]. The effluent from the digester can be used as a fertilizer because it is rich in nitrogen, potassium, and phosphorus. The digestate that is left over can be directly used as a fertilizer in farming [2,3]. Therefore, the development of technologies and biogas production for biomethane generation has been encouraged by many countries as an alternative for the cogeneration of internal engines of electricity generation [4]. Household digesters could reduce the pressure on the environment by loss of cultivable land, soil erosion, greenhouse gas emissions, and reducing deforestation [2,5,6].

Large-capacity biogas plants (natural rubber tube, floating drum, and fixed-dome) were not attractive due to high investment costs, problematic access to spare parts as well as maintenance, and difficulties in installation. The disadvantages of this model are its high cost, difficulty in transport, and lack of ability of technicians and skilled laborers on biogas construction, operation, and maintenance works [1].

Millions of simple biogas digesters have been constructed to produce biogas, mainly for cooking and lighting in India, China, Bangladesh, Vietnam, Pakistan, and Tibet. Most biogas digesters in these countries are made out of concrete or plastic composite bricks and are unstirred and unheated. Approximately 40% of CH4 losses from small-scale digesters are due to emissions from outlets and inlets, leaking from non-airtight gas valves, and intentional releases or broken/cracked caps of digesters [7].

In a fixed-dome biodigester, the design lacks agitation action that causes a slower anaerobic digestion reaction, which affects the volume of biogas produced. The gas pressure will fluctuate substantially depending on the volume of biogas stored, which is invisible. Water particles become separated after some time and create two unusual layers [8]. Because it is underground, if such a leak occurs in the digester construction, it would be difficult to repair. The leak certainly will cause the formation of the biogas process not to take place as it should be [3,9,10].

An improved design from the fixed-dome bio-digester is a floating drum digester. A gasholder provides more space to store biogas with constant pressure. For this design, mild steel is commonly used to create the gas holder, making it less costly. The volume of stored biogas is visible directly as the drum rises when biogas is produced and moves down when it is consumed. The fixed dome type could last longer than the floating drum because the floating drum is not prone to corrosion [3,8,10]. Plug flow bio-digesters were introduced to separate two processes; therefore, two-phase systems were produced, which are acidogenesis and methanogenesis longitudinally. Plug-flow biodigesters have a constant working volume [8]. A balloon biodigester consists of a heat-sealed rubber bag or plastic, combining biogas storage and digestion parts. If the gas pressure exceeds the limit of the balloon’s designed pressure, the balloon explodes. One limitation of this design is its shorter lifespan, which does not exceed 2–5 years [3,8].

For optimum performance, anaerobic digestion depends on several different parameters; these parameters are hydraulic retention time, temperature, pH, mixing, C/N ratio, and substrate [2,6]. The household digesters often stop being used by people in the long run due to gas leakage, lack of knowledge, inadequate supply of substrate, low gas production, and slow recovery. A solution for these is needed; however, it demands more research and development. For instance, straw is a potential substrate for household biogas digesters [2].

Hydrolysis, acidogenesis, acetogenesis, and methanogenesis are the four-step processes that typically occur in anaerobic processes [6,11]. Nitrate and sulfate reduction are other processes that also occur, with side products being gases of hydrogen sulfide, nitrogen, and ammonia. The breakdown of protein, lipids, and carbohydrates (i.e., complex polymeric organic substrates) into fatty acids, sugar, and amino acids (i.e., smaller monomeric compounds) occurs during the hydrolysis reaction. The enzymes that are produced by a variety of consortium hydrolytic bacteria facilitate this reaction. During hydrolysis, the monomer is released and converted by fermentative bacteria (also known as acid-forming bacteria) into alcohols, lactic acid, fatty acids, ammonia, pyruvate, carbon dioxide, and formate or hydrogen. The gaseous byproducts are mainly carbon dioxide (CO2) and methane (CH4). The trace gases are hydrogen (H2) and hydrogen sulfide (H2S) [3,12,13]. The biogas is also detected containing water, siloxanes, nitrogen, and ammonia [3].

The disadvantages of batch systems are that the quality of biogas is different every day, and even at the beginning of the process, the biogas cannot be used as a fuel because of minimum or low methane content. Another disadvantage is that, by the batch system, the waste cannot be processed daily. It developed then the continuous system of anaerobic digester that makes it possible to process organic waste daily with a high methane content of biogas so that it can be used as a fuel daily and also can process animal waste (cattle dung) daily. In this continuous system, the feeding volume and retention time should be carefully studied for optimum results because all four processes (hydrolysis, acidogenesis, acetogenesis, and methanogenesis) in an anaerobic digester will be run at the same time. A more complex situation will be faced if continuous anaerobic digestion is used also for processing vegetable waste. The volume of vegetable waste and retention time in the anaerobic digester should be well studied. Organic or lignocellulosic waste is collected from markets, municipal, agricultural, and other similar areas in large quantities. The slurry of animal manure, municipal solid waste, food waste, and sewage sludge are the most typical forms used in anaerobic digesters used in the energy industry. This is typical of waste that can be used in anaerobic digesters for biogas production with a wide range of applications [14].

To avoid failure and increase efficiency during the process of that wide range of lignocellulosic waste, the pretreatment application method is necessary to enhance the degradation process of the substrate. The decomposition process can be sped up by applying enzymatic, mechanical, thermal, and chemical methods, although the result is not necessarily higher biogas production yield [14].

Since animal manure contains methanogenic bacteria, it is not difficult to proceed with the use of animal dung in the anaerobic digester. Many projects were successful in processing animal waste in anaerobic digesters such as poultry [15], goat [16], elephant [17], and pig [18]. In comparison to animal waste, processing vegetable waste is more complex since it should be accelerated with methanogenic bacteria that are present in an established aerobic digester. Vegetable waste is an example of biomass residue that can be used to produce bioenergy, for example, biohydrogen, biogas, biodiesel, and bioethanol, rather than being disposed of and causing environmental pollution and contamination. It can be said that this is a solution to solve various problems such as waste management, energy shortages, incineration and greenhouse gas emissions in landfills, the emergence of unpleasant odors, protecting natural landscapes, and thousands of other environmental problems. However, despite the many benefits and potential obtained from converting fruit and vegetable waste into bioenergy, technological developments for utilizing vegetable and fruit waste into bioenergy are not yet widely available. This means that stakeholders and active activists from the global energy industry do not have sufficient information to make this happen [19].

Furthermore, pretreatment has both advantages and disadvantages; especially if it is too excessive, it can cause a decrease in the CH4 content in the biogas. Besides that, various operational variations in parameters such as pH, temperature, carbon/nitrogen ratio, correct types of microbes (inoculum), and grain size of the feedstock are challenges for the anaerobic digestion process [19].

The addition of vegetable waste into the batch type of anaerobic digester was a common method that was practiced to process organic waste and at the same time provide a beneficial product of energy and fertilizer [20]. The addition of vegetable waste into the feeding system of continuous anaerobic digestion is not well practiced at the moment since the route to optimum results is not well understood.

This work specifically gives attention to the processing waste of cabbage in a continuous anaerobic digester. The established anaerobic digester was fed cattle dung. The way of feeding is interspersed with cattle dung to ensure the availability of methanogenic bacteria inside the anaerobic digester. Cabbage is a type of vegetable that is consumed worldwide. This type of vegetable is easy to grow and produces in large quantities. This is risky because this type of vegetable cannot be stored for long and will rot quickly. This is what caused cabbage to be chosen in this study.

2. Materials and Methods

The source of the substrate is cattle dung from the Bali cattle species (Bos javanicus). This species of cattle is an important livestock species for Malaysia and Indonesia and is easy to reproduce, very efficient even when fed with low-quality food, and well adapted to tropical areas [21]. The vegetable waste that was used in this research was from cabbage (Brassica oleracea).

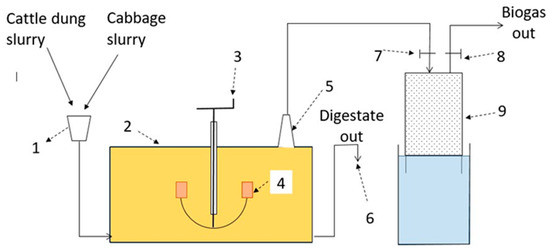

In this work, a 200-L continuous anaerobic digester was operated as presented in Figure 1, for ease of its transportation to the research site [22]. The biochemical processes that occur are simplified, as presented in Equation (1), for the hydrolysis and acidogenesis processes. Moreover, Equation (2) represents the acetogenesis and methanogenesis processes [13].

Organics + nutrients → Volatile acids + alcohols + H2 + CO2 + H2S + NH3 + cells

Volatile acids + alcohols + H2 + CO2 + nutrients → CH4 + CO2 + cells.

Figure 1.

Schematic of an 200-L continuous anaerobic digester. 1. Inlet slurry, 2. Anaerobic digester tank, 3. Stirrer, 4. Agitator, 5. Biogas outlet 6. Digestate out, 7. Inlet biogas valve, 8. Outlet biogas valve, 9. Floating drum for biogas storage.

The digester contained a stirrer, which was used for mixing the substrate. Mixing in a biogas digester needs to be carried out so that it reduces precipitation, no scum is formed, it can facilitate the release of gas produced by bacteria to the biogas reservoir, and mixing methanogenic bacteria with substrates [23]. Stirring increases both the biogas production and the degradation of organic compounds because it improves the hydrodynamics inside the reactor, and the hydrodynamics has a great influence on mass transfer phenomena [24]. The advantages of making this mini-sized biogas digester are that it allows users to make repairs if something goes wrong at the time of manufacture and has a relatively low manufacturing cost. Mini-sized biogas digesters can be a solution for energy shortages [9].

The anaerobic digester tank in this research was using steel. The steel is easily corroded by hydrogen sulfide (H2S) that is found in the biogas itself [3,6,8,25]. To overcome this problem, a small cut of magnesium metals was affixed outside the steel tank as a sacrificial anode to provide cathodic protection [26,27]. The most electrochemically active metal is magnesium (Mg). This metal has important uses in the field of engineering. Magnesium will immediately experience corrosion in certain environments. Magnesium metal and magnesium alloys are used to prevent corrosion through a sacrificial anode mechanism for structures made of steel, such as pipelines and ship hulls [26].

As seen in Figure 1, the anaerobic digester was filled with slurry in the inlet slurry (1). The digester tank (2) was fully filled with slurry. The stirrer (3) was provided to rotate the agitator to make the slurry well mixed and flow from the inlet (1) to the outlet (6) while feeding the digester. Various researchers have observed the effect of stirring on anaerobic digesters on a laboratory scale and also on a pilot scale. It was found that the anaerobic digester required efficient and adequate stirring [28,29,30]. The system in this research is equipped with a stirrer. However, the stirring process is only carried out during feeding. This was carried out based on information from previous research, which explained that minimal and intermittent stirring produced more biogas than if it was stirred continuously. This also means that performance will be better if stirred slowly compared to vigorously [31]. The biogas was produced and collected in the floating drum (9) by opening the inlet valve (7) and closing the biogas outlet valve (8). If the biogas inside the floating drum will be used as fuel, the inlet valve (7) should be closed and the outlet valve (8) should be closed.

The digester was operated in a batch system for about 1 month at the beginning. The digester was then operated by continuously adding a 5-L mixture of cattle dung and water (50%:50%) every day for 1 month. Subsequently, the digester was operated for 1 month with an additional 5-L slurry of cabbage waste and water (50%:50%) for odd-numbered days and the mixture of cattle dung and water (50%:50%) for even-numbered days. The purpose of feeding interspersed was to keep supplying methanogenic bacteria into the digester as an inoculum [32,33]. The cabbage slurry was prepared by putting waste cabbage and water in the blender.

For all processes, the digester was stirred only during feeding time for easy flow of the substrate inside an anaerobic digester. Also, too much mixing stresses micro-organisms. Without mixing, foaming and the formation of scum occur [2,12]. Rapid mixing inhibits flock structure, thereby disrupting the relationships between the nutrients of the organism (dystrophic). Meanwhile, stirring at a medium speed was found to be optimal for substrate conversion [34].

The biogas digester that was developed in this work, according to feed types, was classified as a continuous type. The scale was a type of small-scale household [35], and it was from a wet digester [24].

The biogas production was measured, and methane and carbon dioxide compositions were detected. The CH4 and CO2 composition was measured using gas sensors that adopt hot catalytic working principles, and consist of black and white inside elements. The black element is the catalytic carrier of methane gas and will cause a thermal catalytic reaction with methane in order to change its own resistance value. The white element is a pure carrier, and its resistance value is very stable. The signal is amplified and displayed by amplifying circuit technology so that it achieves the wanted detection concentration. The data on pH and temperature inside and outside the digester were provided to understand the process that may occur inside the digester. The replication is repeated 3 times to ensure the reliability, and the average value is taken.

3. Results and Discussion

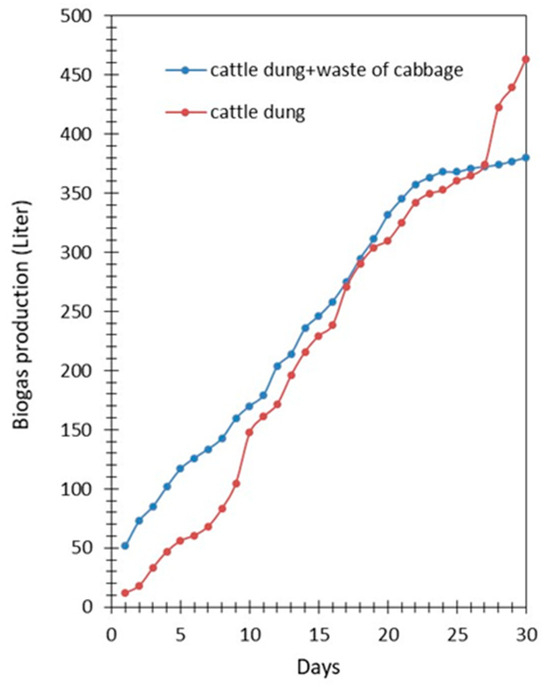

The biogas production with only cattle dung as a substrate is found to have an almost-linear increase. The additional cabbage waste made the production of biogas higher up until the 17th day; the biogas production was then found to be the same until it reached the 22nd day; and after the 22nd day, the production of biogas was found to flatten with the addition of cabbage waste (Figure 2).

Figure 2.

Comparison between biogas productions in continuous anaerobic digestion fed with cattle dung and digestion fed with a mix of cattle dung and cabbage waste.

The main composition of cabbage is 89% water, 7% carbohydrates, mainly fiber and sugar, 3% protein, and 0.4% lipids [36]. If the cabbage was processed in the form of flour, then the following composition is found: moisture (10.35%), ash (18.05%), protein (12.28%), lipid (0.80%), and total carbohydrate (59.59%). In this report, the moisture and ash contents of the flours were determined gravimetrically [36,37]. Both reports [36,37] informed that the main composition of cabbage includes carbohydrates, protein, and lipids that make the process of hydrolysis longer, produce less CH4, and increase the production of CO2 gas (Figure 3 and Figure 4) as explained in detail by [12,13]. The system with cabbage waste was fed until the 22nd day, resulting in the process of hydrolysis being washed out [12]. Moreover, limited biogas was produced, resulting in flattening of the biogas production (Figure 2).

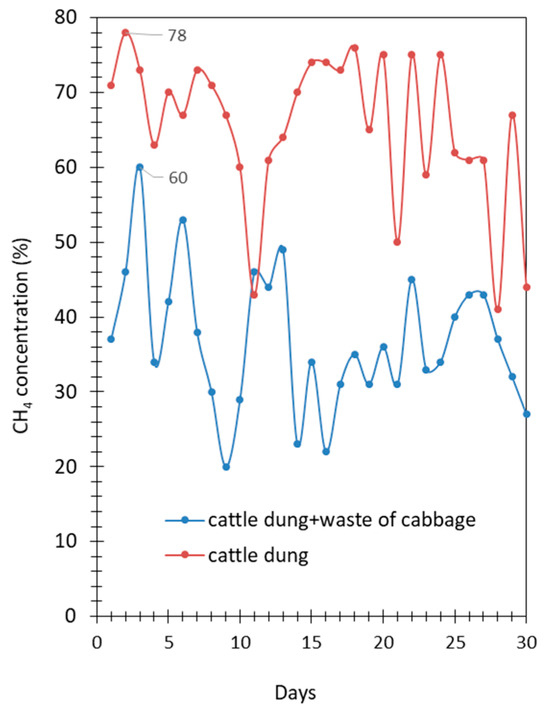

Figure 3.

Presentation of methane composition in biogas that was produced in a continuous anaerobic digester.

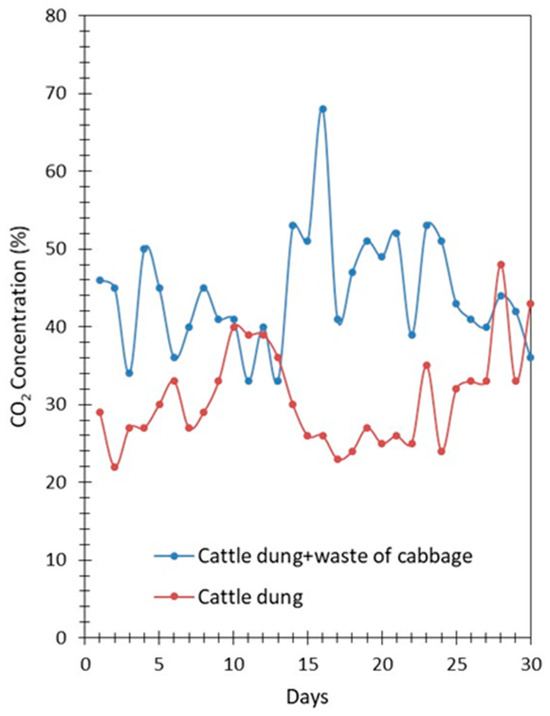

Figure 4.

Comparison between carbon dioxide composition in biogas that was produced in continuous aerobic digester fed with cattle dung and the one that is fed with the cattle dung and cabbage waste mixture.

Even though the biogas production was higher when fed with the mixture of cattle dung and cabbage waste during the first 17 days, this does not necessarily result in a sufficient methane concentration. Methane is often targeted as it has well-pronounced characteristics of gas [3]. It was found that the methane composition was lower in the biogas that was produced with the addition of cabbage waste for almost 30 days of observation (Figure 3). The CH4 content in the biogas produced with only cattle dung is in the range of 41–78%, which is suitable to be used as fuel [4,21,38,39]. This condition is better when compared with the batch system in the same volume of floating drum [24] that can only reach a maximum of 60.9% of methane yield.

It is observed in this work that if the system is fed with mixed cattle dung and cabbage interspersed, the CH4 content is in the range of 22–60%. Since the methane content was lower in the biogas produced by feeding with mixed cattle dung and cabbage waste, it can be expected that the CO2 composition will be higher, as can be seen in Figure 4. The addition of cabbage waste to cattle dung for a continuous anaerobic digester results in an increase in CO2 composition during the full 30 days of observation except between the 10th and 13th days. This condition convinced us that the addition of cabbage into the system made the process slow in reaching the following three stages (namely, acidogenesis, acetogenesis, and methanogenesis), as can be proven by adding lower CH4 concentrations to cabbage. This condition can be overcome by a reduction in the organic waste load (increase in the residence time) [12], meaning that the addition of cabbage should be performed more frequently, i.e., more than every 2 days. Simple modeling for gas production is presented in Table 1. Biogas production, if using cattle dung as a substrate, will follow a linear pattern, whereas if the substrate used is cattle dung and cabbage interspersed, it will follow a polynomial pattern of order 3.

Table 1.

Modeling of the biogas yield in continuous anaerobic digester.

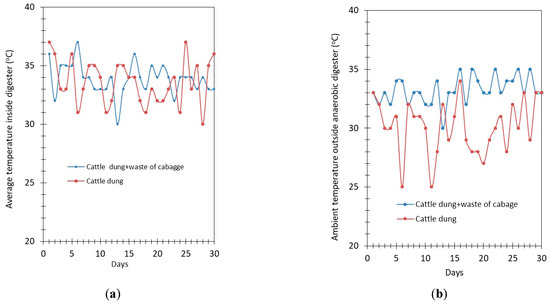

The temperatures inside the digester for 30 days are presented in Figure 5. The lowest is 30 °C and the highest is 37 °C for feeding with cattle dung and cabbage waste. In this study, the temperature inside the digester never reached 38 °C, which is a condition that reportedly destroys 99.9% of pathogens [34]. It is to be noted that the digesters were not operated in the same month; therefore, there was a bit of a difference in ambient temperature outside the digester. For the digester operated by being feed with cattle dung, the lowest ambient temperature was 25 °C, and the highest was 34 °C. Meanwhile, during operation with the cattle dung and cabbage waste mixture, the lowest ambient temperature recorded was 30 °C, and the highest was 35 °C. Even though the anaerobic digester that is being fed with cattle dung operated at an ambient temperature lower than the one that is used in digestors being fed the cattle dung and cabbage waste mixture; both temperatures inside the digesters were found to be about the same as they are during the mesophilic process [12]. To increase the temperature, the concept of a greenhouse coupled with a digester should be introduced for future research studies. This one-year study revealed an almost 100% increase in biogas yield when the digester was placed inside a greenhouse [40].

Figure 5.

The temperature inside a continuous anaerobic digester (a). Ambient temperature outside the digester (b).

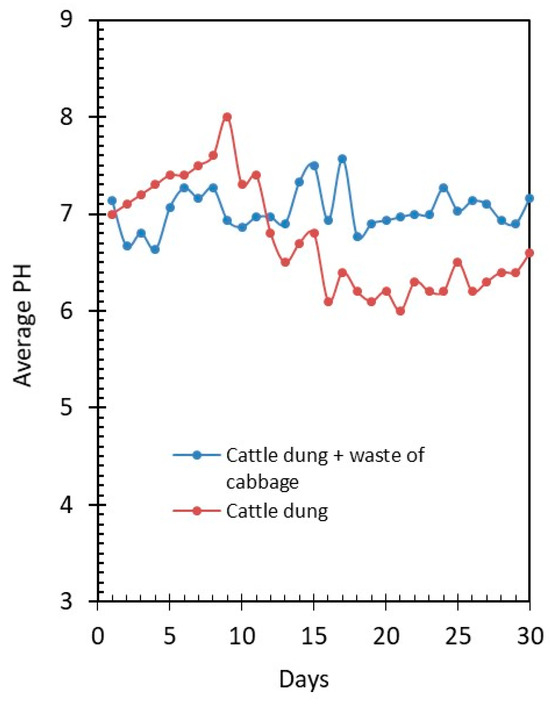

Anaerobic digestion is influenced by the concentration of hydrogen ions (pH) present in the digesting material. Because excess acidity prevents digestion, the hydrogen ion concentration of the culture medium immediately influences microbial growth [6]. The pH for the system that is being fed cattle dung is found to swing up to 8.0 and down to 6.0 (Figure 6). This condition yields biogas with a high CH4 content (Figure 3). Methanogens thrive in neutral to slightly alkaline conditions and die in acidic environments. The optimum pH of the system is in the range of 7–8.5 [6]; the nitrogen will be released and will accumulate into ammonia, which in turn can raise the pH of the substrate [9]. The swing in pH is an indication that all processes of anaerobic digestion (hydrolysis, acidogenesis, acetogenesis, and methanogenesis) occur. Meanwhile, the addition of cabbage puts the pH in the range of about neutral for all 30 days, which indicates that acidogenesis process does not occur and that the process of hydrolysis is washed out [12].

Figure 6.

The pH of slurry inside an anaerobic digester.

Methanogens thrive in neutral to slightly alkaline conditions and die in acidic environments. The optimum pH of the system is in the range of 7–8.5, with values approaching 7 for optimal activity when the aerobic digestion process is stable. To overcome this situation, the appropriate pretreatment of cabbage waste should be discovered so suitable pH conditions are achieved. The pretreatment could be thermal, chemical, or biological [14,41], which can be explored as future work of this research. The required pH for an anaerobic digester should be in the range of 6.5–8 [3]. The rate of methane production declines at pH values below 6.3 or exceeding 7.8. Most methanogenic bacteria function optimally at pH 7 to 7.2 [34].

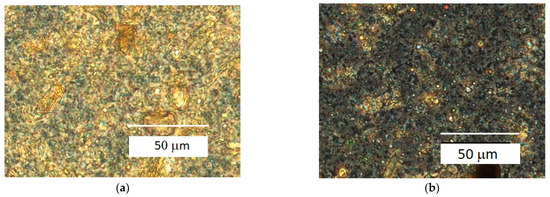

The concentrations of microorganisms play a vital role in anaerobic digestion. Methanogenic microorganisms have a long regeneration time in general. To avoid washing out from the reactor, hydraulic residence times must be at least 10–15 days with reactor systems that do not have any facilities for retaining and returning biomass [12]. In this regard, observation under an inverted phase contrast optical microscope revealed that the concentration of microorganisms in the system that is fed with cattle dung is higher (Figure 7a) compared to the system that is fed with cattle dung and cabbage waste interspersed (Figure 7b); therefore, for more optimum results, if cabbage waste is introduced into the system, the retention time should be made longer [2].

Figure 7.

Observation of the digestate under phase contrast inverted microscope after 30 days. System fed with cattle dung (a), and system fed with cattle dung mixed with cabbage waste (b).

For better clarity, Table 2 summarizes the observed key operational parameters.

Table 2.

A summary of key operational parameters.

Microbial diversity of anaerobic digesters depends on various factors such as pretreatment type, granulation, seed inoculum, feedstock type, temperature, mixing speed, aeration, digester design, organic loading rate, hydraulic retention time, and solids retention time). The microbial granule resembles a filamentous consortium through which fluids and gases can flow slowly [42].

Biogas production may benefit from the use of specialized microbial consortia (inocula) to increase biogas yields in anaerobic digesters. Inoculum can be provided from a raw pig slurry by applying an innovative procedure [43]. A unique and effective inoculum can be developed from wastewater treatment, thin stillage, and agricultural waste with different retention times [43,44]. Other sources of inoculum can be sewage sludge [33]. The ratio of inoculum and substrate should also become a consideration [45]. In this work the ratio of inoculum (cow dung) and substrate (waste cabbage) is 1:1. Other ratios should be introduced for future work. As another consideration, the inoculum can also be prepared from solid-state anaerobic digestion for the substrate from empty fruit bunches, using recycled solid anaerobic digested sludge and liquid anaerobic digested sludge [46]. The more complex method of preparing inoculum is by using rumen fluid. A flexible oral stomach tube with a metal strainer was inserted into the rumen, and the content was collected by suction [47]. Over the past decade, Indonesia and Malaysia have become two countries that provide many palm oil products to the world. Both countries produce around 85% of the world’s palm oil [48,49,50]. Anaerobic digestion for palm oil mill effluent is widely known for its potential in biogas production and can be used as inoculum with cattle manure [51]. In this work, the waste of cabbage just adds to the existing cattle dung systems without any concern for the effectivity of additional inoculum from the previous research. Therefore, future work is addressed for finding suitable inoculum to enhance the performance of processing cabbage waste into cattle dung in the continuous anaerobic digestion.

Besides the addition of inoculum, another important process, i.e., acclimatization, is not yet applied in this work due to the limitation of time and experience in this field. An example of this work is in the case of long-term acclimatization of anaerobic sludge that was conducted by operating a mesophilic, continuously stirred anaerobic reactor with continuous feeding of food wastes and cow manure. During the long-term acclimatization, a continued increase in enzyme activity was revealed, while the microbial structure tended to be stable and had a methane yield about 13 times higher than the initial anaerobic sludge [33,52]. The acclimatization event can introduce other types of microorganisms that are not related to established methanogenic bacteria within the system [53]. It is suggested that acclimatization of the methanogenic bacteria in this work should experience acclimatization with the addition of waste cabbage to enhance the performance of the aerobic digester in producing higher CH4 content in the biogas.

The advantage of this work is that the anaerobic digester is small in size, so it is portable, operated continuously so it can produce biogas with a fairly high methane content stably, and it can also be used to process cabbage waste alternately with cattle dung waste. The government usually utilizes voluntary biogas programs by providing grants from the government budget, foreign development aid, and funding from non-governmental bodies. The biogas program targeted households and small community groups such as farmers groups and forest communities [54]. From this point of view, the result of this research can be used as a consideration during the implementation of government programs. Investigating other co-substrate combinations together with exploring cost-effectiveness will be covered in the continuation of this work.

4. Conclusions

For a 200-L continuous anaerobic digester system that is fed a 5 L slurry of water and cattle dung (50%:50%) every day, the CH4 content in the biogas is in the range of 41–78%, which is suitable for fuel applications. However, if it is fed with a mixed slurry of water and cattle dung (50%:50%) mixed slurry of water and cabbage (50%:50%) interspersed, the CH4 content is in the range of 22–60%. The temperatures inside the digester for both systems are approximately the same and in the range of the mesophilic process. The pH for the system that is fed cattle dung is found to swing up to 8.0 and down to 6.0. This condition yields biogas with a high CH4 content. Meanwhile, the addition of cabbage makes the pH in the range of about neutral for all 30 days, which indicates that the acidogenesis process did not occur and that the hydrolysis is washed out. For more optimum results in the system fed with an addition of cabbage waste, it is suggested that the retention time should be longer and that the cabbage waste should be pretreated. Another concern for future work is the acclimatization of methanogenic bacteria due to the addition of cabbage waste that. This study’s main limitation is the fact that the work focuses only on tropical areas; the results obtained for areas with low temperatures may be different. Practical implementation includes the usage of vegetable waste together with cattle dung waste, which is to be processed by means of a method developed in this study with by-products being in the form of biogas energy and organic fertilizer.

Author Contributions

Methodology, I.P.S.; Validation, I.G.N.G.B.; Investigation, T.S.N.; Project administration, T.G.T.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study did not require ethical approval.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors acknowledge the assistance provided by M. B. Krishnan, a research fellow from the Udayana University, under UNISERF 2023 Program.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nguyen, V.C.N. Small-scale An aerobic Digesters in Vietnam—Development and Challenges. J. Viet. Environ. 2011, 1, 12–18. [Google Scholar]

- Rajendran, K.; Aslanzadeh, S.; Taherzadeh, M.J. Household Biogas Digesters—A Review. Energies 2021, 5, 2911–2942. [Google Scholar] [CrossRef]

- Abubakar, A.M. Biodigester and Feedstock Type: Characteristic, Selection, and Global Biogas Production. J. Eng. Res. Sci. 2022, 1, 170–187. [Google Scholar] [CrossRef]

- Guimaraes, C.D.; Maia, D.R.D. Development of Anaerobic Biodigester for The Production of Biogas Used in Semi-Continuous System Bioprocesses: An Efficient Alternative for Co-Digestion of Low Biodegradability Biomass. Biomass 2023, 3, 18–30. [Google Scholar] [CrossRef]

- Jegede, A.O.; Zeeman, G.; Bruning, H. A review of mixing, design and loading conditions in household anaerobic digesters. Crit. Rev. Environ. Sci. Technol. 2019, 49, 2117–2153. [Google Scholar] [CrossRef]

- Banerjee, S.; Prasad, N.; Selvaraju, S. Reactor Design for Biogas Production-A Short Review. J. Energy Power Technol. 2022, 4, 1–14. [Google Scholar] [CrossRef]

- Pham, C.H.; Vu, C.C.; Sommer, S.G.; Bruun, S. Factors Affecting Process Temperature and Biogas Production in Small-scale Rural Biogas Digesters in Winter in Northern Vietnam, Asian Australas. J. Anim. Sci. 2014, 27, 1050–1056. [Google Scholar]

- Zaki, M.B.M.; Shamsudin, R.; Yusoff, M.Z.M. Portable Bio-digester System for Household Use—A Review. Adv. Agric. Food Res. J. 2021, 2, a000014. [Google Scholar]

- Randjawali, E.; Waris, A. Design and testing of mini-size biogas plant. J. Phys. Conf. Ser. 2016, 739, 012038. [Google Scholar] [CrossRef]

- Budiman, I. The Role of Fixed-Dome and Floating Drum Biogas Digester for Energy Security in Indonesia. Indones. J. Energy 2020, 3, 83–93. [Google Scholar] [CrossRef]

- Postawa, K.; Szczygieł, J.; Kułażyński, M. Innovations in anaerobic digestion: A model-based study. Biotechnol. Biofuels 2021, 14, 19. [Google Scholar] [CrossRef]

- Deublein, D.; Steinhauser, A. Biogas from Waste and Renewable Resources; Wiley-Vch Verlag GmbH & Co., Ltd.: Weinheim, Germany, 2011. [Google Scholar]

- Akunna, J.C. Anaerobic Waste-Wastewater Treatment and Biogas Plants; Taylor & Francis Group: Boca Raton, FL, USA, 2019. [Google Scholar]

- Achinas, S.; Achinas, V.; Euverink, G.J. A Technological Overview of Biogas Production from Biowaste. Engineering 2017, 3, 299–307. [Google Scholar] [CrossRef]

- Marchioro, V.; Steinmetz, R.L.; Amaral, A.C.; Gaspareto, T.C.; Treichel, H.; Kunz, A. Poultry Litter Solid State Anaerobic Digestion: Effect of Digestate Recirculation Intervals and Substrate/Inoculum Ratios on Process Efficiency. Front. Sustain. Food Syst. 2018, 2, 46. [Google Scholar] [CrossRef]

- Hanafiah, M.M.; Ali, M.M.; Aziz, N.I.A.; Ashraf, M.A.; Halim, A.A.; Lee, K.E.; Dris, M. Biogas Production from Goat and Chicken Manure in Malaysia. Appl. Ecol. Environ. Res. 2017, 15, 529–535. [Google Scholar] [CrossRef]

- Rangseesuriyachai, T.; Boonnorat, J.; Glanpracha, N.; Khetkorn, W.; Thiamngoen, P.; Pinpatthanapong, K. Anaerobic Co-digestion of Elephant Dung and Biological Pretreated Napiergrass: Synergistic Effect and Kinetics of Methane Production. Biomass Bioenergy 2023, 175, 106849. [Google Scholar] [CrossRef]

- Gaworski, M.; Jabłoński, S.; Pawlaczyk-Graja, I.; Ziewiecki, R.; Rutkowski, P.; Wieczyńska, A.; Gancarz, R.; Tukaszewicz, M. Enhancing biogas plant production using pig manure and corn silage by adding wheat straw processed with liquid hot water and steam explosion. Biotechnol. Biofuels 2017, 10, 259. [Google Scholar] [CrossRef] [PubMed]

- Adamu, H.; Bello, U.; Yuguda, A.U.; Tafida, U.I.; Jalam, A.M.; Sabo, A.; Qamar, M. Production processes, techno-economic and policy challenges of bioenergy production from fruit and vegetable wastes. Renew. Sustain. Energy Rev. 2023, 186, 113686. [Google Scholar] [CrossRef]

- Lahbab, A.; Djaafri, M.; Kalloum, S.; Benatiallah, A.; Atelge, M.R.; Atabani, A.E. Co-digestion of vegetable peel with cow dung without external inoculum for biogas production: Experimental and a new modelling test in a batch mode. Fuel 2021, 306, 121627. [Google Scholar] [CrossRef]

- Nindhia, T.G.; McDonald, M.; Styles, D. Greenhouse Gas Mitigation and Rural Electricity Generation by a Novel Two-Stroke Biogas Engine. J. Clean. Prod. 2021, 280, 124473. [Google Scholar] [CrossRef]

- Taghinazhad, J.; Abdib, R.; Adlc, M. Kinetic and Enhancement of Biogas Production for The Purpose of Renewable Fuel Generation by Co-digestion of Cow Manure and Corn Straw in A Pilot Scale CSTR System. Int. J. Renew. Energy Dev. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- Fahriansyah; Andrianto, M.; Sriharti. Design of conventional mixer for biogas digester. IOP Conf. Ser. Earth Environ. Sci. 2019, 277, 012017. [Google Scholar] [CrossRef]

- Elsawy, K.; E-Kadi, S.; Elhenawy, Y.; Abdelmotalip, A.; Ibrahim, I.A. Biogas Production by Anaerobic Digestion of Cow Dung using Floating Type Fermenter. J. Environ. Treat. Tech. 2021, 9, 446–451. [Google Scholar]

- Nindhia, T.G.; Sucipta, I.M.; Surata, I.W.; Adiatmika, I.K.; Negara, D.N.; Negara, K.M.T. Processing of Steel Chips Waste for Regenerative type of Biogas Desulfurizer. Int. J. Renew. Energy Res. 2013, 3, 84–87. [Google Scholar]

- Pathak, S.S.; Mendon, S.K.; Blanton, M.D.; Rawlins, J.W. Magnesium-Based Sacrificial Anode Cathodic Protection Coatings (Mg-Rich Primers) for Aluminum Alloys. Metals 2012, 2, 353–376. [Google Scholar] [CrossRef]

- Nindhia, T.G.; Surata, I.W.; Swastika, I.D.P.; Widiana, P. Processing Zinc from Waste of Used Zinc-Carbon Battery with Natrium Chloride (NaCl) for Biogas Desulfurizer. Key Eng. Mater. 2016, 705, 368–373. [Google Scholar] [CrossRef]

- Bridgeman, J. Computational fluid dynamics modeling of sewage sludge mixing in an anaerobic digester. Adv. Eng. Softw. 2012, 44, 54–62. [Google Scholar] [CrossRef]

- Conklin, A.S.; Chapman, T.; Zahller, J.D.; Stensel, H.D.; Ferguson, J.F. Monitoring the role of aceticlasts in anaerobic digestion: Activity and capacity. Water Res. 2008, 42, 4895–4904. [Google Scholar] [CrossRef] [PubMed]

- Halalsheh, M.; Kassab, G.; Yazajeen, H.; Qumsieh, S.; Field, J. Effect of increasing the surface area of primary sludge on anaerobic digestion at low temperature. Bioresour. Technol. 2011, 102, 748–752. [Google Scholar] [CrossRef] [PubMed]

- Karapaju, P.L.; Rintala, J.A. Effects of solid-liquid separation on recovering residual methane and nitrogen of a digested dairy cow manure. Bioresour. Technol. 2008, 99, 120–127. [Google Scholar] [CrossRef]

- Maamri, S.; Amrani, M. Biogas Production from Waste Activated Sludge Using Cattle Dung Inoculums: Effect of total solid contents and kinetics study. Energy Procedia 2014, 50, 352–359. [Google Scholar] [CrossRef]

- Bella, K.; Rao, P.V. Anaerobic co-digestion of cheese whey and septage: Effect of substrate and inoculum on biogas production. J. Environ. Manag. 2022, 308, 114581. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Hadi, M.A.; El-Azeem, S.A.A. Effect of heating, mixing and digester type on biogas production from buffalo dung. Misr J. Agric. Eng. 2008, 25, 1454–1477. [Google Scholar] [CrossRef]

- Rianawati, E.; Damanhuri, E.; Handajani, M.; Padmi, T. Comparison of Household and Communal Biogas Digester Performance to Treat Kitchen Waste, Case Study: Bandung City, Indonesia. E3S Web Conf. 2018, 73, 01019. [Google Scholar] [CrossRef]

- Streitwieser, D.A. Comparison of The Anaerobic Digestion at The Mesophilic and Thermophilic Temperature Regime of Organic Wastes from The Agribusiness. Bioresour. Technol. 2017, 241, 985–992. [Google Scholar] [CrossRef] [PubMed]

- Brito, T.B.; Pereira, A.P.; Pastore, B.M.; Moreira, R.F.; Ferreira, M.S.; Fai, A.E. Chemical composition and physicochemical characterization for cabbage and pineapple by-products flour valorization. LWT Food Sci. Technol. 2020, 124, 109028. [Google Scholar] [CrossRef]

- Dana, I.W.A.R.; Lie, D.; Adnyana, I.W.B.; Nindhia, T.G.; Khanal, S.K.; Nindhia, T.S. Comparison of Fuel Consumption and Emission of Small Two-stroke Engine of Electric Generator Fuelled by Methanol, Biogas, and Mixed Methanol-biogas. J. Appl. Eng. Sci. 2022, 20, 1034–1039. [Google Scholar] [CrossRef]

- Haryanto, A.; Nindhia, T.G.; Hasanudin, W.R.U.; Saputrat, W.; Santosa, A.B.; Tamrin; Triyono, S. Effect of load on the performance of a family scale biogas-fuelled electricity generator. IOP Conf. Ser. Earth Environ. Sci. 2019, 355, 012078. [Google Scholar] [CrossRef]

- Sodha, M.S.; Ram, S.; Bansal, N.K.; Bansal, P.K. Effect of PVC greenhouse in increasing the biogas production in temperate cold climatic conditions. Energy Convers. Manag. 1987, 27, 83–90. [Google Scholar] [CrossRef]

- Mozhiarasi, V. Overview of pretreatment technologies on vegetable, fruit and flower market wastes disintegration and bioenergy potential: Indian scenario. Chemosphere 2022, 288, 132604. [Google Scholar] [CrossRef] [PubMed]

- Harirchi, S.; Wainaina, S.; Sar, T.; Nojoumi, S.A.; Parchami, M.; Varjani, S.; Khanal, S.K.; Wong, J.; Awasthi, M.K.; Taherzadeh, M.J. Microbiological insights into anaerobic digestion for biogas, hydrogen or volatile fatty acids (VFAs): A review. Bioengineered 2022, 13, 6521–6557. [Google Scholar] [CrossRef] [PubMed]

- Marchetti, R.; Vasmara, C.; Orsi, A. Inoculum Production from Pig Slurry for Potential Use in Agricultural Biogas Plants. Sustain. Energy Technol. Assess. 2022, 52, 102310. [Google Scholar] [CrossRef]

- Liu, T.; Sun, L.; Müller, B.; Schnürer, A. Importance of inoculum source and initial community structure for biogas production from agricultural substrates. Bioresour. Technol. 2017, 245, 768–777. [Google Scholar] [CrossRef] [PubMed]

- Owamah, H.I.; Ikpeseni, S.C.; Alfa, M.I.; Oyebisi, S.O.; Gopikumar, S.; Samuel, O.D.; Ilabor, S.C. Influence of Inoculum/Substrate Ratio on Biogas Yield and Kinetics from The Anaerobic Co-digestion of Food Waste and Maize Husk. Environ. Nanotechnol. Monit. Manag. 2021, 16, 100558. [Google Scholar] [CrossRef]

- Suksong, W.; Mamimin, C.; Prasertsan, P.; Kongjan, P.; O-Thong, S. Effect of inoculum types and microbial community on thermophilic and mesophilic solid-state anaerobic digestion of empty fruit bunches for biogas production. Ind. Crops Prod. 2019, 133, 193–202. [Google Scholar] [CrossRef]

- Sohail, M.; Khan, A.; Badshah, M.; Degen, A.; Yang, G.; Liu, H.; Zhou, J.; Long, R. Yak Rumen Fluid Inoculum Increases Biogas Production from Sheep Manure Substrate. Bioresour. Technol. 2022, 362, 127801. [Google Scholar] [CrossRef] [PubMed]

- Papilo, P.; Marimin, M.; Hambali, E.; Machfud, M.; Yani, M.; Asrol, M.; Evanila, E.; Prasetya, H.; Mahmud, J. Palm Oil-based Bioenergy Sustainability and Policy in Indonesia and Malaysia: A systematic review and future agendas. Heliyon 2022, 8, e10919. [Google Scholar] [CrossRef] [PubMed]

- Mahlia, T.M.; Abdulmuin, M.; Alamsyah, T.M.; Mukhlishien, D. An Alternative Energy Source from Palm Wastes Industry for Malaysia and Indonesia. Energy Convers. Manag. 2001, 42, 2109–2118. [Google Scholar] [CrossRef]

- Jayed, M.H.; Masjuki, H.H.; Kalam, M.A.; Mahlia, T.M.; Husnawan, M.; Liaquat, A.M. Prospects of Dedicated Biodiesel Engine Vehicles in Malaysia and Indonesia. Renew. Sustain. Energy Rev. 2011, 15, 220–235. [Google Scholar] [CrossRef]

- Saidu, M.; Yuzir, A.; Salim, M.R.; Salmiati; Azman, S.; Abdullah, N. Influence of Palm Oil Mill Effluent as Inoculum on Anaerobic Digestion of Cattle Manure for Biogas Production. Bioresour. Technol. 2013, 141, 174–176. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Cao, L.; Liu, Y.; Zhang, Q.; Ruan, R.; Luo, X. Effect of Acclimatized Paddy Soil Microorganisms Using Swine Wastewater on Degradation of Rice Straw. Bioresour. Technol. 2021, 332, 125039. [Google Scholar] [CrossRef] [PubMed]

- Xinga, B.S.; Hana, Y.; Wanga, X.C.; Caoa, S.; Wena, J.; Zhanga, K. Acclimatization of Anaerobic Sludge with Cow Manure and Realization of High-rate Food Waste Digestion for Biogas Production. Bioresour. Technol. 2020, 315, 123830. [Google Scholar] [CrossRef] [PubMed]

- Budiman, I. The complexity of barriers to biogas digester dissemination in Indonesia: Challenges for agriculture waste management. J. Mater. Cycles Waste Manag. 2021, 23, 1918–1929. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).