Abstract

This experiment was aimed at comparing how a chemical additive or an inoculant would affect the dry matter (DM) losses, fermentation pattern, yeast and mold counts, and aerobic stability (AS) of the ensiled high-moisture barley grain (675 g kg−1 DM). Crimped barley grain was ensiled with or without chemical additive AIV Ässä Na and an inoculant SiloSolve FC, totaling three treatments (1 × 3 factorial scheme) for the fermentation periods lasting 7, 14, 28, 60, and 90 days. The application of a chemical additive showed higher pH levels, retained water-soluble carbohydrates (WSCs) better, lowered DM loss, and reduced concentrations of fermentation products. Barley grain treated with chemicals initially showed a marked reduction in yeast and fungal growth and a higher AS up to day 60 of storage but became less effective in later stages of storage, leading to decreased AS. Barley grain inoculated with homo- and heterofermentative strains had decreased silage pH; its WSC content was similar to control and had higher content of weak acids and 1,2 propanediol, reducing mold and yeast counts. With fermentation duration from 28 days and beyond (i.e., 90 days), the inoculant treatment achieved the longest AS and the lowest increase in pH and weight loss during the period of air exposure.

1. Introduction

Spring barley (Hordeum vulgare L.) is a major crop for the feed. Traditionally, grain should be stored dry at 14% moisture to prevent deterioration [1], and this may require drying after harvest. However, this can significantly increase costs for energy and additional investments into drying capacities. A strategically desirable approach involves the ensiling of early-harvested moist grains to produce a highly digestible moist feed that brings benefits for both farmers and their livestock. Ensiling early-harvested high-moisture grain does not affect nutrient content, but reduces in-field grain losses, does not require expensive storage facilities, saves energy for preservation, has a high palatability and high nutritive value, and leads to similar or superior animal performance [2]. Good fermentation quality of ensiled crimped grain is obtained when the crop is harvested with 30–40% moisture content [3]. The ensiling of low-moisture crimped grain is common; however, there is a high risk of poor fermentation and nutrient losses when additives are not used [4]. High-moisture grain preservation could be based on a procedure similar to that used when ensiling grass or other green plants like whole-crop maize. Therefore, important factors for optimizing the fermentation and reducing dry-matter losses include the use of various additives such as chemicals (organic acids and their salts) and lactic-acid-bacteria-based inoculants. Organic acids and their salts fall into the category of silage fermentation inhibitors whereas inoculants are classified as fermentation activators [5]. The addition of formic-acid-based additives to ensiled forages causes a quick drop in the pH, restricts the fermentation of water-soluble carbohydrates (WSCs), and reduces acetic acid concentration and proteolysis [6]. On the other hand, sorbic, benzoic, propionic, and acetic acids improve silage aerobic stability at the feed-out stage through the direct inhibition of yeasts and mold [7]. The most common fermentation stimulators for making silage are bacterial inoculants—the homofermentative lactic acid bacteria strains include Lactiplantibacillus plantarum, Lacticaseibacillus casei, Enterococcus faecium, and various Pediococcus species, and heterofermentative lactic acid bacteria strains include Lentilactobacillus buchneri, Levilactobacillus brevis, Lentilactobacillus diolivorans, and Lentilactobacillus kefiri. Silages treated with one or more homofermentative strains are often lower in pH, acetic acid, butyric acid, and ammonia N but higher in lactic acid content and exhibit lower dry-matter losses compared with untreated silages [5]. Heterofermentative strains have shown some promise to shift the fermentation toward acetic acid and 1,2 propanediol and improve the aerobic stability of the silages [8]. The development of the inoculants that combine homo- and heterofermentative lactic acid bacteria has the goal of achieving the benefits of both types of inoculants in one product. The initial timeframe for fermentation provided by some authors last from 7 days to 45 days [9]. However, newer studies [10,11], have observed that fermentation can extend for much longer. Windle [10] specifically noted a pH decline in the silage over a period of up to 150 days of fermentation and even up to 180 days of storage. This extended duration of the fermentation led to increased concentrations of ammonia N and soluble crude protein. These findings suggest that the fermentation process in some forage can continue well beyond the previously established timeframe, affecting the nutrient composition and fermentation quality of the silage. This prolonged duration of the fermentation might have implications for the storage and utilization, potentially impacting the nutritional profile and overall quality of the silage. The objective of the current study was to evaluate the nutrient content, fermentation parameters, microbial populations, and aerobic stability of high-moisture barley grain when ensiled with the silage inoculant containing Lactococcus lactis (DSM 11037) and Lentilactobacillus buchneri (DSM 22501) or the chemical additive AIV Ässä Na containing formic acid, sodium formate, propionic acid, and potassium sorbate at fermentation periods lasting 7, 14, 28, 60, and 90 days.

2. Materials and Methods

2.1. Experimental Design

Spring barley (Hordeum vulgare L., variety Katniss) was sown on 26 April 2022 at the experimental farm of the Institute of Animal Science at Lithuanian University of Health Sciences. Barley grain at the dough line stage was harvested on 22 July 2022 with a John Deere W 540 (John Deere Walldorf GmbH & Co. KG, Walldorf, Baden-Württemberg, Germany) grain harvester. After harvesting, the grain was crimped immediately using a crimper 700 HD, Murska Ltd. (Aimo Kortteen Konepaja Oy Pohjolantie, Ylivieska, Finland) without any additives. Ensiling was conducted immediately after crimping of grain. Three additive treatments were performed:

- (1)

- C—Control, with no inoculant or other additive added;

- (2)

- FC—Inoculant SiloSolve® FC-treated (150,000 cfu/g);

- (3)

- AIV—Chemical-additive-treated (AIV Ässä Na, 4 mL/kg).

Descriptions of the additives are presented in Table 1.

Table 1.

Details of additives used in experiment.

Glass jars of 3.0 L volume were used to ensile the crimped barley grain. Ten replicates were made for each additive treatment and 7-, 14-, 28-, 60-, and 90-day fermentation periods. Five mini-silos were used per treatment and fermentation period for testing fermentation quality, and another five were used for testing aerobic stability (Table 2).

Table 2.

Experimental design.

The amount of crimped grain for a given treatment was weighed in order to ensure the expected application rate of the additive (see Table 1). Samples of water and inoculant suspension were collected and analyzed immediately for LAB counting according ISO method 15214 [13] to ensure the correct concentration of bacteria in the inoculant suspension. Grain was sprayed with water or an appropriate additive using a hand sprayer (one sprayer per treatment) and mixed manually during and after applying the additive. Thereafter, the treated and mixed forage were weighed for each mini-silo (to achieve target density of 450 kg dry matter (DM)/m3) and then placed into 3 L volume glass jars by hand with periodic tamping as carefully as possible to minimize the volume of air headspace. The equipment coming in contact with the inoculated forage was washed and disinfected with ethanol between treatments to prevent cross-contamination. The jars were closed and made airtight with caps within 30 min after being filled and stored at room temperature (20 °C) in the dark. Each mini-silo was weighed while empty and again after filling to determine the actual amount of forage ensiled. To determine fermentation loss, the mini-silages were weighed before closing and at the end of each fermentation period after opening to determine fresh weight loss during fermentation. The DM losses were calculated, with DM content and the decrease in weight of the mini-silo expressed in grams per kg DM. The silage DM concentration was corrected for the loss of volatiles during drying according to Weissbach and Strubelt (2008) [14] using the DM correction formula (DMc = DMn + 0.95 FA + 0.08 LA + 0.77 PD + 1.00 OA (g kg−1 FM), where FA = fatty acids (C2 … C6); LA = lactic acid; PD 1,2 propanediol; and OA = other alcohols C2 … C4, including 2,3-butanediol. All values are entered into equation in the dimension g per kg fresh weight).

2.2. Sampling and Chemical Analyses

Crimped barley grain was sampled before the additive treatments were applied, then analyzed for DM, ash, crude protein (CP), neutral detergent fiber (NDF), starch, WSCs, pH, and microbial parameters (LAB, yeast, mold). Ensiled barley grain at the end of each fermentation period (7, 14, 28, 60, and 90 days) was sampled (five replicates for each treatment and fermentation period) and analyzed for DM, nutrient content, fermentation parameters (pH, ammonia N, alcohols, 1,2 propanediol, lactic acid, VFAs), and microbial characteristics (LAB, yeasts, and mold).

Chemical analyses were carried out at the analytical laboratory of the Institute of Animal Science of the LHUS in Baisogala. Dry matter was determined through oven drying at 60 °C for 24 h, equilibrated to room humidity overnight, milled through a 1 mm sieve and further dried at 105 °C to constant weight and corrected for volatile loss. Nitrogen (N) content, measured using Kjeldahl-AOAC 984.13 [15], and 10.5 g of catalyst and Block Digestion and TecatorKjeltec system 1002 Distilling Unit were used. Crude fat was measured through extraction using Soxtec System using petrol ether at 40–600 °C Crude fat residue was determined gravimetrically after drying. Crude fiber was determined with Fibercap (Foss Tecator) using sulfuric acid and Na hydroxide treatment. Acid detergent fiber (ADF) was determined using ANKOM A200 Filter Bag Technique (FBT), neutral detergent fiber (NDF was determined using A200 Filter Bag Technique (FBT) and amylase was added to help break down the starch; starch was measured using AOAC Method 996.11 [15]. WSC content was determined using the anthrone reaction assay (MAFF, 1986), from the herbage or silage extracts obtained from steeping fresh herbage or silage in water. Crude ash was determined using AOAC Method 942.05 [15]. Lactic acid, volatile fatty acids (VFAs), 1,2-propandiol, and alcohols were determined using gas–liquid chromatograph “GC-2010 Shimadzu” with capillary column (Stabilwax®-DA 30 m, 0.53 mm, ID, 0.5 µm), which was used according to Gas Chromatography and Biochemistry Analyzer official methods. pH value was determined using silage extracts obtained from steeping fresh herbage in water and analyzed using Thermo OrionPosi-pHloSympHony Electrode and Thermo Orion 410 meter. Ammonia N concentration was determined through direct distillation using the “Kjeltec Auto System 1030” (AOAC 1990 941.04) [15].

2.3. Microbiological Analyses

Microbiological analyses were performed at the National Food and Veterinary risk assessment institute (Vilnius, Lithuania), accredited by ILAC MRA (International Laboratory Accreditation Cooperation). The number of viable LAB was counted on De Man–Rogosa–Sharpe (MRS) agar after incubation anaerobically at 37 °C for 48 h (ISO 15214:2009) [13]. The yeast and mold were counted using horizontal method for the enumeration of viable yeasts and molds (ISO—21527-1:2008) [16].

2.4. Aerobic Stability Measurements

To assess the aerobic stability of the silages, the temperature monitoring method according to that used by Honig (1986) [17] was used. Temperature dynamics were monitored by placing thermocouple wires within the silage samples (1000 g each and with five replicate samples per treatment and fermentation period) loosely filled and placed in plastic open-aerated polystyrene boxes (180 mm diameter and 150 mm height). The top and bottom of each box contained a 2 cm diameter hole to allow air to enter and CO2 to escape. Thermocouple wires were inserted into the geometric center of the silage mass through a hole in the cover of the box, which exposed the silage to air. The boxes were kept at constant room temperature 20 ± 0.5 °C. The data loggers connected to thermocouple wires recorded silage and ambient temperature at 6 h intervals. Aerobic stability was defined as the number of hours for which the silage remained stable before rising more than 3 °C above the ambient temperature [18]. Moreover, at the end of the aerobic stability test, weight losses during exposure to air were calculated based on the silage weight before and after the aerobic stability test. The increase in temperature, the change in the pH value, the fresh weight loss, and the quantities of yeast and mold at the end of aerobic exposure period were used as indicators of aerobic spoilage.

2.5. Statistical Analysis

Statistical analysis was performed as part of a completely randomized design using the GLM (general linear model) procedure of SAS, version 9.4 (SAS Institute Inc., Cary, NC, USA). The model statement included the fixed effect of treatment. Significance was declared at p < 0.05, and tendencies were considered at 0.10 ≥ p ≥ 0.05. To separate treatment means protected by the overall F-test, the PDIFF option of the LSMEANS procedure was used.

3. Results and Discussions

3.1. Fresh Materials Characteristics

The chemical and microbiological composition of the crimped high-moisture barley grain before additive application and ensiling are presented in Table 3. The crimped high-moisture barley grain had a DM concentration of 675.0 g kg−1 and contained 33.5 g kg−1 DM WSCs, 605.6 g kg−1 starch, 19.9 g kg−1 ash, and 117.4 g kg−1 crude protein. The total lactic acid bacteria, yeast, and mold counts of the barley grain fresh material were 5.78, 6.43, and 5.30 log cfu g−1 FM, respectively.

Table 3.

The chemical and microbiological characteristics of high-moisture barley grain before additive application (n = 5).

3.2. Fermentation and Microbial Characteristics

Table 4 presents the fermentative parameters and microbial characteristics of high-moisture crimped barley grain according to the additive treatment and fermentation period. The pH value and fermentation product contents, such as those of lactic acid and acetic acid at all fermentation periods, showed evident activated fermentation when high-moisture barley was treated with LAB inoculant FC and considerably restricted fermentation when chemical additive AIV was added. When compared with untreated (C) ensiled high-moisture crimped barley grain, using FC additive was effective in reducing (p < 0.001) both pH as well as concentrations of ammonia N and alcohols. The study found that the FC inoculant led to a statistically significant impact on increasing the concentrations of lactic acid and acetic acid in ensiled high-moisture barley grain. Chemical additive AIV, when compared with other treatments, had the highest DM content and produced the lowest (p < 0.001) amounts of ammonia N and alcohols during the ensiling process. High-moisture barley grain ensiled with AIV had the lowest concentrations of lactic acid and acetic acid at all fermentation periods. The pH value was the highest in high-moisture barley grain ensiled with AIV. This means that the ensiled barley grain treated with AIV had higher (p < 0.001) pH value compared to other treatments, indicating a less acidic environment. A lower pH in silage is generally desired because it helps inhibit the growth of undesirable microorganisms and promote the preservation of nutrients [5]. The increase in lactic acid production indicates that desirable LAB were active in the silage, which helped to reduce the pH value and support retaining the nutritional value of the forage. A recent study [18] report on forage fermentation found that homolactic bacteria can rapidly convert fermentable sugars to lactic acid and exhibit lower pH values for the silages. Silages with higher acetic acid concentration tend to be more stable when exposed to air whereas low acetic acid concentration tends to lead to aerobic instability wherein the silages can heat up and spoil when exposed to air [19]. The comparison showed that the concentration of propanediol 1,2 was significantly higher (p < 0.001) in high-moisture barley grain ensiled with the inoculant (FC) when compared to the untreated control (C) and the chemical additive AIV Ässä Na (AIV). The concentration of ammonia N (ammonia nitrogen) in the ensiled high-moisture barley grain had also decreased (p < 0.001) when the additive FC was used. Ammonia N is generated during the breakdown of proteins in plant and microbial matter and inevitably associated with silage fermentation [20,21]. In the context of silage fermentation, it is very important to control ammonia N levels because high levels of ammonia N can indicate excessive proteolysis, which may lead to the loss of protein content and reduced the hygienic quality of feed [22]. Similarly, the concentrations of alcohols in the ensiled high-moisture barley grain were reduced (p < 0.001) in FC treatment. Significantly higher concentration of alcohols in untreated (C) high-moisture barley grain silages at day 60 and day 90 of the fermentation can be indicative of an undesirable fermentation process, while low alcohol concentrations are a normal part of the silage fermentation process. During all fermentation periods, butyric acid concentration was lower (p < 0.001) in both inoculant-treated (p < 0.001) and ensiled-with-a-chemical-additive (AIV) high-moisture barley grain. Reducing butyric acid formation in a silage is essentially crucial for maintaining the quality of the silage. Butyric acid is a fermentation byproduct with an unpleasant odor and taste, which can negatively affect the quality of the silage, which can lead to the loss of energy and protein content in the silage and result in yeast and mold growth. In both cases, the conversion of organic matter into different metabolic products (butyric acid, alcohol) leads to a loss of dry matter [5]. Propanediol 1,2 and propylene glycol are known to have properties that can help reduce the aerobic deterioration of ensiled forage or grains by creating a barrier that limits the entry of oxygen into the ensiled material and helps inhibit the growth of aerobic spoilage microorganisms that require oxygen like yeast and fungi [23,24,25]. The comparison of WSC concentrations determined in fresh high-moisture barley grain at ensiling and in the silage revealed that from 42% to 78% (from day 7 to day 90 of fermentation), the WSC content was utilized during the fermentation of C and FC silages, while, in AIV-treated silages, the WSC content was utilized from 5% to 25% (from day 7 to day 90 of fermentation). The trial data indicate that the utilization of WSCs during the fermentation of high-moisture barley grain into silage varies depending on the type of silage. C and FC silages experienced a more significant reduction in WSC content during fermentation compared to the AIV-treated silage. This suggests that a smaller amount of WSC content in the AIV-treated silage was consumed during restricted fermentation compared to the C and FC silages. The comparison of WSC concentration in fresh barley grain and ensiled barley grain agrees with the data from Auerbach [26], who reported a decline in WSC content after 91 days of green rye fermentation.

Table 4.

Fermentation, microbial characteristics, and dry-matter losses of ensiled high-moisture crimped barley grain at different periods of fermentation.

3.3. Dry Matter Corrected for the Losses of Volatiles (DMc) and Dry Matter (DM)

The efficiency of the FC and AIV additives was reflected by DMc and DM losses compared to high-moisture barley grain ensiled without any additives (Table 4). When barley grain with high moisture content was ensiled with the chemical additive AIV, it resulted in the highest (p < 0.001) DMc content among all the treatments and fermentation periods. When barley grain was ensiled with the inoculant FC, it had a higher dry matter content compared to the silage without any additives (C). The addition of FC inoculant improved the efficiency of the fermentation process, resulting in lower (p < 0.001) dry-matter loss when compared to high-moisture barley grain ensiled without any additives. The use of the chemical additive AIV restricted the fermentation process, which also led to lower DM losses compared to the control group C. Among the tested additives, the chemical additive AIV was found to have the most significant impact on DM loss reduction. The observed significant differences in DM loss were not due to the fortuity but were results of the additives’ impact on the fermentation process. Our results support the recent data by other authors [2,27], wherein the largest restriction was found for the chemical additives and inoculant regardless of their composition and where the reduction in DM loss was observed by the use of LAB inoculant.

3.4. Microbiological Characteristics

Definitely, the additives used in our study affected microbial populations. The quantities of yeast and mold were lower in all treated barley grain silages compared to the raw material (Table 3 and Table 4). Initially, the yeast counts in the ensiled high-moisture barley grain without additives (C) were higher (p < 0.001) compared to barley grain ensiled with the additives FC and AIV for up to 60 days of storage. This suggests that the absence of additives led to a higher yeast population during this period. However, by day 60 of fermentation, the quantity of yeasts in the AIV-treated barley grain silage did not differ significantly from that in the control (C) silage. This could mean that the AIV additive had an effect on yeast population, bringing it to a level similar to that of the control. By day 90 of fermentation, barley grain ensiled with the inoculant FC had the lowest (p < 0.001) quantity of yeast among all the groups. This suggests that the FC additive had a sustained inhibitory effect on the yeast growth, resulting in significantly lower yeast counts compared to both the control (C) and AIV-treated silages throughout the entire 90 days of storage. The differences in the quantities of yeast and mold between the treatments can be ascribed to different acetic acid concentrations because acetic acid had been shown to suppress microbial growth [28]. Similar results were observed when analyzing the changes in the quantity of mold. However, in the silage treated with the chemical additive AIV, mold counts were the highest on the 60th and 90th days of fermentation compared to all other treatments. This suggests that the chemical additive AIV may have promoted mold growth or failed to inhibit it effectively during the latter stages of the 90-day storage period. At that time, the FC additive had a sustained inhibitory effect on the mold growth throughout the entire 90 days of storage. In the previous study [29], it was found that the inoculant that contained Lentilactobacillus buchneri and Pediococcus pentosaceus treatment reduced the bacterial and fungal community composition of corn hybrids ensiled at low dry-matter concentrations.

3.5. Aerobic Stability Characteristics Based on Temperature Changes

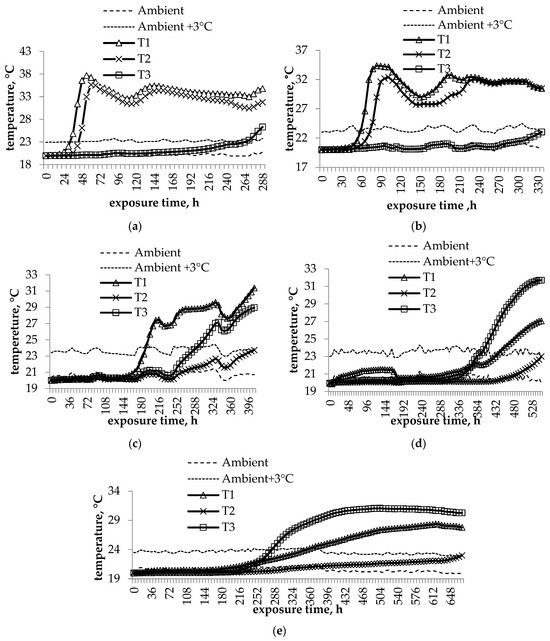

Aerobic stability (AS) is a critical parameter in many biological processes, including fermentation. It indicates how well the system can maintain its stability and functionality in the presence of oxygen [30]. Aerobic deterioration and silage heating are typically initiated by yeasts and continued by molds. As the oxygen levels in silage mass increase, yeast that are less pH-sensitive utilize lactic acid as a growth substrate, thereby increasing the pH, which allows the growth of a more pH-sensitive mold. Mold can produce mycotoxins, which can be harmful to animals [19]. In our study, the AS varied, which suggests that certain additives may have enhanced stability while others compromised it. The additives used in our study affected aerobic deterioration and displayed a large variation in AS based on the temperature rise, pH value, and microbial population at the end of the aerobic exposure period for different fermentation times (Table 5 and Figure 1).

Table 5.

Results of aerobic stability of ensiled crimped barley grain at different storage periods.

Figure 1.

Temperature dynamics during aerobic exposure in high-moisture barley grain ensiled for five fermentation periods and with different additives. T1—control (tap water, T2—SiloSolve® FC (Lactococcus lactis (DSM 11037) and Lentilactobacillus buchneri (DSM 22501)—50:50), T3—AIV Ässä Na (Formic acid—58.3; Propionic acid—20.1; Sodium formate—5.2; Potassium sorbate—2.5; Colorant—0.1; Water—13.8). (a) Day 7 of fermentation; (b) day 14 of fermentation; (c) day 28 of fermentation; (d) day 60 of fermentation; (e) day 90 of fermentation.

The control (C) ensiled barley grain had the lowest (p < 0.001) aerobic stability (AS) based on the temperature rise during the first 28 days of storage. In the early stages of fermentation (up to day 28), the treatment with AIV had the highest (p < 0.001) AS based on the temperature rise. After 28, 60, and 90 days of fermentation, the FC treatment achieved the longest (p < 0.001) AS. The temperature for this treatment remained stable, and did not increase more than 3 oC above the ambient temperature throughout the aerobic exposure period. The reviewed studies [31] showed that LAB can improve the silage aerobic stability by producing different metabolites such as acetic acid and 1,2-propanediol. However, according to Franco [2], formic-acid-based additives, except for pure formic acid (80%), and the propionic acid and ammonium propionate-based additive proved to be efficient at prolonging the AS of crimped wheat grain. The highest temperature (p < 0.001) was achieved in both the ensiled control (C) and inoculant-treated (FC) barley grain when compared with the AIV-treated barley grain up to day 14 of fermentation. However, the barley grain silage treated with a chemical additive (AIV) showed the highest temperature (p < 0.001) compared to other treatments at day 90 of fermentation. A previous study [32] reported that increases in temperature in the silage are clearly linked to aerobic activity of yeast and mold growth. Due to restricted fermentation, the WSC content remained high and was a potential source of readily available substrate for the growth of yeast when the silos were opened and exposed to air [29]. Studies [33,34] have reported that combining specific strains of Lactococcus lactis and Lentilactobacillus buchneri in a silage inoculant can efficiently control the yeast and mold growth in grass and maize silages.

3.6. pH Value and Weight Loss at the End of the Aerobic Exposure Period

The control (C) ensiled barley grain had the highest (p < 0.001) pH value at the end of aerobic exposure, when fermented from 7 to 60 days, during the first 60 days of storage (Table 4). AIV-treated barley grain initially had the lowest (p < 0.001) pH value among the treatments when fermented from 7 to 28 days. This suggests that the AIV treatment may have a greater impact on pH reduction during aerobic exposure at the early phase of fermentation. Yeast and mold are known for their ability, in aerobic conditions, to ferment sugars and break down organic matter, which can contribute to an increase in pH. Our study confirmed increases in yeast and mold counts and the pH value if fermented for more than 28 days. Franco [2] stated that the grain is more prone to aerobic spoilage due low organic acid production as undissociated organic acids are strong inhibitors for aerobic microbes. Some authors [35] found comparable results when studying the effects of propionic- and formic-acid-based additives on crimped barley grain. Low concentrations of lactic acid can lead to an insufficient reduction in the pH of ensiled grain, allowing yeast and molds to grow and further spoil the silage [36].

From day 28 of fermentation and beyond (60 and 90 days), the lowest (p < 0.001) increase in pH was observed in the barley grain treated with FC. This indicates that FC treatment may have a more prolonged and pronounced effect on reducing yeast and mold numbers and the pH value over time compared to the other treatments. The data suggest that there is a delay in the anaerobic conversion of lactic acid to acetic acid by Lentilactobacillus buchneri. This conversion process becomes apparent after about 30 to 60 days of storage. This is an important insight into the microbial dynamics during the ensiling process for high-moisture barley grains as it indicates a time lag in the production of acetic acid [37] and contrasts earlier observations made [38]. AIV-treated ensiled barley grain had the lowest (p < 0.001) weight loss during aerobic exposure compared to other treatments when fermented for up to 28 days. From 28, 60, and 90 days of fermentation, the lowest (p < 0.001) weight loss was observed in barley grain treated with FC. The highest (p < 0.001) weight loss was found in barley grain ensiled with AIV additive at 60 and 90 days of fermentation. The lowest weight loss in FC silage could be ascribed to the strong antibacterial properties of acetic acid and propanediol 1,2 that inhibit the nutrient loss in silage. Acetic acid and propanediol 1,2 were lower in concentration in the AIV and C silages, possibly explaining the greater weight loss in these treatments as acetic acid acts as an effective suppressor of yeast and mold, the primary consumers of silage nutrients during aerobic deterioration [5,36,39]. Weight loss during the period when the grain is exposed to air is closely related to the pH value and yeast and mold counts. This implies that the pH value and the presence of yeast and mold play significant roles in the weight loss of barley grain during this period. It also underscores the importance of monitoring pH and microbial counts as factors influencing weight loss during the aerobic exposure period.

4. Conclusions

In our study, chemical additives and those based on homo- and heterofermentative LAB differently affected the efficiency of fermentation during the storage period, as reflected by fermentation products and DM losses, and displayed a large variation in AS between treatments. The addition of the LAB inoculant positively affected the fermentation parameters and microbial composition and improved the aerobic stability of the ensiled high-moisture barley grain. The study showed that the fermentation restricted by a chemical additive had the lowest DM loss throughout the entire 90 days of storage and the highest aerobic stability in the silages fermented for 28 days. However, as the storage period progressed, the inoculant treatment proved to be the most effective in maintaining stable temperatures during the aerobic exposure, with a very small temperature increase above the ambient conditions. This was confirmed by the lowest DM loss and yeast and mold counts in the inoculant treated silages after aerobic exposure. Overall, the choice of the chemical additives or inoculants can have a significant impact on the fermentation quality and aerobic stability of the ensiled high-moisture barley grain.

Author Contributions

Conceptualization, J.J., V.V., I.E. and K.L.W.; investigation, J.J. and V.V.; resources, J.J., I.E. and K.L.W.; writing—original draft preparation, J.J. and V.V.; writing—review and editing, I.E., K.L.W. and R.C.d.A.; supervision, J.J. and I.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable, as the study did not involve humans or animals.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study. Written informed consent has been obtained from the patient(s) to publish this paper.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

Authors Kristian Lybek Witt, Ivan Eisner and Rafael Carmargo do Amaral are employed by the company Chr Hansen A/S. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be constructed as a potential conflict of interest.

References

- Fleurat-Lessard, F. Stored grain, physic-chemical treatment. In Encyclopedia of Grain Science, 1st ed.; Wrightley, C., Corke, H., Walker, C.E., Eds.; Elsevier Academic Press: London, UK, 2004; pp. 254–263. [Google Scholar] [CrossRef]

- Franco, M.; Stefanski, T.; Jalava, T.; Kuoppala, K.; Huuskonen, A.; Rinne, M. Fermentation quality and aerobic stability of low moisture-crimped wheat grains manipulated by organic acid-based additives. J. Agric. Sci. 2019, 157, 245–253. [Google Scholar] [CrossRef]

- Huhtanen, P.; Jaakkola, S.; Nousiainen, J. An overview of silage research in Finland: From ensiling innovation to advances in dairy cow feeding. Agric. Food Sci. 2013, 22, 35–56. [Google Scholar] [CrossRef]

- Pieper, R.; Hackl, W.; Korn, U.; Zeyner, A.; Souffrant, W.B.; Pieper, B. Effect of ensiling triticale, barley and wheat grains at different moisture content and addition of Lactobacillus plantarum (DSMZ 8866 and 8862) on fermentation characteristics and nutrient digestibility in pigs. Anim. Feed Sci. Technol. 2011, 164, 96–105. [Google Scholar] [CrossRef]

- Muck, R.E.; Nadeau, E.M.G.; McAllister, T.A.; Contreras-Govea, F.E.; Santos, M.C.; Kung, L. Silage review: Recent advances and future uses of silage additives. J. Dairy Sci. 2018, 101, 3980–4000. [Google Scholar] [CrossRef] [PubMed]

- Seppälä, A.; Heikkilä, T.; Mäki, M.; Rinne, M. Effects of additives on the fermentation and aerobic stability of grass silages and total mixed rations. Grass Forage Sci. 2016, 71, 458–471. [Google Scholar] [CrossRef]

- Nadeau, E.; Arnesson, A.; Jakobsson, J.; Auerbach, H. Chemical additives reduce yeast count and enhance aerobic stability in high dry matter corn silage. In Proceedings of the 17th International Silage Conference, Sao Paulo, Brazil, 1–3 July 2015; University of Sao Paulo: Piracicaba, Brazil, 2015; pp. 354–355. Available online: https://www.isfqcbrazil.com.br/proceedings/2015/Proceedings-of-the-XVII-International-Silage-Conference-Brazil-2015.pdf (accessed on 1 July 2023).

- Morais, G.; Danniel, J.L.P.; Kleinshmitt, C.; Carvalho, P.A.; Fernandes, J.; Nussio, L.G. Additives for grain silages: A review. Slovak J. Ani. Sci. 2017, 50, 42–54. Available online: http://www.cvzv.sk/slju/17_1/6_Morais.pdf (accessed on 1 July 2023).

- Pahlow, G.; Muck, R.E.; Driehuis, F.; Oude Elferink, S.J.W.H.; Spoelstra, S.F. Microbiology of ensiling. In Silage Science and Technology; Buxton, D.R., Muck, R.E., Harrison, J.H., Eds.; American Society of Agronomy: Madison, WI, USA, 2003; pp. 31–93. [Google Scholar] [CrossRef]

- Windle, M.C.; Walker, N.; Kung, L., Jr. Effects of an exogenous protease on the fermentation and nutritive value of corn silage harvested at different dry matter contents and ensiled for various lengths of time. J. Dairy Sci. 2014, 97, 3053–3060. [Google Scholar] [CrossRef] [PubMed]

- Kung, L., Jr.; Windle, M.C.; Walker, N. The effect of an exogenous protease on the fermentation and nutritive value of high-moisture corn. J. Dairy Sci. 2014, 97, 1707–1712. [Google Scholar] [CrossRef]

- Schwarz, F.J.; München, T.U.; Thalmann, A. (Eds.) DLG Testing Guidelines for the Award und Use of the DLG Quality Mark for Ensiling Agents, Prepared under the Auspices of the DLG Commission for Ensiling Agents; DLG Test Service GmbH: Groß-Umstadt, Germany, 2018; p. 60. [Google Scholar]

- ISO 15214:1998; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Mesophilic Lactic Acid Bacteria—Colony-Count Technique at 30 Degrees C. ISO: Geneva, Switzerland, 1998. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:15214:ed-1:v1:en (accessed on 1 July 2023).

- Weissbach, F.E.; Strubelt, C. Correcting the dry matter content of maize silages as a substrate for biogas production. Landtech. Net63 2008, 2, 82–83. Available online: https://www.landtechnik-online.eu/ojs-2.4.5/index.php/landtechnik/article/view/2008-2-082-083/1237 (accessed on 19 June 2016).

- AOAC. Official Methods of Analysis, 17th ed.; The Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2020. [Google Scholar]

- ISO 21527-1:2008; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Yeasts and Moulds—Part 1: Colony Count Technique in Products with Water Activity Greater than 0.95. ISO: Geneva, Switzerland, 2008. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:21527:-1:ed-1:v1:en (accessed on 1 July 2023).

- Honig, H. Evaluation of aerobic stability. In Proceedings of the EUROBAC Conference, Uppsala, Sweden, 12–16 August 1986; Swedish University of Agricultural Sciences: Uppsala, Sweden, 1990; pp. 76–82. [Google Scholar]

- Moran, J.; Weinberg, Z.G.; Ashbell, G. A comparison of two methods for the evaluation of the aerobic stability of whole crop wheat silage. In Proceedings of the 11th International Silage Conference, Aberystwyth, UK, 8–11 September 1996; University of Wales: Aberystwyth, UK, 1996; pp. 162–163. [Google Scholar]

- Bai, J.; Ding, Z.; Ke, W.; Xu, D.; Wang, M.; Huang, W.; Zhang, Y.; Liu, F.; Guo, X. Different lactic acid bacteria and their combinations regulated the fermentation process of ensiled alfalfa: Ensiling characteristics, dynamics of bacterial community and their functional shifts. Microb. Biotechnol. 2021, 14, 1171–1182. [Google Scholar] [CrossRef]

- Kung, L., Jr.; Shaver, R.D.; Grant, R.J.; Schmidt, R.J. Silage review: Interpretation of chemical, microbial, and organoleptic components of silages. J. Dairy Sci. 2018, 101, 4020–4033. [Google Scholar] [CrossRef] [PubMed]

- Hassanat, F.; Mustafa, A.F.; Seguin, P. Effects of inoculation on ensiling characteristics, chemical composition and aerobic stability of regular and brown midrib millet silages. Anim. Feed Sci. Technol. 2007, 139, 125–140. [Google Scholar] [CrossRef]

- Rinne, M.; Leppä, M.M.; Kuoppala, K.; Koivunen, E.; Kahala, M.; Jalava, T.; Salminen, J.-P.; Mani, K. Fermentation quality of ensiled crimped faba beans using different additives with special attention to changes in bioactive compounds. Anim. Feed Sci. Technol. 2020, 265, 114497. [Google Scholar] [CrossRef]

- Zielińska, K.; Fabiszewska, A.; Świątek, M.; Szymanowska-Powałowska, D. Evaluation of the ability to metabolize 1,2-propanediol by heterofermentative bacteria of the genus Lactobacillus. Electron. J. Biotechnol. 2017, 26, 60–63. [Google Scholar] [CrossRef]

- Yanbing, L.; Jingchun, L.; Anshan, S. Detection and analysis of 1,2-propanediol content in whole-crop corn. Anim. Husb. Feed Sci. 2017, 9, 239–242. [Google Scholar] [CrossRef]

- da Silva, N.C.; Nascimento, C.F.; Campos, V.M.A.; Alves, M.A.P.; Resende, F.D.; Daniel, J.L.P.; Siqueira, G.R. Influence of storage length and inoculation with Lactobacillus buchneri on fermentation, aerobic stability, and ruminal degradability of high-moisture corn and rehydrated corn grain silage. Anim. Feed Sci. Technol. 2019, 251, 124–133. [Google Scholar] [CrossRef]

- Auerbach, H.; Weiss, K.; Theobald, P.; Nadeau, E. Effects of inoculant type on dry matter losses, fermentation pattern, yeast count and aerobic stability of green rye silages. In Proceedings of the 12. BOKU-Symposium Tierernährung, Vienna, Austria, 11 April 2013; University of Natural Resources and Life Sciences: Vienna, Austria, 2013; pp. 179–185. Available online: https://boku.ac.at/fileadmin/data/H03000/H97000/H97600/Symptagungsbaende/BOKU_Symposium_2013.pdf (accessed on 1 July 2023).

- Auerbach, H.; Theobald, P. Additive type Affects fermentation, aerobic stability and mycotoxins formation during air exposure of early-cut rye (Secale cereale L.) silage. Agronomy 2020, 10, 1432. [Google Scholar] [CrossRef]

- Kleinschmit, D.H.; Kung, L., Jr. A meta-analysis of the effects of Lactobacillus buchneri on the fermentation and aerobic stability of corn and grass and small-grain silages. J. Dairy Sci. 2006, 89, 4005–4113. [Google Scholar] [CrossRef]

- Romero, J.; Park, J.; Joo, Y.; Zhao, Y.; Killerby, M.; Reyes, D.C.; Tiezzi, F.; Gutierrez-Rodriguez, E.; Castillo, M.S. A combination of Lactobacillus buchneri and Pediococcus pentosaceus extended the aerobic stability of conventional and brown midrib mutants–corn hybrids ensiled at low dry matter concentrations by causing a major shift in their bacterial and fungal community. J. Anim. Sci. 2021, 99, skab141. [Google Scholar] [CrossRef]

- Wilkinson, J.M.; Davies, D.R. The aerobic stability of silage: Key findings and recent developments. Grass Forage Sci. 2013, 68, 1–19. [Google Scholar] [CrossRef]

- Reich, L.J.; Kung, L. Effects of combining Lactobacillus buchneri 40788 with various lactic acid bacteria on the fermentation and aerobic stability of corn silage. Anim. Feed Sci. Technol. 2010, 159, 105–109. [Google Scholar] [CrossRef]

- Borreani, G.; Tabacco, E. The relationship of silage temperature with the microbiological status of the face of corn silage bunkers. J. Dairy Sci. 2010, 93, 2620–2629. [Google Scholar] [CrossRef] [PubMed]

- Copani, G.; Milora, N.; Bryan, K.A.; Nielsen, N.G.; Witt, K.L. Fermentation and aerobic stability of grass and grass-legume silages ensiled for 14 days. In Proceedings of the 18th International Silage Conference, Bonn, Germany, 24–26 July 2018; Gerlach, K., Südekum, K.H., Eds.; University of Bonn: Bonn, Germany, 2018; pp. 286–287. Available online: https://www.researchgate.net/publication/338740229_Fermentation_and_aerobic_stability_of_grass_and_grass-legume_silages_ensiled_for_14_days#fullTextFileContent (accessed on 1 July 2023).

- Copani, G.; Bryan, K.A.; Nielsen, N.G.; Witt, K.L.; Queiroz, O.; Ghilardelli, F.; Masoero, F.; Gallo, A. The effect of bacterial inoculant and packing density on corn silage quality and safety. In Proceedings of the 18th International Silage Conference, Bonn, Germany, 24–26 July 2018; University of Bonn: Bonn, Germany, 2018; pp. 42–43. Available online: https://www.researchgate.net/publication/338740427_The_effect_of_bacterial_inoculant_and_packing_density_on_corn_silage_quality_and_safety (accessed on 1 July 2023).

- Seppälä, A.; Nysand, M.; Mäki, M.; Miettinen, H.; Rinne, M. Ensiling crimped barley grain at farm scale in plastic tube bag with formic and propionic acid-based additives. In Proceedings of the 16th International Silage Conference, Hämeenlinna, Finland, 2–4 July 2012; MTT Agrifood Research Finland and University of Helsinki: Helsinki, Finland, 2012; pp. 436–437. Available online: http://jukuri.luke.fi/handle/10024/479786 (accessed on 1 July 2023).

- McDonald, P.; Henderson, A.R.; Heron, S.J.E. The Biochemistry of Silage, 2nd ed.; Chalcombe Publications: Marlow, UK, 1991; 340p, Available online: http://books.google.com/books?id=oUcjAQAAMAAJ (accessed on 1 July 2023).

- Driehuis, F.; Oude Elferink, S.J.W.H.; Spoelstra, S.F. Anaerobic lactic acid degradation during ensilage of whole crop maize inoculated with Lactobacillus buchneri inhibits yeast growth and improves aerobic stability. J. Appl. Microbiol. 1999, 87, 583–594. [Google Scholar] [CrossRef] [PubMed]

- Copani, G.; Nielsen, N.G.; Bryan, K.A.; Vrotniakiene, V.; Jatkauskas, J.; Witt, K.L. Effects of a dual strain inoculant on alfalfa silage fermentation and aerobic stability through 32 days of ensiling. In Proceedings of the 5th International Symposium on Forage Quality and Conservation, Praccicaba, Brazil, 2017; Available online: https://www.researchgate.net/publication/322223422_Effects_of_a_dual_strain_inoculant_on_alfalfa_silage_fermentation_and_aerobic_stability_through_32_days_of_ensiling#fullTextFileContent (accessed on 5 May 2023).

- Danner, H.; Holzer, M.; Mayrhuber, E.; Braun, R. Acetic acid increases stability of silage under aerobic conditions. Appl. Environ. Microbiol. 2003, 69, 562–567. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).